Sintering Behaviors, Microstructure, and Microwave Dielectric Properties of CaTiO3–LaAlO3 Ceramics Using CuO/B2O3 Additions

Abstract

:1. Introduction

2. Experimental Procedure

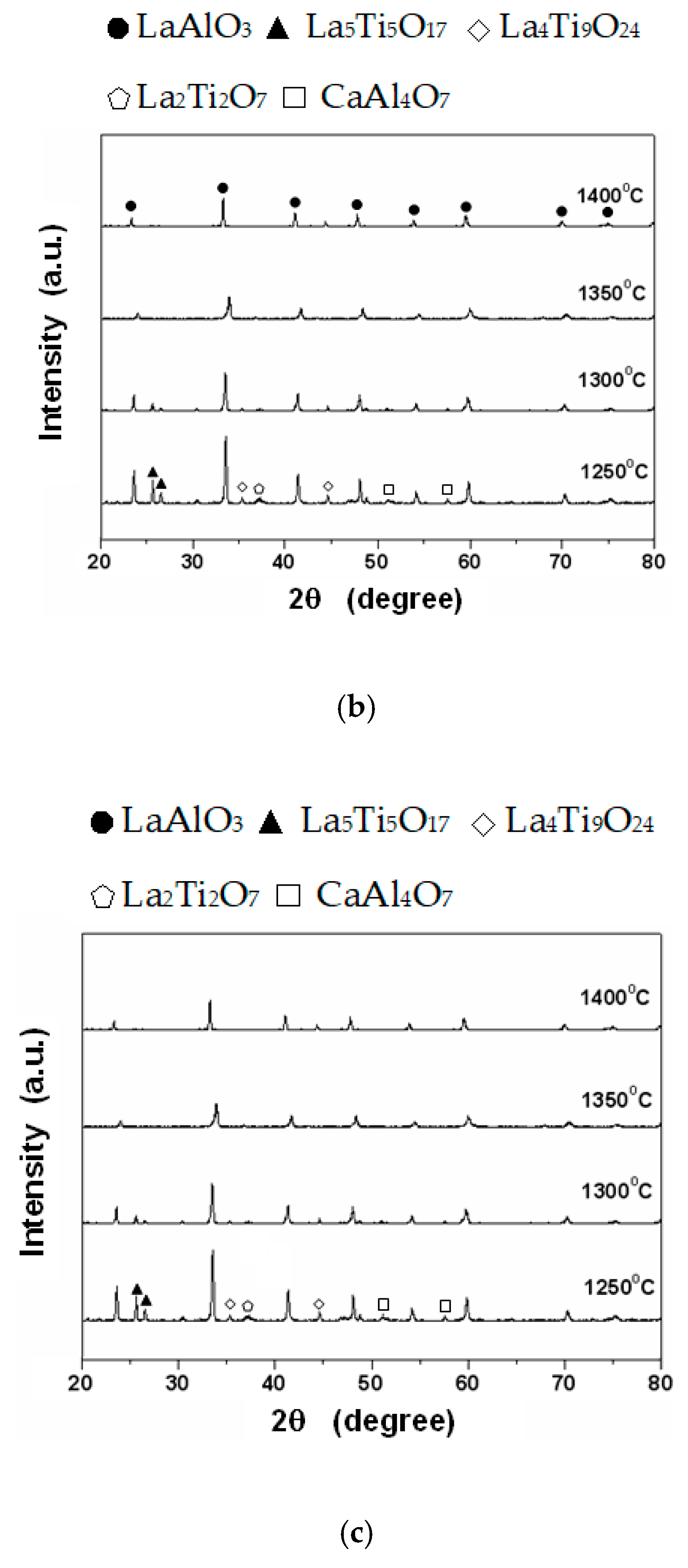

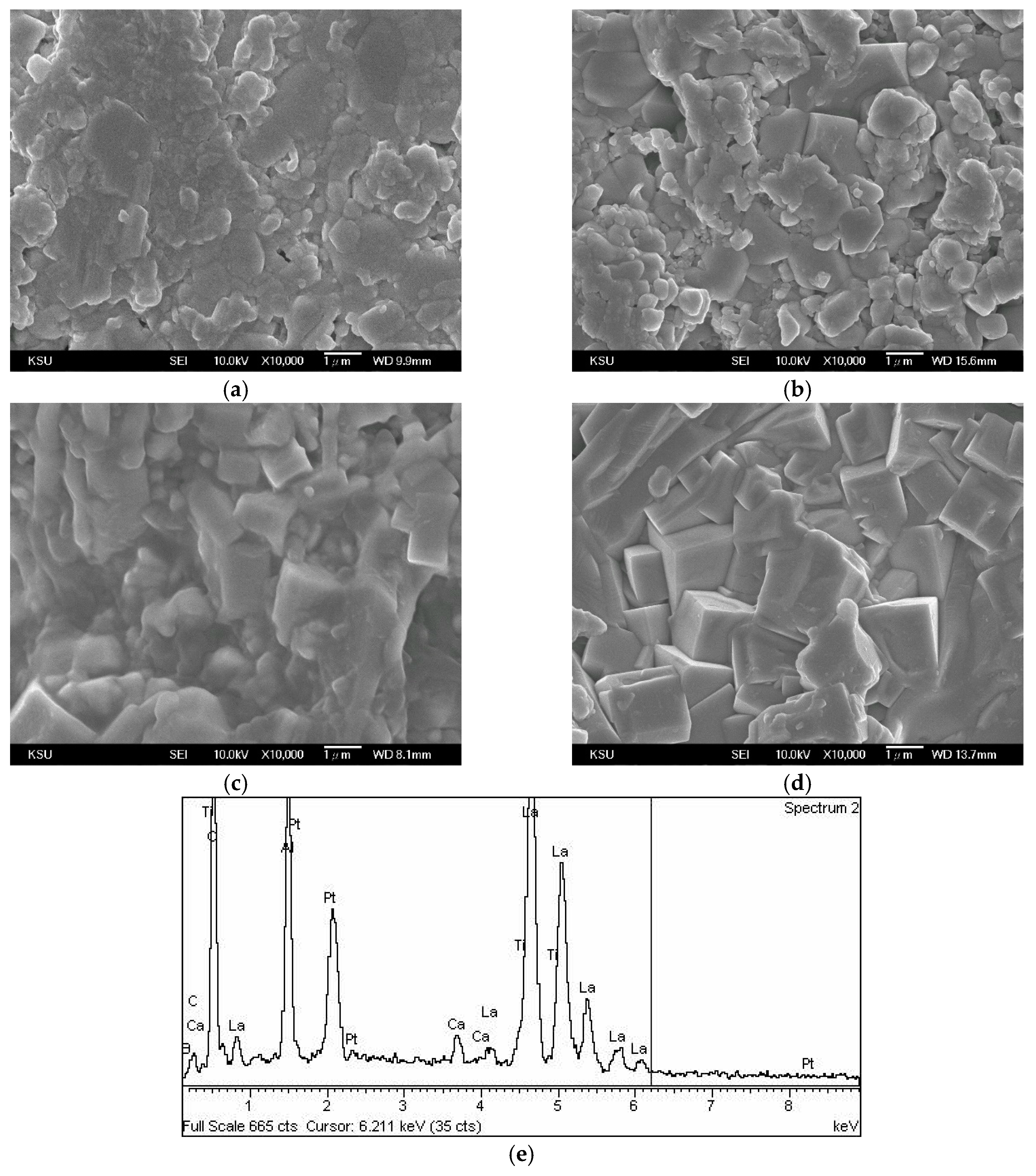

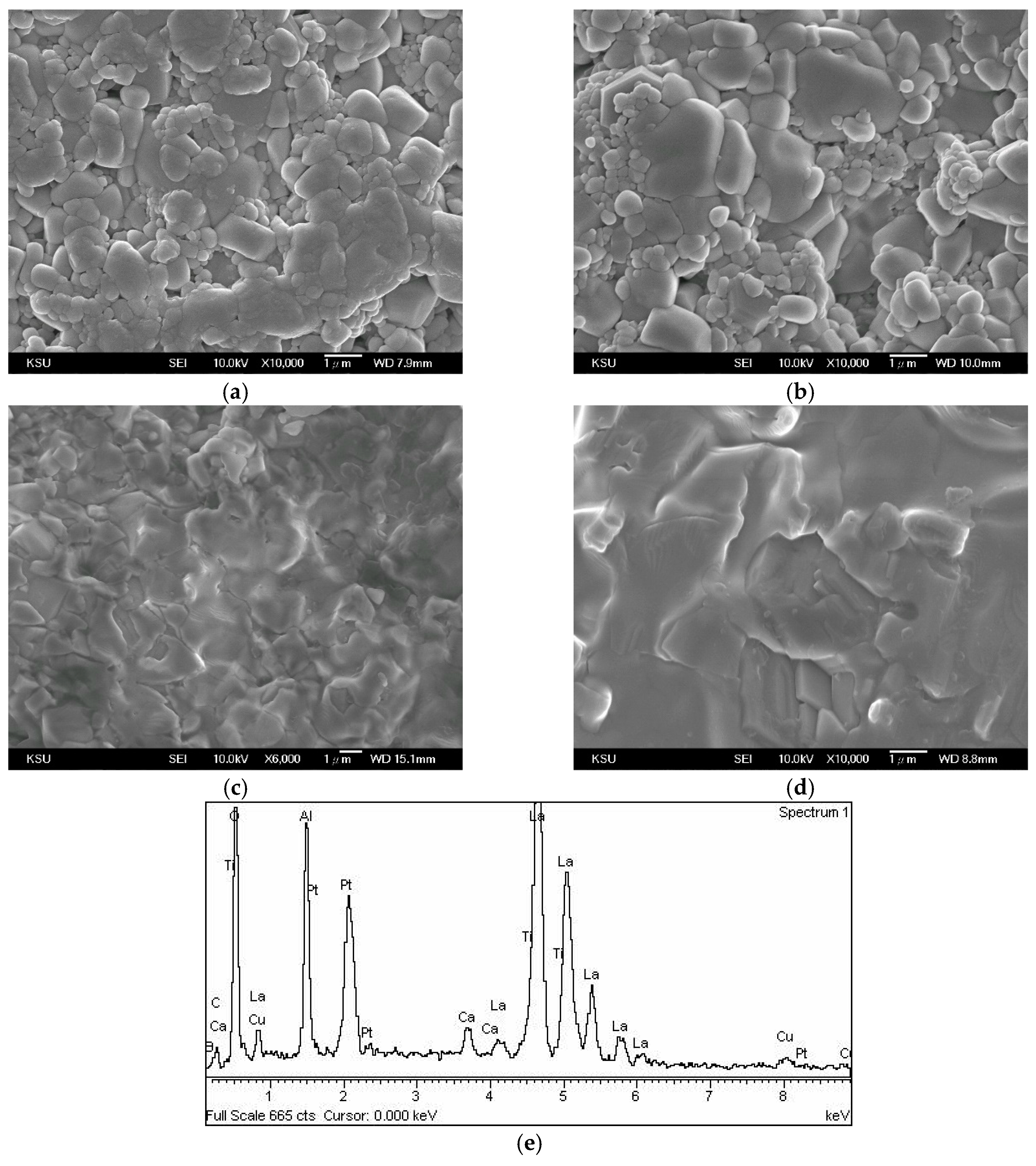

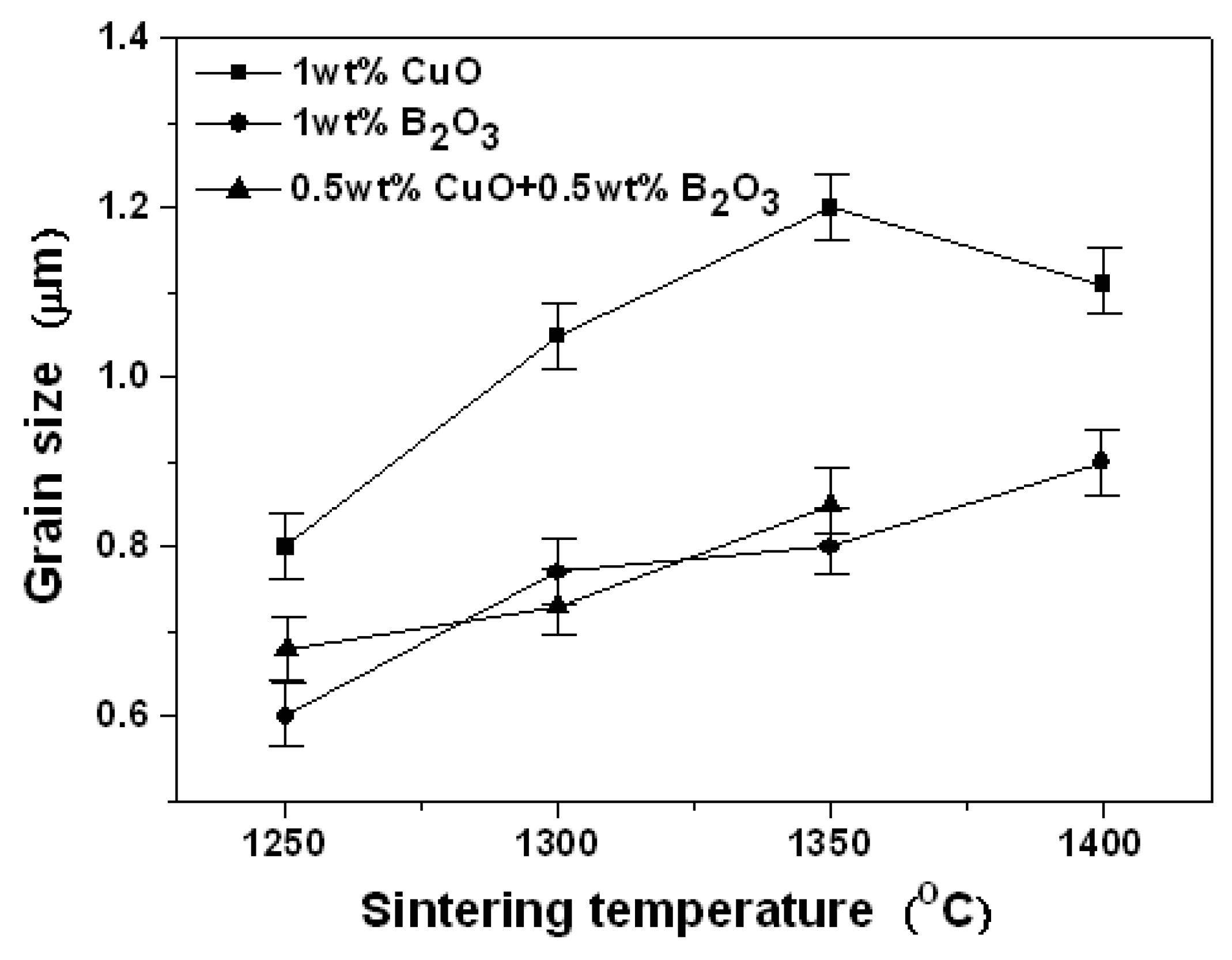

3. Results and Discussion

3.1. Microstructure

3.2. Dielectric Properties

4. Conclusions

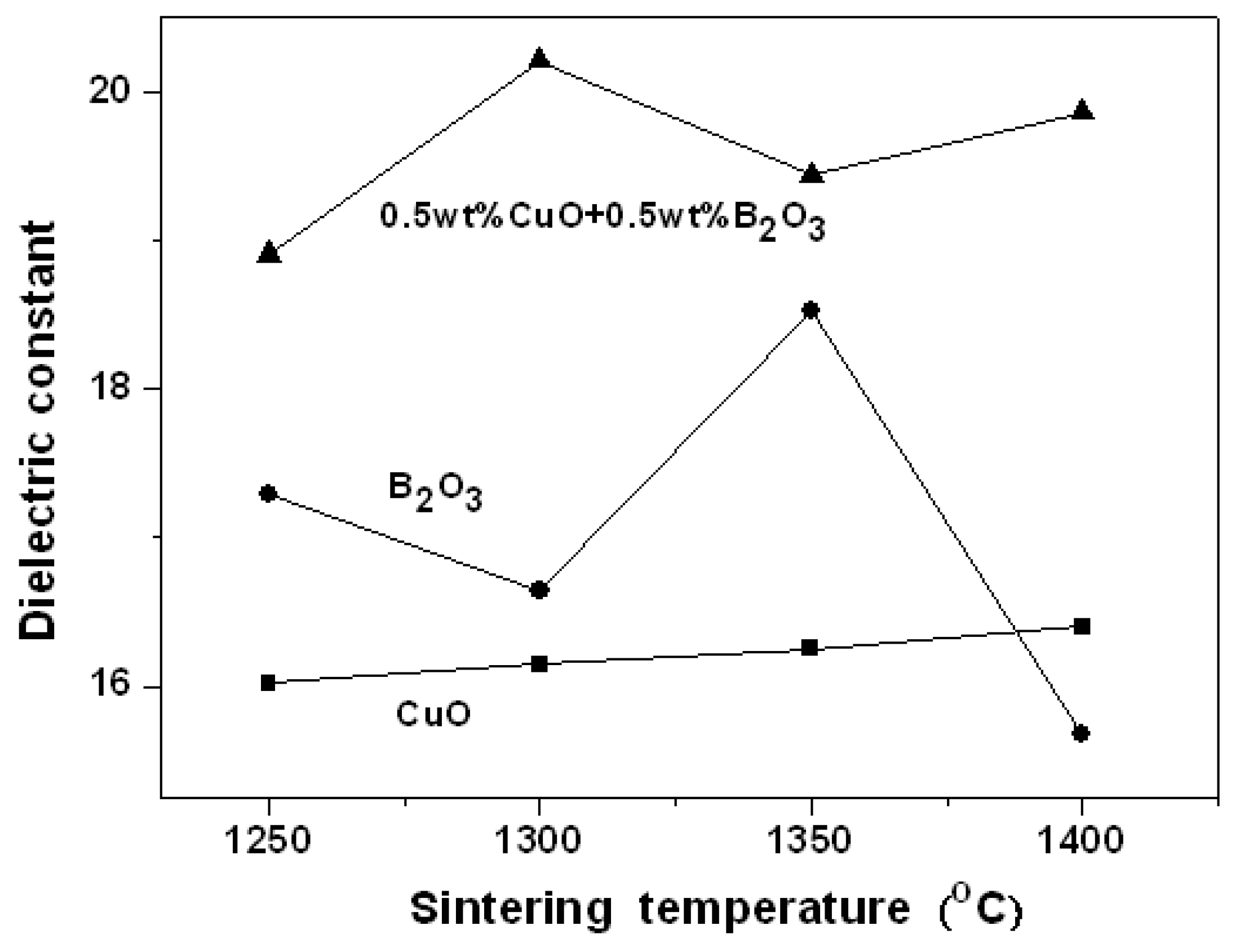

- For the addition of 1 wt % CuO to the 0.95LaAlO3–0.05CaTiO3 ceramics, the effect is the worst. When the sintering temperature is 1400 °C, the dielectric constant (εr) is about 16, the highest quality factor (Q × f) value is about 7500 GHz, and the temperature coefficient of resonant frequency (τf) is about −11 ppm/°C.

- For the addition of 1 wt % B2O3 to the 0.95LaAlO3–0.05CaTiO3 ceramics, the sintering temperature is lowered to 1400 °C, the electrical constant (εr) is about 18, the highest quality factor (Q × f) value is about 10,000 GHz and the temperature coefficient of resonant frequency (τf) is about −5 ppm/°C.

- For the addition of 0.5 wt % CuO + 0.5 wt % B2O3 to the 0.95LaAlO3–0.05CaTiO3 ceramics, its sintering temperature can be reduced to 1300 °C (about 250 °C reduction, as compared to the same relative theoretic density of the 0.95LaAlO3–0.05CaTiO3 ceramic without a sintering aid), the dielectric constant (εr) is about 21, the highest quality factor (Q × f) value is 22,500 GHz, and the temperature coefficient of the resonant frequency (τf) is about −3 ppm/°C.

Author Contributions

Funding

Conflicts of Interest

References

- Sebastian, M.T. Dielectric Materials for Wireless Communication; Elsevier: Amsterdam, The Netherland, 2008. [Google Scholar]

- Kagata, H.; Kato, J. Dielectric Properties of Ca-Based Complex Perovskite at Microwave Frequencies. Jpn. J. Appl. Phys. 1994, 33, 5463–5465. [Google Scholar] [CrossRef]

- Huang, C.C.; Yang, R.Y.; Weng, M.H. Dielectric properties of Ca(Mg,Nb)O3-CaTiO3 solid solution at microwave frequency. Jpn. J. Appl. Phys. 2000, 39, 6608–6611. [Google Scholar] [CrossRef]

- Huang, C.L.; Weng, M.H. Improved high Q value of MgTiO3–CaTiO3 microwave dielectric ceramics at low sintering temperature. Mat. Res. Bull. 2000, 36, 2741–2750. [Google Scholar] [CrossRef]

- Pang, L.; Zhou, D.; Wang, D.; Zhao, J.; Liu, W.; Yue, Z.; Reaney, I.M. Temperature stable K0.5(Nd1-xBix)0.5MoO4 microwave dielectrics ceramics with ultra-low sintering temperature. J. Am. Ceram. Soc. 2018, 101, 1806–1810. [Google Scholar] [CrossRef]

- Tian, L.J.; Wng, N.H.; Shen, C.Y. Effect of Microwave Sintering on the Properties of 0.95 (Ca0.88Sr0.12)TiO3–0.05 (Bi0.5Na0.5)TiO3 Ceramics. Materials 2019, 12, 803. [Google Scholar] [CrossRef] [Green Version]

- Wang, D.; Zhang, S.; Zhou, D.; Song, K.; Feteira, A.; Vardaxoglou, Y.; Whittow, W.; Cadman, D.; Reaney, I.M. Temperature Stable Cold Sintered (Bi0.95Li0.05) (V0.9Mo0.1)O4-Na2Mo2O7 microwave dielectric composites. Materials 2019, 12, 1370. [Google Scholar] [CrossRef] [Green Version]

- Weng, M.H.; Liang, T.J.; Huang, C.L. Lowering of sintering temperature and microwave dielectric properties of BaTi4O9 ceramics prepared by the polymeric precursor method. J. Eur. Ceram. Soc. 2002, 22, 1693–1698. [Google Scholar] [CrossRef]

- Hsian, H.I.; Chen, C.C.; Yang, S.Y. Microwave dielectric properties of Ca0.7Nd0.2TiO3 ceramic-filled CaO–B2O3–SiO2 glass for LTCC applications. J. Adv. Ceram. 2019, 8, 345–351. [Google Scholar] [CrossRef] [Green Version]

- Hunag, C.L.; Weng, M.H.; Lion, C.C.; Wu, C.C. Low temperature sintering and microwave dielectric ceramics of Ba2Ti9O20 using glass additions. Mat. Res. Bull. 2000, 35, 2445–2456. [Google Scholar] [CrossRef]

- Huang, C.L.; Weng, M.H.; Chen, H.L. Effects of additives on microstructures and microwave dielectric properties of (Zr, Sn)TiO4 ceramics. Mat. Chem. Phys. 2001, 71, 17–22. [Google Scholar] [CrossRef]

- Kim, M.H.; Jeong, Y.H.; Nahm, S.; Kim, H.T.; Lee, H.J. Effect of B2O3 and CuO additives on the sintering temperature and microwave dielectric properties of Ba(Zn1/3Nb2/3)O3 ceramics. J. Eur. Ceram. Soc. 2006, 26, 2139–2142. [Google Scholar] [CrossRef]

- Lim, J.B.; Nahm, S.; Kim, H.T.; Kim, J.H.; Park, J.H.; Lee, H. Effect of B2O3 and CuO on the sintering temperature and microwave dielectric properties of the BaTi4O9 ceramics. J. Electroceramics Ceram. 2006, 17, 2–4. [Google Scholar] [CrossRef]

- Yim, D.K.; Kim, J.R.; Kim, D.W.; Hong, K.S. Microwave dielectric properties and low-temperature sintering of Ba3Ti4Nb4O21 ceramics with B2O3 and CuO additions. J. Eur. Ceram. Soc. 2007, 27, 3053–3057. [Google Scholar] [CrossRef]

- Moon, J.H.; Park, H.S.; Lee, K.T.; Choi, J.H.; Yeo, D.H.; Yoon, S.J.; Kim, H.J. Microwave dielectric properties of the (1-x)La2/3TiO3-xLaAlO3 system. Jpn. J. Appl. Phys. 1997, 36, 6814–6817. [Google Scholar] [CrossRef]

- Sun, P.H.; Nakamira, T.; Shn, Y.J.; Inaguma, Y.; Itoh, M.; Kitamura, T. Dielectric behavior of (1-x)LaAlO3-xSrTiO3 solid solution system at microwave frequencies. Jpn. J. Appl. Phys. 1998, 37, 5625–5629. [Google Scholar] [CrossRef]

- Cho, S.Y.; Hong, K.S.; Ko, K.H. Mixture-like behavior in microwave dielectric propeties of the (1-x)LaAlO3-xSrTiO3 System. Mat. Re. Bull. 1999, 34, 511–516. [Google Scholar] [CrossRef]

- Jiang, J.; Fang, D.; Lu, C.; Dou, Z.; Wang, G.; Zhang, F.; Zhang, T. Solid-state reaction mechanism and microwave dielectric properties of CaTiO3–LaAlO3 ceramics. J. Alloys Compd. 2015, 638, 443–447. [Google Scholar] [CrossRef]

- Vidmar, M.; Golobic, A.; Meden, A.; Suvorov, D.; Skapin, S.D. Sub-solidus phase relations and a structure determination of new phases in the CaO–La2O3–TiO2 system. J. Eur. Ceram. Soc. 2015, 35, 2801–2814. [Google Scholar] [CrossRef]

- Dou, Z.M.; Wang, G.; Jiang, J.; Zhang, F.; Zhang, T.J. Understanding microwave dielectric properties of (1−x) CaTiO3–xLaAlO3 ceramics in terms of A/B-site ionic-parameters. J. Adv. Ceram. 2017, 6, 20–26. [Google Scholar] [CrossRef] [Green Version]

- Eteira, A.; Sinclair, D.C.; Lanagan, M.T. Structure and microwave dielectric properties of Ca1-xY xTi1−xAl xO3 (CYTA) ceramics. J. Mat. Res. 2005, 20, 2391–2399. [Google Scholar]

- Marison, J.E.; Hsueh, C.H.; Evans, A.G. Liquid phase sintering of ceramics. J. Am. Ceram. Soc. 1987, 70, 708–713. [Google Scholar] [CrossRef]

- Hakkit, B.W.; Coleman, P.D. A dielectric resonator method of measuring inductive capacities in the millimeter range. IEEE Trans. Microw. Theory Tech. 1960, 8, 402–410. [Google Scholar] [CrossRef]

- Courtney, W.E. Analysis and evaluation of a method of measuring the complex permittivity and permeability microwave insulators. IEEE Trans. Microw. Theory Tech. 1970, 18, 476–485. [Google Scholar] [CrossRef]

- Huang, C.L.; Weng, M.H. Liquid phase sintering of (Zr, Sn)TiO4 microwave dielectric ceramics. Mat. Res. Bull. 2000, 35, 1881–1888. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Weng, M.-H.; Liauh, C.-T.; Lin, S.-M.; Wang, H.-H.; Yang, R.-Y. Sintering Behaviors, Microstructure, and Microwave Dielectric Properties of CaTiO3–LaAlO3 Ceramics Using CuO/B2O3 Additions. Materials 2019, 12, 4187. https://doi.org/10.3390/ma12244187

Weng M-H, Liauh C-T, Lin S-M, Wang H-H, Yang R-Y. Sintering Behaviors, Microstructure, and Microwave Dielectric Properties of CaTiO3–LaAlO3 Ceramics Using CuO/B2O3 Additions. Materials. 2019; 12(24):4187. https://doi.org/10.3390/ma12244187

Chicago/Turabian StyleWeng, Min-Hang, Chihng-Tsung Liauh, Shueei-Muh Lin, Hung-Hsiang Wang, and Ru-Yuan Yang. 2019. "Sintering Behaviors, Microstructure, and Microwave Dielectric Properties of CaTiO3–LaAlO3 Ceramics Using CuO/B2O3 Additions" Materials 12, no. 24: 4187. https://doi.org/10.3390/ma12244187