Oxidation Resistance and Microstructure Evaluation of a Polymer Derived Ceramic (PDC) Composite Coating Applied onto Sintered Steel

Abstract

1. Introduction

2. Materials and Methods

2.1. Processing of the Sintered Steel Substrate

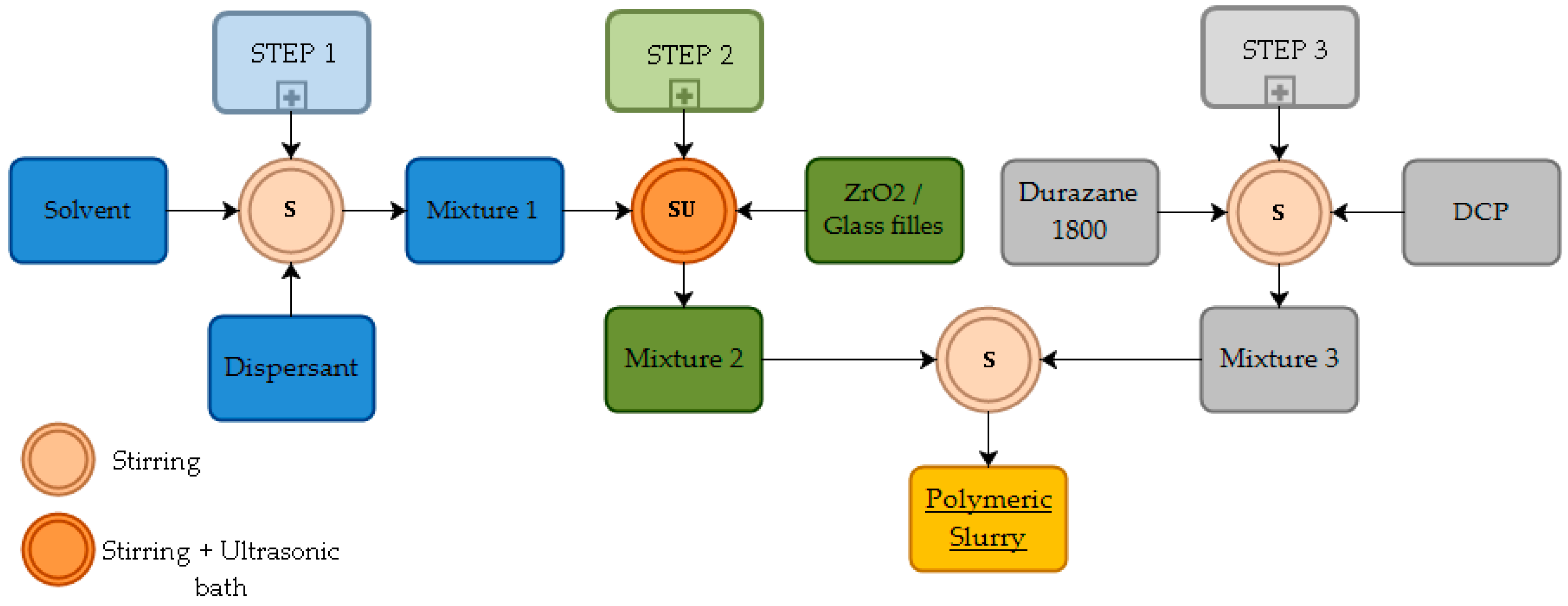

2.2. Development of the Composite Barrier Coating

2.3. Characterization Methodology

3. Results and Discussion

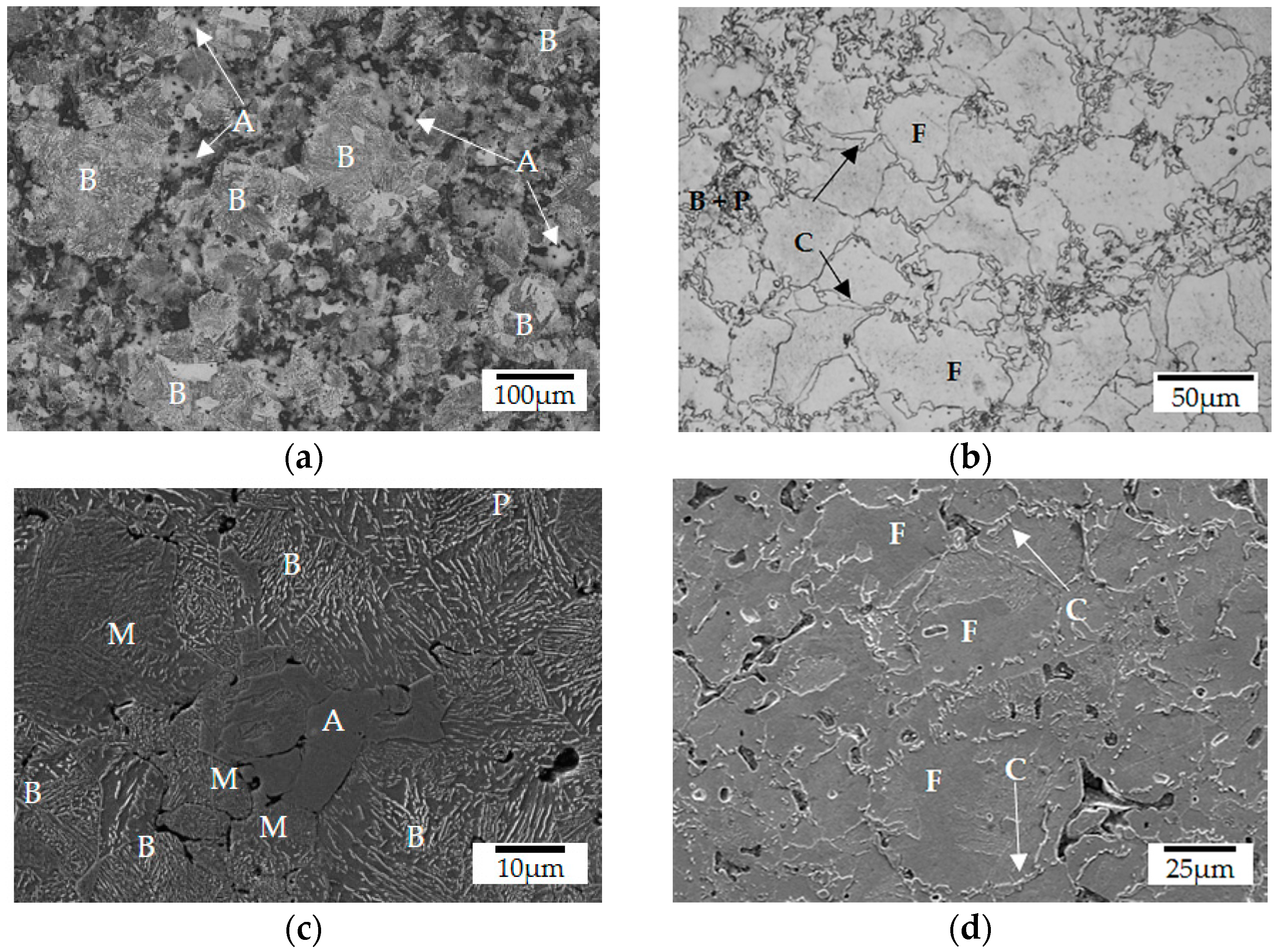

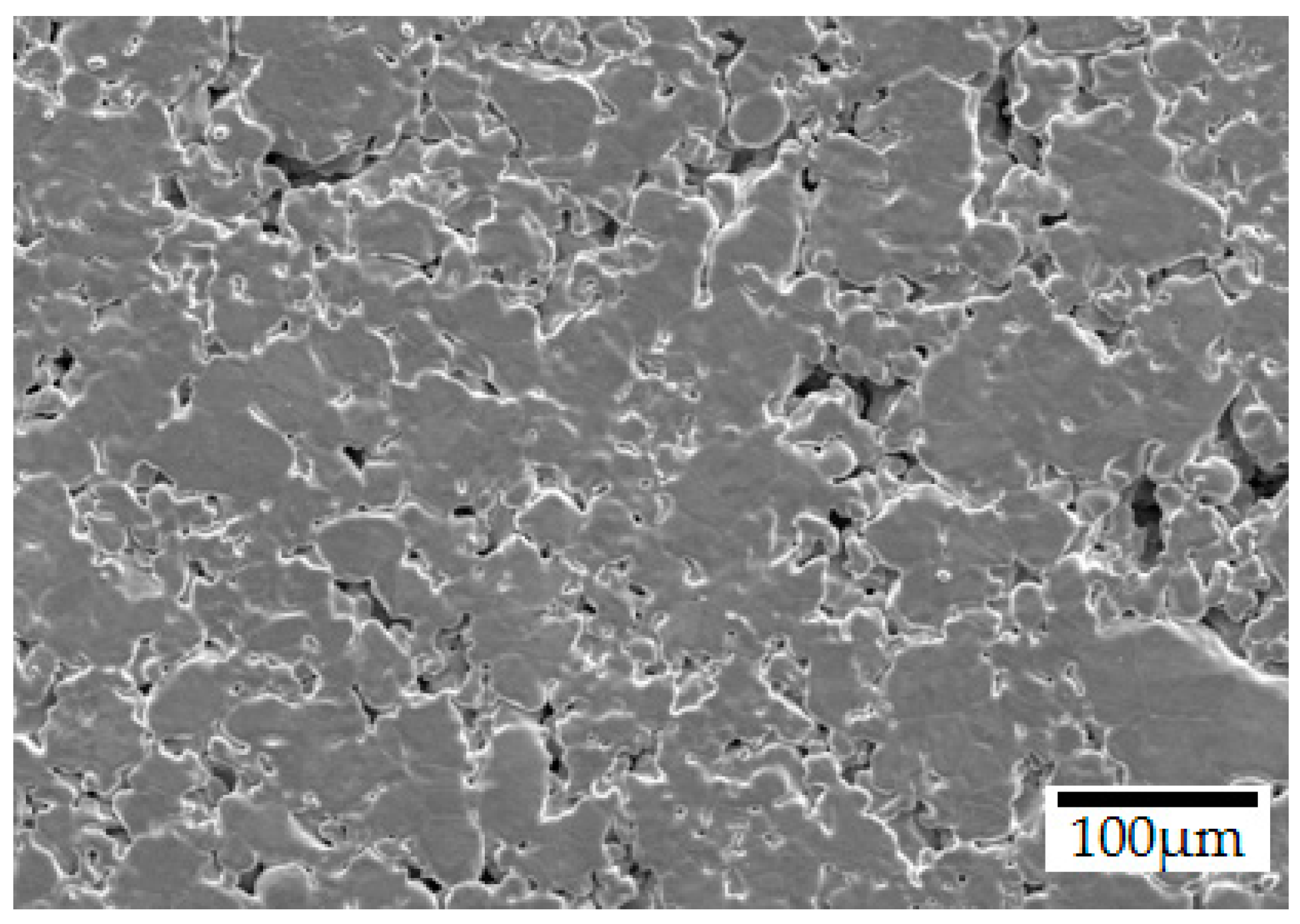

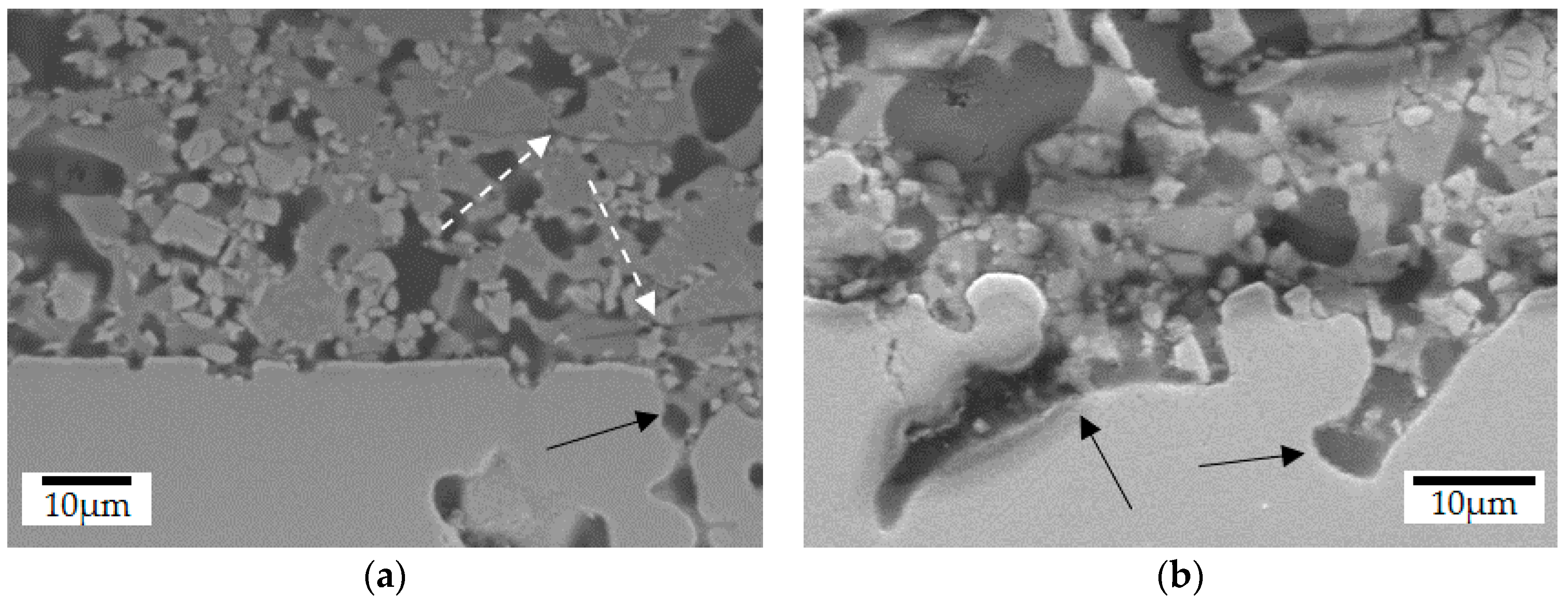

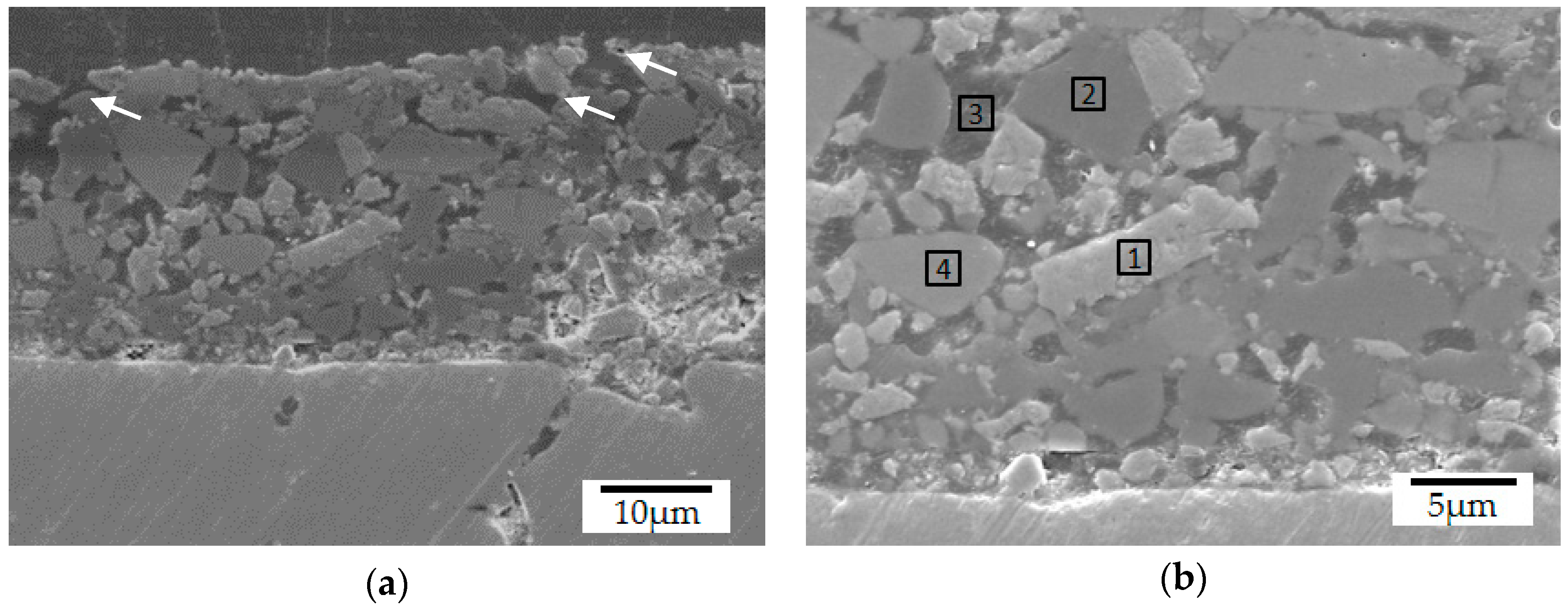

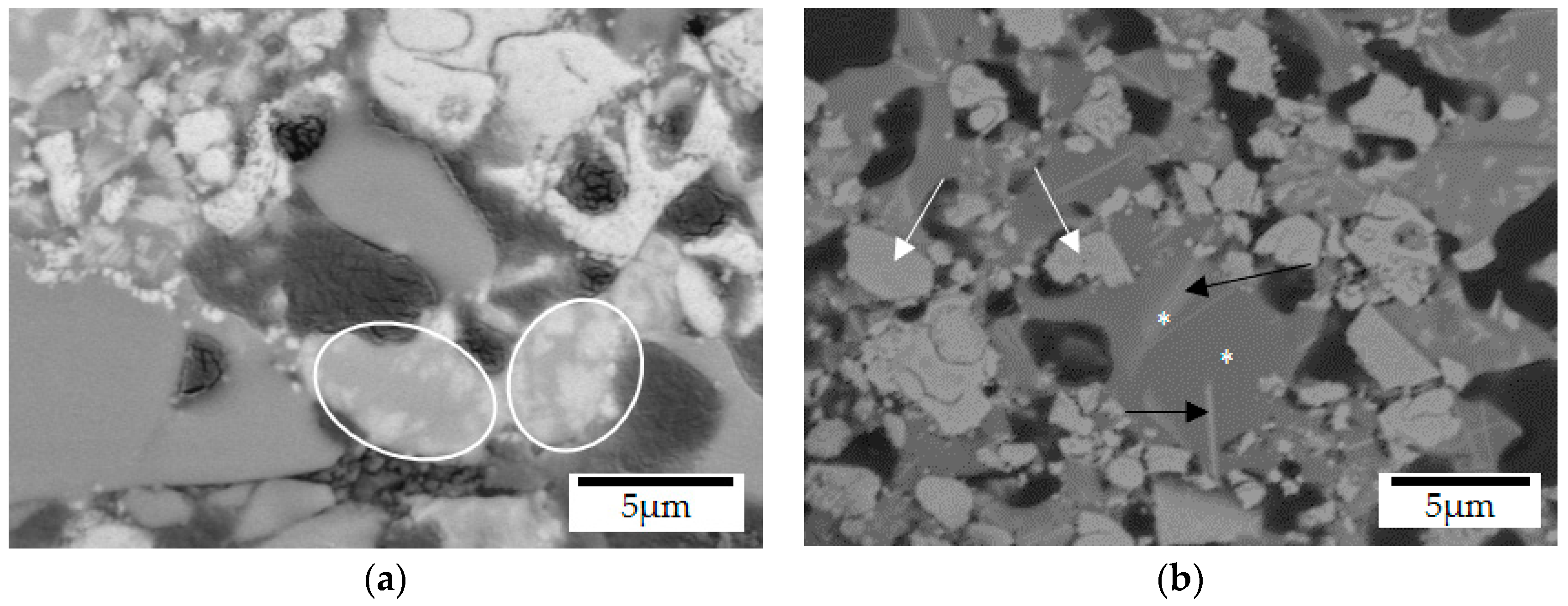

3.1. Sintered Steel

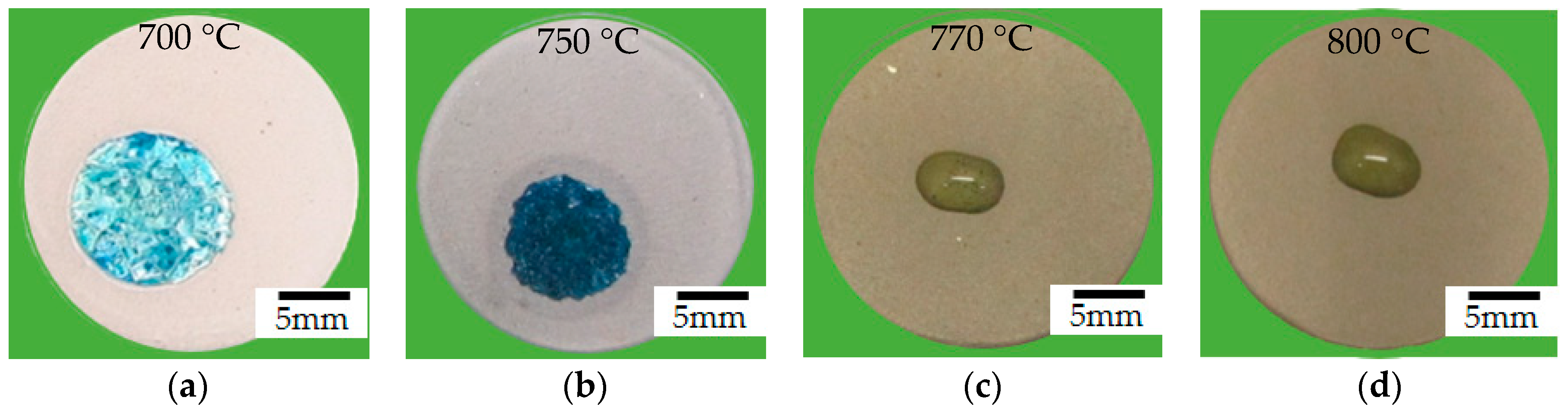

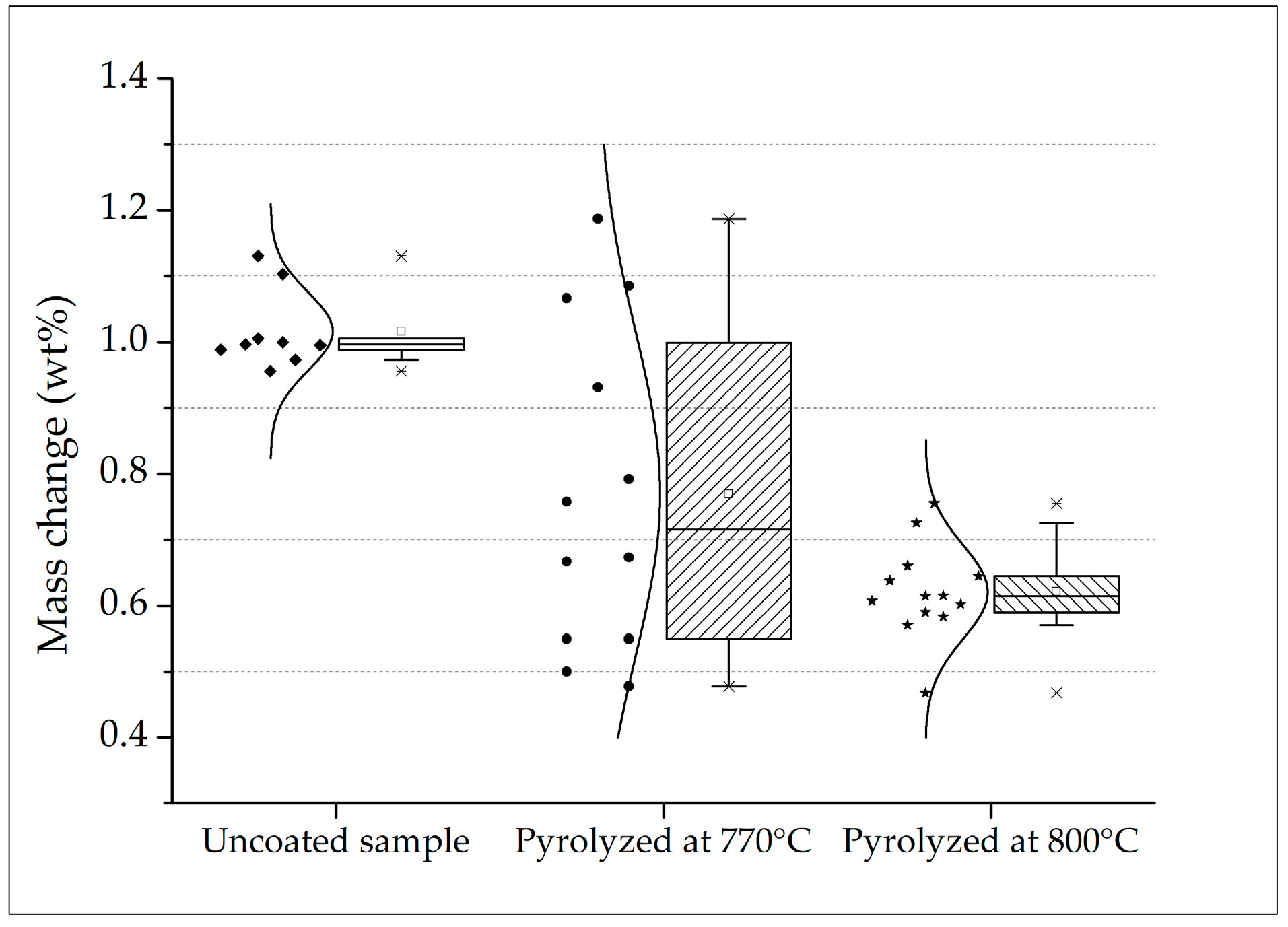

3.2. Composite Barrier Coating onto the Sintered Steel Substrate

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Martin, P.M. Handbook of Deposition Technologies for Films and Coatings, 3rd ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2010; ISBN 978-0-8155-2031-3. [Google Scholar]

- Koch, G.; Varney, J.; Thompson, N.; Moghissi, O.; Gould, M.; Payer, J. International Measures of Prevention, Application, and Economics of Corrosion Technologies Study. In NACE International IMPACT Report; NACE International: Houston, TX, USA, 2016; pp. 1–3. [Google Scholar]

- Brain James, W.H.C. Powder Metallurgy Methods and Applications. In ASM Handbook; Samal, P., Newkirk, J., Eds.; ASM International: Novelty, OH, USA, 2015; Volume 7, pp. 9–19. [Google Scholar]

- German, R.M. Markets applications, and financial aspects of global metal powder injection moulding (MIM) technologies. Met. Powder Rep. 2012, 67, 18–26. [Google Scholar] [CrossRef]

- Etaat, M.; Emamy, M.; Ghambari, M.; Fadaei, E. Surface treatment and nickel plating of iron powder metallurgy parts for corrosion protection. Mater. Des. 2009, 30, 3560–3565. [Google Scholar] [CrossRef]

- Narasimhan, K. Sintering of powder mixtures and the growth of ferrous powder metallurgy. Mater. Chem. Phys. 2001, 67, 56–65. [Google Scholar] [CrossRef]

- Stølen, S.; Grande, T. Chemical Thermodynamics of Materials; John Wiley & Sons, Ltd.: Chichester, UK, 2003; ISBN 0471492302. [Google Scholar]

- Landolt, D. Corrosion and Surface Chemistry of Metals, 1st ed.; EPFL Press: New York, NY, USA, 2007; ISBN 978-0-8493-8233-8. [Google Scholar]

- Shreir, L.L.; Jarman, R.A.; Burstein, G.T. Corrosion-Metal/Environment Reactions, 3rd ed.; Butterworth-Heinemann: Oxford, UK, 1994; ISBN 0-7506-1077-8. [Google Scholar]

- Gabe, D.R. Corrosion and Protection of Sintered Metal Parts. Powder Metall. 1977, 20, 227–231. [Google Scholar] [CrossRef]

- Fedrizzi, L.; Deflorian, F.; Rossi, S. Corrosion protection of sintered metal parts by coating deposition. Part II: Corrosion and electrochemical characterization. Mater. Corros. Korros. 1994, 45, 264–271. [Google Scholar] [CrossRef]

- Surface treatment of powder metallurgy parts to enhance corrosion resistance. Br. Corros. J. 1990, 25, 171–174. [CrossRef]

- Leisner, P.; Leu, R.C.; Møller, P. Electroplating of Porous PM Compacts. Powder Metall. 1997, 40, 207–210. [Google Scholar] [CrossRef]

- Colombo, P.; Mera, G.; Riedel, R.; Sorarù, G.D. Polymer-Derived Ceramics: 40 Years of Research and Innovation in Advanced Ceramics. J. Am. Ceram. Soc. 2010, 1805–1837. [Google Scholar] [CrossRef]

- Greil, P. Polymer Derived Engineering Ceramics. Adv. Eng. Mater. 2000, 2, 339–348. [Google Scholar] [CrossRef]

- Weinmann, M.; Ionescu, E.; Riedel, R.; Aldinger, F. Precursor-Derived Ceramics. In Handbook of Advanced Ceramics; Elsevier: Amsterdam, The Netherlands, 2013; pp. 1025–1101. [Google Scholar]

- Riedel, R.; Mera, G.; Hauser, R.; Klonczynski, A. Silicon-Based Polymer-Derived Ceramics: Synthesis Properties and Applications-A Review. J. Ceram. Soc. Jpn. 2006, 114, 425–444. [Google Scholar] [CrossRef]

- Flores, O.; Schmalz, T.; Krenkel, W.; Heymann, L.; Motz, G. Selective cross-linking of oligosilazanes to tailored meltable polysilazanes for the processing of ceramic SiCN fibers. J. Mater. Chem. A 2013, 1, 15406. [Google Scholar] [CrossRef]

- Coan, T.; Barroso, G.S.; Machado, R.A.F.; de Souza, F.S.; Spinelli, A.; Motz, G. A novel organic-inorganic PMMA/polysilazane hybrid polymer for corrosion protection. Prog. Org. Coat. 2015, 89, 220–230. [Google Scholar] [CrossRef]

- Galusek, D.; Sedláček, J.; Riedel, R. Al2O3-SiC composites prepared by warm pressing and sintering of an organosilicon polymer-coated alumina powder. J. Eur. Ceram. Soc. 2007, 27, 2385–2392. [Google Scholar] [CrossRef]

- Günthner, M.; Kraus, T.; Dierdorf, A.; Decker, D.; Krenkel, W.; Motz, G. Advanced coatings on the basis of Si(C)N precursors for protection of steel against oxidation. J. Eur. Ceram. Soc. 2009, 29, 2061–2068. [Google Scholar] [CrossRef]

- Wang, K.; Günthner, M.; Motz, G.; Bordia, R.K. High performance environmental barrier coatings, Part II: Active filler loaded SiOC system for superalloys. J. Eur. Ceram. Soc. 2011, 31, 3011–3020. [Google Scholar] [CrossRef]

- Torrey, J.D.; Bordia, R.K.; Henager, C.H.; Blum, Y.; Shin, Y.; Samuels, W.D. Composite polymer derived ceramic system for oxidizing environments. J. Mater. Sci. 2006, 41, 4617–4622. [Google Scholar] [CrossRef]

- Günthner, M.; Schütz, A.; Glatzel, U.; Wang, K.; Bordia, R.K.; Greißl, O.; Krenkel, W.; Motz, G. High performance environmental barrier coatings, Part I: Passive filler loaded SiCN system for steel. J. Eur. Ceram. Soc. 2011, 31, 3003–3010. [Google Scholar] [CrossRef]

- Schütz, A.; Günthner, M.; Motz, G.; Greißl, O.; Glatzel, U. Characterisation of novel precursor-derived ceramic coatings with glass filler particles on steel substrates. Surf. Coat. Technol. 2012, 207, 319–327. [Google Scholar] [CrossRef]

- Barroso, G.; Li, Q.; Bordia, K.B.; Motz, G. Polymeric and ceramic silicon-based coatings—A review. J. Mater. Chem. A 2018. [Google Scholar] [CrossRef]

- Greil, P. Advancements in polymer-filler derived ceramics. J. Korean Ceram. Soc. 2012, 49, 279–286. [Google Scholar] [CrossRef]

- Howard, R.G.; Graham, A.H.; Davala, A.B. Sinter Hardening P/M Steels. In Proceedings of the International Conference on Powder Metallurgy and Particulate Materials, Chigaco, IL, USA, 29 June 1997; p. 23. [Google Scholar]

- Michael, M.L.; Michael, B.C.; Narasimhan, K.S. Properties of High-Density Sinter Hardening P/M Steels Processed Using an Advanced Binder System. In Proceedings of the World Congress on Powder Metallurgy and Particulate Materials, Orlando, FL, USA, 16–21 June 2002; p. 12. [Google Scholar]

- Ziegler, G.; Kleebe, H.-J.; Motz, G.; Müller, H.; Traßl, S.; Weibelzahl, W. Synthesis, microstructure and properties of SiCN ceramics prepared from tailored polymers. Mater. Chem. Phys. 1999, 61, 55–63. [Google Scholar] [CrossRef]

- Gadelmawla, E.S.; Koura, M.M.; Maksoud, T.M.A.; Elewa, I.M.; Soliman, H.H. Roughness parameters. J. Mater. Process. Technol. 2002, 123, 133–145. [Google Scholar] [CrossRef]

- Leach, R. Characterisation of Areal Surface Texture; Springer: Berlin, Germany, 2013; ISBN 9783642364570. [Google Scholar]

- Stout, K.J. Surface Roughness—Measurement, Interpretation and Significance of Data. Mater. Des. 1981, 2, 260–265. [Google Scholar] [CrossRef]

- Dunbar, K.R.; Heintz, R.A. Chemistry of Transition Metal Cyanide Compounds: Modern Perspectives; Karlim, K.D., Ed.; John Wiley & Sons Ltd.: Noboken, NJ, USA, 1996; pp. 283–391. [Google Scholar]

- Lourenço, J.M.; Maliska, A.M.; Klein, A.N.; Muzart, J.L.R. Plasma sintering of unalloyed iron: A study of surface porosity. Mater. Res. 2004, 7, 269–275. [Google Scholar] [CrossRef]

- Youseffi, M.; Wright, C.S.; Jeyacheya, F.M. Effect of carbon content, sintering temperature, density, and cooling rate upon properties of pre-alloyed Fe–1·5Mo powder. Powder Metall. 2000, 43, 270–274. [Google Scholar] [CrossRef]

- Lindsley, B.; Rutz, H. Effect of molybdenum content in pm steels. In Advances in Powder Metallurgy and Particulate Materials; MPIF: Cinnaminson, NJ, USA, 2008; Part 7; p. 26. [Google Scholar]

- Graham, A.H.; Cimino, T.M.; Rawlings, A.J.; Rutz, H.G. The effect of nickel content, sintering temperature and density on the properties of warm compacted 0.85 wt% molybdenum pre-alloy. In Proceedings of the International Conference on Powder Metallurgy and Particulate Materials, Chicago, IL, USA, 29 June–2 July 1997; p. 24. [Google Scholar]

- Smith, W.F. Structure and Properties of Engineering Alloys; McGraw-Hill, Inc.: New York, NY, USA, 1993. [Google Scholar]

- Hoganas Höganäs Handbook for Sintered Components. In 6 Metallography; Höganäs AB: Höganäs, Sweden, 1999; p. 270.

- Briant, C.L.; Banerji, S.K. Intergranularfailure in steel: The role of grain-boundary composition. Int. Met. Rev. 1978, 23, 164–199. [Google Scholar] [CrossRef]

- Spanos, G.; Kral, M.V. The pro-eutectoid cementite transformation in steels. Int. Mater. Rev. 2009, 54, 19–47. [Google Scholar] [CrossRef]

- Whitehouse, D. Surface and Their Measurement; Hermes Penton Ltd.: London, UK, 2002; ISBN 1903996015. [Google Scholar]

- Stout, K.; Sullivan, P.; Dong, W.; Mainsah, E.; Luo, N.; Mathia, T.; Zahouani, H. The Development of Methods for the Characterization of Roughness in Three Dimensions; Commission of the European Communities: Brussels, Belgium, 1993. [Google Scholar]

- Montgomery, D.C.; Runger, G.C.; Hubele, N.F. Engineering Statistics, 5th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2011; ISBN 978-0-470-63147-8. [Google Scholar]

- Richmond, J.C.; Moore, D.G.; Kirkpatrick, H.B.; Harrison, W.N. Relation Between Roughness of Interface and Adherence of Porcelain Enamel to Steel. J. Am. Ceram. Soc. 1953, 36, 410–416. [Google Scholar] [CrossRef]

- Wachtman, J.B.; Haber, R.A. Ceramic Films and Coatings; Reprinted; Noyes Publications: Saddle River, NJ, USA, 1993; Volume 1, ISBN 0815513186. [Google Scholar]

- Shieu, F.S.; Deng, M.J.; Lin, K.C.; Wong, J.C.; Wu, J.Y. Effect of surface pretreatments on the adherence of porcelain enamel to a type 316L stainless steel. J. Mater. Sci. 1999, 34, 5265–5272. [Google Scholar] [CrossRef]

- Paul, A. Chemistry of Glasses, 2nd ed.; Chapman and Hall: London, UK, 1990; ISBN 0412278200. [Google Scholar]

- Barsoum, M.W. Fundamentals of Ceramics; CRC Press: Boca Raton, FL, USA, 2003; ISBN 0849384443. [Google Scholar]

- Motz, G.; Schmalz, T.; Trassl, S.; Kempe, R. Oxidation behavior of SiCN Materials. In Des. Process. Prop. Ceram. Mater from Preceramic Precursors; Bernard, S., Ed.; Nova Press: Burleigh Heads, Australia, 2011; pp. 15–36. [Google Scholar]

- Lenz Leite, M.; Barroso, G.; Parchovianský, M.; Galusek, D.; Ionescu, E.; Krenkel, W.; Motz, G. Synthesis and characterization of yttrium and ytterbium silicates from their oxides and an oligosilazane by the PDC route for coating applications to protect Si3N4 in hot gas environments. J. Eur. Ceram. Soc. 2017, 37, 5177–5191. [Google Scholar] [CrossRef]

- Seifert, M.; Travitzky, N.; Krenkel, W.; Motz, G. Multiphase ceramic composites derived by reaction of Nb and SiCN precursor. J. Eur. Ceram. Soc. 2014, 34, 1913–1921. [Google Scholar] [CrossRef]

- Birks, N.; Meier, G.H.; Pettit, F.S. Introduction to the High-Temperature Oxidation of Metals; Cambridge University Press: Cambridge, UK, 2006; ISBN 9780511159169. [Google Scholar]

- Hauffe, K. Oxidation of Metals; Plenum Press: New York, NY, USA, 1965; Volume 53, ISBN 9781468489224. [Google Scholar]

- John Young, D. High-Temperature Oxidation and Corrosion of Metals; Burstein, T., Ed.; Elsevier Ltd.: Amsterdam, The Netherlands, 2008; ISBN 978-0-08-044587-8. [Google Scholar]

- Bertrand, N.; Desgranges, C.; Poquillon, D.; Lafont, M.C.; Monceau, D. Iron Oxidation at Low Temperature (260–500 °C) in Air and the Effect of Water Vapor. Oxid. Met. 2010, 73, 139–162. [Google Scholar] [CrossRef]

- Bautista, A.; Velasco, F.; Abenojar, J. Oxidation resistance of sintered stainless steels: Effect of yttria additions. Corros. Sci. 2003, 45, 1343–1354. [Google Scholar] [CrossRef]

- Trindade, V.B.; Borin, R.; Hanjari, B.Z.; Yang, S.; Krupp, U.; Christ, H.-J. High-Temperature Oxidation of Pure Fe and the Ferritic Steel 2.25Cr1Mo. Mater. Res. 2005, 8, 365–369. [Google Scholar] [CrossRef]

- Chang, Y.-N.; Wei, F.-I. Review High-temperature oxidation of low alloy steels. J. Mater. Sci. 1989, 24, 14–22. [Google Scholar] [CrossRef]

- Monceau, D.; Pieraggi, B. Determination of Parabolic Rate Constants from a Local Analysis of Mass-Gain Curves. Oxid. Met. 1998, 50, 477–493. [Google Scholar] [CrossRef]

- Brown, C.E. Applied Multivariate Statistics in Geohydrology and Related Sciences; Springer: Berlin/Heidelberg, Germany, 1998; ISBN 978-3-642-80330-7. [Google Scholar]

| Processing Steps | Apparatus | Parameters |

|---|---|---|

| Mixing | Y-type mixer | 45 min |

| Pressing | Hydraulic press | 600 MPa |

| Lubricant-debinding | Tubular furnace | 500 °C, 30 min |

| Sintering | 1150 °C, 60 min |

| Material | Manufacturer | Description | vol% | d50 (µm) |

|---|---|---|---|---|

| Durazane 1800 | Merck KGaA, Germany | Polymeric precursor | 20.0 | - |

| Glass 8470 | Schott AG, Germany | Borosilicate glass | 27.5 | 3.3 |

| Glass G018-311 | Barium silicate glass | 27.5 | 3.1 | |

| ZrO2 | Alfa Aesar GmbH & Co KG, Germany | Zirconium oxide | 25.0 | 1.0 |

| Measurement No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| Oxidation time (h) | 0 | 0.5 | 1 | 2 | 5 | 20 | 60 | 100 |

| After Sintering | (HV) | Fe | Ni | Mo |

| Bainite | 316 ± 44 | 96.0 | 0.1 | 1.2 |

| Austenite/Martensite | 393 ± 107 | 89.6 | 6.8 | 1.3 |

| Perlite/Bainite | 379 ± 46 | 95.5 | 0.5 | 1.3 |

| After Pyrolysis | (HV) | Fe | Ni | Mo |

| Cementite | 782 ± 113 | 89.6 | 2.1 | 1.6 |

| Ferrite | 162 ± 11 | 93.7 | 1.7 | 1.7 |

| Perlite/Bainite | 265 ± 34 | 89.7 | - | 1.8 |

| Parameter | Acronym | Average | Standard Deviation |

|---|---|---|---|

| Arithmetical mean height | Sa | 2.03 µm | 0.13 |

| Root mean square roughness | Sq | 3.15 µm | 0.21 |

| Maximum peak height | Sp | 11.25 µm | 1.60 |

| Maximum valley depth | Sv | 23.37 µm | 3.60 |

| Maximum height of the surface | Sz | 34.60 µm | 3.62 |

| Skewness | Ssk | −2.70 | 0.31 |

| Kurtosis | Sku | 12.37 | 2.46 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Justus, T.; Gonçalves, P.; Seifert, M.; Leite, M.L.; Probst, S.M.H.; Binder, C.; Motz, G.; Klein, A.N. Oxidation Resistance and Microstructure Evaluation of a Polymer Derived Ceramic (PDC) Composite Coating Applied onto Sintered Steel. Materials 2019, 12, 914. https://doi.org/10.3390/ma12060914

Justus T, Gonçalves P, Seifert M, Leite ML, Probst SMH, Binder C, Motz G, Klein AN. Oxidation Resistance and Microstructure Evaluation of a Polymer Derived Ceramic (PDC) Composite Coating Applied onto Sintered Steel. Materials. 2019; 12(6):914. https://doi.org/10.3390/ma12060914

Chicago/Turabian StyleJustus, Tercius, Priscila Gonçalves, Martin Seifert, Mateus L. Leite, Sônia M. H. Probst, Cristiano Binder, Günter Motz, and Aloisio N. Klein. 2019. "Oxidation Resistance and Microstructure Evaluation of a Polymer Derived Ceramic (PDC) Composite Coating Applied onto Sintered Steel" Materials 12, no. 6: 914. https://doi.org/10.3390/ma12060914

APA StyleJustus, T., Gonçalves, P., Seifert, M., Leite, M. L., Probst, S. M. H., Binder, C., Motz, G., & Klein, A. N. (2019). Oxidation Resistance and Microstructure Evaluation of a Polymer Derived Ceramic (PDC) Composite Coating Applied onto Sintered Steel. Materials, 12(6), 914. https://doi.org/10.3390/ma12060914