Effect of Plasma Nitriding Pretreatment on the Mechanical Properties of AlCrSiN-Coated Tool Steels

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

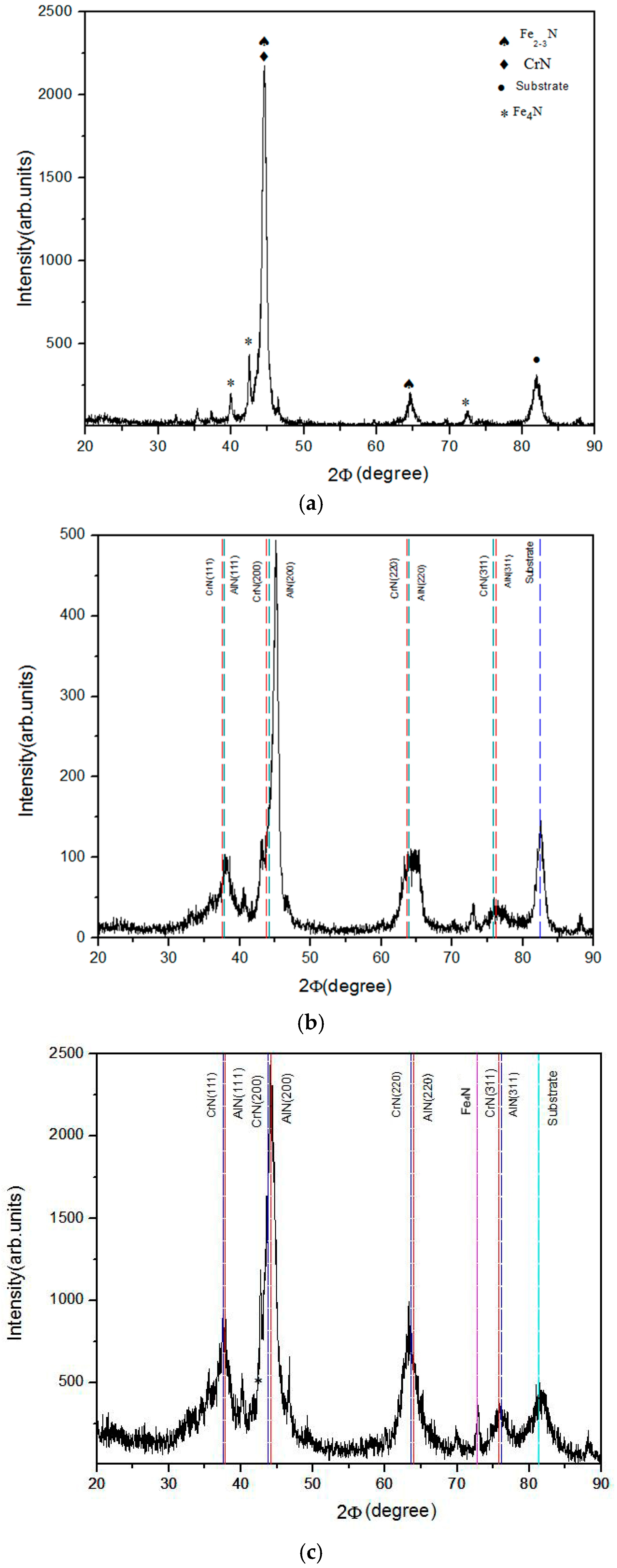

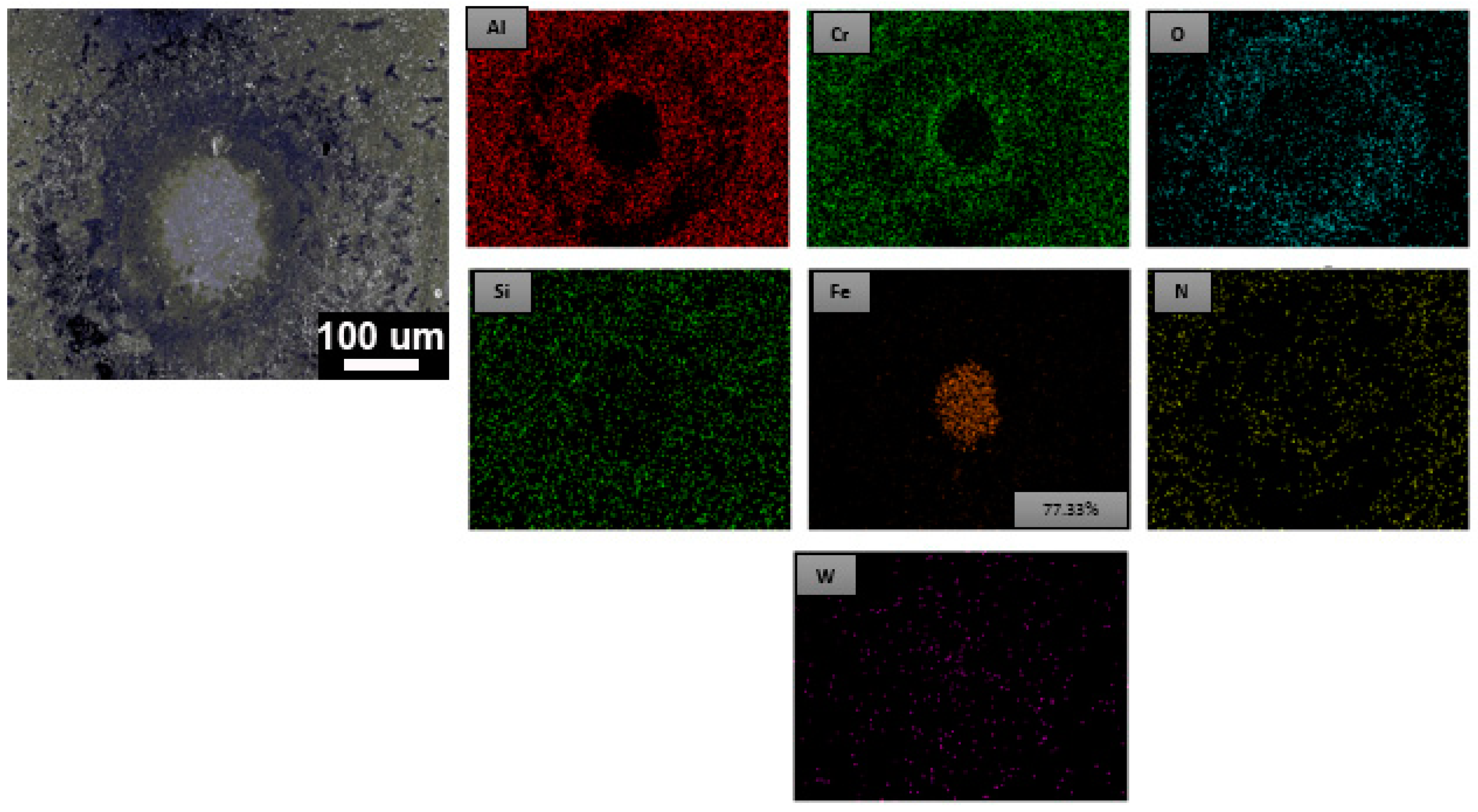

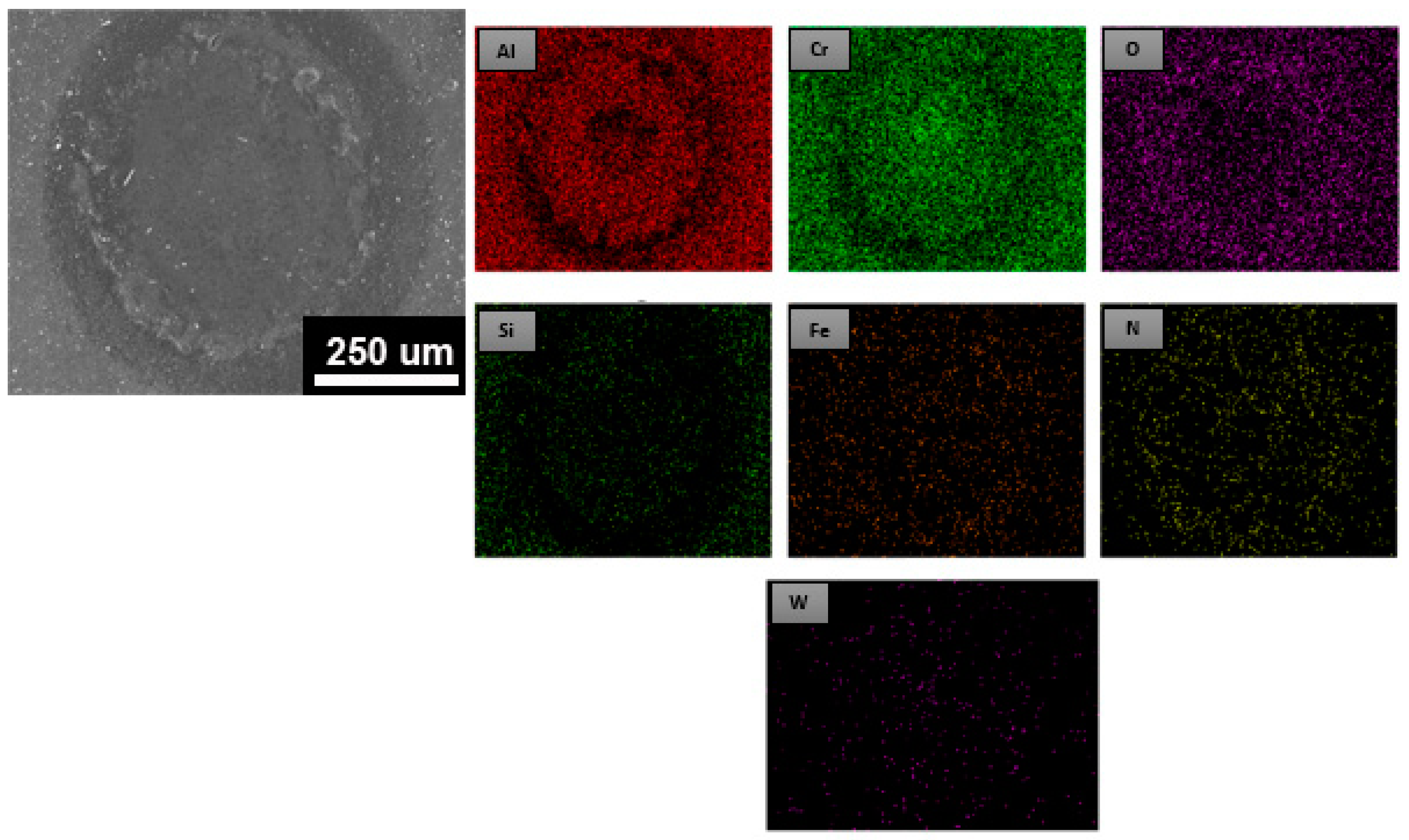

3.1. Microstructure Characterization

3.2. Mechanical Properties

3.2.1. Hardness Test

3.2.2. Adhesion Test

3.2.3. Impact Fatigue Test

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Höck, K.; Spies, H.J.; Larisch, B.; Leonhardt, G.; Buecken, B. Wear resistance of prenitrided hardcoated steels for tools and machine components. Surf. Coat. Technol. 1997, 88, 44–49. [Google Scholar] [CrossRef]

- Paosawatyanyong, B.; Pongsopa, J.; Visuttipitukul, P.; Bhanthumnavin, W. Nitriding of tool steel using dual DC/RFICP plasma process. Surf. Coat. Technol. 2016, 306, 351–357. [Google Scholar] [CrossRef]

- Das, K.; Alphonsa, J.; Ghosh, M.; Ghanshyam, J.; Rane, R.; Mukherjee, S. Influence of pretreatment on surface behavior of duplex plasma treated AISI H13 tool steel. Surf. Interfaces 2017, 8, 206–213. [Google Scholar] [CrossRef]

- Škorić, B.; Kakaš, D.; Rakita, M.; Bibić, N.; Peruškob, D. Structure, hardness and adhesion of thin coatings deposited by PVD, IBAD on nitrided steels. Vacuum 2004, 76, 169–172. [Google Scholar] [CrossRef]

- Hawryluk, M.; Gronostajski, Z.; Widomski, P.; Kaszuba, M.; Ziemba, J.; Smolik, J. Influence of the application of a PN+Cr/CrN hybrid layer on the improvement of the lifetime of hot forging tools. J. Mater. Process. Technol. 2018, 258, 226–238. [Google Scholar] [CrossRef]

- Fontes, M.A.; Pereira, R.G.; Fernandes, F.A.P.; Casteletti, L.C.; de Paula Nascente, P.A. Characterization of plasma nitrided layers produced on sintered iron. J. Mater. Res. Technol. 2014, 3, 210–216. [Google Scholar] [CrossRef] [Green Version]

- Navinšek, B.; Panjan, P.; Milošev, I. Industrial applications of CrN (PVD) coatings, deposited at high and low temperatures. Surf. Coat. Technol. 1997, 97, 182–191. [Google Scholar] [CrossRef]

- Lee, D.B.; Kim, M.H.; Lee, Y.C.; Kwon, S.C. High temperature oxidation of TiCrN coatings deposited on a steel substrate by ion plating. Surf. Coat. Technol. 2001, 141, 232–239. [Google Scholar] [CrossRef]

- Falsafein, M.; Ashrafizadeh, F.; Kheirandish, A. Influence of thickness on adhesion of nanostructured multilayer CrN/CrAlN coatings to stainless steel substrate. Surf. Interfaces 2018, 13, 178–185. [Google Scholar] [CrossRef]

- Liu, W.; Chu, Q.; Zeng, J.; He, R.; Wu, H.; Wu, Z.; Wu, S. PVD-CrAlN and TiAlN coated Si3N4 ceramic cutting tools—1. Microstructure, turning performance and wear mechanism. Ceram. Int. 2017, 43, 8999–9004. [Google Scholar] [CrossRef]

- Zhang, K.; Deng, J.; Guo, X.; Sun, L.; Lei, S. Study on the adhesion and tribological behavior of PVD TiAlN coatings with a multi-scale textured substrate surface. Int. J. Refract. Met. Hard Mater. 2018, 72, 292–305. [Google Scholar] [CrossRef]

- Haršáni, M.; Sahul, M.; Zacková, P.; Čaplovič, Ľ. Study of cathode current effect on the properties of CrAlSiN coatings prepared by LARC. Vacuum 2017, 139, 1–8. [Google Scholar] [CrossRef]

- Chang, C.-C.; Duh, J.-G. Duplex coating technique to improve the adhesion and tribological properties of CrAlSiN nanocomposite coating. Surf. Coat. Technol. 2017, 326, 375–381. [Google Scholar] [CrossRef]

- Chang, Y.-Y.; Chang, C.-P.; Wang, D.-Y.; Yang, S.-M.; Wu, W. High temperature oxidation resistance of CrAlSiN coatings synthesized by a cathodic arc deposition process. J. Alloys Compd. 2008, 461, 336–341. [Google Scholar] [CrossRef]

- Leyland, A.; Matthews, A. On the significance of the H/E ratio in wear control: A nanocomposite coating approach to optimised tribological behaviour. Wear 2000, 246, 1–11. [Google Scholar] [CrossRef]

- Chang, Y.-Y.; Chiu, W.-T.; Hung, J.-P. Mechanical properties and high temperature oxidation of CrAlSiN/TiVN hard coatings synthesized by cathodic arc evaporation. Surf. Coat. Technol. 2016, 303, 18–24. [Google Scholar] [CrossRef]

- Chang, Y.-Y.; Chang, H.; Jhao, L.-J.; Chuang, C.-C. Tribological and mechanical properties of multilayered TiVN/TiSiN coatings synthesized by cathodic arc evaporation. Surf. Coat. Technol. 2018, 350, 1071–1079. [Google Scholar] [CrossRef]

- Basso, R.L.O.; Pastore, H.O.; Schmidt, V.; Baumvol, I.J.R.; Abarca, S.A.C.; de Souza, F.S.; Spinelli, A.; Figueroa, C.A.; Giacomelli, C. Microstructure and corrosion behaviour of pulsed plasma-nitrided AISI H13 tool steel. Corros. Sci. 2010, 52, 3133–3139. [Google Scholar] [CrossRef]

- Naeem, M.; Waqas, M.; Jan, I.; Zaka-ul-Islam, M.; Díaz-Guillén, J.C.; Rehman, N.U.; Shafiq, M.; Zakaullah, M. Influence of pulsed power supply parameters on active screen plasma nitriding. Surf. Coat. Technol. 2016, 300, 67–77. [Google Scholar] [CrossRef]

- Naeem, M.; Iqbal, J.; Abrar, M.; Khan, K.H.; Díaz-Guillén, J.C.; Lopez-Badillo, C.M.; Shafiq, M.; Zaka-ul-Islam, M.; Zakaullah, M. The effect of argon admixing on nitriding of plain carbon steel in N2 and N2-H2 plasma. Surf. Coat. Technol. 2018, 350, 48–56. [Google Scholar] [CrossRef]

- Rother, B.; Jehn, H.A.; Gabriel, H.M. Multilayer hard coatings by coordinated substrate rotation modes in industrial PVD deposition systems. Surf. Coat. Technol. 1996, 86–87, 207–211. [Google Scholar] [CrossRef]

- Beake, B.D.; Isern, L.; Endrino, J.L.; Fox-Rabinovich, G.S. Micro-impact testing of AlTiN and TiAlCrN coatings. Wear 2019, 418–419, 102–110. [Google Scholar] [CrossRef]

- Yan, M.F.; Chen, B.F.; Li, B. Microstructure and mechanical properties from an attractive combination of plasma nitriding and secondary hardening of M50 steel. Appl. Surf. Sci. 2018, 455, 1–7. [Google Scholar] [CrossRef]

- Tschiptschin, A.P.; Varela, L.B.; Pinedo, C.E.; Li, X.Y.; Dong, H. Development and microstructure characterization of single and duplex nitriding of UNS S31803 duplex stainless steel. Surf. Coat. Technol. 2017, 327, 83–92. [Google Scholar] [CrossRef]

- Menthe, E.; Bulak, A.; Olfe, J.; Zimmermann, A.; Rie, K.T. Improvement of the mechanical properties of austenitic stainless steel after plasma nitriding. Surf. Coat. Technol. 2000, 133–134, 259–263. [Google Scholar] [CrossRef]

- Tien, S.-K.; Lin, C.-H.; Tsai, Y.-Z.; Duh, J.-G. Effect of nitrogen flow on the properties of quaternary CrAlSiN coatings at elevated temperatures. Surf. Coat. Technol. 2007, 202, 735–739. [Google Scholar] [CrossRef]

- Kuo, Y.-C.; Wang, C.-J.; Lee, J.-W. The microstructure and mechanical properties evaluation of CrTiAlSiN coatings: Effects of silicon content. Thin Solid Films 2017, 638, 220–229. [Google Scholar] [CrossRef]

- Soldán, J.; Neidhardt, J.; Sartory, B.; Kaindl, R.; Čerstvý, R.; Mayrhofer, P.H.; Tessadri, R.; Polcik, P.; Lechthaler, M.; Mitterer, C. Structure–property relations of arc-evaporated Al–Cr–Si–N coatings. Surf. Coat. Technol. 2008, 202, 3555–3562. [Google Scholar] [CrossRef]

- Chang, Y.-Y.; Lai, H.-M. Wear behavior and cutting performance of CrAlSiN and TiAlSiN hard coatings on cemented carbide cutting tools for Ti alloys. Surf. Coat. Technol. 2014, 259, 152–158. [Google Scholar] [CrossRef]

- Sun, S.Q.; Ye, Y.W.; Wang, Y.X.; Liu, M.Q.; Liu, X.; Li, J.L.; Wang, L.P. Structure and tribological performances of CrAlSiN coatings with different Si percentages in seawater. Tribol. Int. 2017, 115, 591–599. [Google Scholar] [CrossRef]

- He, L.; Chen, L.; Xu, Y. Interfacial structure, mechanical properties and thermal stability of CrAlSiN/CrAlN multilayer coatings. Mater. Charact. 2017, 125, 1–6. [Google Scholar] [CrossRef]

- Wang, Y.X.; Zhang, S.; Lee, J.-W.; Lew, W.S.; Sun, D.; Li, B. Toward hard yet tough CrAlSiN coatings via compositional grading. Surf. Coat. Technol. 2013, 231, 346–352. [Google Scholar] [CrossRef]

- Chang, C.-C.; Chen, H.-W.; Lee, J.-W.; Duh, J.-G. Influence of Si contents on tribological characteristics of CrAlSiN nanocomposite coatings. Thin Solid Films 2015, 584, 46–51. [Google Scholar] [CrossRef]

- Chen, H.-W.; Chan, Y.-C.; Lee, J.-W.; Duh, J.-G. Oxidation behavior of Si-doped nanocomposite CrAlSiN coatings. Surf. Coat. Technol. 2010, 205, 1189–1194. [Google Scholar] [CrossRef]

- Deng, Y.; Tan, C.; Wang, Y.; Chen, L.; Cai, P.; Kuang, T.; Lei, S.; Zhou, K. Effects of tailored nitriding layers on comprehensive properties of duplex plasma-treated AlTiN coatings. Ceram. Int. 2017, 43, 8721–8729. [Google Scholar] [CrossRef]

- Tan, C.; Kuang, T.; Zhou, K.; Zhu, H.; Deng, Y.; Li, X.; Cai, P.; Liu, Z. Fabrication and characterization of in-situ duplex plasma-treated nanocrystalline Ti/AlTiN coatings. Ceram. Int. 2016, 42, 10793–10800. [Google Scholar] [CrossRef]

- Tillmann, W.; Grisales, D.; Stangier, D. Effects of AISI H11 surface integrity on the residual stresses and adhesion of TiAlN/substrate compounds. Surf. Coat. Technol. 2019, 357, 466–472. [Google Scholar] [CrossRef]

- Vidakis, N.; Antoniadis, A.; Bilalis, N. The VDI 3198 indentation test evaluation of a reliable qualitative control for layered compounds. J. Mater. Process. Technol. 2003, 143–144, 481–485. [Google Scholar] [CrossRef]

- Haršáni, M.; Ghafoor, N.; Calamba, K.; Zacková, P.; Sahul, M.; Vopát, T.; Satrapinskyy, L.; Čaplovičová, M.; Čaplovič, Ľ. Adhesive-deformation relationships and mechanical properties of nc-AlCrN/a-SiNx hard coatings deposited at different bias voltages. Thin Solid Films 2018, 650, 11–19. [Google Scholar] [CrossRef]

- He, Y.; Apachitei, I.; Zhou, J.; Walstock, T.; Duszczyk, J. Effect of prior plasma nitriding applied to a hot-work tool steel on the scratch-resistant properties of PACVD TiBN and TiCN coatings. Surf. Coat. Technol. 2006, 201, 2534–2539. [Google Scholar] [CrossRef]

- Borodich, F.M. Chapter Three—The Hertz-Type and Adhesive Contact Problems for Depth-Sensing Indentation. In Advances in Applied Mechanics; Bordas, S.P.A., Ed.; Elsevier: New York, NY, USA, 2014; Volume 47, pp. 225–366. [Google Scholar]

- Batista, J.C.A.; Godoy, C.; Matthews, A. Impact testing of duplex and non-duplex (Ti,Al)N and Cr–N PVD coatings. Surf. Coat. Technol. 2003, 163–164, 353–361. [Google Scholar] [CrossRef]

- Cassar, G.; Banfield, S.; Avelar-Batista Wilson, J.C.; Housden, J.; Matthews, A.; Leyland, A. Impact wear resistance of plasma diffusion treated and duplex treated/PVD-coated Ti–6Al–4V alloy. Surf. Coat. Technol. 2012, 206, 2645–2654. [Google Scholar] [CrossRef] [Green Version]

- Zhang, S.; Wang, L.; Wang, Q.; Li, M. A superhard CrAlSiN superlattice coating deposited by a multi-arc ion plating: II. Thermal stability and oxidation resistance. Surf. Coat. Technol. 2013, 214, 153–159. [Google Scholar] [CrossRef]

- Chen, H.-W.; Chan, Y.-C.; Lee, J.-W.; Duh, J.-G. Oxidation resistance of nanocomposite CrAlSiN under long-time heat treatment. Surf. Coat. Technol. 2011, 206, 1571–1576. [Google Scholar] [CrossRef]

- Chang, Y.-Y.; Cheng, C.-M.; Liou, Y.-Y.; Tillmann, W.; Hoffmann, F.; Sprute, T. High temperature wettability of multicomponent CrAlSiN and TiAlSiN coatings by molten glass. Surf. Coat. Technol. 2013, 231, 24–28. [Google Scholar] [CrossRef]

| Parameters | |

|---|---|

| Base pressure | <1 Pa |

| Ar ion cleaning | Bias voltage = −700 V, Pressure = 2 Pa, Time = 30 min |

| Nitriding | T = 450 °C, Time = 7 h, Bias voltage = −500 V, N2/H2 = 80/20 sccm |

| Duty Cycle | 82% |

| Pressure | 250 Pa |

| Parameters | |

|---|---|

| Target | Cr, Al0.7Cr0.3, Al0.6Cr0.3Si0.1 |

| Base pressure | <0.004 Pa |

| Ar ion cleaning | Bias voltage = −700 V, Pressure = 2 Pa, Time = 20 min |

| Reactive gas | Ar/N2 |

| Working pressure | 3 Pa |

| Deposition temperature | 250 °C |

| Target current | 70 A |

| Bias voltage | −120 V |

| Rotation speed | 2 rpm |

| Deposition time | 90 min |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, Y.-Y.; Amrutwar, S. Effect of Plasma Nitriding Pretreatment on the Mechanical Properties of AlCrSiN-Coated Tool Steels. Materials 2019, 12, 795. https://doi.org/10.3390/ma12050795

Chang Y-Y, Amrutwar S. Effect of Plasma Nitriding Pretreatment on the Mechanical Properties of AlCrSiN-Coated Tool Steels. Materials. 2019; 12(5):795. https://doi.org/10.3390/ma12050795

Chicago/Turabian StyleChang, Yin-Yu, and Siddhant Amrutwar. 2019. "Effect of Plasma Nitriding Pretreatment on the Mechanical Properties of AlCrSiN-Coated Tool Steels" Materials 12, no. 5: 795. https://doi.org/10.3390/ma12050795

APA StyleChang, Y.-Y., & Amrutwar, S. (2019). Effect of Plasma Nitriding Pretreatment on the Mechanical Properties of AlCrSiN-Coated Tool Steels. Materials, 12(5), 795. https://doi.org/10.3390/ma12050795