Cold Isostatic Pressing to Improve the Mechanical Performance of Additively Manufactured Metallic Components

Abstract

:1. Introduction

2. Material

- L. Orientation defined by the advance direction of the printhead;

- T. Orientation defined by the direction perpendicular to the advance of the printhead, i.e., normal to the L orientation;

- S. Orientation perpendicular to the plane LT and coincident with the vertical movement of the printing bed.

3. Methodology

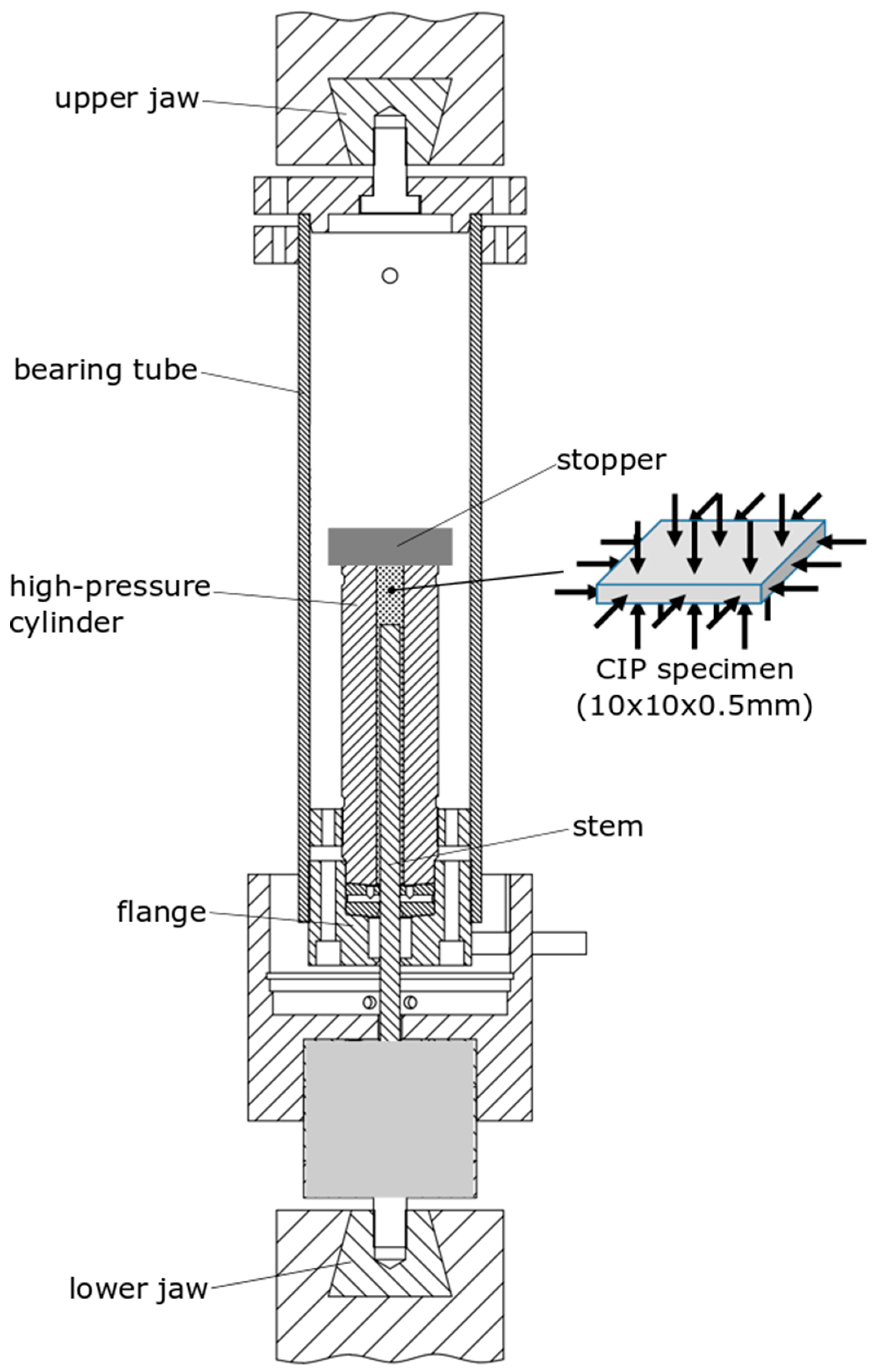

3.1. Cold Isostatic Pressing

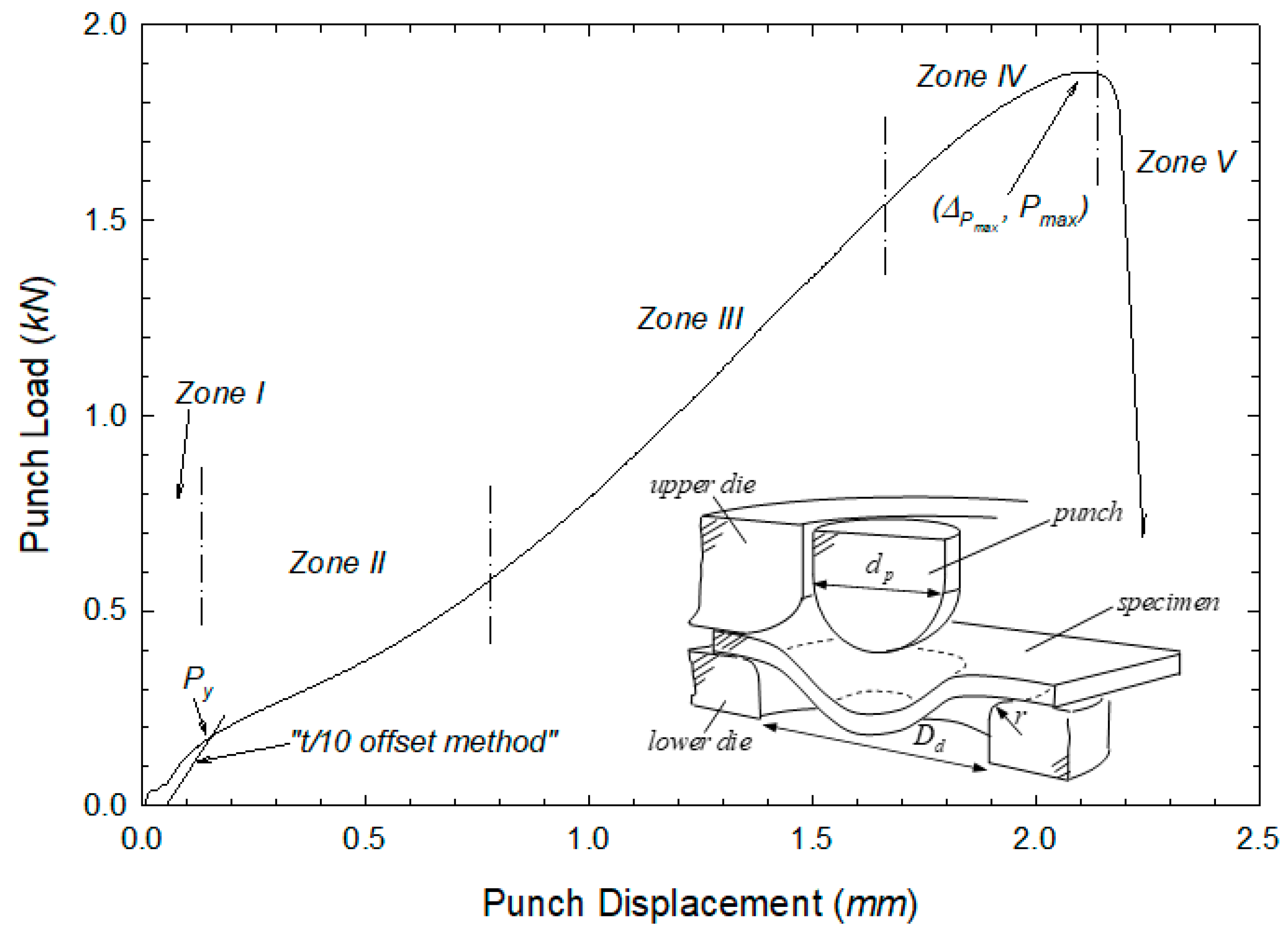

3.2. Small Punch Testing

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Frazier, W.E. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Akhoundi, B.; Behravesh, A.H. Effect of Filling Pattern on the Tensile and Flexural Mechanical Properties of FDM 3D Printed Products. Exp. Mech. 2019, in press. [Google Scholar] [CrossRef]

- Bilal, O.R.; Foehr, A.; Daraio, C. Observation of trampoline phenomena in 3D-printed metamaterial plates. Extrem. Mech. Lett. 2017, 15, 103–107. [Google Scholar] [CrossRef]

- Somireddy, M.; Singh, C.V.; Czekanski, A. Analysis of the Material Behavior of 3D Printed Laminates via FFF. Exp. Mech. 2019, in press. [Google Scholar] [CrossRef]

- Dadbakhsh, S.; Hao, L. Effect of hot isostatic pressing (HIP) on Al composite parts made from laser consolidated Al/Fe2O3 powder mixtures. J. Mater. Process. Technol. 2012, 212, 2474–2483. [Google Scholar] [CrossRef]

- Srivastava, A.P.; Tong, M.; Ștefanov, T.; Browne, D.J. Elimination of porosity in bulk metallic glass castings using hot isostatic pressing. J. Non-Cryst. Solids 2017, 468, 5–11. [Google Scholar] [CrossRef] [Green Version]

- AlMangour, B.; Grzesiak, D.; Yang, J.M. Selective laser melting of TiB2/H13 steel nanocomposites: Influence of hot isostatic pressing post-treatment. J. Mater. Process. Technol. 2017, 244, 344–353. [Google Scholar] [CrossRef]

- Kim, H.S. Densification mechanisms during hot isostatic pressing of stainless steel powder compacts. J. Mater. Process. Technol. 2002, 123, 319–322. [Google Scholar] [CrossRef]

- Ng, L.S.; Loh, N.L.; Boey, F.Y.C. Cold-hot isostatic pressing of Mar M200 superalloy powders. J. Mater. Process. Technol. 1997, 67, 143–149. [Google Scholar] [CrossRef]

- Baik, J.M.; Kameda, J.; Back, O. Small Punch Test evaluation of intergranular embrittlement of an alloy steel. Scr. Metall. Mater. 1983, 17, 1443–1447. [Google Scholar] [CrossRef]

- Saucedo-Muñoz, M.L.; Liu, S.C.; Hashida, T.; Takahashi, H.; Nakajima, H. Correlationship between JIc and equivalent fracture strain determined by small-punch tests in JN1, JJ1 and JK2 austenitic stainless steels. Cryogenics 2001, 41, 713–719. [Google Scholar] [CrossRef]

- Ju, J.-B.; Jang, J.; Kwon, D. Evaluation of fracture toughness by small-punch testing techniques using sharp notched specimens. Int. J. Press. Vessel. Pip. 2003, 80, 221–228. [Google Scholar] [CrossRef]

- Alegre, J.M.; Cuesta, I.I.; Lorenzo, M. An Extension of the Monkman-Grant Model for the Prediction of the Creep Rupture Time Using Small Punch Tests. Exp. Mech. 2014, 54, 1441–1451. [Google Scholar] [CrossRef]

- Hou, F.; Xu, H.; Wang, Y.; Zhang, L. Determination of creep property of 1.25Cr0.5Mo pearlitic steels by small punch test. Eng. Fail. Anal. 2013, 28, 215–221. [Google Scholar] [CrossRef]

- Nastac, M.; Lucas, R.; Klein, A. Microstructure and mechanical properties comparison of 316L parts produced by different additive manufacturing processes. In Proceedings of the 28th Annual International Solid Freeform Fabrication, Austin, TX, USA, 7–9 August 2017; pp. 332–341. [Google Scholar]

- CEN Workshop Agreement. CWA 15627:2007 D/E/F, Small Punch Test Method for Metallic Materials; CEN: Brussels, Belgium, 2007. [Google Scholar]

- Cuesta, I.I.; Alegre, J.M. Determination of the fracture toughness by applying a structural integrity approach to pre-cracked Small Punch Test specimens. Eng. Fract. Mech. 2011, 78, 289–300. [Google Scholar] [CrossRef]

- Martínez-Pañeda, E.; García, T.E.; Rodríguez, C. Fracture toughness characterization through notched small punch test specimens. Mater. Sci. Eng. A 2016, 657, 422–430. [Google Scholar] [CrossRef] [Green Version]

- Martínez-Pañeda, E.; Cuesta, I.I.; Peñuelas, I.; Díaz, A.; Alegre, J.M. Damage modeling in small punch test specimens. Theor. Appl. Fract. Mech. 2016, 86, 51–60. [Google Scholar] [CrossRef]

- Mao, X.; Takahashi, H. Development of a further-miniaturized specimen of 3 mm diameter for tem disk small punch tests. J. Nucl. Mater. 1987, 150, 42–52. [Google Scholar] [CrossRef]

- García, T.E.; Rodríguez, C.; Belzunce, F.J.; Suárez, C. Estimation of the mechanical properties of metallic materials by means of the small punch test. J. Alloys Compd. 2014, 582, 708–717. [Google Scholar] [CrossRef]

- Cuesta, I.I.; Alegre, J.M. Hardening evaluation of stamped aluminium alloy components using the Small Punch Test. Eng. Fail. Anal. 2012, 26, 240–246. [Google Scholar] [CrossRef]

- Sket, F.; Fernández, A.; Jérusalem, A.; Molina-Aldareguía, J.M.; Pérez-Prado, M.T. Effect of hydrostatic pressure on the 3D porosity distribution and mechanical behavior of a high pressure die cast Mg AZ91 alloy. Metall. Mater. Trans. A 2015, 46, 4056–4069. [Google Scholar] [CrossRef]

| Element | Cr | Ni | Mo | Mn | Si | P | C | S | Fe |

|---|---|---|---|---|---|---|---|---|---|

| wt % | 16.0–18.0 | 10.0–14.0 | 2.0–3.0 | Max 2 | Max 1 | Max 0.04 | Max 0.03 | Max 0.03 | balance |

| Elongation at Break, % | Hardness (HRB) | |||

|---|---|---|---|---|

| 214 | 517 | 43 | 66 | 7.7 |

| Orientation | Specimen | |||

|---|---|---|---|---|

| TS | A1 | 0.193 | 1.749 | 2.147 |

| A2 | 0.195 | 1.817 | 2.073 | |

| A3 | 0.206 | 1.883 | 2.210 | |

| A4 | 0.209 | 1.878 | 2.101 | |

| A5 | 0.205 | 1.801 | 1.985 | |

| LS | B1 | 0.214 | 1.804 | 2.213 |

| B2 | 0.185 | 1.851 | 2.226 | |

| B3 | - | - | - | |

| LT | C1 | 0.201 | 1.807 | 2.257 |

| C2 | 0.204 | 1.914 | 2.286 | |

| C3 | 0.205 | 1.914 | 2.225 | |

| Average: | 0.202 ± 0.008 | 1.841 ± 0.055 | 2.170 ± 0.094 | |

| Orientation | Specimen | |||

|---|---|---|---|---|

| TS | D1 | 0.212 | 1.945 | 2.268 |

| D2 | 0.215 | 1.828 | 2.214 | |

| D3 | 0.231 | 1.840 | 2.159 | |

| D4 | 0.233 | 1.929 | 2.163 | |

| LS | E1 | 0.208 | 1.842 | 2.156 |

| E2 | 0.203 | 1.952 | 2.259 | |

| E3 | - | - | - | |

| LT | F1 | 0.209 | 1.808 | 2.180 |

| F2 | 0.212 | 1.943 | 2.180 | |

| F3 | 0.217 | 2.061 | 2.316 | |

| Average: | 0.215 ± 0.010 | 1.904 ± 0.082 | 2.210 ± 0.058 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cuesta, I.I.; Martínez-Pañeda, E.; Díaz, A.; Alegre, J.M. Cold Isostatic Pressing to Improve the Mechanical Performance of Additively Manufactured Metallic Components. Materials 2019, 12, 2495. https://doi.org/10.3390/ma12152495

Cuesta II, Martínez-Pañeda E, Díaz A, Alegre JM. Cold Isostatic Pressing to Improve the Mechanical Performance of Additively Manufactured Metallic Components. Materials. 2019; 12(15):2495. https://doi.org/10.3390/ma12152495

Chicago/Turabian StyleCuesta, Isidoro Iván, Emilio Martínez-Pañeda, Andrés Díaz, and Jesús Manuel Alegre. 2019. "Cold Isostatic Pressing to Improve the Mechanical Performance of Additively Manufactured Metallic Components" Materials 12, no. 15: 2495. https://doi.org/10.3390/ma12152495