Effect of Shear Strain Rate on Microstructure and Properties of Austenitic Steel Processed by Cyclic Forward/Reverse Torsion

Abstract

:1. Introduction

2. Experimental Studies

3. Results and Discussion

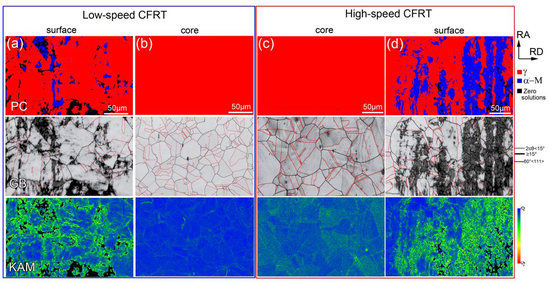

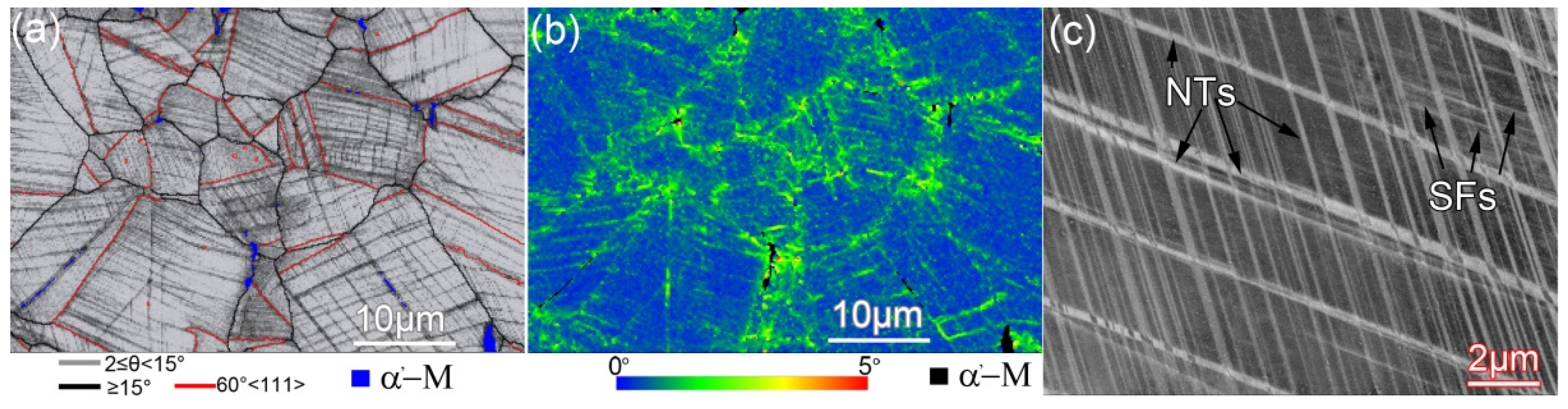

3.1. Microstructure Evolution

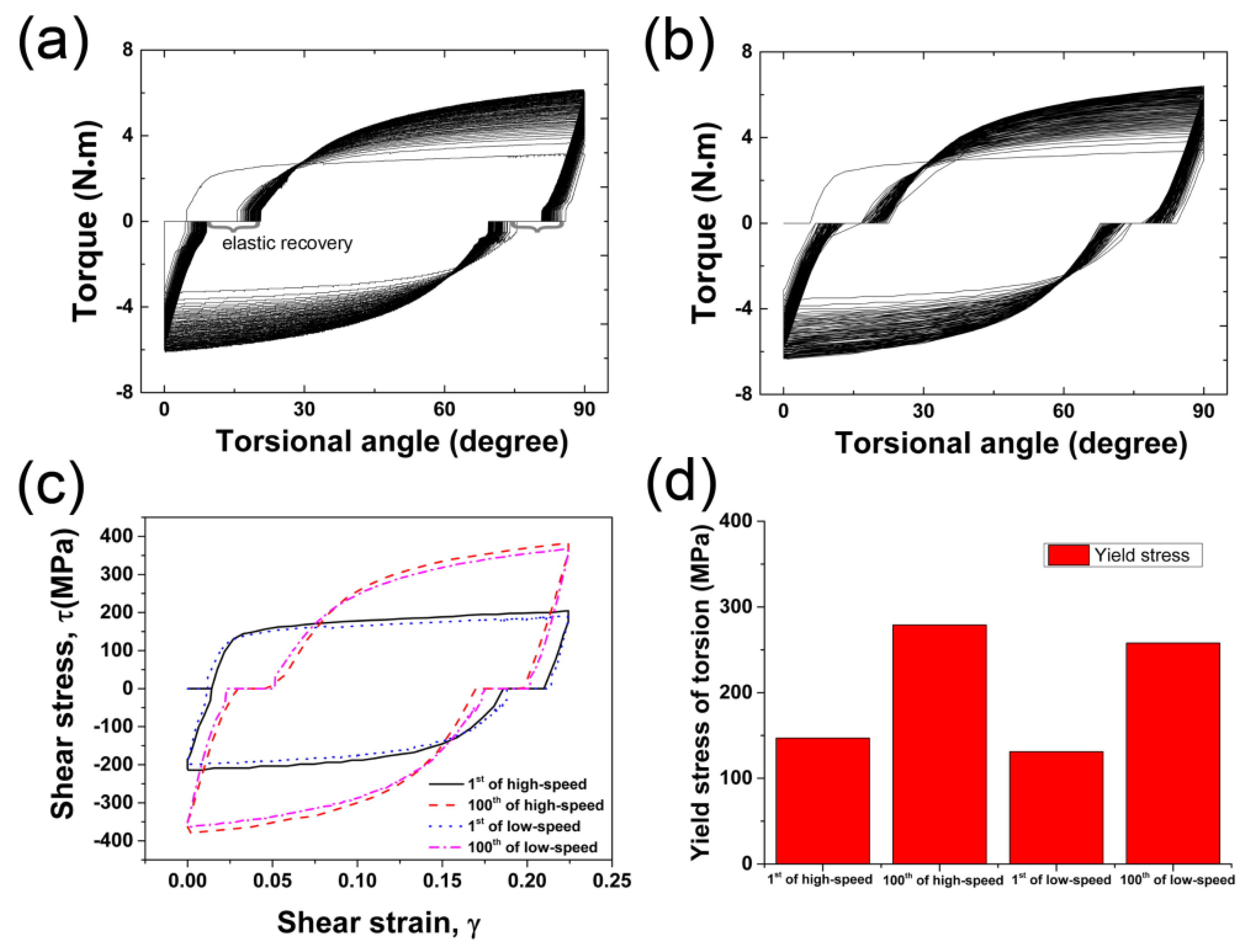

3.2. Effect of Twisting Speed on Torsion Behavior

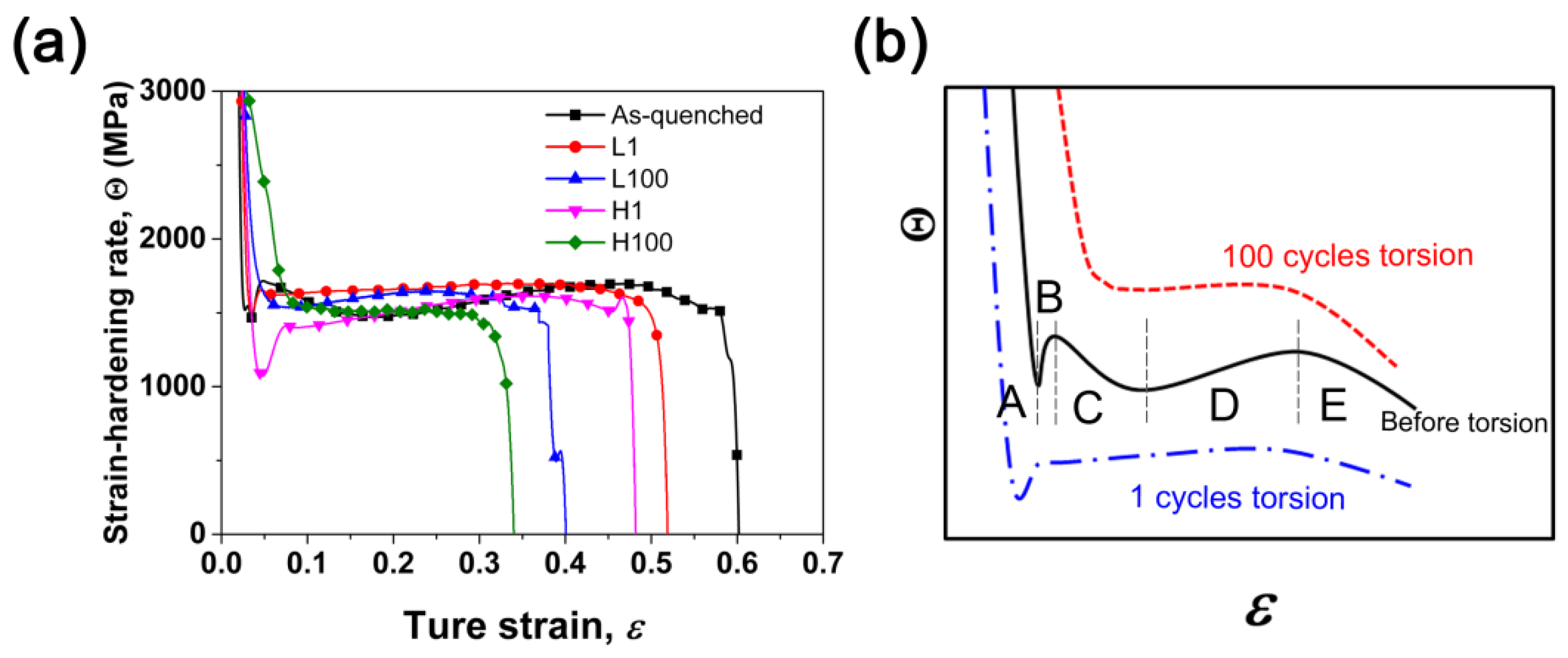

3.3. Strain-Hardening Behavior during Tension

3.4. Fracture Behavior

4. Conclusions

- (1)

- The torsional yield strength of the high-speed twisted sample is higher than that of the low-speed twisted sample. Faster torsion results in lower dislocation recovery rates and higher flow stresses.

- (2)

- A higher gradient martensite content results in a higher surface hardness of the material, but less overall tensile properties. The tensile strain-hardening behavior of the gradient structured material is related to the content of its gradient defects. With increasing of gradient martensite phase, the strain-hardening rate transits directly from stage A (dislocation slipping-dominated) to stages D (martensite-dominated) and E (necking), without stages B (twinning-dominated) and C (dominated by dislocation slipping combined with twinning).

- (3)

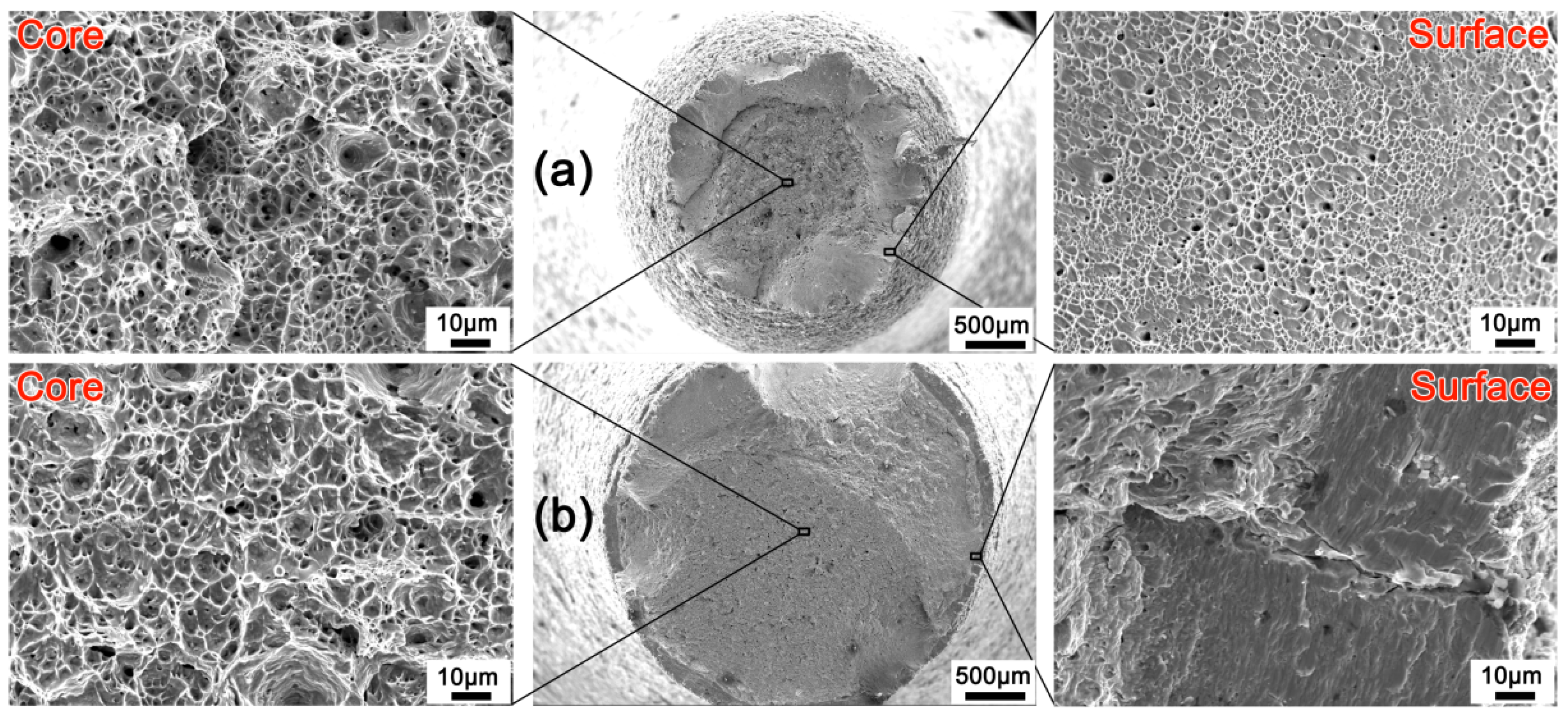

- Both the low-speed and high-speed twisted samples show dimples in the core after the tensile fracture. In the surface layer, the low-speed twisted sample has a macro-shear lip which is microscopically composed of slanted dimples, while the high-speed twisted sample has many cleavage planes instead of macro-shear lips with slanted dimples.

Author Contributions

Funding

Conflicts of Interest

References

- Ritchie, R.O. The conflicts between strength and toughness. Nat. Mater. 2011, 10, 817–822. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Fu, P.; Liu, H.; Li, D. Improvement of strength-toughness-hardness balance in large cross-section 718h pre-hardened mold steel. Materials 2018, 11, 583. [Google Scholar] [CrossRef]

- Li, X.; Lu, K. Playing with defects in metals. Nat. Mater. 2017, 16, 700–701. [Google Scholar] [CrossRef] [PubMed]

- Fang, T.H.; Li, W.L.; Tao, N.R.; Lu, K. Revealing Extraordinary intrinsic tensile plasticity in gradient nano-grained copper. Science 2011, 331, 1587–1590. [Google Scholar] [CrossRef]

- Tao, N.R.; Wang, Z.B.; Tong, W.P.; Sui, M.L.; Lu, J.; Lu, K. An investigation of surface nanocrystallization mechanism in Fe induced by surface mechanical attrition treatment. Acta Mater. 2002, 50, 4603–4616. [Google Scholar] [CrossRef]

- Liu, X.C.; Zhang, H.W.; Lu, K. Strain-Induced ultrahard and ultrastable nanolaminated structure in nickel. Science 2013, 342, 337–340. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Li, F.; Li, J.; Ma, X.; Li, J.; Wan, Q. Hardening and softening analysis of pure titanium based on the dislocation density during torsion deformation. Mater. Sci. Eng. A Struct. 2016, 671, 17–31. [Google Scholar] [CrossRef]

- Guo, N.; Song, B.; Yu, H.; Xin, R.; Wang, B.; Liu, T. Enhancing tensile strength of Cu by introducing gradient microstructures via a simple torsion deformation. Mater. Des. 2016, 90, 545–550. [Google Scholar] [CrossRef]

- Wei, Y.; Li, Y.; Zhu, L.; Liu, Y.; Lei, X.; Wang, G.; Wu, Y.; Mi, Z.; Liu, J.; Wang, H.; et al. Evading the strength–Ductility trade-off dilemma in steel through gradient hierarchical nanotwins. Nat. Commun. 2014, 5, 580. [Google Scholar] [CrossRef]

- Cheng, Z.; Zhou, H.F.; Lu, Q.H.; Gao, H.J.; Lu, L. Extra strengthening and work hardening in gradient nanotwinned metals. Science 2018, 362. [Google Scholar] [CrossRef]

- Yang, L.; Tao, N.R.; Lu, K.; Lu, L. Enhanced fatigue resistance of Cu with a gradient nanograined surface layer. Scr. Mater. 2013, 68, 801–804. [Google Scholar] [CrossRef]

- Wang, K.; Wei, A.; Shi, Z.; Chen, X.; Lin, J.; Tong, X.; Tao, Z.; Chen, X. The preparation and performance of grain size gradient TWIP steel fabricated by laser heat treatment. Mater. Sci. Eng. A Struct. 2019, 743, 294–300. [Google Scholar] [CrossRef]

- Song, B.; Wang, C.; Guo, N.; Pan, H.; Xin, R. Improving tensile and compressive properties of an extruded AZ91 rod by the combined use of torsion deformation and aging treatment. Materials 2017, 10, 280. [Google Scholar] [CrossRef] [PubMed]

- Guo, N.; Zhang, Z.; Dong, Q.; Yu, H.; Song, B.; Chai, L.; Liu, C.; Yao, Z.; Daymond, M.R. Strengthening and toughening austenitic steel by introducing gradient martensite via cyclic forward/reverse torsion. Mater. Des. 2018, 143, 150–159. [Google Scholar] [CrossRef]

- Ma, X.; Li, F.; Fang, X.; Li, Z.; Sun, Z.; Hou, J.; Cao, J. Effect of strain reversal on the stress-induced martensitic transformation and tensile properties of a metastable β titanium alloy. J. Alloy. Comp. 2019, 784, 111–116. [Google Scholar] [CrossRef]

- Guo, N.; Song, B.; Guo, C.; Xin, R.; Liu, Q. Improving tensile and compressive properties of magnesium alloy rods via a simple pre-torsion deformation. Mater. Des. 2015, 83, 270–275. [Google Scholar] [CrossRef]

- Song, B.; Shu, X.; Pan, H.; Li, G.; Guo, N.; Liu, T.; Chai, L.; Xin, R. Influence of torsion route on the microstructure and mechanical properties of extruded AZ31 rods. Adv. Eng. Mater. 2017, 19, 1700267. [Google Scholar] [CrossRef]

- Chen, H.; Liu, T.; Yu, H.; Song, B.; Hou, D.; Guo, N.; He, J. Dependence of microstructure and hardening behavior on torsion strain and strain rate in extruded AZ31 rods. Adv. Eng. Mater. 2016, 18, 1683–1689. [Google Scholar]

- Song, B.; Guo, N.; Xin, R.; Pan, H.; Guo, C. Strengthening and toughening of extruded magnesium alloy rods by combining pre-torsion deformation with subsequent annealing. Mater. Sci. Eng. A Struct. 2016, 650, 300–304. [Google Scholar] [CrossRef]

- Guo, N.; Li, D.; Yu, H.; Xin, R.; Zhang, Z.; Li, X.; Liu, C.; Song, B.; Chai, L. Annealing behavior of gradient structured copper and its effect on mechanical properties. Mater. Sci. Eng. A Struct. 2017, 702, 331–342. [Google Scholar] [CrossRef]

- Humphreys, F.J. Characterisation of fine-scale microstructures by electron backscatter diffraction (EBSD). Scr. Mater. 2004, 51, 771–776. [Google Scholar] [CrossRef]

- Calcagnotto, M.; Ponge, D.; Demir, E.; Raabe, D. Orientation gradients and geometrically necessary dislocations in ultrafine grained dual-phase steels studied by 2D and 3D EBSD. Mater. Sci. Eng. A Struct. 2010, 527, 2738–2746. [Google Scholar] [CrossRef]

- Song, B.; Zhao, H.; Chai, L.; Guo, N.; Pan, H.; Chen, H.; Xin, R. Preparation and characterization of Mg alloy rods with gradient microstructure by torsion deformation. Met. Mater. Int. 2016, 22, 887–896. [Google Scholar] [CrossRef]

- Guo, N.; Li, X.; Xiao, M.; Xin, R.; Chai, L.; Song, B.; Yu, H.; Li, L. Microstructures and mechanical properties of commercial hot-extruded copper processed by torsion deformation. Adv. Eng. Mater. 2016, 18, 1738–1746. [Google Scholar]

- Yang, X.-S.; Sun, S.; Ruan, H.-H.; Shi, S.-Q.; Zhang, T.-Y. Shear and shuffling accomplishing polymorphic fcc γ→hcp ε→bct α martensitic phase transformation. Acta Mater. 2017, 136, 347–354. [Google Scholar] [CrossRef]

- Talonen, J.; Hänninen, H. Formation of shear bands and strain-induced martensite during plastic deformation of metastable austenitic stainless steels. Acta Mater. 2007, 55, 6108–6118. [Google Scholar] [CrossRef]

- Ehinger, D.; Weise, J.; Baumeister, J.; Funk, A.; Waske, A.; Krüger, L.; Martin, U. Microstructure and deformation response of TRIP-steel syntactic foams to quasi-static and dynamic compressive loads. Materials 2018, 11, 656. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y.F.; Li, X.X.; Sun, X.; Wang, Y.D.; Zuo, L. Twinning and martensite in a 304 austenitic stainless steel. Mater. Sci. Eng. A Struct. 2012, 552, 514–522. [Google Scholar] [CrossRef]

- Kim, H.S.; Hong, S.I.; Lee, Y.S.; Dubravina, A.A.; Alexandrov, I.V. Deformation behavior of copper during a high pressure torsion process. J. Mater. Process. Technol. 2003, 142, 334–337. [Google Scholar] [CrossRef]

- Mehrabi, R.; Andani, M.T.; Kadkhodaei, M.; Elahinia, M. Experimental study of NiTi thin-walled tubes under uniaxial tension, torsion, proportional and non-proportional loadings. Exp. Mech. 2015, 55, 1151–1164. [Google Scholar] [CrossRef]

- Yang, C.; Liu, H.; Yang, B.; Shi, B.; Peng, Y.; Pan, F.; Wu, L. The effect of pre-twinning on the mechanical behavior of free-end torsion for an extruded AZ31 magnesium alloy. Mater. Sci. Eng. A Struct. 2019, 743, 391–396. [Google Scholar] [CrossRef]

- Spirdione, J.; Visser, W.; Maciejewski, K.; Ghonem, H. Role of pearlite colonies on the dynamic flow stress of low carbon steel. Mater. Sci. Eng. A Struct. 2017, 679, 446–454. [Google Scholar] [CrossRef]

- Rusinek, A.; Klepaczko, J.R. Shear testing of a sheet steel at wide range of strain rates and a constitutive relation with strain-rate and temperature dependence of the flow stress. Int. J. Plasicity 2001, 17, 87–115. [Google Scholar] [CrossRef]

- Rosenthal, I.; Stern, A.; Frage, N. Strain rate sensitivity and fracture mechanism of AlSi10Mg parts produced by selective laser melting. Mater. Sci. Eng. A Struct. 2017, 682, 509–517. [Google Scholar] [CrossRef]

- Blum, W.; Zeng, X.H. A simple dislocation model of deformation resistance of ultrafine-grained materials explaining Hall–Petch strengthening and enhanced strain rate sensitivity. Acta Mater. 2009, 57, 1966–1974. [Google Scholar] [CrossRef]

- Tian, Y.Z.; Zhao, L.J.; Chen, S.; Shibata, A.; Zhang, Z.F.; Tsuji, N. Significant contribution of stacking faults to the strain hardening behavior of Cu-15%Al alloy with different grain sizes. Sci. Rep. UK 2015, 5, 16707. [Google Scholar] [CrossRef] [Green Version]

- Salem, A.A.; Kalidindi, S.R.; Semiatin, S.L. Strain hardening due to deformation twinning in α-titanium: Constitutive relations and crystal-plasticity modeling. Acta Mater. 2005, 53, 3495–3502. [Google Scholar] [CrossRef]

- Hecker, S.S.; Stout, M.G.; Staudhammer, K.P.; Smith, J.L. Effects of strain state and strain rate on deformation-induced transformation in 304 stainless steel: Part I. Magnetic measurements and mechanical behavior. Mater. Trans. 1982, 13, 619–626. [Google Scholar] [CrossRef]

- Konovalenko, I.; Maruschak, P.; Prentkovskis, O.; Junevičius, R. Investigation of the rupture surface of the titanium alloy using convolutional neural networks. Materials 2018, 11, 2467. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, Y.H.; Luo, K.Y.; Zhang, Y.K.; Zhao, Y.; Huang, J.Y.; Wu, X.D.; Zhou, C. Tensile property of ANSI 304 stainless steel weldments subjected to cavitation erosion based on treatment of laser shock processing. Materials 2018, 11, 805. [Google Scholar] [CrossRef]

- Edacherian, A.; Algahtani, A.; Tirth, V. Investigations of the tribological performance of A390 alloy hybrid aluminum matrix composite. Materials 2018, 11, 2524. [Google Scholar] [CrossRef] [PubMed]

- Hu, J.; Zhang, Y.; Yang, X.; Li, H.; Xu, H.; Ma, C.; Dong, Q.; Guo, N.; Yao, Z. Effect of pack-chromizing temperature on microstructure and performance of AISI 5140 steel with Cr-coatings. Surf. Coat. Technol. 2018, 344, 656–663. [Google Scholar] [CrossRef]

| Defects | Low-Speed | High-Speed | ||

|---|---|---|---|---|

| Core | Surface | Core | Surface | |

| 2° ≤ θ <15° | 0.001 | 0.121 | 0.002 | 0.143 |

| θ ≥ 15° | 0.020 | 0.052 | 0.033 | 0.069 |

| 60° <111> | 0.024 | - | 0.023 | - |

| α′-M | 0 | 5.4% | 0 | 25.3% |

| Samples | YS (MPa) | PS (MPa) | UE (%) |

|---|---|---|---|

| As-quenched | 310 | 1220 | 60 |

| L1 | 486 | 1297 | 53 |

| L100 | 781 | 1381 | 44 |

| H1 | 560 | 1236 | 51 |

| H100 | 790 | 1276 | 37 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Dong, Q.; Song, B.; He, H.; Chai, L.; Guo, N.; Wang, B.; Yao, Z. Effect of Shear Strain Rate on Microstructure and Properties of Austenitic Steel Processed by Cyclic Forward/Reverse Torsion. Materials 2019, 12, 506. https://doi.org/10.3390/ma12030506

Zhang Z, Dong Q, Song B, He H, Chai L, Guo N, Wang B, Yao Z. Effect of Shear Strain Rate on Microstructure and Properties of Austenitic Steel Processed by Cyclic Forward/Reverse Torsion. Materials. 2019; 12(3):506. https://doi.org/10.3390/ma12030506

Chicago/Turabian StyleZhang, Zhimin, Qingshan Dong, Bo Song, Hong He, Linjiang Chai, Ning Guo, Bingshu Wang, and Zhongwen Yao. 2019. "Effect of Shear Strain Rate on Microstructure and Properties of Austenitic Steel Processed by Cyclic Forward/Reverse Torsion" Materials 12, no. 3: 506. https://doi.org/10.3390/ma12030506