Tuning Collective Plasmon Resonances of Femtosecond Laser-Printed Metasurface

Abstract

:1. Introduction

2. Materials and Methods

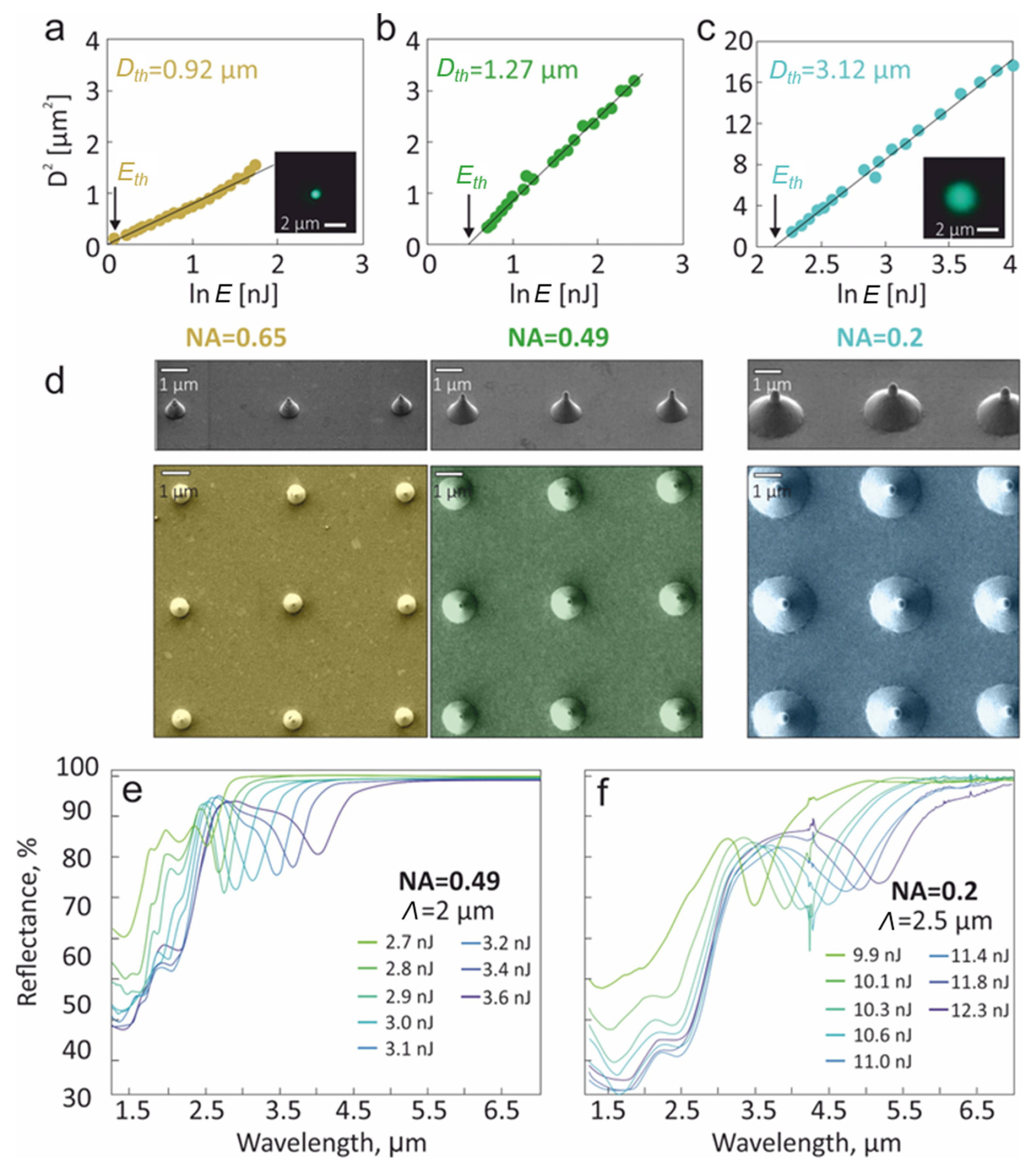

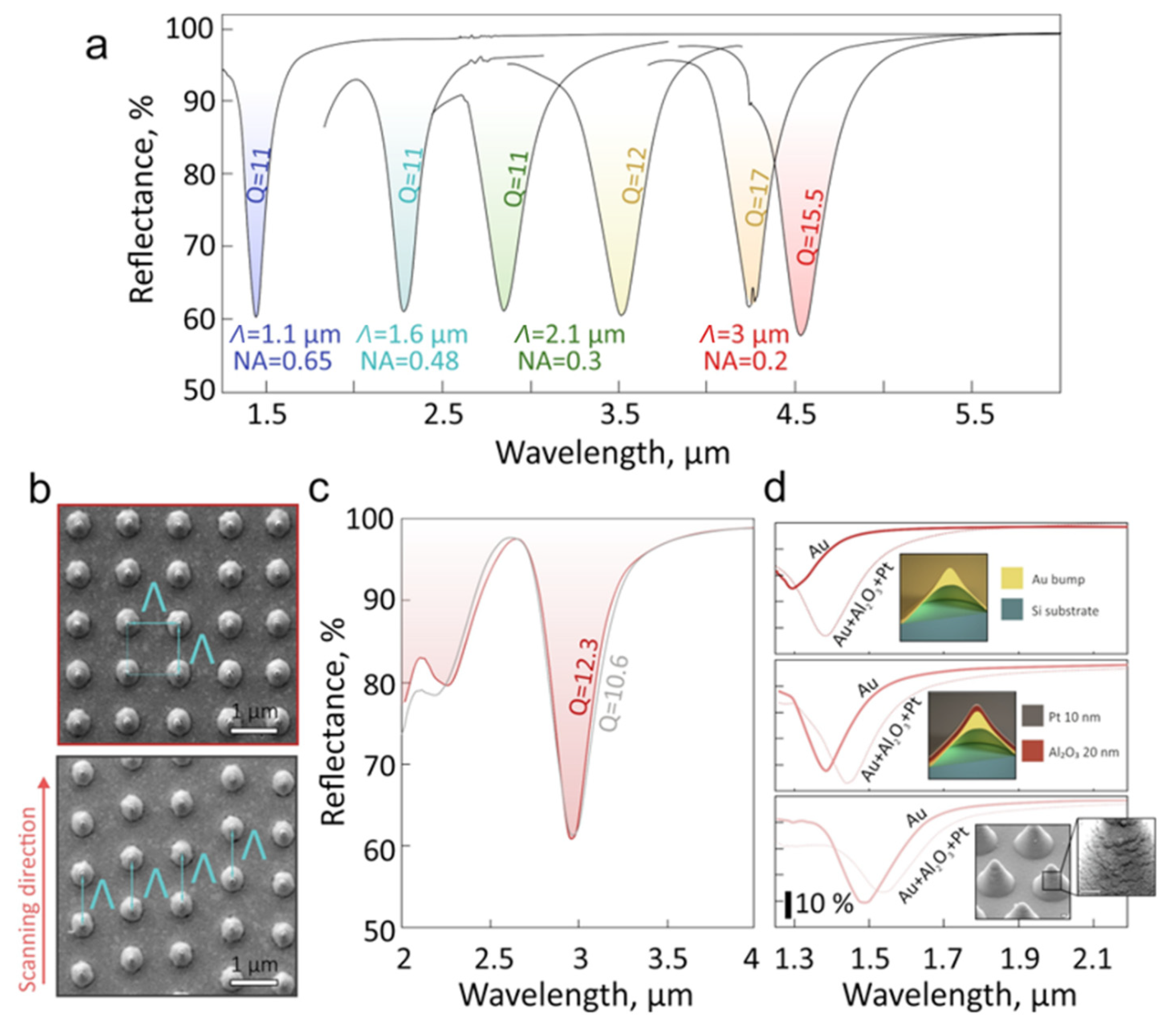

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Homola, J.; Yee, S.S.; Gauglitz, G. Surface plasmon resonance sensors. Sens. Actuator B-Chem. 1999, 54, 3–15. [Google Scholar] [CrossRef]

- Li, W.; Jason, V. Metamaterial perfect absorber based hot electron photodetection. Nano lett. 2014, 14, 3510–3514. [Google Scholar] [CrossRef] [PubMed]

- Sobhani, A.; Knight, M.W.; Wang, Y.; Zheng, B.; King, N.S.; Brown, L.V.; Fang, Z.; Nordlander, P.; Halas, N.J. Narrowband photodetection in the near-infrared with a plasmon-induced hot electron device. Nat. Commun. 2013, 4, 1643. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ding, F.; Yang, Y.; Deshpande, R.A.; Bozhevolnyi, S.I. A review of gap-surface plasmon metasurfaces: Fundamentals and applications. Nanophotonics 2018, 7, 1129–1156. [Google Scholar] [CrossRef]

- Altug, H.; Oh, S.-H.; Maier, S.A.; Homola, J. Advances and applications of nanophotonic biosensors. Nat. Nanotechnol. 2022, 17, 5–16. [Google Scholar] [CrossRef]

- Arya, M.; Ranjan, M.; Bhatnagar, M.; Nath, R.; Mitra, A. In-Plane and Out-of-Plane Plasmons in Random Silver Nanoisland Films. Plasmonics 2018, 13, 373. [Google Scholar] [CrossRef]

- De Abajo, F.G. Colloquium: Light scattering by particle and hole arrays. Rev. Mod. Phys. 2007, 79, 1267. [Google Scholar] [CrossRef] [Green Version]

- Ross, M.B.; Mirkin, C.A.; Schatz, G.C. Optical properties of one-, two-, and three-dimensional arrays of plasmonic nanostructures. J. Phys. Chem. C 2016, 120, 816–830. [Google Scholar] [CrossRef]

- Kravets, V.G.; Kabashin, A.V.; Barnes, W.L.; Grigorenko, A.N. Plasmonic surface lattice resonances: A review of properties and applications. Chem. Rev. 2018, 118, 5912–5951. [Google Scholar] [CrossRef]

- Caligiuri, V.; Tedeschi, G.; Palei, M.; Miscuglio, M.; Martin-Garcia, B.; Guzman-Puyol, S.; Hedayati, M.K.; Kristensen, A.; Athanassiou, A.; Cingolani, R.; et al. Biodegradable and Insoluble Cellulose Photonic Crystals and Metasurfaces. ACS Nano 2020, 14, 9502. [Google Scholar] [CrossRef]

- Malinauskas, M.; Žukauskas, A.; Hasegawa, S.; Hayasaki, Y.; Mizeikis, V.; Buividas, R.; Juodkazis, S. Ultrafast laser processing of materials: From science to industry. Light Sci. Appl. 2016, 5, e16133. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sugioka, K.; Cheng, Y. Ultrafast lasers—reliable tools for advanced materials processing. Light Sci. Appl. 2014, 3, e149. [Google Scholar] [CrossRef]

- Meshcheryakov, Y.P.; Bulgakova, N.M. Thermoelastic modeling of microbump and nanojet formation on nanosize gold films under femtosecond laser irradiation. Appl. Phys. A 2006, 82, 363–368. [Google Scholar] [CrossRef]

- Lin, Z.; Zhigilei, L.V.; Celli, V. Electron-phonon coupling and electron heat capacity of metals under conditions of strong electron-phonon nonequilibrium. Phys. Rev. B 2008, 77, 075133. [Google Scholar] [CrossRef] [Green Version]

- Demaske, B.J.; Zhakhovsky, V.V.; Inogamov, N.A.; Oleynik, I.I. Ablation and spallation of gold films irradiated by ultrashort laser pulses. Phys. Rev. B 2010, 82, 064113. [Google Scholar] [CrossRef] [Green Version]

- Inogamov, N.A.; Zhakhovsky, V.V.; Khokhlov, V.A.; Petrov, Y.V.; Migdal, K.P. Solitary nanostructures produced by ultrashort laser pulse. Nanoscale Res. Lett. 2016, 11, 177. [Google Scholar] [CrossRef] [Green Version]

- Nakata, Y.; Okada, T.; Maeda, M. Nano-sized hollow bump array generated by single femtosecond laser pulse. Jpn. J. Appl. Phys. 2003, 42, L1452. [Google Scholar] [CrossRef]

- Koch, J.; Korte, F.; Bauer, T.; Fallnich, C.; Ostendorf, A.; Chichkov, B.N. Nanotexturing of gold films by femtosecond laser-induced melt dynamics. Appl. Phys. A 2005, 81, 325–328. [Google Scholar] [CrossRef]

- Unger, C.; Koch, J.; Overmeyer, L.; Chichkov, B.N. Time-resolved studies of femtosecond-laser induced melt dynamics. Opt. Express 2012, 20, 24864–24872. [Google Scholar] [CrossRef]

- Nakata, Y.; Miyanaga, N.; Momoo, K.; Hiromoto, T. Solid–liquid–solid process for forming free-standing gold nanowhisker superlattice by interfering femtosecond laser irradiation. Appl. Surf. Sci. 2013, 274, 27–32. [Google Scholar] [CrossRef]

- Kuchmizhak, A.A.; Pavlov, D.V.; Vitrik, O.B.; Kulchin, Y.N. Laser ablative fabrication of nanocrowns and nanojets on the Cu supported film surface using femtosecond laser pulses. Appl. Surf. Sci. 2015, 357, 2378–2384. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.W.; Kuchmizhak, A.A.; Li, X.; Juodkazis, S.; Vitrik, O.B.; Kulchin, Y.N.; Zhakhovsky, V.V.; Danilov, P.A.; Ionin, A.A.; Kudryashov, S.I.; et al. Laser-induced translative hydrodynamic mass snapshots: Noninvasive characterization and predictive modeling via mapping at nanoscale. Phys. Rev. Appl. 2017, 8, 044016. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Kuchmizhak, A.; Storozhenko, D.; Makarov, S.; Juodkazis, S. Single-step laser plasmonic coloration of metal films. ACS Appl. Mater. Interfaces 2018, 10, 1422–1427. [Google Scholar] [CrossRef] [PubMed]

- Pavlov, D.; Gurbatov, S.; Kudryashov, S.I.; Danilov, P.A.; Porfirev, A.P.; Khonina, S.N.; Vitrik, O.; Kulinich, S.; Lapine, M.; Kuchmizhak, A.A. 10-million-elements-per-second printing of infrared-resonant plasmonic arrays by multiplexed laser pulses. Opt. Lett. 2019, 44, 283–286. [Google Scholar] [CrossRef] [PubMed]

- Reininghaus, M.; Wortmann, D.; Cao, Z.; Hoffmann, J.M.; Taubner, T. Fabrication and spectral tuning of standing gold infrared antennas using single fs-laser pulses. Opt. Express 2013, 21, 32176–32183. [Google Scholar] [CrossRef] [PubMed]

- Pavlov, D.V.; Zhizhchenko, A.Y.; Honda, M.; Yamanaka, M.; Vitrik, O.B.; Kulinich, S.A.; Juodkazis, S.; Kudryashov, S.I.; Kuchmizhak, A.A. Multi-purpose nanovoid array plasmonic sensor produced by direct laser patterning. Nanomaterials 2019, 9, 1348. [Google Scholar] [CrossRef] [Green Version]

- Guo, Y.; Zhang, K.; Zhang, M.; Chai, Y.; Du, Y.; Hu, G. Plasmonic gold nanojets fabricated by a femtosecond laser irradiation. Opt. Express 2021, 29, 20063–20076. [Google Scholar] [CrossRef]

- Stankevičius, E.; Vilkevičius, K.; Gedvilas, M.; Bužavaitė-Vertelienė, E.; Selskis, A.; Balevičius, Z. Direct Laser Writing for the Formation of Large-Scale Gold Microbumps Arrays Generating Hybrid Lattice Plasmon Polaritons in Vis–NIR Range. Adv. Opt. Mater. 2021, 9, 2100027. [Google Scholar] [CrossRef]

- Cherepakhin, A.B.; Pavlov, D.V.; Shishkin, I.I.; Voroshilov, P.M.; Juodkazis, S.; Makarov, S.V.; Kuchmizhak, A.A. Laser-printed hollow nanostructures for nonlinear plasmonics. Appl. Phys. Lett. 2020, 117, 041108. [Google Scholar] [CrossRef]

- Sergeev, A.A.; Pavlov, D.V.; Kuchmizhak, A.A.; Lapine, M.V.; Yiu, W.K.; Dong, Y.; Ke, N.; Juodkazis, S.; Zhao, N.; Kershaw, S.V.; et al. Tailoring spontaneous infrared emission of HgTe quantum dots with laser-printed plasmonic arrays. Light Sci. Appl. 2020, 9, 16. [Google Scholar] [CrossRef]

- Pavlov, D.; Syubaev, S.; Kuchmizhak, A.; Gurbatov, S.; Vitrik, O.; Modin, E.; Kudryashov, S.I.; Wang, X.; Juodkazis, S.; Lapine, M. Direct laser printing of tunable IR resonant nanoantenna arrays. Appl. Surf. Sci. 2019, 469, 514–520. [Google Scholar] [CrossRef]

- Pavlov, D.V.; Gurbatov, S.O.; Kudryashov, S.I.; Gurevich, E.L.; Kuchmizhak, A.A. Laser-induced surface relief nanocrowns as a manifestation of nanoscale Rayleigh-Plateau hydrodynamic instability. Appl. Surf. Sci. 2020, 511, 145463. [Google Scholar] [CrossRef] [Green Version]

- Rodrigo, S.G.; García-Vidal, F.J.; Martín-Moreno, L. Influence of material properties on extraordinary optical transmission through hole arrays. Phys. Rev. B 2008, 77, 075401. [Google Scholar] [CrossRef] [Green Version]

- Murray-Méthot, M.-P.; Ratel, M.; Masson, J.-F. Optical properties of Au, Ag, and bimetallic Au on Ag nanohole arrays. J. Phys. Chem. C 2010, 114, 8268–8275. [Google Scholar] [CrossRef]

- Kudryashov, S.I.; Danilov, P.A.; Porfirev, A.P.; Saraeva, I.N.; Nguyen, T.H.; Rudenko, A.A.; Khmelnitskii, R.A.; Zayarny, D.A.; Ionin, A.A.; Kuchmizhak, A.A.; et al. High-throughput micropatterning of plasmonic surfaces by multiplexed femtosecond laser pulses for advanced IR-sensing applications. Appl. Surf. Sci. 2019, 484, 948–956. [Google Scholar] [CrossRef]

- Pavlov, D.; Porfirev, A.; Khonina, S.; Pan, L.; Kudryashov, S.I.; Kuchmizhak, A.A. Coaxial hole array fabricated by ultrafast femtosecond-laser processing with spatially multiplexed vortex beams for surface enhanced infrared absorption. Appl. Surf. Sci. 2021, 541, 148602. [Google Scholar] [CrossRef]

- Ruiz de Galarreta, C.; Casquero, N.; Humphreys, E.; Bertolotti, J.; Solis, J.; Wright, C.D.; Siegel, J. Single-Step Fabrication of High-Performance Extraordinary Transmission Plasmonic Metasurfaces Employing Ultrafast Lasers. ACS Appl. Mater. Interfaces 2022, 14, 3446–3454. [Google Scholar] [CrossRef]

- Liu, J.M. Simple technique for measurements of pulsed Gaussian-beam spot sizes. Opt. Lett. 1982, 7, 196–198. [Google Scholar] [CrossRef]

- Liang, Y.; Lin, H.; Lin, S.; Wu, J.; Li, W.; Meng, F.; Yang, Y.; Huang, X.; Jia, B.; Kivshar, Y. Hybrid anisotropic plasmonic metasurfaces with multiple resonances of focused light beams. Nano Lett. 2021, 21, 8917–8923. [Google Scholar] [CrossRef]

- Liang, Y.; Koshelev, K.; Zhang, F.; Lin, H.; Lin, S.; Wu, J.; Jia, B.; Kivshar, Y. Bound states in the continuum in anisotropic plasmonic metasurfaces. Nano Lett. 2020, 20, 6351–6356. [Google Scholar] [CrossRef]

- Reshef, O.; Saad-Bin-Alam, M.; Huttunen, M.J.; Carlow, G.; Sullivan, B.T.; Ménard, J.M.; Boyd, R.W. Multiresonant high-Q plasmonic metasurfaces. Nano Lett. 2019, 19, 6429–6434. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yanik, A.A.; Cetin, A.E.; Huang, M.; Artar, A.; Mousavi, S.H.; Khanikaev, A.; Altug, H. Seeing protein monolayers with naked eye through plasmonic Fano resonances. Proc. Nat. Acad. Sci. USA 2011, 108, 11784–11789. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Romain, A.-C.; Nicolas, J. Long term stability of metal oxide-based gas sensors for e-nose environmental applications: An overview. Sens. Actuator B Chem. 2010, 146, 502–506. [Google Scholar] [CrossRef] [Green Version]

- Beni, T.; Yamasaku, N.; Kurotsu, T.; To, N.; Okazaki, S.; Arakawa, T.; Balcytis, A.; Seniutinas, G.; Juodkazis, S.; Nishijima, Y. Metamaterial for hydrogen sensing. ACS Sens. 2019, 4, 2389–2394. [Google Scholar] [CrossRef] [PubMed]

- Neubrech, F.; Huck, C.; Weber, K.; Pucci, A.; Giessen, H. Surface-enhanced infrared spectroscopy using resonant nanoantennas. Chem. Rev. 2017, 117, 5110–5145. [Google Scholar] [CrossRef]

- Tittl, A.; Leitis, A.; Liu, M.; Yesilkoy, F.; Choi, D.-Y.; Neshev, D.N.; Kivshar, Y.S.; Altug, H. Imaging-based molecular barcoding with pixelated dielectric metasurfaces. Science 2018, 360, 1105–1109. [Google Scholar] [CrossRef] [Green Version]

- Berzins, J.; Indrisiunas, S.; Van Erve, K.; Nagarajan, A.; Fasold, S.; Steinert, M.; Gerini, G.; Gecys, P.; Pertisch, T.; Baumer, S.M.; et al. Direct and high-throughput fabrication of Mie-resonant metasurfaces via single-pulse laser interference. ACS Nano 2020, 14, 6138–6149. [Google Scholar] [CrossRef] [Green Version]

- El-Khoury, M.; Voisiat, B.; Kunze, T.; Lasagni, A.F. Utilizing a Diffractive Focus Beam Shaper to Enhance Pattern Uniformity and Process Throughput during Direct Laser Interference Patterning. Materials 2022, 15, 591. [Google Scholar] [CrossRef]

- Nakata, Y.; Tsubakimoto, K.; Miyanaga, N.; Narazaki, A.; Shoji, T.; Tsuboi, Y. Laser-induced transfer of noble metal nanodots with femtosecond laser-interference processing. Nanomaterials 2021, 11, 305. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pavlov, D.; Zhizhchenko, A.; Pan, L.; Kuchmizhak, A.A. Tuning Collective Plasmon Resonances of Femtosecond Laser-Printed Metasurface. Materials 2022, 15, 1834. https://doi.org/10.3390/ma15051834

Pavlov D, Zhizhchenko A, Pan L, Kuchmizhak AA. Tuning Collective Plasmon Resonances of Femtosecond Laser-Printed Metasurface. Materials. 2022; 15(5):1834. https://doi.org/10.3390/ma15051834

Chicago/Turabian StylePavlov, Dmitrii, Alexey Zhizhchenko, Lei Pan, and Aleksandr A. Kuchmizhak. 2022. "Tuning Collective Plasmon Resonances of Femtosecond Laser-Printed Metasurface" Materials 15, no. 5: 1834. https://doi.org/10.3390/ma15051834