Hysteretic Behavior of Geopolymer Concrete with Active Confinement Subjected to Monotonic and Cyclic Axial Compression: An Experimental Study

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Specimen Preparation

2.2. Experiment Design

3. Results and Discussions

3.1. Failure Patterns of Unconfined and Confined GPC

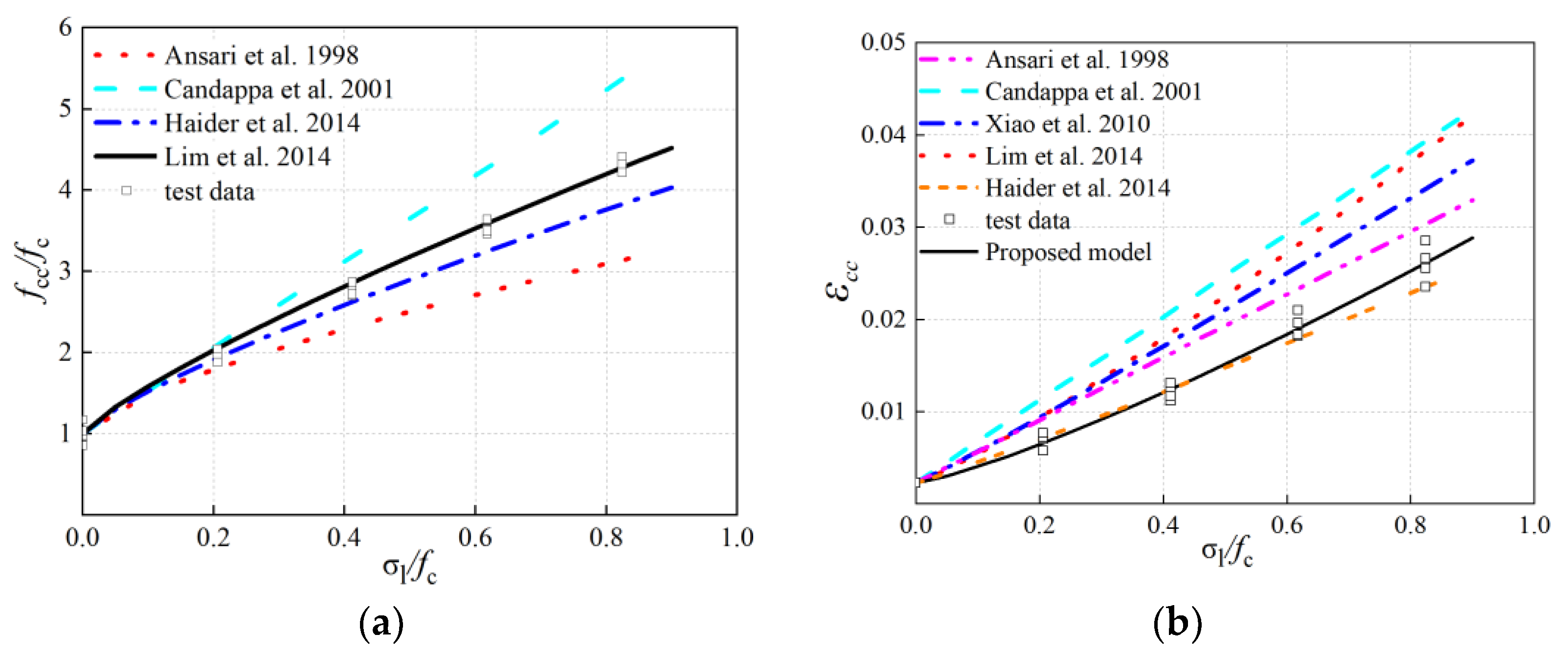

3.2. The Peak Value of Axial Stress and Strain

3.3. Monotonic Constitutive Behavior

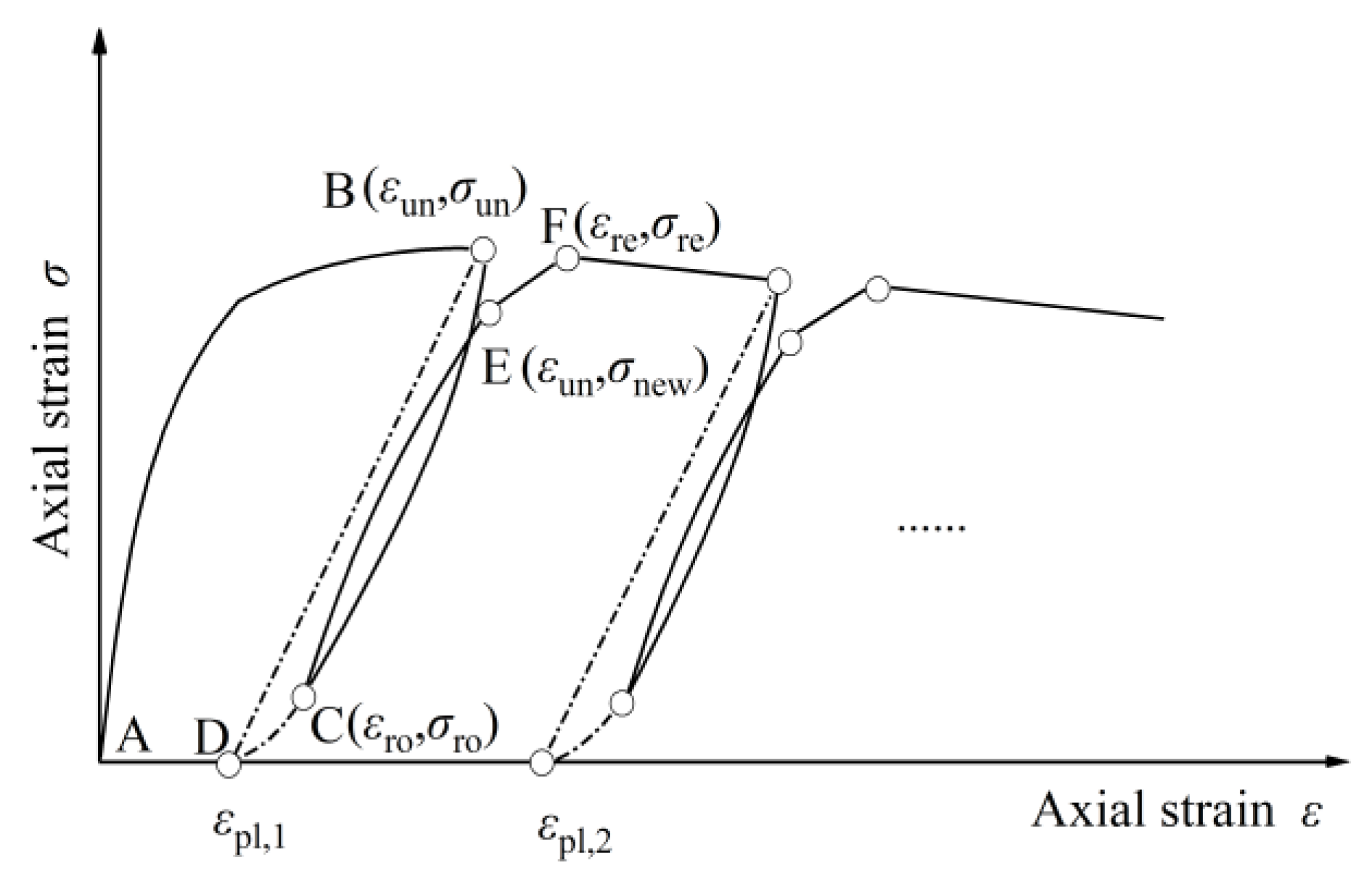

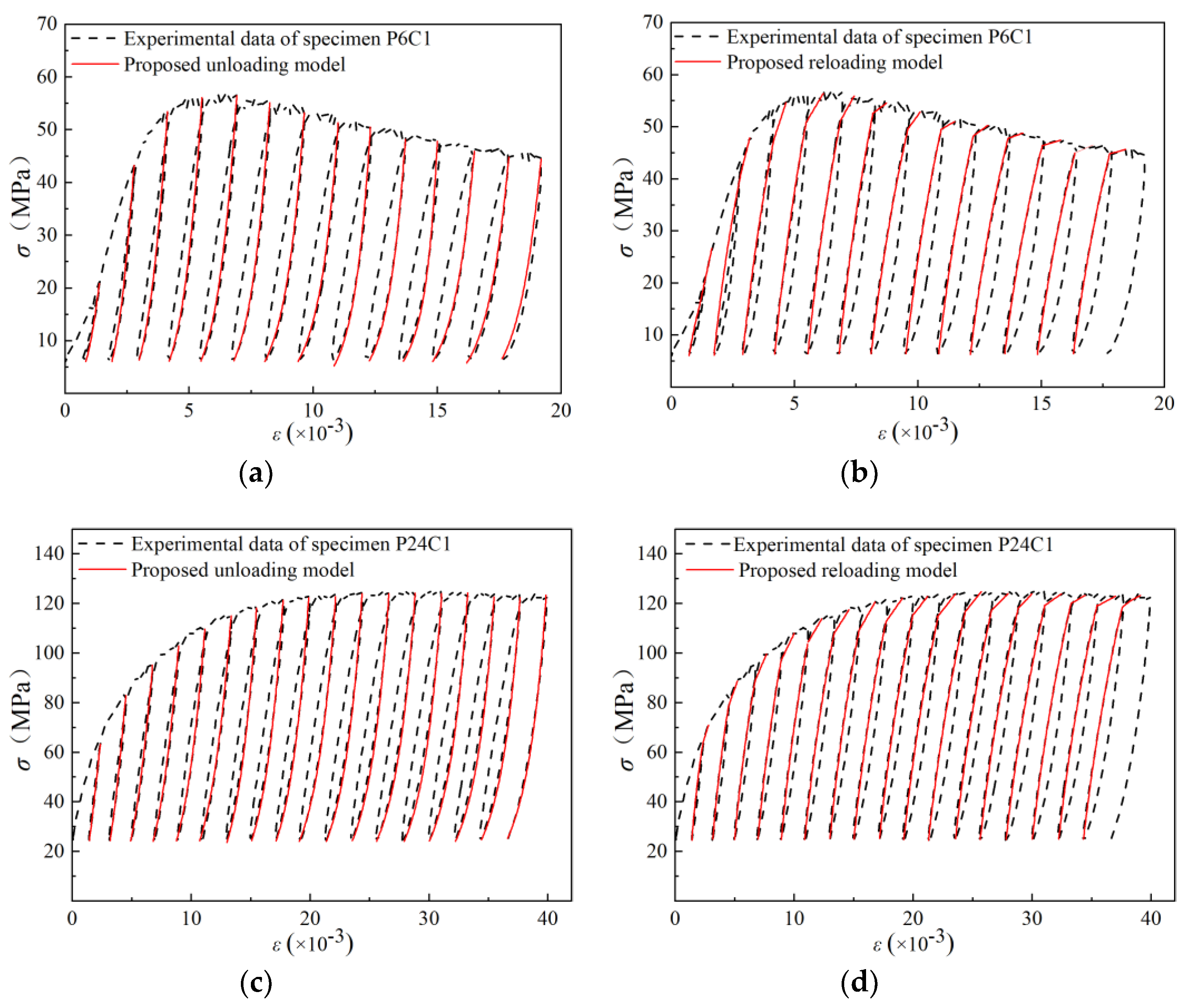

3.4. Stress–Strain Behavior under Cyclic Loading

3.5. The Energy Absorption and Specific Toughness under Uniaxial and Triaxial Compression

4. Conclusions

- The loading path had little effect on the axial peak strength and strain of confined GPC. In the triaxial test, the GPC with brittleness turns into a ductile material when the confined stress ratio (σl/fc) exceeded 0.4. The peak stress prediction model proposed by Lim et al. [31] for cement concretes can also accurately predict the peak strength of confined GPC, which showed that GPC and cement concrete had a similar strength enhancement coefficient. However, the strain enhancement coefficient of GPC was lower than that of cement concrete under a similar confinement level.

- The constitutive behavior of actively confined GPC was similar to that of the conventional cement concrete. Under the condition of same confinement level, the envelope curves under cyclic compression were consistent with the stress–strain curves under monotonic loading, which can be simulated by Mander’s model with enough accuracy. This means the model provided by Mander et al. for conventional cement concrete was proved to be a necessary material model to study the mechanical behavior of actively confined GPC.

- A cyclic axial compressive stress–strain model composed of a monotonic envelope curve (modified Mander’s model) and cyclic hysteresis curve (modified Lokuge’s model) can be used for the constitutive behavior of actively confined GPC under cyclic loading. The comparison among the experimental results showed that the model accurately predicted the residual plastic strain, the transition point, and reloading strain of GPC with active confinement, and fully simulated the degradation of stiffness caused by unloading/reloading cycles, which was consistent with the experimental results.

- The energy absorption and specific toughness were calculated and discussed by both monotonic and cyclic stress–strain curves. The presented values and the discussion of the results could provide important indications for future studies.

Author Contributions

Funding

Conflicts of Interest

References

- Yan, D.; Xie, L.; Qian, X.; Ruan, S.; Zeng, Q. Compositional dependence of pore structure, strength and freezing-thawing resistance of metakaolin-based geopolymers. Materials 2020, 13, 2573. [Google Scholar] [CrossRef]

- Yifei, C.; Kaikai, G.; Peng, Z. Experimental and statistical study on mechanical characteristics of geopolymer concrete. Materials 2020, 13, 1561. [Google Scholar]

- Schneider, M.; Romer, M.; Tschudin, M.; Bolio, H. sustainable cement production—Present and future. Cem. Concr. Res. 2011, 41, 642–650. [Google Scholar] [CrossRef]

- Palmero, P.; Formia, A.; Antonaci, P.; Brini, S.; Tulliani, J. Geopolymer technology for application-oriented dense and lightened materials. Elaboration and characterization. Ceram. Int. 2015, 41, 12967–12979. [Google Scholar] [CrossRef]

- Lee, N.K.; Lee, H.K. Setting and mechanical properties of alkali-activated fly ash/slag concrete manufactured at room temperature. Constr. Build. Mater. 2013, 47, 1201–1209. [Google Scholar] [CrossRef]

- Nath, P.; Sarker, P.K. Effect of GGBFS on setting, workability and early strength properties of fly ash geopolymer concrete cured in ambient condition. Constr. Build. Mater. 2014, 66, 163–171. [Google Scholar] [CrossRef] [Green Version]

- Thomas, R.J.; Peethamparan, S. Alkali-activated concrete: Engineering properties and stress–strain behavior. Constr. Build. Mater. 2015, 93, 49–56. [Google Scholar] [CrossRef] [Green Version]

- Ma, C.; Awang, A.Z.; Omar, W. Structural and material performance of geopolymer concrete: A review. Constr. Build. Mater. 2018, 186, 90–102. [Google Scholar] [CrossRef]

- Elchalakani, M.; Dong, M.; Karrech, A.; Li, G.; Ali, M.S.M.; Yang, B. Experimental investigation of rectangular air-cured geopolymer concrete columns reinforced with GFRP bars and stirrups. J. Compos. Constr. 2019, 23, 04019011.1–04019011.11. [Google Scholar] [CrossRef]

- Noushini, A.; Aslani, F.; Castel, A.; Gilbert, R.I.; Uy, B.; Foster, S. Compressive stress-strain model for low-calcium fly ash-based geopolymer and heat-cured Portland cement concrete. Cem. Concr. Compos. 2016, 73, 136–146. [Google Scholar] [CrossRef]

- Xie, J.; Wang, J.; Rao, R.; Wang, C.; Fang, C. Effects of combined usage of GGBS and fly ash on workability and mechanical properties of alkali activated geopolymer concrete with recycled aggregate. Compos. Part B Eng. 2019, 164, 179–190. [Google Scholar] [CrossRef]

- Keulen, A.; Yu, Q.L.; Zhang, S.; Grünewald, S. Effect of admixture on the pore structure refinement and enhanced performance of alkali-activated fly ash-slag concrete. Constr. Build. Mater. 2018, 162, 27–36. [Google Scholar] [CrossRef]

- Mo, K.H.; Alengaram, U.J.; Jumaat, M.Z. Structural performance of reinforced geopolymer concrete members: A review. Constr. Build. Mater. 2016, 120, 251–264. [Google Scholar] [CrossRef]

- Hassan, A.; Arif, M.; Shariq, M. A review of properties and behaviour of reinforced geopolymer concrete structural elements- A clean technology option for sustainable development. J. Clean. Prod. 2020, 245, 118762. [Google Scholar] [CrossRef]

- Shi, X.; Wang, Q.; Zhao, X.; Collins, F.G. Structural behaviour of geopolymeric recycled concrete filled steel tubular columns under axial loading. Constr. Build. Mater. 2015, 81, 187–197. [Google Scholar] [CrossRef]

- Ozbakkaloglu, T.; Xie, T. Geopolymer concrete-filled FRP tubes: Behavior of circular and square columns under axial compression. Compos. Part B 2016, 96, 215–230. [Google Scholar] [CrossRef]

- Gholampour, A.; Ozbakkaloglu, T.; Ng, C. Ambient- and oven-cured geopolymer concretes under active confinement. Constr. Build. Mater. 2019, 228, 116722. [Google Scholar] [CrossRef]

- Lokuge, W.P.; Sanjayan, J.G.; Setunge, S. Constitutive model for confined high strength concrete subjected to cyclic loading. J. Mater. Civil Eng. 2004, 16, 297–305. [Google Scholar] [CrossRef]

- Li, P.; Wu, Y. Stress–strain behavior of actively and passively confined concrete under cyclic axial load. Compos. Struct. 2016, 149, 369–384. [Google Scholar] [CrossRef]

- China, M.O.C.O. Standard for Test Method of Mechanical Properties on Ordinary Concrete; China Architecture & Building Press: Beijing, China, 2002. [Google Scholar]

- Zhou, W.; Shi, X.; Lu, X.; Qi, C.; Luan, B.; Liu, F. The mechanical and microstructural properties of refuse mudstone-GGBS-red mud based geopolymer composites made with sand. Constr. Build. Mater. 2020, 253, 119193. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Z.; Xue, S.; Wang, R.; Xiao, M. Stability analysis of a typical landslide mass in the Three Gorges Reservoir under varying reservoir water levels. Environ. Earth Sci. 2020, 79, 42. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, S.; Zhang, W.; Liu, H. Analysis of deformation characteristics and stability mechanisms of typical landslide mass based on the fifield monitoring in the Three Gorges Reservoir. China J. Earth Syst. Sci. 2018, 128. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Zhu, S.; Tan, J.; Li, L.; Yin, X. The influence of water level fluctuation on the stability of landslide in the Three Gorges Reservoir. Arab. J. Geosci. 2020, 13, 845. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, X.; Zhang, Y.; Wu, F.; Chen, F.; Wang, W.; Guo, F. Application of GWO-ELM model to prediction of caojiatuo landslide displacement in the Three Gorge Reservoir Area. Water 2020, 12, 1860. [Google Scholar] [CrossRef]

- Lu, X.; Hsu, C.T. Stress-strain relations of high-strength concrete under triaxial compression. J. Mater. Civ. Eng. 2007, 19, 261–268. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, Z.; Xu, J.; Lui, E.M.; Wu, B. Performance evaluation of recycled aggregate concrete under multiaxial compression. Constr. Build. Mater. 2019, 229, 116935. [Google Scholar] [CrossRef]

- Farhad, A.; Qingbin, L. High-Strength Concrete Subjected to Triaxial Compression. Mater. J. 1998, 95, 747–755. [Google Scholar]

- Candappa, D.C.; Sanjayan, J.G.; Setunge, S. Complete triaxial stress-strain curves of high-strength concrete. J. Mater. Civil Eng. 2001, 13, 209–215. [Google Scholar] [CrossRef]

- Xiao, Q.G.; Teng, J.G.; Yu, T. Behavior and modeling of confined high-strength concrete. J. Compos. Constr. 2010, 14, 249–259. [Google Scholar] [CrossRef]

- Lim, J.C.; Ozbakkaloglu, T. Stress–strain model for normal- and light-weight concretes under uniaxial and triaxial compression. Constr. Build. Mater. 2014, 71, 492–509. [Google Scholar] [CrossRef]

- Haider, G.M.; Sanjayan, J.G.; Ranjith, P.G. Complete triaxial stress–strain curves for geopolymer. Constr. Build. Mater. 2014, 69, 196–202. [Google Scholar] [CrossRef]

- Binici, B. An analytical model for stress–strain behavior of confined concrete. Eng. Struct. 2005, 27, 1040–1051. [Google Scholar] [CrossRef]

- Mander, J.A.B.; Priestley, M.J.N. Theoretical stress-strain model for confined concrete. J. Struct. Eng. 1998, 114, 1804–1826. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.; Teng, Y.; Zhang, Y.; Wang, X.; Chen, Y.F. Axial stress-strain behavior of high-strength concrete confined by circular thin-walled steel tubes. Constr. Build. Mater. 2018, 177, 366–377. [Google Scholar] [CrossRef]

- Hutagi, A.; Khadiranaikar, R.B.; Zende, A.A. Behavior of geopolymer concrete under cyclic loading. Constr. Build. Mater. 2020, 246, 118430. [Google Scholar] [CrossRef]

- Albitar, M.; Ozbakkaloglu, T.; Fanggi, B.A.L. Behavior of FRP-HSC-Steel double-skin tubular columns under cyclic axial compression. J. Compos. Constr. 2014, 19, 04014041.1–04014041.13. [Google Scholar] [CrossRef]

- Medine, I. Monotonic and cyclic compression tests on concrete confined with PET-FRP. J. Compos. Constr. 2014, 19, 04014034. [Google Scholar]

- Konstantinidis, D.K.; Kappos, A.J.; Izzuddin, B.A. Analytical stress-strain model for high-strength concrete members under cyclic loading. J. Struct. Eng. 2007, 133, 484–494. [Google Scholar] [CrossRef]

- Zhang, Y.; Bicici, E.; Sezen, H.; Zheng, S. Reinforcement slip model considering corrosion effects. Constr. Build. Mater. 2020, 235, 117348. [Google Scholar] [CrossRef]

- Wang, Z.; Li, L.; Zhang, Y.; Zheng, S. Reinforcement model considering slip effect. Eng. Struct. 2019, 198, 109493. [Google Scholar] [CrossRef]

- Wang, J.; Huang, S.; Guo, W.; Qiu, Z.; Kang, K. Experimental study on fracture toughness of a compacted clay using semi-circular bend specimen. Eng. Fract. Mech. 2020, 224, 106814. [Google Scholar] [CrossRef]

| Binding Materials | SiO2 | Al2O3 | CaO | Fe2O3 | TiO2 | K2O | SO3 | MgO | Na2O | L.O.I |

|---|---|---|---|---|---|---|---|---|---|---|

| FA | 49.10 | 36.70 | 4.96 | 3.67 | 1.39 | 0.943 | 0.49 | 0.37 | 0.20 | 2.08 |

| GBFS | 32.28 | 13.80 | 37.85 | 2.74 | 1.30 | 0.96 | 2.90 | 3.73 | 0.70 | 1.30 |

| FA | GBFS | SS | SH | Sand | CA | Added W | SP |

|---|---|---|---|---|---|---|---|

| 234 | 156 | 122 | 49 | 764 | 1023 | 11.5 | 5.4 |

| Load Path | Confining Lateral Stress σl (MPa) | Peak AXIAL Stress fcc (MPa) | Peak Axial Strain εcc (×10−3) |

|---|---|---|---|

| Uniaxial | 0 | 27.13 | 2.18 |

| Uniaxial | 0 | 28.86 | 2.23 |

| Uniaxial | 0 | 31.49 | 2.38 |

| P6M1 | 6 | 57.01 | 7.02 |

| P6M2 | 6 | 57.04 | 7.13 |

| P6C1 | 6 | 54.70 | 5.73 |

| P6C2 | 6 | 59.40 | 7.63 |

| P12M1 | 12 | 81.14 | 12.01 |

| P12M2 | 12 | 78.66 | 11.11 |

| P12C1 | 12 | 79.23 | 11.68 |

| P12C2 | 12 | 83.46 | 13.04 |

| P18M1 | 18 | 106.02 | 20.95 |

| P18M2 | 18 | 102.50 | 19.60 |

| P18C1 | 18 | 100.89 | 18.23 |

| P18C2 | 18 | 101.94 | 18.28 |

| P24M1 | 24 | 128.38 | 26.60 |

| P24M2 | 24 | 124.27 | 25.51 |

| P24C1 | 24 | 122.88 | 23.51 |

| P24C2 | 24 | 125.91 | 28.52 |

| Concrete Type | Source | Analytical Expressions of fcc and εcc |

|---|---|---|

| High-strength cement concrete | Ansari et al. [28] | |

| High-strength cement concrete | Candappa et al. [29] | |

| High-strength cement concrete | Xiao et al. [30] | |

| Normal-and light-weight cement concretes | Lim et al. [31] | |

| Geopolymer concretes | Haider et al. [32] | |

| Ambient- and oven-cured geopolymer concretes | Aliakbar et al. [17] |

| Specimen Type | Wexp(10−3) | Wthe(10−3) | δexp(10−3) | δthe(10−3) |

|---|---|---|---|---|

| P0M1 | 72.70 | 80.57 | 2.50 | 2.77 |

| P0M2 | 70.15 | 2.41 | ||

| P0M3 | 73.20 | 2.52 | ||

| P6M1 | 671.62 | 740.85 | 11.78 | 12.99 |

| P6M2 | 695.35 | 12.20 | ||

| P6C1 | 680.42 | 12.44 | ||

| P6C2 | 672.25 | 11.32 | ||

| P12M1 | 2242.64 | 2232.15 | 27.82 | 27.69 |

| P12M2 | 2180.54 | 27.05 | ||

| P12C1 | 2250.24 | 28.40 | ||

| P12C2 | 2180.56 | 26.13 | ||

| P18M1 | N/A | 5904.01 | N/A | 57.411 |

| P18M2 | N/A | N/A | ||

| P18C1 | N/A | N/A | ||

| P18C2 | N/A | N/A | ||

| P24M1 | N/A | 8182.56 | N/A | 65.27 |

| P24M2 | N/A | N/A | ||

| P24C1 | N/A | N/A | ||

| P24C2 | N/A | N/A |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Wu, Y.; Wei, M.; Wang, L.; Cheng, B. Hysteretic Behavior of Geopolymer Concrete with Active Confinement Subjected to Monotonic and Cyclic Axial Compression: An Experimental Study. Materials 2020, 13, 3997. https://doi.org/10.3390/ma13183997

Wang H, Wu Y, Wei M, Wang L, Cheng B. Hysteretic Behavior of Geopolymer Concrete with Active Confinement Subjected to Monotonic and Cyclic Axial Compression: An Experimental Study. Materials. 2020; 13(18):3997. https://doi.org/10.3390/ma13183997

Chicago/Turabian StyleWang, Huailiang, Yuhui Wu, Min Wei, Lang Wang, and Baoquan Cheng. 2020. "Hysteretic Behavior of Geopolymer Concrete with Active Confinement Subjected to Monotonic and Cyclic Axial Compression: An Experimental Study" Materials 13, no. 18: 3997. https://doi.org/10.3390/ma13183997