High Critical Current Density in the Textured Nanofiber Structure in Multifilament MgB2 Wires Made by the Powder-In-Tube (PIT) Technique

Abstract

:1. Introduction

2. Materials and Methods

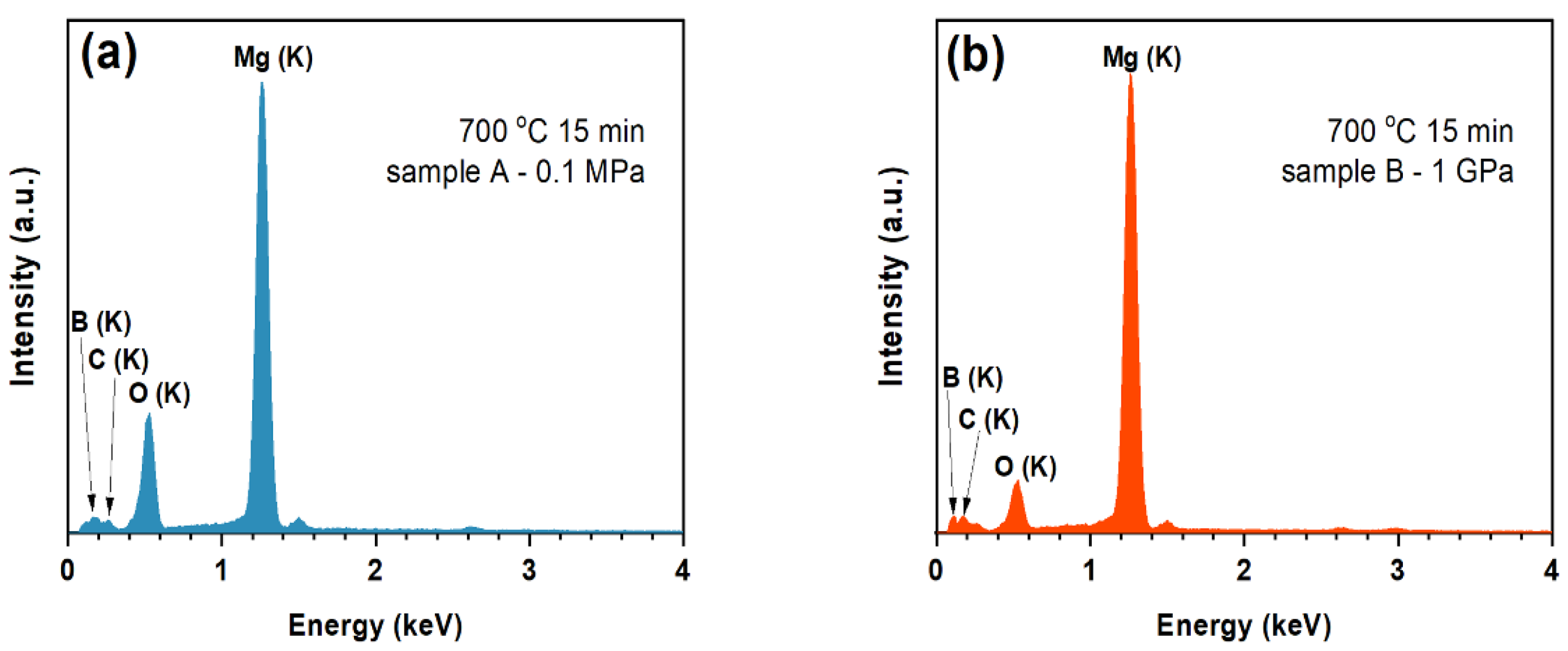

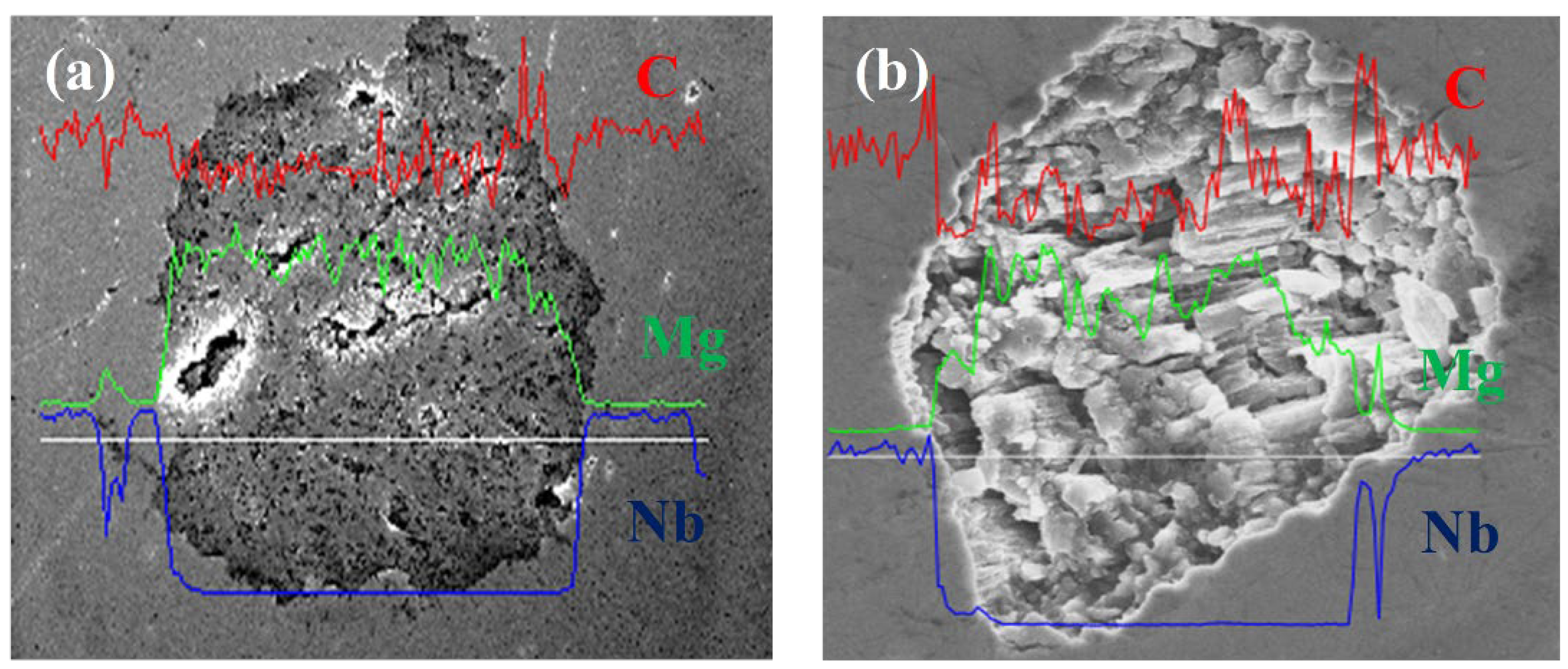

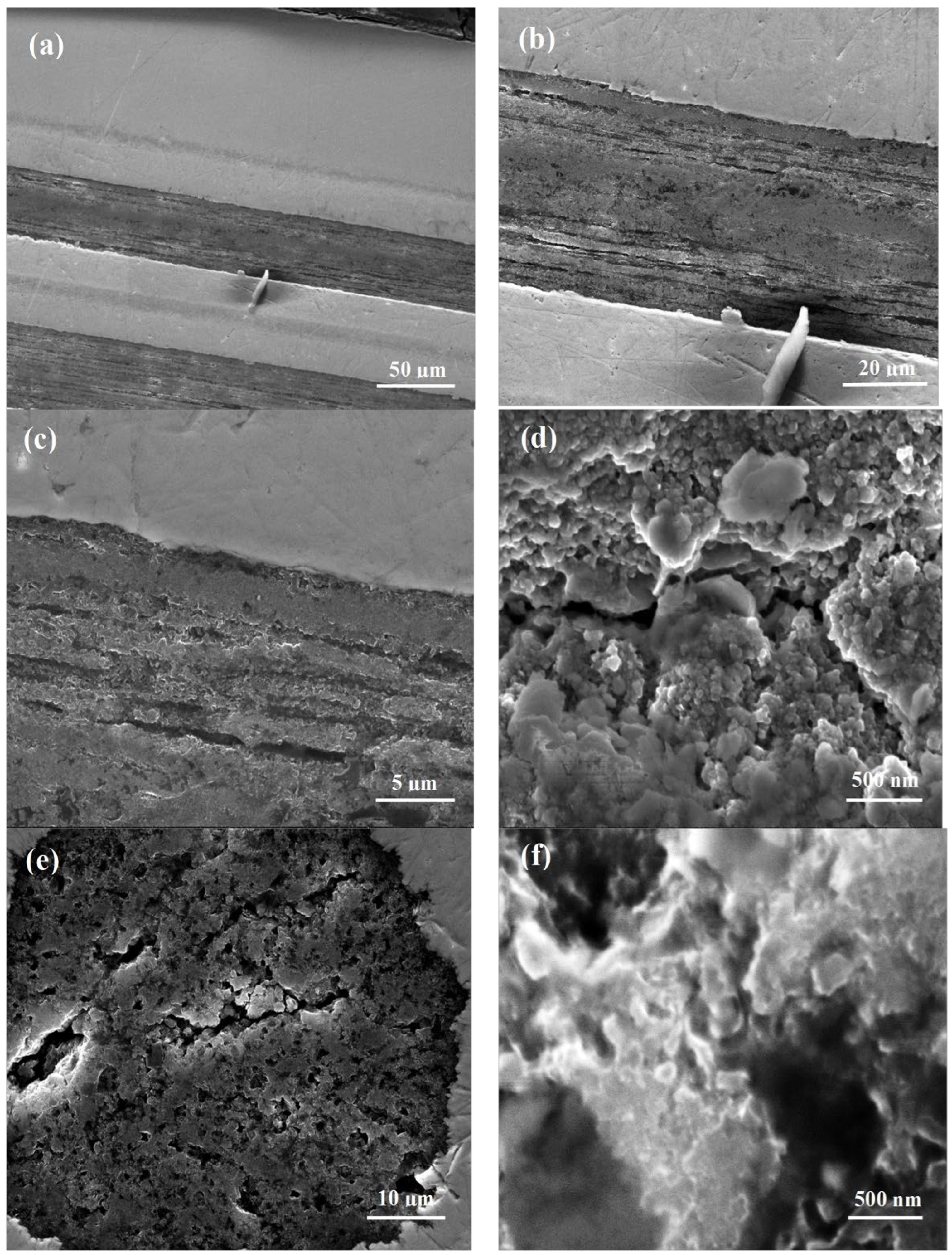

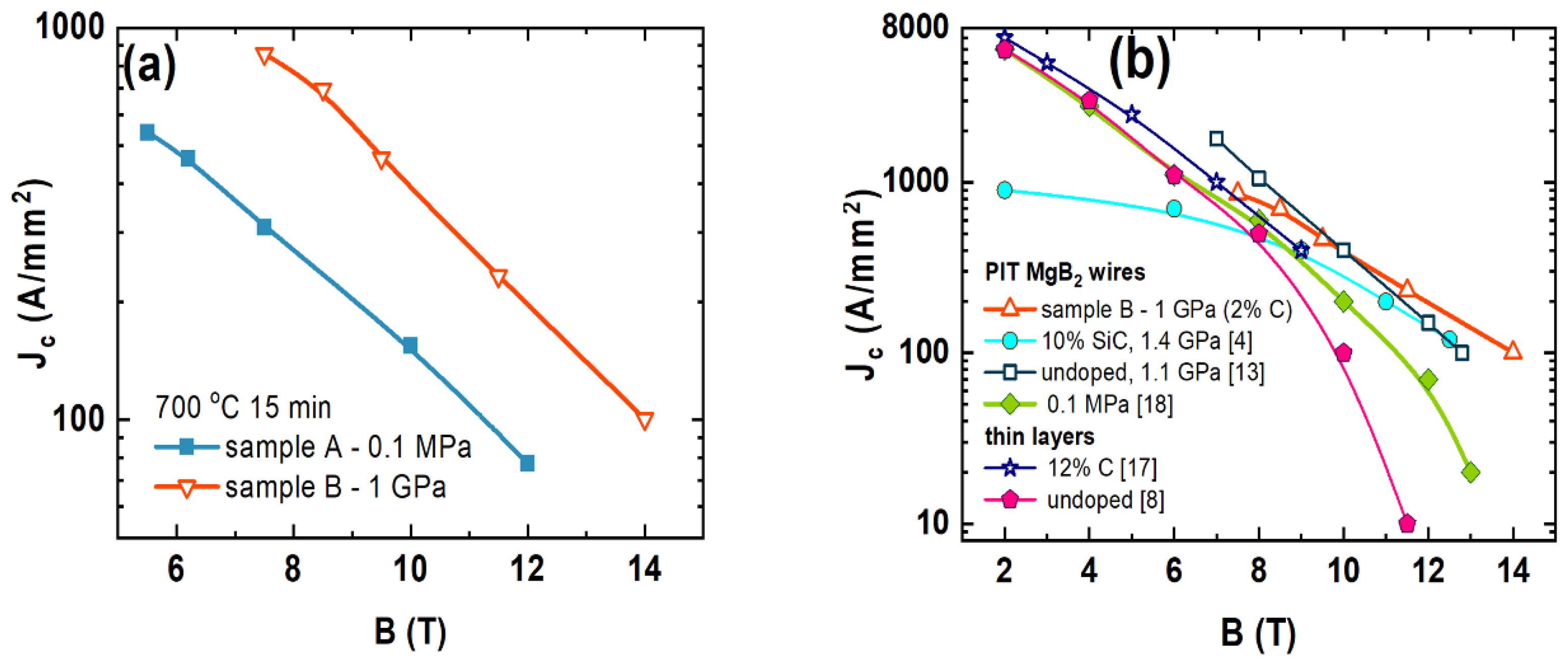

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Uchiyama, U.; Mizuno, K.; Akao, T.; Maeda, M.; Kawakami, T.; Kobayashi, H.; Kubota, Y.; Yasohama, K. Fibrous structure and critical current density of MgB2 superconducting wire. Cryogenics 2013, 47, 282–286. [Google Scholar] [CrossRef]

- Susner, M.A.; Daniels, T.W.; Sumption, M.D.; Rindfleisch, M.A.; Thong, C.J.; Collings, E.W. Drawing induced texture and the evolution of superconductive properties with heat treatment time in powder-in-tube in-situ processed MgB2 strands. Supercond. Sci. Technol. 2012, 25, 65002. [Google Scholar] [CrossRef] [Green Version]

- Beilin, V.; Lapides, I.; Roth, M.; Dulkin, E.; Mojaev, E.; Gerber, A.; Riss, O. Rolling-induced texturing in metal-clad MgB2 tapes and magnetoresistivity anisotropy. J. Appl. Phys. 2006, 100, 43903. [Google Scholar] [CrossRef]

- Kang, W.N.; Kim, H.J.; Choi, E.M.; Jung, C.U.; Lee, S.I. MgB2 Superconducting thin films with a transition temperature of 39 kelvin. Science 2001, 292, 1521–1523. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Grassano, G.; Marre, D.; Pallecchi, I.; Ricci, F.; Siri, A.S.; Ferdeghini, C. Growth of in-plane textured LuNi2B2C thin films: Correlation among structural, morphological and electrical properties. Supercond. Sci. Technol. 2001, 14, 762–764. [Google Scholar] [CrossRef]

- Zhuang, C.G.; Meng, S.; Zhang, C.Y.; Feng, Q.R.; Gan, Z.Z.; Yang, H.; Jia, Y.; Wen, H.H.; Xi, X.X. Clean MgB2 thin films on different types of single-crystal substrate fabricated by hybrid physical–chemical vapor deposition. J. Appl. Phys. 2008, 104, 13924. [Google Scholar] [CrossRef]

- Xi, X.X. MgB2 thin films. Supercond. Sci. Technol. 2009, 22, 43001. [Google Scholar] [CrossRef]

- Matsumoto, A.; Kobayashi, Y.; Takahashi, K.; Kumakura, H.; Kitaguchi, H. MgB2 thin films fabricated by a precursor and post-annealing method have a high Jc in high magnetic fields. Appl. Phys. Express. 2008, 1, 21702. [Google Scholar] [CrossRef]

- Tomsic, M.; Rindflesich, M.; Yue, J.; McFadden, K.; Phillips, J.; Sumption, M.D.; Bhatia, M.; Bohnenstiehl, S.; Collings, E.W. Overview of MgB2 Superconductor Applications. Int. J. Appl. Ceram. Technol. 2007, 4, 250. [Google Scholar] [CrossRef]

- Mroczek, Z.; Morawski, A.; Czujko, T.; Karaboğa, F.; Akdoğan, M.; Zaleski, A.J.; Małecka, M.; Cetner, T.; Yetiş, H.; Gajda, D.; et al. Influence of the lamella structure and high isostatic pressure on the critical current density in in situ MgB2 wires without a barier. J. Alloys Compd. 2019, 776, 636–645. [Google Scholar] [CrossRef]

- Serquis, A.; Civale, L.; Hammon, D.L.; Liao, X.Z.; Coulter, J.Y.; Zhu, Y.J.; Jaime, M.; Peterson, D.E.; Mueller, F.M. Hot isostatic pressing of powder in tube MgB2 wires. Appl. Phys. Lett. 2003, 82, 2847–2849. [Google Scholar] [CrossRef] [Green Version]

- Gajda, D.; Morawski, A.; Zaleski, A.J.; Akdoğan, M.; Yetiş, H.; Karaboğa, F.; Cetner, T.; Belenli, I. Formation of high-field pinning centers in superconducting MgB2 wires by using high hot isostatic pressure process. J. Supercond. Nov. Magn. 2017, 30, 3397–3402. [Google Scholar] [CrossRef]

- Adamczyk, K.; Morawski, A.; Cetner, T.; Zaleski, A.; Gajda, D.; Rindfleisch, M.; Tomsic, M.; Diduszko, R.; Presz, A. Superconducting properties comparison of SiC doped multifilamentary wires of various sheaths (Cu, Monel, Glidcop) after high pressure HIP treatment. IEEE Trans. Appl. Supercond. 2012, 22, 6200204. [Google Scholar] [CrossRef]

- Gajda, D.; Zaleski, A.; Morawski, A.; Cetner, T.; Thong, C.J.; Rindfleisch, M.A. Point pinning centers in SiC doped MgB2 wires after HIP. Supercond. Sci. Technol. 2016, 29, 85010. [Google Scholar] [CrossRef]

- Gajda, D.; Morawski, A.; Zaleski, A.; Yamamoto, A.; Cetner, T. A defect detection method for MgB2 superconducting and iron-based Ba (Fe, Co)2As2 wires. Appl. Phys. Lett. 2016, 108, 152601. [Google Scholar] [CrossRef]

- Serquis, A.; Liao, X.Z.; Zhu, Y.T.; Coulter, J.Y.; Huang, J.Y.; Willis, J.O.; Peterson, D.E.; Mueller, F.M.; Moreno, N.O.; Thompson, J.D.; et al. Influence of microstructures and crystalline defects on the superconductivity of MgB2. J. Appl. Phys. 2002, 92, 351. [Google Scholar] [CrossRef] [Green Version]

- Gajda, D.; Morawski, A.; Zaleski, A.J.; Haßler, W.; Nenkov, K.; Małecka, M.; Rindfleisch, M.A.; Hossain, M.S.A.; Tomsic, M. Experimental research of high field pinning centers in 2% C doped MgB2 wires at 20 K and 25 K. J. Appl. Phys. 2016, 120, 113901. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.; Ferrando, V.; Orgiani, P.; Pogrebnyakov, A.V.; Wilke, R.H.T.; Betts, J.B.; Mielke, C.H.; Redwing, J.M.; Xi, X.X.; Li, O. Enhancement of flux pinning and high-field critical current density in carbon-alloyed MgB2 thin films. Phys. Rev. B 2006, 74, 174511. [Google Scholar] [CrossRef]

- Yang, Y.; Susner, M.; Sumption, M.D.; Rindfleisch, M.; Tomsic, M.; Collings, E.W. Influence of strand design, boron type, and carbon doping method on the transport properties of powder-in-tube MgB2−XCX strands. IEEE Trans. Appl. Supercond. 2012, 22, 6200110. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gajda, D.; Zaleski, A.J.; Morawski, A.J.; Małecka, M.; Tran, L.M.; Rindfleisch, M.; Durejko, T.; Czujko, T. High Critical Current Density in the Textured Nanofiber Structure in Multifilament MgB2 Wires Made by the Powder-In-Tube (PIT) Technique. Materials 2022, 15, 5419. https://doi.org/10.3390/ma15155419

Gajda D, Zaleski AJ, Morawski AJ, Małecka M, Tran LM, Rindfleisch M, Durejko T, Czujko T. High Critical Current Density in the Textured Nanofiber Structure in Multifilament MgB2 Wires Made by the Powder-In-Tube (PIT) Technique. Materials. 2022; 15(15):5419. https://doi.org/10.3390/ma15155419

Chicago/Turabian StyleGajda, Daniel, Andrzej J. Zaleski, Andrzej J. Morawski, Małgorzata Małecka, Lan Maria Tran, Matt Rindfleisch, Tomasz Durejko, and Tomasz Czujko. 2022. "High Critical Current Density in the Textured Nanofiber Structure in Multifilament MgB2 Wires Made by the Powder-In-Tube (PIT) Technique" Materials 15, no. 15: 5419. https://doi.org/10.3390/ma15155419