Deformation Analysis of Reinforced Beams Made of Lightweight Aggregate Concrete

Abstract

1. Introduction

2. Calculation Methods Employed for Comparative Analysis

2.1. Eurocode 2 (EC2)

2.2. ACI 318-19 (ACI)

2.3. Numerical Method for Deformation Analysis Using a Tension-Stiffening Model of Lightweight Aggregate Concrete

3. Database of Experimental Results and Accuracy Analysis of Predictions

4. Conclusions

- In engineering practice, the analysis of lightweight concrete elements is usually performed using the same algorithms used for normal concrete elements. The influence of lightweight concrete on the structural behavior is evaluated by additional density-dependent empirical coefficients. This prediction of the behavior of lightweight concrete often does not correspond to the real behavior of the structure. In many cases, the deformation of reinforced lightweight aggregate concrete elements is underestimated, and the resulting errors can reach 100%.

- As an alternative to traditional engineering methods, nonlinear numerical algorithms based on physical material models that reflect the behavior of elements at various stages of operation may be used. Although many physical models of concrete have been proposed for the prediction of load carrying capacity and deformations in conventional reinforced concrete elements, there are no reliable physical models for the numerical analysis of reinforced lightweight aggregate concrete elements.

- The constitutive model of cracked tensile lightweight concrete earlier proposed by the authors wasused in a comparative deformation analysis of reinforced lightweight concrete beams. Stresses characterizing the cracking limit were reduced in the modified model by considering the characteristics of formation of lightweight concrete cracks. The proposed model is approximated by a three-curve diagram. The rising part of the curve describes the elastic behavior of concrete before cracking. The horizontal and descending parts of the curve describe the stages of formation and development of cracks, respectively.

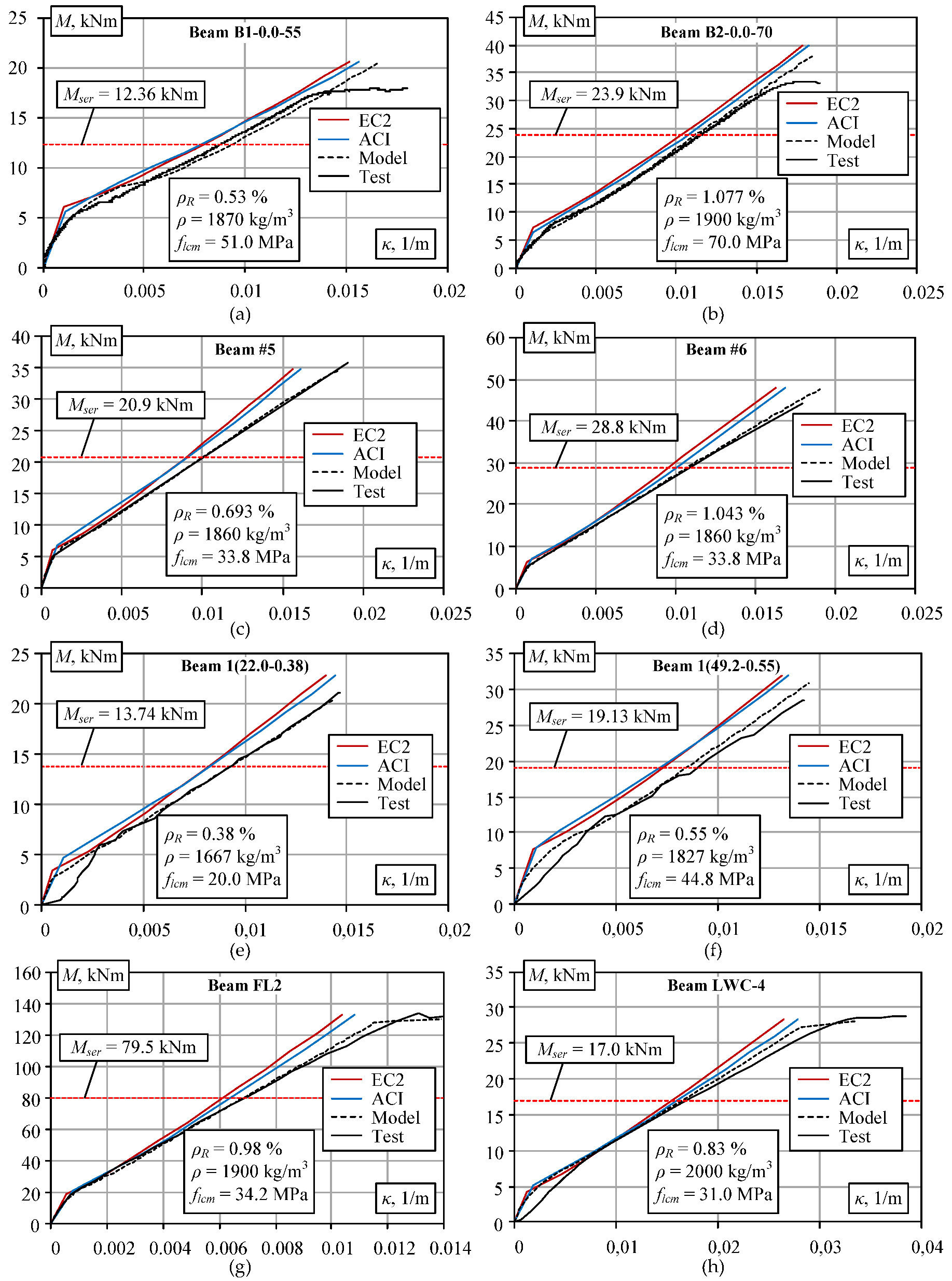

- The adequacy of results obtained by design code techniques and numerical modeling method was verified by employing experimental data of reinforced lightweight aggregate concrete elements published in the literature. The data sample consisted of 51 flexural elements obtained from five different test programs. Numerical analysis of experimental beams was performed using the nonlinear finite element software ATENA and the constitutive model proposed by the authors to model the behavior of the cracked tensile concrete.

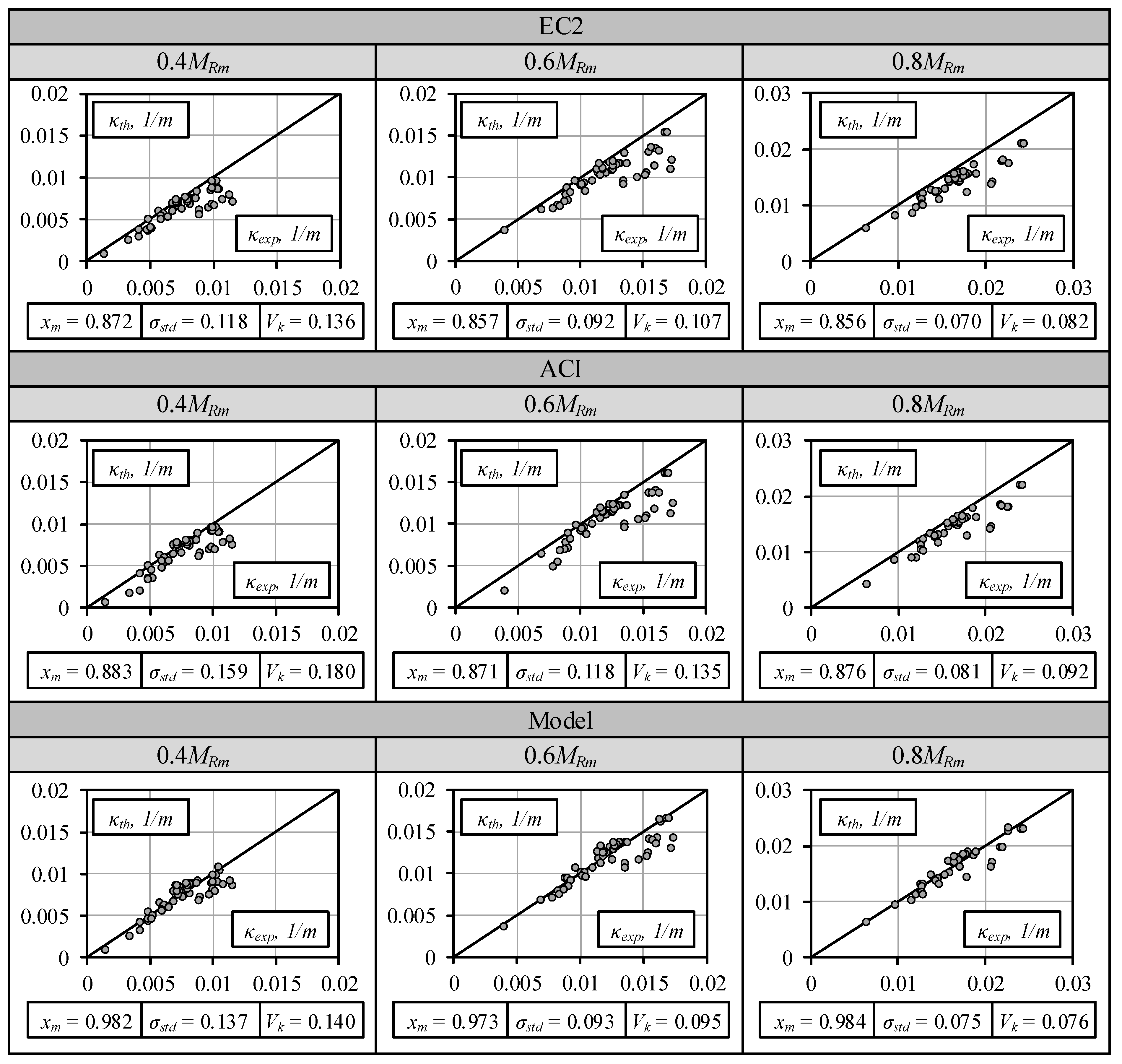

- A comparison of theoretical and experimental results revealed that the most accurate calculation results were obtained by using the numerical model. At the service load level (Mser = 0.6MRm, where MRm is the theoretical average bearing bending moment calculated by EC2), the mean value of the relative curvature (κth/κexp) obtained by using the numerical model was 0.973, and the standard deviation was 0.093. By using the EC2 standard, the mean value of the relative curvature κth/κexp was 0.857, and the standard deviation was 0.092. The mean and standard deviation values of 0.871 and 0.118, respectively, were obtained by using the ACI standard method. The comparative analysis shows that EC2 and ACI code methods produced predictions that were too stiff.

- The influence of the reinforcement percentage ρR, concrete density ρ, compressive strength of concrete, flcm, and shrinkage deformation εshr has little effect on the mean curvatures predicted by the code and numerical methods. There is a general tendency that the accuracy of the methods decreases with the rise in density and the increase in free shrinkage strain. Comparison of results demonstrates that in all cases the proposed approach gives the most accurate predictions of mean normalized curvature.

- In the future, the proposed constitutive model of lightweight aggregate concrete together with numerical finite element algorithms can be used as a reliable tool for improving the design code techniques or for adequate numerical modeling of reinforced lightweight aggregate concrete elements under short-term loading.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mindess, S. Developments in the Formulation and Reinforcement of Concrete, 1st ed.; Woodhead Publishing: Cambridge, UK, 2008. [Google Scholar]

- Karen, L.; Scrivener, R.; Kirkpatrick, J. Innovation in use and research on cementitious material. Cem. Concr. Res. 2008, 38, 128–136. [Google Scholar] [CrossRef]

- Damtoft, J.S.; Lukasik, J.; Herfort, D.; Sorrentino, D.; Gartner, E.M. Sustainable development and climate change initiatives. Cem. Concr. Res. 2008, 38, 115–127. [Google Scholar] [CrossRef]

- Zhou, M.; Lu, W.; Song, J.; Lee, G.C. Application of ultra-high performance concrete in bridge engineering. Constr. Build. Mater. 2018, 186, 1256–1267. [Google Scholar] [CrossRef]

- Rumsys, D. Model for Deformational Analysis of Reinforced Structural Lightweight Concrete Flexural Members. Ph.D. Thesis, Vilnius Gediminas Technical University, Vilnius, Lithuania, 2019. [Google Scholar]

- Rumsys, D.; Spudulis, E.; Bacinskas, D.; Kaklauskas, G. Compressive strength and durability properties of structural lightweight concrete with fine expanded glass and/or clay aggregates. Materials 2018, 11, 2434. [Google Scholar] [CrossRef] [PubMed]

- Khan, M.I.; Usman, M.; Rizwan, S.A.; Hanif, A. Self-consolidating lightweight concrete incorporating limestone powder and fly ash as supplementary cementing material. Materials 2019, 12, 3050. [Google Scholar] [CrossRef]

- Elrahman, M.A.; Chung, S.-Y.; Sikora, P.; Rucinska, T.; Stephan, D. Influence of nanosilica on mechanical properties, sorptivity, and microstructure of lightweight concrete. Materials 2019, 12, 3078. [Google Scholar] [CrossRef]

- Chen, H.-J.; Wu, K.-C.; Tang, C.-W.; Huang, C.-H. Engineering properties of self-consolidating lightweight aggregate concrete and its application in prestressed concrete members. Sustainability 2018, 10, 142. [Google Scholar] [CrossRef]

- Parra, C.; Sánchez, E.M.; Miñano, I.; Benito, F.; Hidalgo, P. Recycled plastic and cork waste for structural lightweight concrete production. Sustainability 2019, 11, 1876. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Yu, Q.; Li, G.-H. Excessive long-time deflections of prestressed box girders: I. Record-span bridge in Palau and other paradigms. J. Struct. Eng. 2012, 138, 676–686. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Yu, Q.; Li, G.-H. Excessive long-time deflections of collapsed prestressed box girders: II. Numerical analysis and lessons learned. J. Struct. Eng. 2012, 138, 687–696. [Google Scholar] [CrossRef]

- Walraven, J.; Den Uijl, J.; Stroband, J.; Gijsbers, J.; Naaktgeboren, M. Structural lightweight concrete: Recent research. Heron 1995, 40, 5–30. [Google Scholar]

- Sin, L.H.; Huan, W.T.; Islam, M.R.; Mansur, M.A. Reinforced lightweight concrete beams in flexure. ACI Struct. J. 2011, 108, 3–12. [Google Scholar]

- Carmo, R.N.F.; Costa, H.; Simões, T.; Lourenço, C.; Andrade, D. Influence of both concrete strength and transverse confinement on bending behavior of reinforced LWAC beams. Eng. Struct. 2013, 48, 329–341. [Google Scholar] [CrossRef]

- Kockal, N.U.; Ozturan, T. Strength and elastic properties of structural lightweight concretes. Mater. Design. 2011, 32, 2396–2403. [Google Scholar] [CrossRef]

- Domone, P.L. Self-compacting concrete: An analysis of 11 years of case studies. Cem. Concr. Comp. 2006, 28, 197–208. [Google Scholar] [CrossRef]

- Vakhshouri, B.; Nejadi, S. Mix design of light-weight self-compacting concrete. Case Stud. Constr. Mater. 2016, 4, 1–14. [Google Scholar] [CrossRef]

- Kaklauskas, G.; Tamulėnas, V.; Bado, M.F.; Bacinskas, D. Shrinkage-free tension stiffening law for various concrete grades. Constr. Build. Mater. 2018, 189, 736–744. [Google Scholar] [CrossRef]

- Kaklauskas, G.; Gribniak, V. Eliminating shrinkage effect from moment curvature and tension stiffening relationships of reinforced concrete members. J. Struct. Eng. 2011, 137, 1460–1469. [Google Scholar] [CrossRef]

- Scanlon, A.; Bischoff, P.H. Shrinkage restraint and loading history effects on deflections of flexural members. ACI Struct. J. 2008, 105, 498–506. [Google Scholar] [CrossRef]

- Sirico, A.; Michelini, E.; Bernardi, P.; Cerioni, R. Simulation of the response of shrunk reinforced concrete elements subjected to short-term loading: A bi-dimensional numerical approach. Eng. Fract. Mech. 2017, 174, 64–79. [Google Scholar] [CrossRef]

- Rumsys, D.; Bacinskas, D.; Kaklauskas, G.; Gribniak, V. Flexural stiffness of lightly reinforced beams made of structural lightweight aggregate concrete. ACI Struct. J. 2019, 116, 17–28. [Google Scholar] [CrossRef]

- Khan, I.; Castel, A.; Gilbert, R.I. Tensile creep and early-age concrete cracking due to restrained shrinkage. Constr. Build. Mater. 2017, 149, 705–715. [Google Scholar] [CrossRef]

- Yuan, Z.; Ng, P.L.; Bacinskas, D.; Du, J. Analysis of non-uniform shrinkage effect in box girder sections for long-span continuous rigid frame bridge. Balt. J. Road Bridge Eng. 2018, 13, 146–155. [Google Scholar] [CrossRef]

- Jakubovskis, R.; Kaklauskas, G. Bond-stress and bar-strain profiles in RC tension members modelled via finite elements. Eng. Struct. 2019, 194, 138–146. [Google Scholar] [CrossRef]

- Kaklauskas, G.; Sokolov, A.; Ramanauskas, R.; Jakubovskis, R. Reinforcement strains in reinforced concrete tensile members recorded by strain gauges and FBG sensors: experimental and numerical analysis. Sensors 2019, 19, 200. [Google Scholar] [CrossRef] [PubMed]

- Murray, A.; Gilbert, R.I.; Castel, A. A new approach to modeling tension stiffening in reinforced concrete. ACI Struct. J. 2018, 115, 127–137. [Google Scholar] [CrossRef]

- Sokolov, A. Tension Stiffening Model for Reinforced Concrete Beams. Ph.D. Thesis, Vilnius Gediminas Technical University, Vilnius, Lithuania, 2010. [Google Scholar]

- Vakhshouri, B. Comparative Study of the Long-Term Deflection of Conventional and Self-Compacting Concrete with Light-Weight Concrete Slabs. Ph.D. Thesis, University of Technology Sydney, Sydney, Australia, 2017. [Google Scholar]

- Koh, C.G.; Teng, M.Q.; Wee, T.H. A plastic-damage model for lightweight concrete and normal weight concrete. Int. J. Concr. Struct. Mater. 2008, 2, 123–136. [Google Scholar] [CrossRef][Green Version]

- EN 1992-1-1:2004/A1. Eurocode 2: Design of Concrete Structures—Part 1-1: General Rules and Rules for Buildings; European Committee for Standardization: Brussels, Belgium, 2015. [Google Scholar]

- ACI 318-19. Building Code Requirements for Structural Concrete (ACI 318-19) and Commentary; ACI Committee 318: Farmington Hills, MI, USA, 2019. [Google Scholar]

- Kaklauskas, G.; Ghaboussi, J. Stress-strain relations for cracked tensile concrete from RC beam tests. J. Struct. Eng. 2001, 127, 64–73. [Google Scholar] [CrossRef]

- Kaklauskas, G.; Gribniak, V.; Girdžius, R. Average stress-average strain tension-stiffening relationships based on provisions of design codes. J. Zhejiang Univ. Sci. A 2011, 12, 731–736. [Google Scholar] [CrossRef]

- Gribniak, V.; Kaklauskas, G.; Idnurm, S.; Bacinskas, D. Finite element mesh size effect on deformation predictions of reinforced concrete bridge girder. Balt. J. Road Bridge Eng. 2010, 5, 19–27. [Google Scholar] [CrossRef]

- Gribniak, V.; Cervenka, V.; Kaklauskas, G. Deflection prediction of reinforced concrete beams by design codes and computer simulation. Eng. Struct. 2013, 56, 2175–2186. [Google Scholar] [CrossRef]

- Bernardo, L.F.; Nepomuceno, M.C.; Pinto, H.A. Flexural ductility of lightweight-aggregate concrete beams. J. Civ. Eng. Manag. 2016, 22, 622–633. [Google Scholar] [CrossRef]

- Wu, C.H.; Kan, Y.C.; Huang, C.H.; Yen, T.; Chen, L.H. Flexural behavior and size effect of full scale reinforced lightweight concrete beams. J. Mar. Sci. Technol.-Taiwan 2011, 19, 132–140. [Google Scholar]

| No. | Reference | Number of Beams | Span L0, m | Shear Span a, m | Depth h, mm | Width b, mm | Reinforcement Percentage ρR, % |

|---|---|---|---|---|---|---|---|

| 1 | Carmo et al. [15] | 13 | 2.80 | 1.0 | 270 | 120 | 0.53–2.82 |

| 2 | Sin et al. [14] | 18 | 2.80 | 1.0 | 300 | 150 | 0.69–2.27 |

| 3 | Bernardo et al. [38] | 14 | 2.40 | 0.8 | 300 | 150 | 0.38–2.69 |

| 4 | Wu et al. [39] | 3 | 4.00 | 1.4 | 400 | 250 | 0.33–1.310 |

| 5 | Vakhshouri [30] | 3 | 3.50 | 1.167 | 161 | 400 | 0.83 |

| Total: | 51 | 2.40–4.00 | 0.8–1.4 | 161–400 | 120–400 | 0.33–2.82 |

| No. | Reference | Concrete Density ρ, kg/m3 | Compressive Strength flcm, MPa | Tensile Strength flctm, MPa | Shrinkage Strain εshr, × −10−6 |

|---|---|---|---|---|---|

| 1 | Carmo et al. [15] | 1870–1900 | 37.0–70.0 | 2.84–4.37 | 313–395 |

| 2 | Sin et al. [14] | 1700–2000 | 25.1–70.1 | 1.72–4.17 | 141–175 |

| 3 | Bernardo et al. [38] | 1651–1953 | 20.0–55.0 | 1.36–3.78 | 249–388 |

| 4 | Wu et al. [39] | 1900 | 34.2 | 2.43 | 134 |

| 5 | Vakhshouri [30] | 2000 | 31.0 | 2.29 | 180 |

| Total: | 1651–2000 | 20.0–70.1 | 1.36–4.37 | 134–395 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bacinskas, D.; Rumsys, D.; Sokolov, A.; Kaklauskas, G. Deformation Analysis of Reinforced Beams Made of Lightweight Aggregate Concrete. Materials 2020, 13, 20. https://doi.org/10.3390/ma13010020

Bacinskas D, Rumsys D, Sokolov A, Kaklauskas G. Deformation Analysis of Reinforced Beams Made of Lightweight Aggregate Concrete. Materials. 2020; 13(1):20. https://doi.org/10.3390/ma13010020

Chicago/Turabian StyleBacinskas, Darius, Deividas Rumsys, Aleksandr Sokolov, and Gintaris Kaklauskas. 2020. "Deformation Analysis of Reinforced Beams Made of Lightweight Aggregate Concrete" Materials 13, no. 1: 20. https://doi.org/10.3390/ma13010020

APA StyleBacinskas, D., Rumsys, D., Sokolov, A., & Kaklauskas, G. (2020). Deformation Analysis of Reinforced Beams Made of Lightweight Aggregate Concrete. Materials, 13(1), 20. https://doi.org/10.3390/ma13010020