Flash Sintering Research Perspective: A Bibliometric Analysis

Abstract

:1. Introduction

2. Methods

2.1. Document Search

2.2. Bibliometric Analysis

3. Results and Discussion

3.1. Flash Sintering (FS)

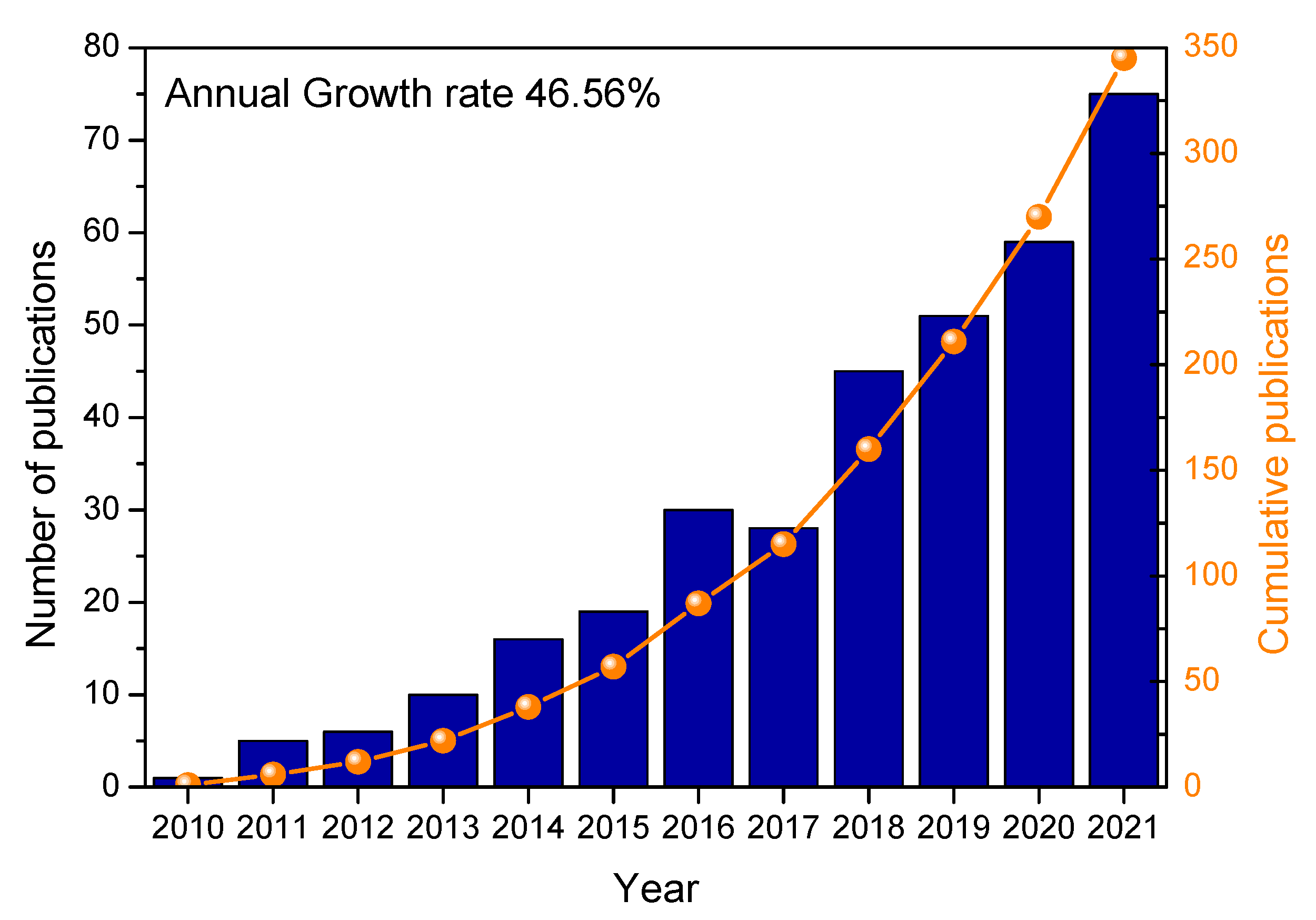

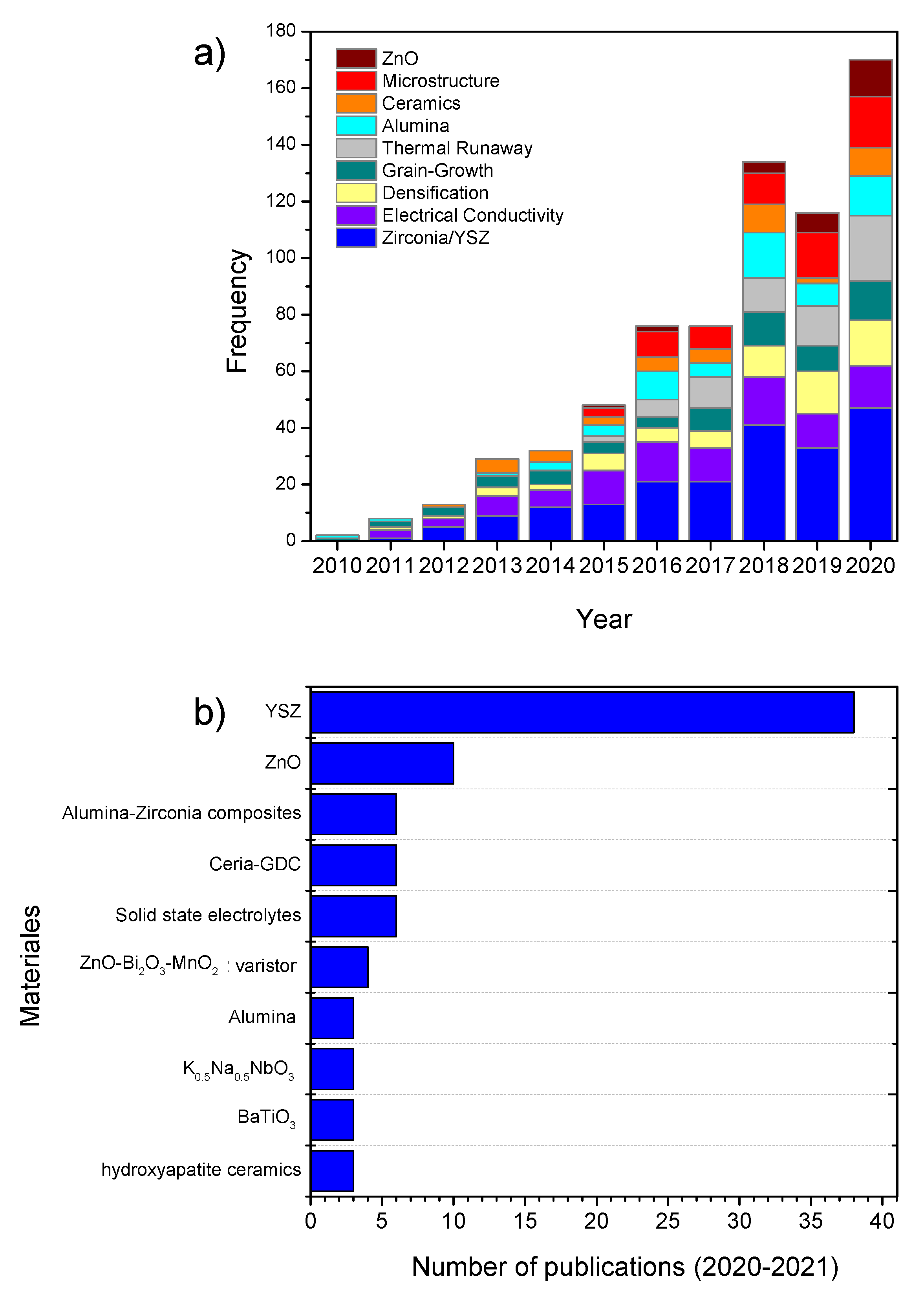

3.1.1. General Descriptive Information

3.1.2. Scientific Production

3.1.3. Source-Level Analysis

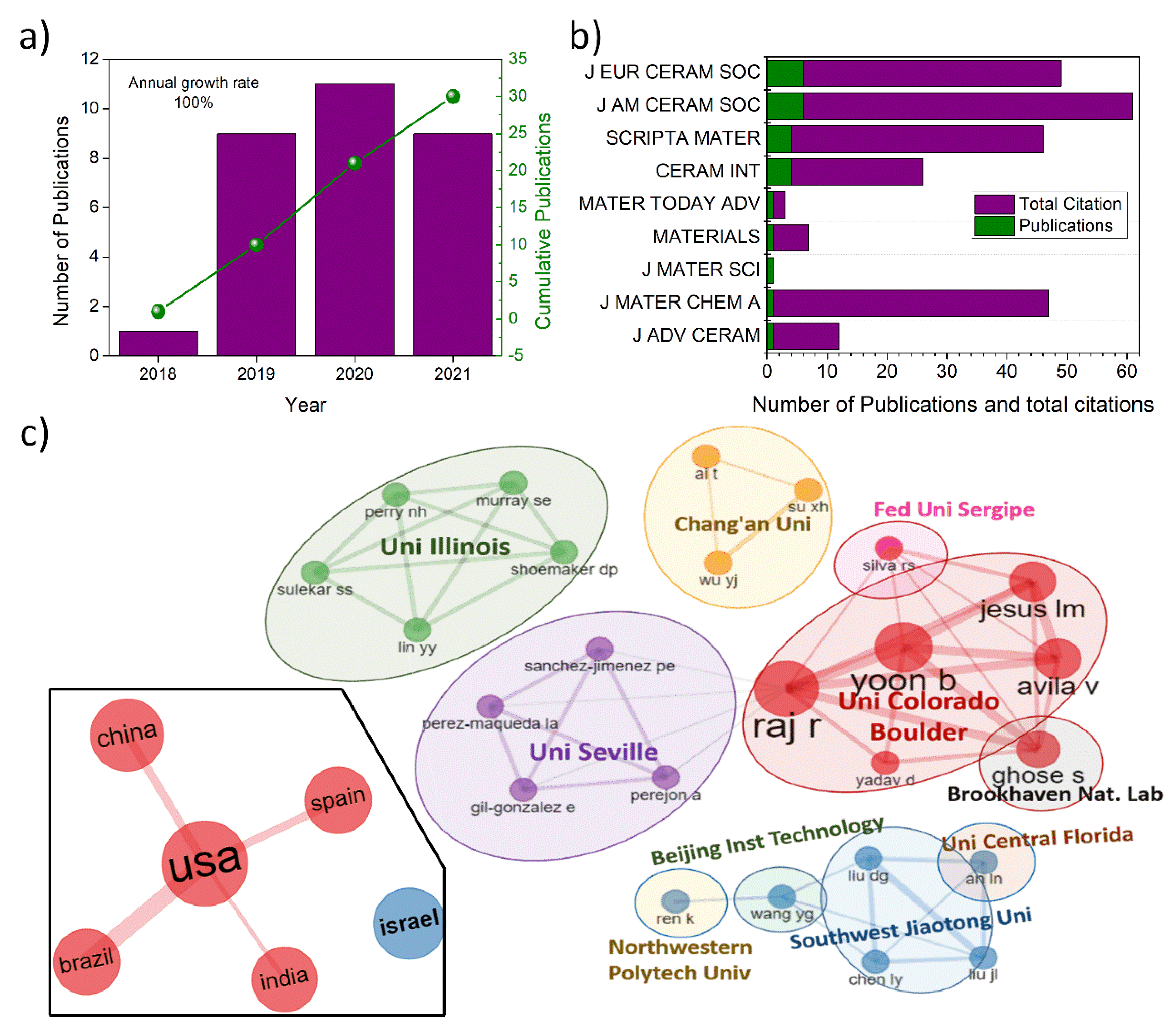

3.1.4. Author-Level Analysis and Networking

3.1.5. Document-Level Analysis. Influential Documents and Trending Topics

3.2. Reactive Flash-Sintering (RFS)

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Guillon, O.; Gonzalez-Julian, J.; Dargatz, B.; Kessel, T.; Schierning, G.; Räthel, J.; Herrmann, M. Field-Assisted Sintering Technology/Spark Plasma Sintering: Mechanisms, Materials, and Technology Developments. Adv. Eng. Mater. 2014, 16, 830–849. [Google Scholar] [CrossRef]

- Cologna, M.; Rashkova, B.; Raj, R. Flash Sintering of Nanograin Zirconia in <5 s at 850 °C. J. Am. Ceram. Soc. 2010, 93, 3556–3559. [Google Scholar] [CrossRef]

- Naik, K.; Jha, S.K.; Raj, R. Correlations between conductivity, electroluminescence and flash sintering. Scr. Mater. 2016, 118, 1–4. [Google Scholar] [CrossRef]

- Todd, R.I.; Zapata-Solvas, E.; Bonilla, R.S.; Sneddon, T.; Wilshaw, P.R. Electrical characteristics of flash sintering: Thermal runaway of Joule heating. J. Eur. Ceram. Soc. 2015, 35, 1865–1877. [Google Scholar] [CrossRef]

- Zhang, Y.; Jung, J.-I.; Luo, J. Thermal runaway, flash sintering and asymmetrical microstructural development of ZnO and ZnO–Bi2O3 under direct currents. Acta Mater. 2015, 94, 87–100. [Google Scholar] [CrossRef] [Green Version]

- Narayan, J. A new mechanism for field-assisted processing and flash sintering of materials. Scr. Mater. 2013, 69, 107–111. [Google Scholar] [CrossRef]

- Chaim, R. Liquid Film Capillary Mechanism for Densification of Ceramic Powders during Flash Sintering. Materials 2016, 9, 280. [Google Scholar] [CrossRef] [Green Version]

- Raj, R. Joule heating during flash-sintering. J. Eur. Ceram. Soc. 2012, 32, 2293–2301. [Google Scholar] [CrossRef]

- Raj, R.; Kulkarni, A.; Lebrun, J.-M.; Jha, S. Flash sintering: A new frontier in defect physics and materials science. MRS Bull. 2021, 46, 36–43. [Google Scholar] [CrossRef]

- Becker, M.Z.; Shomrat, N.; Tsur, Y. Recent Advances in Mechanism Research and Methods for Electric-Field-Assisted Sintering of Ceramics. Adv. Mater. 2018, 30, 1706369. [Google Scholar] [CrossRef]

- Chaim, R. Particle surface softening as universal behaviour during flash sintering of oxide nano-powders. Materials 2017, 10, 179. [Google Scholar] [CrossRef] [Green Version]

- Yoshida, H.; Sakka, Y.; Yamamoto, T.; Lebrun, J.-M.; Raj, R. Densification behaviour and microstructural development in undoped yttria prepared by flash-sintering. J. Eur. Ceram. Soc. 2014, 34, 991–1000. [Google Scholar] [CrossRef]

- Cologna, M.; Francis, J.S.C.; Raj, R. Field assisted and flash sintering of alumina and its relationship to conductivity and MgO-doping. J. Eur. Ceram. Soc. 2011, 31, 2827–2837. [Google Scholar] [CrossRef]

- Zhang, Y.; Luo, J. Promoting the flash sintering of ZnO in reduced atmospheres to achieve nearly full densities at furnace temperatures of <120 °C. Scr. Mater. 2015, 106, 26–29. [Google Scholar] [CrossRef]

- Bicer, H.; Beyoglu, B.; Ozdemir, T.E.; Okasinski, J.; Tsakalakos, T. Direct in situ observation of electric field assisted densification of ZnO by energy dispersive X-ray diffraction. Ceram. Int. 2019, 45, 7614–7618. [Google Scholar] [CrossRef]

- Prette, A.L.G.; Cologna, M.; Sglavo, V.; Raj, R. Flash-sintering of Co2MnO4 spinel for solid oxide fuel cell applications. J. Power Sources 2011, 196, 2061–2065. [Google Scholar] [CrossRef]

- Zapata-Solvas, E.; Bonilla, S.; Wilshaw, P.R.; Todd, R.I. Preliminary investigation of flash sintering of SiC. J. Eur. Ceram. Soc. 2013, 33, 2811–2816. [Google Scholar] [CrossRef]

- Biesuz, M.; Sglavo, V.M. Flash sintering of ceramics. J. Eur. Ceram. Soc. 2019, 39, 115–143. [Google Scholar] [CrossRef]

- Wang, Q.; Watts, C.S.; Athanasiou, C.E.; Dai, Z.; Hu, M.; Sheldon, B.W.; Padture, N.P. The effect of atmosphere on the flash-sintering of nanoscale titania ceramics. Scr. Mater. 2021, 199, 113894. [Google Scholar] [CrossRef]

- Hwang, C.; Yun, J. Effect of processing conditions on the flash onset temperature in hydroxyapatite. Materials 2021, 14, 5229. [Google Scholar] [CrossRef] [PubMed]

- Klauke, K.; Kayaalp, B.; Biesuz, M.; Iannaci, A.; Sglavo, V.M.; D’Arienzo, M.; Lee, S.; Seo, J.; Jung, W.; Mascotto, S. Enhancement of the SrTiO3 Surface Reactivity by Exposure to Electric Fields. ChemNanoMat 2019, 5, 948–956. [Google Scholar] [CrossRef]

- Li, J.; Cho, J.; Ding, J.; Charalambous, H.; Xue, S.; Wang, H.; Phuah, X.L.; Jian, J.; Wang, X.; Ophus, C.; et al. Nanoscale stacking fault–assisted room temperature plasticity in flash-sintered TiO2. Sci. Adv. 2019, 5, eaaw5519. [Google Scholar] [CrossRef] [Green Version]

- Perez-Maqueda, L.A.; Gil-Gonzalez, E.; Perejon, A.; Lebrun, J.-M.; Sanchez-Jimenez, P.E.; Raj, R. Flash sintering of highly insulating nanostructured phase-pure BiFeO3. J. Am. Ceram. Soc. 2017, 100, 3365–3369. [Google Scholar] [CrossRef]

- Gil-González, E.; Perejón, A.; Sánchez-Jiménez, P.E.; Raj, R.; Pérez-Maqueda, L.A. Processing and properties of Bi0.98R0.02FeO3 (R = La, Sm, Y) ceramics flash sintered at ~650 °C in <5 s. J. Am. Ceram. Soc. 2020, 103, 136–144. [Google Scholar] [CrossRef] [Green Version]

- Clemenceau, T.; Andriamady, N.; Kumar M.K., P.; Badran, A.; Avila, V.; Dahl, K.; Hopkins, M.; Vendrell, X.; Marshall, D.; Raj, R. Flash sintering of Li-ion conducting ceramic in a few seconds at 850 °C. Scr. Mater. 2019, 172, 1–5. [Google Scholar] [CrossRef]

- Serrazina, R.; Ribeiro, C.; Costa, M.E.; Pereira, L.; Vilarinho, P.M.; Senos, A.M.O.R. Particle characteristics’ influence on FLASH sintering of potassium sodium niobate: A relationship with conduction mechanisms. Materials 2021, 14, 1321. [Google Scholar] [CrossRef] [PubMed]

- Gil-González, E.; Perejón, A.; Sánchez-Jiménez, P.E.; Sayagués, M.J.; Raj, R.; Pérez-Maqueda, L.A. Phase-pure BiFeO3 produced by reaction flash-sintering of Bi2O3 and Fe2O3. J. Mater. Chem. A 2018, 6, 5356–5366. [Google Scholar] [CrossRef] [Green Version]

- Yu, M.; Grasso, S.; Mckinnon, R.; Saunders, T.; Reece, M.J. Review of flash sintering: Materials, mechanisms and modelling. Adv. Appl. Ceram. 2017, 116, 24–60. [Google Scholar] [CrossRef] [Green Version]

- Pritchard, A. Statistical Bibliography or Bibliometrics? J. Doc. 1969, 25, 348–349. [Google Scholar]

- Dancer, C.E.J. Flash sintering of ceramic materials. Mater. Res. Express 2016, 3, 1–25. [Google Scholar] [CrossRef] [Green Version]

- Zhou, H.; Li, X.; Zhu, Y.; Liu, J.; Wu, A.; Ma, G.; Wang, X.; Jia, Z.; Wang, L. Review of flash sintering with strong electric field. High Volt. 2021, 1–11. [Google Scholar] [CrossRef]

- Aria, M.; Cuccurullo, C. bibliometrix: An R-tool for comprehensive science mapping analysis. J. Informetr. 2017, 11, 959–975. [Google Scholar] [CrossRef]

- Durieux, V.; Gevenois, P.A. Bibliometric indicators: Quality measurements of scientific publication. Radiology 2010, 255, 342–351. [Google Scholar] [CrossRef]

- Zupic, I.; Čater, T. Bibliometric Methods in Management and Organization. Organ. Res. Methods 2014, 18, 429–472. [Google Scholar] [CrossRef]

- Morris, S.A.; Van der Veer Martens, B. Mapping research specialties. Annu. Rev. Inf. Sci. Technol. 2008, 42, 213–295. [Google Scholar] [CrossRef]

- Grasso, S.; Saunders, T.; Porwal, H.; Milsom, B.; Tudball, A.; Reece, M.; Chen, I.-W. Flash Spark Plasma Sintering (FSPS) of α and β SiC. J. Am. Ceram. Soc. 2016, 99, 1534–1543. [Google Scholar] [CrossRef] [Green Version]

- Grasso, S.; Saunders, T.; Porwal, H.; Cedillos-Barraza, O.; Jayaseelan, D.D.; Lee, W.E.; Reece, M.J. Flash spark plasma sintering (FSPS) of pure ZrB2. J. Am. Ceram. Soc. 2014, 97, 2405–2408. [Google Scholar] [CrossRef]

- Manière, C.; Lee, G.; Zahrah, T.; Olevsky, E.A. Microwave flash sintering of metal powders: From experimental evidence to multiphysics simulation. Acta Mater. 2018, 147, 24–34. [Google Scholar] [CrossRef]

- Bykov, Y.V.; Egorov, S.V.; Eremeev, A.G.; Kholoptsev, V.V.; Rybakov, K.I.; Sorokin, A.A. Flash Microwave Sintering of Transparent Yb:(LaY)2O3 Ceramics. J. Am. Ceram. Soc. 2015, 98, 3518–3524. [Google Scholar] [CrossRef]

- Wang, C.; Ping, W.; Bai, Q.; Cui, H.; Hensleigh, R.; Wang, R.; Brozena, A.H.; Xu, Z.; Dai, J.; Pei, Y.; et al. A general method to synthesize and sinter bulk ceramics in seconds. Science 2020, 368, 521–526. [Google Scholar] [CrossRef]

- Shi, R.; Pu, Y.; Wang, W.; Shi, Y.; Li, J.; Guo, X.; Yang, M. Flash sintering of barium titanate. Ceram. Int. 2019, 45, 7085–7089. [Google Scholar] [CrossRef]

- M’Peko, J.-C.; Francis, J.S.C.; Raj, R. Field-assisted sintering of undoped BaTiO3: Microstructure evolution and dielectric permittivity. J. Eur. Ceram. Soc. 2014, 34, 3655–3660. [Google Scholar] [CrossRef]

- Yoshida, H.; Uehashi, A.; Tokunaga, T.; Sasaki, K.; Yamamoto, T. Formation of grain boundary second phase in BaTiO3 polycrystal under a high DC electric field at elevated temperatures. J. Ceram. Soc. Jpn. 2016, 124, 388–392. [Google Scholar] [CrossRef] [Green Version]

- Uehashi, A.; Yoshida, H.; Tokunaga, T.; Sasaki, K.; Yamamoto, T. Enhancement of sintering rates in BaTiO3 by controlling of DC electric current. J. Ceram. Soc. Jpn. 2015, 123, 465–468. [Google Scholar] [CrossRef] [Green Version]

- Nakagawa, Y.; Yoshida, H.; Uehashi, A.; Tokunaga, T.; Sasaki, K.; Yamamoto, T. Electric current-controlled synthesis of BaTiO3. J. Am. Ceram. Soc. 2017, 100, 3843–3850. [Google Scholar] [CrossRef]

- Ren, K.; Huang, S.; Cao, Y.; Shao, G.; Wang, Y. The densification behavior of flash sintered BaTiO3. Scr. Mater. 2020, 186, 362–365. [Google Scholar] [CrossRef]

- Umemura, R.; Tokunaga, T.; Yamamoto, T. Flash sintering for BaTiO3 with square alternating current field including zero-field duration. J. Ceram. Soc. Jpn. 2020, 128, 1018–1023. [Google Scholar] [CrossRef]

- Liu, J.; Ren, K.; Ma, C.; Du, H.; Wang, Y. Dielectric and energy storage properties of flash-sintered high-entropy (Bi0.2Na0.2K0.2Ba0.2Ca0.2)TiO3 ceramic. Ceram. Int. 2020, 46, 20576–20581. [Google Scholar] [CrossRef]

- Jha, S.K.; Terauds, K.; Lebrun, J.-M.; Raj, R. Beyond flash sintering in 3 mol % yttria stabilized zirconia. J. Ceram. Soc. Jpn. 2016, 124, 283–288. [Google Scholar] [CrossRef] [Green Version]

- Downs, J.A.; Sglavo, V.M.; Industriale, I. Electric Field Assisted Sintering of Cubic Zirconia at 390 °C. J. Am. Ceram. Soc. 2013, 1344, 1342–1344. [Google Scholar] [CrossRef]

- Lavagnini, I.R.; Campos, J.V.; Ferreira, J.A.; Pallone, E.M.J.A. Microstructural evolution of 3YSZ flash-sintered with current ramp control. J. Am. Ceram. Soc. 2020, 103, 3493–3499. [Google Scholar] [CrossRef]

- Biesuz, M.; Pinter, L.; Saunders, T.; Reece, M.; Binner, J.; Sglavo, V.M.; Grasso, S. Investigation of electrochemical, optical and thermal effects during flash sintering of 8YSZ. Materials 2018, 11, 1214. [Google Scholar] [CrossRef] [Green Version]

- Jha, S.K.; Charalambous, H.; Wang, H.; Phuah, X.L.; Mead, C.; Okasinski, J.; Wang, H.; Tsakalakos, T. In-situ observation of oxygen mobility and abnormal lattice expansion in ceria during flash sintering. Ceram. Int. 2018, 44, 15362–15369. [Google Scholar] [CrossRef]

- Phuah, X.L.; Wang, H.; Qi, Z.; Misra, S.; Kalaswad, M.; Wang, H. Field-assisted heating of Gd-doped ceria thin film. J. Am. Ceram. Soc. 2020, 103, 2309–2314. [Google Scholar] [CrossRef]

- Mishra, T.P.; Lenser, C.; Raj, R.; Guillon, O.; Bram, M. Development of a processing map for safe flash sintering of gadolinium-doped ceria. J. Am. Ceram. Soc. 2021, 1–13. [Google Scholar] [CrossRef]

- Guan, L.; Li, J.; Song, X.; Bao, J.; Jiang, T. Graphite assisted flash sintering of Sm2O3 doped CeO2 ceramics at the onset temperature of 25 °C. Scr. Mater. 2019, 159, 72–75. [Google Scholar] [CrossRef]

- Gaur, A.; Sglavo, V.M. Tuning the flash sintering characteristics of ceria with MnCo2O4. Mater. Sci. Eng. B Solid-State Mater. Adv. Technol. 2018, 228, 160–166. [Google Scholar] [CrossRef]

- Spiridigliozzi, L.; Pinter, L.; Biesuz, M.; Dell’Agli, G.; Accardo, G.; Sglavo, V.M. Gd/Sm-Pr co-doped ceria: A first report of the precipitation method effect on flash sintering. Materials 2019, 12, 1218. [Google Scholar] [CrossRef] [Green Version]

- Yoon, B.; Yadav, D.; Raj, R.; Sortino, E.P.; Ghose, S.; Sarin, P.; Shoemaker, D. Measurement of O and Ti atom displacements in TiO2 during flash sintering experiments. J. Am. Ceram. Soc. 2018, 101, 1811–1817. [Google Scholar] [CrossRef]

- Zhang, Y.; Nie, J.; Luo, J. Effects of phase and doping on flash sintering of TiO2. J. Ceram. Soc. Jpn. 2016, 124, 296–300. [Google Scholar] [CrossRef] [Green Version]

- Charalambous, H.; Jha, S.K.; Phuah, X.L.; Wang, H.; Wang, H.; Okasinski, J.S.; Tsakalakos, T. In situ measurement of temperature and reduction of rutile titania using energy dispersive x-ray diffraction. J. Eur. Ceram. Soc. 2018, 38, 5503–5511. [Google Scholar] [CrossRef]

- Jongmanns, M.; Wolf, D.E. Element-specific displacements in defect-enriched TiO2: Indication of a flash sintering mechanism. J. Am. Ceram. Soc. 2020, 103, 589–596. [Google Scholar] [CrossRef] [Green Version]

- Biesuz, M.; Ometto, A.; Sglavo, V.M. Flash sintering of YSZ/Al2O3 composites: Effect of processing and testing conditions. Materials 2021, 14, 1031. [Google Scholar] [CrossRef]

- Syed, K.; Xu, M.; Ohtaki, K.K.; Kok, D.; Karandikar, K.K.; Graeve, O.A.; Bowman, W.J.; Mecartney, M.L. Correlations of grain boundary segregation to sintering techniques in a three-phase ceramic. Materialia 2020, 14. [Google Scholar] [CrossRef]

- Biesuz, M.; Ometto, A.; Tyrpekl, V.; Vilémová, M.; Sglavo, V.M. On the power density at the onset for flash sintering in ceramic composites. Scr. Mater. 2021, 201, 113984. [Google Scholar] [CrossRef]

- Sun, K.; Zhang, J.; Jiang, T.; Qiao, J.; Sun, W.; Rooney, D.; Wang, Z. Flash-Sintering and Characterization of La0.8Sr0.2Ga0.8Mg0.2O3-δ Electrolytes for Solid Oxide Fuel Cells. Electrochim. Acta 2016, 196, 487–495. [Google Scholar] [CrossRef]

- Ren, K.; Cao, Y.; Chen, Y.; Shao, G.; Dai, J.; Wang, Y. Flash sintering of Na3Zr2(SiO4)2(PO4) solid-state electrolyte at furnace temperature of 700 °C. Scr. Mater. 2020, 187, 384–389. [Google Scholar] [CrossRef]

- Perez-Maqueda, L.A.; Gil-Gonzalez, E.; Wassel, M.A.; Jha, S.K.; Perejon, A.; Charalambous, H.; Okasinski, J.; Sanchez-Jimenez, P.E.; Tsakalakos, T. Insight into the BiFeO3 flash sintering process by in-situ energy dispersive X-ray diffraction (ED-XRD). Ceram. Int. 2019, 45, 2828–2834. [Google Scholar] [CrossRef]

- Wassel, M.A.B.; Pérez-Maqueda, L.A.; Gil-Gonzalez, E.; Charalambous, H.; Perejon, A.; Jha, S.K.; Okasinski, J.; Tsakalakos, T. Anisotropic lattice expansion determined during flash sintering of BiFeO3 by in-situ energy-dispersive X-ray diffraction. Scr. Mater. 2019, 162, 268–291. [Google Scholar] [CrossRef]

- Şavklıyıldız, İ.; Okur, Ç.; Akdoğan, E.K. Flash sintering and dielectric properties of K0.5Na0.5NbO3. J. Am. Ceram. Soc. 2021, 105, 469–480. [Google Scholar] [CrossRef]

- Corapcioglu, G.; Ali Gulgun, M.; Kisslinger, K.; Sturm, S.; Jha, S.K.; Raj, R. Microstructure and microchemistry of flash sintered K0.5Na0.5NbO3. J. Ceram. Soc. Jpn. 2016, 124, 321–328. [Google Scholar] [CrossRef] [Green Version]

- Serrazina, R.; Dean, J.S.; Reaney, I.M.; Pereira, L.; Vilarinho, P.M.; Senos, A.M.O.R. Mechanism of densification in low-temperature FLASH sintered lead free potassium sodium niobate (KNN) piezoelectrics. J. Mater. Chem. C 2019, 7, 14334–14341. [Google Scholar] [CrossRef]

- Serrazina, R.; Senos, A.M.O.R.; Pereira, L.; Dean, J.S.; Reaney, I.M.; Vilarinho, P.M. The Role of Particle Contact in Densification of FLASH Sintered Potassium Sodium Niobate. Eur. J. Inorg. Chem. 2020, 2020, 3720–3728. [Google Scholar] [CrossRef]

- Cho, J.; Li, Q.; Wang, H.; Fan, Z.; Li, J.; Xue, S.; Vikrant, K.S.N.; Wang, H.; Holland, T.B.; Mukherjee, A.K.; et al. High temperature deformability of ductile flash-sintered ceramics via in-situ compression. Nat. Commun. 2018, 9, 2063. [Google Scholar] [CrossRef] [PubMed]

- Kayaalp, B.; Klauke, K.; Biesuz, M.; Iannaci, A.; Sglavo, V.M.; D’Arienzo, M.; Noei, H.; Lee, S.; Jung, W.; Mascotto, S. Surface Reconstruction under the Exposure of Electric Fields Enhances the Reactivity of Donor-Doped SrTiO3. J. Phys. Chem. C 2019, 123, 16883–16892. [Google Scholar] [CrossRef]

- Saunders, T.; Grasso, S.; Reece, M.J. Ultrafast-Contactless Flash Sintering using Plasma Electrodes. Sci. Rep. 2016, 6, 27222. [Google Scholar] [CrossRef] [PubMed]

- Lebrun, J.-M.; Hellberg, C.S.; Jha, S.K.; Kriven, W.M.; Steveson, A.; Seymour, K.C.; Bernstein, N.; Erwin, S.C.; Raj, R. In-situ measurements of lattice expansion related to defect generation during flash sintering. J. Am. Ceram. Soc. 2017, 100, 4965–4970. [Google Scholar] [CrossRef]

- Kathiria, R.; Wolf, D.E.; Raj, R.; Jongmanns, M. Frenkel pairs cause elastic softening in zirconia: Theory and experiments. New J. Phys. 2021, 23, 53013. [Google Scholar] [CrossRef]

- Jongmanns, M.; Raj, R.; Wolf, D.E. Generation of Frenkel defects above the Debye temperature by proliferation of phonons near the Brillouin zone edge. New J. Phys. 2018, 20, 93013. [Google Scholar] [CrossRef]

- Taibi, A.; Chaguetmi, S.; Sánchez-Jiménez, P.E.; Perejón, A.; García, J.E.; Satha, H.; Pérez-Maqueda, L.A. Pure perovskite BiFeO3-BaTiO3 ceramics prepared by reaction flash sintering of Bi2O3-Fe2O3-BaTiO3 mixed powders. Ceram. Int. 2021. [Google Scholar] [CrossRef]

- Sortino, E.; Lebrun, J.-M.; Sansone, A.; Raj, R. Continuous flash sintering. J. Am. Ceram. Soc. 2018, 101, 1432–1440. [Google Scholar] [CrossRef]

- Lucideon Materials Development and Commercialization [Homepage on the Internet]. Available online: https://www.lucideon.com/ceramics/technologies/flash-sintering (accessed on 22 October 2021).

- Molina-Molina, S.; Gil-González, E.; Durán-Olivencia, F.J.; Valverde, J.M.; Perejón, A.; Sánchez-Jiménez, P.E.; Pérez-Maqueda, L.A. A novel Multi-Phase Flash Sintering (MPFS) technique for 3D complex-shaped ceramics. Appl. Mater. Today 2022, 26, 101274. [Google Scholar] [CrossRef]

- Manière, C.; Lee, G.; Olevsky, E.A. All-Materials-Inclusive Flash Spark Plasma Sintering. Sci. Rep. 2017, 7, 15071. [Google Scholar] [CrossRef]

- Niu, B.; Zhang, F.; Zhang, J.; Ji, W.; Wang, W.; Fu, Z. Ultra-fast densification of boron carbide by flash spark plasma sintering. Scr. Mater. 2016, 116, 127–130. [Google Scholar] [CrossRef]

- Vasylkiv, O.; Borodianska, H.; Sakka, Y.; Demirskyi, D. Flash spark plasma sintering of ultrafine yttria-stabilized zirconia ceramics. Scr. Mater. 2016, 121, 32–36. [Google Scholar] [CrossRef]

- Manière, C.; Harnois, C.; Riquet, G.; Lecourt, J.; Bilot, C.; Marinel, S. Flash spark plasma sintering of zirconia nanoparticles: Electro-thermal-mechanical-microstructural simulation and scalability solutions. J. Eur. Ceram. Soc. 2022, 42, 216–226. [Google Scholar] [CrossRef]

- Hérisson de Beauvoir, T.; Ghomari, Z.; Chevallier, G.; Flaureau, A.; Weibel, A.; Elissalde, C.; Mauvy, F.; Chaim, R.; Estournès, C. Flash Spark Plasma Sintering of 3YSZ: Modified sintering pathway and impact on grain boundary formation. J. Eur. Ceram. Soc. 2021, 41, 7762–7770. [Google Scholar] [CrossRef]

- Johnson, S.L.; Venugopal, G.; Hunt, A.T. Flame-assisted flash sintering: A noncontact method to flash sinter coatings on conductive substrates. J. Am. Ceram. Soc. 2018, 101, 536–541. [Google Scholar] [CrossRef]

- Kermani, M.; Biesuz, M.; Dong, J.; Deng, H.; Bortolotti, M.; Chiappini, A.; Reece, M.J.; Sglavo, V.M.; Hu, C.; Grasso, S. Flash cold sintering: Combining water and electricity. J. Eur. Ceram. Soc. 2020, 40, 6266–6271. [Google Scholar] [CrossRef]

- Dong, J.; Kermani, M.; Hu, C.F.; Grasso, S. Flash cold sintering of Nb2O5: Polarity and electrolyte effects. J. Asian Ceram. Soc. 2021, 9, 934–939. [Google Scholar] [CrossRef]

- Hirsch, J.E. An index to quantify an individual’s scientific research output. Proc. Natl. Acad. Sci. USA 2005, 102, 16569–16572. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cho, J.; Phuah, X.L.; Li, J.; Shang, Z.; Wang, H.; Charalambous, H.; Tsakalakos, T.; Mukherjee, A.K.; Wang, H.; Zhang, X. Temperature effect on mechanical response of flash-sintered ZnO by in-situ compression tests. Acta Mater. 2020, 200, 699–709. [Google Scholar] [CrossRef]

- Mishra, T.P.; Neto, R.R.I.; Speranza, G.; Quaranta, A.; Sglavo, V.M.; Raj, R.; Guillon, O.; Bram, M.; Biesuz, M. Electronic conductivity in gadolinium doped ceria under direct current as a trigger for flash sintering. Scr. Mater. 2020, 179, 55–60. [Google Scholar] [CrossRef]

- Phuah, X.L.; Cho, J.; Akriti; Dou, L.; Rheinheimer, W.; García, R.E.; Zhang, X.; Wang, H. Field-assisted growth of one-dimensional ZnO nanostructures with high defect density. Nanotechnology 2021, 32, 95603. [Google Scholar] [CrossRef]

- Storion, A.G.; Ferreira, J.A.; Maestrelli, S.C.; Maria de Jesus Agnolon Pallone, E. Influence of the forming method on flash sintering of ZnO ceramics. Ceram. Int. 2021, 47, 965–972. [Google Scholar] [CrossRef]

- Mishra, T.P.; Neto, R.R.I.; Raj, R.; Guillon, O.; Bram, M. Current-rate flash sintering of gadolinium doped ceria: Microstructure and Defect generation. Acta Mater. 2020, 189, 145–153. [Google Scholar] [CrossRef]

- Phuah, X.L.; Cho, J.; Tsakalakos, T.; Mukherjee, A.K.; Wang, H.; Zhang, X. Defects in flash-sintered ceramics and their effects on mechanical properties. MRS Bull. 2021, 46, 44–51. [Google Scholar] [CrossRef]

- Xie, H.; Zhang, Y.; Wu, Z.; Lv, T. A Bibliometric Analysis on Land Degradation. Land 2020, 9, 28. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Yu, Q.; Zheng, F.; Long, C.; Lu, Z.; Duan, Z. Comparing keywords plus of WOS and author keywords: A case study of patient adherence research. J. Assoc. Inf. Sci. Technol. 2016, 67, 967–972. [Google Scholar] [CrossRef]

- Yang, B. Flash sintering of additively manufactured 3YSZ gears. J. Am. Ceram. Soc. 2021, 3828–3832. [Google Scholar] [CrossRef]

- Steil, M.C.; Marinha, D.; Aman, Y.; Gomes, J.R.C.; Kleitz, M. From conventional ac flash-sintering of YSZ to hyper-flash and double flash. J. Eur. Ceram. Soc. 2013, 33, 2093–2101. [Google Scholar] [CrossRef]

- Phuah, X.L.; Wang, H.; Charalambous, H.; Jha, S.K.; Tsakalakos, T.; Zhang, X.; Wang, H. Comparison of the grain growth behavior and defect structures of flash sintered ZnO with and without controlled current ramp. Scr. Mater. 2019, 162, 251–255. [Google Scholar] [CrossRef]

- Chaim, R.; Chevallier, G.; Weibel, A.; Estournès, C. Grain growth during spark plasma and flash sintering of ceramic nanoparticles: A review. J. Mater. Sci. 2018, 53, 3087–3105. [Google Scholar] [CrossRef] [Green Version]

- Nie, J.; Zhang, Y.; Chan, J.M.; Huang, R.; Luo, J. Water-assisted flash sintering: Flashing ZnO at room temperature to achieve ~98% density in seconds. Scr. Mater. 2018, 142, 79–82. [Google Scholar] [CrossRef]

- Charalambous, H.; Jha, S.K.; Christian, K.H.; Lay, R.T.; Tsakalakos, T. Flash Sintering using Controlled Current Ramp. J. Eur. Ceram. Soc. 2018, 38, 3689–3693. [Google Scholar] [CrossRef]

- Lachal, M.; El Khal, H.; Bouvard, D.; Chaix, J.-M.; Bouchet, R.; Steil, M.C. Flash sintering of cationic conductive ceramics: A way to build multilayer systems. J. Am. Ceram. Soc. 2021, 104, 3845–3854. [Google Scholar] [CrossRef]

- Mei, Y.; Pandey, S.; Long, W.; Liu, J.; Zhong, S.; Zhang, L.; Du, S.; Xu, D. Processing and characterizations of flash sintered ZnO-Bi2O3-MnO2 varistor ceramics under different electric fields. J. Eur. Ceram. Soc. 2020, 40, 1330–1337. [Google Scholar] [CrossRef]

- Cui, B.; Niu, J.; Peng, P.; Shi, L.; Du, S.; Liu, J.; Xu, D. Flash sintering preparation and electrical properties of ZnO–Bi2O3-M (M = Cr2O3, MnO2 or Co2O3) varistor ceramics. Ceram. Int. 2020, 46, 14913–14918. [Google Scholar] [CrossRef]

- Niu, J.; She, H.; Liu, Z.; Cheng, M.; Xu, J.; Liu, J.; Chen, G.; Tang, B.; Xu, D. A current-controlled flash sintering processing leading to dense and fine-grained typical multi-element ZnO varistor ceramics. J. Alloys Compd. 2021, 876, 160124. [Google Scholar] [CrossRef]

- Mao, H.-R.; Guo, R.-F.; Cao, Y.; Jin, S.-B.; Qiu, X.-M.; Shen, P. Ultrafast densification of high-entropy oxide (La0.2Nd0.2Sm0.2Eu0.2Gd0.2)2Zr2O7 by reactive flash sintering. J. Eur. Ceram. Soc. 2021, 41, 2855–2860. [Google Scholar] [CrossRef]

- Wang, K.; Ma, B.; Li, T.; Xie, C.; Sun, Z.; Liu, D.; Liu, J.; An, L. Fabrication of high-entropy perovskite oxide by reactive flash sintering. Ceram. Int. 2020, 46, 18358–18361. [Google Scholar] [CrossRef]

- Liu, D.; Peng, X.; Liu, J.; Chen, L.; Yang, Y.; An, L. Ultrafast synthesis of entropy-stabilized oxide at room temperature. J. Eur. Ceram. Soc. 2020, 40, 2504–2508. [Google Scholar] [CrossRef]

- Li, W.; Chen, L.; Liu, D.; Liu, J.; An, L. Ultra-low temperature reactive flash sintering synthesis of high-enthalpy and high-entropy Ca0.2Co0.2Ni0.2Cu0.2Zn0.2O oxide ceramics. Mater. Lett. 2021, 304, 130679. [Google Scholar] [CrossRef]

- Yoon, B.; Avila, V.; Raj, R.; Jesus, L.M. Reactive flash sintering of the entropy-stabilized oxide Mg0.2Ni0.2Co0.2Cu0.2Zn0.2O. Scr. Mater. 2020, 181, 48–52. [Google Scholar] [CrossRef]

- Gil-González, E.; Perejón, A.; Sánchez-Jiménez, P.E.; Román-González, D.; Pérez-Maqueda, L.A. Control of experimental conditions in reaction flash-sintering of complex stoichiometry ceramics. Ceram. Int. 2020, 46, 29413–29420. [Google Scholar] [CrossRef]

- Avila, V.; Yoon, B.; Ingraci Neto, R.R.; Silva, R.S.; Ghose, S.; Raj, R.; Jesus, L.M. Reactive flash sintering of the complex oxide Li0.5La0.5TiO3 starting from an amorphous precursor powder. Scr. Mater. 2020, 176, 78–82. [Google Scholar] [CrossRef]

- Avila, V.; Yoon, B.; Ghose, S.; Raj, R.; Jesus, L.M. Phase evolution during reactive flash sintering of Li6.25Al0.25La3Zr2O12 starting from a chemically prepared powder. J. Eur. Ceram. Soc. 2021, 41, 4552–4557. [Google Scholar] [CrossRef]

- Avila, V.; Raj, R. Reactive flash sintering of powders of four constituents into a single phase of a complex oxide in a few seconds below 700 °C. J. Am. Ceram. Soc. 2019, 102, 6443–6448. [Google Scholar] [CrossRef]

- Su, X.; Jiao, Z.; Fu, M.; An, G.; Wu, Y.; Tian, Q.; Xu, P.; Wu, W.; Chang, X.; Liu, J. Ultrafast synthesis and densification of ZrO2 doped KNN ceramics by reactive flash sintering. Int. J. Appl. Ceram. Technol. 2021, 18, 1999–2009. [Google Scholar] [CrossRef]

- Wu, Y.; Su, X.; An, G.; Hong, W. Dense Na0.5K0.5NbO3 ceramics produced by reactive flash sintering of NaNbO3-KNbO3 mixed powders. Scr. Mater. 2020, 174, 49–52. [Google Scholar] [CrossRef]

- Yoon, B.; Yadav, D.; Ghose, S.; Sarin, P.; Raj, R. On the synchronicity of flash sintering and phase transformation. J. Am. Ceram. Soc. 2019, 102, 3110–3116. [Google Scholar] [CrossRef]

- Yoon, B.; Yadav, D.; Ghose, S.; Raj, R. Reactive flash sintering: MgO and α-Al2O3 transform and sinter into single-phase polycrystals of MgAl2O4. J. Am. Ceram. Soc. 2019, 102, 2294–2303. [Google Scholar] [CrossRef]

- Chaim, R. Reactive flash sintering (RFS) in oxide systems: Kinetics and thermodynamics. J. Mater. Sci. 2021, 56, 278–289. [Google Scholar] [CrossRef]

- Chaim, R.; Amouyal, Y. Liquid-Film Assisted Mechanism of Reactive Flash Sintering in Oxide Systems. Materials 2019, 12, 1494. [Google Scholar] [CrossRef] [Green Version]

- Jia, Y.; Su, X.; Wu, Y.; Bai, G.; Wang, Z.; Yan, X.; Ai, T.; Zhao, P. Fabrication of lead zirconate titanate ceramics by reaction flash sintering of PbO-ZrO2-TiO2 mixed oxides. J. Eur. Ceram. Soc. 2019, 39, 3915–3919. [Google Scholar] [CrossRef]

- Murray, S.E.; Jensen, T.J.; Sulekar, S.S.; Lin, Y.-Y.; Perry, N.H.; Shoemaker, D.P. Propagation of the contact-driven reduction of Mn2O3 during reactive flash sintering. J. Am. Ceram. Soc. 2019, 102, 7210–7216. [Google Scholar] [CrossRef]

- Murray, S.E.; Lin, Y.-Y.; Sulekar, S.S.; Gebre, M.S.; Perry, N.H.; Shoemaker, D.P. Predicting transformations during reactive flash sintering in CuO and Mn2O3. J. Am. Ceram. Soc. 2021, 104, 76–85. [Google Scholar] [CrossRef]

| Description | Results |

|---|---|

| Period | 2010–2021 |

| Documents | 318 |

| Sources (Journals, Books, etc.) | 63 |

| Average citations per documents | 25.07 |

| References | 4852 |

| Authors | |

| Authors | 670 |

| Author appearances | 1498 |

| Authors of single-authored documents | 7 |

| Authors of multi-authored documents | 663 |

| Authors Collaboration | |

| Single-authored documents | 17 |

| Documents per Author | 0.475 |

| Authors per Document | 2.11 |

| Co-Authors per Documents | 4.71 |

| Collaboration Index | 2.2 |

| Authors | Articles | h-Index |

|---|---|---|

| Raj R | 53 | 27 |

| Sglavo VM | 36 | 17 |

| Biesuz M | 30 | 14 |

| Jha SK | 22 | 15 |

| Yamamoto T | 18 | 8 |

| Tsakalakos T | 16 | 9 |

| Wang YG | 16 | 9 |

| Wang HY | 16 | 8 |

| Wang H | 15 | 9 |

| Yoshida H | 15 | 9 |

| Charalambous H | 14 | 9 |

| Phuah XL | 14 | 7 |

| Tokunaga T | 14 | 6 |

| Liu JL | 13 | 8 |

| Lebrun JM | 12 | 11 |

| Liu DG | 12 | 8 |

| Chaim R | 12 | 7 |

| Muccillo R | 12 | 7 |

| Grasso S | 12 | 6 |

| Luo J | 11 | 9 |

| Keywords Plus | Frequency | Author’s Keywords | Frequency |

|---|---|---|---|

| Zirconia/YSZ | 160 | Zirconia | 32 |

| Electrical Conductivity | 105 | Microstructure | 29 |

| Densification | 73 | Joule Heating | 19 |

| Grain-growth | 73 | Grain Growth | 16 |

| Thermal Runaway | 71 | ZnO | 14 |

| Alumina | 65 | Impedance Spectroscopy | 12 |

| Ceramics | 49 | Ceramics | 11 |

| Microstructure | 41 | Defects | 11 |

| ZnO | 30 | Electrical Conductivity | 9 |

| Defect Structure | 15 | Alumina | 8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gil-González, E.; Pérez-Maqueda, L.A.; Sánchez-Jiménez, P.E.; Perejón, A. Flash Sintering Research Perspective: A Bibliometric Analysis. Materials 2022, 15, 416. https://doi.org/10.3390/ma15020416

Gil-González E, Pérez-Maqueda LA, Sánchez-Jiménez PE, Perejón A. Flash Sintering Research Perspective: A Bibliometric Analysis. Materials. 2022; 15(2):416. https://doi.org/10.3390/ma15020416

Chicago/Turabian StyleGil-González, Eva, Luis A. Pérez-Maqueda, Pedro E. Sánchez-Jiménez, and Antonio Perejón. 2022. "Flash Sintering Research Perspective: A Bibliometric Analysis" Materials 15, no. 2: 416. https://doi.org/10.3390/ma15020416

APA StyleGil-González, E., Pérez-Maqueda, L. A., Sánchez-Jiménez, P. E., & Perejón, A. (2022). Flash Sintering Research Perspective: A Bibliometric Analysis. Materials, 15(2), 416. https://doi.org/10.3390/ma15020416