An Empirical Approach for the Development of Process Parameters for Laser Powder Bed Fusion

Abstract

:1. Introduction

2. State of the Art

3. Methodology

3.1. Basic Determinations

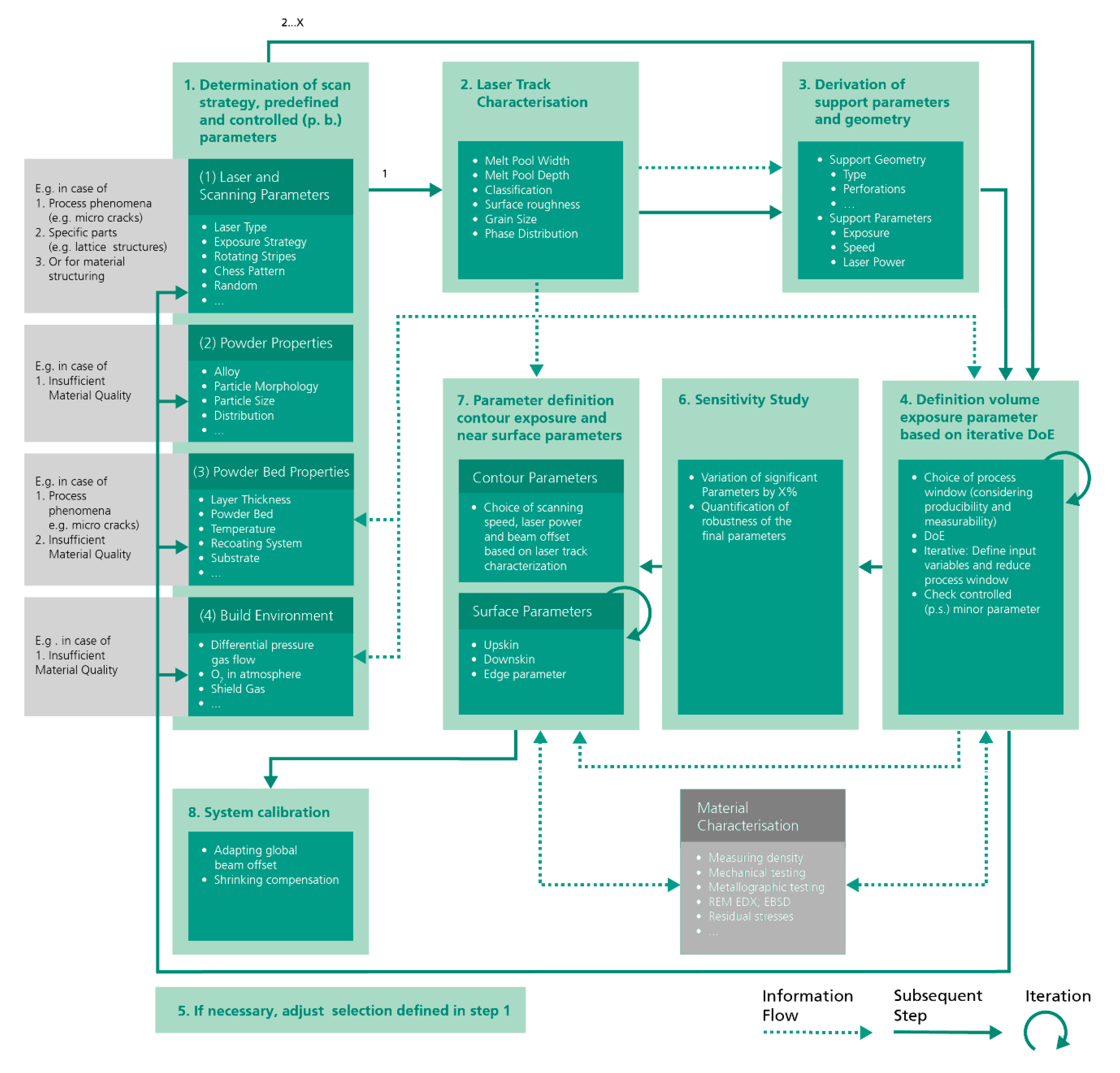

3.2. General Workflow

- Determination of scan strategy, predefined and controlled (per built) parameters;

- Laser track characterization;

- Derivation of support parameters and geometry;

- Definition of volume exposure parameters (by iterative DoE);

- If necessary, adjustment of the selection defined in step 1;

- Sensitivity study;

- Definition of contour exposure and near surface parameters;

- System calibration and compensation of shrink factors.

3.3. Single Workflow Steps

3.3.1. Step 1: Determination of Scan Strategy, Predefined and Controlled (Per Built) Parameters

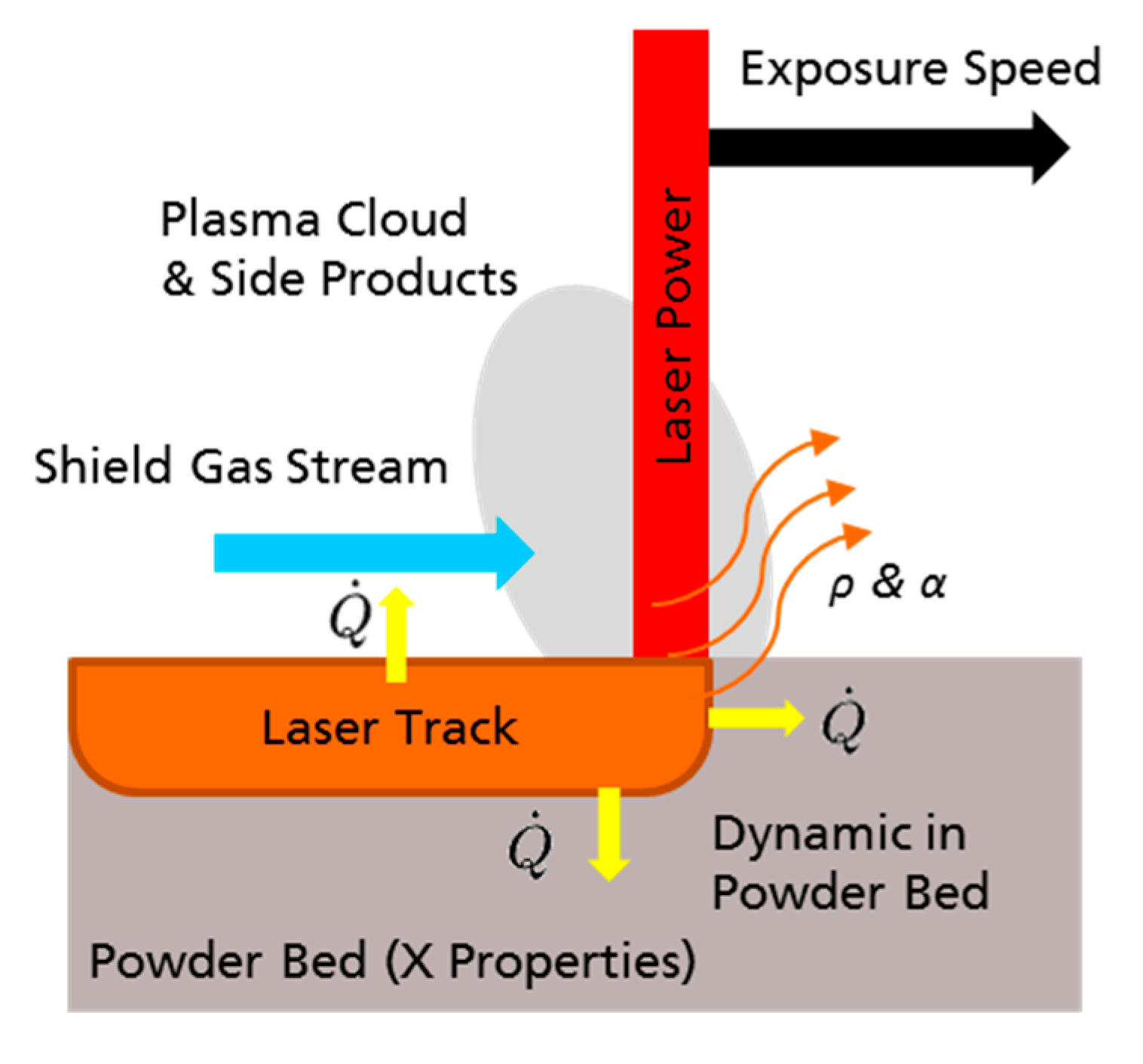

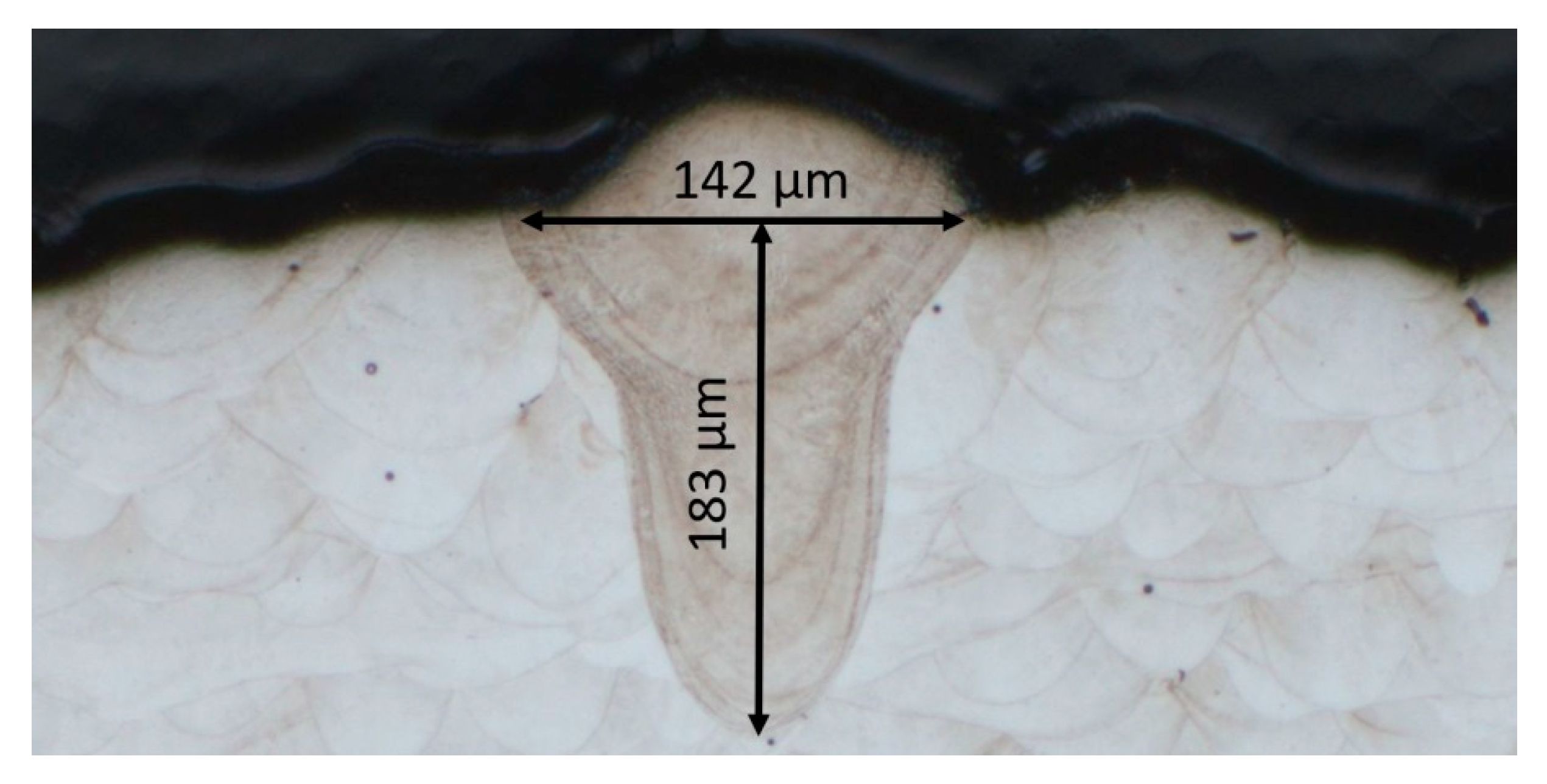

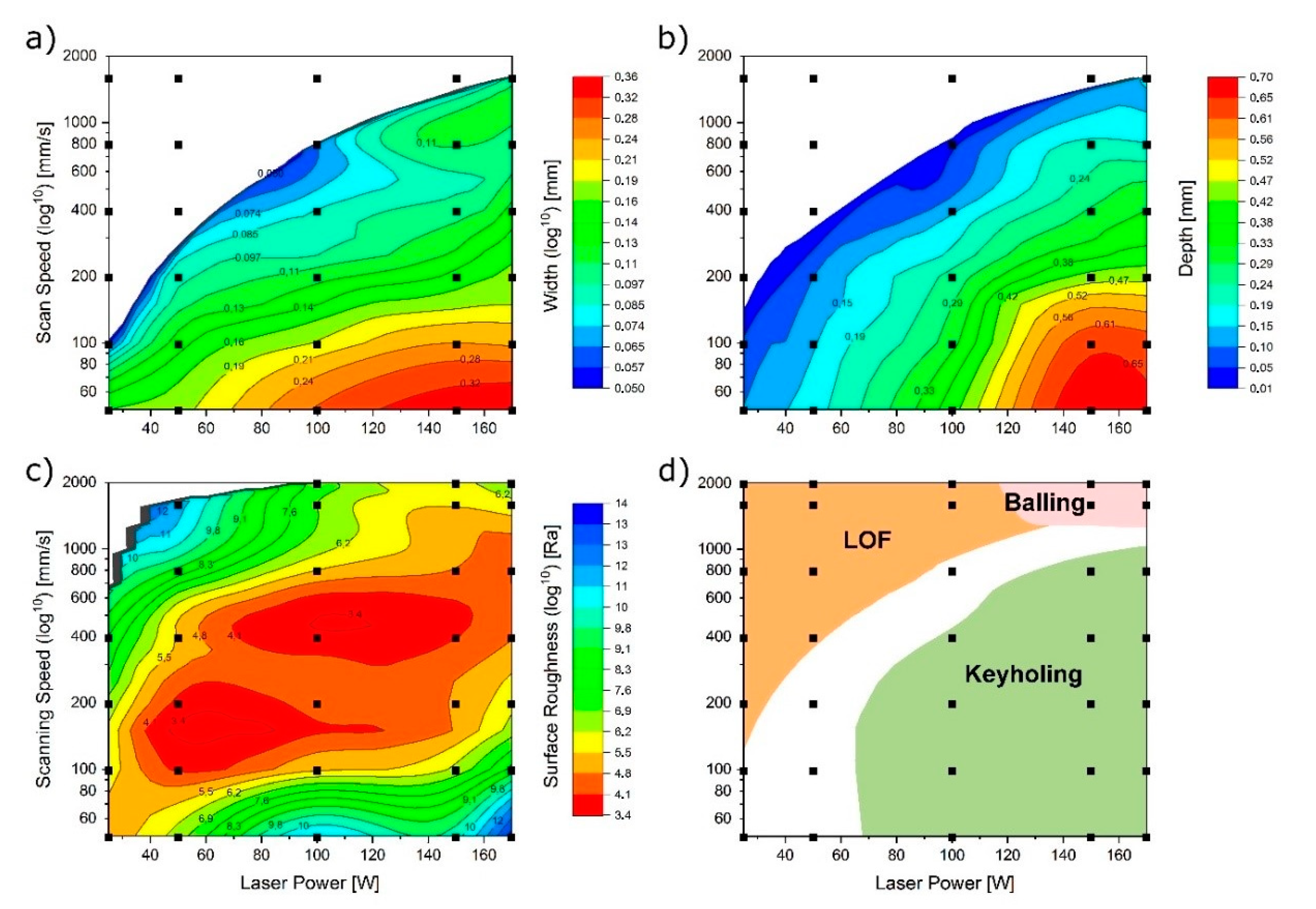

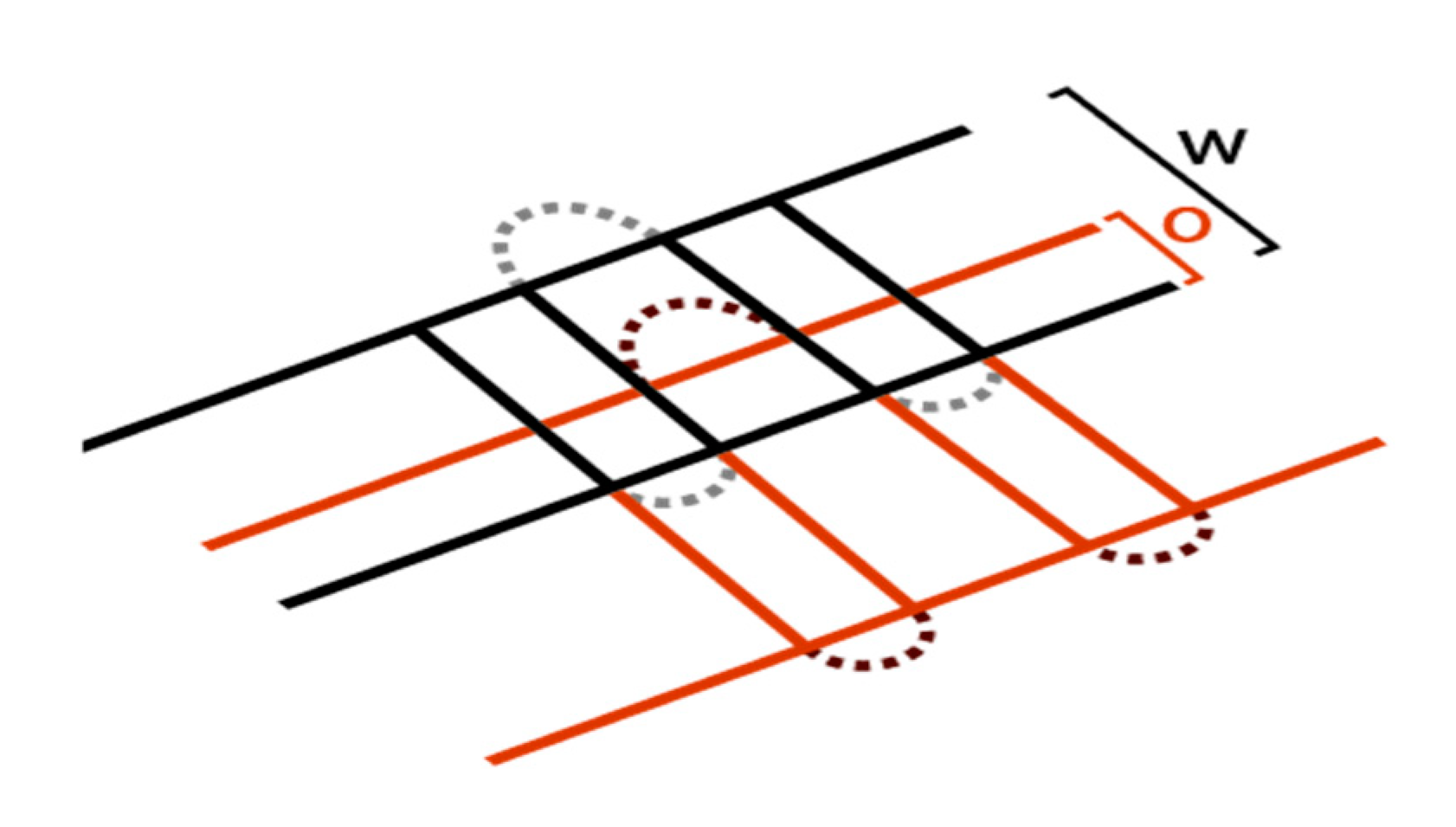

3.3.2. Step 2: Laser Track Characterization

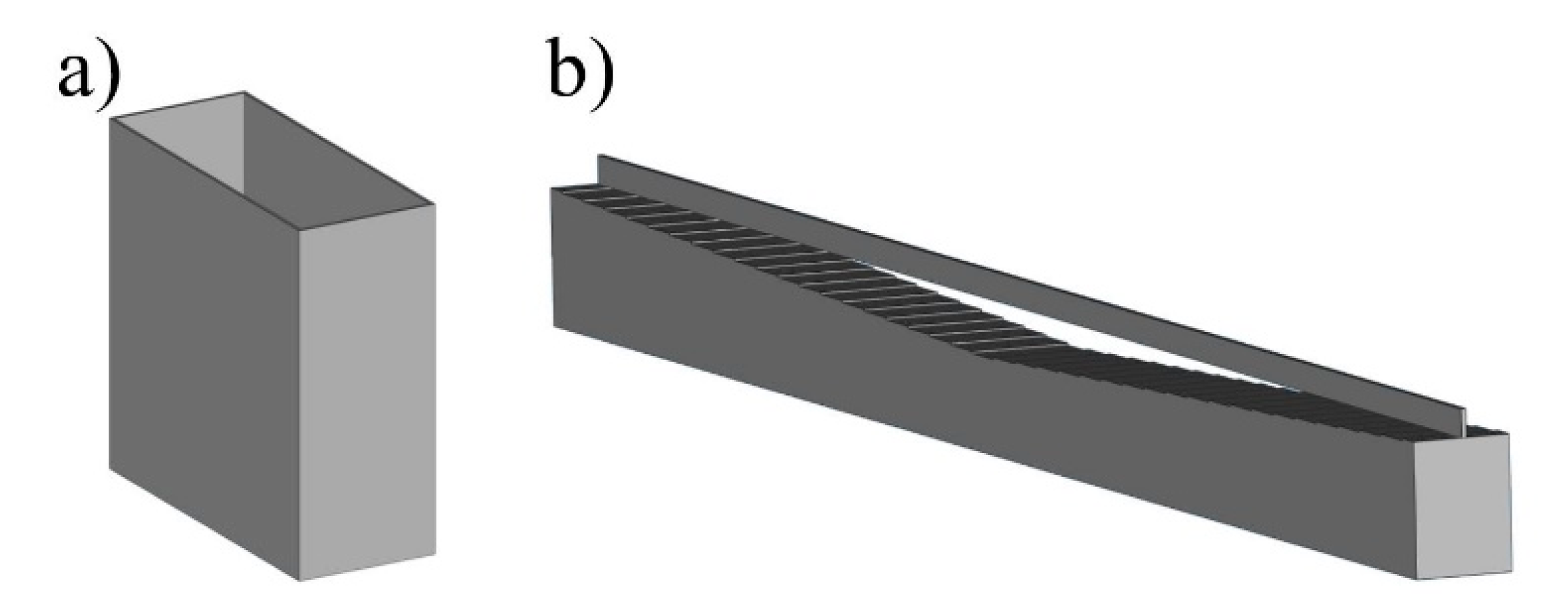

3.3.3. Step 3: Derivation of Support Parameters and Geometry

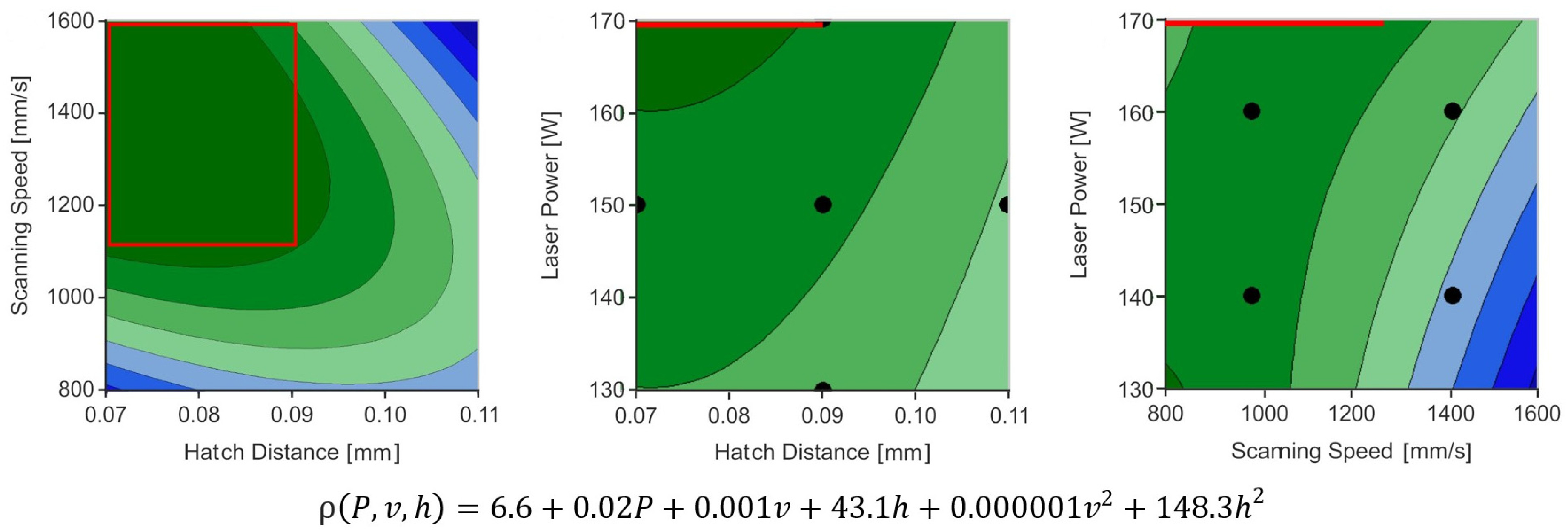

3.3.4. Step 4: Definition Volume Exposure Parameter (by Iterative DoE)

- Choice of process window based on suitable major controlled (p.s.) main parameters: laser power, scanning speed and hatching.

- DoE: Central Composite Design (CCC).

- Limit variables and reduce process window.

- Check controlled (p.s.) minor parameter.

3.3.5. Step 5: If Necessary, Adjust the Selection Defined in Step 1

3.3.6. Step 6: Sensitivity Study

3.3.7. Step 7: Definition of Contour Exposure and Near-Surface Parameters

3.3.8. Step 8: System Calibration and Compensation Shrink Factors

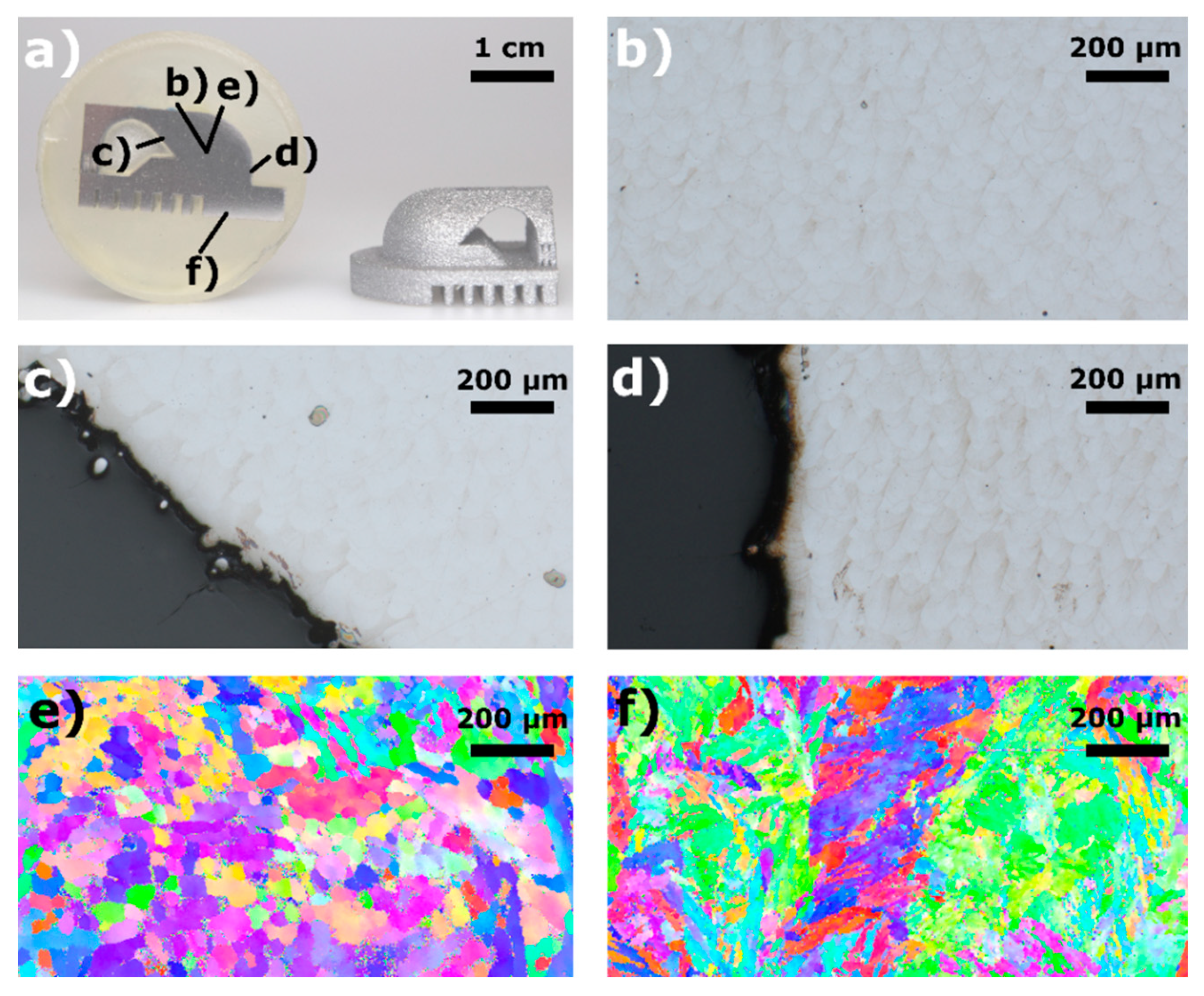

3.4. Validation of the Resulting Material Quality

4. Extended Fields of Application

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wohlers, T.T.; Caffrey, T.; Campbell, R.I. Wohlers Report 2016: 3D Printing and Additive Manufacturing State of the Industry: Annual Worldwide Progress Report, 21st ed.; Wohlers Associates: Fort Collins, CO, USA, 2016. [Google Scholar]

- Bajaj, P.; Hariharan, A.; Kini, A.; Kürnsteiner, P.; Raabe, D.; Jägle, E.A. Steels in additive manufacturing: A review of their microstructure and properties. Mater. Sci. Eng. A 2020, 772, 138633. [Google Scholar] [CrossRef]

- Fayazfar, H.; Salarian, M.; Rogalsky, A.; Sarker, D.; Russo, P.; Paserin, V.; Toyserkani, E. A critical review of powder-based additive manufacturing of ferrous alloys: Process parameters, microstructure and mechanical properties. Mater. Des. 2018, 144, 98–128. [Google Scholar] [CrossRef]

- Spears, T.G.; Gold, S.A. In-process sensing in selective laser melting (SLM) additive manufacturing. Integr. Mater. Manuf. Innov. 2016, 5, 16–40. [Google Scholar] [CrossRef] [Green Version]

- Yadroitsev, I. Selective Laser Melting: Direct Manufacturing of 3D-Objects by Selective Laser Melting of Metal Powders; Lambert Academic Publishing: Saarbrücken, Germany, 2009. [Google Scholar]

- van Elsen, M. Complexity of Selective Laser Melting: A New Optimisation Approach; Katholieke Universiteit Leuven–Faculteit Ingenieurswetenschappen Arenbergkasteel: Heverlee, Belgium, 2007; ISBN 978-90-5682-768-7. [Google Scholar]

- Yadroitsev, I.; Bertrand, P.; Smurov, I. Parametric analysis of the selective laser melting process. Appl. Surf. Sci. 2007, 253, 8064–8069. [Google Scholar] [CrossRef]

- Kamath, C.; El-dasher, B.; Gallegos, G.F.; King, W.E.; Sisto, A. Density of additively-manufactured, 316L SS parts using laser powder-bed fusion at powers up to 400 W. Int. J. Adv. Manuf. Technol. 2014, 74, 65–78. [Google Scholar] [CrossRef] [Green Version]

- Delgado, J.; Ciurana, J.; Rodríguez, C.A. Influence of process parameters on part quality and mechanical properties for DMLS and SLM with iron-based materials. Int. J. Adv. Manuf. Technol. 2012, 60, 601–610. [Google Scholar] [CrossRef]

- Enneti, R.K.; Morgan, R.; Wolfe, T. Direct Metal Laser Sintering (DMLS)/Selective Laser Melting (SLM) of Tungsten Powders. In Proceedings of the AMPM 2017, Las Vegas, NV, USA, 13–15 June 2017. [Google Scholar]

- Scipioni Bertoli, U.; Wolfer, A.J.; Matthews, M.J.; Delplanque, J.-P.R.; Schoenung, J.M. On the limitations of Volumetric Energy Density as a design parameter for Selective Laser Melting. Mater. Des. 2017, 113, 331–340. [Google Scholar] [CrossRef] [Green Version]

- Prashanth, K.G.; Scudino, S.; Maity, T.; Das, J.; Eckert, J. Is the energy density a reliable parameter for materials synthesis by selective laser melting? Mater. Res. Lett. 2017, 5, 386–390. [Google Scholar] [CrossRef] [Green Version]

- Niu, P.D.; Li, R.D.; Yuan, T.C.; Zhu, S.Y.; Chen, C.; Wang, M.B.; Huang, L. Microstructures and properties of an equimolar AlCoCrFeNi high entropy alloy printed by selective laser melting. Intermetallics 2019, 104, 24–32. [Google Scholar] [CrossRef]

- Li, R.; Niu, P.; Yuan, T.; Cao, P.; Chen, C.; Zhou, K. Selective laser melting of an equiatomic CoCrFeMnNi high-entropy alloy: Processability, non-equilibrium microstructure and mechanical property. J. Alloy. Compd. 2018, 746, 125–134. [Google Scholar] [CrossRef]

- Gu, D.D.; Meiners, W.; Wissenbach, K.; Poprawe, R. Laser additive manufacturing of metallic components: Materials, processes and mechanisms. Int. Mater. Rev. 2013, 57, 133–164. [Google Scholar] [CrossRef]

- Dilip, J.J.S.; Zhang, S.; Teng, C.; Zeng, K.; Robinson, C.; Pal, D.; Stucker, B. Influence of processing parameters on the evolution of melt pool, porosity, and microstructures in Ti-6Al-4V alloy parts fabricated by selective laser melting. Prog. Addit. Manuf. 2017, 2, 157–167. [Google Scholar] [CrossRef] [Green Version]

- Gong, H.; Gu, H.; Zeng, K.; Dilip, J.J.S.; Pal, D.; Stucker, B.; Christiansen, D.; Beuth, J.; Lewandowski, J.J. Melt Pool Characterization for Selective Laser Melting of Ti-6Al-4V Pre-alloyed Powder. In Proceedings of the 25th Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 4–6 August 2014; pp. 256–267. [Google Scholar]

- Pfaff, A.; Jäcklein, M.; Hoschke, K.; Wickert, M. Designed Materials by Additive Manufacturing—Impact of Exposure Strategies and Parameters on Material Characteristics of AlSi10Mg Processed by Laser Beam Melting. Metals 2018, 8, 491. [Google Scholar] [CrossRef] [Green Version]

- Kempen, K.; Thijs, L.; Yasa, E.; Badrossamay, M.; Verheecke, W.; Kruth, J.P. Process Optimization and Microstructural Analysis for Selective Laser Melting of AlSi10Mg. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 8–10 August 2011; pp. 484–495. [Google Scholar]

- Wits, W.W.; Bruins, R.; Terpstra, L.; Huls, R.A.; Geijselaers, H.J.M. Single scan vector prediction in selective laser melting. Addit. Manuf. 2016, 9, 1–6. [Google Scholar] [CrossRef]

- Sadowski, M.; Ladani, L.; Brindley, W.; Romano, J. Optimizing quality of additively manufactured Inconel 718 using powder bed laser melting process. Addit. Manuf. 2016, 11, 60–70. [Google Scholar] [CrossRef]

- Xiong, W.; Hao, L.; Li, Y.; Tang, D.; Cui, Q.; Feng, Z.; Yan, C. Effect of selective laser melting parameters on morphology, microstructure, densification and mechanical properties of supersaturated silver alloy. Mater. Des. 2019, 170, 107697. [Google Scholar] [CrossRef]

- Kempen, K.; Thijs, L.; van Humbeeck, J.; Kruth, J.-P. Mechanical Properties of AlSi10Mg Produced by Selective Laser Melting. Phys. Procedia 2012, 39, 439–446. [Google Scholar] [CrossRef] [Green Version]

- Seede, R.; Shoukr, D.; Zhang, B.; Whitt, A.; Gibbons, S.; Flater, P.; Elwany, A.; Arroyave, R.; Karaman, I. An ultra-high strength martensitic steel fabricated using selective laser melting additive manufacturing: Densification, microstructure, and mechanical properties. Acta Mater. 2020, 186, 199–214. [Google Scholar] [CrossRef]

- Madison, J.D.; Aagesen, L.K. Quantitative characterization of porosity in laser welds of stainless steel. Scr. Mater. 2012, 67, 783–786. [Google Scholar] [CrossRef]

- Johnson, L.; Mahmoudi, M.; Zhang, B.; Seede, R.; Huang, X.; Maier, J.T.; Maier, H.J.; Karaman, I.; Elwany, A.; Arróyave, R. Assessing Printability Maps in Additive Manufacturing of Metal Alloys. Acta Mater. 2019, 176, 199–210. [Google Scholar] [CrossRef]

- Childs, T.H.C.; Hauser, C.; Badrossamay, M. Mapping and Modelling Single Scan Track Formation in Direct Metal Selective Laser Melting. CIRP Ann. 2004, 53, 191–194. [Google Scholar] [CrossRef]

- Chandrasekhar, S. Hydrodynamic and Hydromagnetic Stability; Dover Publications Inc: New York, NY, USA, 2013; ISBN 978-0486640716. [Google Scholar]

- Yadroitsev, I.; Gusarov, A.; Yadroitsava, I.; Smurov, I. Single track formation in selective laser melting of metal powders. J. Mater. Process. Technol. 2010, 210, 1624–1631. [Google Scholar] [CrossRef]

- Letenneur, M.; Kreitcberg, A.; Brailovski, V. Optimization of Laser Powder Bed Fusion Processing Using a Combination of Melt Pool Modeling and Design of Experiment Approaches: Density Control. J. Manuf. Mater. Process 2019, 3, 21. [Google Scholar] [CrossRef] [Green Version]

- Rashid, R.; Masood, S.H.; Ruan, D.; Palanisamy, S.; Rahman Rashid, R.A.; Brandt, M. Effect of scan strategy on density and metallurgical properties of 17-4PH parts printed by Selective Laser Melting (SLM). J. Mater. Process. Technol. 2017, 249, 502–511. [Google Scholar] [CrossRef]

- Foroozmehr, A.; Badrossamay, M.; Foroozmehr, E.; Golabi, S.I. Finite Element Simulation of Selective Laser Melting process considering Optical Penetration Depth of laser in powder bed. Mater. Des. 2016, 89, 255–263. [Google Scholar] [CrossRef]

- Pfaff, A.; Jäcklein, M.; Hoschke, K.; Wickert, M. LBM Process Parameter Optimization for Designed Materials. In Proceedings of the Direct Digital Manufacturing Conference, Berlin, Germany, 14–15 March 2018; Fraunhofer Verlag: Stuttgart, Germany, 2018. ISBN 9783839613207. [Google Scholar]

- Popovich, V.A.; Borisov, E.V.; Sufiyarov, V.S.; Popovich, A.A. Tailoring the Properties in Functionally Graded Alloy Inconel 718 Using Additive Technologies. Met. Sci. Heat Treat. 2019, 60, 701–709. [Google Scholar] [CrossRef]

- Popovich, V.A.; Borisov, E.V.; Popovich, A.A.; Sufiiarov, V.S.; Masaylo, D.V.; Alzina, L. Functionally graded Inconel 718 processed by additive manufacturing: Crystallographic texture, anisotropy of microstructure and mechanical properties. Mater. Des. 2017, 114, 441–449. [Google Scholar] [CrossRef]

- Mani, M.; Lane, B.; Donmez, A.; Feng, S.; Moylan, S.; Fesperman, R. Measurement Science Needs for Real-Time Control of Additive Manufacturing Powder Bed Fusion Processes; NISTIR 8036; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2015.

- Siebertz, K.; van Bebber, D.; Hochkirchen, T. Statistische Versuchsplanung. Design of Experiments (DOE); Springer: Heidelberg, Germany, 2010. [Google Scholar]

- Undurchlässige Sintermetallwerkstoffe und Hartmetalle—Ermittlung der Dichte (ISO 3369:2006); Deutsche Fassung EN ISO 3369:2010; Beuth Verlag GmbH: Berlin, Germany, 2010.

- Spierings, A.B.; Voegtlin, M.; Bauer, T.; Wegener, K. Powder flowability characterisation methodology for powder-bed-based metal additive manufacturing. Prog. Addit. Manuf. 2016, 1, 9–20. [Google Scholar] [CrossRef] [Green Version]

- Kasperovich, G.; Haubrich, J.; Gussone, J.; Requena, G. Correlation between porosity and processing parameters in TiAl6V4 produced by selective laser melting. Mater. Des. 2016, 105, 160–170. [Google Scholar] [CrossRef] [Green Version]

- Hrbáčková, T.; Simson, T.; Koch, J.; Wolf, G. The effect of heat treatment on mechanical properties and microstructure of additively manufactured components. In Proceedings of the 5th International Conference Recent Trends in Structural Materials, Pilsen, Czech Republic, 14–16 November 2018; Volume 461, p. 012026. [Google Scholar] [CrossRef]

- Metallische Werkstoffe—Zugversuch—Teil 1: Prüfverfahren bei Raumtemperatur (ISO 6892-1:2009); Deutsche Fassung EN ISO 6892-1:2009; Beuth Verlag GmbH: Berlin, Germany, 2009.

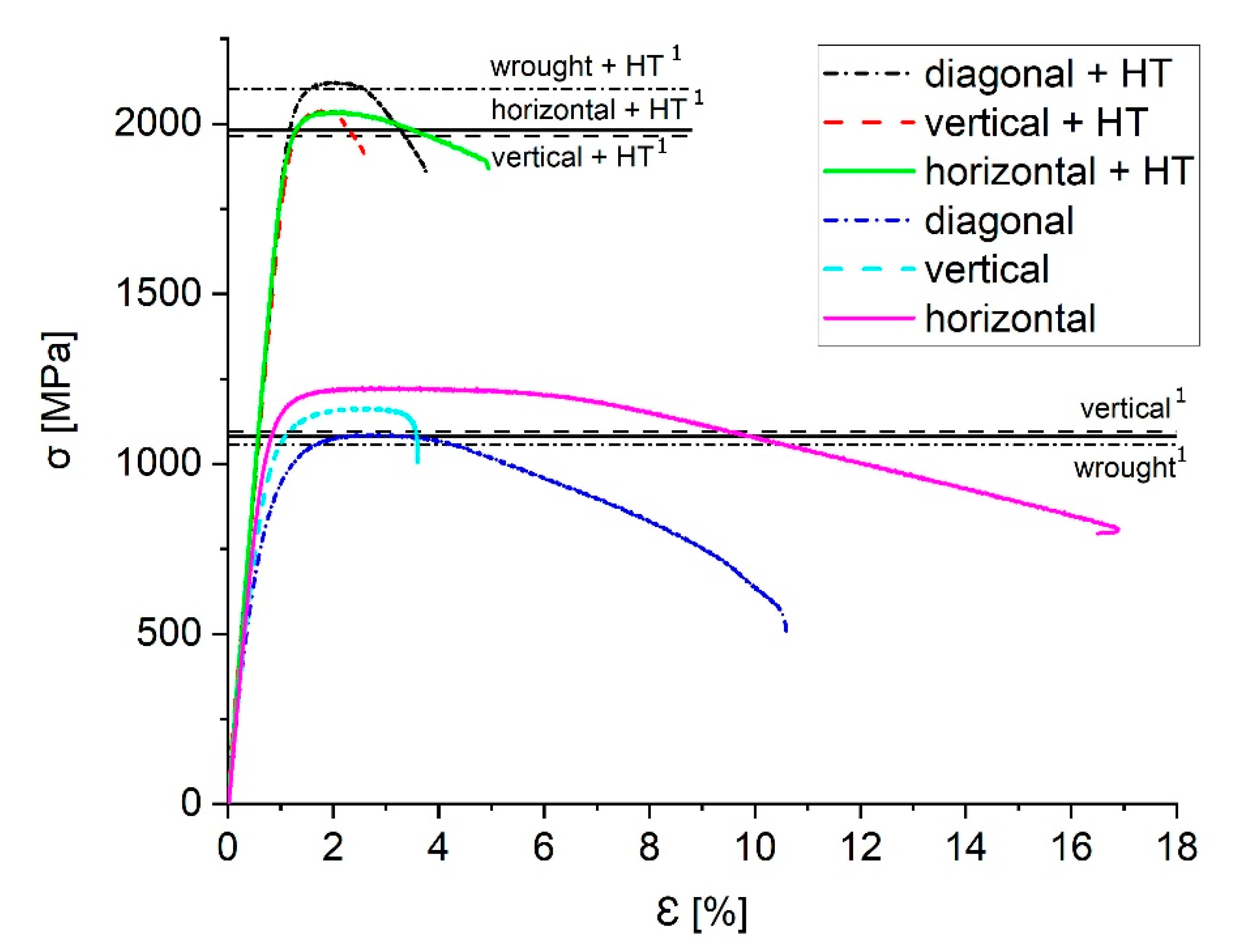

- Simson, T.; Koch, J.; Rosenthal, J.; Kepka, M.; Zetek, M.; Zetková, I.; Wolf, G.; Tomčík, P.; Kulhánek, J. Mechanical Properties of 18Ni-300 maraging steel manufactured by LPBF. Procedia Struct. Integr. 2019, 17, 843–849. [Google Scholar] [CrossRef]

| Alloy | Achieved Relative Density |

|---|---|

| Pure Tungsten 1 (t = 20 µm) | 99.51% (σ = 0.018) |

| Pure Tantalum 1 (t = 20 µm) | 99.99% (σ = 0.022) |

| MS1 1 (t = 30 µm) | 99.52% (σ = 0.048) |

| AlSi10Mg 2 (t = 90 µm) | 99.18% (σ = 0.091) |

| Scalmalloy® 2 (t = 60 µm) | 99.69% (σ = 0.197) |

| 1.6947 1 (t = 30 µm) | 99.55% (σ = 0.056) |

| Parameter | Value | Type | |

|---|---|---|---|

| Class: (1) Laser and Scanning Parameters | |||

| Mode | Continuous wave | Predefined (m.s.) | |

| Wavelength λ | 1070 nm | Predefined (m.s.) | |

| Beam Product | <2 | Predefined (m.s.) | |

| Beam quality M2 | <1.1 | Predefined (m.s.) | |

| Intensity profile I | See report | Predefined (m.s.) | |

| Spot size | 40 µm | Predefined (m.s.) | |

| Laser power | tbd | Controlled (p.s.) | |

| Scan speed | tbd | Controlled (p.s.) | |

| Hatch spacing | tbd | Controlled (p.s.) | |

| Scan strategy | Stripes and surface | Controlled (p.b.) | |

| Stripes | Stripe width | tbd | Controlled (p.s.) |

| Stripe overlap | tbd | Controlled (p.s.) | |

| Rotation | tbd | Controlled (p.s.) | |

| Beam Offset stripes | tbd | Controlled (p.s.) | |

| Contour | Laser power | tbd | Controlled (p.s.) |

| Scan speed | tbd | Controlled (p.s.) | |

| Beam Offset Contour | tbd | Controlled (p.s.) | |

| Downskin | Laser power | tbd | Controlled (p.s.) |

| Scan speed | tbd | Controlled (p.s.) | |

| Stripe width | tbd | Controlled (p.s.) | |

| Beam Offset Donwskin | tbd | Controlled (p.s.) | |

| Class: (2) Powder Material Properties | |||

| Alloy | 1.2709 | Predefined (u.m.) | |

| Particle morphology | Spherical | Predefined (u.m.) | |

| PSD (ASTM-B822) | D10: 17 µm D50: 31 µm D90: 54 µm | Predefined (u.m.) | |

| Pollution | Virgin | Predefined (u.m.) | |

| Tap density | 5.2 g/cm3 | Predefined (u.m.) | |

| Class: (3) Powder Bed Properties and Recoat Parameters | |||

| Layer thickness | 30 µm | Controlled (p.b.) | |

| Powder bed temperature | Set to room temperature | Controlled (p.b.) | |

| Recoater system | Flexible blade (PU) | Controlled (p.b.) | |

| Recoater speed | 0.1 m/s | Controlled (p.b.) | |

| Alloy substrate | Steel (C45/AISI 1045) | Controlled (p.b.) | |

| Class: (4) Build Environment Parameters | |||

| Shield Gas | Argon | Predefined (u.m.) | |

| Max. Oxygen | 0.1% | Controlled (p.b.) | |

| Overpressure | 35 mbar | Predefined (m.s.) | |

| Gas flow | 60% | Predefined (m.s.) | |

| Global Offset | tbd | Controlled (p.b.) | |

| Shrinking compensation | tbd | Controlled (p.b.) | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pfaff, A.; Jäcklein, M.; Schlager, M.; Harwick, W.; Hoschke, K.; Balle, F. An Empirical Approach for the Development of Process Parameters for Laser Powder Bed Fusion. Materials 2020, 13, 5400. https://doi.org/10.3390/ma13235400

Pfaff A, Jäcklein M, Schlager M, Harwick W, Hoschke K, Balle F. An Empirical Approach for the Development of Process Parameters for Laser Powder Bed Fusion. Materials. 2020; 13(23):5400. https://doi.org/10.3390/ma13235400

Chicago/Turabian StylePfaff, Aron, Martin Jäcklein, Max Schlager, Wilfried Harwick, Klaus Hoschke, and Frank Balle. 2020. "An Empirical Approach for the Development of Process Parameters for Laser Powder Bed Fusion" Materials 13, no. 23: 5400. https://doi.org/10.3390/ma13235400