Utilizing a Single Silica Nanospring as an Insulating Support to Characterize the Electrical Transport and Morphology of Nanocrystalline Graphite

Abstract

:1. Introduction

2. Experimental

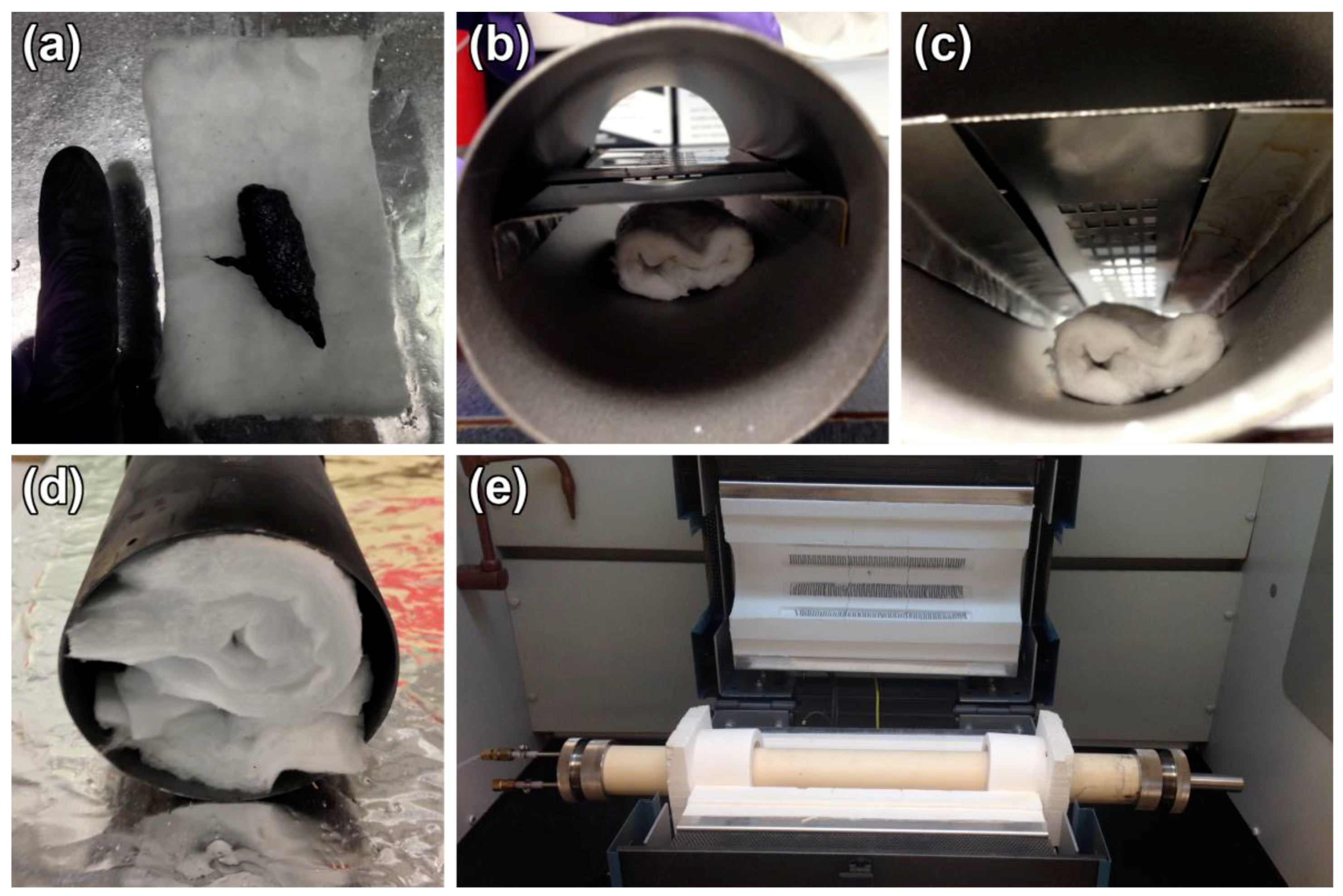

2.1. Silica NS Growth and GUITAR Deposition

2.2. Device Fabrication

2.3. Electrical Measurements and Microscopy Equipment

2.4. Raman Spectroscopy

3. Results and Discussion

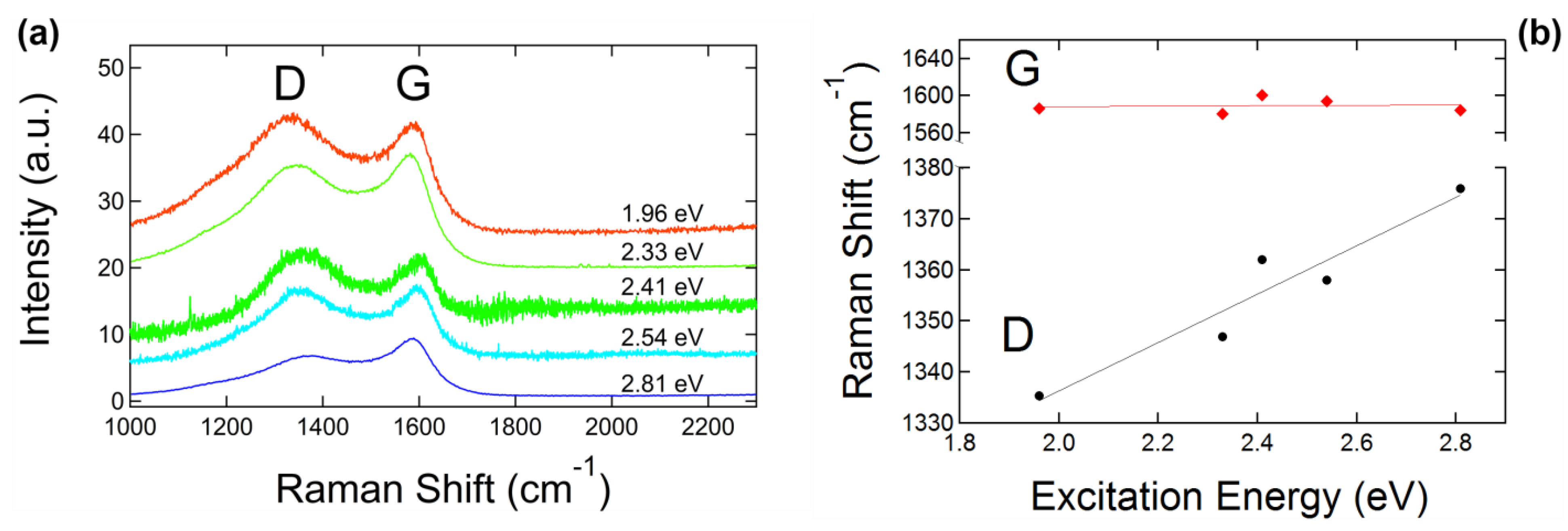

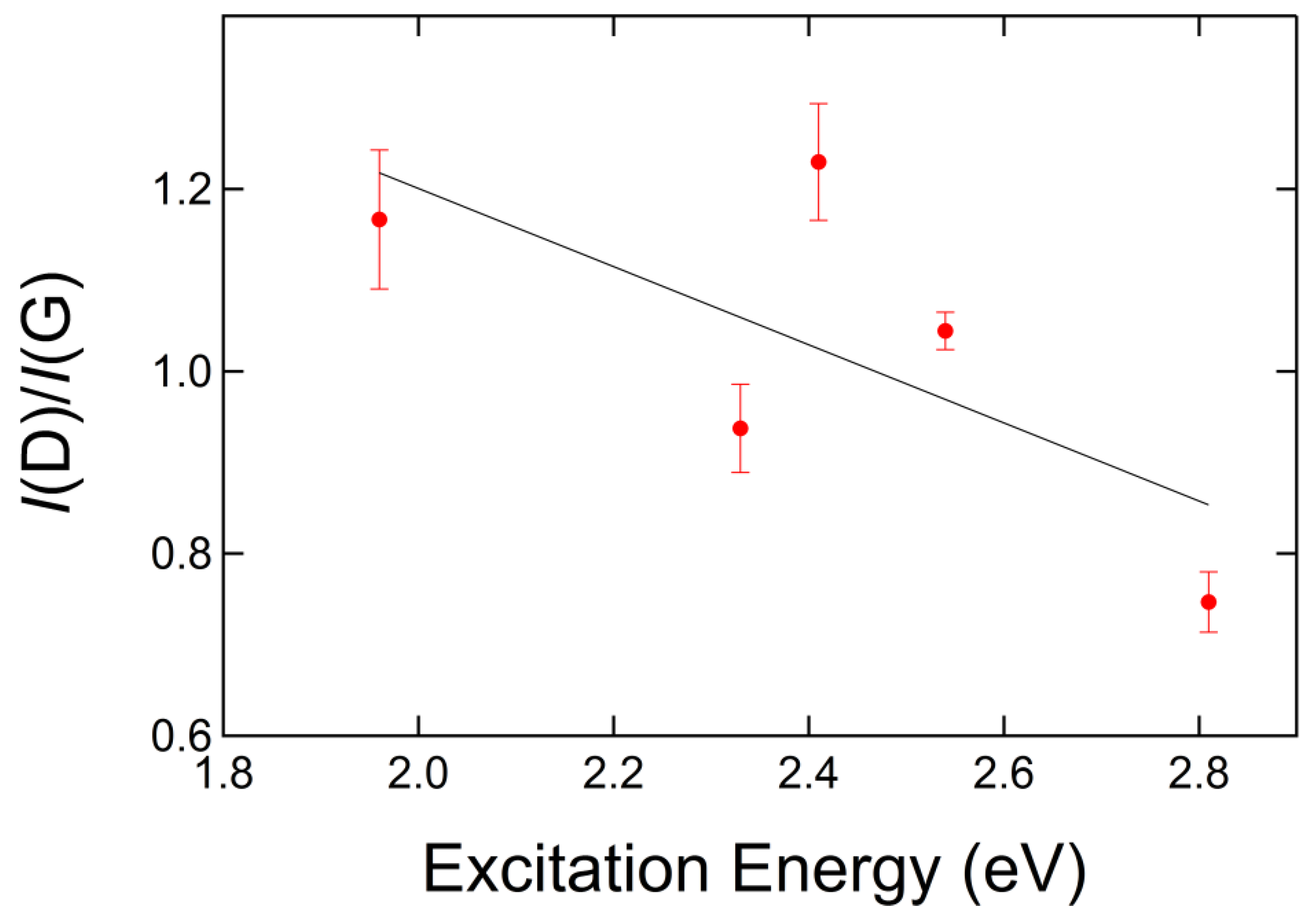

3.1. Raman Spectroscopy

3.2. GUITAR Surface Morphology

3.3. Electrical Characteristics

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Cheng, I.F.; Xie, Y.; Allen Gonzales, R.; Brejna, P.R.; Sundararajan, J.P.; Fouetio Kengne, B.A.; Eric Aston, D.; McIlroy, D.N.; Foutch, J.D.; Griffiths, P.R. Synthesis of graphene paper from pyrolyzed asphalt. Carbon 2011, 49, 2852–2861. [Google Scholar] [CrossRef]

- Gyan, I.O.; Wojcik, P.M.; Aston, D.E.; McIlroy, D.N.; Cheng, I.F. A Study of the Electrochemical Properties of a New Graphitic Material: GUITAR. ChemElectroChem 2015, 2, 700–706. [Google Scholar] [CrossRef]

- Villarreal, C.C.; Pham, T.; Ramnani, P.; Mulchandani, A. Carbon allotropes as sensors for environmental monitoring. Curr. Opin. Electrochem. 2017, 3, 106–113. [Google Scholar] [CrossRef]

- Cheng, I.F.; Xie, Y.; Gyan, I.O.; Nicholas, N.W. Highest measured anodic stability in aqueous solutions: Graphenic electrodes from the thermolyzed asphalt reaction. RSC Adv. 2013, 3, 2379. [Google Scholar] [CrossRef]

- Gyan, I.O.; Cheng, I.F. Electrochemical study of biologically relevant molecules at electrodes constructed from GUITAR, a new carbon allotrope. Microchem. J. 2015, 122, 39–44. [Google Scholar] [CrossRef]

- Kabir, H.; Gyan, I.; Foutch, J.; Zhu, H.; Cheng, I. Application of GUITAR on the Negative Electrode of the Vanadium Redox Flow Battery: Improved V3 +/2 + Heterogeneous Electron Transfer with Reduced Hydrogen Gassing. C 2016, 2, 13. [Google Scholar] [CrossRef]

- Morgan, M. Electrical conduction in amorphous carbon films. Thin Solid Film. 1971, 7, 313–323. [Google Scholar] [CrossRef]

- Hauser, J.J. Hopping conductivity in amorphous carbon films. Solid State Commun. 1975, 17, 1577–1580. [Google Scholar] [CrossRef]

- Romanenko, A.I.; Anikeeva, O.B.; Okotrub, A.V.; Kuznetsov, V.L.; Butenko, Y.V.; Chuvilin, A.L.; Dong, C.; Ni, Y. Temperature Dependence of Electroresistivity, Negative and Positive Magnetoresistivity of Graphite/Diamond Nanocomposites and Onion-Like Carbon. MRS Proc. 2001, 703. [Google Scholar] [CrossRef]

- Tyler, W.W.; Wilson, A.C., Jr. Thermal Conductivity, Electrical Resistivity and Thermoelectric Power of Graphite. Phys. Rev. 1953, 89, 870–875. [Google Scholar] [CrossRef]

- Powell, R.W.; Schofield, F.H. The thermal and electrical conductivities of carbon and graphite to high temperatures. Proc. Phys. Soc. 1939, 51, 153–172. [Google Scholar] [CrossRef]

- Buerschaper, R.A. Thermal and Electrical Conductivity of Graphite and Carbon at Low Temperatures. J. Appl. Phys. 1944, 15, 452–454. [Google Scholar] [CrossRef]

- Smith, A.W.; Rasor, N.S. Observed Dependence of the Low-Temperature Thermal and Electrical Conductivity of Graphite on Temperature, Type, Neutron Irradiation, and Bromination. Phys. Rev. 1956, 104, 885–891. [Google Scholar] [CrossRef]

- Mal’tseva, L.F.; Marmer, É.N. Determination of the electrical properties of graphite at high temperatures. Sov. Powder Metall. Met. Ceram. 1962, 1, 34–38. [Google Scholar] [CrossRef]

- Adkins, C.J.; Freake, S.M.; Hamilton, E.M. Electrical conduction in amorphous carbon. Philos. Mag. 1970, 22, 183–188. [Google Scholar] [CrossRef]

- Matsubara, K.; Sugihara, K.; Tsuzuku, T. Electrical resistance in the c direction of graphite. Phys. Rev. B 1990, 41, 969–974. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, C.; Pan, L.; Fu, X.; Yin, P.; Zou, H. Electrical conductivity of single polycrystalline-amorphous carbon nanocoils. Carbon 2016, 98, 285–290. [Google Scholar] [CrossRef]

- Ma, H.; Nakata, K.; Pan, L.; Hirahara, K.; Nakayama, Y. Relationship between the structure of carbon nanocoils and their electrical property. Carbon 2014, 73, 71–77. [Google Scholar] [CrossRef]

- Fujii, M.; Matsui, M.; Motojima, S.; Hishikawa, Y. Magnetoresistance in carbon micro-coils annealed at various temperatures. J. Cryst. Growth 2002, 237, 1937–1941. [Google Scholar] [CrossRef]

- Knight, D.S.; White, W.B. Characterization of diamond films by Raman spectroscopy. J. Mater. Res. 1989, 4, 385–393. [Google Scholar] [CrossRef]

- Tuinstra, F.; Koenig, J.L. Raman Spectrum of Graphite. J. Chem. Phys. 1970, 53, 1126–1130. [Google Scholar] [CrossRef]

- Nemanich, R.J.; Solin, S.A. First-and second-order Raman scattering from finite-size crystals of graphite. Phys. Rev. B 1979, 20, 392. [Google Scholar] [CrossRef]

- Lespade, P.; Al-Jishi, R.; Dresselhaus, M.S. Model for Raman scattering from incompletely graphitized carbons. Carbon 1982, 20, 427–431. [Google Scholar] [CrossRef]

- Wada, N.; Gaczi, P.J.; Solin, S.A. “Diamond-like” 3-fold coordinated amorphous carbon. J. Non Cryst. Solids 1980, 35, 543–548. [Google Scholar] [CrossRef]

- Dillon, R.O.; Woollam, J.A.; Katkanant, V. Use of Raman scattering to investigate disorder and crystallite formation in as-deposited and annealed carbon films. Phys. Rev. B 1984, 29, 3482. [Google Scholar] [CrossRef]

- Yoshikawa, M.; Nagai, N.; Matsuki, M.; Fukuda, H.; Katagiri, G.; Ishida, H.; Ishitani, A.; Nagai, I. Raman scattering from sp 2 carbon clusters. Phys. Rev. B 1992, 46, 7169. [Google Scholar] [CrossRef] [PubMed]

- Wagner, J.; Ramsteiner, M.; Wild, C.; Koidl, P. Resonant Raman scattering of amorphous carbon and polycrystalline diamond films. Phys. Rev. B 1989, 40, 1817. [Google Scholar] [CrossRef]

- Schwan, J.; Ulrich, S.; Batori, V.; Ehrhardt, H.; Silva, S.R.P. Raman spectroscopy on amorphous carbon films. J. Appl. Phys. 1996, 80, 440–447. [Google Scholar] [CrossRef]

- Wojcik, P.M.; Bakharev, P.V.; Corti, G.; McIlroy, D.N. Nucleation, evolution, and growth dynamics of amorphous silica nanosprings. Mater. Res. Express 2017, 4, 015004. [Google Scholar] [CrossRef]

- Wang, L.; Major, D.; Paga, P.; Zhang, D.; Norton, M.G.; McIlroy, D.N. High yield synthesis and lithography of silica-based nanospring mats. Nanotechnology 2006, 17, S298–S303. [Google Scholar] [CrossRef]

- Xie, Y.; McAllister, S.D.; Hyde, S.A.; Sundararajan, J.P.; FouetioKengne, B.A.; McIlroy, D.N.; Cheng, I.F. Sulfur as an important co-factor in the formation of multilayer graphene in the thermolyzed asphalt reaction. J. Mater. Chem. 2012, 22, 5723. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Robertson, J. Interpretation of Raman spectra of disordered and amorphous carbon. Phys. Rev. B 2000, 61, 14095. [Google Scholar] [CrossRef] [Green Version]

- Gruen, D.M. Nanocrystalline diamond films. Annu. Rev. Mater. Sci. 1999, 29, 211–259. [Google Scholar] [CrossRef]

- Zhou, D.; Gruen, D.M.; Qin, L.C.; McCauley, T.G.; Krauss, A.R. Control of diamond film microstructure by Ar additions to CH4/H2 microwave plasmas. J. Appl. Phys. 1998, 84, 1981–1989. [Google Scholar] [CrossRef] [Green Version]

- Nemanich, R.J.; Glass, J.T.; Lucovsky, G.; Shroder, R.E. Raman scattering characterization of carbon bonding in diamond and diamondlike thin films. J. Vac. Sci. Technol. Vac. Surf. Film. 1988, 6, 1783–1787. [Google Scholar] [CrossRef]

- Shroder, R.E.; Nemanich, R.J.; Glass, J.T. Analysis of the composite structures in diamond thin films by Raman spectroscopy. Phys. Rev. B 1990, 41, 3738. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Robertson, J. Origin of the 1150—cm−1 Raman mode in nanocrystalline diamond. Phys. Rev. B 2001, 63. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Basko, D.M. Raman spectroscopy as a versatile tool for studying the properties of graphene. Nat. Nanotechnol. 2013, 8, 235–246. [Google Scholar] [CrossRef] [Green Version]

- Martins Ferreira, E.H.; Moutinho, M.V.O.; Stavale, F.; Lucchese, M.M.; Capaz, R.B.; Achete, C.A.; Jorio, A. Evolution of the Raman spectra from single-, few-, and many-layer graphene with increasing disorder. Phys. Rev. B 2010, 82. [Google Scholar] [CrossRef] [Green Version]

- Pócsik, I.; Hundhausen, M.; Koós, M.; Ley, L. Origin of the D peak in the Raman spectrum of microcrystalline graphite. J. Non-Cryst. Solids 1998, 227, 1083–1086. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Robertson, J. Resonant Raman spectroscopy of disordered, amorphous, and diamondlike carbon. Phys. Rev. B 2001, 64. [Google Scholar] [CrossRef] [Green Version]

- Matthews, M.J.; Pimenta, M.A.; Dresselhaus, G.; Dresselhaus, M.S.; Endo, M. Origin of dispersive effects of the Raman D band in carbon materials. Phys. Rev. B 1999, 59, R6585. [Google Scholar] [CrossRef]

- Inagaki, M. Discussion of the formation of nanometric texture in spherical carbon bodies. Carbon 1997, 35, 711–713. [Google Scholar] [CrossRef]

- Serp, P.; Feurer, R.; Kalck, P.; Kihn, Y.; Faria, J.L.; Figueiredo, J.L. A chemical vapour deposition process for the production of carbon nanospheres. Carbon 2001, 39, 621–626. [Google Scholar] [CrossRef]

- Kang, Z.C.; Wang, Z.L. On accretion of nanosize carbon spheres. J. Phys. Chem. 1996, 100, 5163–5165. [Google Scholar] [CrossRef] [Green Version]

- Kang, Z.C.; Wang, Z.L. Chemical activities of graphitic carbon spheres. J. Mol. Catal. Chem. 1997, 118, 215–222. [Google Scholar] [CrossRef] [Green Version]

- Qian, H.; Han, F.; Zhang, B.; Guo, Y.; Yue, J.; Peng, B. Non-catalytic CVD preparation of carbon spheres with a specific size. Carbon 2004, 42, 761–766. [Google Scholar] [CrossRef]

- Jin, Y.Z.; Gao, C.; Hsu, W.K.; Zhu, Y.; Huczko, A.; Bystrzejewski, M.; Roe, M.; Lee, C.Y.; Acquah, S.; Kroto, H.; et al. Large-scale synthesis and characterization of carbon spheres prepared by direct pyrolysis of hydrocarbons. Carbon 2005, 43, 1944–1953. [Google Scholar] [CrossRef]

- Nieto-Márquez, A.; Valverde, J.L.; Keane, M.A. Selective low temperature synthesis of carbon nanospheres via the catalytic decomposition of trichloroethylene. Appl. Catal. Gen. 2009, 352, 159–170. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, W.; Luo, R.; Shang, H. Preparation of carbon nanospheres by non-catalytic chemical vapor deposition and their formation mechanism. New Carbon Mater. 2016, 31, 467–474. [Google Scholar] [CrossRef]

- Venugopal, A.; Pirkle, A.; Wallace, R.M.; Colombo, L.; Vogel, E.M.; Secula, E.M.; Seiler, D.G.; Khosla, R.P.; Herr, D.; Michael Garner, C.; et al. Contact Resistance Studies of Metal on HOPG and Graphene Stacks; AIP: College Park, MD, USA, 2009; pp. 324–327. [Google Scholar]

- Anteroinen, J.; Kim, W.; Stadius, K.; Riikonen, J.; Lipsanen, H.; Ryynanen, J. Extraction of graphene-titanium contact resistances using transfer length measurement and a curve-fit method. World Acad. Sci. Eng. Technol. 2012, 6, 8–25. [Google Scholar]

- Zeiger, M.; Jäckel, N.; Mochalin, V.N.; Presser, V. Review: Carbon onions for electrochemical energy storage. J. Mater. Chem. A 2016, 4, 3172–3196. [Google Scholar] [CrossRef] [Green Version]

- Liu, M. Coating Technology of Nuclear Fuel Kernels: A Multiscale View. In Modern Surface Engineering Treatments; Aliofkhazraei, M., Ed.; InTech Open: London, UK, 2013; ISBN 978-953-51-1149-8. [Google Scholar]

- Pawlyta, M.; Hercman, H. Transmission electron microscopy (TEM) as a tool for identification of combustion products: Application to black layers in speleothems. Ann. Soc. Geol. Pol. 2016, 86, 237–248. [Google Scholar] [CrossRef] [Green Version]

- Buseck, P.R.; Adachi, K.; Gelencsér, A.; Tompa, É.; Pósfai, M. Ns-Soot: A Material-Based Term for Strongly Light-Absorbing Carbonaceous Particles. Aerosol Sci. Technol. 2014, 48, 777–788. [Google Scholar] [CrossRef]

| Device | Average Resistivity (Ω m) at 20 °C |

|---|---|

| 1 | 3.1 ± 0.62 × 10−3 |

| 2 | 20 ± 3.8 × 10−3 |

| 3 | 7.4 ± 1.4 × 10−3 |

| 4 | 3.6 ± 0.75 × 10−3 |

| 5 | 2.1 ± 0.62 × 10−3 |

| 6 | 4.9 ± 1.1 × 10−3 |

| 7 | 1.6 ± 0.18 × 10−3 |

| 8 | 1.3 ± 0.25 × 10−3 |

| 9 | 1.2 ± 0.19 × 10−3 |

| 10 | 1.6 ± 0.34 × 10−3 |

| 11 | 0.92 ± 0.16 × 10−3 |

| Device | (Ω m/°C) | (Ω m) | TCOR (°C−1) |

|---|---|---|---|

| 1 | −8.9 ± 1.2 × 10−6 | 3.1 ± 0.62 × 10−3 | −2.9 ± 0.69 × 10−3 |

| 2 | −5.0 ± 1.5 × 10−5 | 20 ± 3.8 × 10−3 | −2.5 ± 0.88 × 10−3 |

| 3 | −1.8 ± 0.036 × 10−5 | 7.4 ± 1.4 × 10−3 | −2.4 ± 0.46 × 10−3 |

| 4 | −3.1 ± 0.32 × 10−6 | 3.6 ± 0.75 × 10−3 | −0.87 ± 0.20 × 10−3 |

| 5 | −3.7 ± 0.097 × 10−6 | 2.1 ± 0.62 × 10−3 | −1.8 ± 0.52 × 10−3 |

| 6 | −7.9 ± 0.36 × 10−6 | 4.9 ± 1.1 × 10−3 | −1.6 ± 0.37 × 10−3 |

| 7 | −2.3 ± 0.032 × 10−6 | 1.6 ± 0.18 × 10−3 | −1.4 ± 0.17 × 10−3 |

| 8 | −1.6 ± 0.043 × 10−6 | 1.3 ± 0.25 × 10−3 | −1.2 ± 0.24 × 10−3 |

| 9 | −1.3 ± 0.056 × 10−6 | 1.2 ± 0.19 × 10−3 | −1.0 ± 0.17 × 10−3 |

| 10 | −2.2 ± 0.049 × 10−6 | 1.6 ± 0.34 × 10−3 | −1.4 ± 0.29 × 10−3 |

| 11 | −1.2 ± 0.069 × 10−6 | 0.92 ± 0.16 × 10−3 | −1.3 ± 0.24 × 10−3 |

| Material | Resistivity (Ω m) at 20 °C | Conductivity (S/m) at 20 °C | Temperature Coefficient at 20 °C (°C−1) | Reference |

|---|---|---|---|---|

| GUITAR | 4.3 × 10−3 | 2.3 × 102 | −0.0017 | This Study |

| Carbon Onions | 2.5 × 10−3 | 4.0 × 102 | N/A | [53] |

| Carbon Black | 1.7 × 10−3 | 6.0 × 102 | −0.00094* | [9] |

| a-C (70 nm thick) | 1.0 × 10−3 | 1.0 × 103 | N/A | [7] |

| Graphitized Soot | 3.3 × 10−4 | 3.0 × 103 | −0.0014* | [9] |

| Carbon NC | 1.9 × 10−4 | 5.3 × 103 | −0.0012* | [18] |

| POCO Graphite AF | 9.6 × 10−5 | 1.0 × 104 | −0.0023* | [9] |

| Lampblack Graphite | 5.5 × 10−5 | 1.8 × 104 | −0.0013* | [10] |

| Carbon | 4.5 × 10−5 | 2.2 × 104 | −0.00040* | [12] |

| Grade AGOT Graphite | 1.0 × 10−5 | 9.7 × 104 | −0.0016* | [10] |

| Natural Graphite | 9.8 × 10−6 | 1.0 × 105 | −0.0010* | [10] |

| Grade CS Graphite | 7.7 × 10−6 | 1.3 × 105 | −0.0017* | [10] |

| Acheson Graphite | 6.3 × 10−6 | 1.6 × 105 | −0.0011* | [12] |

| Carbon NC (as grown) | 3.6 × 10−6 | 2.8 × 105 | −0.0015* | [19] |

| Carbon NC (annealed) | 4.1 × 10−7 | 2.4 × 106 | −0.00072* | [19] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wojcik, P.M.; Rajabi, N.; Zhu, H.; Estrada, D.; Davis, P.H.; Pandhi, T.; Cheng, I.F.; McIlroy, D.N. Utilizing a Single Silica Nanospring as an Insulating Support to Characterize the Electrical Transport and Morphology of Nanocrystalline Graphite. Materials 2019, 12, 3794. https://doi.org/10.3390/ma12223794

Wojcik PM, Rajabi N, Zhu H, Estrada D, Davis PH, Pandhi T, Cheng IF, McIlroy DN. Utilizing a Single Silica Nanospring as an Insulating Support to Characterize the Electrical Transport and Morphology of Nanocrystalline Graphite. Materials. 2019; 12(22):3794. https://doi.org/10.3390/ma12223794

Chicago/Turabian StyleWojcik, Peter M., Negar Rajabi, Haoyu Zhu, David Estrada, Paul H. Davis, Twinkle Pandhi, I. Francis Cheng, and David N. McIlroy. 2019. "Utilizing a Single Silica Nanospring as an Insulating Support to Characterize the Electrical Transport and Morphology of Nanocrystalline Graphite" Materials 12, no. 22: 3794. https://doi.org/10.3390/ma12223794