Experimental Investigation of Hybrid Carbon Nanotubes and Graphite Nanoplatelets on Rheology, Shrinkage, Mechanical, and Microstructure of SCCM

Abstract

:1. Introduction

2. Experimental Program

2.1. Material and Methods

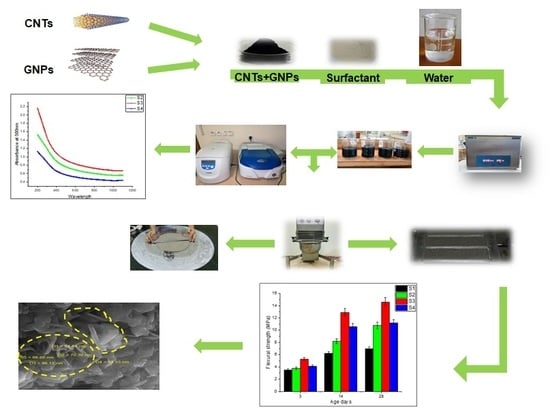

2.2. Dispersion of Nanomaterials

2.3. Mixing and Preparation of Samples

2.4. Slump Test of SCCM

2.5. Water Absorption and Air Content

2.6. Rheological Properties

2.7. Shrinkage Control Investigation

2.8. Mechanical Properties

3. Result and Discussion

3.1. Dispersion of Nano Intruded Cement Mortar

3.2. Superplasticizer Demand and Slump Flow Test

3.3. Linear Shrinkage Protocols

3.4. Air Content and Water Absorption of Nanomaterials

3.5. Rheological Properties

3.6. Flexural Strength

3.7. Compressive Strength

4. Conclusions

- The results reveal that using carbon nanotubes with graphite nanoplatelets decreases the workability of nano intruded cement mortar, which ultimately requires more superplasticizer demand for achieving a total spread of self-compacting cementitious mortar within the desired range.

- Volumetric stability or shrinkage response of formulations containing nano-media improved.

- Though a varying trend is achieved for viscosity and yield stress. It is fair to say that yield stress and viscosity increase upon the induction of nano-media.

- Flexural and compressive strength of modified specimen increase in comparison to the modified samples. However, the hybrid formulation performed the best.

- Scanning electron microscopy reveals the crack bridging phenomena of hybrid CNTs/GNPs with the adjacent matrix.

Author Contributions

Funding

Conflicts of Interest

References

- Zhou, C.; Li, F.; Hu, J.; Ren, M.; Wei, J.; Yu, Q. Enhanced mechanical properties of cement paste by hybrid graphene oxide/carbon nanotubes. Constr. Build. Mater. 2017, 134, 336–345. [Google Scholar] [CrossRef]

- Xu, S.; Liu, J.; Li, Q. Mechanical properties and microstructure of multi-walled carbon nanotube-reinforced cement paste. Constr. Build. Mater. 2015, 76, 16–23. [Google Scholar] [CrossRef]

- Gdoutos, E.E.; Konsta-Gdoutos, M.S.; Danoglidis, P.A. Portland cement mortar nanocomposites at low carbon nanotube and carbon nanofiber content: A fracture mechanics experimental study. Cem. Concr. Compos. 2016, 70, 110–118. [Google Scholar] [CrossRef]

- Peyvandi, A.; Soroushian, P.; Balachandra, A.M.; Sobolev, K. Enhancement of the durability characteristics of concrete nanocomposite pipes with modified graphite nanoplatelets. Constr. Build. Mater. 2013, 47, 111–117. [Google Scholar] [CrossRef]

- Collins, F.; Lambert, J.; Duan, W.H. The Influences of Admixtures on the Dispersion, Workability, and Strength of Carbon Nanotube–OPC Paste Mixtures, Elsevier. Available online: https://www.sciencedirect.com/science/article/pii/S0958946511001703 (accessed on 20 January 2019).

- Siddique, R.; Mehta, A. Effect of Carbon Nanotubes on Properties of Cement Mortars, Elsevier. Available online: https://www.sciencedirect.com/science/article/pii/S0950061813008593 (accessed on 20 January 2019).

- Konsta-Gdoutos, M.S.; Metaxa, Z.S.; Shah, S.P. Highly Dispersed Carbon Nanotube Reinforced Cement Based Materials, Elsevier. Available online: https://www.sciencedirect.com/science/article/pii/S0008884610000542 (accessed on 20 January 2019).

- Nochaiya, T.; Chaipanich, A. Behavior of Multi-Walled Carbon Nanotubes on the Porosity and Microstructure of Cement-Based Materials, Elsevier. Available online: https://www.sciencedirect.com/science/article/pii/S0169433210012626 (accessed on 20 January 2019).

- Sobolkina, A.; Mechtcherine, V.; Khavrus, V.; Maier, D.; Mende, M.; Ritschel, M.; Leonhardt, A. Dispersion of Carbon Nanotubes and Its Influence on the Mechanical Properties of the Cement Matrix, Elsevier. Available online: https://www.sciencedirect.com/science/article/pii/S095894651200162X (accessed on 20 January 2019).

- Kumar, S.; Kolay, P.; Malla, S.; Mishra, S. Effect of Multiwalled Carbon Nanotubes on Mechanical Strength of Cement Paste. J. Mater. Civ. Eng. 2012, 24, 84–91. [Google Scholar] [CrossRef]

- Rehman, S.K.U.; Ibrahim, Z.; Memon, S.A.; Javed, M.F.; Khushnood, R.A. A Sustainable Graphene Based Cement Composite. Sustainability 2017, 9, 1229. [Google Scholar] [CrossRef] [Green Version]

- Wang, B.; Han, Y.; Liu, S. Effect of Highly Dispersed Carbon Nanotubes on the Flexural Toughness of Cement-Based Composites, Elsevier. Available online: https://www.sciencedirect.com/science/article/pii/S0950061813003310 (accessed on 20 January 2019).

- Sedaghatdoost, A.; Behfarnia, K. Mechanical Properties of Portland Cement Mortar Containing Multi-Walled Carbon Nanotubes at Elevated Temperatures, Elsevier. Available online: https://www.sciencedirect.com/science/article/pii/S0950061818311632 (accessed on 20 January 2019).

- Cote, L.J.; Kim, J.; Tung, V.C.; Luo, J.; Kim, F.; Huang, J. Graphene Oxide as Surfactant Sheets, Degruyter.Com. Available online: https://www.degruyter.com/view/j/pac.2011.83.issue-1/pac-con-10-10-25/pac-con-10-10-25.xml?format=INT&intcmp=trendmd (accessed on 20 January 2019).

- Kim, J.; Cote, L.J.; Huang, J. Two Dimensional Soft Material: New Faces of Graphene Oxide. Acc. Chem. Res. 2012, 45, 1356–1364. [Google Scholar] [CrossRef]

- Kashif Ur Rehman, S.; Ibrahim, Z.; Memon, S.A.; Aunkor, M.T.H.; Faisal Javed, M.; Mehmood, K.; Shah, S.M.A. Influence of Graphene Nanosheets on Rheology, Microstructure, Strength Development and Self-Sensing Properties of Cement Based Composites. Sustainability 2018, 10, 822. [Google Scholar] [CrossRef] [Green Version]

- Peyvandi, A.; Soroushian, P.; Abdol, N.; Balachandra, A.M. Surface-Modified Graphite Nanomaterials for Improved Reinforcement Efficiency in Cementitious Paste, Elsevier. Available online: https://www.sciencedirect.com/science/article/pii/S0008622313005903 (accessed on 20 January 2019).

- Meng, W.; Khayat, K.H. Mechanical Properties of Ultra-High-Performance Concrete Enhanced with Graphite Nanoplatelets and Carbon Nanofibers, Elsevier. Available online: https://www.sciencedirect.com/science/article/pii/S1359836816314986 (accessed on 20 January 2019).

- Sun, X.; Wu, Q.; Zhang, J.; Qing, Y.; Wu, Y.; Lee, S. Rheology, Curing Temperature and Mechanical Performance of Oil Well Cement: Combined Effect of Cellulose Nanofibers and Graphene Nano-Platelets, Elsevier. Available online: https://www.sciencedirect.com/science/article/pii/S026412751631348X (accessed on 20 January 2019).

- Li, G.Y.; Wang, P.M.; Zhao, X. Mechanical Behavior and Microstructure of Cement Composites Incorporating Surface-Treated Multi-Walled Carbon Nanotubes, Elsevier. Available online: https://www.sciencedirect.com/science/article/pii/S0008622305000199 (accessed on 20 January 2019).

- Gillani, S.S.U.H.; Khitab, A.; Ahmad, S.; Khushnood, R.A.; Ferro, G.A.; Kazmi, S.M.S.; Restuccia, L. Improving the Mechanical Performance of Cement Composites by Carbon Nanotubes Addition, Elsevier. Available online: https://www.sciencedirect.com/science/article/pii/S2452321617300045 (accessed on 20 January 2019).

- Wille, K.; Loh, K.J. Nanoengineering ultra-high-performance concrete with multiwalled carbon nanotubes. Transp. Res. Rec. 2010, 2142, 119–126. [Google Scholar] [CrossRef]

- Chen, Z.; Lim, J.L.G.; Yang, E.H. Ultra high performance cement-based composites incorporating low dosage of plasma synthesized carbon nanotubes. Mater. Des. 2016, 108, 479–487. [Google Scholar] [CrossRef]

- Hilding, J.; Grulke, E.A.; Zhang, Z.G.; Lockwood, F. Dispersion of carbon nanotubes in liquids. J. Dispers. Sci. Technol. 2003, 24, 1–41. [Google Scholar] [CrossRef]

- Chaipanich, A.; Nochaiya, T.; Wongkeo, W.; Torkittikul, P. Compressive Strength and Microstructure of Carbon Nanotubes–Fly Ash Cement Composites, Elsevier. Available online: https://www.sciencedirect.com/science/article/pii/S0921509309010880 (accessed on 20 January 2019).

- Morsy, M.S.; Alsayed, S.H.; Aqel, M. Hybrid Effect of Carbon Nanotube and Nano-Clay on Physico-Mechanical Properties of Cement Mortar, Elsevier. Available online: https://www.sciencedirect.com/science/article/pii/S0950061810002953 (accessed on 20 January 2019).

- Kim, H.K.; Nam, I.W.; Lee, H.K. Enhanced Effect of Carbon Nanotube on Mechanical and Electrical Properties of Cement Composites by Incorporation of Silica Fume, Elsevier. Available online: https://www.sciencedirect.com/science/article/pii/S0263822313003760 (accessed on 20 January 2019).

- Lu, Z.; Hou, D.; Meng, L.; Sun, G.; Lu, C.; Li, Z. Mechanism of Cement Paste Reinforced by Graphene Oxide/Carbon Nanotubes Composites with Enhanced Mechanical Properties. RSC Adv. 2015, 5, 100598–100605. [Google Scholar] [CrossRef]

- Alrekabi, S.; Cundy, A.; Whitby, R.L.D.; Lampropoulos, A.; Savina, I. Effect of Undensified Silica Fume on the Dispersion of Carbon Nanotubes within a Cementitious Composite. J. Phys. Conf. Ser. 2017, 829, 012011. [Google Scholar] [CrossRef] [Green Version]

- Mohan, V.B.; Lau, K.T.; Hui, D.; Bhattacharyya, D. Graphene-based materials and their composites: a review on production, applications and product limitations. Compos. Part B Eng. 2018, 142, 200–220. [Google Scholar] [CrossRef]

- Chen, Y.-H.; Lin, S.-C.; Wang, J.-A.; Hsu, S.-Y.; Ma, C.-C.M. Preparation and properties of graphene/carbon nanotube hybrid reinforced mortar composites. Mag. Concr. Res. 2018, 71, 395–407. [Google Scholar] [CrossRef]

- C. ASTM, 150-00—Standard Specification for Portland Cement; ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C494/C494M-16—Standard Specification for Chemical Admixtures for Concrete; ASTM Internationa: West Conshohocken, PA, USA, 2016.

- BS EN 934-2: 2001: Admixtures for Concrete, Mortar and Grout–Part 2: Concrete Admixtures–Definitions, Requirements, Conformity, Marking and Labelling; British Standards Institution: London, UK, 2001.

- Shah, S.P.; Konsta-Gdoutos, M.S.; Metaxa, Z.S.; Mondal, P. Nanoscale Modification of Cementitious Materials. In Nanotechnology in Construction 3; Springer: Berlin/Heidelberg, Germany, 2009; pp. 125–130. [Google Scholar] [CrossRef]

- Cwirzen, A.; Habermehl-Cwirzen, K.; Penttala, V. Surface decoration of carbon nanotubes and mechanical properties of cement/carbon nanotube composites. Adv. Cem. Res. 2008, 20, 65–73. [Google Scholar] [CrossRef]

- De Ibarra, Y.S.; Gaitero, J.J.; Erkizia, E.; Campillo, I. Atomic force microscopy and nanoindentation of cement pastes with nanotube dispersions. Phys. Status Solidi 2006, 203, 1076–1081. [Google Scholar] [CrossRef]

- Rastogi, R.; Kaushal, R.; Tripathi, S.K.; Sharma, A.L.; Kaur, I.; Bharadwaj, L.M. Comparative study of carbon nanotube dispersion using surfactants. J. Colloid Interface Sci. 2008, 328, 421–428. [Google Scholar] [CrossRef]

- BS EN 196-1: Methods of Testing Cement. Determination of Strength; British Standards Institution: London, UK, 2005.

- Specification and Guidelines for Self-Compacting Concrete; EFNARC: Farnham, UK, 2002; Available online: http://www.efnarc.org/pdf/SandGforSCC.PDF (accessed on 18 November 2019).

- Rizwan, S.A.; Bier, T.A. Blends of limestone powder and fly-ash enhance the response of self-compacting mortars. Constr. Build. Mater. 2012, 27, 398–403. [Google Scholar] [CrossRef]

- Rizwan, S.A.; Ahmad, S.; Bier, T.A. Application of packing concepts to high performance self-consolidating mortar (SCM) systems. Spec. Publ. 2012, 289, 1–17. [Google Scholar]

- Rizwan, S.A.; Bier, T.A. Self-consolidating mortars using various secondary raw materials. ACI Mater. J. 2009, 106, 25. [Google Scholar] [CrossRef]

- ASTM C642: Standard Test Method for Density, Absorption, and Voids in Hardened Concrete; ASTM International: West Conshohocken, PA, USA, 2001.

- ASTM C231: Standard Test Method for Air Content of Freshly Mixed Concrete by the Pressure Method; ASTM International: West Conshohocken, PA, USA, 2017.

- Nehdi, M.; Rahman, M.A. Estimating Rheological Properties of Cement Pastes Using Various Rheological Models for Different Test Geometry, Gap and Surface Friction, Elsevier. Available online: https://www.sciencedirect.com/science/article/pii/S000888460400105X (accessed on 21 January 2019).

- ASTM C348:Flexural Strength of Hydraulic-Cement Mortars; ASTM International: West Conshohocken, PA, USA, 2002.

- ASTM-C349-02:Standard Test Method for Compressive Strength of Hydraulic-Cement Mortars (Using Portions of Prisms Broken in Flexure); ASTM International: West Conshohockn, PA, USA, 1957.

- Rizwan, S.A.; Gul, S.; Bier, T.A. Self-consolidating paste systems containing Acacia nilotica gum powder. ACI Mater. J. 2019, 116, 5–14. [Google Scholar] [CrossRef]

- Rizwan, S.A.; Latif, W.; Bier, T.A. Response of self-consolidating cement paste systems containing Acacia Nilotica Gum as an organic admixture. Constr. Build. Mater. 2016, 126, 768–776. [Google Scholar] [CrossRef]

- Khalid, A.R.; Rizwan, S.A.; Hanif, U.; Hameed, M.H. Effect of Mixing Time on Flowability and Slump Retention of Self-Compacting Paste System Incorporating Various Secondary Raw Materials. Arab. J. Sci. Eng. 2016, 41, 1283–1290. [Google Scholar] [CrossRef]

- Meng, W.; Khayat, K.H. Effect of graphite nanoplatelets and carbon nanofibers on rheology, hydration, shrinkage, mechanical properties, and microstructure of UHPC. Cem. Concr. Res. 2018, 105, 64–71. [Google Scholar] [CrossRef]

- Meng, W.; Lunkad, P.; Kumar, A.; Khayat, K. Influence of silica fume and polycarboxylate ether dispersant on hydration mechanisms of cement. J. Phys. Chem. C 2016, 120, 26814–26823. [Google Scholar] [CrossRef]

- Baloch, W.L.; Khushnood, R.A.; Khaliq, W. Influence of multi-walled carbon nanotubes on the residual performance of concrete exposed to high temperatures. Constr. Build. Mater. 2018, 185, 44–56. [Google Scholar] [CrossRef]

- Brooks, J.J.; Jiang, X. The Influence of Chemical Admixtures on Restrained Drying Shrinkage of Concrete. ACI Symp. Publ. 1997, 173, 249–266. [Google Scholar] [CrossRef]

- Shaughnessy, R., III; Clark, P.E. The Rheological Behavior of Fresh Cement Pastes, Elsevier. Available online: https://www.sciencedirect.com/science/article/pii/0008884688900671 (accessed on 21 January 2019).

- Mitsoulis, E.; Zisis, T. Flow of Bingham plastics in a lid-driven square cavity. J. Nonnewton. Fluid Mech. 2001, 101, 173–180. [Google Scholar] [CrossRef]

- Rehman, S.K.U.; Ibrahim, Z.; Jameel, M.; Memon, S.A.; Javed, M.F.; Aslam, M.; Mehmood, K.; Nazar, S. Assessment of Rheological and Piezoresistive Properties of Graphene based Cement Composites. Int. J. Concr. Struct. Mater. 2018, 12, 64. [Google Scholar] [CrossRef]

| Chemical Composition | Content (%) | Physical Properties | Content (%) |

|---|---|---|---|

| CaO | 65.11 | Insoluble residue (% by mass) | 0.54 |

| SiO2 | 19.17 | Specific gravity (g/cm3) | 3.18 |

| Al2O3 | 4.96 | Particle size (d50) (mm) | 16.42 |

| Fe3O4 | 3.21 | Specific surface area (m2/g) | 0.86 |

| MgO | 2.23 | Loss on ignition (% mass) | 2.24 |

| MnO + K2O | 0.55 | ||

| TiO2 | 0.28 | ||

| P2O5 + Na2O | 0.64 |

| Physical Properties of Sand | Fineness Modulus | Specific Gravity (SSD) | Water Absorption | D50 (μm) |

|---|---|---|---|---|

| 2.25 | 2.66 | 1.54% | 0.53 |

| External Diameter (nm) | Internal Diameter (nm) | Length (μm) | Purity (%) | Specific Surface Area (m2/g) | Ash Content (wt.%) | Density (g/cm3) |

|---|---|---|---|---|---|---|

| 20–30 | 5–10 | 10–30 | > 97 | 110 | < 1.5 | 2.1 |

| Specific Surface Area (cm2/g) | Particle Size Analysis (μm) | Specific Gravity |

|---|---|---|

| 154 | 6.78 | 1.62 |

| Master Glenium ®51 | Aspect | Relative Density | pH | Chloride Ion Content |

| Light Brown Liquid | 1.08 ± 0.01 at 25 °C | ≥ 6 | < 0.2% |

| Chemical Composition | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | SrO | K2O | Cr2O3 |

|---|---|---|---|---|---|---|---|---|

| Content (%) | 48.9 | – | – | 20.3 | – | 15.22 | 6.89 | 6.43 |

| Physical Property | Specific Gravity (g/cm3) | Insoluble Residue (% mass) | Specific Surface area (m2/g) | Particle Size (D50) (µm) | Loss on Ignition (% mass) | |||

| Content | 1.49 | 5.89 | 36.97 | 208 | – |

| S.No. | Formulation | CNTs (%) | GNPs (%) | W/C | SP % Binder |

|---|---|---|---|---|---|

| 1 | S1 | 0 | 0 | 0.38 | 1.8 |

| 3 | S2 | 0.080 | 0.000 | 0.38 | 2.86 |

| 4 | S3 | 0.040 | 0.040 | 0.38 | 2.61 |

| 5 | S4 | 0.000 | 0.080 | 0.38 | 2.48 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Farooq, F.; Akbar, A.; Khushnood, R.A.; Muhammad, W.L.B.; Rehman, S.K.U.; Javed, M.F. Experimental Investigation of Hybrid Carbon Nanotubes and Graphite Nanoplatelets on Rheology, Shrinkage, Mechanical, and Microstructure of SCCM. Materials 2020, 13, 230. https://doi.org/10.3390/ma13010230

Farooq F, Akbar A, Khushnood RA, Muhammad WLB, Rehman SKU, Javed MF. Experimental Investigation of Hybrid Carbon Nanotubes and Graphite Nanoplatelets on Rheology, Shrinkage, Mechanical, and Microstructure of SCCM. Materials. 2020; 13(1):230. https://doi.org/10.3390/ma13010230

Chicago/Turabian StyleFarooq, Furqan, Arslan Akbar, Rao Arsalan Khushnood, Waqas Latif Baloch Muhammad, Sardar Kashif Ur Rehman, and Muhammad Faisal Javed. 2020. "Experimental Investigation of Hybrid Carbon Nanotubes and Graphite Nanoplatelets on Rheology, Shrinkage, Mechanical, and Microstructure of SCCM" Materials 13, no. 1: 230. https://doi.org/10.3390/ma13010230