The Optoelectronic Properties of p-Type Cr-Deficient Cu[Cr0.95−xMg0.05]O2 Films Deposited by Reactive Magnetron Sputtering

Abstract

:1. Introduction

2. Materials and Methods

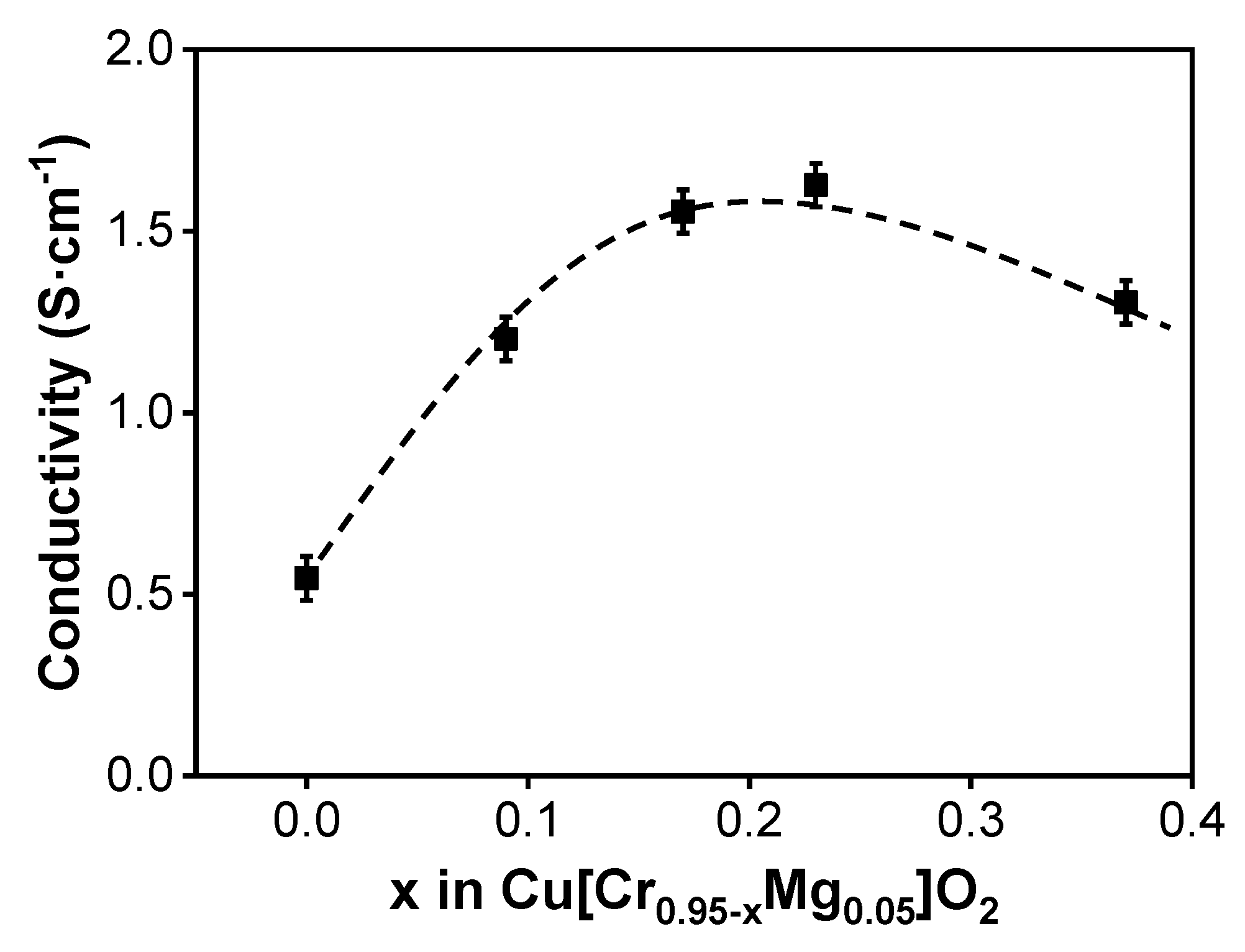

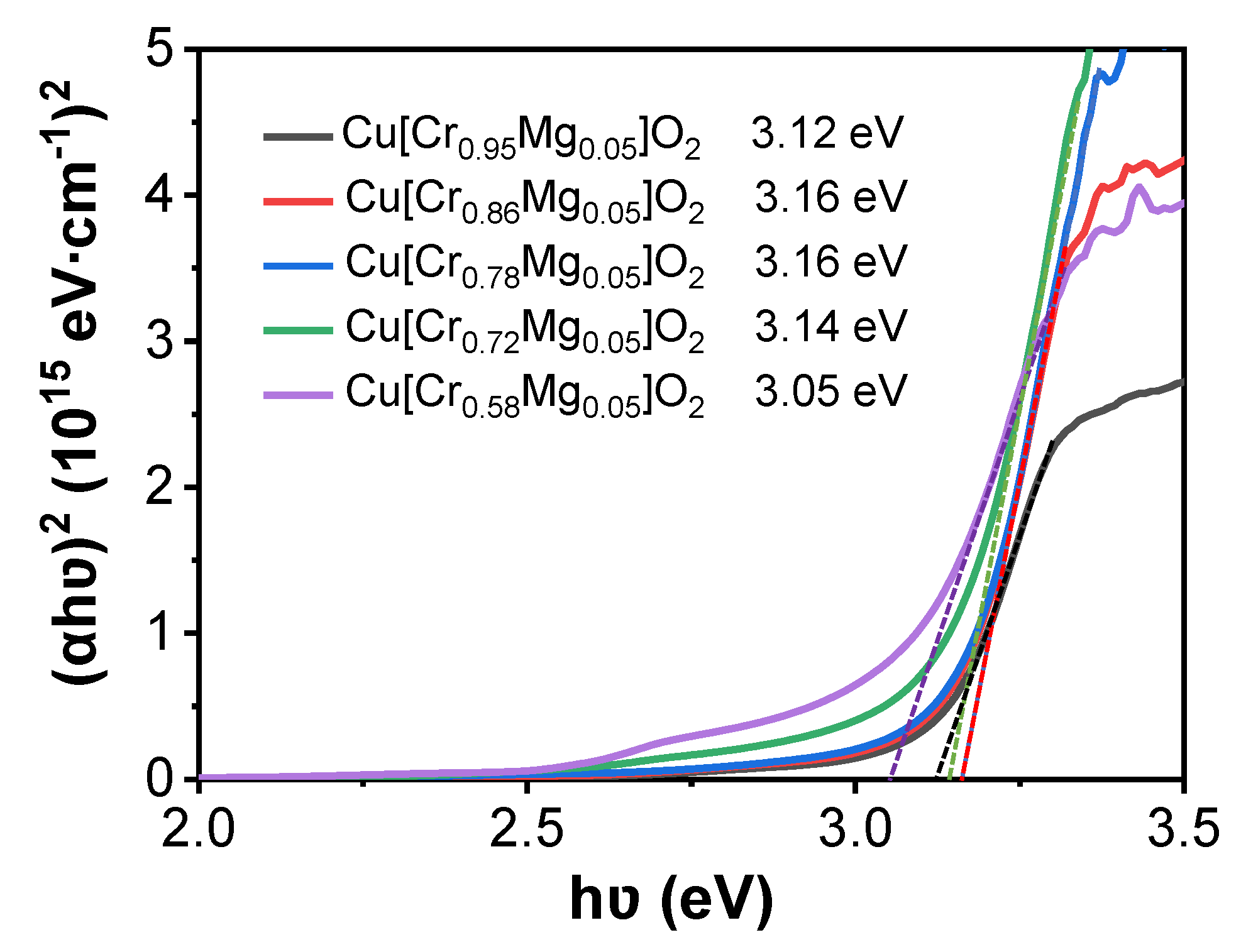

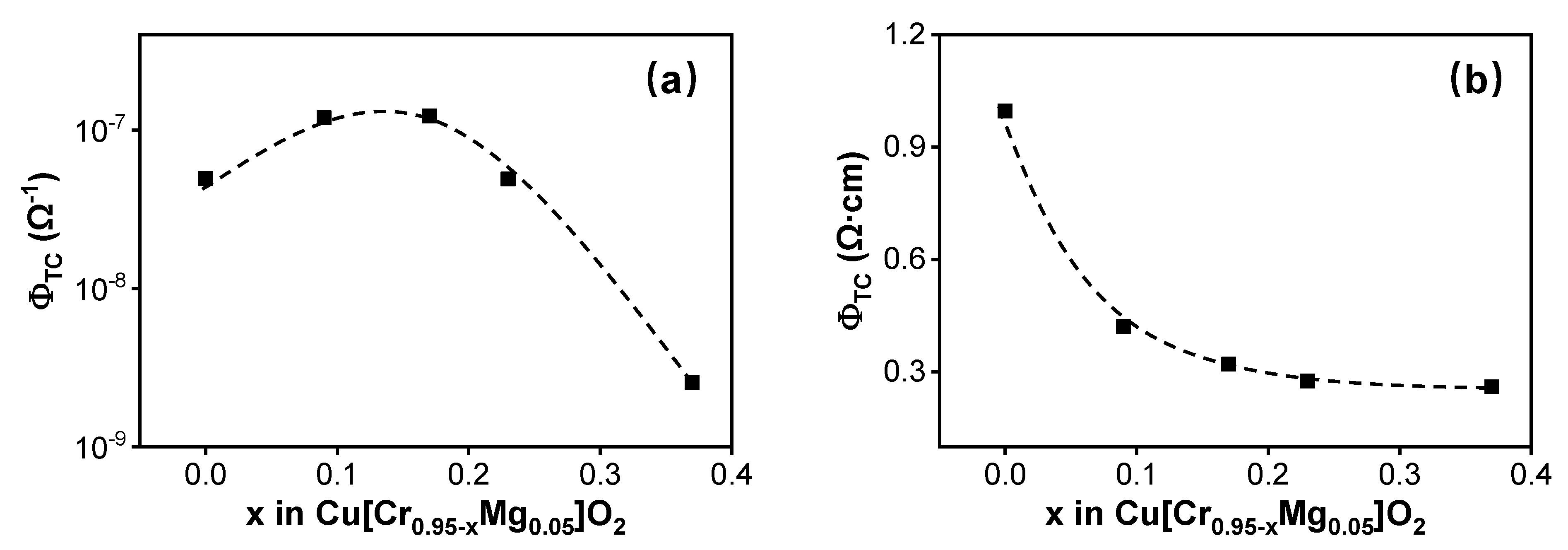

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wen, L.; Sahu, B.B.; Kim, H.R.; Han, J.G. Study on the electrical, optical, structural, and morphological properties of highly transparent and conductive AZO thin films prepared near room temperature. Appl. Surf. Sci. 2019, 473, 649–656. [Google Scholar] [CrossRef]

- Sun, H.; Jen, S.U.; Chen, S.C.; Ye, S.S.; Wang, X. The electrical stability of In-doped ZnO thin films deposited by RF sputtering. J. Phys. D 2017, 50, 045102. [Google Scholar] [CrossRef]

- Wang, K.L.; Xin, Y.Q.; Zhao, J.F.; Song, S.M.; Chen, S.C.; Lv, Y.B.; Sun, H. High transmittance in IR region of conductive ITO/AZO multilayers deposited by RF magnetron sputtering. Ceram. Int. 2018, 44, 6769–6774. [Google Scholar] [CrossRef]

- Sun, H.; Jen, S.U.; Chiang, H.P.; Chen, S.C.; Lin, M.H.; Chen, J.Y.; Wang, X. Investigation of optoelectronic performance in In, Ga co-doped ZnO thin films with various In and Ga levels. Thin Solid Film. 2017, 641, 12–18. [Google Scholar] [CrossRef]

- Fan, J.C.; Sreekamth, K.M.; Xie, Z.; Chang, S.L.; Rao, K.V. p-Type ZnO materials: Theory, growth, properties and devices. Prog. Mater. Sci. 2013, 58, 874–985. [Google Scholar] [CrossRef]

- He, L.X.; Tjong, S.C. Nanostructured transparent conductive films: Fabrication, characterization and applications. Mater. Sci. Eng. R 2016, 109, 1–101. [Google Scholar] [CrossRef]

- Hautier, G.; Miglio, A.; Ceder, G.; Rignanese, G.M.; Gonze, X. Identification and design principles of low hole effective mass p-type transparent conducting oxides. Nat. Commun. 2013, 4, 2292. [Google Scholar] [CrossRef] [Green Version]

- Al-Jawhari, H.A. A review of recent advances in transparent p-type Cu2O-based thin film transistors. Mater. Sci. Semicond. Process. 2015, 40, 241–252. [Google Scholar] [CrossRef]

- Chen, S.C.; Kuo, T.Y.; Lin, H.C.; Chen, R.Z.; Sun, H. Optoelectronic properties of p-type NiO films deposited by direct current magnetron sputtering versus high power impulse magnetron sputtering. Appl. Surf. Sci. 2020, 508, 145106. [Google Scholar] [CrossRef]

- Wang, Z.W.; Nayak, P.K.; Caraveo-Frescas, J.A.; Alshareef, H.N. Recent developments in p-type oxide semiconductor materials and devices. Adv. Mater. 2016, 28, 3831–3892. [Google Scholar] [CrossRef] [Green Version]

- Sun, H.; Yazdi, M.A.P.; Chen, S.C.; Wen, C.K.; Sanchette, F.; Billard, A. Ag composition gradient CuCr0.93Mg0.07O2/Ag/CuCr0.93Mg0.07O2 coatings with improved p-type optoelectronic performances. J. Mater. Sci. 2017, 52, 11537–11546. [Google Scholar] [CrossRef]

- Xiao, Z.W.; Yan, Y.F. Progress in Theoretical Study of Metal Halide Perovskite Solar Cell Materials. Adv. Energy Mater. 2017, 7, 1701136. [Google Scholar] [CrossRef]

- Sun, H.; Liao, M.H.; Chen, S.C.; Li, Z.Y.; Lin, P.C.; Song, S.M. Synthesis and characterization of n-type NiO:Al thin films for fabrication of p-n NiO homojunctions. J. Phys. D 2018, 51, 105109. [Google Scholar] [CrossRef]

- Blochwitz, J.; Pfeiffer, M.; Hofmann, M.; Leo, K. Non-polymeric OLEDs with a doped amorphous hole transport layer and operating voltages down to 3.2 V to achieve 100 cd/m2. Synth. Met. 2002, 127, 169–173. [Google Scholar] [CrossRef]

- Kawazoe, H.; Yasukawa, M.; Hyodo, H.; Kurita, M.; Yanagi, H.; Hosono, H. p-type electrical conduction in transparent thin films of CuAlO2. Nature 1997, 389, 939–942. [Google Scholar] [CrossRef]

- Sun, H.; Chen, S.C.; Wen, C.K.; Chuang, T.H.; Yazdi, M.A.P.; Sanchette, F.; Billard, A. p-type cuprous oxide thin films with high conductivity deposited by high power impulse magnetron sputtering. Ceram. Int. 2017, 43, 6214–6220. [Google Scholar] [CrossRef]

- Kawazoe, H.; Yanagi, H.; Ueda, K.; Hosono, H. Transparent p-type conducting oxides: Design and fabrication of p-n heterojunctions. MRS Bull. 2000, 25, 28–36. [Google Scholar] [CrossRef] [Green Version]

- Nagarajan, R.; Draeseke, A.D.; Sleight, A.W.; Tate, J. P-type conductivity in CuCr1-xMgxO2 films and powders. J. Appl. Phys. 2001, 89, 8022–8025. [Google Scholar] [CrossRef]

- Sun, H.; Yazdi, M.A.P.; Briois, P.; Pierson, J.F.; Sanchette, F.; Billard, A. Towards delafossite structure of Cu-Cr-O thin films deposited by reactive magnetron sputtering: Influence of substrate temperature on optoelectronics properties. Vacuum 2015, 114, 101–107. [Google Scholar] [CrossRef]

- Chuai, Y.H.; Wang, X.; Zheng, C.T.; Zhang, Y.; Shen, H.Z.; Wang, Y.D. Highly infrared-transparent and p-type conductive CuSc1−xSnxO2 thin films and a p-CuScO2:Sn/n-ZnO heterojunction fabricated by the polymer-assisted deposition method. RSC Adv. 2016, 6, 31726–31731. [Google Scholar] [CrossRef]

- Sun, H.; Yazdi, M.A.P.; Sanchette, F.; Billard, A. Optoelectronic properties of delafossite structure CuCr0.93Mg0.07O2 sputter deposited coatings. J. Phys. D Appl. Phys. 2016, 49, 185105. [Google Scholar] [CrossRef]

- Fang, Z.J.; Zhu, J.Z.; Zhou, J.; Mo, M. Defect properties of CuCrO2: A density functional theory calculation. Chin. Phys. B 2012, 21, 087105. [Google Scholar] [CrossRef]

- Ahmadi, M.; Asemi, M.; Ghanaatshoar, M. Mg and N co-doped CuCrO2: A record breaking p-type TCO. Appl. Phys. Lett. 2018, 113, 242101. [Google Scholar] [CrossRef]

- Chen, H.Y.; Chang, K.P.; Yang, C.C. Characterization of transparent conductive delafossite-CuCr1−xO2 films. Appl. Surf. Sci. 2013, 273, 324–329. [Google Scholar] [CrossRef]

- Ling, D.C.; Chiang, C.W.; Wang, Y.F.; Lee, Y.J.; Yeh, P.H. Effect of Cr deficiency on physical properties of triangular-lattice antiferromagnets CuCr1-xO2 (0 ≤ x ≤ 0.10). J. Appl. Phys. 2011, 109, 07D908. [Google Scholar] [CrossRef] [Green Version]

- Poienar, M.; Hardy, V.; Kundys, B.; Singh, K.; Maignan, A.; Damay, F.; Martin, C. Revisiting the properties of delafossite CuCrO2: A single crystal study. J. Solid State Chem. 2012, 185, 56–61. [Google Scholar] [CrossRef]

- Daou, R.; Fresard, R.; Eyert, V.; Hebert, S.; Maignan, A. Unconventional aspects of electronic transport in delafossite oxides. Sci. Technol. Adv. Mater. 2017, 18, 919–938. [Google Scholar] [CrossRef]

- Singh, S.B.; Yang, L.T.; Wang, Y.F.; Shao, Y.C.; Chiang, C.W.; Chiou, J.W.; Lin, K.T.; Chen, S.C.; Wang, B.Y.; Chuang, C.H.; et al. Correlation between p-type conductivity and electronic structure of Cr-deficient CuCr1−xO2 (x = 0–0.1). Phys. Rev. B 2012, 86, 241103. [Google Scholar] [CrossRef]

- Terasak, I. Thermal conductivity and thermoelectric power of semiconductors. In Comprehensive Semiconductor Science and Technology; Bhattacharya, P., Fomari, R., Kamimura, H., Eds.; Elsevier: Amsterdam, The Netherlands, 2011; Volume 1, pp. 326–358. [Google Scholar]

- Zhang, N.D.; Sun, J.; Gong, H. Transparent p-type semiconductors: Copper-based oxides and oxychalcogenides. Coatings 2019, 9, 137. [Google Scholar] [CrossRef] [Green Version]

- Sun, H.; Yazdi, M.A.P.; Ducros, C.; Chen, S.C.; Aubry, E.; Wen, C.K.; Hsieh, J.H.; Sanchette, F.; Billard, A. Thickness-dependence optoelectronic properties of CuCr0.93Mg0.07O2 thin films deposited by reactive magnetron sputtering. Mat. Sci. Semicon. Proc. 2017, 63, 295–302. [Google Scholar] [CrossRef]

- Demichelis, F.; Kaniadakis, G.; Tagliaferro, A.; Tresso, E. New approach to optical analysis of absorbing thin solid films. Appl. Opt. 1987, 26, 1737–1740. [Google Scholar] [CrossRef] [PubMed]

- Tauc, J. Amorphous and Liquid Semiconductors; Plenum: London, UK, 1974. [Google Scholar]

- Tripathi, T.S.; Karppinen, M. Enhanced p-type transparent semiconducting characteristics for ALD-grown Mg-substituted CuCrO2 thin films. Adv. Electron. Mater. 2017, 3, 1600341. [Google Scholar] [CrossRef] [Green Version]

- Dong, G.B.; Zhang, M.; Zhao, X.P.; Yan, H.; Tian, C.Y.; Ren, Y.G. Improving the electrical conductivity of CuCrO2 thin film by N doping. Appl. Surf. Sci. 2010, 256, 4121–4124. [Google Scholar] [CrossRef]

- Sun, H.; Wen, C.K.; Chen, S.C.; Chuang, T.H.; Yarzdi, M.A.P.; Sanchette, F.; Billard, A. Microstructures and optoelectronic properties of CuxO films deposited by high-power impulse magnetron sputtering. J. Alloy. Compd. 2016, 688, 672–678. [Google Scholar] [CrossRef]

- Scanlon, D.O.; Watson, G.W. Understanding the p-type defect chemistry of CuCrO2. J. Mater. Chem. 2011, 21, 3655–3663. [Google Scholar] [CrossRef]

- Benko, F.A.; Koffybery, F.P. Preparation and opto-electronic properties of semiconducting CuCrO2. Mat. Res. Bull. 1986, 21, 753–757. [Google Scholar] [CrossRef]

- Rastogi, A.C.; Lim, S.H.; Desu, S.B. Structure and optoelectronic properties of spray deposited Mg doped p-CuCrO2 semiconductor oxide thin films. J. Appl. Phys. 2008, 104, 023712. [Google Scholar] [CrossRef]

- Haacke, G. New figure of merit for transparent conductors. J. Appl. Phys. 1976, 47, 4086–4089. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, S.-S.; Shi, Q.; Dai, M.-J.; Wang, K.-L.; Chen, S.-C.; Kuo, T.-Y.; Liu, D.-G.; Song, S.-M.; Sun, H. The Optoelectronic Properties of p-Type Cr-Deficient Cu[Cr0.95−xMg0.05]O2 Films Deposited by Reactive Magnetron Sputtering. Materials 2020, 13, 2376. https://doi.org/10.3390/ma13102376

Lin S-S, Shi Q, Dai M-J, Wang K-L, Chen S-C, Kuo T-Y, Liu D-G, Song S-M, Sun H. The Optoelectronic Properties of p-Type Cr-Deficient Cu[Cr0.95−xMg0.05]O2 Films Deposited by Reactive Magnetron Sputtering. Materials. 2020; 13(10):2376. https://doi.org/10.3390/ma13102376

Chicago/Turabian StyleLin, Song-Sheng, Qian Shi, Ming-Jiang Dai, Kun-Lun Wang, Sheng-Chi Chen, Tsung-Yen Kuo, Dian-Guang Liu, Shu-Mei Song, and Hui Sun. 2020. "The Optoelectronic Properties of p-Type Cr-Deficient Cu[Cr0.95−xMg0.05]O2 Films Deposited by Reactive Magnetron Sputtering" Materials 13, no. 10: 2376. https://doi.org/10.3390/ma13102376