Microstructure and Mechanical Performance of Additively Manufactured Aluminum 2024-T3/Acrylonitrile Butadiene Styrene Hybrid Joints Using an AddJoining Technique

Abstract

:1. Introduction

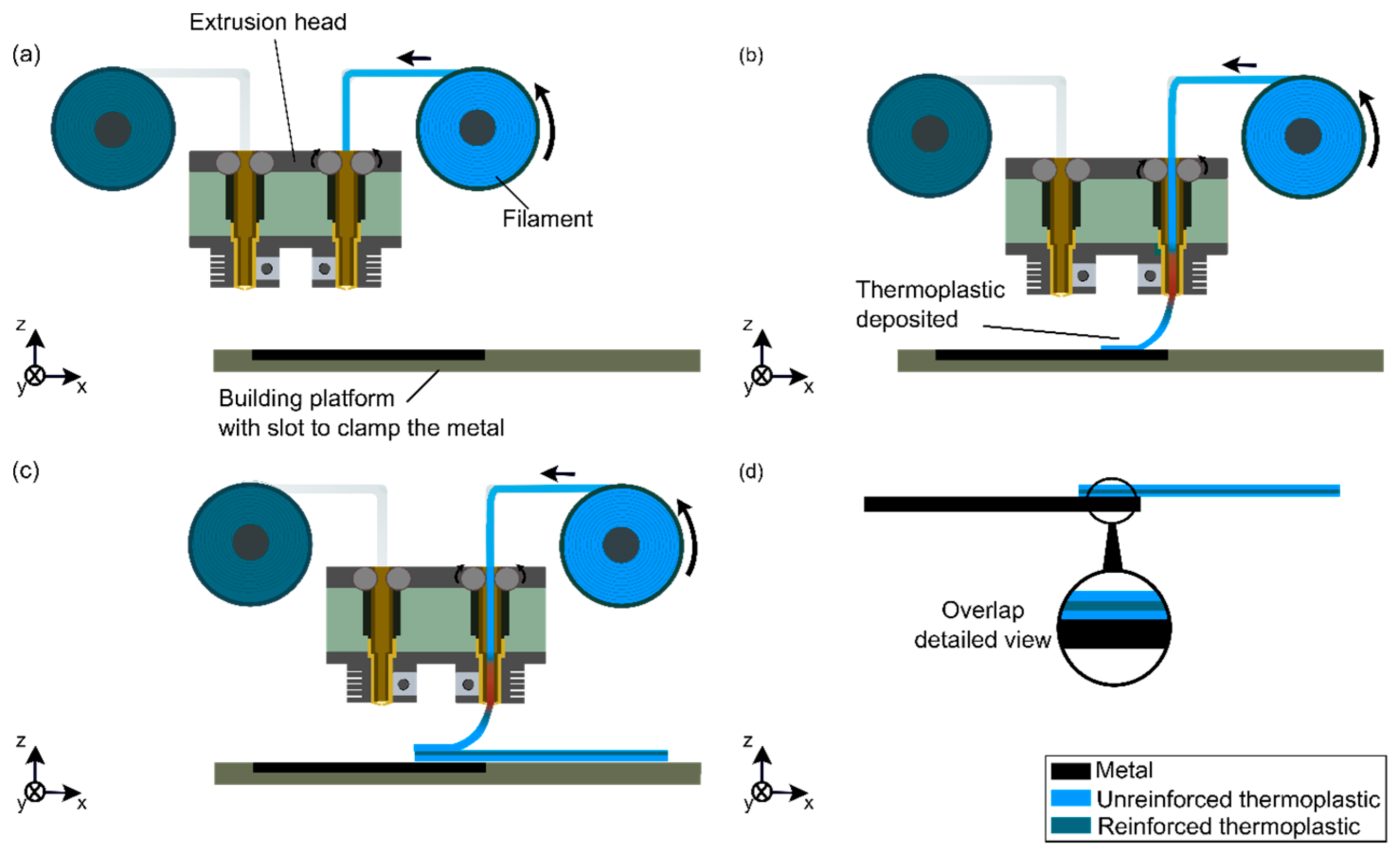

AddJoining Principles

2. Materials and Methods

2.1. Aluminum 2024-T3

2.2. Acrylonitrile Butadiene Styrene (ABS)

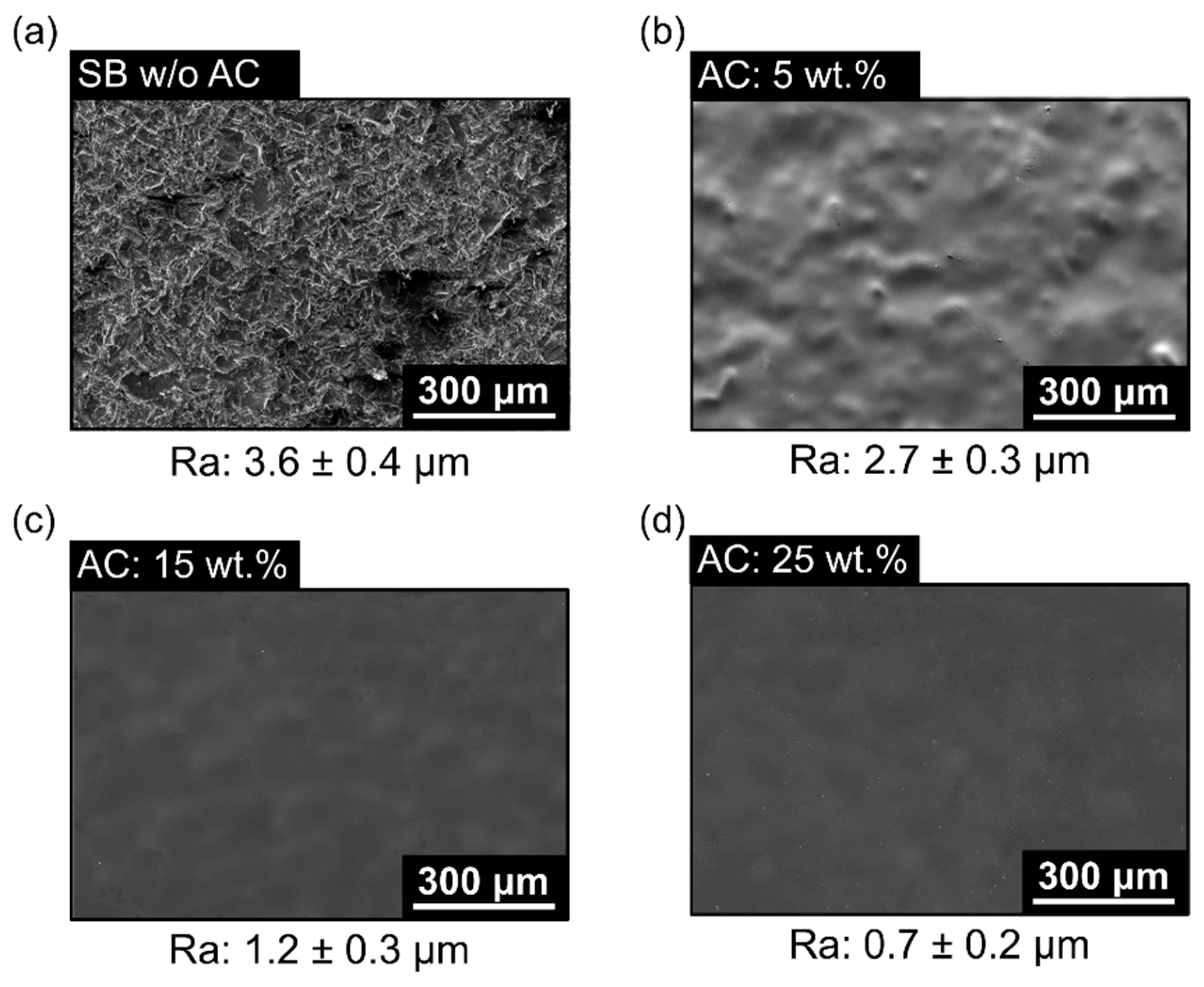

2.3. Surface Preparation

2.4. Manufacturing Procedure

- Printing temperature (PT) refers to the working temperature at the extruder head (Figure 3a), which was above the glass transition temperature or melting temperature, respectively, for amorphous and semi-crystalline thermoplastics.

- Road thickness (RT) is the thickness of the consolidated road, which is the vertical distance between each layer (Figure 3b).

- Deposition speed (DS) means the speed of the extruder head during operation (Figure 3c).

- ABS coating concentration (AC) is the polymer concentration applied as the coating on the metallic surface.

- The number of contours (NC) refers to the enclosed loops of road deposition in the filled-perimeter region (Figure 3d).

2.5. Mechanical Performance

2.6. Microstructural and Fracture Surface Analysis

2.7. Statistical Analysis of Mechanical Performance

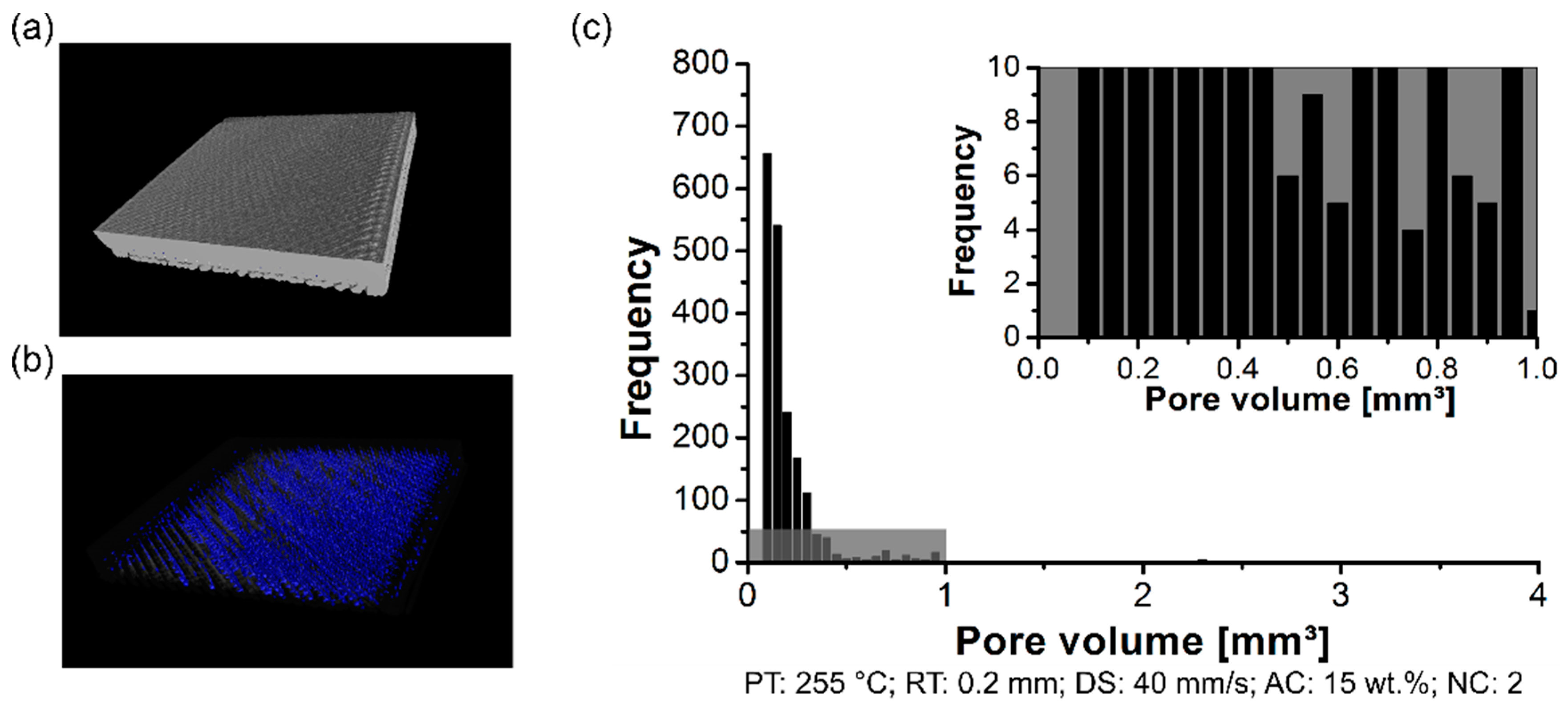

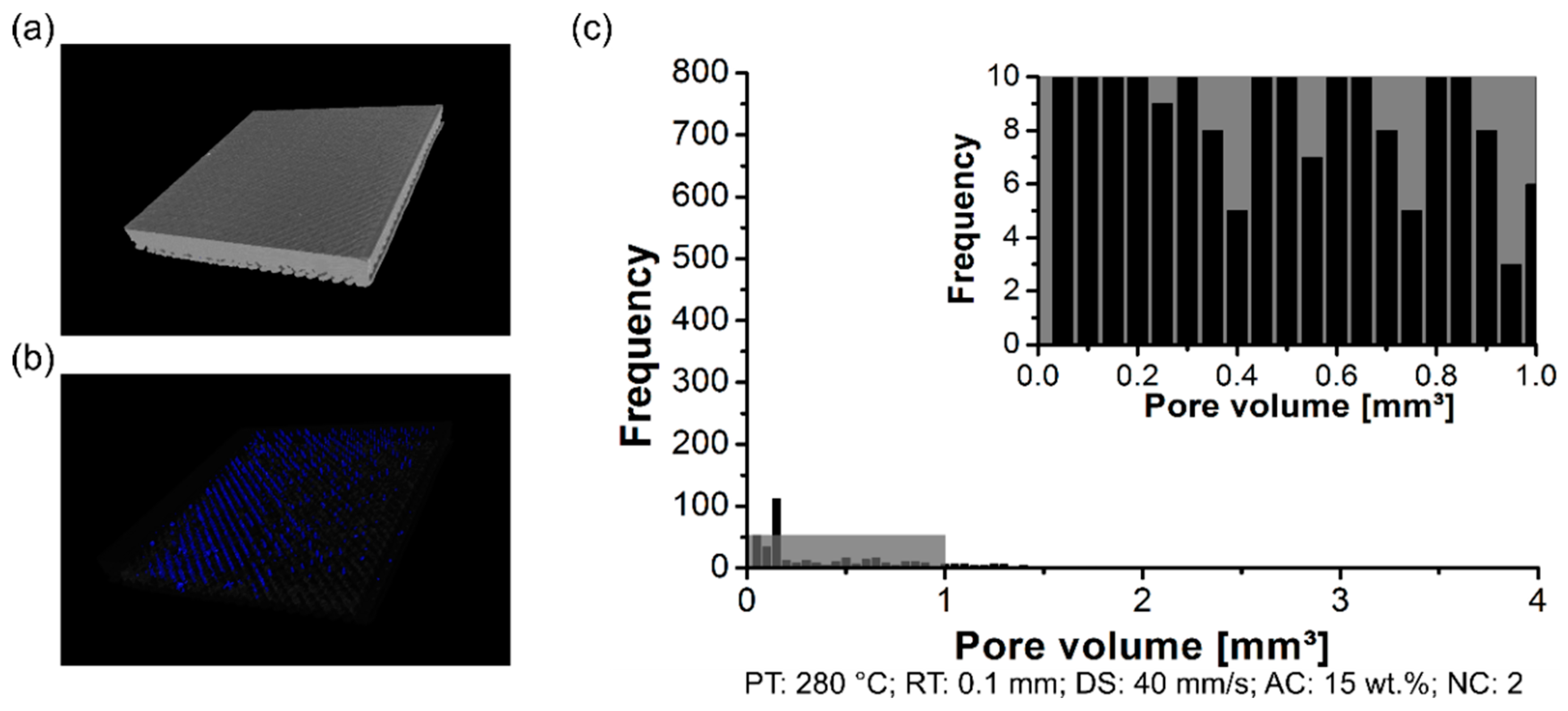

2.8. Non-Destructive Testing

3. Results

3.1. Influence of the AddJoining Process Parameters on the ULSF

3.1.1. Printing Temperature

3.1.2. Road Thickness

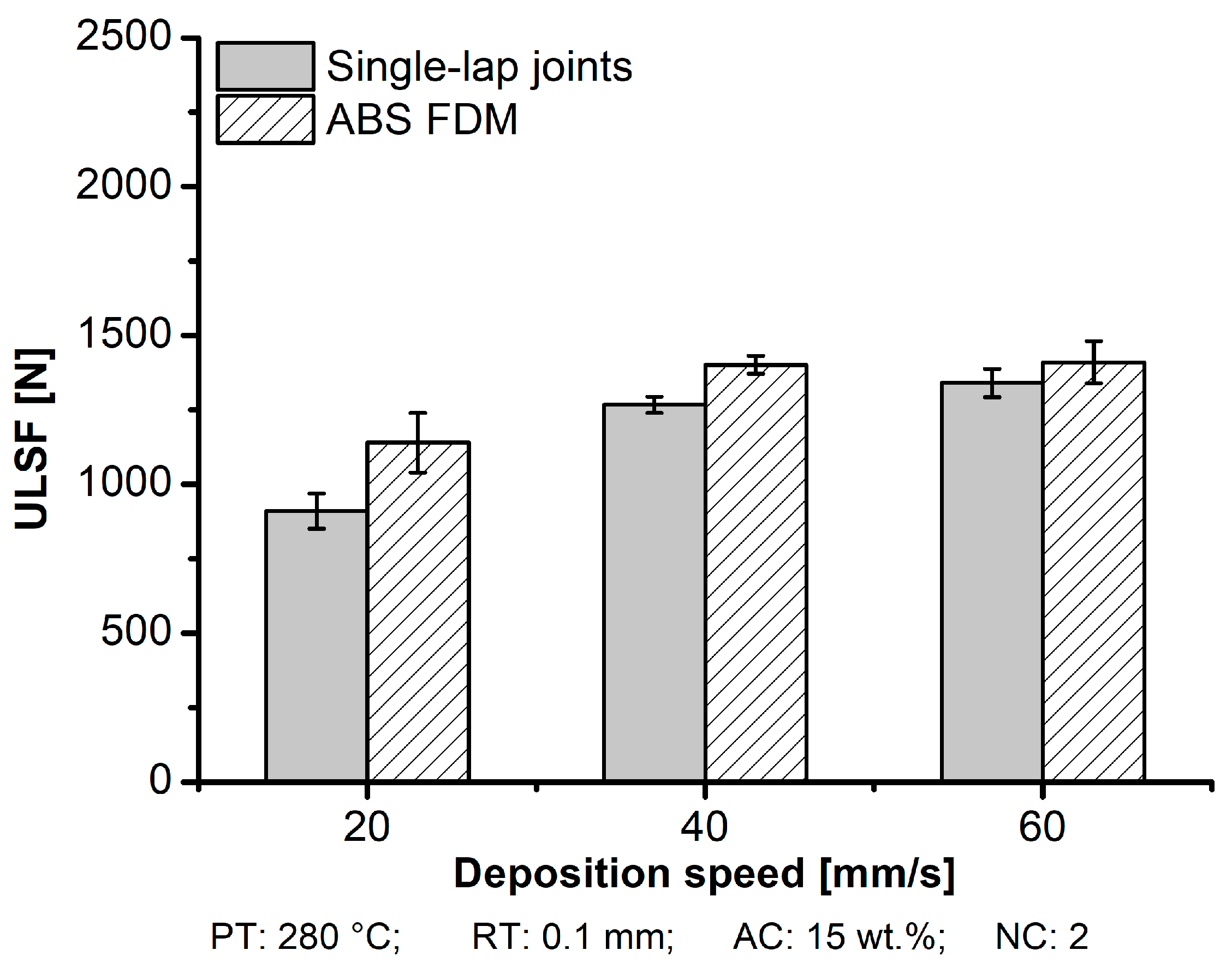

3.1.3. Deposition Speed

3.1.4. ABS Coating Concentration

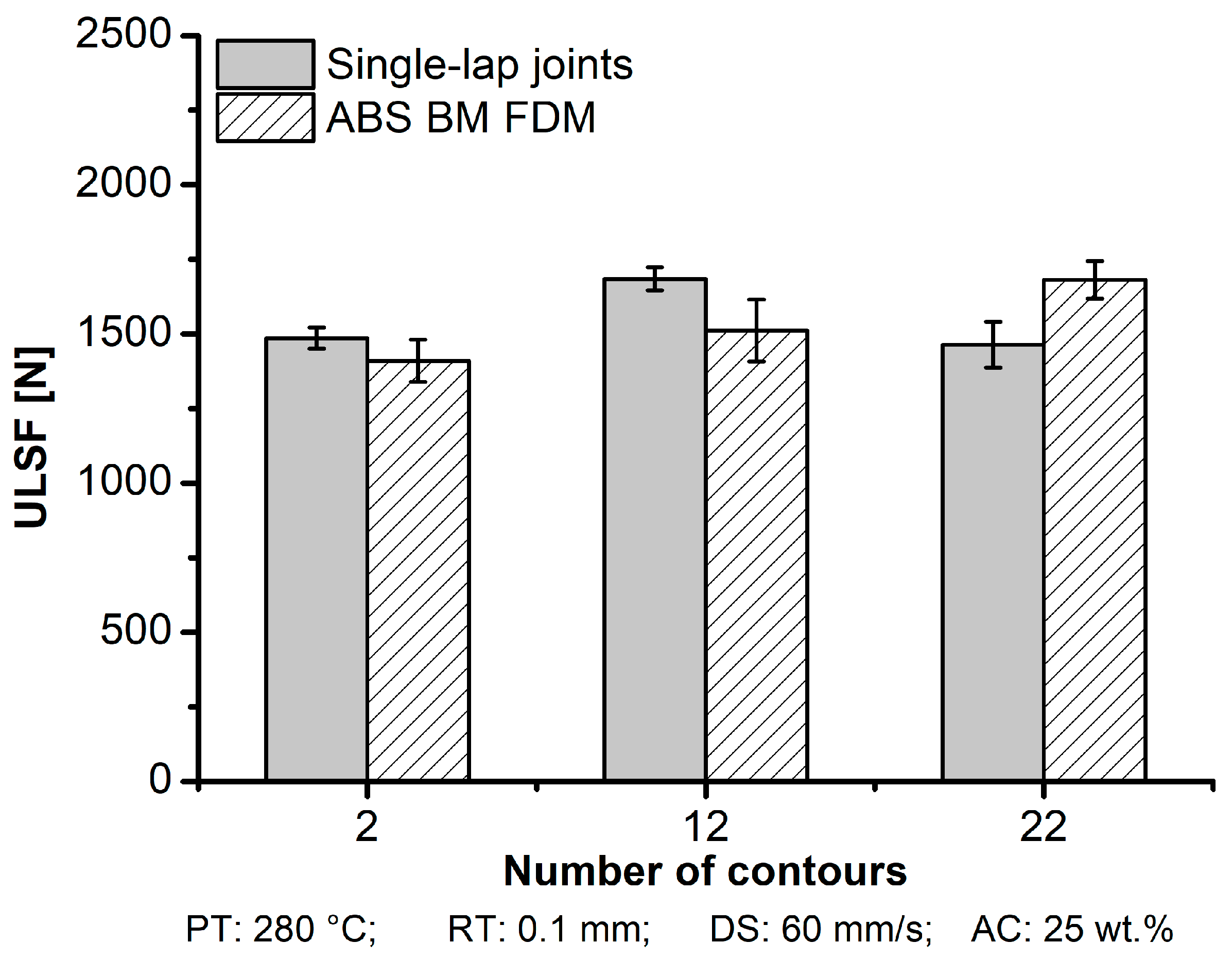

3.1.5. Number of Contours

3.2. Optimum Condition Based on Maximum ULSF

4. Conclusions

- At a higher deposition speed (60 mm/s), the road lost the heat to the consolidated neighboring road or the road below. Hence, it facilitated intermolecular diffusion where the deposited road remained softened upon the deposition of the following road. Therefore, it allowed for a better bonding between the layers and promotes a reduction in pores.

- Higher ABS coating concentration (25 wt.%) increased the coating thickness to nearly 100 µm. Therefore, it had a smoother surface reducing local stress concentration. Moreover, it had more mass to deform, promoting a better interaction of the metal–polymer leading to plastic deformation and low shear and peel stress.

- For the highest number of contours (22), the carrying load was decreased by the road orientation in the overlap area. The road deposition for 90° was inevitably formed in the overlap area, which caused the joint to turn weaker. For ABS BM FDM, the road deposition for 90° was in the grips during mechanical testing, which was far from the carrying loading area, and which did not directly influence the performance of the specimen.

- Thinner road thickness (0.1 mm) resulted in considerable inter-bonding strength and compact interactions with the roads, where the low pores formation in the internal structure of the 3D-printed polymer was found.

Author Contributions

Funding

Conflicts of Interest

References

- Goede, M.; Stehlin, M.; Rafflenbeul, L.; Kopp, G.; Beeh, E. Super Light Car—Lightweight construction thanks to a multi-material design and function integration. Eur. Transp. Res. Rev. 2009, 1, 5–10. [Google Scholar] [CrossRef]

- Amancio-Filho, S. Friction Riveting: Development and analysis of a new joining technique for polymer-metal multi-material structures. Weld. World 2011, 55, 13–24. [Google Scholar]

- Goushegir, S.M.; Santos, J.F.; Amancio-Filho, S.T. Influence of process parameters on mechanical performance and bonding area of AA2024/carbon-fiber-reinforced poly (phenylene sulfide) friction spot single lap joints. Mater. Des. 2015, 83, 431–442. [Google Scholar] [CrossRef]

- Goushegir, S.M.; Santos, J.F.; Amancio-Filho, S.T. Friction Spot Joining of aluminum AA2024/carbon-fiber reinforced poly (phenylene sulfide) composite single lap joints: Microstructure and mechanical performance. Mater. Des. 2014, 54, 196–206. [Google Scholar] [CrossRef]

- Abibe, A.B.; Sônego, M.; Santos, J.F.; Canto, L.B.; Amancio-Filho, S.T. On the feasibility of a friction-based staking joining method for polymer-metal hybrid structures. Mater. Des. 2016, 92, 632–642. [Google Scholar] [CrossRef]

- Abibe, A.B.; Amancio-Filho, S.T.; Dos Santos, J.F.; Hage, E., Jr. Mechanical and failure behaviour of hybrid polymer-metal staked joints. Mater. Des. 2013, 46, 338–347. [Google Scholar] [CrossRef]

- Feistauer, E.E.; Guimarães, R.P.M.; Ebel, T.; Dos Santos, J.F.; Amancio-Filho, S.T. Ultrasonic joining: A novel direct-assembly technique for metal-composite hybrid structures. Mater. Lett. 2016, 170, 1–4. [Google Scholar] [CrossRef]

- Feistauer, E.E.; Ebel, T.; Santos, J.F.; Amancio-Filho, S.T. Ultrasonic joining of through-the-thickness reinforced Ti-4Al-6V and polyetherimide hybrid joints. In Proceedings of the ANTEC, Anaheim, CA, USA, 8–10 May 2017; pp. 1718–1724. [Google Scholar]

- Balle, B.F.; Wagner, G.; Eifler, D. Ultrasonic metal welding of aluminium sheets to carbon fibre Reinforced thermoplastic composites. Adv. Eng. Mater. 2009, 11, 35–39. [Google Scholar] [CrossRef]

- Balle, F.; Wagner, G.; Eifler, D. Ultrasonic spot welding of aluminum sheet/carbon fiber reinforced polymer–joints. Materialwissenschaft und Werkstofftechnik: Entwicklung, Fertigung, Prüfung, Eigenschaften und Anwendungen Technischer Werkstoffe 2007, 38, 934–938. [Google Scholar] [CrossRef]

- Mitschang, P.; Velthuis, R.; Emrich, S.; Kopnarski, M. Induction Heated Joining of Aluminum and Carbon Fiber Reinforced. Thermoplast. Compos. Mater. 2008, 22, 17–27. [Google Scholar] [CrossRef]

- Türk, D.; Kussmaul, R.; Zogg, M.; Klahn, C.; Spierings, A.; Ermanni, P.; Meboldt, M. Additive manufacturing with composites for integrated aircraft structures. In Proceedings of the International SAMPE Technical Conference, Long Beach, CA, USA, 23–26 May 2016; pp. 1404–1418. [Google Scholar]

- Riss, F.; Schilp, J.; Reinhart, G. Load-dependent optimization of honeycombs for sandwich components-new possibilities by using additive layer manufacturing. Phys. Procedia 2014, 56, 327–335. [Google Scholar] [CrossRef]

- Falck, R.; Goushegir, S.M.; dos Santos, J.F.; Amancio-Filho, S.T. AddJoining: A novel additive manufacturing approach for layered metal-polymer hybrid structures. Mater. Lett. 2018. [Google Scholar] [CrossRef]

- Jarvela, P.; Heponen, V.P.; Jarvela, P. Hot isostatic pressing of plastics. Polym. Commun. 1986, 27, 180–181. [Google Scholar]

- Aluminum AA2024-T3 Technical Datasheet; Constellium: Issoire, France, 2012.

- Boyer, H.; Gall, T. Metals Handbook; American Society for Metals: Metals Park, OH, USA, 1985. [Google Scholar]

- Sun, Q.; Rizvi, G.M.; Bellehumeur, C.T.; Gu, P. Effect of processing conditions on the bonding quality of FDM polymer filaments. Rapid Prototyp. J. 2008, 14, 72–80. [Google Scholar] [CrossRef]

- Agarwala, M.K.; Jamalabad, V.R.; Langrana, N.A.; Safari, A.; Whalen, P.J.; Danforth, S.C. Structural quality of parts processed by fused deposition. Rapid Prototyp. J. 1996, 2, 4–19. [Google Scholar] [CrossRef]

- Stratasys ABS-ESD7—Production Grade Thermoplastic for Fortus 3D Production Systems. Available online: https://www.google.com.hk/url?sa=t&rct=j&q=&esrc=s&source=web&cd=5&cad=rja&uact=8&ved=2ahUKEwiqsJHhpYHhAhV8JaYKHVckDyYQFjAEegQIBhAC&url=https%3A%2F%2Fwww.stratasys.com%2F-%2Fmedia%2Ffiles%2Fmaterial-spec-sheets%2Fmss_fdm_absesd7_1117a.pdf&usg=AOvVaw303AzA8Xxr7XtUNjz0XsWS (accessed on 14 March 2019).

- Uddandapu, P.K. Impact Analysis on Car Bumper by varying speeds using Materials ABS Plastic and Poly Ether Imide by Finite Element Analysis software Solid Works. Int. J. Mod. Eng. Res. 2013, 3, 391–395. [Google Scholar]

- Froelich, D.; Maris, E.; Haoues, N.; Chemineau, L.; Renard, H.; Abraham, F.; Lassartesses, R. State of the art of plastic sorting and recycling: Feedback to vehicle design. Miner. Eng. 2007, 20, 902–912. [Google Scholar] [CrossRef]

- Thompson, A.; Maskery, I.; Leach, R.K. X-ray computed tomography for additive manufacturing: A review. Meas. Sci. Technol. 2016, 27, 72001. [Google Scholar] [CrossRef]

- Mendelson, R.A. A generalized melt viscosity-temperature dependence for styrene and styrene-acrylonitrile-based polymers. Polym. Eng. Sci. 1976, 16, 690–696. [Google Scholar] [CrossRef]

- Rosenzweig, N.; Narkis, M. Sintering rheology of amorphous polymers. Polym. Eng. Sci. 1981, 21, 1167–1170. [Google Scholar] [CrossRef]

- Davis, C.S.; Hillgartner, K.E.; Han, S.H.; Seppala, J.E. Mechanical strength of welding zones produced by polymer extrusion additive manufacturing. Addit. Manuf. 2017, 16, 162–166. [Google Scholar] [CrossRef] [PubMed]

- Anitha, R.; Arunachalam, S.; Radhakrishnan, P. Critical parameters influencing the quality of prototypes in fused deposition modelling. J. Mater. Process. Technol. 2001, 118, 385–388. [Google Scholar] [CrossRef]

- Sood, A.K.; Ohdar, R.K.; Mahapatra, S.S. Parametric appraisal of mechanical property of fused deposition modelling processed parts. Mater. Des. 2010, 31, 287–295. [Google Scholar] [CrossRef]

- Wu, W.; Geng, P.; Li, G.; Zhao, D.; Zhang, H.; Zhao, J. Influence of layer thickness and raster angle on the mechanical properties of 3D-printed PEEK and a comparative mechanical study between PEEK and ABS. Materials 2015, 8, 5834–5846. [Google Scholar] [CrossRef] [PubMed]

- Shubham, P.; Sikidar, A.; Chand, T. The Influence of Layer Thickness on Mechanical Properties of the 3D Printed ABS Polymer by Fused Deposition Modeling. Key Eng. Mater. 2016, 706, 63–67. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W.; Hu, Y.; Wang, H. Additive manufacturing of carbon fiber-reinforced plastic composites using fused deposition modeling: Effects of process parameters on tensile properties. J. Compos. Mater. 2016. [Google Scholar] [CrossRef]

- Hashemi Sanatgar, R.; Campagne, C.; Nierstrasz, V. Investigation of the adhesion properties of direct 3D printing of polymers and nanocomposites on textiles: Effect of FDM printing process parameters. Appl. Surf. Sci. 2017, 403, 551–563. [Google Scholar] [CrossRef]

- Eiliat, H.; Urbanic, R.J. Minimizing voids for a material extrusion based process. Rapid Prototyp. J. 2018, 24, 485–500. [Google Scholar] [CrossRef]

- Bellehumeur, C.; Li, L.; Sun, Q.; Gu, P. Modeling of Bond Formation Between Polymer Filaments in the Fused Deposition Modeling Process. J. Manuf. Process. 2004, 6, 170–178. [Google Scholar] [CrossRef]

- Seppala, J.E.; Hoon Han, S.; Hillgartner, K.E.; Davis, C.S.; Migler, K.B. Weld formation during material extrusion additive manufacturing. Soft Matter 2017. [Google Scholar] [CrossRef]

- Objois, A.; Gilibert, Y.; Fargette, B. Theoretical and experimental analysis of the scarf joint bonded structure: Influence of the adhesive thickness on the micro-mechanical behavior. J. Adhes. 1999, 70, 13–32. [Google Scholar] [CrossRef]

- Rodríguez, J.F.; Thomas, J.P.; Renaud, J.E. Mechanical behaviour of acrylonitrile butadiene styrene fused deposition materials modeling. Rapid Prototyp. 2003, 9, 219–230. [Google Scholar] [CrossRef]

- Ahn, S.H.; Baek, C.; Lee, S.; Ahn, I.S. Anisotropic Tensile Failure Model of Rapid Prototyping Parts—Fused Deposition Modeling (FDM). Int. J. Mod. Phys. B 2003, 17, 1510–1516. [Google Scholar] [CrossRef]

- Ziemian, C.; Sharma, M.; Ziemian, S. Anisotropic mechanical properties of ABS parts fabricated by fused deposition modelling. In Mechanical Engineering; Gokcek, M., Ed.; InTech: Rijeka, Croatia, 2012; pp. 159–180. ISBN 978-953-51-0505-3. [Google Scholar]

| Coeff. of Thermal Expansion (µm/m·°C) | Thermal Conductivity (W/m·K) | Melting Temperature (°C) | Elastic Modulus (GPa) | Tensile Strength (MPa) |

|---|---|---|---|---|

| 24.7 | 121 | 500–638 | 72 | 480 |

| Coeff. of Thermal Expansion (µm/m·°C) | Thermal Conductivity (W/m·K) | Glass Transition Temperature (°C) | Elastic Modulus (GPa) | Tensile Strength (MPa) |

|---|---|---|---|---|

| 10.1 | 0.21 | 94 | 2.4 | 26 |

| Factor | Abbreviation | Unit | Level 1 | Level 2 | Level 3 |

|---|---|---|---|---|---|

| Printing temperature | PT | °C | 230 | 255 | 280 |

| Road thickness | RT | mm | 0.1 | 0.2 | 0.3 |

| Deposition speed | DS | mm/s | 20 | 40 | 60 |

| ABS coating concentration | AC | wt.% | 5 | 15 | 25 |

| Number of contours | NC | - | 2 | 12 | 22 |

| Condition | PT (°C) | RT (mm) | DS (mm/s) | AC (wt.%) | NC (-) | ULSF (N) | DaB (mm) |

|---|---|---|---|---|---|---|---|

| C1 | 230 | 0.2 | 40 | 15 | 2 | 1228 ± 132 | 4.7 ± 0.7 |

| C2 | 255 | 0.2 | 40 | 15 | 2 | 1209 ± 95 | 5.1 ± 0.3 |

| C3 | 280 | 0.2 | 40 | 15 | 2 | 1259 ± 128 | 5.7 ± 0.5 |

| C4 | 280 | 0.1 | 40 | 15 | 2 | 1401 ± 30 | 4.8 ± 0.3 |

| C5 | 280 | 0.3 | 40 | 15 | 2 | 1152 ± 75 | 4.2 ± 0.2 |

| C6 | 280 | 0.1 | 20 | 15 | 2 | 1142 ± 33 | 4.5 ± 0.6 |

| C7 | 280 | 0.1 | 60 | 15 | 2 | 1410 ± 71 | 6.2 ± 0.9 |

| C8 | 280 | 0.1 | 60 | 5 | 2 | 1410 ± 71 | 6.2 ± 0.9 |

| C9 | 280 | 0.1 | 60 | 25 | 2 | 1410 ± 71 | 6.2 ± 0.9 |

| C10 | 280 | 0.1 | 60 | 25 | 12 | 1412 ± 104 | 3.8 ± 0.1 |

| C11 | 280 | 0.1 | 60 | 25 | 22 | 1682 ± 63 | 4.7 ± 0.7 |

| Condition | PT (°C) | RT (mm) | DS (mm/s) | AC (wt.%) | NC (-) | ULSF (N) | DaB (mm) |

|---|---|---|---|---|---|---|---|

| C1 | 230 | 0.2 | 40 | 15 | 2 | 1058 ± 89 | 1.2 ± 0.3 |

| C2 | 255 | 0.2 | 40 | 15 | 2 | 1121 ± 94 | 1.3 ± 0.2 |

| C3 | 280 | 0.2 | 40 | 15 | 2 | 1159 ± 50 | 1.3 ± 0.2 |

| C4 | 280 | 0.1 | 40 | 15 | 2 | 1267 ± 27 | 1.5 ± 0.5 |

| C5 | 280 | 0.3 | 40 | 15 | 2 | 1062 ± 39 | 1.3 ± 0.3 |

| C6 | 280 | 0.1 | 20 | 15 | 2 | 910 ± 59 | 0.9 ± 0.1 |

| C7 | 280 | 0.1 | 60 | 15 | 2 | 1340 ± 47 | 1.8 ± 0.3 |

| C8 | 280 | 0.1 | 60 | 5 | 2 | 1142 ± 35 | 0.8 ± 0.4 |

| C9 | 280 | 0.1 | 60 | 25 | 2 | 1486 ± 36 | 1.9 ± 0.2 |

| C10 | 280 | 0.1 | 60 | 25 | 12 | 1686 ± 39 | 2.3 ± 0.4 |

| C11 | 280 | 0.1 | 60 | 25 | 22 | 1464 ± 77 | 2.0 ± 0.7 |

| Factor | Unit | Level 1 | Level 2 | Level 3 | f-Value | p-Value |

|---|---|---|---|---|---|---|

| PT | °C | 230 | 255 | 280 | 2.15 | 1.34 × 10−1 |

| RT | mm | 0.1 | 0.2 | 0.3 | 5.73 | 8.0 × 10−3 |

| DS | mm/s | 20 | 40 | 60 | 32.38 | 1.24 × 10−6 |

| AC | wt.% | 5 | 15 | 25 | 29.42 | 2.43 × 10−5 |

| NC | - | 2 | 12 | 22 | 15.64 | 1.46 × 10−5 |

| Factor | Unit | Level 1 | Level 2 | Level 3 | F-Value | p-Value |

|---|---|---|---|---|---|---|

| PT | °C | 230 | 255 | 280 | 1.28 | 2.97 × 10−1 |

| RT | mm | 0.1 | 0.2 | 0.3 | 5.65 | 1.0 × 10−2 |

| DS | mm/s | 20 | 40 | 60 | 14.09 | 1.78 × 10−6 |

| NC | - | 2 | 12 | 22 | 17.19 | 2.32 × 10−5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Falck, R.; dos Santos, J.F.; Amancio-Filho, S.T. Microstructure and Mechanical Performance of Additively Manufactured Aluminum 2024-T3/Acrylonitrile Butadiene Styrene Hybrid Joints Using an AddJoining Technique. Materials 2019, 12, 864. https://doi.org/10.3390/ma12060864

Falck R, dos Santos JF, Amancio-Filho ST. Microstructure and Mechanical Performance of Additively Manufactured Aluminum 2024-T3/Acrylonitrile Butadiene Styrene Hybrid Joints Using an AddJoining Technique. Materials. 2019; 12(6):864. https://doi.org/10.3390/ma12060864

Chicago/Turabian StyleFalck, Rielson, Jorge F. dos Santos, and Sergio T. Amancio-Filho. 2019. "Microstructure and Mechanical Performance of Additively Manufactured Aluminum 2024-T3/Acrylonitrile Butadiene Styrene Hybrid Joints Using an AddJoining Technique" Materials 12, no. 6: 864. https://doi.org/10.3390/ma12060864

APA StyleFalck, R., dos Santos, J. F., & Amancio-Filho, S. T. (2019). Microstructure and Mechanical Performance of Additively Manufactured Aluminum 2024-T3/Acrylonitrile Butadiene Styrene Hybrid Joints Using an AddJoining Technique. Materials, 12(6), 864. https://doi.org/10.3390/ma12060864