3D Plotting using Camphene as Pore-regulating Agent to Produce Hierarchical Macro/micro-porous Poly(ε-caprolactone)/calcium phosphate Composite Scaffolds

Abstract

:1. Introduction

2. Materials and Methods

2.1. PCL and PCL–CaP Solutions Preparation

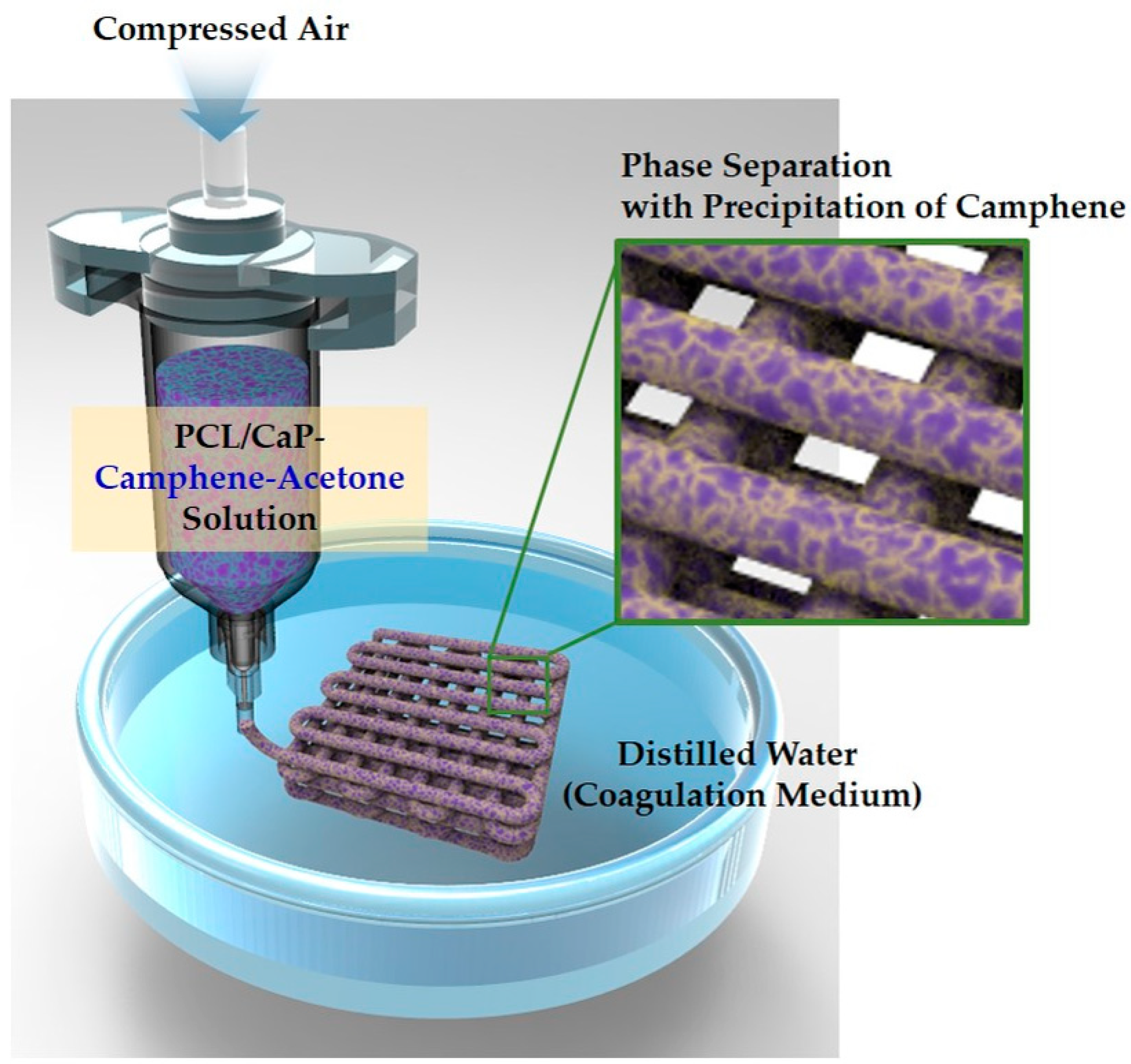

2.2. 3D Plotting Process

2.3. Hierarchical Porous Structure, Crystalline Phase, and Chemical Structure Evaluations

2.4. In Vitro Biocompatibility Evaluation

2.5. In Vitro Apatite-Forming Ability Evaluation

2.6. Mechanical Properties Tests

2.7. Statistical Analysis

3. Results and Discussion

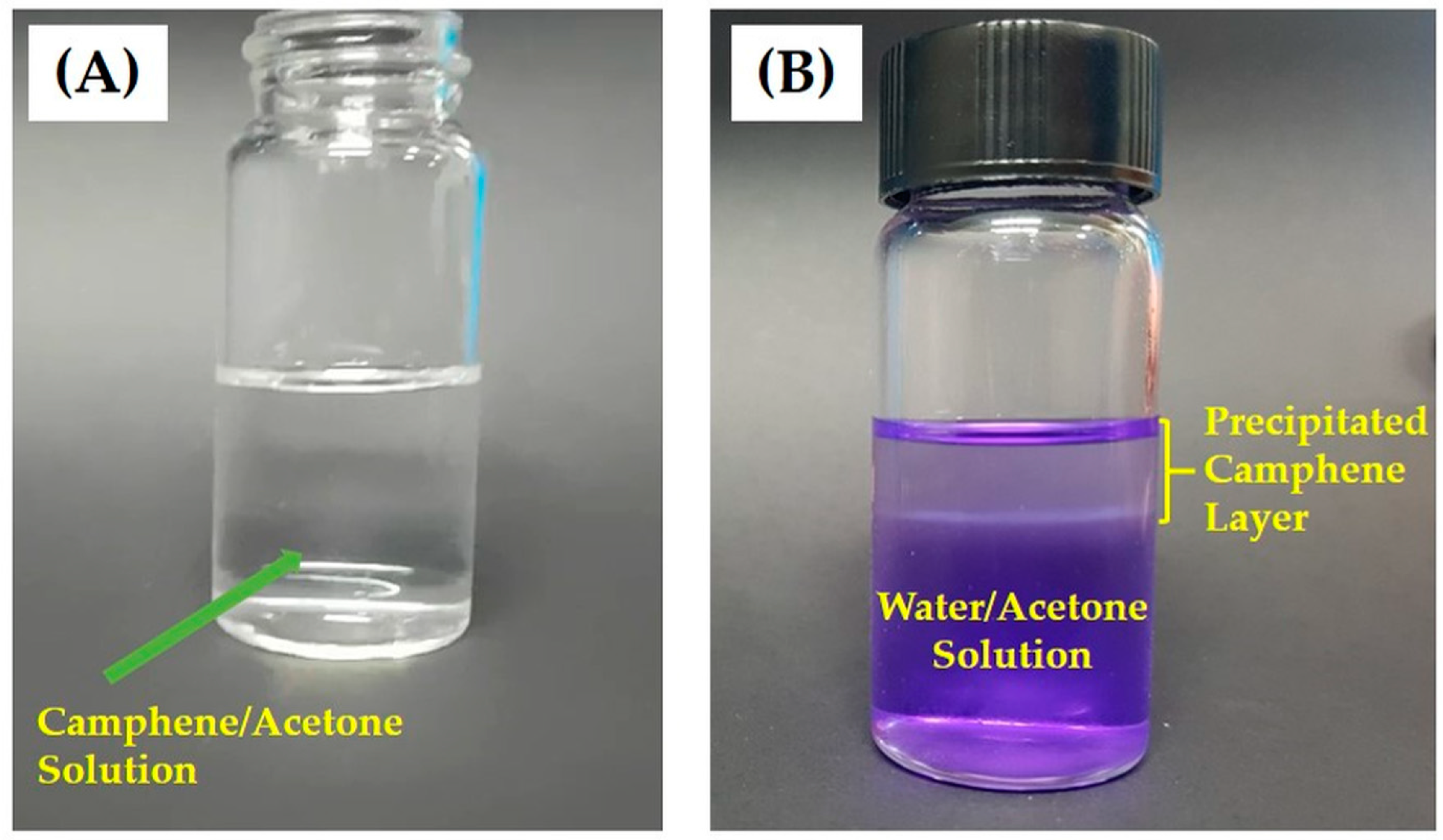

3.1. Utility of Camphene as Pore-Regulating Agent

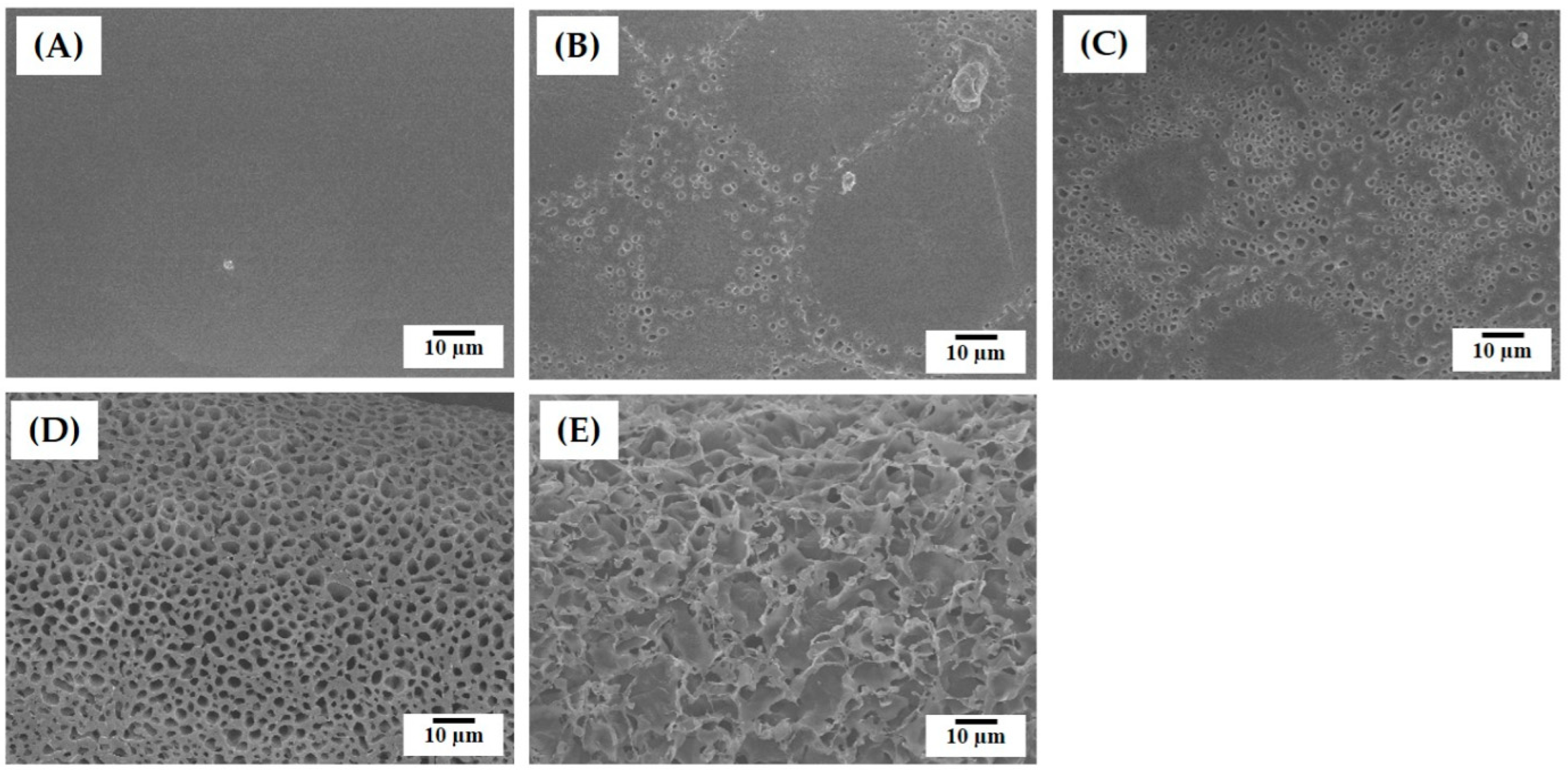

3.2. Effect of Camphene Content on Micropore Generation

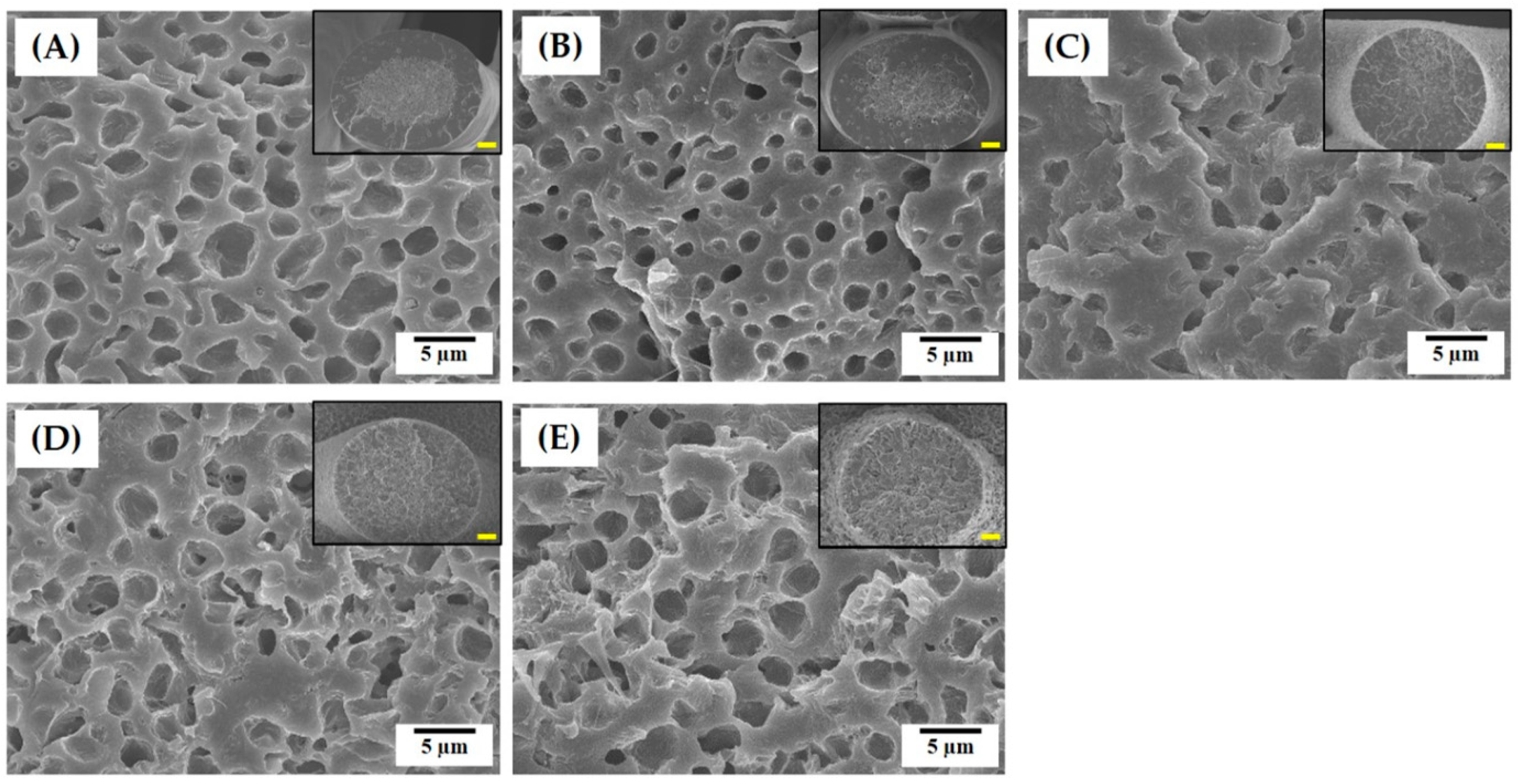

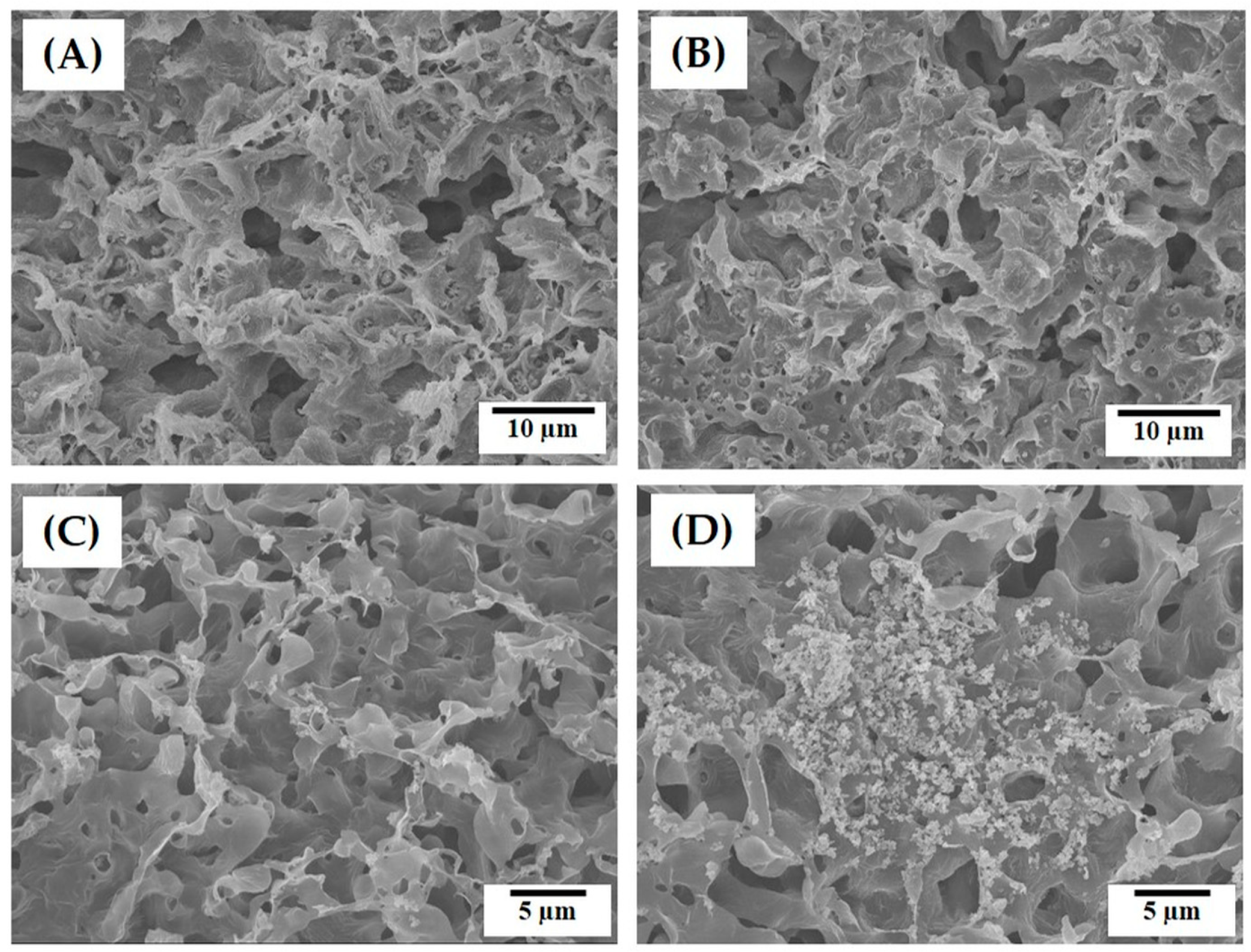

3.3. Surface Microporous Structures of PCL Filaments

3.4. Internal and Surface Microposities of PCL Filaments

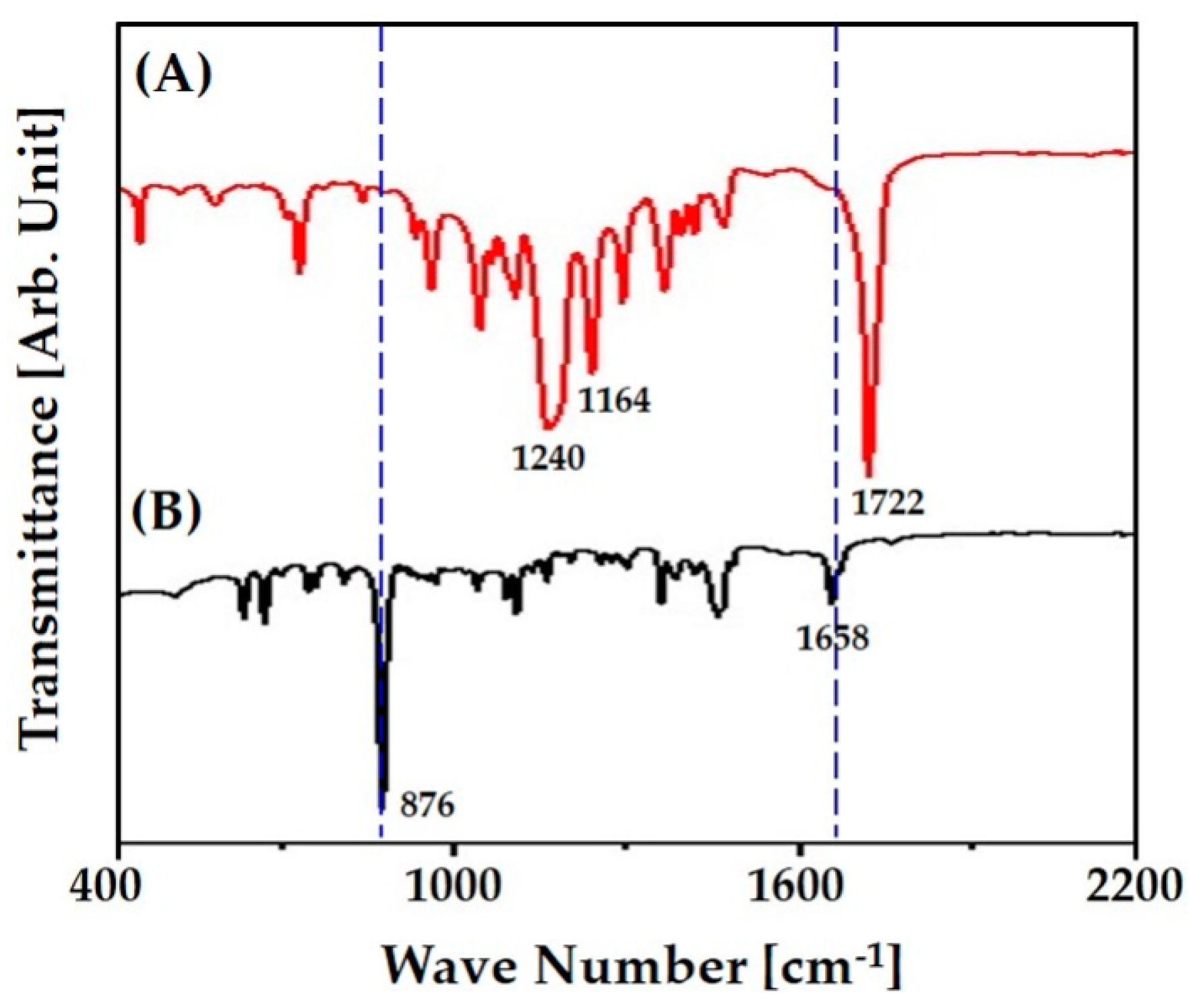

3.5. Chemical Structure of PCL Filaments

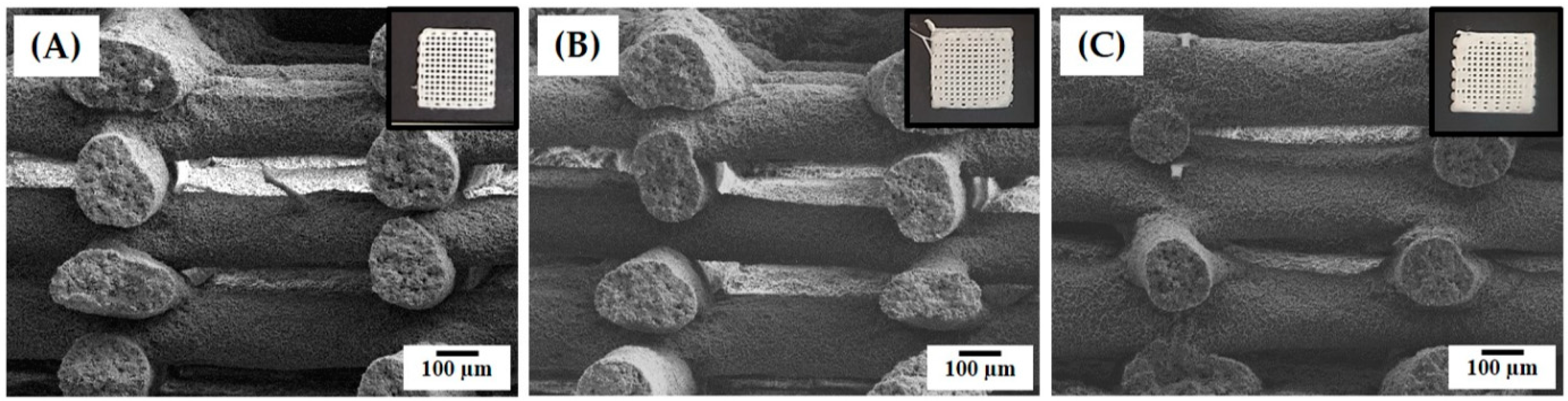

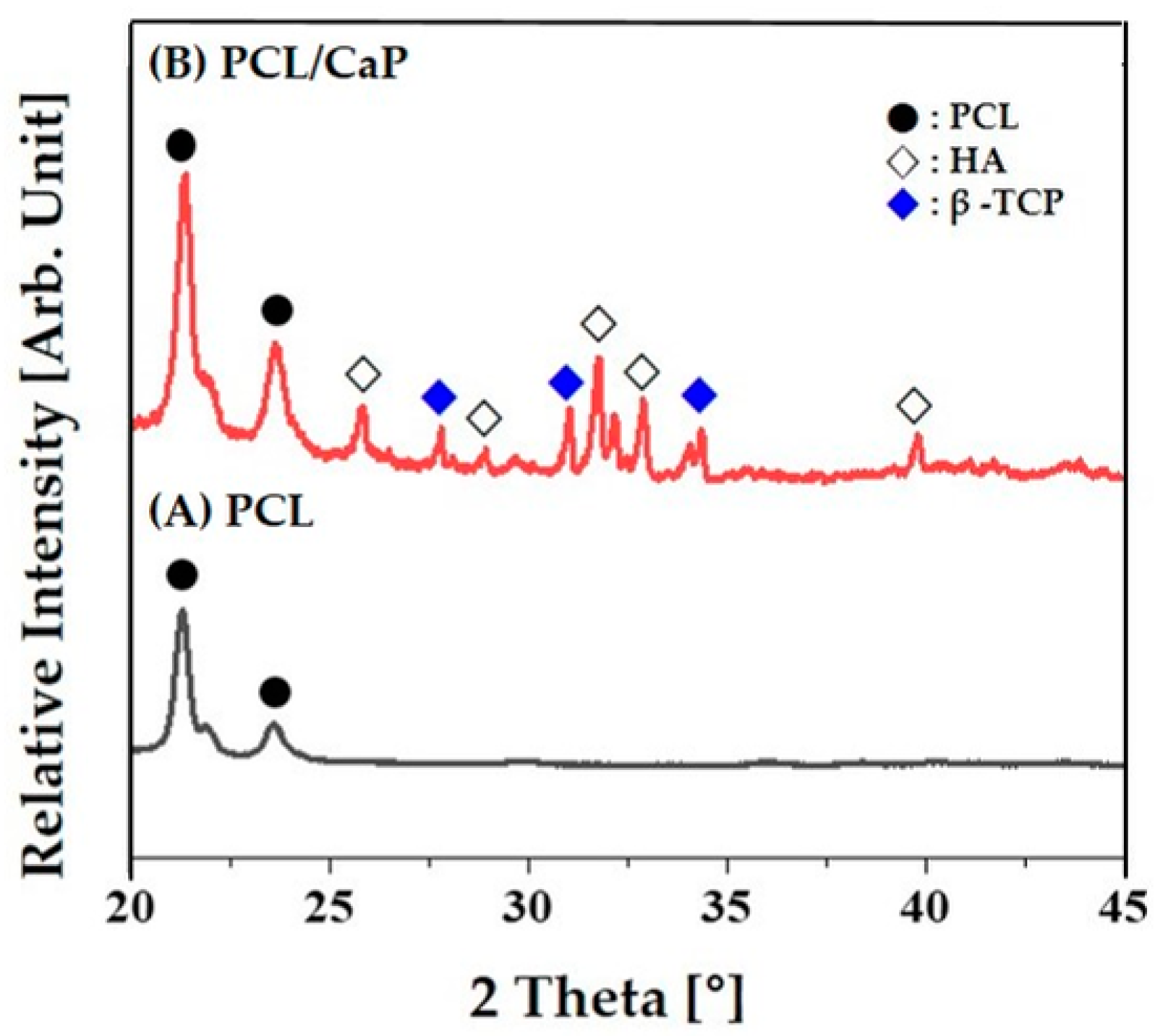

3.6. Hierarchical Porous Structures of PCL–CaP Composite Scaffolds

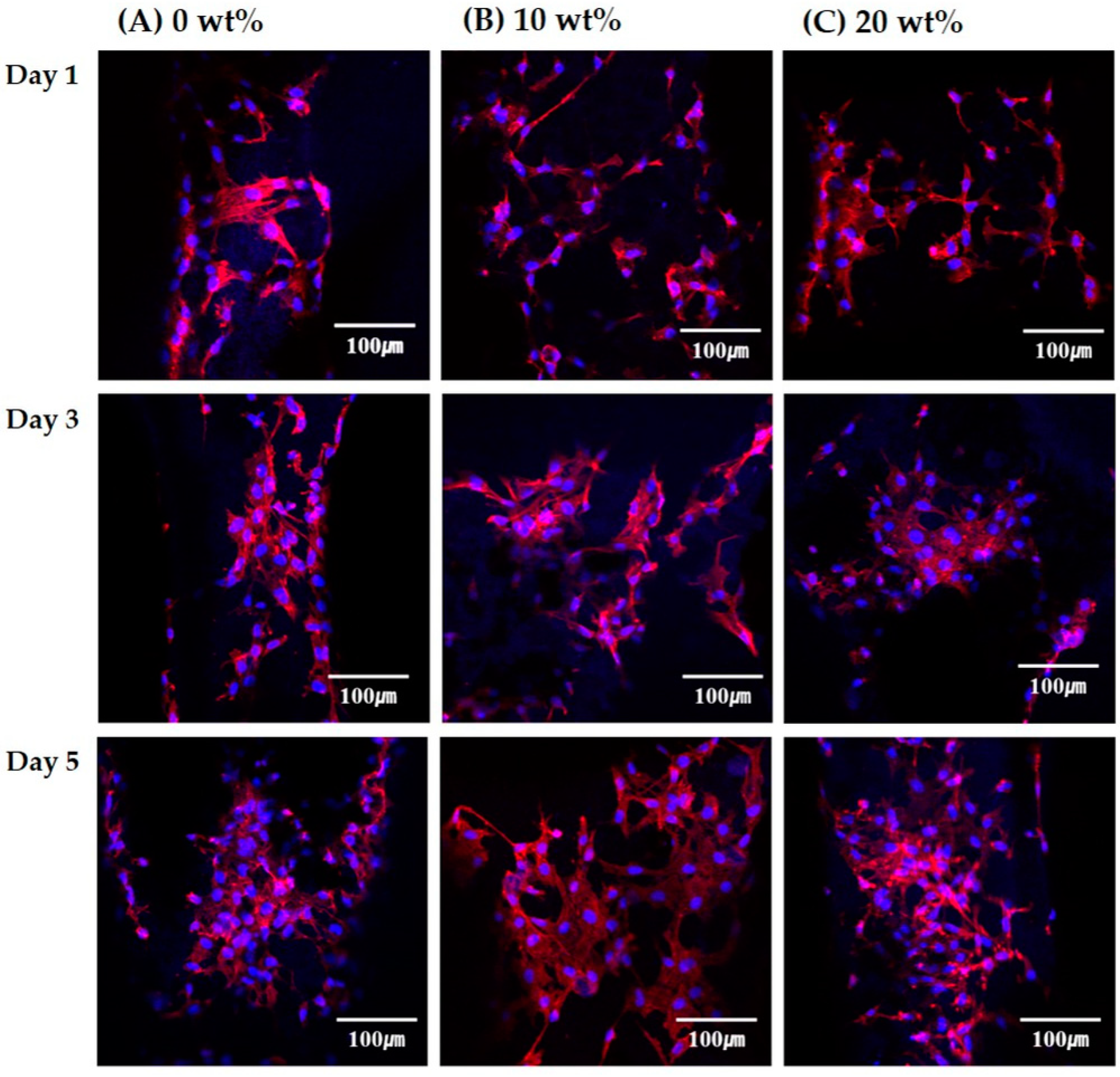

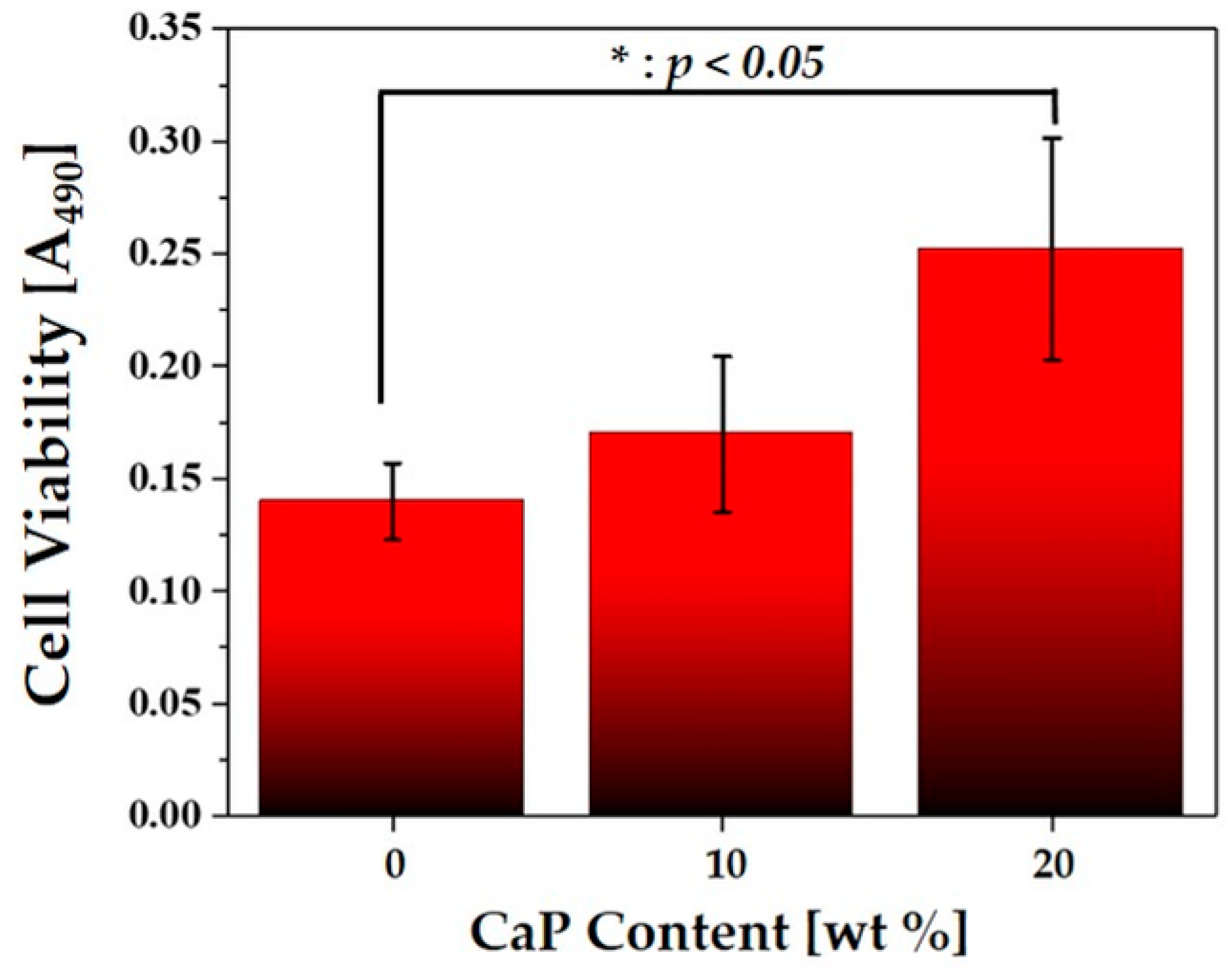

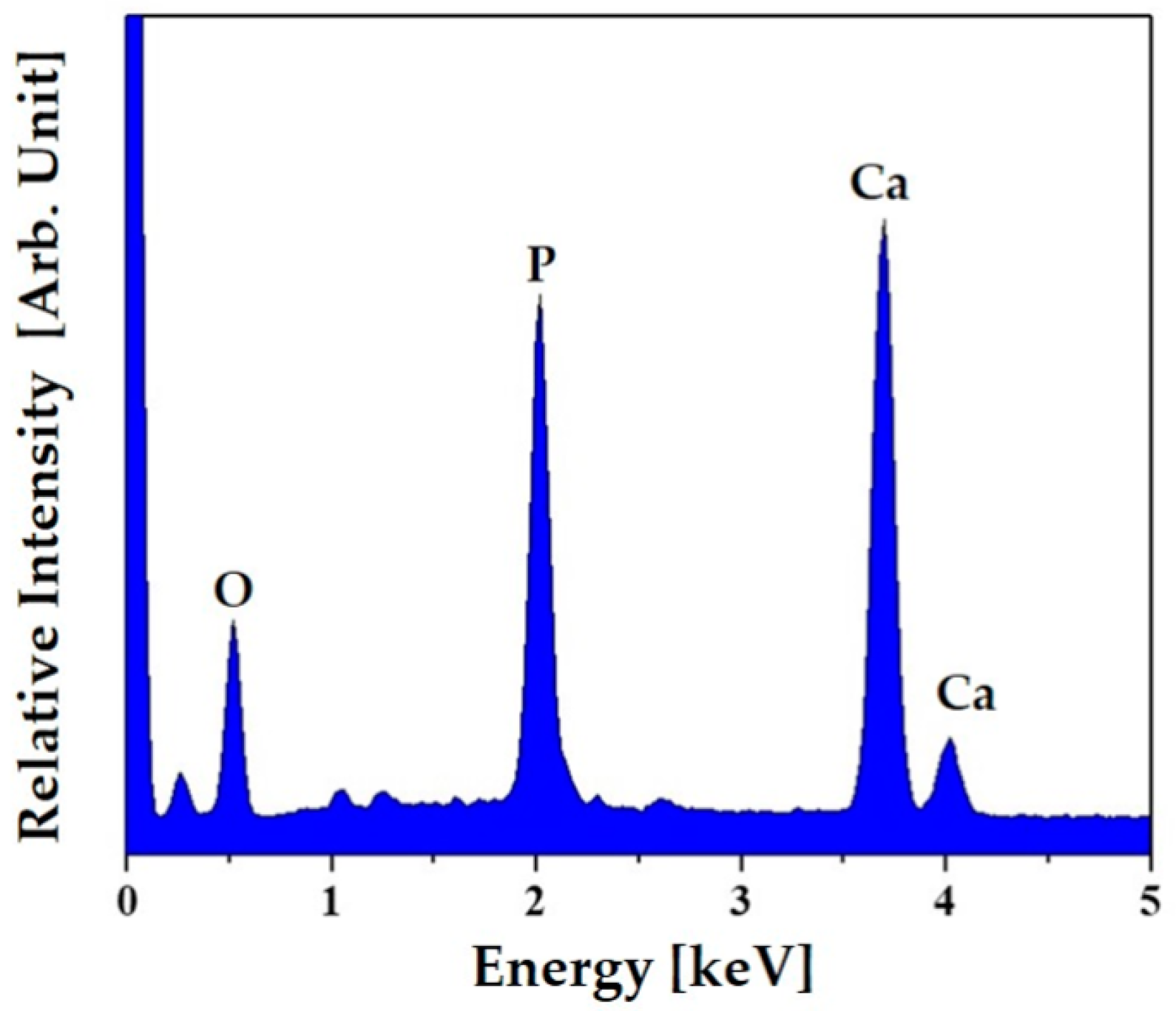

3.7. In Vitro Biocompatibility and Apatite-Forming Ability of PCL–CaP Composite Scaffolds

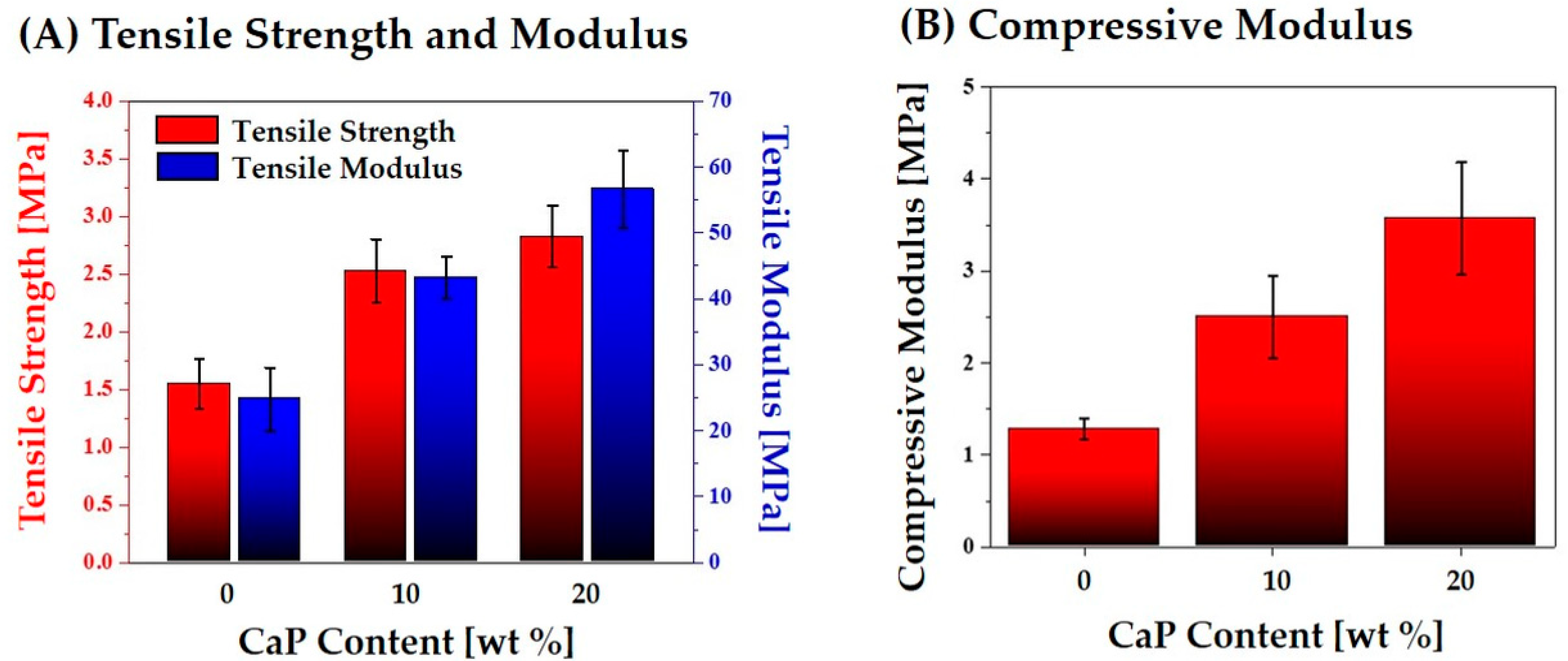

3.8. Mechanical Properties of PCL–CaP Composite Scaffolds

3.9. Utility of Present Study

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Dash, T.K.; Konkimalla, V.B. Poly-ε-caprolactone based formulations for drug delivery and tissue engineering: A review. J. Control. Release 2012, 158, 15–33. [Google Scholar] [CrossRef]

- Abedalwafa, M.; Wang, F.; Wang, L.; Li, C. Biodegradable poly-epsilon-caprolactone (PCL) for tissue engineering applications: A review. Rev. Adv. Mater. Sci. 2013, 34, 123–140. [Google Scholar]

- Hajiali, F.; Tajbakhsh, S.; Shojaei, A. Fabrication and properties of polycaprolactone composites containing calcium phosphate-based ceramics and bioactive glasses in bone tissue engineering: A review. Polym. Rev. 2018, 58, 164–207. [Google Scholar] [CrossRef]

- Sabir, M.I.; Xu, X.; Li, L. A review on biodegradable polymeric materials for bone tissue engineering applications. J. Mater. Sci. 2009, 44, 5713–5724. [Google Scholar] [CrossRef]

- Goonoo, N.; Bhaw-Luximon, A.; Bowlin, G.L.; Jhurry, D. An assessment of biopolymer- and synthetic polymer-based scaffolds for bone and vascular tissue engineering. Polym. Int. 2013, 62, 523–533. [Google Scholar] [CrossRef]

- Leong, K.F.; Cheah, C.M.; Chua, C.K. Solid freeform fabrication of three-dimensional scaffolds for engineering replacement tissues and organs. Biomaterials 2003, 24, 2363–2378. [Google Scholar] [CrossRef]

- Zhang, L.; Yang, G.; Johnson, B.N.; Jia, X. Three-dimensional (3D) printed scaffold and material selection for bone repair. Acta Biomater. 2010, 84, 16–33. [Google Scholar] [CrossRef]

- Wu, G.H.; Hsu, S.H. Review: Polymeric-based 3D printing for tissue engineering. J. Med. Biol. Eng. 2015, 35, 285–292. [Google Scholar] [CrossRef]

- Hollister, S.J. Porous scaffold design for tissue engineering. Nat. Mater. 2005, 4, 518–524. [Google Scholar] [CrossRef]

- Dhandayuthapani, B.; Yoshida, Y.; Maekawa, T.; Kumar, D.S. Polymeric scaffolds in tissue engineering application: A review. Int. J. Polym. Sci. 2011, 2011, 290602. [Google Scholar] [CrossRef]

- Giannitelli, S.M.; Accoto, D.; Trombetta, M.; Rainer, A. Current trends in the design of scaffolds for computer-aided tissue engineering. Acta Biomater. 2014, 10, 580–594. [Google Scholar] [CrossRef] [PubMed]

- Stratton, S.; Shelke, N.B.; Hoshino, K.; Rudraiah, S.; Kumbar, S.G. Bioactive polymeric scaffolds for tissue engineering. Bioact. Mater. 2016, 1, 93–108. [Google Scholar] [CrossRef] [PubMed]

- Hutmacher, D.W.; Schantz, T.; Zein, I.; Ng, K.W.; Teoh, S.H.; Tan, K.C. Mechanical properties and cell cultural response of polycaprolactone scaffolds designed and fabricated via fused deposition modeling. J. Biomed. Mater. Res. A 2001, 55, 203–216. [Google Scholar] [CrossRef]

- Zein, I.; Hutmacher, D.W.; Tan, K.C.; Teoh, S.H. Fused deposition modeling of novel scaffold architectures for tissue engineering applications. Biomaterials 2002, 23, 1169–1185. [Google Scholar] [CrossRef]

- Cao, T.; Ho, K.H.; Teoh, S.H. Scaffold design and in vitro study of osteochondral coculture in a three-dimensional porous polycaprolactone scaffold fabricated by fused deposition modeling. J. Tissue Eng. 2003, 9, 103–112. [Google Scholar] [CrossRef] [PubMed]

- Rai, B.; Teoh, S.H.; Hutmacher, D.W.; Cao, T.; Ho, K.H. Novel PCL-based honeycomb scaffolds as drug delivery systems for rhBMP-2. Biomaterials 2005, 26, 3739–3748. [Google Scholar] [CrossRef] [PubMed]

- Yilgor, P.; Sousa, R.A.; Reis, R.L.; Hasirci, N.; Hasirci, V. 3D plotted PCL scaffolds for stem cell based bone tissue engineering. Macromol. Symp. 2008, 269, 92–99. [Google Scholar] [CrossRef]

- Park, S.; Kim, G.; Jeon, Y.C.; Koh, Y.; Kim, W. 3D polycaprolactone scaffolds with controlled pore structure using a rapid prototyping system. J. Mater. Sci. Mater. Med. 2009, 20, 229–234. [Google Scholar] [CrossRef] [PubMed]

- Park, S.A.; Lee, S.H.; Kim, W.D. Fabrication of porous polycaprolactone/hydroxyapatite (PCL/HA) blend scaffolds using a 3D plotting system for bone tissue engineering. Bioprocess Biosyst. Eng. 2011, 34, 505–513. [Google Scholar] [CrossRef]

- Domingos, M.; Chiellini, F.; Gloria, A.; Ambrosio, L.; Bartolo, P.; Chiellini, E. Effect of process parameters on the morphological and mechanical properties of 3D bioextruded poly(ε-caprolactone) scaffolds. Rapid Prototyp. J. 2012, 18, 56–67. [Google Scholar] [CrossRef]

- Park, S.A.; Lee, J.B.; Kim, Y.E.; Kim, J.E.; Lee, J.H.; Shin, J.W.; Kim, W. Fabrication of biomimetic PCL scaffold using rapid prototyping for bone tissue engineering. Macromol. Res. 2014, 22, 882–887. [Google Scholar] [CrossRef]

- Koh, Y.H.; Jun, I.K.; Kim, H.E. Fabrication of poly(ε-caprolactone)/hydroxyapatite scaffold using rapid direct deposition. Mater. Lett. 2006, 60, 1184–1187. [Google Scholar] [CrossRef]

- Hong, S.J.; Jeong, I.; Noh, K.T.; Yu, H.S.; Lee, G.S.; Kim, H.W. Robotic dispensing of composite scaffolds and in vitro responses of bone marrow stromal cells. J. Mater. Sci. Mater. Med. 2009, 20, 1955–1962. [Google Scholar] [CrossRef] [PubMed]

- Dorj, B.; Won, J.E.; Kim, J.H.; Choi, S.J.; Shin, U.S.; Kim, H.W. Robocasting nanocomposite scaffolds of poly(caprolactone)/hydroxyapatite incorporating modified carbon nanotubes for hard tissue reconstruction. J. Biomed. Mater. Res. A 2013, 101, 1670–1681. [Google Scholar] [CrossRef] [PubMed]

- Bohner, M.; Loosli, Y.; Baroud, G.; Lacroix, D. Commentary: Deciphering the link between architecture and biological response of a bone graft substitute. Acta Biomater. 2011, 7, 478–484. [Google Scholar] [CrossRef] [PubMed]

- Tamaddon, M.; Czernuszka, J.T. The need for hierarchical scaffolds in bone tissue engineering. Hard Tissue 2013, 2, 37. [Google Scholar] [CrossRef]

- Zhang, K.; Fan, Y.; Dunne, N.; Li, X. Effect of microporosity on scaffolds for bone tissue engineering. Regen. Biomater. 2018, 5, 115–124. [Google Scholar] [CrossRef]

- Visscher, L.E.; Dang, H.P.; Knackstedt, M.A.; Hutmacher, D.W.; Tran, P.A. 3D printed polycaprolactone scaffolds with dual macro-microporosity for applications in local delivery of antibiotics. Mater. Sci. Eng. C 2018, 87, 78–89. [Google Scholar] [CrossRef] [PubMed]

- Wei, X.; Luo, Y.; Huang, P. 3D bioprinting of alginate scaffolds with controlled micropores by leaching of recrystallized salts. Polym. Bull. 2019, 1–12. [Google Scholar] [CrossRef]

- Dang, H.P.; Shabab, T.; Shafiee, A.; Peiffer, Q.C.; Fox, K.; Tran, N.; Dargaville, T.R.; Hutmacher, D.W.; Tran, P.A. 3D printed dual macro-, microscale porous network as a tissue engineering scaffold with drug delivering function. Biofabrication 2019, 11, 035014. [Google Scholar] [CrossRef] [Green Version]

- Kim, G.; Ahn, S.; Yoon, H.; Kim, Y.; Chun, W. A cryogenic direct-plotting system for fabrication of 3D collagen scaffolds for tissue engineering. J. Mater. Chem. 2009, 19, 8817–8823. [Google Scholar] [CrossRef]

- Lim, T.C.; Chian, K.S.; Leong, K.F. Cryogenic prototyping of chitosan scaffolds with controlled micro and macro architecture and their effect on in vivo neo-vascularization and cellular infiltration. J. Biomed. Mater. Res. A 2010, 94, 1303–1311. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.; Kim, G.H. Cryogenically fabricated three-dimensional chitosan scaffolds with pore size-controlled structures for biomedical applications. Carbohydr. Polym. 2011, 85, 817–823. [Google Scholar] [CrossRef]

- Lee, H.J.; Kim, G.H. Cryogenically direct-plotted alginate scaffolds consisting of micro/nano-architecture for bone tissue regeneration. RSC Adv. 2012, 2, 7578–7587. [Google Scholar]

- Dorj, B.; Park, J.H.; Kim, H.W. Robocasting chitosan/nanobioactive glass dual-pore structured scaffolds for bone engineering. Mater. Lett. 2012, 73, 119–122. [Google Scholar] [CrossRef]

- Tan, Z.; Parisi, C.; Di Silvio, L.; Dini, D.; Forte, A.E. Cryogenic 3D printing of super soft hydrogels. Sci. Rep. 2017, 7, 16293. [Google Scholar] [CrossRef]

- Wang, C.; Zhao, Q.; Wang, M. Cryogenic 3D printing for producing hierarchical porous and rhBMP-2-loaded Ca-P/PLLA nanocomposite scaffolds for bone tissue engineering. Biofabrication 2017, 9, 025031. [Google Scholar] [CrossRef]

- Gupta, D.; Singh, A.K.; Dravid, A.; Bellare, J.R. Multiscale porosity in compressible cryogenically 3D printed gel for bone tissue engineering. ACS Appl. Mater. Interfaces 2019, 11, 20437–20452. [Google Scholar] [CrossRef]

- Mota, C.; Puppi, D.; Dinucci, D.; Gazzarri, M.; Chiellini, F. Additive manufacturing of star poly(ε-caprolactone) wet-spun scaffolds for bone tissue engineering applications. J. Bioact. Compat. Polym. 2013, 28, 320–340. [Google Scholar] [CrossRef]

- Shin, K.H.; Jo, I.H.; Kim, S.E.; Koh, Y.H.; Kim, H.E. Nonsolvent induced phase separation (NIPS)-based 3D plotting for 3-dimensionally macrochanneled poly(ε-caprolactone) scaffolds with highly porous frameworks. Mater. Lett. 2014, 122, 348–351. [Google Scholar] [CrossRef]

- Shin, K.H.; Kim, J.W.; Koh, Y.H.; Kim, H.E. Novel self-assembly-induced 3D plotting for macro/nano-porous collagen scaffolds comprised of nanofibrous collagen filaments. Mater. Lett. 2015, 143, 265–268. [Google Scholar] [CrossRef]

- Kim, J.W.; Shin, K.H.; Koh, Y.H.; Hah, M.J.; Moon, J.; Kim, H.E. Production of poly (ε-caprolactone)/hydroxyapatite composite scaffolds with a tailored macro/micro-porous structure, high mechanical properties, and excellent bioactivity. Materials 2017, 10, 1123. [Google Scholar] [CrossRef]

- Lee, E.J.; Koh, Y.H.; Yoon, B.H.; Kim, H.E.; Kim, H.W. Highly porous hydroxyapatite bioceramics with interconnected pore channels using camphene-based freeze casting. Mater. Lett. 2007, 61, 2270–2273. [Google Scholar] [CrossRef]

- Soon, Y.M.; Shin, K.H.; Koh, Y.H.; Lee, J.H.; Kim, H.E. Compressive strength and processing of camphene-based freeze cast calcium phosphate scaffolds with aligned pores. Mater. Lett. 2009, 63, 1548–1550. [Google Scholar] [CrossRef]

- Liu, X.; Rahaman, M.N.; Fu, Q.; Tomsia, A.P. Porous and strong bioactive glass (13-93) scaffolds prepared by unidirectional freezing of camphene-based suspensions. Acta Biomater. 2012, 8, 415–423. [Google Scholar] [CrossRef] [Green Version]

- Millera, S.M.; Fabera, K.T. Freeze-cast alumina pore networks: Effects of freezing conditions and dispersion medium. J. Eur. Ceram. Soc. 2015, 35, 3595–3605. [Google Scholar] [CrossRef] [Green Version]

- Sepúlveda, R.; Plunk, A.A.; Dunand, D.C. Microstructure of Fe2O3 scaffolds created by freeze-casting and sintering. Mater. Lett. 2015, 142, 56–59. [Google Scholar] [CrossRef]

- Prins, H.J.; Braat, A.K.; Gawlitta, D.; Dhert, W.J.; Egan, D.A.; Tijssen-Slump, E.; Yuan, H.; Coffer, P.J.; Rozemuller, H.; Martens, A.C. In vitro induction of alkaline phosphatase levels predicts in vivo bone forming capacity of human bone marrow stromal cells. Stem Cell Res. 2014, 12, 428–440. [Google Scholar] [CrossRef] [Green Version]

- Buizer, A.T.; Veldhuizen, A.G.; Bulstra, S.K.; Kuijer, R. Static versus vacuum cell seeding on high and low porosity ceramic scaffolds. J. Biomater. Appl. 2014, 29, 3–13. [Google Scholar] [CrossRef]

- Zadpoor, A.A. Relationship between in vitro apatite-forming ability measured using simulated body fluid and in vivo bioactivity of biomaterials. Mater. Sci. Eng. C 2014, 35, 134–143. [Google Scholar] [CrossRef]

- Shkarina, S.; Shkarin, R.; Weinhardt, V.; Melnik, E.; Vacun, G.; Kluger, P.J.; Surmeneva, M.A. 3D biodegradable scaffolds of polycaprolactone with silicate-containing hydroxyapatite microparticles for bone tissue engineering: High-resolution tomography and in vitro study. Sci. Rep. 2018, 1, 8907. [Google Scholar] [CrossRef]

- Genc, Z.K.; Canbay, C.A.; Acar, S.S.; Sekerci, M.; Genc, M. Preparation and thermal properties of heterogeneous composite phase change materials based on camphene–palmitic acid. J. Therm. Anal. Calorim. 2015, 120, 1679–1688. [Google Scholar] [CrossRef]

- Vallianou, I.; Peroulis, N.; Pantazis, P.; Hadzopoulou-Cladaras, M. Camphene, a plant-derived monoterpene, reduces plasma cholesterol and triglycerides in hyperlipidemic rats independently of HMG-CoA reductase activity. PLoS ONE 2011, 6, e20516. [Google Scholar] [CrossRef]

- Dorozhkin, S.V. Biphasic, triphasic and multiphasic calcium orthophosphates. Acta Biomater. 2012, 8, 963–977. [Google Scholar] [PubMed]

- Derakhshanfar, S.; Mbeleck, R.; Xu, K.; Zhang, X.; Zhong, W.; Xing, M. 3D bioprinting for biomedical devices and tissue engineering: A review of recent trends and advances. Bioact. Mater. 2018, 3, 144–156. [Google Scholar] [CrossRef]

- Siddiqui, N.; Asawa, S.; Birru, B.; Baadhe, R.; Rao, S. PCL-based composite scaffold matrices for tissue engineering applications. Mol. Biotechnol. 2018, 60, 506–532. [Google Scholar]

- Gómez-Cerezo, N.; Casarrubios, L.; Saiz-Pardo, M.; Ortega, L.; de Pablo, D.; Díaz-Güemes, I.; Fernández-Tomé, B.; Enciso, S.; Sánchez-Margallo Arcos, F.M.; Portolés, M.T.; et al. Mesoporous bioactive glass/ɛ-polycaprolactone scaffolds promote bone regeneration in osteoporotic sheep. Acta Biomater. 2019, 90, 393–402. [Google Scholar] [CrossRef]

- Lei, Q.; He, J.; Li, D. Electrohydrodynamic 3D Printing of Layer-specifically Oriented, Multiscale Conductive Scaffolds for Cardiac Tissue Engineering. Nanoscale 2019. [Google Scholar] [CrossRef] [PubMed]

- Yang, G.H.; Lee, J.; Kim, G. The fabrication of uniaxially aligned micro-textured polycaprolactone struts and application for skeletal muscle tissue regeneration. Biofabrication 2019, 11, 025005. [Google Scholar] [CrossRef]

| Camphene Content [wt %] | 0 | 20 | 30 | 40 | 50 |

|---|---|---|---|---|---|

| Air Pressure [kPa] | 10 | 8 | 6 | 4 | 3 |

| Porosity | Camphene Content [wt %] | ||||

|---|---|---|---|---|---|

| 0 | 20 | 30 | 40 | 50 | |

| Internal Porosity [vol%] | 13.2 | 15.5 | 17.7 | 20.4 | 25.5 |

| Surface Porosity [vol%] | 0.35 | 6.2 | 11.2 | 30.2 | 32.5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, J.-W.; Maeng, W.-Y.; Koh, Y.-H.; Lee, H.; Kim, H.-E. 3D Plotting using Camphene as Pore-regulating Agent to Produce Hierarchical Macro/micro-porous Poly(ε-caprolactone)/calcium phosphate Composite Scaffolds. Materials 2019, 12, 2650. https://doi.org/10.3390/ma12172650

Choi J-W, Maeng W-Y, Koh Y-H, Lee H, Kim H-E. 3D Plotting using Camphene as Pore-regulating Agent to Produce Hierarchical Macro/micro-porous Poly(ε-caprolactone)/calcium phosphate Composite Scaffolds. Materials. 2019; 12(17):2650. https://doi.org/10.3390/ma12172650

Chicago/Turabian StyleChoi, Jae-Won, Woo-Youl Maeng, Young-Hag Koh, Hyun Lee, and Hyoun-Ee Kim. 2019. "3D Plotting using Camphene as Pore-regulating Agent to Produce Hierarchical Macro/micro-porous Poly(ε-caprolactone)/calcium phosphate Composite Scaffolds" Materials 12, no. 17: 2650. https://doi.org/10.3390/ma12172650