Calibration of a Multiphase Model Based on a Comprehensive Data Set for a Normal Strength Concrete

Abstract

:1. Introduction

2. Basic Equations of the Multiphase Concrete Model

2.1. Balance Equations

2.2. Reaction and Constitutive Models

2.2.1. Hydration Model

2.2.2. Evolution of Compressive Strength

2.2.3. Desorption Isotherm

2.2.4. Shrinkage and Creep Models

3. Parameter Identification

3.1. Calibration of Parameters Concerning Water Consumption and Porosity Evolution

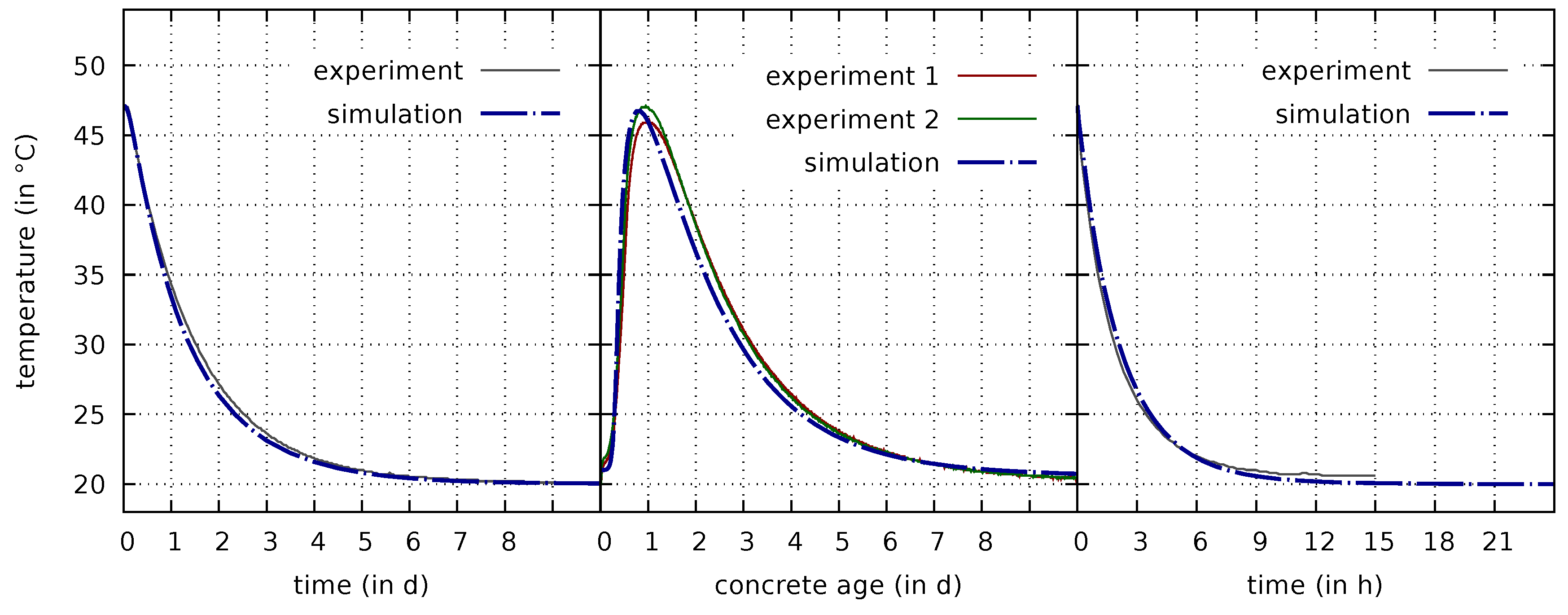

3.2. Calibration of Parameters Related to Reaction Kinetics

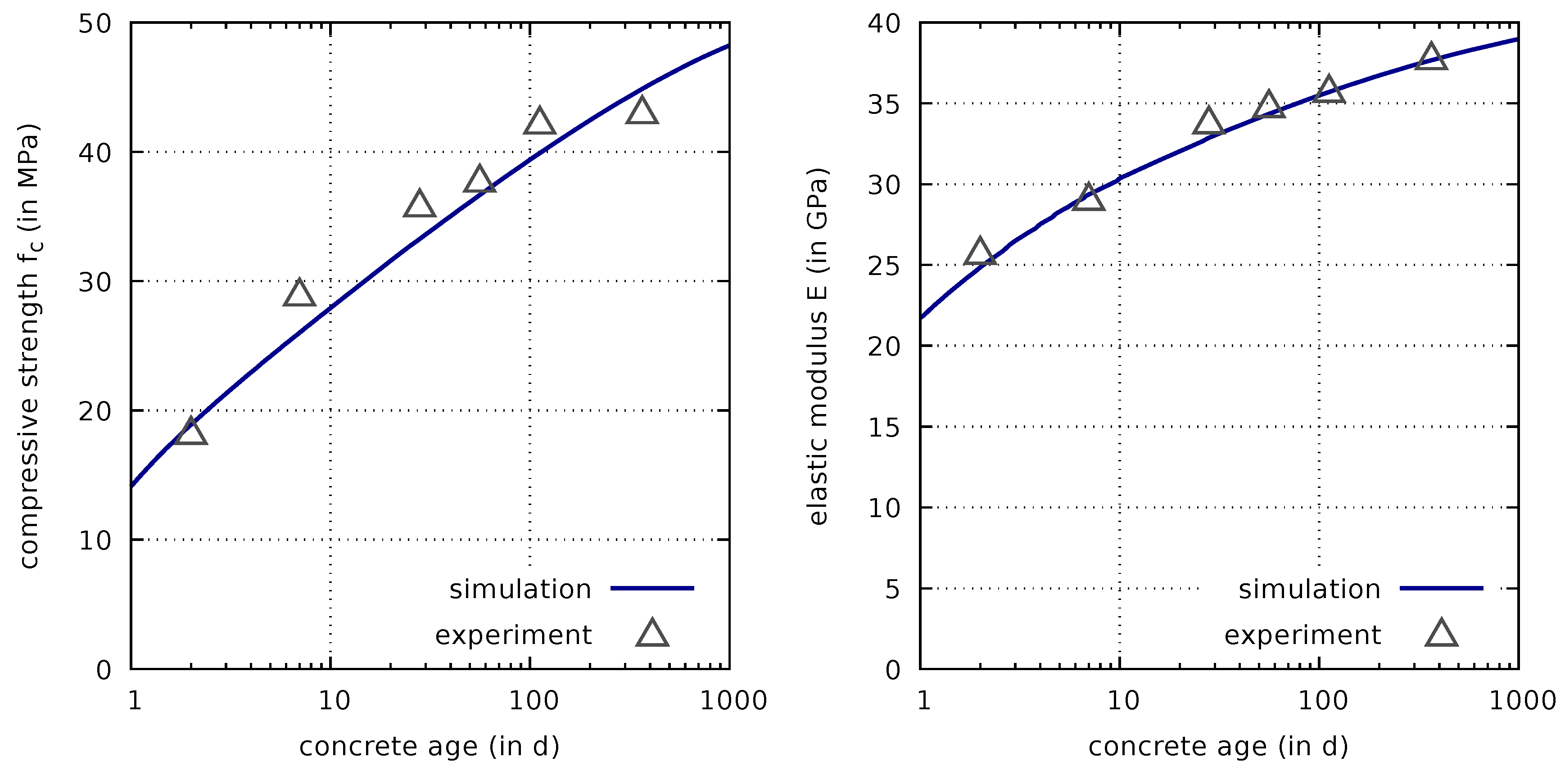

3.3. Calibration of the Compressive Strength and Elastic Modulus

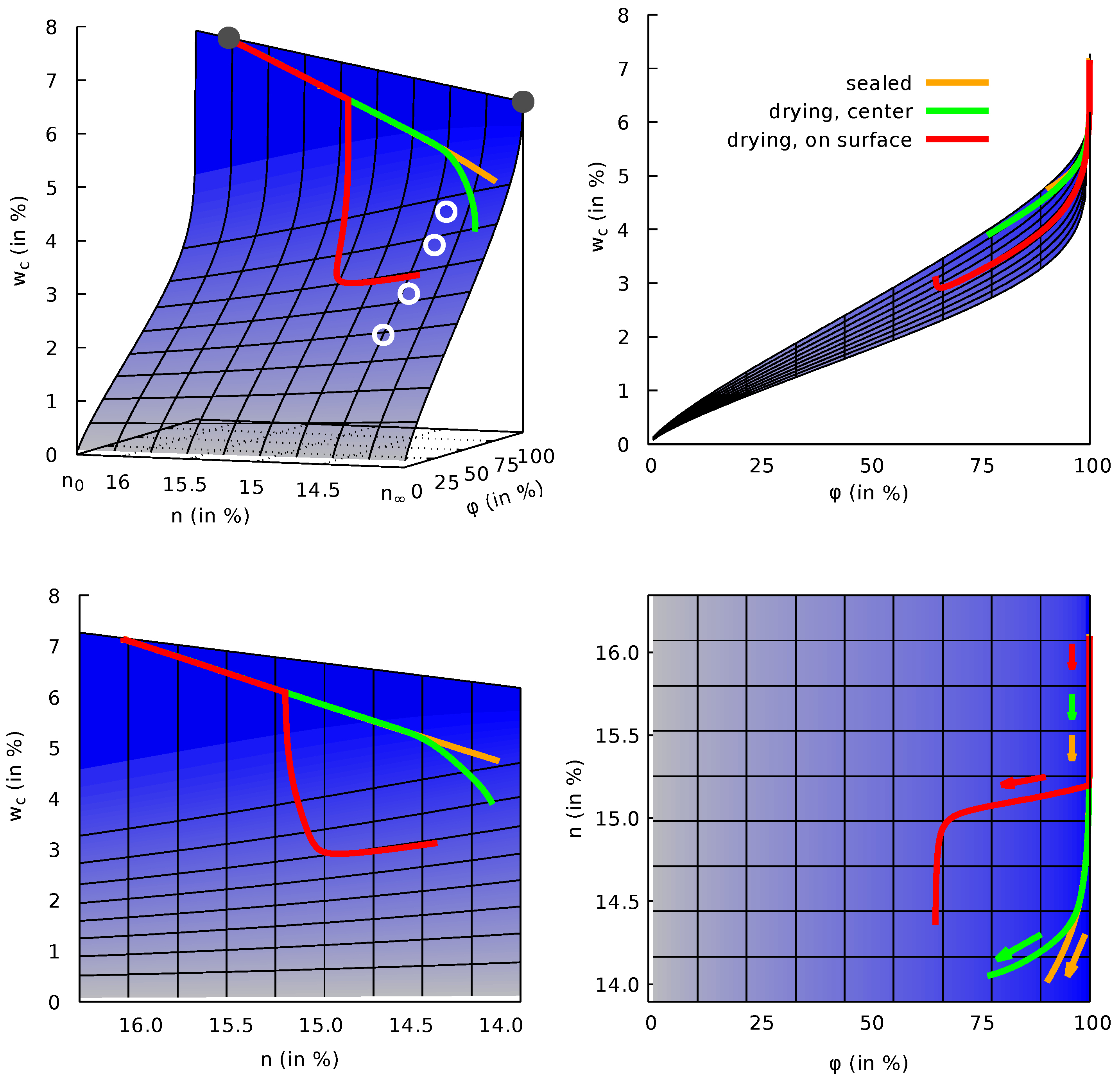

3.4. Modelling and Calibration of a Porosity-Dependent Desorption Isotherm

3.4.1. Desorption Isotherm

3.4.2. Calibration of the Desorption Isotherm Parameters

3.5. Calibration of Permeability Parameters

3.6. Calibration of the Coupled Shrinkage and Creep Formulation

3.6.1. Identification of the Parameters of the Generalized Effective Stress

3.6.2. Calibration of the Parameter for the Early-Age Autogenous Shrinkage

3.6.3. Calibration of the Parameters of the Viscous Creep Formulation

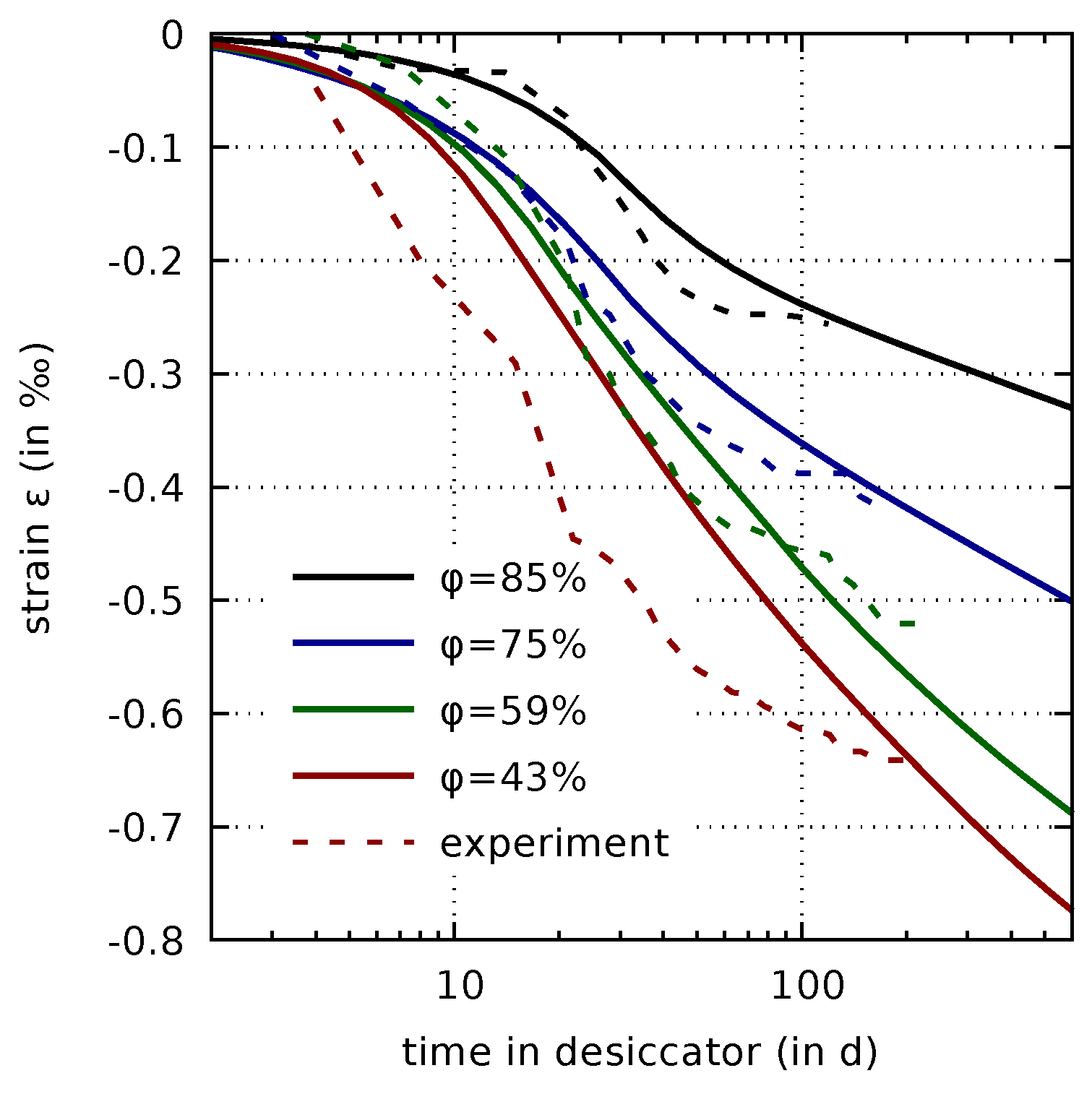

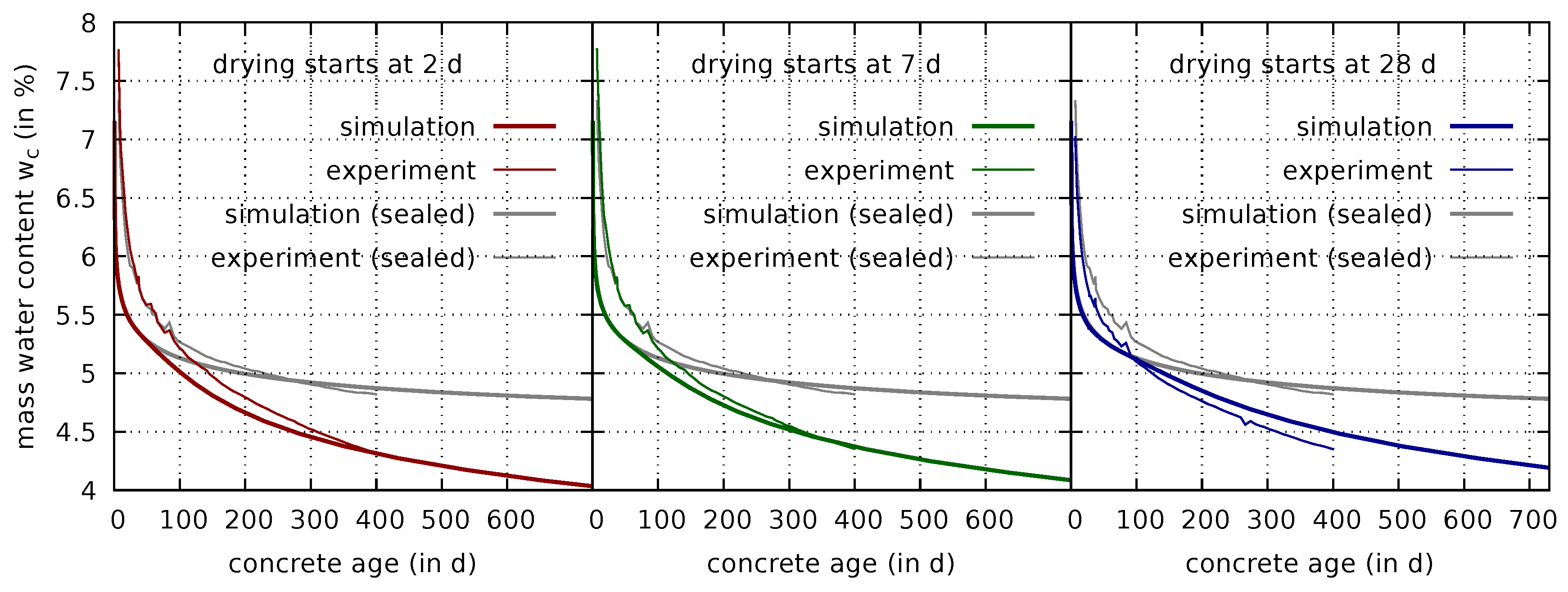

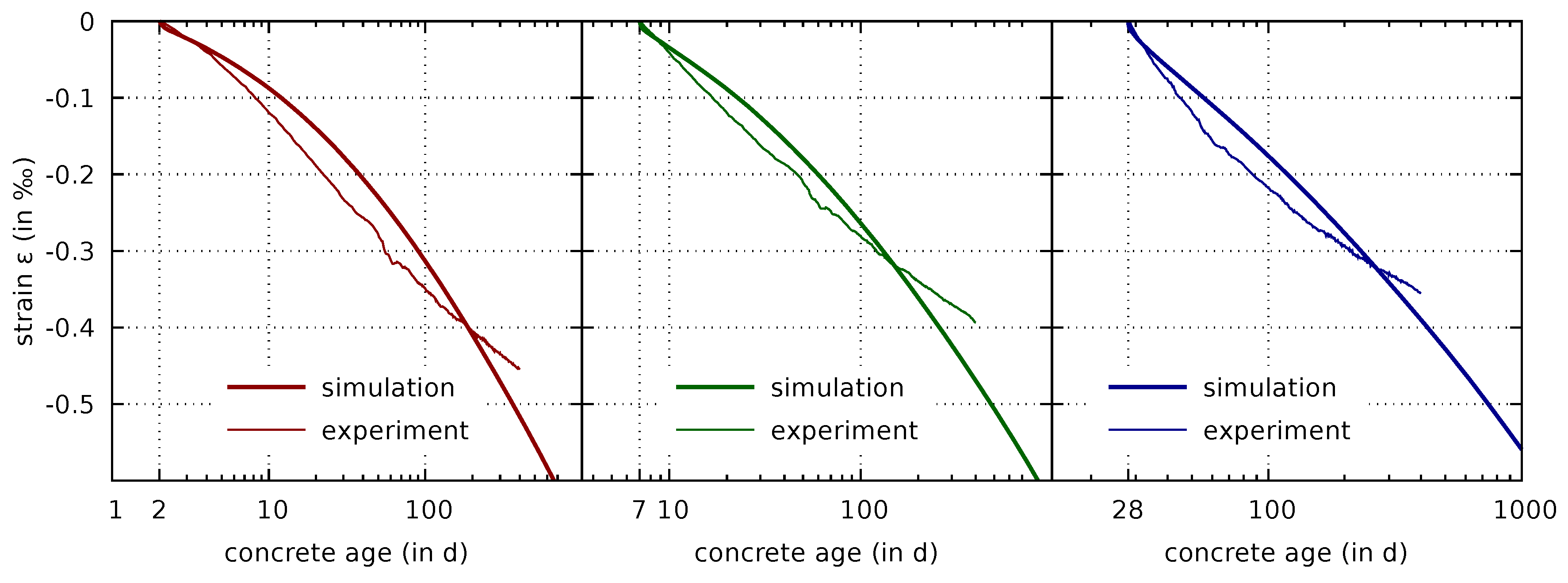

3.6.4. Confirmation of the Calibrated Permeability and Shrinkage Parameters by Simulations of Drying Tests on Concrete Cylinders

4. Summary of the Calibration Steps

- Calibrate the parameters of the reaction law (10) for the evolution of the degree of hydration by performing a chemo-hygro-thermal simulation of an insulated hardening specimen. Note that only the short-term behavior is directly visible in this test. The long-term reactive behavior is rather visible in the long-term evolutions of mechanical parameters and mass water content in sealed specimens.

- Calibrate the parameters of the relation (11) for the evolution of the uniaxial compressive strength and the visco-elastic short-term creep parameters in (22) and (24) for the evolution of the elastic modulus. The accurate prediction of the mechanical parameters and of the mass water content in sealed maturing specimens indicates correct fitting of the parameters used in the reaction law (10).

- Calibrate the parameters for the desorption isotherm in (43) on the basis of (i) measurement data for the mass water content obtained from thin concrete slices exposed to drying and (ii) measurements of the autogenous shrinkage strain. The former is used for determining the parameters such that the measured values for the mass water content are reproduced for the values of porosity determined from the concrete slices dried at different levels of relative humidity. The porosity-dependence of the desorption isotherm is calibrated by the measured evolution of the autogenous shrinkage strain. The latter step requires a reasonable guess for the Bishop parameter and may have to be repeated in the course of the calibration of the shrinkage model.

- Calibrate the permeability parameters, i.e., the parameters governing the diffusion of water vapor as well as the parameters governing the transport of liquid water. This is done based on (i) the measured mass water content evolution for thin concrete slices dried at different ambient relative humidities, (ii) the mass water content evolution measured at the center of cylindrical concrete specimens exposed to drying. Calibrate the hydration-dependency of the intrinsic permeability (49) by the measured evolution of the shrinkage strain of maturing cylindrical specimens exposed to drying at different concrete ages.

- Calibrate the parameters for the Bishop parameter (15) on the basis of the shrinkage strain measurements on thin concrete slices.

- Evaluate the compliances of sealed and unsealed specimens loaded in compression at different concrete ages and use the results for calibrating the viscous creep parameters in the microprestress formulation (26) and (27). Since long-term creep is assumed to be driven by the effective stress, every change in the basic creep and drying creep parameters will affect drying shrinkage, i.e., the calibration of the Bishop-parameter.

5. Conclusions

- The complete calibration of a multiphase concrete model is based on a comprehensive data set from a particular concrete mixture. It includes results from calorimetry tests, results from tests for age-dependent mechanical properties, mass water content and corresponding shrinkage measurements, and results from compressive creep tests on sealed and unsealed specimens loaded at different concrete ages. This thorough calibration allows to fully exploit the capabilities of the coupled multiphase approach.

- A new desorption isotherm is presented with a porosity-dependent (or, equivalently, a hydration-dependent) air entry value and an extra parameter for the improved approximation of the mass water content at low levels of relative humidity and a suitable calibration procedure is deduced. Compared to existing approaches, the proposed desorption isotherm enables considerably improved predictions of early-age autogenous shrinkage strain.

- Visualizations of -n--paths for the center and the surface of drying cylindrical specimens are provided, which contribute to a better understanding of the connection between the shape of the desorption isotherm and the predicted evolution of the shrinkage strain.

- A connection between the evolutions of the porosity and of the mass water content in a sealed hardening concrete sample is established. Thereby, a relation between porosity and degree of hydration is established, based on measured mass water contents and using the mass balances of the water and solid phase, neglecting thermal and mechanical deformation. It is consistent with the applied multiphase model.

- The viscous, long-term creep parameters of the multiphase model are calibrated by creep compliance data only. The added value of this procedure is especially prominent for a creep formulation in terms of the effective stress, for which shrinkage is coupled to creep while the modelled creep compliance is independent of the predicted shrinkage behavior. The short-term elastic-viscoelastic creep parameters are fitted independently using data from tests for the elastic modulus at different concrete ages.

- A further highlight of the paper is the use of separate experiments for calibrating and confirming the parameters of the shrinkage formulation in terms of the effective stress. The former is based on experiments on thin concrete slices, whereas the latter is based on tests on cylindrical concrete specimens. The added value of confirming identified parameters is further enhanced by simultaneously assessing the quality of the predictions for both the strain and the accompanying mass water content.

Author Contributions

Funding

Conflicts of Interest

References

- Gawin, D.; Pesavento, F.; Schrefler, B.A. Hygro-thermo-chemo-mechanical modelling of concrete at early ages and beyond. Part I: Hydration and hygro-thermal phenomena. Int. J. Numer. Meth. Eng. 2006, 67, 299–331. [Google Scholar] [CrossRef]

- Gawin, D.; Pesavento, F.; Schrefler, B.A. Hygro-thermo-chemo-mechanical modelling of concrete at early ages and beyond. Part II: Shrinkage and creep of concrete. Int. J. Numer. Meth. Eng. 2006, 67, 332–363. [Google Scholar] [CrossRef]

- Sciumè, G.; Benboudjema, F.; De Sa, C.; Pesavento, F.; Berthaud, Y.; Schrefler, B.A. A multiphysics model for concrete at early age applied to repairs problems. Eng. Struct. 2013, 57, 374–387. [Google Scholar] [CrossRef]

- Valentini, B.; Theiner, Y.; Aschaber, M.; Lehar, H.; Hofstetter, G. Single-phase and multi-phase modeling of concrete structures. Eng. Struct. 2013, 47, 25–34. [Google Scholar] [CrossRef]

- Gasch, T.; Eriksson, D.; Ansell, A. On the behaviour of concrete at early-ages: A multiphase description of hygro-thermo-chemo-mechanical properties. Cem. Concr. Res. 2019, 116, 202–216. [Google Scholar] [CrossRef]

- Theiner, Y.; Hartl, H.; Drexel, M.; Hofstetter, G. Experimental Study of Strengthening an RC Bridge Deck by Adding a Concrete Overlay. Strain 2013, 49, 377–392. [Google Scholar] [CrossRef]

- Theiner, Y.; Drexel, M.; Neuner, M.; Hofstetter, G. Comprehensive study of concrete creep, shrinkage, and water content evolution under sealed and drying conditions. Strain 2017, 53, e12223. [Google Scholar] [CrossRef]

- Drexel, M.; Theiner, Y.; Hofstetter, G. Versuche zum Schwinden und Kriechen von Beton unter Berücksichtigung des Feuchtegehalts. Bauingenieur 2018, 93, 95–102. [Google Scholar]

- Drexel, M.; Theiner, Y.; Hofstetter, G. Investigation of tensile creep of a normal strength overlay concrete. Materials 2018, 11, 993. [Google Scholar] [CrossRef] [PubMed]

- Drexel, M.; Smaniotto, S.; Hofstetter, G. Complementary experimental study of a normal strength overlay concrete. Mater. Today-Proc. 2019. accepted. [Google Scholar]

- Austrian Standards Institute. Test Methods for Concrete-National Application of Testing Standards for Concrete and Its Source Materials; ONR 23303; Austrian Standards Institute: Vienna, Austria, 2010. [Google Scholar]

- Neuner, M.; Gamnitzer, P.; Hofstetter, G. An extended damage plasticity model for shotcrete: Formulation and comparison with other shotcrete models. Materials 2017, 10, 82. [Google Scholar] [CrossRef] [PubMed]

- Gallipoli, D.; Wheeler, S.J.; Karstunen, M. Modelling the variation of degree of saturation in a deformable unsaturated soil. Géotechnique 2003, 53, 105–112. [Google Scholar] [CrossRef] [Green Version]

- Gawin, D.; Pesavento, F.; Schrefler, B.A. Modelling of hygro-thermal behaviour of concrete at high temperature with thermo-chemical and mechanical material degradation. Comput. Methods Appl. Mech. Engrg. 2003, 192, 1731–1771. [Google Scholar] [CrossRef]

- Lewis, R.W.; Schrefler, B.A. The Finite Element Method in the Static and Dynamic Deformation and Consolidation of Porous Media; Wiley: Chichester, UK, 1998. [Google Scholar]

- Ulm, F.-J.; Coussy, O. Strength growth as chemo-plastic hardening in early age concrete. J. Eng. Mech. 1996, 122, 1123–1132. [Google Scholar] [CrossRef]

- Gawin, D.; Majorana, C.E.; Schrefler, B.A. Numerical analysis of hygro-thermal behaviour and damage of concrete at high temperature. Mech. Cohes. Frict. Mater. 1999, 4, 37–74. [Google Scholar] [CrossRef]

- Baroghel-Bouny, V. Water vapour sorption experiments on hardened cementituos materials. Part II: Essential tool for assessment of transport properties and for durability predictions. Cem. Concr. Res. 2007, 37, 438–454. [Google Scholar] [CrossRef]

- Cervera, M.; Oliver, J.; Prato, T. Thermo-chemo-mechanical model for concrete I: Hydration and aging. J. Eng. Mech. 1999, 125, 1018–1027. [Google Scholar] [CrossRef]

- De Schutter, G.; Taerwe, L. Degree of hydration-based description of mechanical properties of early age concrete. Mater. Struct. 1996, 29, 335–344. [Google Scholar] [CrossRef]

- Torrenti, J.M.; Benboudjema, F. Mechanical threshold of cementitious materials at early age. Mater. Struct. 2005, 38, 299–304. [Google Scholar] [CrossRef] [Green Version]

- Grasley, Z.C.; Leung, C.K. Desiccation shrinkage of cementitious materials as an aging poroviscoelastic response. Cem. Concr. Res. 2011, 41, 77–89. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Hauggaard, A.B.; Baweja, S.; Ulm, F.J. Microprestress-solidification theory for concrete creep. I: Aging and drying effects. J. Eng. Mech. 1997, 123, 1188–1194. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Hauggaard, A.B.; Baweja, S. Microprestress-solidification theory for concrete creep. II: Algorithm and Verification. J. Eng. Mech. 1997, 123, 1195–1201. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Prasannan, A. Solidification theory for concrete creep. I: Formulation. J. Eng. Mech. 1989, 115, 1691–1703. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Xi, Y. Continuous retardation spectrum for solidification theory of concrete creeps. J. Eng. Mech. 1995, 121, 281–288. [Google Scholar] [CrossRef]

- Jirásek, M.; Havlásek, P. Microprestress-solidification theory of concrete creep: Reformulation and improvement. Cem. Concr. Res. 2014, 60, 51–62. [Google Scholar] [CrossRef]

- Pantazopoulou, S.J.; Mills, R.H. Microstructural aspects of the mechanical response of plain concrete. ACI Mater. J. 1995, 92, 605–616. [Google Scholar]

- Jensen, O.M.; Hansen, P.F. Water-entrained cement-based materials I. Principles and theoretical background. Cem. Concr. Res. 2001, 31, 647–654. [Google Scholar] [CrossRef]

- Sciumè, G. Thermo-Hygro-Chemo-Mechanical Model of Concrete at Early Ages and Its Extension to Tumor Growth Numerical Analysis. Ph.D. Thesis, ENS Cachan, Cachan, France, 2013. [Google Scholar]

- Van Genuchten, M.T. A closed-form equation for predicting the hydraulic conductivity of unsaturated soils. Soil Sci. Soc. Am. J. 1980, 44, 892–898. [Google Scholar] [CrossRef]

- Davie, C.T.; Pearce, C.J.; Kukla, K.; Bićanić, N. Modelling of transport processes in concrete exposed to elevated temperatures—An alternative formulation for sorption isotherms. Cem. Concr. Res. 2018, 106, 144–154. [Google Scholar] [CrossRef]

- Chitez, A.S.; Jefferson, A.D. Porosity development in a thermo-hygral finite element model for cementitious materials. Cem. Concr. Res. 2015, 78, 216–233. [Google Scholar] [CrossRef]

- Mualem, Y. A new model for predicting the hydraulic conductivity of unsaturated porous media. Water Resour. Res. 1976, 12, 513–522. [Google Scholar] [CrossRef]

- Di Luzio, G.; Cusatis, G. Solidification-microprestress-microplane (SMM) theory for concrete at early age: Theory, validation and application. Int. J. Solids Struct. 2013, 50, 957–975. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Cusatis, G.; Cedolin, L. Temperature effect on concrete creep modeled by microprestress-solidification theory. J. Eng. Mech. 2004, 130, 691–699. [Google Scholar] [CrossRef]

- Baroghel-Bouny, V.; Godin, J. Experimental study on drying shrinkage of ordinary and high-performance cementitious materials. Concr. Sci. Eng. 2001, 3, 13–22. [Google Scholar]

| Component | Amount |

|---|---|

| Cement CEM II A-M (S-L) 42.5 N, Lafarge | 375 |

| Added water (water/cement ratio of ) | 165 |

| Limestone sand mm | 810 |

| Limestone aggregates mm | 183 |

| Limestone aggregates mm | 457 |

| Limestone aggregates mm | 367 |

| Plasticizer Proplast 200 | 0.6% of cement mass |

| Air-entraining agent Proair NVX | 0.045% of cement mass |

| Measured | Computed | Calibrated | |

|---|---|---|---|

| 43% | 2.14% | 78% | 2.12% |

| 59% | 2.81% | 80% | 2.83% |

| 75% | 3.62% | 82% | 3.62% |

| 85% | 4.18% | 82% | 4.18% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gamnitzer, P.; Drexel, M.; Brugger, A.; Hofstetter, G. Calibration of a Multiphase Model Based on a Comprehensive Data Set for a Normal Strength Concrete. Materials 2019, 12, 791. https://doi.org/10.3390/ma12050791

Gamnitzer P, Drexel M, Brugger A, Hofstetter G. Calibration of a Multiphase Model Based on a Comprehensive Data Set for a Normal Strength Concrete. Materials. 2019; 12(5):791. https://doi.org/10.3390/ma12050791

Chicago/Turabian StyleGamnitzer, Peter, Martin Drexel, Andreas Brugger, and Günter Hofstetter. 2019. "Calibration of a Multiphase Model Based on a Comprehensive Data Set for a Normal Strength Concrete" Materials 12, no. 5: 791. https://doi.org/10.3390/ma12050791