Fracture Analysis and Shear Strength of Aluminum/CFRP and GFRP Adhesive Joint in Fiber Metal Laminates

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Surface Measurements

2.3. Shear Strength Test

2.4. Microstructural Analysis

3. Results

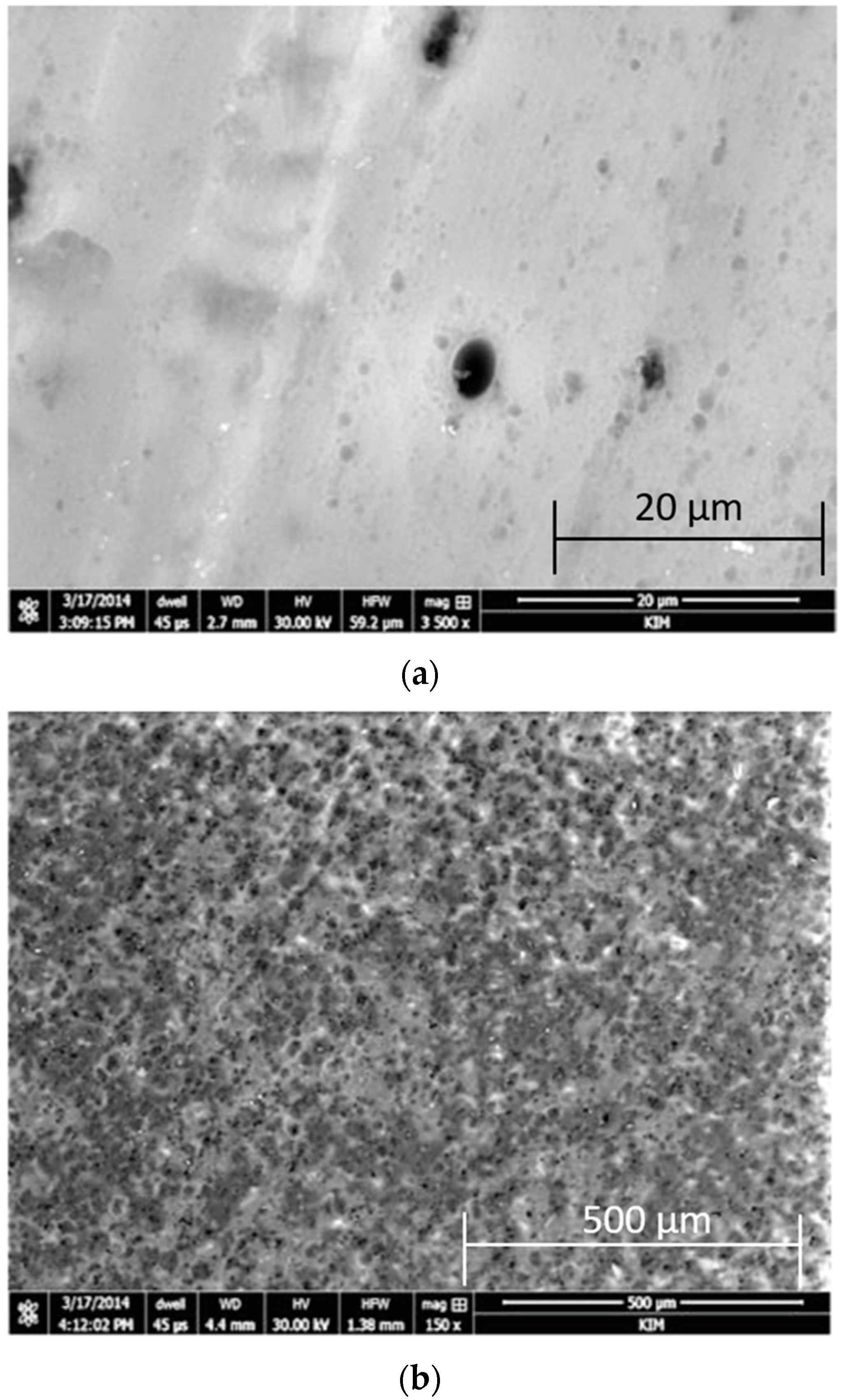

3.1. Surface Analysis

3.2. Shear Strength Test

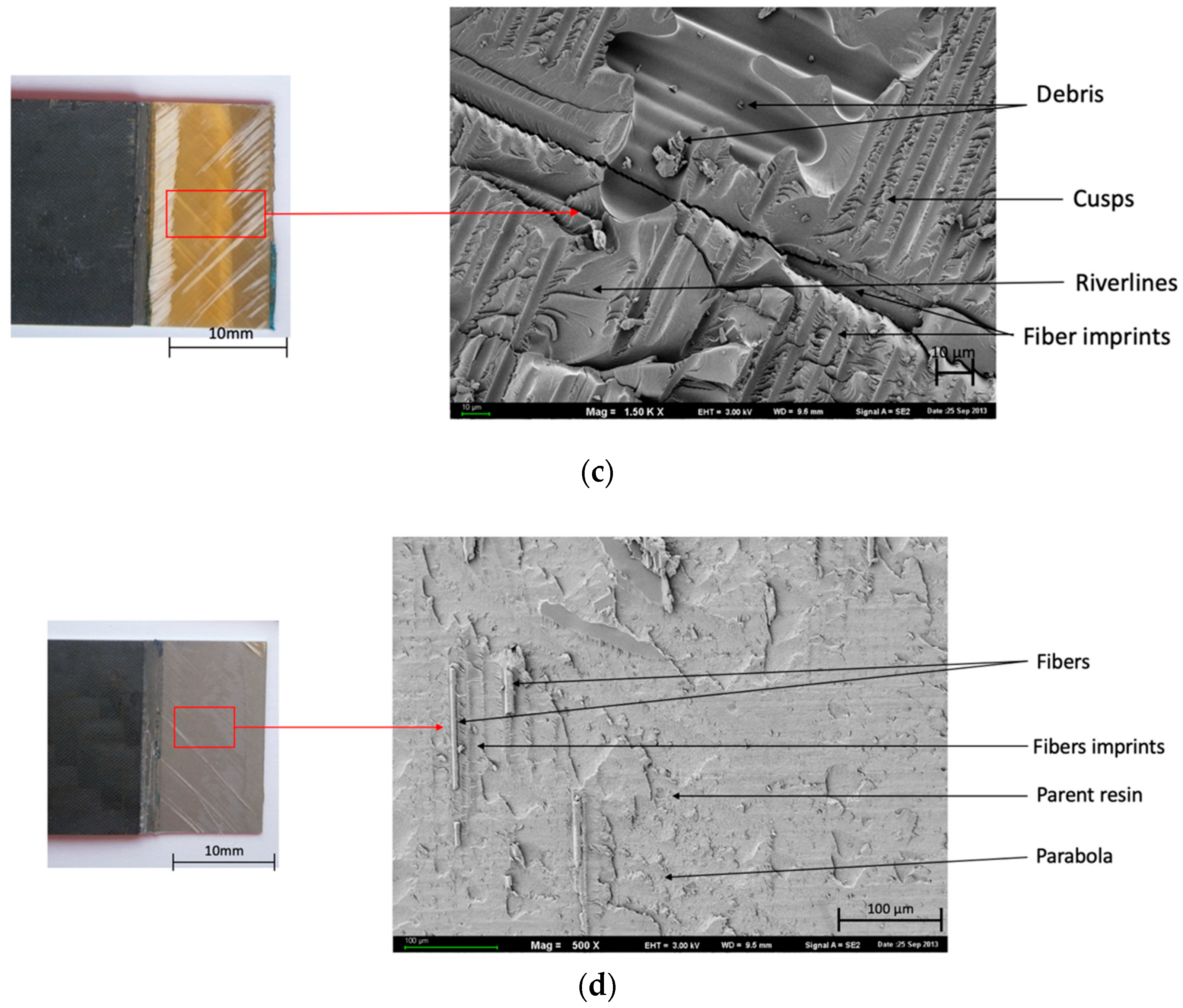

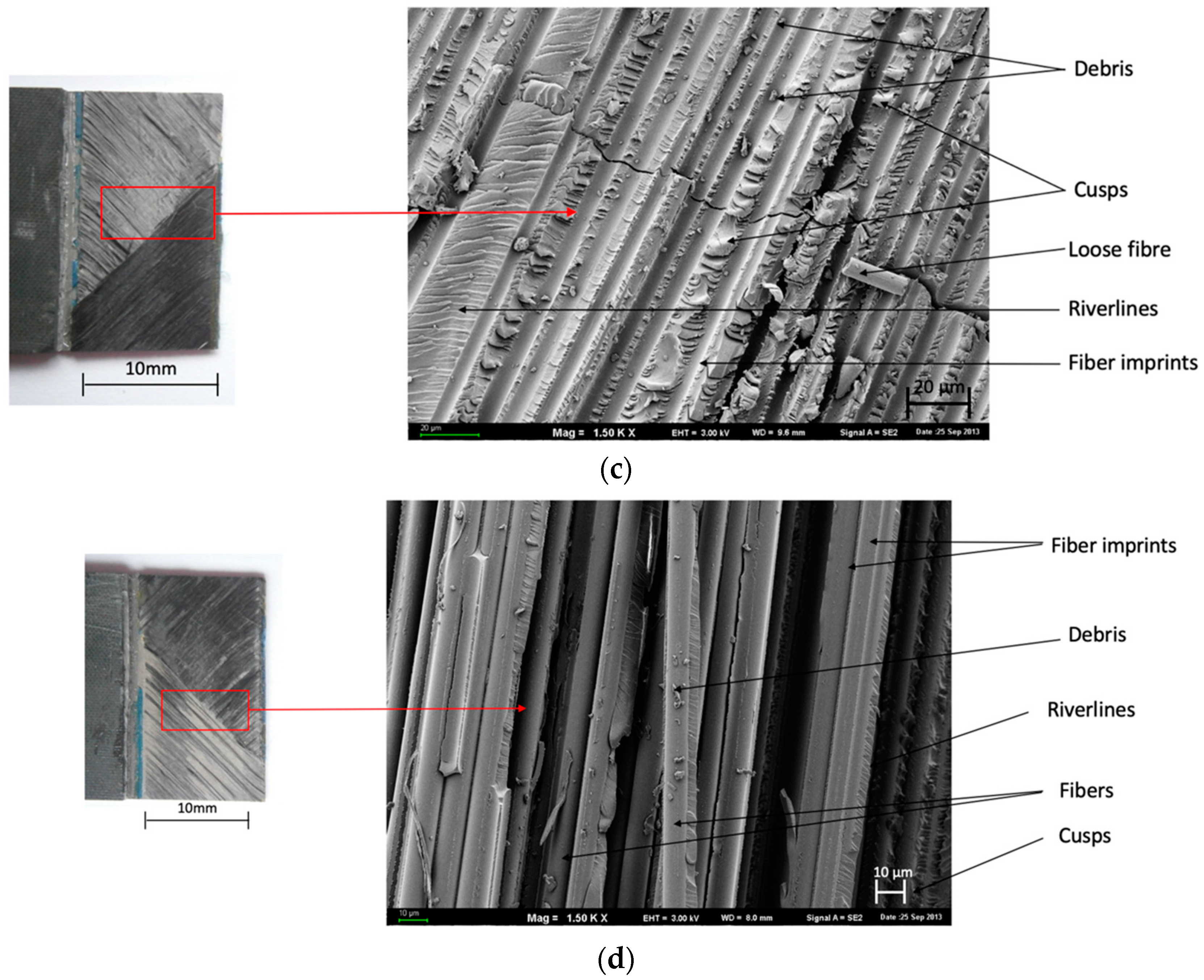

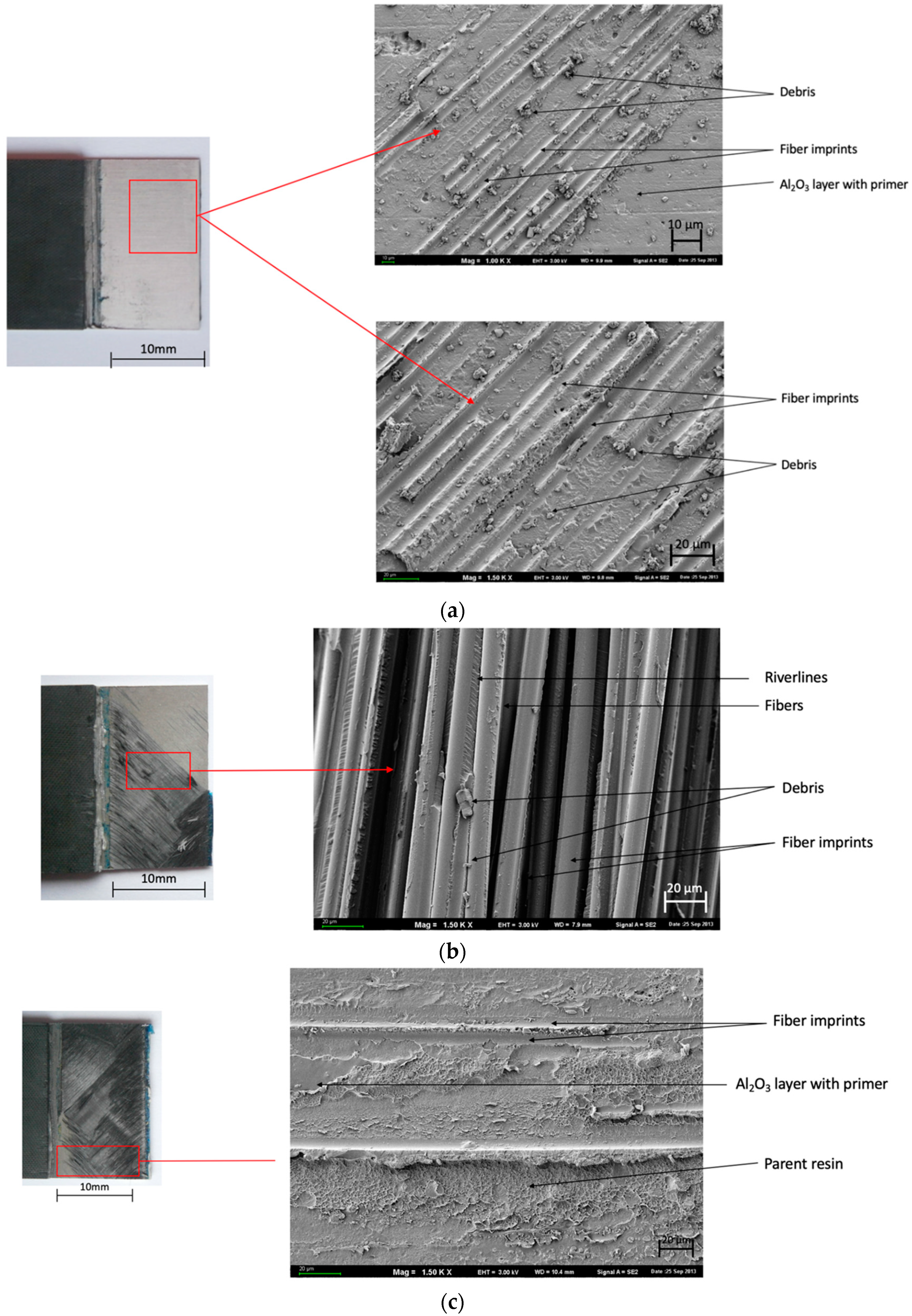

3.3. Fractography Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Vlot, A.; Gunnink, J.W. Fibre Metal Laminates. Netherlands; Kluwer Academic Publishers: Dordrecht, The Netherlands, 2001. [Google Scholar]

- Figlus, T.; Kozioł, M. Evaluation of failure progress in glass- and jute-fibre reinforced polymer laminates by analysis of vibration and noise. J. Vibroeng. 2014, 16, 449–468. [Google Scholar]

- Sinmazcelik, T.; Avcu, E.; Bora, Ö.M.; Çoban, O. A review: Fibre metal laminates, background, bonding types and applied test methods. Mater. Des. 2011, 32, 3671–3685. [Google Scholar] [CrossRef]

- Cortes, P.; Cantwell, W.J. Fracture properties of a fibre–metal laminates based on magnesium alloy. J. Mater. Sci. 2004, 39, 1081–1083. [Google Scholar] [CrossRef]

- Jakubczak, P.; Bieniaś, J.; Surowska, B. Interlaminar shear strength of fibre metal laminates after thermal cycles. Compos. Struct. 2018, 206, 876–887. [Google Scholar] [CrossRef]

- Bieniaś, J.; Jakubczak, P. Impact damage growth in carbon fibre aluminium laminates. Compos. Struct. 2017, 172, 147–154. [Google Scholar] [CrossRef]

- Sinke, J. Development of Fibre Metal Laminates: Concurrent Multi-Scale Modelling and Testing. J. Mater. Sci. 2006, 41, 6777–6788. [Google Scholar] [CrossRef]

- Shang, X.; Marques, E.A.S.; Machado, J.J.M.; Carbas, R.J.C.; Jiang, D.; da Silva, L.F.M. Review on techniques to improve the strength of adhesive joints with composite adherends. Compos. Part B Eng. 2019, 15, 107363. [Google Scholar] [CrossRef]

- Çalık, A. Effect of adherend shape on stress concentration reduction of adhesively bonded single lap joint. Eng. Rev. 2016, 36, 29–34. [Google Scholar]

- Budhe, S.; Sekhar, R.; Ghumatkar, A. Experimental study on different adherend surface roughness on the adhesive bond strength. Mater. Today Proc. 2017, 4, 7801–7809. [Google Scholar]

- Da Silva, L.F.M.; Rodrigues, T.N.S.S.; Figueiredo, M.A.V.; de Moura, M.F.S.F.; Chousal, J.A.G. Effect of Adhesive Type and Thickness on the Lap Shear Strength. J. Adhes. 2006, 82, 1091–1115. [Google Scholar] [CrossRef]

- Sekercioglu, T.; Gulsoz, A.; Rende, H. The Effects of Bonding Clearance and Interference Fit on the Strength of Adhesively Bonded Cylindrical Components. Mater. Des. 2005, 26, 377–381. [Google Scholar] [CrossRef]

- Melcher, R.J.; Johnson, W.S. Mode I fracture toughness of an adhesively bonded composite-composite joint in a cryogenic environment. Compos. Sci. Technol. 2007, 67, 501–506. [Google Scholar] [CrossRef]

- Banea, M.D.; da Silva, L.F.M.; Campilho, R.D.S.G. Temperature dependence of the fracture toughness of adhesively bonded joints. J. Adhes. Sci. Technol. 2010, 24, 2011–2026. [Google Scholar] [CrossRef]

- Banea, M.D.; da Silva, L.F.M.; Campilho, R.D.S.G. Mode I fracture toughness of adhesively bonded joints as a function of temperature: Experimental and numerical study. Int. J. Adhes. Adhes. 2011, 31, 273–279. [Google Scholar] [CrossRef]

- Rotella, G.; Alfano, M.; Schiefer, T.; Jansen, I. Enhancement of static strength and long- term durability of steel/epoxy joints through a fibre laser surface pretreatment. Int. J. Adhes. Adhes. 2015, 63, 87–95. [Google Scholar] [CrossRef]

- Shishesaz, M.; Tehrani, S. The effects of circumferential voids or debonds on stress distribution in tubular adhesive joints under torsion. J. Adhes. 2019. [Google Scholar] [CrossRef]

- Shishesaz, M.; Reza, A.; Daniali, M. Stress Distribution in Single Lap Joints with a Cracked Composite Adherend—Part II: Laminated Adherends. J. Adhes. 2014, 90, 933–954. [Google Scholar] [CrossRef]

- Botelho, E.C.; Silva, R.A.; Pardini, L.C.; Rezende, M.C. A Review on the Development and Properties of Continuous Fibre/epoxy/aluminium Hybrid Composites for Aircraft Structures. Mater. Res. 2006, 9, 247–256. [Google Scholar] [CrossRef]

- Park, S.Y.; Choi, W.J.; Choi, H.S.; Kwon, H. Effects of Surface Pretreatment and Void Content on GLARE Laminate Process Characteristics. J. Mater. Process. Technol. 2010, 210, 1008–1016. [Google Scholar] [CrossRef]

- Botelho, E.C.; Silva, R.A.; Pardini, L.C.; Rezende, M.C. Evaluation of Adhesion of Continuous Fibre-Epoxy Composite/Aluminium Laminates. J. Adhes. Sci. Technol. 2004, 18, 1799–1813. [Google Scholar] [CrossRef]

- Liu, I.; Oehlers, D.; Seracino, R. Moment Redistribution in FRP and Steel-Plated Reinforced Concrete Beams. J. Compos. Constr. 2006, 10, 115–124. [Google Scholar] [CrossRef]

- Liu, J.; Sawa, T.; Toratani, H. A Two-dimensional Stress Analysis and Strength of Single-lap Adhesive Joints of Dissimilar Adherends Subjected to External Bending Moments. J. Adhes. 1999, 69, 3–4. [Google Scholar] [CrossRef]

- Liu, X.F.; Wu, Q.Y.; Wang, H.G. Effect of Surface Modifications and Environment on the Interfacial Adhesion of Polymer/Aluminium Alloy. Mater. Sci. Eng. A 2008, 483, 683–687. [Google Scholar] [CrossRef]

- Kellermann, A. About polymer adhesion. Polymers 1979, 2, 37–40. [Google Scholar]

- Ochoa-Putman, C.; Vaidya, U.K. Mechanisms of Interfacial Adhesion in Metal-Polymer Composites-Effect of Chemical Treatment. Compos Part A Appl. Sci. Manuf. 2011, 42, 906–915. [Google Scholar] [CrossRef]

- Uehara, K.; Sakurai, M. Bonding Strength of Adhesives and Surface Roughness of Joined Parts. J. Mater. Process. Technol. 2002, 127, 178–181. [Google Scholar] [CrossRef]

- Rudawska, A.; Jacniacka, E. Evaluating uncertainty of surface free energy measurement by the van Oss-Chaudhury-Good method. Int. J. Adhes. Adhes. 2018, 82, 139–145. [Google Scholar] [CrossRef]

- Rudawska, A.; Danczak, I.; Müllerc, M.; Valasek, P. The effect of sandblasting on surface properties for adhesion. Int. J. Adhes. Adhes. 2016, 70, 176–190. [Google Scholar] [CrossRef]

- ASTM D3165-00, Standard Test Method for Strength Properties of Adhesives in Shear by Tension Loading of Single-Lap-Joint Laminated Assemblies; ASTM International: West Conshohocken, PA, USA, 2000.

- Masuda, K.; Takashima, T.; Takayama, Y. Emissivity of pure and sea waters for the model sea surface in the infrared window regions. Remote Sens. Environ. 1998, 24, 313–329. [Google Scholar] [CrossRef]

- Greenhalgh, E.S. Failure Analysis and Fractography of Polymer Composites; Woodhead Publishing Limited: Cambridge, UK, 2009. [Google Scholar]

- Purslow, D. Matrix Fractography of Fibre-Reinforced Epoxy Composites. Composites 1986, 17, 289–303. [Google Scholar] [CrossRef]

- Wisnom, M.R. The Relation between Tensile and Flexural Strength of Unidirectional Composites. J. Compos. Mater. 1992, 26, 1173–1180. [Google Scholar] [CrossRef]

- Fink, A.; Sophabmixay, S.; Du Mars, W. Development of an Improved Surface Preparation for Titanium Bonding and Titanium Graphite Laminates for Aircraft and Space Vehicle Applications. In Proceedings of the AIRTEC, 5th International Conference, Frankfurt, Germany, 2–4 November 2010. [Google Scholar]

- Critchlow, G.W.; Yendall, K.A.; Bahrani, D.; Quinn, B.A.; Andrews, F. Strategies for the Replacement of Chromic Acid Anodizing for the Structural Bonding of Aluminium Alloys. Int. J. Adhes. Adhes. 2006, 19, 91–105. [Google Scholar]

- Berg, J.C. Semi-Empirical Strategies for Predicting Adhesion. In Adhesion Science and Engineering; Dillard, D.A., Pocius, A.V., Chaudhury, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2002; Chapter 1; pp. 1–73. [Google Scholar]

- Reburn, A. Analysis of manufacturing parameters on the shear strength of aluminium/GFRP co-cured and adhesively bonded single-lap joints. Plymouth Stud. Sci. 2016, 9, 195–230. [Google Scholar]

- Pereira, A.; Ferreira, J.; Antunes, F.; Bártolo, P. Analysis of manufacturing parameters on the shear strength of aluminium adhesive single-lap joints. J. Mater. Process. Technol. 2010, 210, 610–617. [Google Scholar] [CrossRef]

- Kwang-Soo, K.; Yoo, J.S.; Yi, Y.M.; Kim, C.G. Failure mode and strength of uni-directional composite single lap bonded joints with different bonding methods. Compos. Struct. 2006, 72, 477–485. [Google Scholar]

- Katsiropoulos, C.V.; Chamos, A.N.; Tserpes, K.I.; Pantelakis, S.G. Fracture Toughness and Shear Behaviour of Composite Bonded Joints Based on a Novel Aerospace Adhesive. Compos. Part B Eng. 2012, 43, 240–248. [Google Scholar] [CrossRef]

- Tzetzis, D. Characterisation of GFRP surfaces amenable for bonding and their effect on the strength of co-cured vacuum resin infused single lap joints. J. Adhes. Sci. Technol. 2012, 26, 2683–2707. [Google Scholar] [CrossRef]

| Surface of 2024-T3 Aluminum Alloy | Wetting Angle θ [°] | Surface Free Energy (SFE) (mJ/m2) | |

|---|---|---|---|

| θ [°] Water | θ [°] Diiodomethane | γs | |

| Without surface preparation | 67.27 ± 3.4 | 39.57 ± 2.4 | 43.9 |

| CAA | 16.45 ± 3.0 | 13.89 ± 3.23 | 72.2 |

| SAA | 27.1 ± 1.99 | 32.9 ± 2.99 | 66.4 |

| Type of Surface Preparation for 2024-T3 Aluminum Surface | Average Results For Surface Roughness Parameter Ra (µm) |

|---|---|

| No surface preparation | 0.29 ± 0 |

| CAA | 0.29 ± 0.01 |

| SAA | 0.26 ± 0.05 |

| Kind of FML | Type of Fibers | Anodizing Process | Configuration of Fibers Layers | Shear Strength (MPa) |

|---|---|---|---|---|

| Al/GFRP (0)2/Al | Glass | CAA+P | (0) | 3.56 ± 0.35 |

| Al/GFRP (±45)2/Al | CAA+P | (±45) | 3.93 ± 0.54 | |

| Al/GFRP (0)2/Al | SAA+P | (0) | 3.13 ± 0.05 | |

| Al/GFRP (±45)2/Al | SAA+P | (±45) | 4.23 ± 0.21 | |

| Al/CFRP (0)4/Al | Carbon | CAA+P | (0) | 4.14 ± 0.43 |

| Al/CFRP (±45)4/Al | CAA+P | (±45) | 5.69 ± 0.28 | |

| Al/CFRP (0)4/Al | SAA+P | (0) | 3.92 ± 0.15 | |

| Al/CFRP (±45)4/Al | SAA+P | (±45) | 3.85 ± 0.11 |

| Kind of Sample | Character of Failure |

|---|---|

| Al/GFRP [0] CAA/Al | Adhesive—Cohesive (ADH+COH) |

| Al/GFRP [±45] CAA/Al | Adhesive—Cohesive (ADH+COH) |

| Al/GFRP [0] SAA/Al | Adhesive (ADH) |

| Al/GFRP [±45] SAA/Al | Adhesive (ADH) |

| Al/CFRP [0] CAA/Al | Adhesive—Cohesive (ADH+COH) |

| Al/CFRP [±45] CAA/Al | Adhesive—Cohesive (ADH+COH) |

| Al/CFRP [0] SAA/Al | Adhesive (ADH) |

| Al/CFRP [±45] SAA/Al | Adhesive—Cohesive (ADH+COH) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ostapiuk, M.; Bieniaś, J. Fracture Analysis and Shear Strength of Aluminum/CFRP and GFRP Adhesive Joint in Fiber Metal Laminates. Materials 2020, 13, 7. https://doi.org/10.3390/ma13010007

Ostapiuk M, Bieniaś J. Fracture Analysis and Shear Strength of Aluminum/CFRP and GFRP Adhesive Joint in Fiber Metal Laminates. Materials. 2020; 13(1):7. https://doi.org/10.3390/ma13010007

Chicago/Turabian StyleOstapiuk, Monika, and Jarosław Bieniaś. 2020. "Fracture Analysis and Shear Strength of Aluminum/CFRP and GFRP Adhesive Joint in Fiber Metal Laminates" Materials 13, no. 1: 7. https://doi.org/10.3390/ma13010007