Evaluation of Grain Boundary Network and Improvement of Intergranular Cracking Resistance in 316L Stainless Steel after Grain Boundary Engineering

Abstract

1. Introduction

2. Experimental Methods

2.1. Materials

2.2. Stress Corrosion Cracking

3. Results

3.1. Grain Boundary Character Distribution (GBCD)

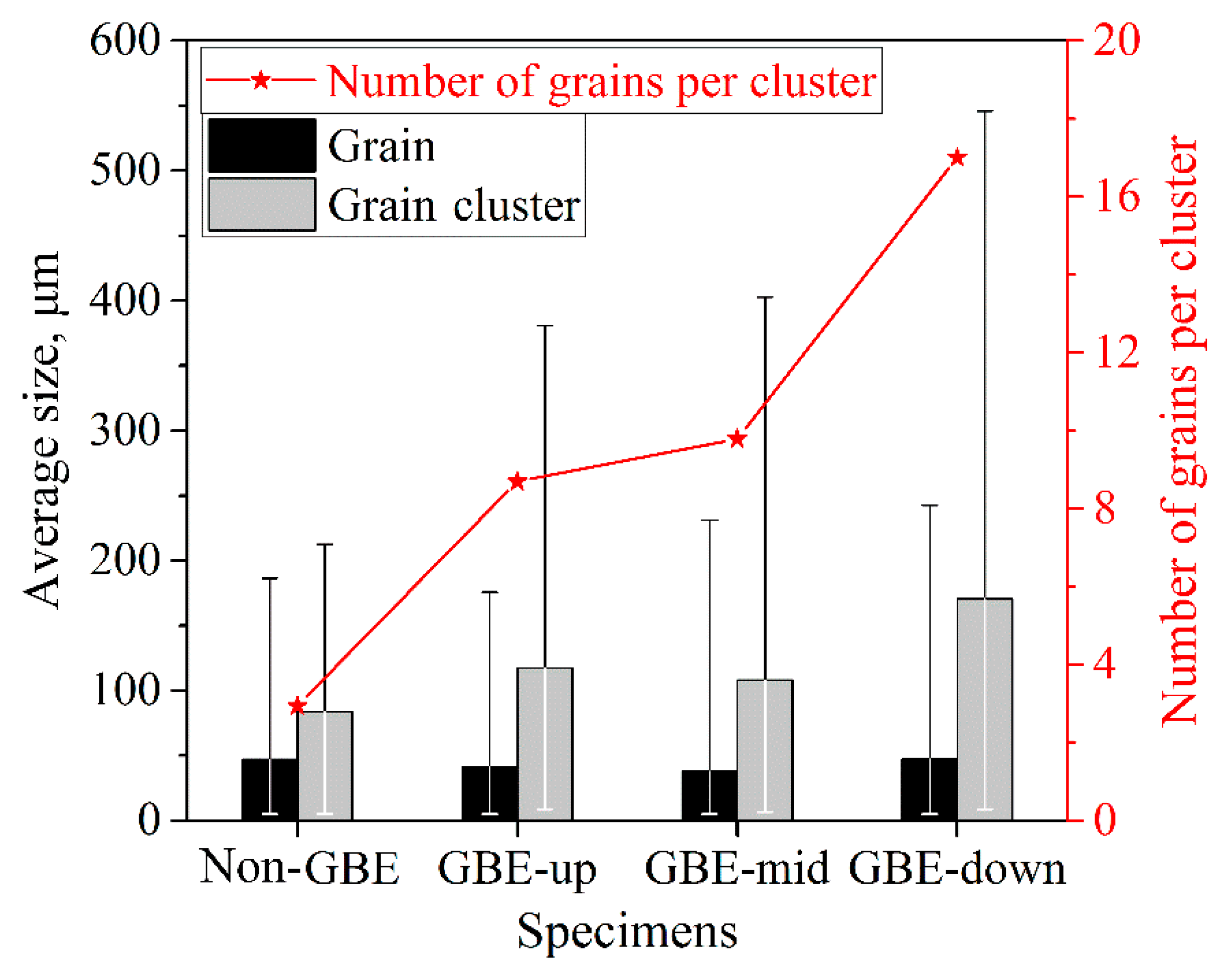

3.2. Topological Characteristics of Grain clusters

3.3. Evaluation of Random Boundary Network

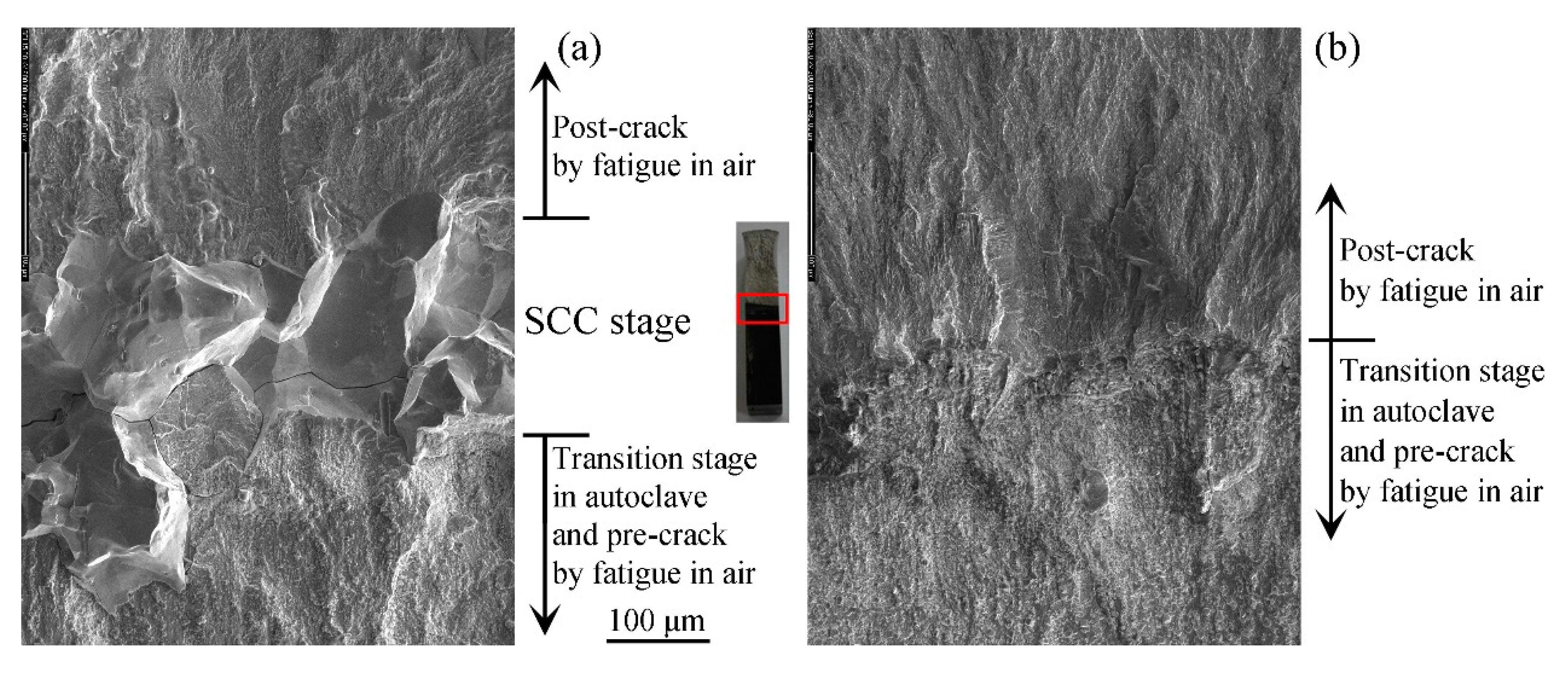

3.4. SCC Cracks

4. Discussion

4.1. Thermo-mechanical Process for GBE

4.2. Quantification of the Extent of GBE

5. Conclusions

- (1)

- Warm-rolling plus annealing is an applicable procedure to increase the fraction of low-∑ CSL boundaries of large-sized 316L stainless steel in terms of GBE. The SCC test shows that the GBE 316L sample exhibited a higher resistance to intergranular SCC than the sample without GBE treatment.

- (2)

- The high fraction of ∑3n boundaries is a highly desired result of GBE processing. However, there is a large difference between the boundary number fraction and the boundary length fraction. Although the length fraction of ∑3n boundaries can be increased to more than 70% after GBE, the number fraction is only approximately 50%. This result is correlated with the mechanism difference to form the ∑3n boundaries. Most of the ∑3 boundaries were generated via twinning operations, and they had a larger size on average. All the high-order ∑3n boundaries were formed by encounters of grain growth, having a smaller size on average.

- (3)

- A connected non-twin boundary network still exists in the 316L after GBE. The relatively low number fraction of twin boundaries and the formation of grain clusters are contributing factors.

- (4)

- The term through-view random boundary path (TRBP) is proposed to evaluate the extent of GBE. As the twin boundary fraction increases, not only does the number of TRBPs decrease, but the normalized length of the minimum TRBP (DR) increases monotonically, which leads to intergranular SCC propagating through a longer path with zigzag. Therefore, intergranular SCC becomes more difficult and even prevented.

Author Contributions

Funding

Conflicts of Interest

References

- Kobayashi, S.; Kobayashi, R.; Watanabe, T. Control of grain boundary connectivity based on fractal analysis for improvement of intergranular corrosion resistance in SUS316L austenitic stainless steel. Acta Mater. 2016, 102, 397–405. [Google Scholar] [CrossRef]

- Shi, F.; Tian, P.C.; Jia, N.; Ye, Z.H.; Qi, Y.; Liu, C.M.; Li, X.W. Improving intergranular corrosion resistance in a nickel-free and manganese-bearing high-nitrogen austenitic stainless steel through grain boundary character distribution optimization. Corros. Sci. 2016, 107, 49–59. [Google Scholar] [CrossRef]

- Hu, C.L.; Xi, S.; Li, H.; Liu, T.G.; Zhou, B.X.; Chen, W.J.; Wang, N. Improving the intergranular corrosion resistance of 304 stainless steel by grain boundary network control. Corros. Sci. 2011, 53, 1880–1886. [Google Scholar] [CrossRef]

- Xia, S.; Li, H.; Liu, T.G.; Zhou, B.X. Appling grain boundary engineering to Alloy 690 tube for enhancing intergranular corrosion resistance. J. Nucl. Mater. 2011, 416, 303–310. [Google Scholar] [CrossRef]

- West, E.A.; Was, G.S. IGSCC of grain boundary engineered 316L and 690 in supercritical water. J. Nucl. Mater. 2009, 392, 264–271. [Google Scholar] [CrossRef]

- Telang, A.; Gill, A.S.; Kumar, M.; Teysseyre, S.; Qian, D.; Mannava, S.R.; Vasudevan, V.K. Iterative thermomechanical processing of alloy 600 for improved resistance to corrosion and stress corrosion cracking. Acta Mater. 2016, 113, 180–193. [Google Scholar] [CrossRef]

- Liu, T.; Xia, S.; Bai, Q.; Zhou, B.; Zhang, L.; Lu, Y.; Shoji, T. Three-dimensional study of grain boundary engineering effects on intergranular stress corrosion cracking of 316 stainless steel in high temperature water. J. Nucl. Mater. 2018, 498, 290–299. [Google Scholar] [CrossRef]

- Telang, A.; Gill, A.S.; Zweiacker, K.; Liu, C.; Wiezorek, J.M.K.; Vasudevan, V.K. Effect of thermo-mechanical processing on sensitization and corrosion in alloy 600 studied by SEM- and TEM-Based diffraction and orientation imaging techniques. J. Nucl. Mater. 2018, 505, 276–288. [Google Scholar] [CrossRef]

- Féron, D. Nuclear Corrosion Science and Engineering; Woodhead Publishing Limited: Sawston, UK, 2012. [Google Scholar]

- Watanabe, T. Approach to grain boundary design for strong and ductile polycrystals. Res. Mech. 1984, 11, 47–84. [Google Scholar]

- Huang, Y.; Wu, W.S.; Cong, S.; Ran, G.; Cen, D.X.; Li, N. Stress Corrosion Behaviors of 316LN Stainless Steel in a Simulated PWR Primary Water Environment. Materials 2018, 11, 1509. [Google Scholar] [CrossRef]

- Frary, M.; Schuh, C.A. Connectivity and percolation behaviour of grain boundary networks in three dimensions. Philos. Mag. 2005, 85, 1123–1143. [Google Scholar] [CrossRef]

- Lin, P.; Palumbo, G.; Erb, U.; Aust, K.T. Influence of grain boundary character distribution on sensitization and intergranular corrosion of alloy 600. Scr. Metall. Mater. 1995, 33, 1387–1392. [Google Scholar] [CrossRef]

- Lehockey, E.M.; Limoges, D.; Palumbo, G.; Sklarchuk, J.; Tomantschger, K.; Vincze, A. On improving the corrosion and growth resistance of positive Pb-acid battery grids by grain boundary engineering. J. Power Sources 1999, 78, 79–83. [Google Scholar] [CrossRef]

- Tan, L.; Allen, T.R.; Busby, J.T. Grain boundary engineering for structure materials of nuclear reactors. J. Nucl. Mater. 2013, 441, 661–666. [Google Scholar] [CrossRef]

- Gertsman, V.Y.; Bruemmer, S.M. Study of grain boundary character along intergranular stress corrosion crack paths in austenitic alloys. Acta Mater. 2001, 49, 1589–1598. [Google Scholar] [CrossRef]

- Alexandreanu, B.; Capell, B.; Was, G.S. Combined effect of special grain boundaries and grain boundary carbides on IGSCC of Ni-16Cr-9Fe-xC alloys. Mater. Sci. Eng. A 2001, 300, 94–104. [Google Scholar] [CrossRef]

- Randle, V. Grain boundary engineering: An overview after 25 years. Mater. Sci. Technol. 2010, 26, 253–261. [Google Scholar] [CrossRef]

- Tsurekawa, S.; Nakamichi, S.; Watanabe, T. Correlation of grain boundary connectivity with grain boundary character distribution in austenitic stainless steel. Acta Mater. 2006, 54, 3617–3626. [Google Scholar] [CrossRef]

- Liu, T.; Xia, S.; Shoji, T.; Bai, Q.; Zhou, B.; Lu, Y. The topology of three-dimensional grain boundary network and its influence on stress corrosion crack propagation characteristics in austenitic stainless steel in a simulated BWR environment. Corros. Sci. 2017, 129, 161–168. [Google Scholar] [CrossRef]

- Schuh, C.A.; Kumar, M.; King, W.E. Analysis of grain boundary networks and their evolution during grain boundary engineering. Acta Mater. 2003, 51, 687–700. [Google Scholar] [CrossRef]

- Gertsman, V.Y. Coincidence Site Lattice Theory of Triple Junctions and Quadruple Points. In Science and Technology of Interfaces; Ankem, S., Pande, C.S., Ovid’ko, I., Ranganathan, S., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2002; pp. 387–398. [Google Scholar]

- Reed, B.W.; Kumar, M. Mathematical methods for analyzing highly-twinned grain boundary networks. Scr. Mater. 2006, 54, 1029–1033. [Google Scholar] [CrossRef]

- Xia, S.; Zhou, B.X.; Chen, W.J. Grain Cluster Microstructure and Grain Boundary Character Distribution in Alloy 690. Metall. Mater. Trans. A 2009, 40, 3016–3030. [Google Scholar] [CrossRef]

- Gertsman, V.Y.; Henager, C.H. Grain boundary junctions in microstructure generated by multiple twinning. Interface Sci. 2003, 11, 403–415. [Google Scholar] [CrossRef]

- Liu, T.G.; Xia, S.; Li, H.; Zhou, B.X.; Bai, Q. The highly twinned grain boundary network formation during grain boundary engineering. Mater. Lett. 2014, 133, 97–100. [Google Scholar] [CrossRef]

- Lind, J.; Li, S.F.; Kumar, M. Twin related domains in 3D microstructures of conventionally processed and grain boundary engineered materials. Acta Mater. 2016, 114, 43–53. [Google Scholar] [CrossRef]

- Barr, C.M.; Leff, A.C.; Demott, R.W.; Doherty, R.D.; Taheri, M.L. Unraveling the origin of twin related domains and grain boundary evolution during grain boundary engineering. Acta Mater. 2018, 144, 281–291. [Google Scholar] [CrossRef]

- Cayron, C. Quantification of multiple twinning in face centred cubic materials. Acta Mater. 2011, 59, 252–262. [Google Scholar] [CrossRef]

- Telang, A.; Gill, A.S.; Tammana, D.; Wen, X.; Kumar, M.; Teysseyre, S.; Mannava, S.R.; Qian, D.; Vasudevan, V.K. Surface grain boundary engineering of Alloy 600 for improved resistance to stress corrosion cracking. Mater. Sci. Eng. A 2015, 648, 280–288. [Google Scholar] [CrossRef]

- Liu, T.; Xia, S.; Du, D.; Bai, Q.; Zhang, L.; Lu, Y. Grain boundary engineering of large-size 316 stainless steel via warm-rolling for improving resistance to intergranular attack. Mater. Lett. 2019, 234, 201–204. [Google Scholar] [CrossRef]

- Brandon, D.G. The structure of high-angle grain boundaries. Acta Metall. 1966, 14, 1479–1484. [Google Scholar] [CrossRef]

- Randle, V. Twinning-related grain boundary engineering. Acta Mater. 2004, 52, 4067–4081. [Google Scholar] [CrossRef]

- Kokawa, H.; Shimada, M.; Michiuchi, M.; Wang, Z.J.; Sato, Y.S. Arrest of weld-decay in 304 austenitic stainless steel by twin-induced grain boundary engineering. Acta Mater. 2007, 55, 5401–5407. [Google Scholar] [CrossRef]

- Liu, T.G.; Xia, S.; Li, H.; Zhou, B.X.; Bai, Q.; Su, C.; Cai, Z.G. Effect of initial grain sizes on the grain boundary network during grain boundary engineering in Alloy 690. J. Mater. Res. 2013, 28, 1165–1176. [Google Scholar] [CrossRef]

- Liu, T.G.; Xia, S.; Li, H.; Zhou, B.X.; Bai, Q. Effect of the pre-existing carbides on the grain boundary network during grain boundary engineering in a nickel based alloy. Mater. Charact. 2014, 91, 89–100. [Google Scholar] [CrossRef]

- Kumar, M.; King, W.E.; Schwartz, A.J. Modifications to the microstructural topology in f.c.c. materials through thermomechanical processing. Acta Mater. 2000, 48, 2081–2091. [Google Scholar] [CrossRef]

- Randle, V.; Coleman, M. A study of low-strain and medium-strain grain boundary engineering. Acta Mater. 2009, 57, 3410–3421. [Google Scholar] [CrossRef]

- Liu, T.; Xia, S.; Zhou, B.; Bai, Q.; Rohrer, G.S. Three-dimensional study of twin boundaries in conventional and grain boundary-engineered 316L stainless steels. J. Mater. Res. 2018, 33, 1742–1754. [Google Scholar] [CrossRef]

- Dash, S.; Brown, N. An investigation of the origin and growth of annealing twins. Acta Metall. 1963, 11, 1067–1075. [Google Scholar] [CrossRef]

- Gleiter, H. The formation of annealing twins. Acta Metall. 1969, 17, 1421–1428. [Google Scholar] [CrossRef]

- Mahajan, S.; Pande, C.S.; Imam, M.A.; Rath, B.B. Formation of annealing twins in f.c.c. crystals. Acta Mater. 1997, 45, 2633–2638. [Google Scholar] [CrossRef]

- Field, D.P.; Bradford, L.T.; Nowell, M.M.; Lillo, T.M. The role of annealing twins during recrystallization of Cu. Acta Mater. 2007, 55, 4233–4241. [Google Scholar] [CrossRef]

- Deepak, K.; Mandal, S.; Athreya, C.N.; Kim, D.-I.; Boer, B.; Subramanya Sarma, V. Implication of grain boundary engineering on high temperature hot corrosion of alloy 617. Corros. Sci. 2016, 106, 293–297. [Google Scholar]

- Michiuchi, M.; Kokawa, H.; Wang, Z.J.; Sato, Y.S.; Sakai, K. Twin-induced grain boundary engineering for 316 austenitic stainless steel. Acta Mater. 2006, 54, 5179–5184. [Google Scholar] [CrossRef]

- Prithiv, T.S.; Bhuyan, P.; Pradhan, S.K.; Subramanya Sarma, V.; Mandal, S. A critical evaluation on efficacy of recrystallization vs. strain induced boundary migration in achieving grain boundary engineered microstructure in a Ni-base superalloy. Acta Mater. 2018, 146, 187–201. [Google Scholar] [CrossRef]

- Lee, S.L.; Richards, N.L. The effect of single-step low strain and annealing of nickel on grain boundary character. Mater. Sci. Eng. A 2005, 390, 81–87. [Google Scholar] [CrossRef]

- Haasen, P. How are new orientations generated during primary recrystallization? MTA 1993, 24, 1001–1015. [Google Scholar] [CrossRef]

- Cayron, C. Multiple twinning in cubic crystals: Geometric/algebraic study and its application for the identification of the Σ3(n) grain boundaries. Acta Crystallogr. Sect. A Found. Crystallogr. 2007, 63 Pt 1, 11–29. [Google Scholar] [CrossRef]

- Abramoff, M.; Magalhaes, P.; Ram, S. Image Processing with ImageJ. Biophotonics Int. 2004, 11, 36–42. [Google Scholar]

- Randle, V. Mechanism of twinning-induced grain boundary engineering in low stacking-fault energy materials. Acta Mater. 1999, 47, 4187–4196. [Google Scholar] [CrossRef]

- Schuh, C.A.; Minich, R.W.; Kumar, M. Connectivity and percolation in simulated grain-boundary networks. Philos. Mag. 2003, 83, 711–726. [Google Scholar] [CrossRef]

- Kobayashi, S.; Maruyama, T.; Tsurekawa, S.; Watanabe, T. Grain boundary engineering based on fractal analysis for control of segregation-induced intergranular brittle fracture in polycrystalline nickel. Acta Mater. 2012, 60, 6200–6212. [Google Scholar] [CrossRef]

| Fe | C | Si | Mn | P | S | Cr | Ni | Mo |

|---|---|---|---|---|---|---|---|---|

| Balance | 0.028 | 0.47 | 1.03 | 0.044 | 0.005 | 16.26 | 10.10 | 2.08 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, T.; Xia, S.; Bai, Q.; Zhou, B.; Lu, Y.; Shoji, T. Evaluation of Grain Boundary Network and Improvement of Intergranular Cracking Resistance in 316L Stainless Steel after Grain Boundary Engineering. Materials 2019, 12, 242. https://doi.org/10.3390/ma12020242

Liu T, Xia S, Bai Q, Zhou B, Lu Y, Shoji T. Evaluation of Grain Boundary Network and Improvement of Intergranular Cracking Resistance in 316L Stainless Steel after Grain Boundary Engineering. Materials. 2019; 12(2):242. https://doi.org/10.3390/ma12020242

Chicago/Turabian StyleLiu, Tingguang, Shuang Xia, Qin Bai, Bangxin Zhou, Yonghao Lu, and Tetsuo Shoji. 2019. "Evaluation of Grain Boundary Network and Improvement of Intergranular Cracking Resistance in 316L Stainless Steel after Grain Boundary Engineering" Materials 12, no. 2: 242. https://doi.org/10.3390/ma12020242

APA StyleLiu, T., Xia, S., Bai, Q., Zhou, B., Lu, Y., & Shoji, T. (2019). Evaluation of Grain Boundary Network and Improvement of Intergranular Cracking Resistance in 316L Stainless Steel after Grain Boundary Engineering. Materials, 12(2), 242. https://doi.org/10.3390/ma12020242