Push-Out Method for Micro Measurements of Interfacial Strength in Aluminium Alloy Matrix Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Composite Plates

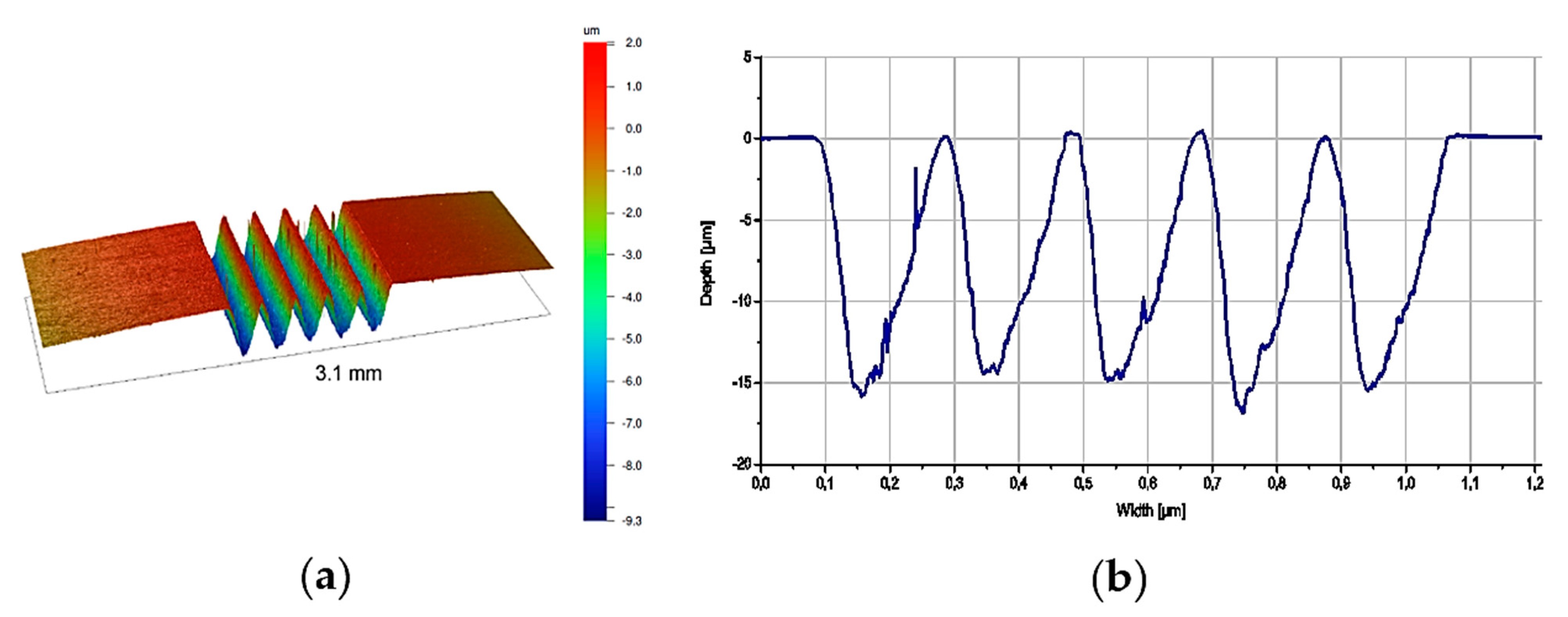

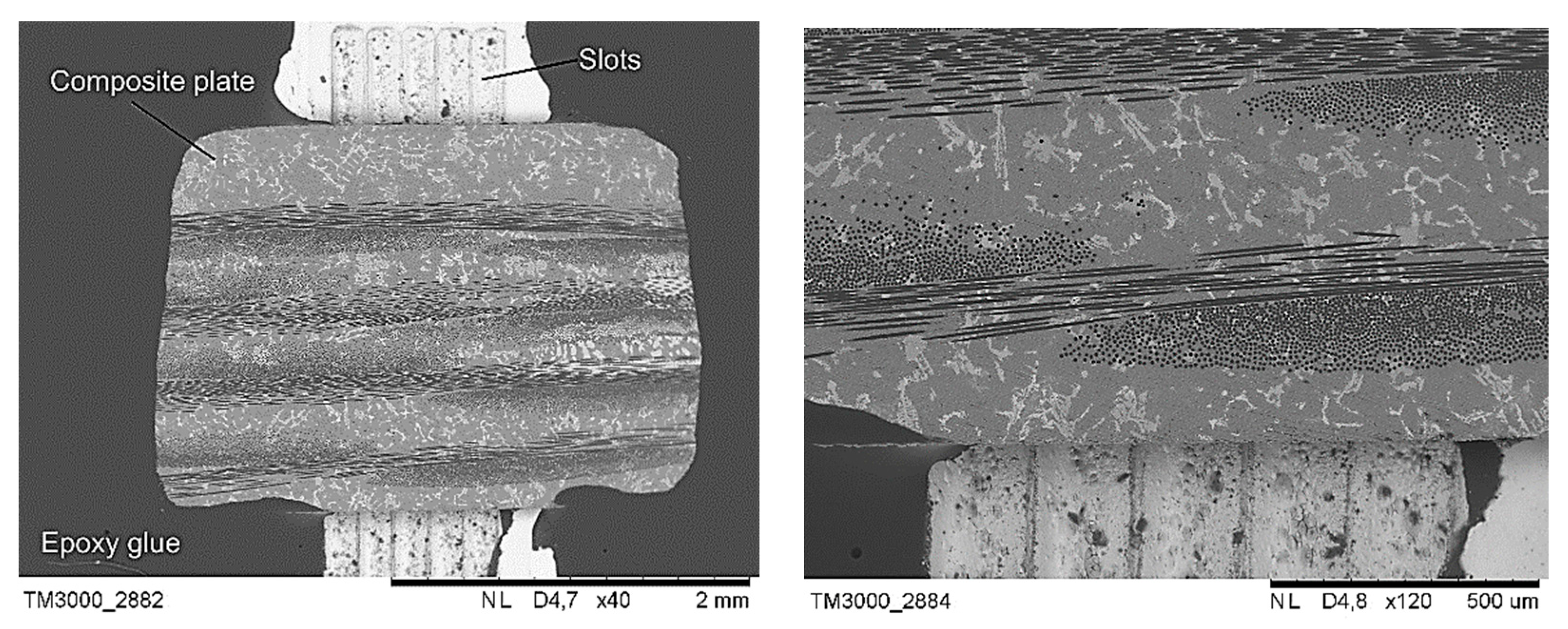

2.2. Samples Preparation for Push Out Investigation

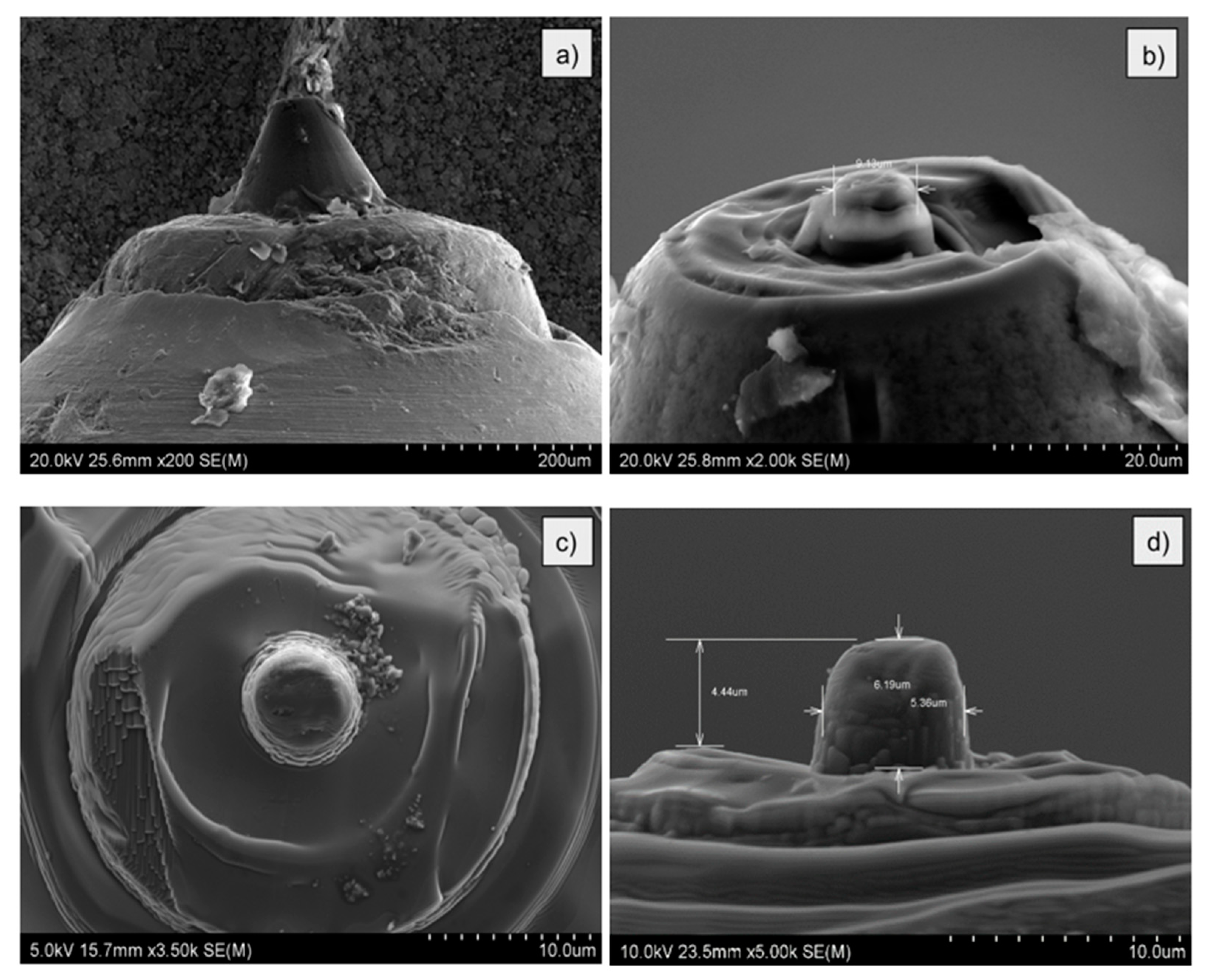

2.3. Fabrication of Micro Intender

2.4. Push-Out Test Procedure

3. Results

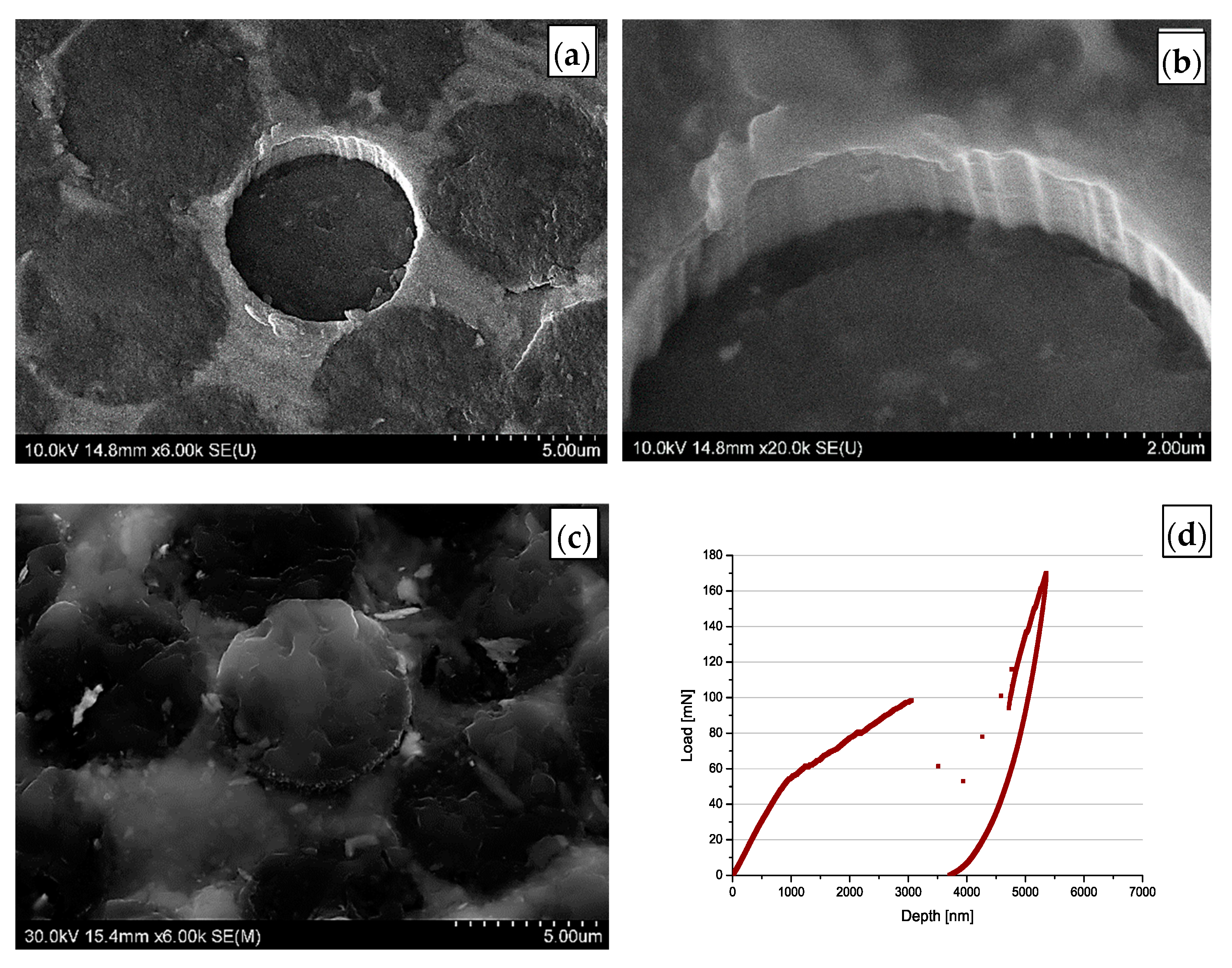

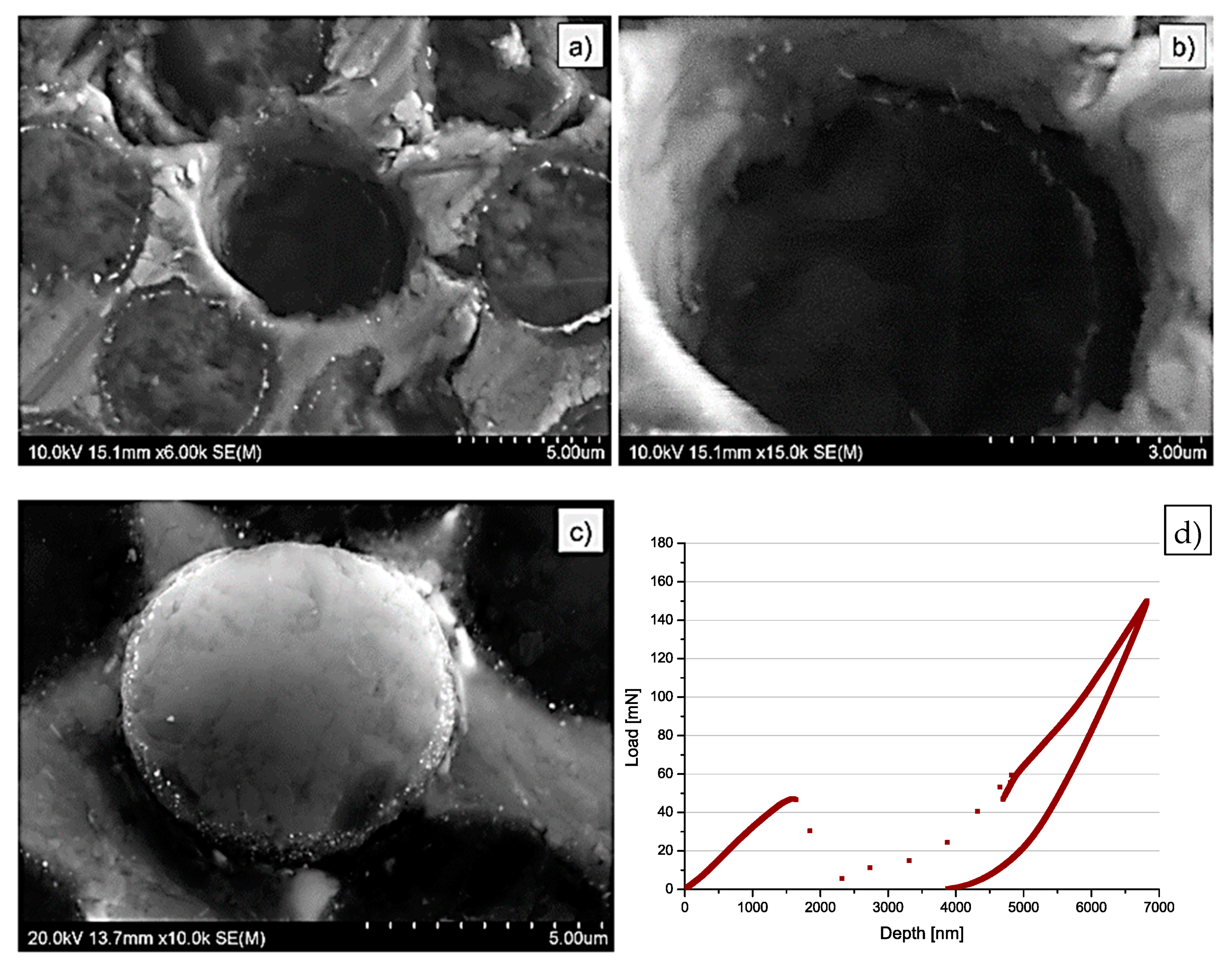

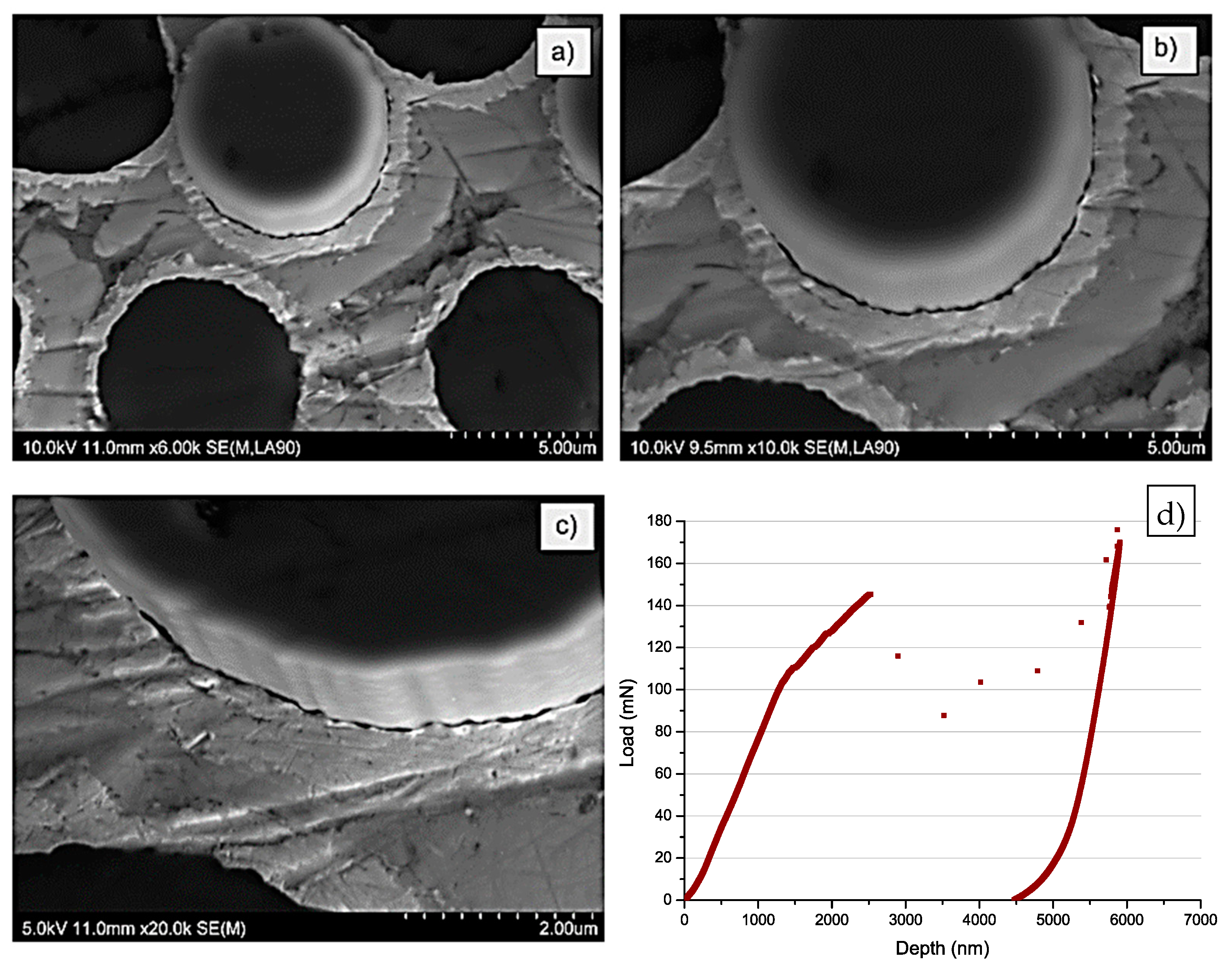

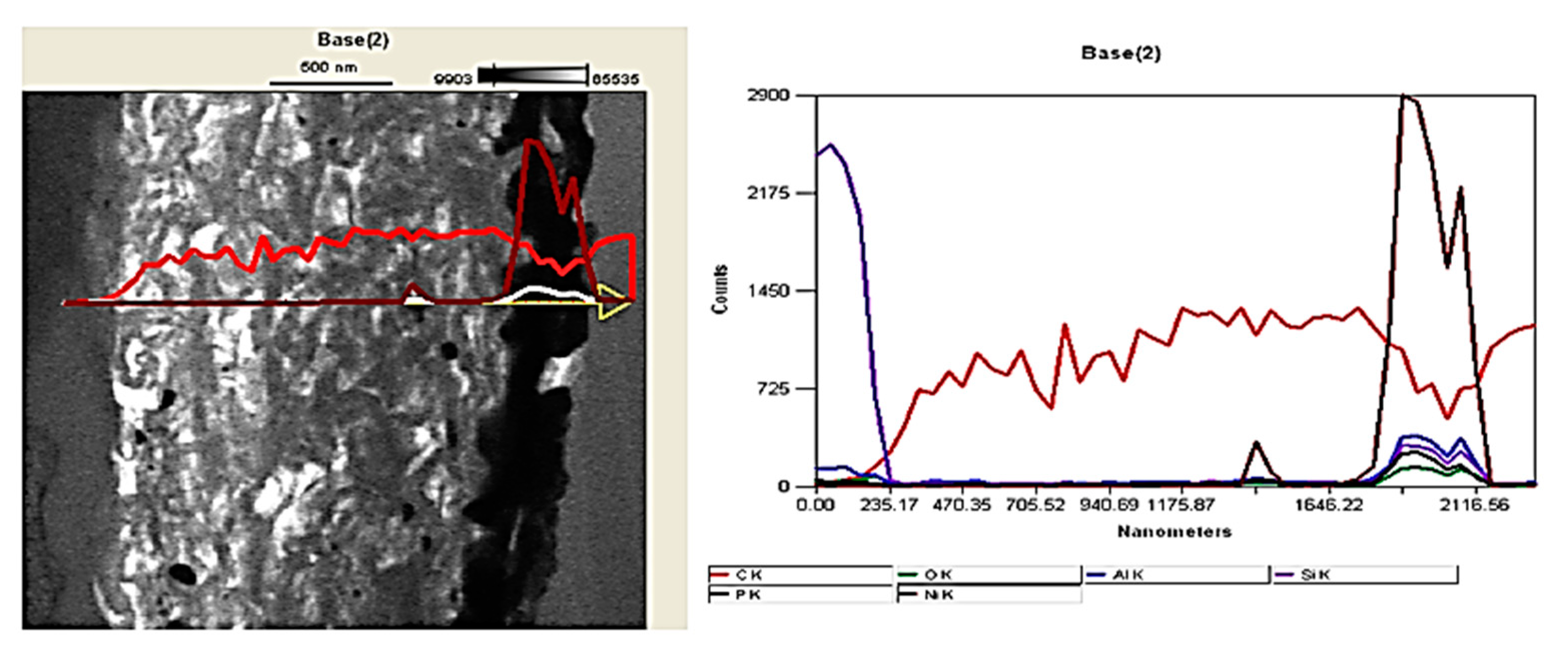

3.1. High Pressure Die Casting, Samples MMC1–MMC3

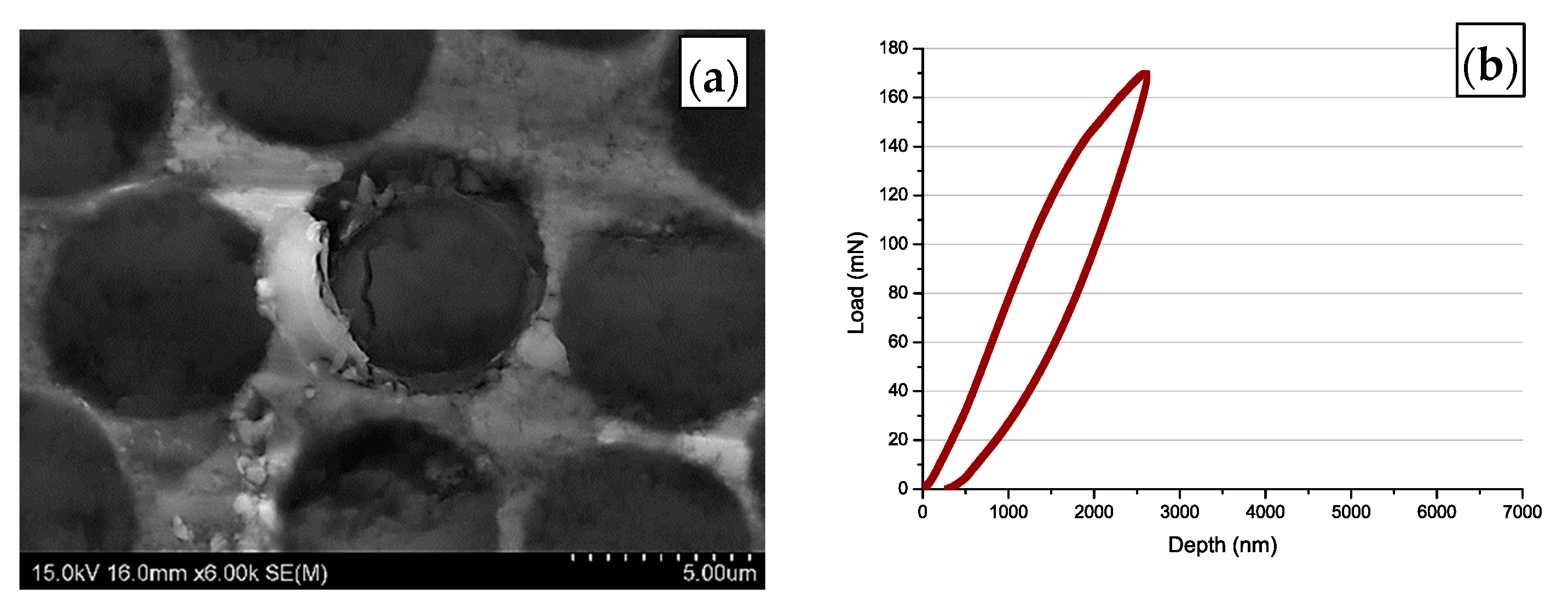

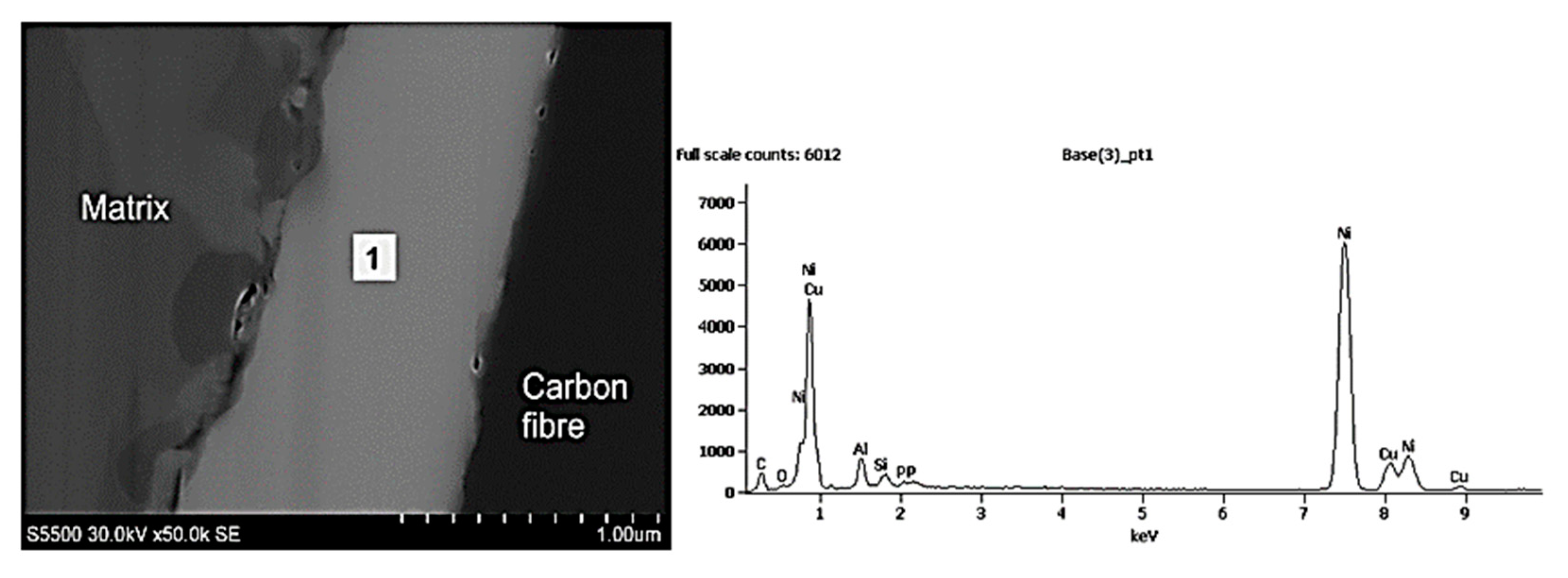

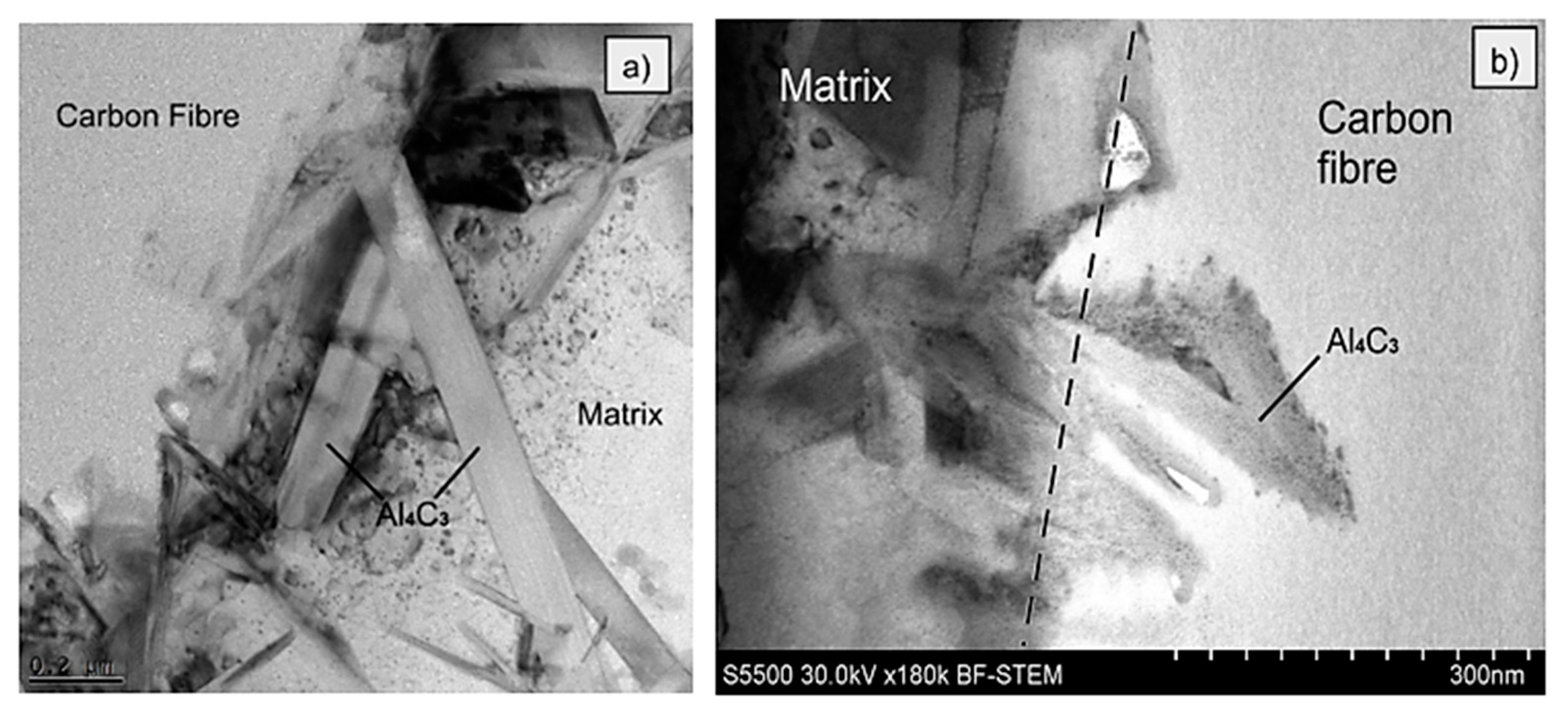

3.2. Gas Pressure Infiltration, Sample MMC4

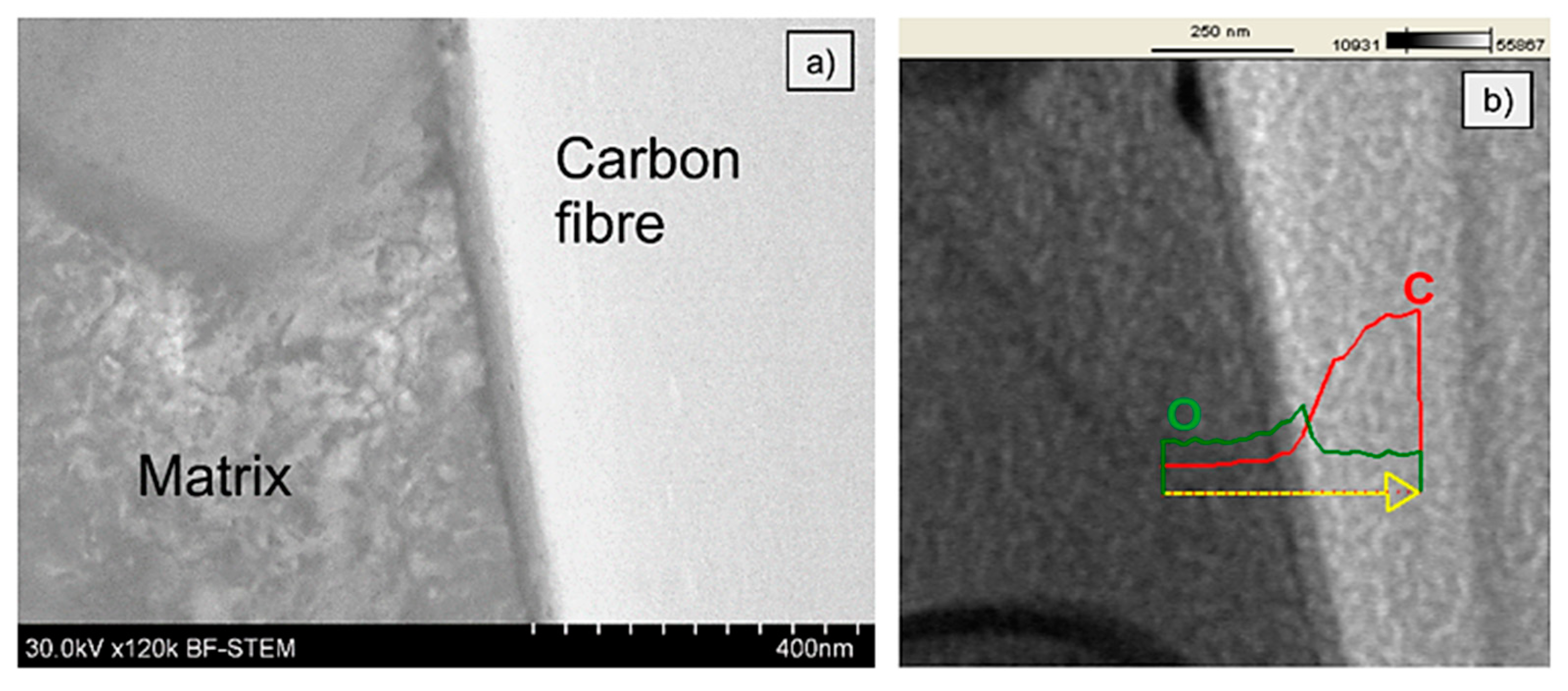

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Morgan, P. Carbon Fibers and Their Composites; CRC Press: Boca Raton, FL, USA, 2005; ISBN 9780429116827. [Google Scholar]

- Kindl, B.; Liu, Y.L.; Nyberg, E.; Hansen, N. The control of interface and microstructure of sic/al composites by sol-gel techniques. Compos. Sci. Technol. 1992, 43, 85–93. [Google Scholar] [CrossRef]

- Kim, J.K.; Mai, Y.W. Interfaces in composites. In Materials Science and Technology. Structure and Properties; Chou, T.W., Ed.; American Cancer Society: Weinheim, Germany, 1993; Volume 13, pp. 229–289. [Google Scholar]

- Lin, C.B.; Chang, R.J.; Weng, W.P. A study on process and tribological behavior of AI alloy/Gr composite. Wear 1998, 217, 167–174. [Google Scholar] [CrossRef]

- Lancin, M.; Marhic, C. TEM study of carbon fibre reinforced aluminium matrix composites: Influence of brittle phases and interface on mechanical properties. J. Eur. Ceram. Soc. 2000, 20, 1493–1503. [Google Scholar] [CrossRef]

- Vidal-Sétif, M.H.; Lancin, M.; Marhic, C.; Valle, R.; Raviart, J.-L.; Daux, J.-C.; Rabinovitch, M. On the role of brittle interfacial phases on the mechanical properties of carbon fibre reinforced Al-based matrix composites. Mater. Sci. Eng. A 1999, 2, 321–333. [Google Scholar] [CrossRef]

- Mussert, K.M.; Vellinga, W.P.; Bakker, A.; Van Der Zwaag, S. A nano-indentation study on the mechanical behaviour of the matrix material in an AA6061—Al2O3 MMC. J. Mater. Sci. 2002, 37, 789–794. [Google Scholar] [CrossRef]

- Hua, W.; Wu, X.; Shen, D.; Lu, H.; Polak, M. Nanohardness and elastic modulus at the interface of TiCx/NiAl composites determined by the nanoindentation technique. Surf. Interface Anal. 2004, 36, 143–147. [Google Scholar] [CrossRef]

- Zidi, M.; Carpentier, L.; Chateauminois, A.; Sidoroff, F. Quantitative analysis of the micro-indentation behaviour of fibre-reinforced composites: Development and validation of an analytical model. Compos. Sci. Technol. 2000, 60, 429–437. [Google Scholar] [CrossRef]

- Kalinka, G.; Leistner, A.; Hampe, A. Characterisation of the fibre/matrix interface in reinforced polymers by the push-in technique. Compos. Sci. Technol. 1997, 57, 845–851. [Google Scholar] [CrossRef]

- Hull, D.; Clyne, T.W. An Introduction to Composite Materials; Cambridge University Press: Cambridge, UK, 1996; ISBN 0521388554. [Google Scholar]

- Awal, A.; Cescutti, G.; Ghosh, S.B.; Müssig, J. Interfacial studies of natural fibre/polypropylene composites using single fibre fragmentation test (SFFT). Compos. Part A Appl. Sci. Manuf. 2011, 42, 50–56. [Google Scholar] [CrossRef]

- Zhang, L.; Ren, C.; Zhou, C.; Xu, H.; Jin, X. Single fiber push-out characterization of interfacial mechanical properties in unidirectional CVI-C/SiC composites by the nano-indentation technique. Appl. Surf. Sci. 2015, 357, 1427–1433. [Google Scholar] [CrossRef]

- Luthi, B.; Reber, R.; Janczak-Rusch, J.; Rohr, L.; Mayer, J. Characterization of the GF/PET Interface in knitted composites by means of the push-out technique. In Proceedings of the Symposium of Interfacial Materials Science on Composites (SIMS-C VI), Osaka, Japan, 7–9 May 1997. [Google Scholar]

- Qingsheng, X.L.; Zhiyuan, L. Interfacial mechanics of fiber push-out test: Nano-indention technique and cohesive element modelling. In Proceedings of the 13th International Conference on Fracture, Beijing, China, 16–21 June 2013. [Google Scholar]

- Nishikawa, M.; Okabe, T.; Hemmi, K.; Takeda, N. Micromechanical modeling of the microbond test to quantify the interfacial properties of fiber-reinforced composites. Int. J. Solids Struct. 2008, 45, 4098–4113. [Google Scholar] [CrossRef] [Green Version]

- Molina-Aldareguía, J.M.; Rodríguez, M.; González, C.; LLorca, J. An experimental and numerical study of the influence of local effects on the application of the fibre push-in test. Philos. Mag. 2011, 91, 1293–1307. [Google Scholar] [CrossRef]

- Metcalfe, A.G. Physical chemical aspects of the interface. In Interfaces in Metal Matrix Composites; Academic Press: New York, NY, USA; London, UK, 1974; ISBN 9781483216676. [Google Scholar]

- Ureña, A.; Rams, J.; Escalera, M.D.; Sánchez, M. Characterization of interfacial mechanical properties in carbon fiber/aluminium matrix composites by the nanoindentation technique. Compos. Sci. Technol. 2005, 65, 2025–2038. [Google Scholar] [CrossRef]

- Landry, K.; Kalogeropoulou, S.; Eustathopoulos, N. Wettability of carbon by aluminum and aluminum alloys. Mater. Sci. Eng. A 1998, 254, 99–111. [Google Scholar] [CrossRef]

- Kozera, R.; Bieliński, J.; Broda, A.; Boczkowska, A.; Kurzydlowski, K.J. Preparation of Carbon Fibres for Aluminium Composites. Adv. Mater. Res. 2011, 264–265, 1487–1493. [Google Scholar] [CrossRef]

- Kaufmann, H.; Schmitt, T.; Degischer, H.P. Wetting-Dewetting Phenomena in Pressure Infiltrated Al-composites. In Proceedings of the 12th International Symposium on Materials Science; Riso: Woburn, MA, USA, 1991; pp. 441–448. [Google Scholar]

- Viala, J.C.; Bosselt, F.; Fortier, P.; Bouix, J. Chemical interaction between silicon carbide Nicalon fibers and liquid aluminium-silicon alloys. In Proceedings of the Conference ICCM 6 & ECCM 2, London, UK, 20–24 July 1987. [Google Scholar]

- Kim, J.-K.; Mai, Y.-W. Engineered Interfaces in Fiber Reinforced Composites. In Engineered Interfaces in Fiber Reinforced Composites; Elsevier: Amsterdam, The Netherlands, 1998. [Google Scholar] [CrossRef]

- Tzeng, S.S. Catalytic graphitization of electroless Ni–P coated PAN-based carbon fibers. Carbon N. Y. 2006, 44, 1986–1993. [Google Scholar] [CrossRef]

- Li, S.-H.; Chao, C.-G. Effects of carbon fiber/Al interface on mechanical properties of carbon-fiber-reinforced aluminum-matrix composites. Metall. Mater. Trans. A 2004, 35, 2153–2160. [Google Scholar] [CrossRef]

- Park, J.K.; Lucas, J.P. Moisture effect on SiCp/6061 Al MMC: Dissolution of interfacial Al4C3. Scr. Mater. 1997, 37, 511–516. [Google Scholar] [CrossRef]

| Sample | Carbon Fibres | Pre-Heating Temperature (C) | Infiltration Temperature (C) | Infiltration Pressure (MPa) | Time of Contact (s) |

|---|---|---|---|---|---|

| MMC1 | Uncoated | 800 | 700 | 60 | <1 |

| MMC2 | Ni-P coated | 1000 | 700 | 60 | <1 |

| MMC3 | Ni-P coated | 800 | 700 | 60 | <1 |

| MMC4 | Ni-P coated | 720 | 720 | 15 | 1800 |

| Sample | Sample Thickness (m) | Load (mN) | Interfacial Strength (MPa) |

|---|---|---|---|

| MMC1 | 173 ± 2 | 110.43 ± 19.4 | 40.13 ± 6.9 |

| MMC2 | 129 ± 3 | 53.95 ± 11.4 | 19.03 ± 4.0 |

| MMC3 | 140 ± 2 | 139.54 ± 20.3 | 45.34 ± 6.6 |

| MMC4 | 70 ± 1 | >170 | >110.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kozera, R.; Boczkowska, A.; Krawczyk, Z.D.; Kozera, P.; Spychalski, M.; Malek, M.; Kosturek, R. Push-Out Method for Micro Measurements of Interfacial Strength in Aluminium Alloy Matrix Composites. Materials 2021, 14, 5092. https://doi.org/10.3390/ma14175092

Kozera R, Boczkowska A, Krawczyk ZD, Kozera P, Spychalski M, Malek M, Kosturek R. Push-Out Method for Micro Measurements of Interfacial Strength in Aluminium Alloy Matrix Composites. Materials. 2021; 14(17):5092. https://doi.org/10.3390/ma14175092

Chicago/Turabian StyleKozera, Rafał, Anna Boczkowska, Zuzanna D. Krawczyk, Paulina Kozera, Maciej Spychalski, Marcin Malek, and Robert Kosturek. 2021. "Push-Out Method for Micro Measurements of Interfacial Strength in Aluminium Alloy Matrix Composites" Materials 14, no. 17: 5092. https://doi.org/10.3390/ma14175092