Interaction of Long Time Pulses of an Nd3+:YAG Laser Beam with the Heusler AlloyNi45Co5Mn35.5In14.5

Abstract

:1. Introduction

- (A)

- Material parameters, such as the coefficient of reflection, density, thermal and temperature conductivity, or temperature;

- (B)

- Laser processing parameters, such as the wavelength, duration and shape of the laser pulse, its fluence, or the diameter of the laser spot.

2. Experimental Section

3. Results and Discussion

3.1. Bulk Sample

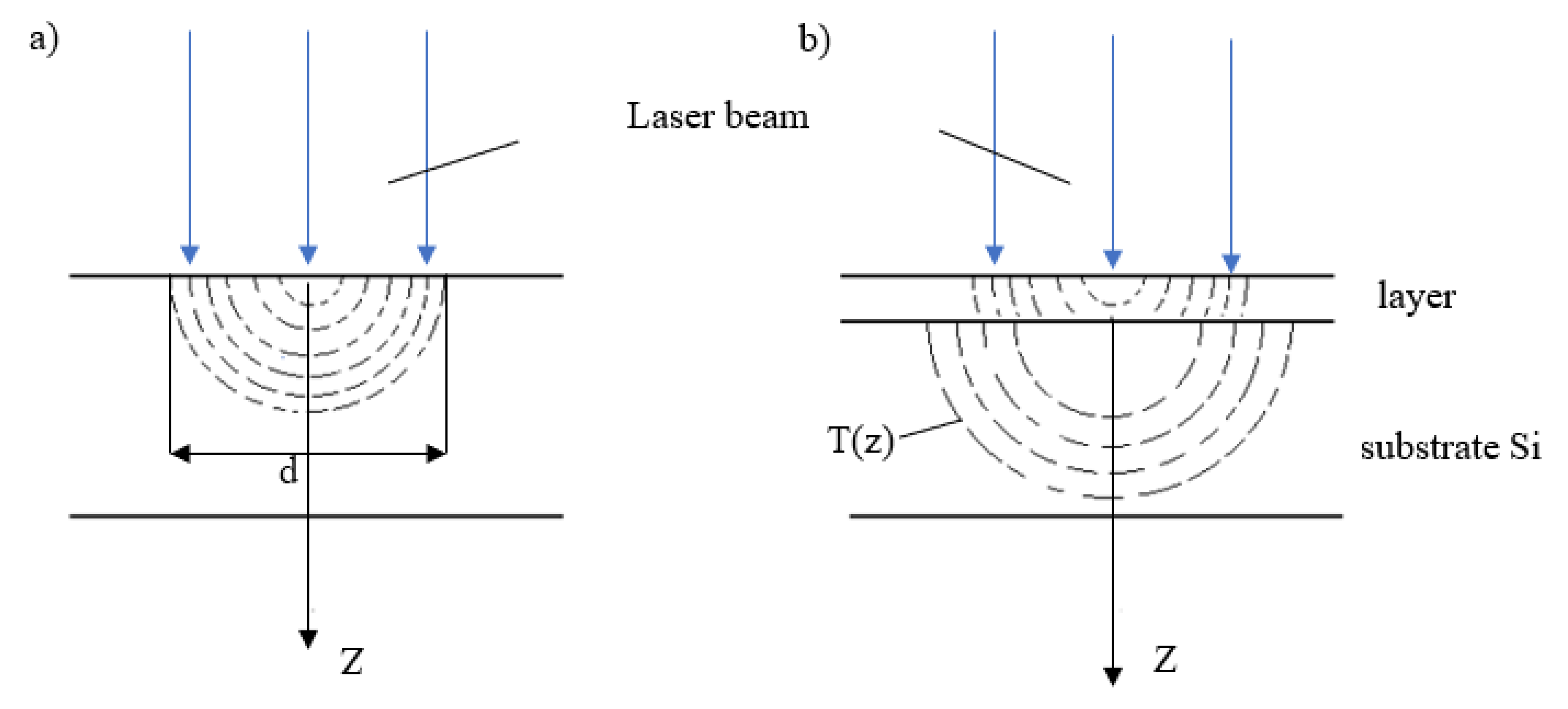

3.2. Thin Layer Sample

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ito, W.; Imano, Y.; Kainuma, R.; Sutou, Y.; Oikawa, K.; Ishida, K. Martensitic and Magnetic Transformation Behaviors in Heusler-Type NiMnIn and NiCoMnIn Metamagnetic Shape Memory Alloys. Met. Mater. Trans. A 2007, 38, 759–766. [Google Scholar] [CrossRef]

- Li, C.-M.; Luo, H.-B.; Hu, Q.-M.; Yang, R.; Johansson, B.; Vitos, L. Role of magnetic and atomic ordering in the martensitic transformation of Ni-Mn-In from a first-principles study. Phys. Rev. B 2012, 86, 214205. [Google Scholar] [CrossRef]

- Liang, X.; Bai, J.; Wang, J.; Shi, S.; Yan, H.; Gu, J.; Zhang, Y.; Esling, C.; Zhao, X.; Zuo, L. Effect of Co doping on martensitic transformation and magneticproperties of Ni50Mn35.4In14.6alloy byfirst-principles calculations. J. Alloys Compd. 2019, 804, 111–118. [Google Scholar] [CrossRef]

- Miller, J.C. (Ed.) Laser Ablation; Springer: Berlin/Heidelberg, Germany, 1994. [Google Scholar]

- Chrisey, D.B.; Hubler, G.K. Pulsed Laser Deposition of Thin Films; Join Wiley &Sons Inc.: New York, NY, USA; Singapore, 1994. [Google Scholar]

- Vonk, V.; Driessen, K.J.I.; Huijben, G.; Rijnders, D.H.A.; Blank, H.; Rogalla, S.; Harkema, I.; Graafsma, H. Initial Structure and Growth Dynamics of YBa2Cu3O7-δ during Pulsed Laser Deposition. Phys. Rev. Lett. 2007, 99, 196196. [Google Scholar] [CrossRef] [Green Version]

- Blank, D.H.; Dekkers, M.; Rijnders, G. Pulsed laser deposition in Twente: From research tool towards industrial deposition. J. Phys. D Appl. Phys. 2014, 47, 034006. [Google Scholar] [CrossRef]

- Maziarz, W. SEM and TEM Studies of Magnetic Shape Memory NiCoMnIn Melt Spun Ribbons. Solid State Phenom. 2012, 186, 251–254. [Google Scholar] [CrossRef]

- Wisz, G.; Sagan, P.; Stefaniuk, I.; Cieniek, B.; Maziarz, W.; Kuzma, M. Structure and composition of layers of Ni-Co-Mn-In Heusler alloys obtained by pulsed laser deposition. EPJ Web Conf. 2017, 133, 02006. [Google Scholar] [CrossRef] [Green Version]

- Cabalin, L.M.; Laserna, J. Experimental determination of laser induced breakdown thresholds of metals under nanosecond Q-switched laser operation. Spectrochim. Acta Part B At. Spectrosc. 1998, 53, 723–730. [Google Scholar] [CrossRef]

- Kaptay, G.; Csicsovszki, G.; Yaghmaee, M.S. An Absolute Scale for the Cohesion Energy of Pure Metals. Mater. Sci. Forum. 2003, 414–415, 235–240. [Google Scholar] [CrossRef]

- Romero, F.J.; Martín-Olalla, J.-M.; Blázquez, J.S.; Gallardo, M.C.; Soto-Parra, D.; Vives, E.; Planes, A. Thermo-magnetic characterization of phase transitions in a Ni-Mn-In metamagnetic shape memory alloy. J. Alloys Compd. 2021, 887, 161395. [Google Scholar] [CrossRef]

- Chen, J.-H. Specific Heat and Magnetic Properties of Ni-Mn-In Heusler Alloy. Ph.D. Thesis, Texas A&M University, College Station, TX, USA, August 2015. [Google Scholar]

- Zheng, Q.; Zhu, G.; Diao, Z.; Banerjee, D.; Cahill, D. High Contrast Thermal Conductivity Change in Ni–Mn–In Heusler Alloys near Room Temperature. Adv. Eng. Mater. 2019, 21, 1801342. [Google Scholar] [CrossRef]

- Matthias, E.; Reichling, M.; Siegel, J.; Petzoldt, S.; Skurk, H.; Bizenberger, P.; Neske, E. The influence of thermal diffusion on laser ablation of metal films. Appl. Phys. A 1994, 58, 129–136. [Google Scholar] [CrossRef]

- Yilbas, B.S.; Sami, M. Liquid ejection and possible nucleate boiling mechanisms in relation to the laser drilling process. J. Phys. D Appl. Phys. 1997, 30, 1996. [Google Scholar] [CrossRef]

- Zhang, Y.; Shen, Z.; Ni, X. Modeling and simulation on long pulse laser drilling processing. Int. J. Heat Mass Transf. 2014, 73, 429–437. [Google Scholar] [CrossRef]

- Lutey, A.H.A.; Ascari, A.; Fortunato, A.; Romoli, L. Long-pulse quasi-CW laser cutting of metals. Int. J. Adv. Manuf. Technol. 2017, 94, 155–162. [Google Scholar] [CrossRef]

- Moya, X.; Manosa, L.; Planes, A. Cooling and heating by adiabetic magnetization in the Ni50Mn34In16 magnetic shape-memory alloy. Phys. Rev. 2007, B75, 184412. [Google Scholar] [CrossRef] [Green Version]

- Shen, B.G.; Sun, J.R.; Hu, F.X.; Zhang, H.W.; Cheng, Z.H. Recent Progress in Exploring Magnetocaloric Materials. Adv. Mater. 2009, 21, 4545–4564. [Google Scholar] [CrossRef] [Green Version]

- Gamzatov, A.G.; Aliev, A.M.; Batdalov, A.B.; Khizriev, S.K.; Kuzmin, D.A.; Kamantsev, A.P.; Kim, D.-H.; Yen, N.H.; Dan, N.H.; Yu, S.-C. Dynamics of the magnetocaloric effect in cyclic magnetic fields in Ni50Mn35Al2Sn13 ribbon sample. J. Mater. Sci. 2021, 56, 15307–15406. [Google Scholar] [CrossRef]

- Kanomata, T.; Yasuda, T.; Sasaki, S.; Nishihara, H.; Kainuma, R.; Ito, W.; Oikawa, K.; Ishida, K.; Neumann, K.-U.; Ziebeck, K.R.A. Magnetic properties on shape memory alloys Ni2Mn1+xIn1−x. J. Magn. Magn. Mater. 2009, 321, 773–776. [Google Scholar] [CrossRef]

- Stevens, E.; Kimes, K.; Chernenko, V.; Lazpita, P.; Wojcik, A.; Maziarz, W.; Chmielus, M. Direct Laser Deposition and Homogenization of Ni-Co-Mn-Sn Magnetocaloric Material. Microsc. Microanal. 2018, 24, 956–957. [Google Scholar] [CrossRef] [Green Version]

- Toman, J.; Müllner, P.; Chmielus, M. Properties of as-deposited and heat-treated Ni-Mn-Ga magnetic shape memory alloy processed by directed energy deposition. J. Alloys Compd. 2018, 752, 455–463. [Google Scholar] [CrossRef] [Green Version]

- Nilsén, F.; Ituarte, I.F.; Salmi, M.; Partanen, J.; Hannula, S.-P. Effect of process parameters on non-modulated Ni-Mn-Ga alloy manufactured using powder bed fusion. Addit. Manuf. 2019, 28, 464–474. [Google Scholar] [CrossRef] [Green Version]

- Stevens, E.L.; Kimes, K.A.; Chernenko, V.A.; Lázpita, P.; Wojcik, A.; Maziarz, W.; Toman, J.; Chmielus, M. Effect of Homogenization on the Microstructure and Magnetic Properties of Direct Laser-Deposited Magnetocaloric Ni43Co7Mn39Sn11. J. Manuf. Sci. Eng. 2020, 142, 1–26. [Google Scholar] [CrossRef]

- Maziarz, W.; Czaja, P.; Chulist, R.; Wójcik, A.; Żrodowski, Ł.; Morończyk, B.; Wróblewski, R.; Kowalczyk, M. Microstructure and Magnetic Properties of Selected Laser Melted Ni-Mn-Ga and Ni-Mn-Ga-Fe Powders Derived from as Melt-Spun Ribbons Precursors. Metals 2021, 11, 903. [Google Scholar] [CrossRef]

- Laitinen, V.; Sozinov, A.; Saren, A.; Chmielus, M.; Ullakko, K. Characterization of as-built and heat-treated Ni-Mn-Ga magnetic shape memory alloy manufactured via laser powder bed fusion. Addit. Manuf. 2021, 39, 101854. [Google Scholar] [CrossRef]

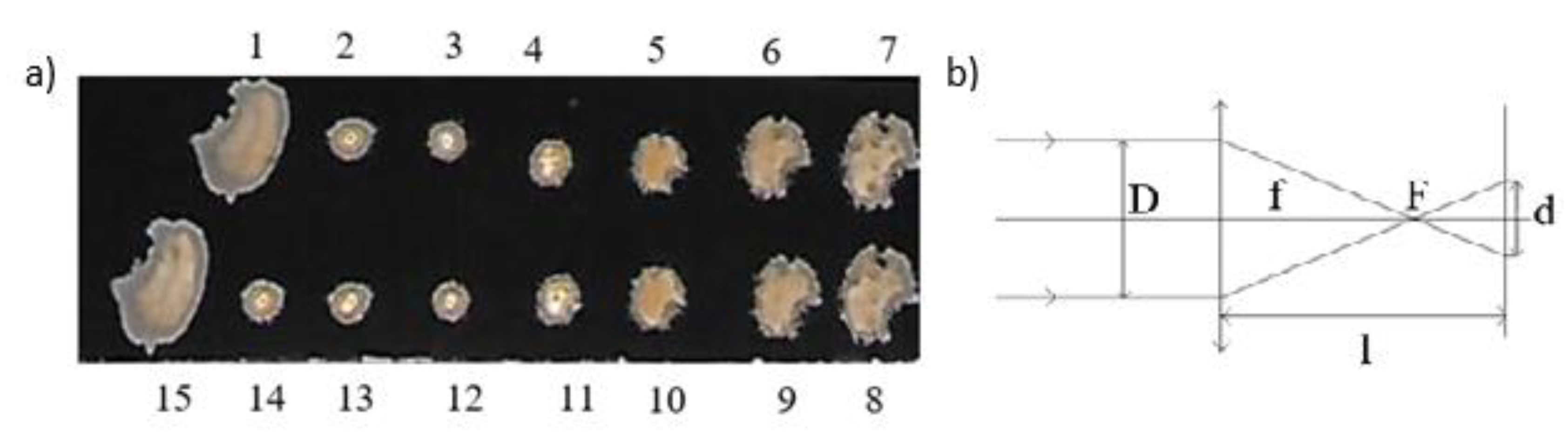

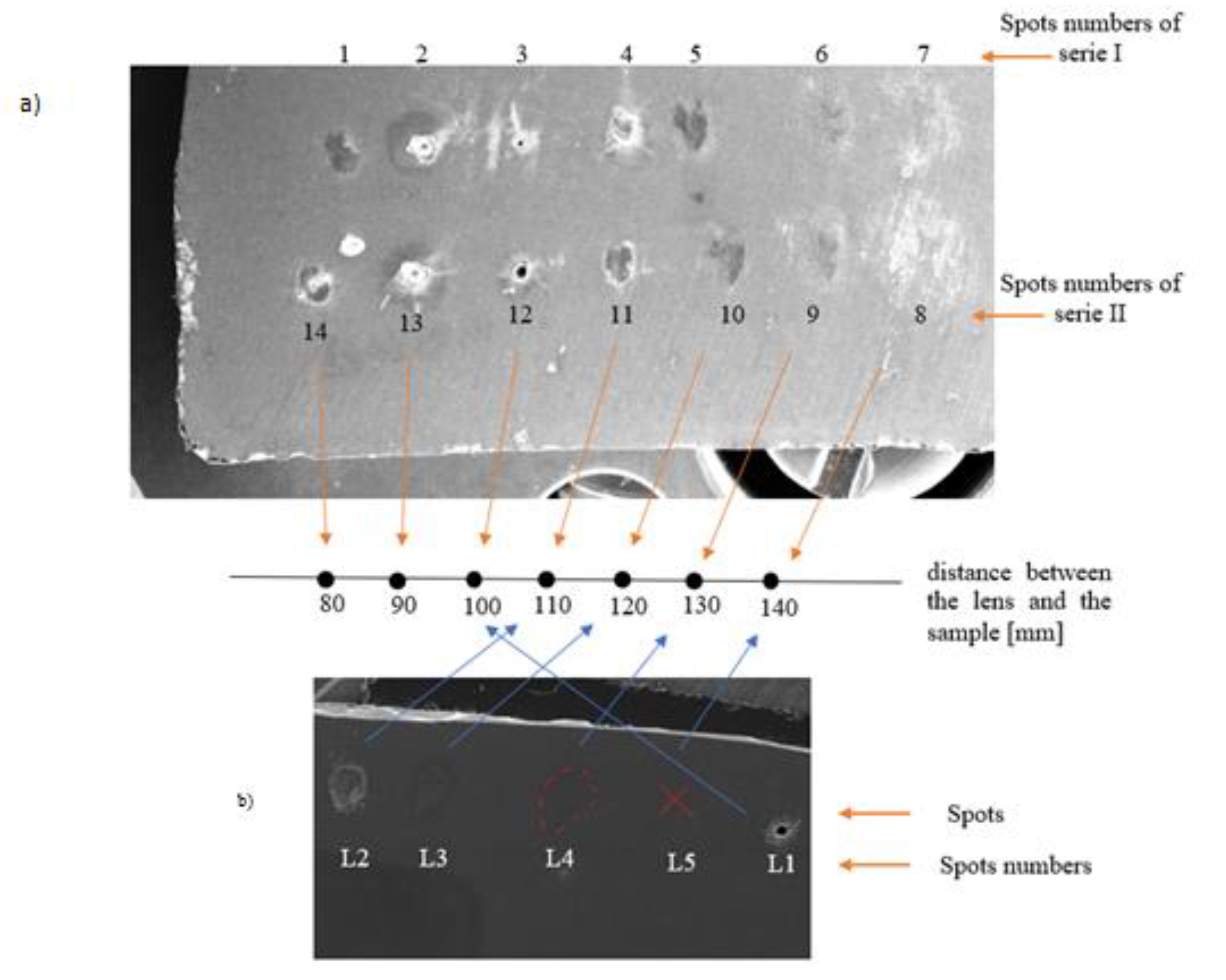

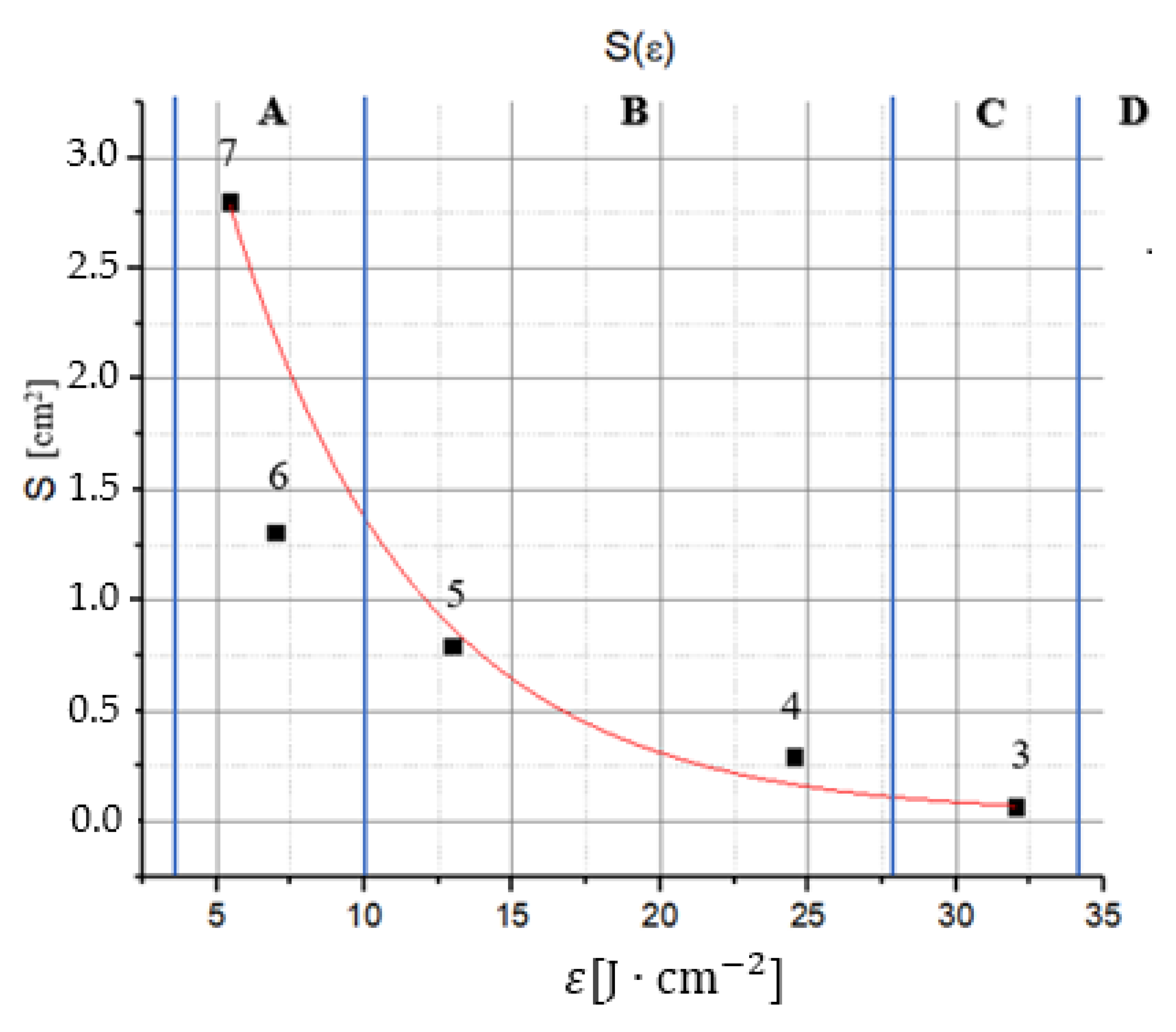

| Series I Spot No | Series II Spot No | l1 [cm] | D1 [mm] | D2 [mm] | d [mm] | S [mm2] | ε [J·cm−2] |

|---|---|---|---|---|---|---|---|

| 1 | 15 | unfocused beam | |||||

| 2 | 13, 14 | 9 | 2 | 1.75 | 1.875 | 2.76 | 27.8 |

| 3 | 12 | 10 | 2 | 1.55 | 1.75 | 2.40 | 32.0 |

| 4 | 11 | 11 | 2 | 2 | 2 | 3.14 | 24.5 |

| 5 | 10 | 12 | 2.5 | 3 | 2.75 | 5.93 | 13.0 |

| 6 | 9 | 13 | 3.5 | 4 | 3.75 | 11.04 | 6.97 |

| 7 | 8 | 14 | 5 | 3.7 | 4.25 | 14.18 | 5.43 |

| Elements or Alloys | ρ [g·cm−3] | Lv [J·g−1] | Lf [J·g−1] | Cp [J·K−1·kg−1] | K [Wm−1·γ−1] | A [cm2·s−1] | Ucoh [kJ/mol] [11] |

|---|---|---|---|---|---|---|---|

| Ag | 10.50 | 2390 | 103 | 237 | 429 | 1.72 | 348.75 |

| Ni | 8.90 | 6378 | 292 | 444 | 91 | 0.23 | 497.76 |

| Fe | 7.87 | 6095 | 272 | 444 | 80 | 0.23 | 528.81 |

| Stainless steel | 7.7–8.0 | 482 | 10–30 | 0.04 | 445.35 | ||

| Ni50Mn50−xInx X = 14–14.7 | 7.8 | [12,13] | [14] | ||||

| -austenite (A) | 425–450 | 11.5–13.0 | 0.03 | ||||

| -martensite (M) | 450 | 7.0–8.5 | 0.025 | ||||

| -near temp. of M-A transition | 550 | 5.5–13 | |||||

| Si | 2.33 | 1370 | 142 | 700 | 148 | 0.88 | 502.00 |

| Bulk Sample | Layered Sample | |||||||

|---|---|---|---|---|---|---|---|---|

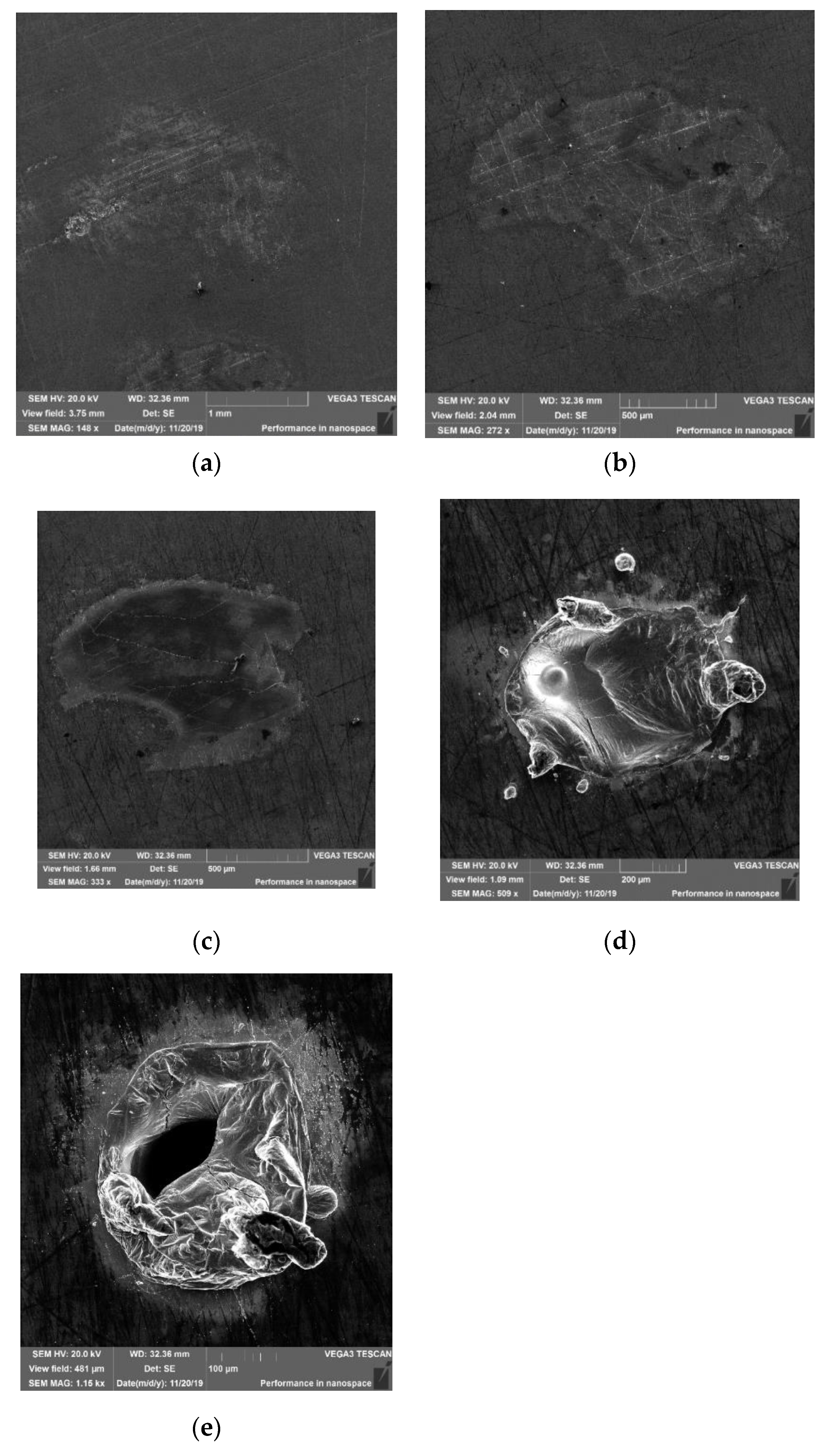

| ε [J·cm−2] | Spot No. | d [mm] | Spot Morphology | Type of Interaction | Spot No. | d [mm] | Spot Morphology | Type of Interaction |

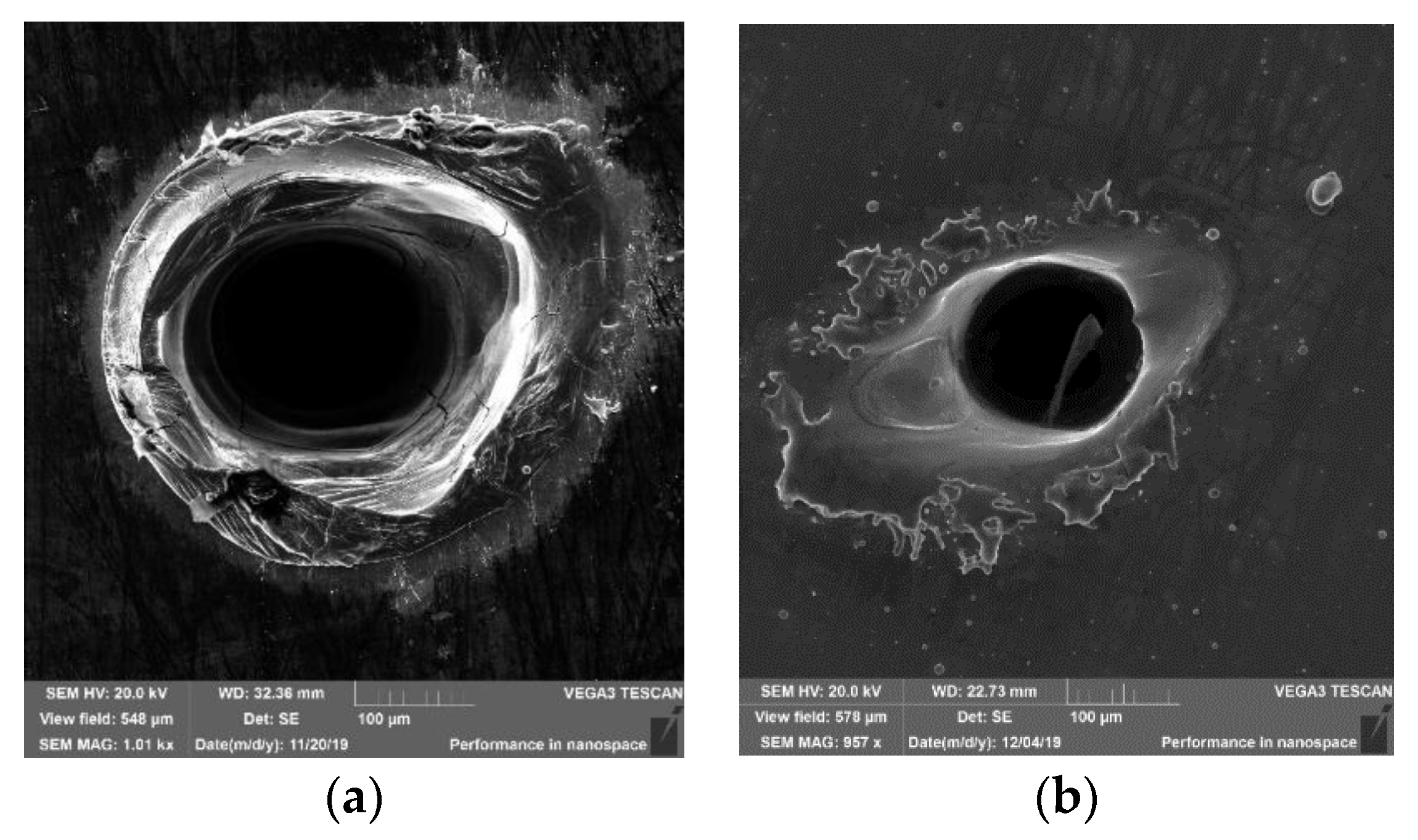

| 32.0 | 3 | 0.230 | deep crater | hole drilling | L1 | 0.166 | deep craters | hole drilling |

| 24.5 | 4 | 0.610 | visible: effusion of material | melting, with effusion | L2 | 0.583 | melted layer of material | surface evaporation |

| 13.0 | 5 | 1.005 | visible: some spots are clearly melted, with evaporation | melting, with surface evaporation | L3 | 0.657 | less clear and smaller spots, compared to the bulk sample | melting, without evaporation |

| 6.97 | 6 | 1.290 | partially melted | melting, without evaporation | L4 | 835.75 | slightly changed colour | slight melting, annealing |

| 5.43 | 7 | 1.890 | colour changing | no melting | L5 | - | no spots | annealing |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ciupak, P.; Barłowski, A.; Sagan, P.; Jasiński, T.; Kuzma, M. Interaction of Long Time Pulses of an Nd3+:YAG Laser Beam with the Heusler AlloyNi45Co5Mn35.5In14.5. Materials 2021, 14, 7016. https://doi.org/10.3390/ma14227016

Ciupak P, Barłowski A, Sagan P, Jasiński T, Kuzma M. Interaction of Long Time Pulses of an Nd3+:YAG Laser Beam with the Heusler AlloyNi45Co5Mn35.5In14.5. Materials. 2021; 14(22):7016. https://doi.org/10.3390/ma14227016

Chicago/Turabian StyleCiupak, Patryk, Artur Barłowski, Piotr Sagan, Tadeusz Jasiński, and Marian Kuzma. 2021. "Interaction of Long Time Pulses of an Nd3+:YAG Laser Beam with the Heusler AlloyNi45Co5Mn35.5In14.5" Materials 14, no. 22: 7016. https://doi.org/10.3390/ma14227016