Influence of Fine Grains on the Bending Fatigue Behavior of Two Implant Titanium Alloys

Abstract

:1. Introduction

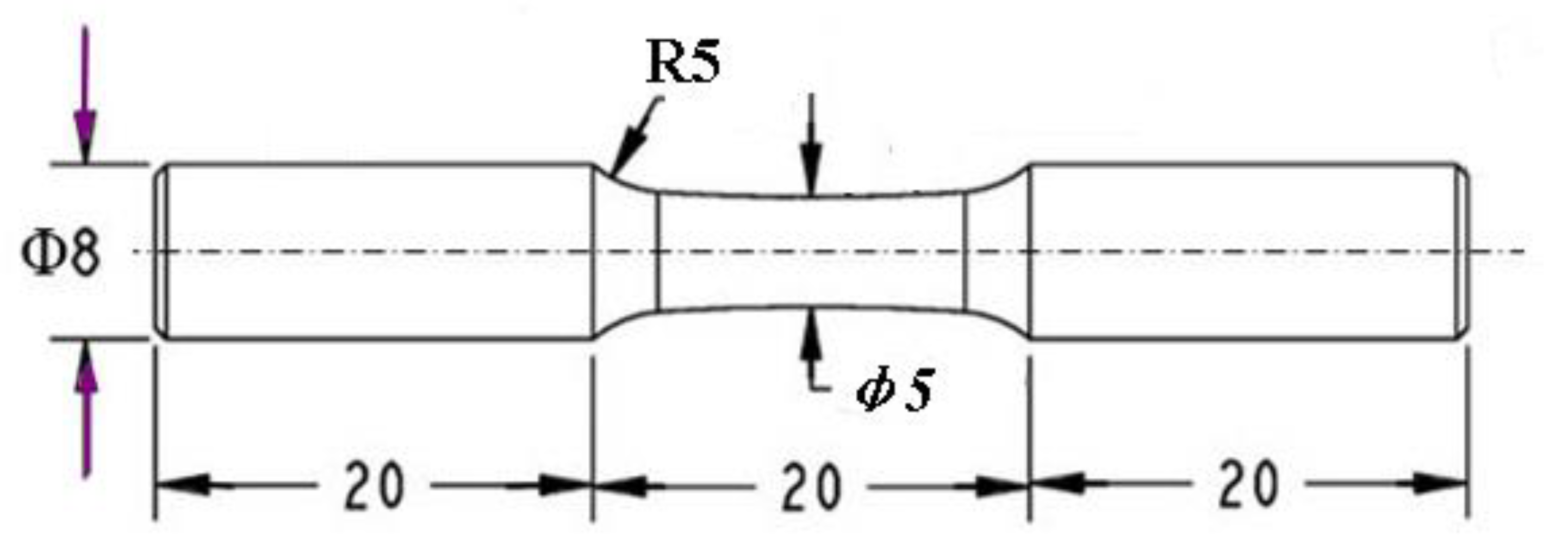

2. Experimental Procedures

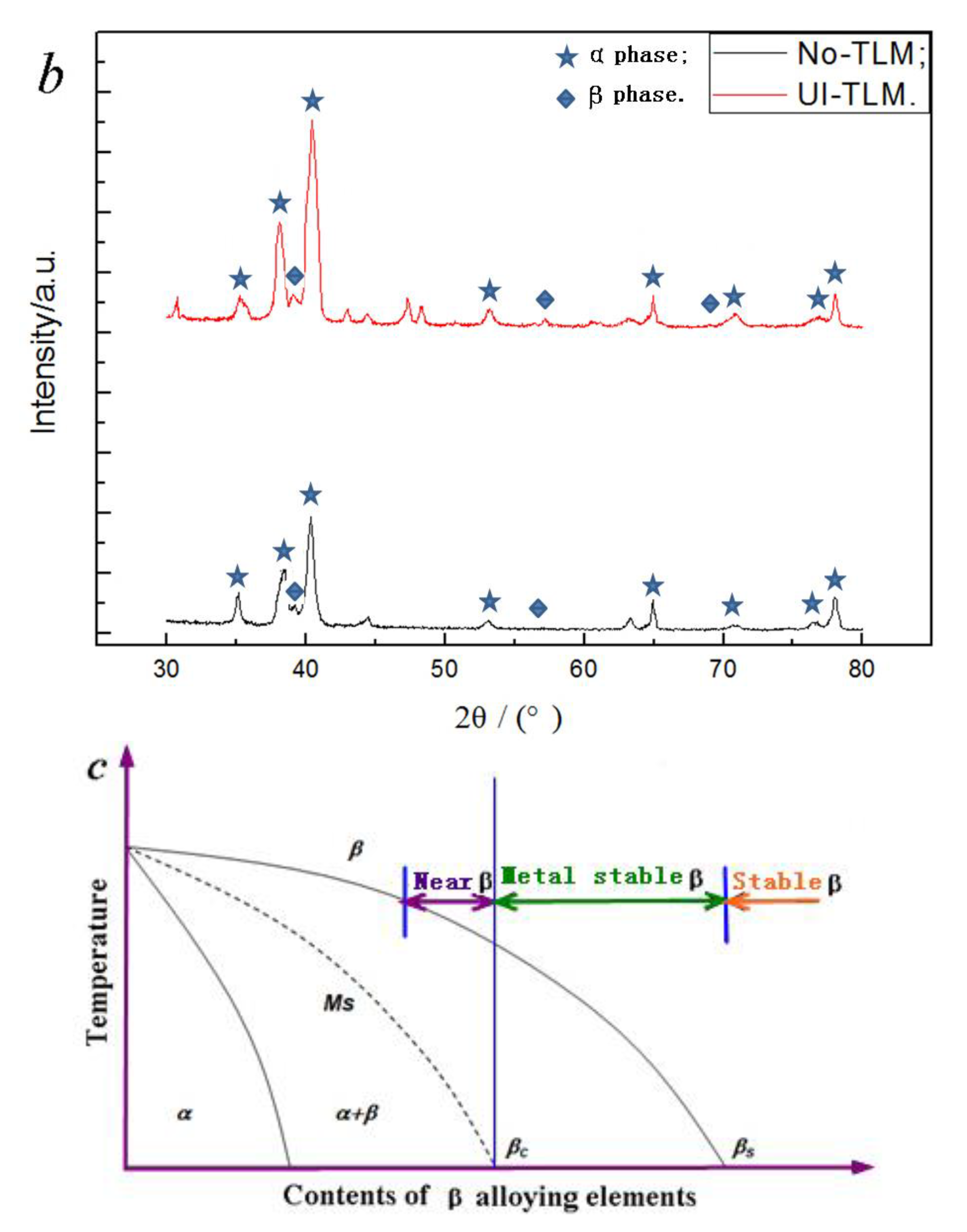

3. Results and Discussion

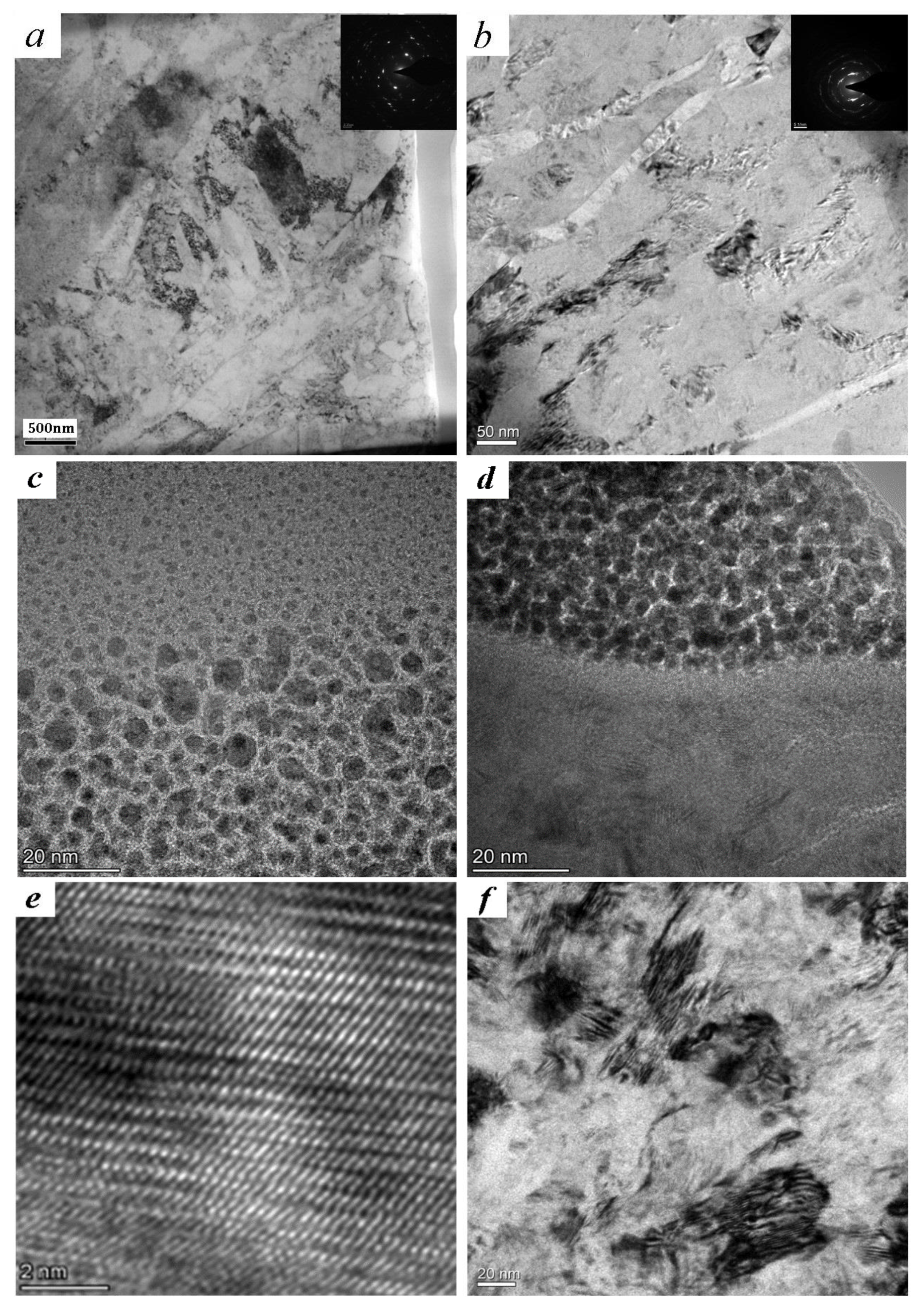

3.1. Observation of the Severe Plastic Deformation Layer

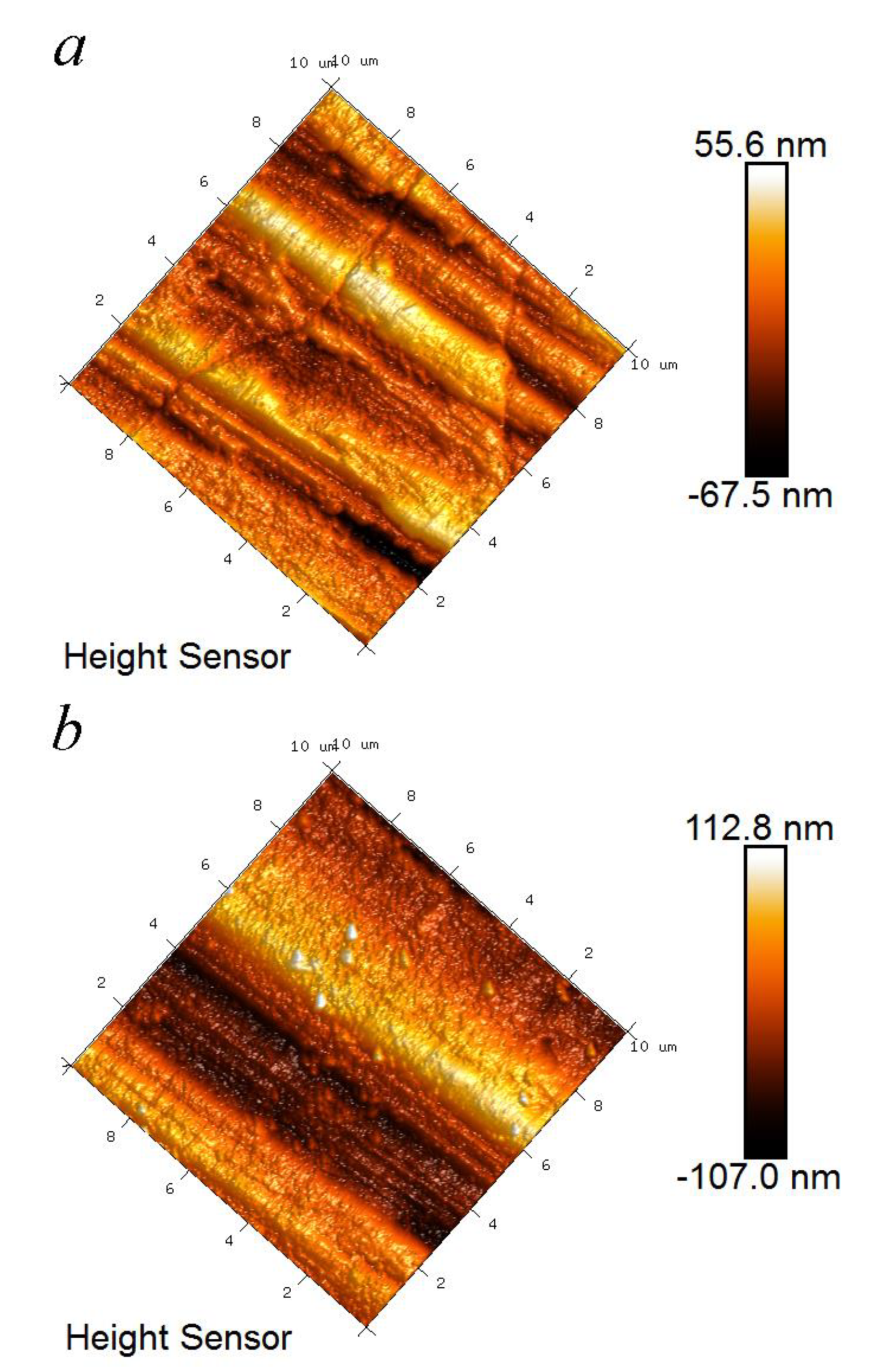

3.2. Surface Investigation

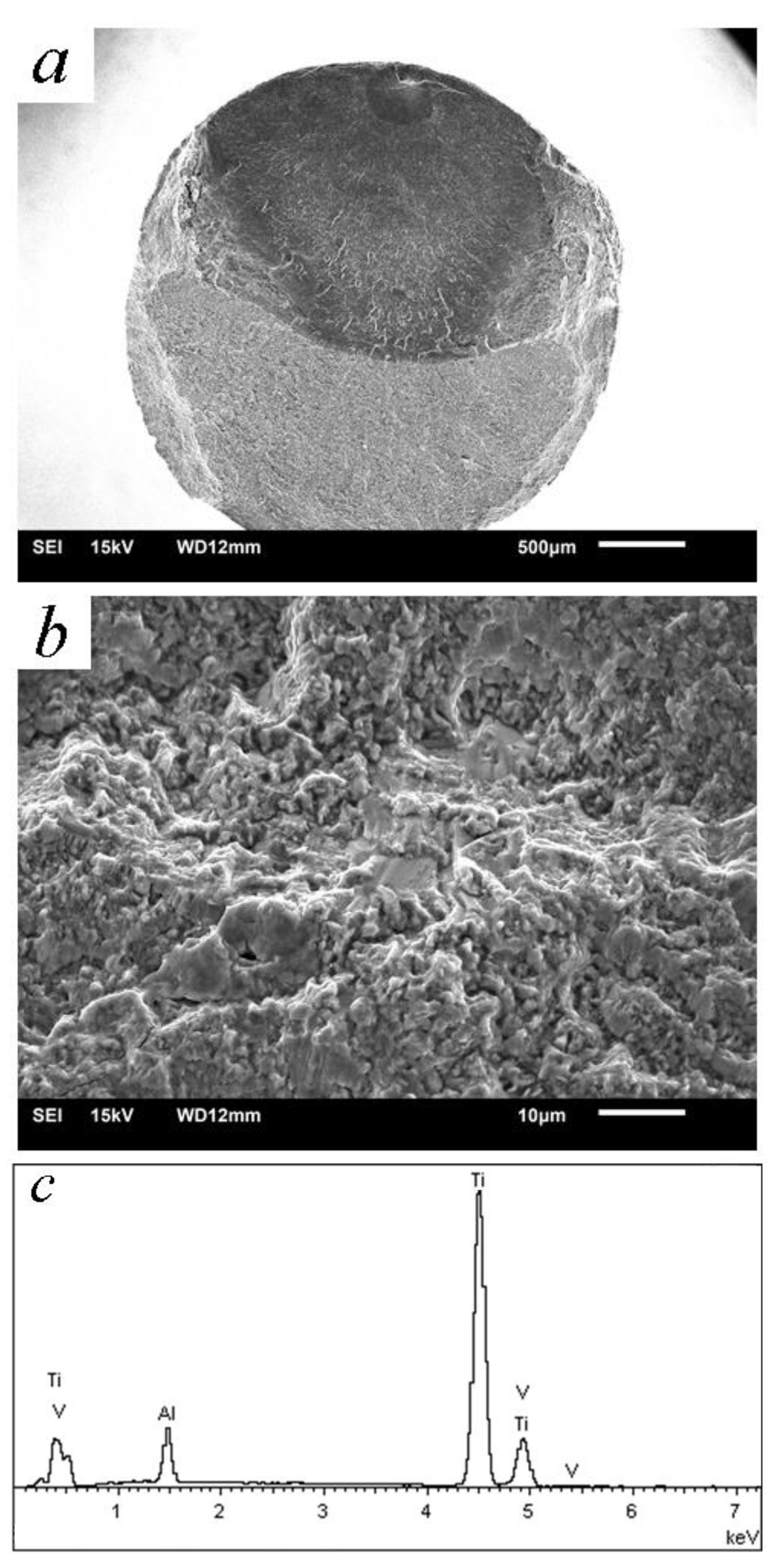

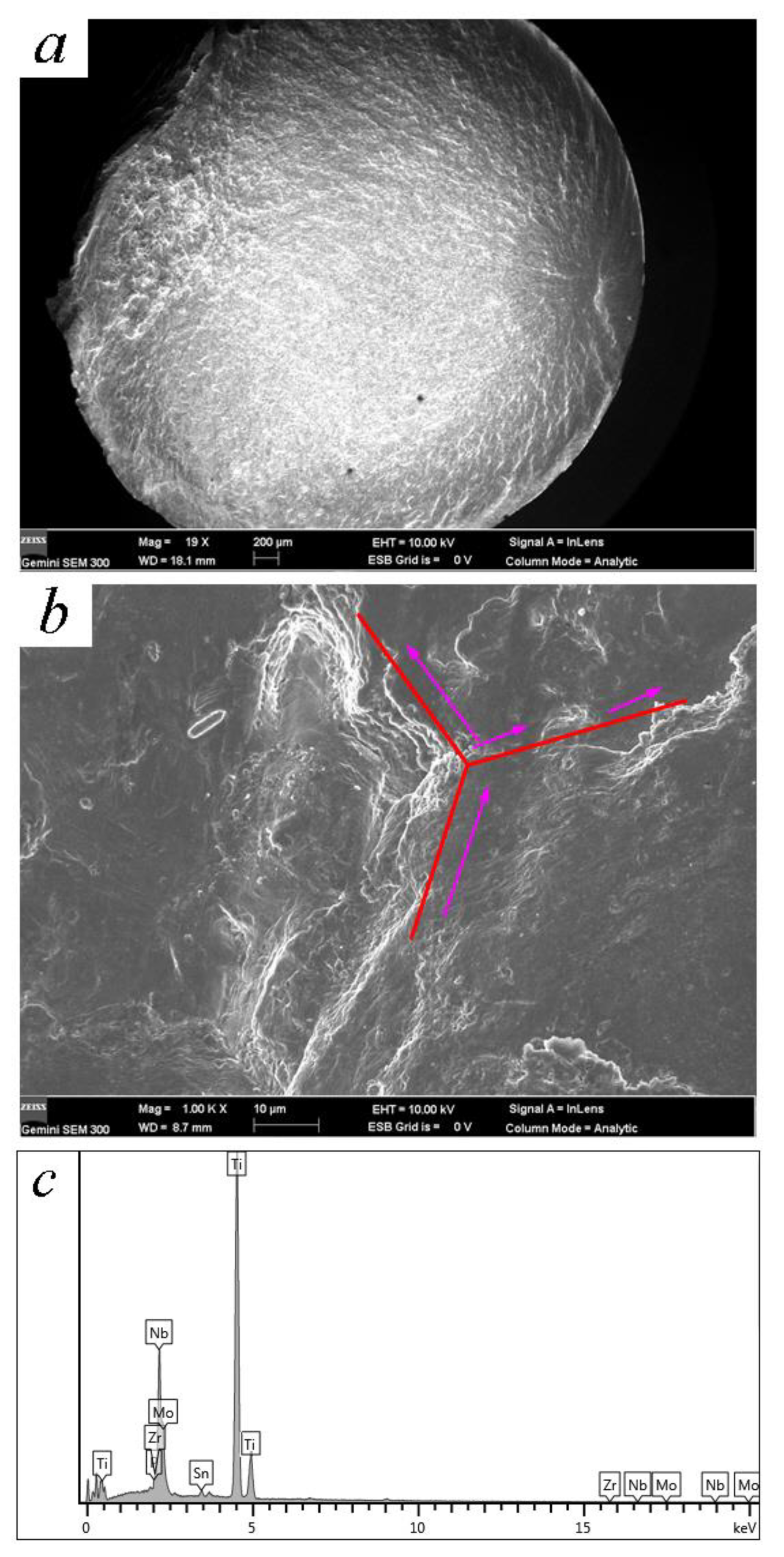

3.3. Fatigue Characteristics

3.4. Mechanical Stratification Model Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Singh, S.; Singh, G.; Bala, N. Electrophoretic deposition of hydroxyapatite-iron oxide-chitosan composite coatings on Ti–13Nb–13Zr alloy for biomedical applications. Thin Solid Film. 2020, 697, 137801. [Google Scholar] [CrossRef]

- Im, Y.D.; Lee, Y.K.; Song, K.H. Effect of grain misorientation angle on twinning propagation in Ti–15Mo alloy. Met. Mater. Int. 2018, 24, 913–917. [Google Scholar] [CrossRef]

- Yang, X.Y.; Hutchinson, C.R. Corrosion-wear of β-Ti alloy TMZF (Ti-12Mo-6Zr-2Fe) in simulated body fluid. Acta Biomater. 2016, 42, 429–439. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Castany, P.; Hao, Y.L.; Gloriant, T. Plastic deformation via hierarchical nano-sized martensitic twinning in the metastable β Ti-24Nb-4Zr-8Sn alloy. Acta Mater. 2020, 194, 27–39. [Google Scholar] [CrossRef]

- Cao, X.J.; Wu, C.J.; Gu, Z.Y.; Chen, Q.; Fukushima, Y.; Liu, Y.J.; Wang, Q.Y. Research status and process on ultrasonic impact nanocrystallization. Surf. Technol. 2019, 48, 113. [Google Scholar]

- Yu, Z.T.; Yu, S.; Cheng, J.; Ma, X. Development and application of novel biomedical titanium alloy materials. Acta Metall. Sin. 2017, 53, 1238–1264. [Google Scholar]

- Bloyce, A.; Morton, P.; Bell, T. ASM Handbook; ASM International: Materials Park, OH, USA, 1994. [Google Scholar]

- Maawad, E.; Sano, Y.; Wagner, L.; Brokmeier, H.; Genzel, C. Investigation of laser shock peening effects on residual stress state and fatigue performance of titanium alloys. Mater. Sci. Eng. A 2012, 536, 82–91. [Google Scholar] [CrossRef]

- Portella, Q.; Chenkhi, M.; Retaint, D. Influence of surface mechanical attrition treatment (SMAT) post-treatment on microstructural, mechanical and tensile behaviour of additive manufactured AISI 316L. Mater. Charact. 2020, 167, 110463. [Google Scholar] [CrossRef]

- Ao, N.; Liu, D.X.; Xu, X.; Zhang, X.; Liu, D. Gradient nanostructure evolution and phase transformation of α phase in Ti-6Al-4V alloy induced by ultrasonic surface rolling process. Surf. Coat. Technol. 2019, 742, 820–834. [Google Scholar] [CrossRef]

- Li, N.B.; Sun, S.J.; Bai, H.Y.; Xu, W.; Xiao, G.; Zhang, Y.; Lu, Y. Effect of ultrasonic shot peening on the evolution of nano/submicro-scale oxide structures on Ti6Al4V achieved by an ultrasonic shot peening-induction heating approach for high-performance surface design of bone implants. J. Alloys Compd. 2020, 831, 154876. [Google Scholar] [CrossRef]

- Liu, H.L.; Tong, Z.P.; Zhou, W.F.; Yang, Y.; Jiao, J.; Ren, X. Improving electrochemical corrosion properties of AZ31 magnesium alloy via phosphate conversion with laser shock peening pretreatment. J. Alloys Compd. 2020, 846, 155837. [Google Scholar] [CrossRef]

- Sembiring, J.; Amanov, A.; Pyun, Y.S. Artificial neural network-based prediction model of residual stress and hardness of Nickel-based alloys for UNSM parameters optimization. J. Alloys Compd. 2020, 25, 101391. [Google Scholar] [CrossRef]

- Lu, K.; Lu, J. Nanostructured surface layer on metallic materials induced by surface mechanical attrition treatment. Mater. Sci. Eng. A 2004, 375, 38–45. [Google Scholar] [CrossRef] [Green Version]

- Zhu, K.Y.; Vassel, A.; Brisset, F.; Lu, K.; Lu, J. Nanostructure formation mechanism of α-titanium using SMAT. Acta Mater. 2004, 52, 4101–4110. [Google Scholar] [CrossRef]

- Zhang, X.; Lu, S.J.; Tian, X.B.; Kan, Q.; Kang, G. Dislocation-grain boundary interaction-based discrete dislocation dynamics modeling and its application to bicrystals with different misorientations. Acta Mater. 2020, 202, 88–98. [Google Scholar] [CrossRef]

- Amanov, A.; Karimbaev, R.; Maleki, E.; Unal, O.; Pyun, Y.; Amanov, T. Effect of combined shot peening and ultrasonic nanocrystal surface modification processes on the fatigue performance of AISI 304. Surf. Coat. Technol. 2019, 358, 695–705. [Google Scholar] [CrossRef]

- Liu, X.L.; Sun, C.Q.; Hong, Y.S. Effects of stress ratio on high-cycle and very-high-cycle fatigue behavior of a Ti-6Al-4V alloy. Mater. Sci. Eng. A 2015, 622, 228–235. [Google Scholar] [CrossRef]

- Ma, X.Q.; Han, Y.; Yu, Z.T.; Sun, Q.Y.; Niu, J.L.; Yuan, S.B. Phase transformation and mechanical properties of TLM titanium alloy for orthopaedic implant application. Rare Met. Mater. Eng. 2012, 41, 1535–1538. [Google Scholar]

- Leyens, C.; Peters, M. Titanium Andtitanium Alloys: Fundamentals and Applications; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2003. [Google Scholar]

- Cao, X.J.; Murakami, R.; Pyoun, Y.S. Fatigue properties of a S45C steel subjected to ultrasonic nanocrystal surface modification. Appl. Surf. Sci. 2010, 256, 6297–6303. [Google Scholar] [CrossRef]

- Cao, X.J.; Xu, L.P.; Xu, X.L.; Wang, Q. Fatigue fracture characteristics of Ti6Al4V subjected to ultrasonic nanocrystal surface modification. Metals 2018, 8, 77. [Google Scholar] [CrossRef] [Green Version]

- Amanov, A.; Umarov, R. The effects of ultrasonic nanocrystal surface modification temperature on the mechanical properties and fretting wear resistance of Inconel 690alloy. Appl. Surf. Sci. 2018, 441, 515–529. [Google Scholar] [CrossRef]

- Suh, M.S.; Pyun, Y.S.; Suh, C.M. Variation of fatigue properties in nanoskined Ti-6Al-4V rotating bending and axial loading tension-compression cycle. Trans. Korean Soc. Mech. Eng. A 2012, 36, 443–449. [Google Scholar] [CrossRef] [Green Version]

- Kheradmandfard, M.; Farshid, S.; Kim, C.; Hanzaki, A.Z.; Pyoun, Y.; Kim, J.; Amanov, A.; Kim, D. Nanostructured β-type titanium alloy fabricated by ultrasonic nanocrystal surface modification. Ultrason. Sonochem. 2017, 39, 698–706. [Google Scholar] [CrossRef] [PubMed]

- Ye, C.; Telang, A.; Gill, A.S.; Suslov, S.; Idell, Y.; Zweiacker, K.; Wiezorek, J.M.K.; Zhou, Z.; Qian, D.; Mannava, S.R.; et al. Gradient nanostructure and residual stresses induced by Ultrasonic Nano-crystal Surface Modification in 304 austenitic stainless steel for high strength and high ductility. Mater. Sci. Eng. A 2014, 613, 274–288. [Google Scholar] [CrossRef] [Green Version]

- Klug, H.P.; Alexandrov, L.E. X-ray Diffraction Procedures for Polycrystalline and Amorphous Materials, 2nd ed.; Wiley: New York, NY, USA, 1974; p. 662. [Google Scholar]

- Cheng, Z.; Cao, X.J.; Xu, X.L.; Shen, Q.; Yu, T.; Jin, J. Effect of ultrasonic surface impact on the fatigue properties of Ti3Zr2Sn3Mo25Nb. Materials 2020, 13, 2107. [Google Scholar] [CrossRef]

- Malecka, J.; Rozumek, D. Metallographic and Mechanical Research of the O–Ti2AlNb Alloy. Materials 2020, 13, 3006. [Google Scholar] [CrossRef]

- Shen, T.D.; Koch, C.C.; Tsui, T.Y.; Pharr, G.M. On the elastic moduli of crystalline Fe, Cu, Ni and Cu-Ni alloys prepared by mechanical milling/alloying. J. Mater. Res. 1995, 10, 2892–2896. [Google Scholar] [CrossRef]

- Wang, G.F.; Feng, X.Q.; Yu, S.W. Effective elastic modulus and interface effect of nanocrystallne materials. Chin. Sci. Bull. 2002, 17, 1493–1496. [Google Scholar] [CrossRef]

- Zhu, P.S.; He, J.C.; Liao, D.; Wang, Q.; Liu, Y. The effect of notch size on critical distance and fatigue life predictions. Mater. Des. 2020, 196, 109095. [Google Scholar] [CrossRef]

- Liao, D.; Zhu, S.P.; Keshtegar, B.; Qian, G.; Wang, Q. Probabilistic framework for fatigue life assessment of notched components under size effects. Int. J. Mech. Sci. 2020, 181, 105685. [Google Scholar] [CrossRef]

| Material | C | O | N | H | Fe | Mo | V | Al | Zr | Sn | Nb | Ti |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TC4 | 0.006 | 0.192 | 0.008 | 0.001 | 0.02 | — | 4.404 | 6.409 | — | — | — | rest |

| TLM | 0.015 | 0.16 | 0.007 | 0.003 | — | 3.10 | — | — | 3.07 | 2.09 | 24.8 | rest |

| Material | Heat Treatment | σ0.2/MPa | σb/MPa | δ/% | ψ/% |

|---|---|---|---|---|---|

| TC4 | 980 °C/1 h + 650 °C/4 h | 850 | 925 | 16 | 26 |

| TLM | 750 °C/30 min + 510 °C/4 h | 567 | 721 | 19.5 | 71 |

| Material | Hardness (HV, 50 g, 20 s) | Residual Stress (MPa) | ||

|---|---|---|---|---|

| Before UI | After UI | After Polishing | After UI | |

| TC4 | 340 | 390 | −35 | −508 |

| TLM | 238 | 294 | −12 | −274 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, X.; Zhu, J.; Gao, F.; Gao, Z. Influence of Fine Grains on the Bending Fatigue Behavior of Two Implant Titanium Alloys. Materials 2021, 14, 171. https://doi.org/10.3390/ma14010171

Cao X, Zhu J, Gao F, Gao Z. Influence of Fine Grains on the Bending Fatigue Behavior of Two Implant Titanium Alloys. Materials. 2021; 14(1):171. https://doi.org/10.3390/ma14010171

Chicago/Turabian StyleCao, Xiaojian, Jiangpei Zhu, Fei Gao, and Zhu Gao. 2021. "Influence of Fine Grains on the Bending Fatigue Behavior of Two Implant Titanium Alloys" Materials 14, no. 1: 171. https://doi.org/10.3390/ma14010171