Analytical Thermal Modeling of Metal Additive Manufacturing by Heat Sink Solution

Abstract

:1. Introduction

2. Materials and Methods

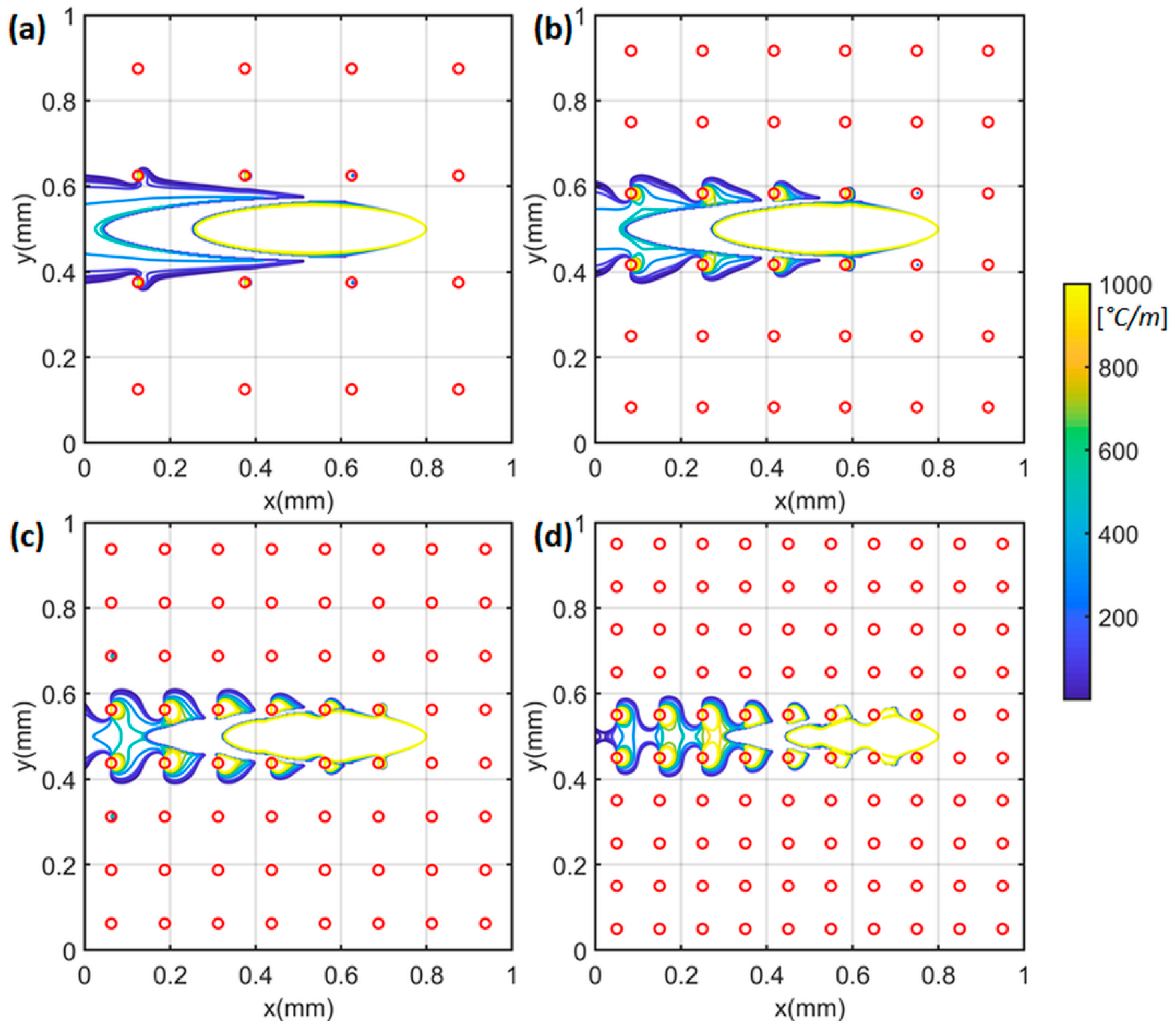

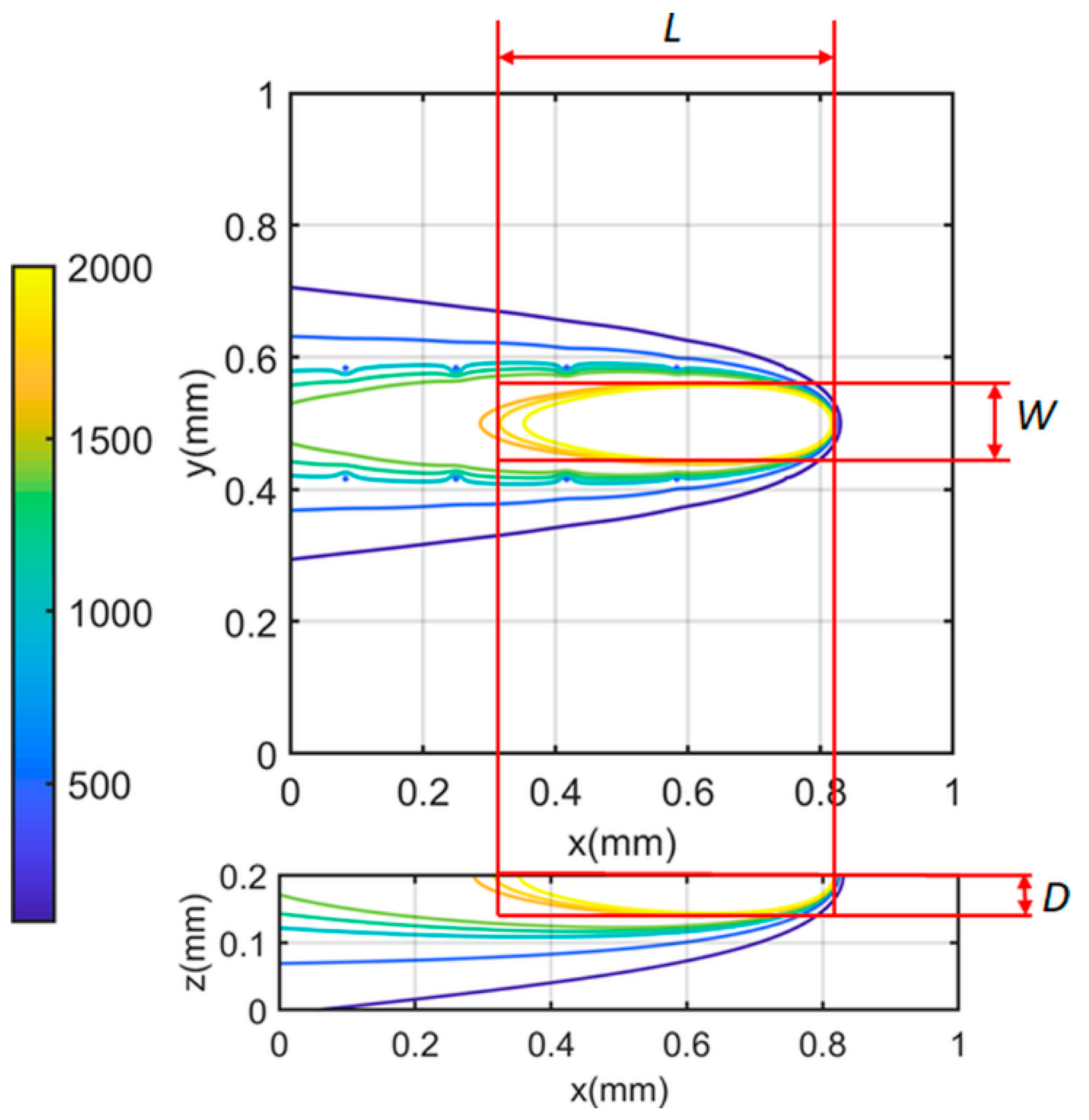

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Test | Power (W) | Scanning Velocity (mm/s) | Molten Pool Width (μm) | Molten Pool Depth (μm) |

|---|---|---|---|---|

| 1 | 100 | 500 | 118 | 62 |

| 2 | 100 | 750 | 98 | 52 |

| 3 | 100 | 1000 | 75 | 31 |

| 4 | 100 | 1200 | 72 | 36 |

| 5 | 150 | 500 | 146 | 122 |

| 6 | 150 | 750 | 136 | 88 |

| 7 | 150 | 1000 | 116 | 85 |

| 8 | 150 | 1200 | 108 | 59 |

| Test | Molten Pool Length (μm) | Molten Pool Width (μm) | Molten Pool Depth (μm) | Computation Time (s) |

|---|---|---|---|---|

| 1 | 530 | 120 | 62.5 | 93.73 |

| 2 | 537.5 | 100 | 50 | 88.52 |

| 3 | 537.5 | 90 | 45 | 88.35 |

| 4 | 537.5 | 80 | 40 | 88.74 |

| 5 | 752.5 | 145 | 112.5 | 90.33 |

| 6 | 787.5 | 125 | 82.5 | 91.10 |

| 7 | 797.5 | 110 | 85 | 91.02 |

| 8 | 800 | 100 | 60 | 89.76 |

References

- Kempen, K.; Vrancken, B.; Buls, S.; Thijs, L.; Van Humbeeck, J.; Kruth, J.P. Selective laser melting of crack-free high density M2 high speed steel parts by baseplate preheating. J. Manuf. Sci. Eng. 2014, 136, 061026. [Google Scholar] [CrossRef]

- Dilip, J.J.S.; Zhang, S.; Teng, C.; Zeng, K.; Robinson, C.; Pal, D.; Stucker, B. Influence of processing parameters on the evolution of melt pool, porosity, and microstructures in Ti-6Al-4V alloy parts fabricated by selective laser melting. Prog. Addit. Manuf. 2017, 2, 157–167. [Google Scholar] [CrossRef] [Green Version]

- Aboulkhair, N.T.; Everitt, N.M.; Ashcroft, I.; Tuck, C. Reducing porosity in AlSi10Mg parts processed by selective laser melting. Addit. Manuf. 2014, 1, 77–86. [Google Scholar] [CrossRef]

- Wu, A.S.; Brown, D.W.; Kumar, M.; Gallegos, G.F.; King, W.E. An experimental investigation into additive manufacturing-induced residual stresses in 316L stainless steel. Metall. Mater. Trans. A 2014, 45, 6260–6270. [Google Scholar] [CrossRef]

- Denlinger, E.R.; Heigel, J.C.; Michaleris, P.; Palmer, T.A. Effect of inter-layer dwell time on distortion and residual stress in additive manufacturing of titanium and nickel alloys. J. Mater. Process. Technol. 2015, 215, 123–131. [Google Scholar] [CrossRef]

- Buchbinder, D.; Meiners, W.; Pirch, N.; Wissenbach, K.; Schrage, J. Investigation on reducing distortion by preheating during manufacture of aluminum components using selective laser melting. J. Laser Appl. 2014, 26, 012004. [Google Scholar] [CrossRef]

- Heigel, J.C.; Michaleris, P.; Reutzel, E.W. Thermo-mechanical model development and validation of directed energy deposition additive manufacturing of Ti–6Al–4V. Addit. Manuf. 2015, 5, 9–19. [Google Scholar] [CrossRef]

- Rodriguez, E.; Mireles, J.; Terrazas, C.A.; Espalin, D.; Perez, M.A.; Wicker, R.B. Approximation of absolute surface temperature measurements of powder bed fusion additive manufacturing technology using in situ infrared thermography. Addit. Manuf. 2015, 5, 31–39. [Google Scholar] [CrossRef]

- Criales, L.E.; Arısoy, Y.M.; Lane, B.; Moylan, S.; Donmez, A.; Özel, T. Laser powder bed fusion of nickel alloy 625: Experimental investigations of effects of process parameters on melt pool size and shape with spatter analysis. Int. J. Mach. Tools Manuf. 2017, 121, 22–36. [Google Scholar] [CrossRef]

- Tapia, G.; Elwany, A. A review on process monitoring and control in metal-based additive manufacturing. J. Manuf. Sci. Eng. 2014, 136, 060801. [Google Scholar] [CrossRef]

- Everton, S.K.; Hirsch, M.; Stravroulakis, P.; Leach, R.K.; Clare, A.T. Review of in-situ process monitoring and in-situ metrology for metal additive manufacturing. Mater. Des. 2016, 95, 431–445. [Google Scholar] [CrossRef]

- Fu, C.H.; Guo, Y.B. Three-dimensional temperature gradient mechanism in selective laser melting of Ti-6Al-4V. J. Manuf. Sci. Eng. 2014, 136, 061004. [Google Scholar] [CrossRef]

- Michaleris, P. Modeling metal deposition in heat transfer analyses of additive manufacturing processes. Finite Elem. Anal. Des. 2014, 86, 51–60. [Google Scholar] [CrossRef]

- Cao, J.; Gharghouri, M.A.; Nash, P. Finite-element analysis and experimental validation of thermal residual stress and distortion in electron beam additive manufactured Ti-6Al-4V build plates. J. Mater. Process. Technol. 2016, 237, 409–419. [Google Scholar] [CrossRef]

- Denlinger, E.R.; Jagdale, V.; Srinivasan, G.V.; El-Wardany, T.; Michaleris, P. Thermal modeling of Inconel 718 processed with powder bed fusion and experimental validation using in situ measurements. Addit. Manuf. 2016, 11, 7–15. [Google Scholar] [CrossRef]

- Li, Y.; Gu, D. Parametric analysis of thermal behavior during selective laser melting additive manufacturing of aluminum alloy powder. Mater. Des. 2014, 63, 856–867. [Google Scholar] [CrossRef]

- Romano, J.; Ladani, L.; Sadowski, M. Thermal modeling of laser based additive manufacturing processes within common materials. Proc. Manuf. 2015, 1, 238–250. [Google Scholar] [CrossRef]

- Wei, P.; Wei, Z.; Chen, Z.; He, Y.; Du, J. Thermal behavior in single track during selective laser melting of AlSi10Mg powder. Appl. Phys. A 2017, 123, 604. [Google Scholar] [CrossRef]

- Xia, M.; Gu, D.; Yu, G.; Dai, D.; Chen, H.; Shi, Q. Porosity evolution and its thermodynamic mechanism of randomly packed powder-bed during selective laser melting of Inconel 718 alloy. Int. J. Mach. Tools Manuf. 2017, 116, 96–106. [Google Scholar] [CrossRef]

- Li, C.; Liu, J.F.; Fang, X.Y.; Guo, Y.B. Efficient predictive model of part distortion and residual stress in selective laser melting. Addit. Manuf. 2017, 17, 157–168. [Google Scholar] [CrossRef]

- Papadakis, L.; Loizou, A.; Risse, J.; Bremen, S.; Schrage, J. A computational reduction model for appraising structural effects in selective laser melting manufacturing: A methodical model reduction proposed for time-efficient finite element analysis of larger components in Selective Laser Melting. Virtual Phys. Prototyp. 2014, 9, 17–25. [Google Scholar] [CrossRef]

- Schoinochoritis, B.; Chantzis, D.; Salonitis, K. Simulation of metallic powder bed additive manufacturing processes with the finite element method: A critical review. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2017, 231, 96–117. [Google Scholar] [CrossRef]

- Bikas, H.; Stavropoulos, P.; Chryssolouris, G. Additive manufacturing methods and modelling approaches: a critical review. Int. J. Adv. Manuf. Technol. 2016, 83, 389–405. [Google Scholar] [CrossRef]

- Ning, J.; Liang, S.Y. Prediction of temperature distribution in orthogonal machining based on the mechanics of the cutting process using a constitutive model. J. Manuf. Mater. Proc. 2018, 2, 37. [Google Scholar] [CrossRef]

- Ning, J.; Liang, S.Y. Predictive Modeling of Machining Temperatures with Force–Temperature Correlation Using Cutting Mechanics and Constitutive Relation. Materials 2019, 12, 284. [Google Scholar] [CrossRef]

- Ning, J.; Liang, S.Y. A comparative study of analytical thermal models to predict the orthogonal cutting temperature of AISI 1045 steel. Inter. J. Adv. Manuf. Technol. 2019, 102, 3109–3119. [Google Scholar] [CrossRef]

- Li, F.; Ning, J.; Liang, S.Y. Analytical modeling of the temperature using uniform moving heat source in planar induction heating process. Appl. Sci. 2019, 9, 1445. [Google Scholar] [CrossRef]

- Ning, J.; Nguyen, V.; Liang, S.Y. Analytical modeling of machining forces of ultra-fine-grained titanium. Inter. J. Adv. Manuf. Technol. 2019, 101, 627–636. [Google Scholar] [CrossRef]

- Ning, J.; Nguyen, V.; Huang, Y.; Hartwig, K.T.; Liang, S.Y. Constitutive modeling of ultra-fine-grained titanium flow stress for machining temperature prediction. Bio-des. Manuf. 2019, 2, 1–8. [Google Scholar] [CrossRef]

- Van Elsen, M.; Baelmans, M.; Mercelis, P.; Kruth, J.P. Solutions for modelling moving heat sources in a semi-infinite medium and applications to laser material processing. Int. J. Heat Mass Transf. 2007, 50, 4872–4882. [Google Scholar] [CrossRef]

- Carslaw, H.; Jaeger, J. Conduction of Heat in Solids; Oxford Science Publication: Oxford, UK, 1990. [Google Scholar]

- Ning, J.; Sievers, D.E.; Garmestani, H.; Liang, S.Y. Analytical modeling of in-process temperature in powder bed additive manufacturing considering laser power absorption, latent heat, scanning strategy, and powder packing. Materials 2019, 12, 808. [Google Scholar] [CrossRef]

- Cline, H.E.; Anthony, T. Heat treating and melting material with a scanning laser or electron beam. J. Appl. Phys. 1977, 48, 3895–3900. [Google Scholar] [CrossRef]

- Rosenthal, D. The theory of moving sources of heat and its application of metal treatments. Trans. ASME 1946, 68, 849–866. [Google Scholar]

- Tan, H.; Chen, J.; Zhang, F.; Lin, X.; Huang, W. Process analysis for laser solid forming of thin-wall structure. Int. J. Mach. Tools Manuf. 2010, 50, 1–8. [Google Scholar] [CrossRef]

- Pinkerton, A.J.; Li, L. The significance of deposition point standoff variations in multiple-layer coaxial laser cladding (coaxial cladding standoff effects). Int. J. Mach. Tools Manuf. 2004, 44, 573–584. [Google Scholar] [CrossRef]

- Ahsan, M.N.; Pinkerton, A.J. An analytical–numerical model of laser direct metal deposition track and microstructure formation. Modell. Simul. Mater. Sci. Eng. 2011, 19, 055003. [Google Scholar] [CrossRef]

- Peyre, P.; Aubry, P.; Fabbro, R.; Neveu, R.; Longuet, A. Analytical and numerical modelling of the direct metal deposition laser process. J. Phys. D Appl. Phys. 2008, 41, 025403. [Google Scholar] [CrossRef]

- Yang, Y.; Knol, M.F.; Van Keulen, F.; Ayas, C. A semi-analytical thermal modelling approach for selective laser melting. Addit. Manuf. 2018, 21, 284–297. [Google Scholar] [CrossRef] [Green Version]

- Ning, J.; Mirkoohi, E.; Dong, Y.; Sievers, D.E.; Garmestani, H.; Liang, S.Y. Analytical modeling of 3D temperature distribution in selective laser melting of Ti-6Al-4V considering part boundary conditions. J. Manuf. Proc. 2019, 44, 319–326. [Google Scholar] [CrossRef]

- Ning, J.; Sievers, D.E.; Garmestani, H.; Liang, S.Y. Analytical modeling of transient temperature in powder feed metal additive manufacturing during heating and cooling stages. Appl. Phys. A 2019, 125, 496. [Google Scholar] [CrossRef]

- de La Batut, B.; Fergani, O.; Brotan, V.; Bambach, M.; El Mansouri, M. Analytical and numerical temperature prediction in direct metal deposition of Ti6Al4V. J. Manuf. Mater. Proc. 2017, 1, 3. [Google Scholar] [CrossRef]

- Mukherjee, T.; Wei, H.L.; De, A.; DebRoy, T. Heat and fluid flow in additive manufacturing-Part I: Modeling of powder bed fusion. Comput. Mater. Sci. 2018, 150, 304–313. [Google Scholar] [CrossRef]

- Valencia, J.J.; Quested, P.N. Thermophysical Properties. ASM Handb. 2008, 15, 468–481. [Google Scholar] [CrossRef]

- Ning, J.; Liang, S.Y. Inverse identification of Johnson-Cook material constants based on modified chip formation model and iterative gradient search using temperature and force measurements. Int. J. Adv. Manuf. Technol. 2019, 102, 2865–2876. [Google Scholar] [CrossRef]

- Ning, J.; Nguyen, V.; Huang, Y.; Hartwig, K.T.; Liang, S.Y. Inverse determination of Johnson–Cook model constants of ultra-fine-grained titanium based on chip formation model and iterative gradient search. Int. J. Adv. Manuf. Technol. 2018, 99, 1131–1140. [Google Scholar] [CrossRef]

| Name | Symbol | Value | Unit |

|---|---|---|---|

| Density | 4428 | kg/m3 | |

| Thermal conductivity (powder at ) | 6.6 | W/(m∙K) | |

| Thermal conductivity (solid) | 33.4 (T > 1923 K) | W/(m∙K) | |

| Specific heat (powder at ) | 580 | J/(kg∙K) | |

| Specific heat (solid) | 830 (T > 1923 K) | J/(kg∙K) | |

| Latent heat | 365,000 | J/kg | |

| Room temperature | 20 | °C | |

| Solidus temperature | 1605 | °C | |

| Liquidus temperature | 1655 | °C | |

| Heat convection coefficient | 24 | W/(m2∙K) | |

| Emissivity | 0.9 | 1 | |

| Stefan-Boltzmann constant | 5.67 | W/(m2∙K4) |

| Name | Symbol | Value | Unit |

|---|---|---|---|

| Laser Powder | 100, 150 | W | |

| Absorption | 0.77 | 1 | |

| Scanning Velocity | 500, 750, 1000, 1200 | mm/s |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ning, J.; Sievers, D.E.; Garmestani, H.; Liang, S.Y. Analytical Thermal Modeling of Metal Additive Manufacturing by Heat Sink Solution. Materials 2019, 12, 2568. https://doi.org/10.3390/ma12162568

Ning J, Sievers DE, Garmestani H, Liang SY. Analytical Thermal Modeling of Metal Additive Manufacturing by Heat Sink Solution. Materials. 2019; 12(16):2568. https://doi.org/10.3390/ma12162568

Chicago/Turabian StyleNing, Jinqiang, Daniel E. Sievers, Hamid Garmestani, and Steven Y. Liang. 2019. "Analytical Thermal Modeling of Metal Additive Manufacturing by Heat Sink Solution" Materials 12, no. 16: 2568. https://doi.org/10.3390/ma12162568