Correlation Analysis between Mechanical Properties and Fractions Composition of Oil-Rejuvenated Asphalt

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.1.1. Asphalt Binders

2.1.2. Oil-Rejuvenator

2.2. Preparation of Oil-Rejuvenated Asphalt

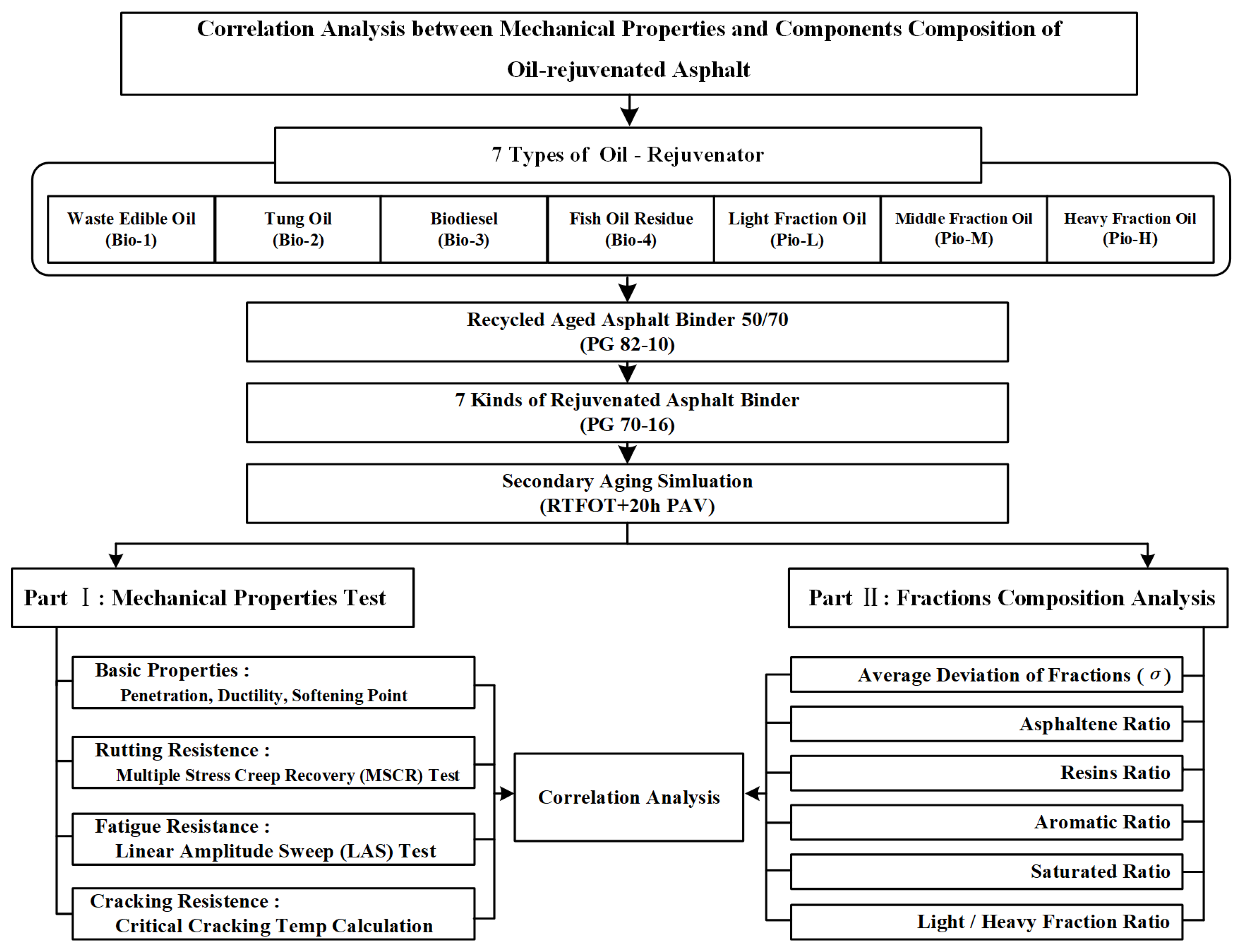

2.3. Design of Experiments

2.4. Measurement and Characterization

2.4.1. Basic Properties Test

2.4.2. Performance Grade (PG)

2.4.3. Low-Temperature Cracking Resistance Test

2.4.4. Linear Amplitude Sweep (LAS) Test

2.4.5. Multiple Stress Creep Recovery (MSCR) Test

2.4.6. Fraction Analysis of the Asphalt

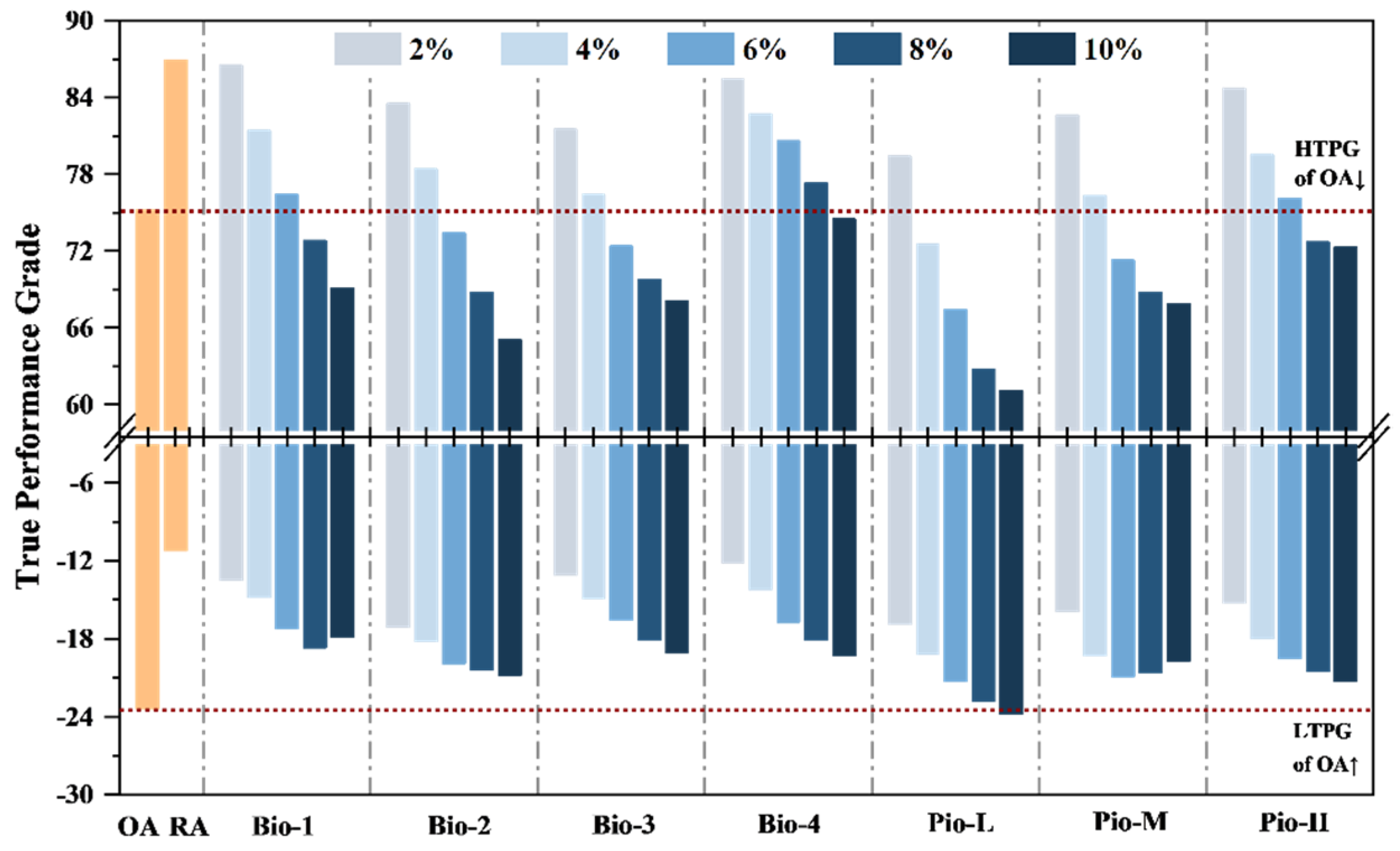

2.5. Dosage of Oil-Rejuvenators

3. Test Results

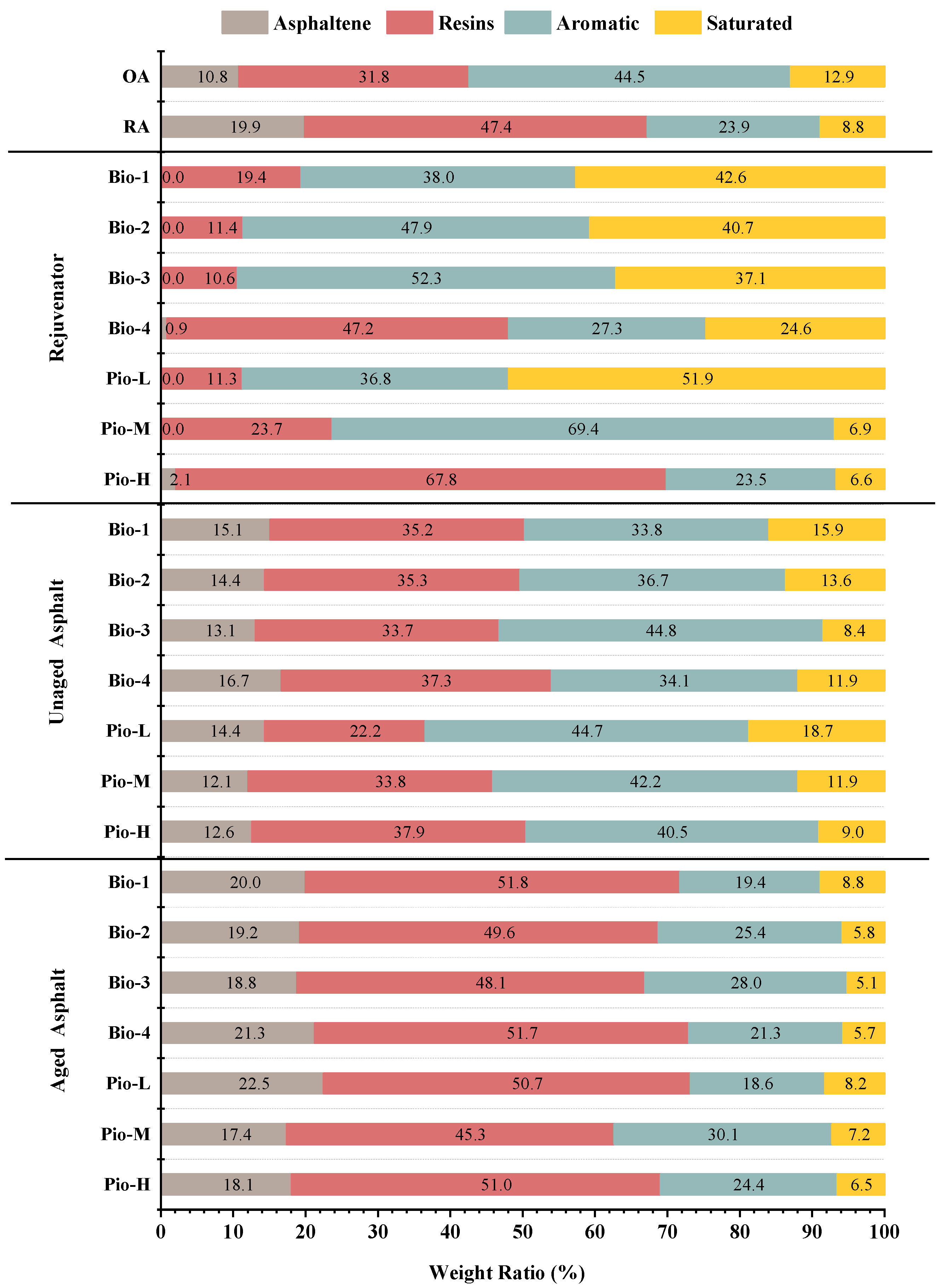

3.1. SARA Fractions Analysis

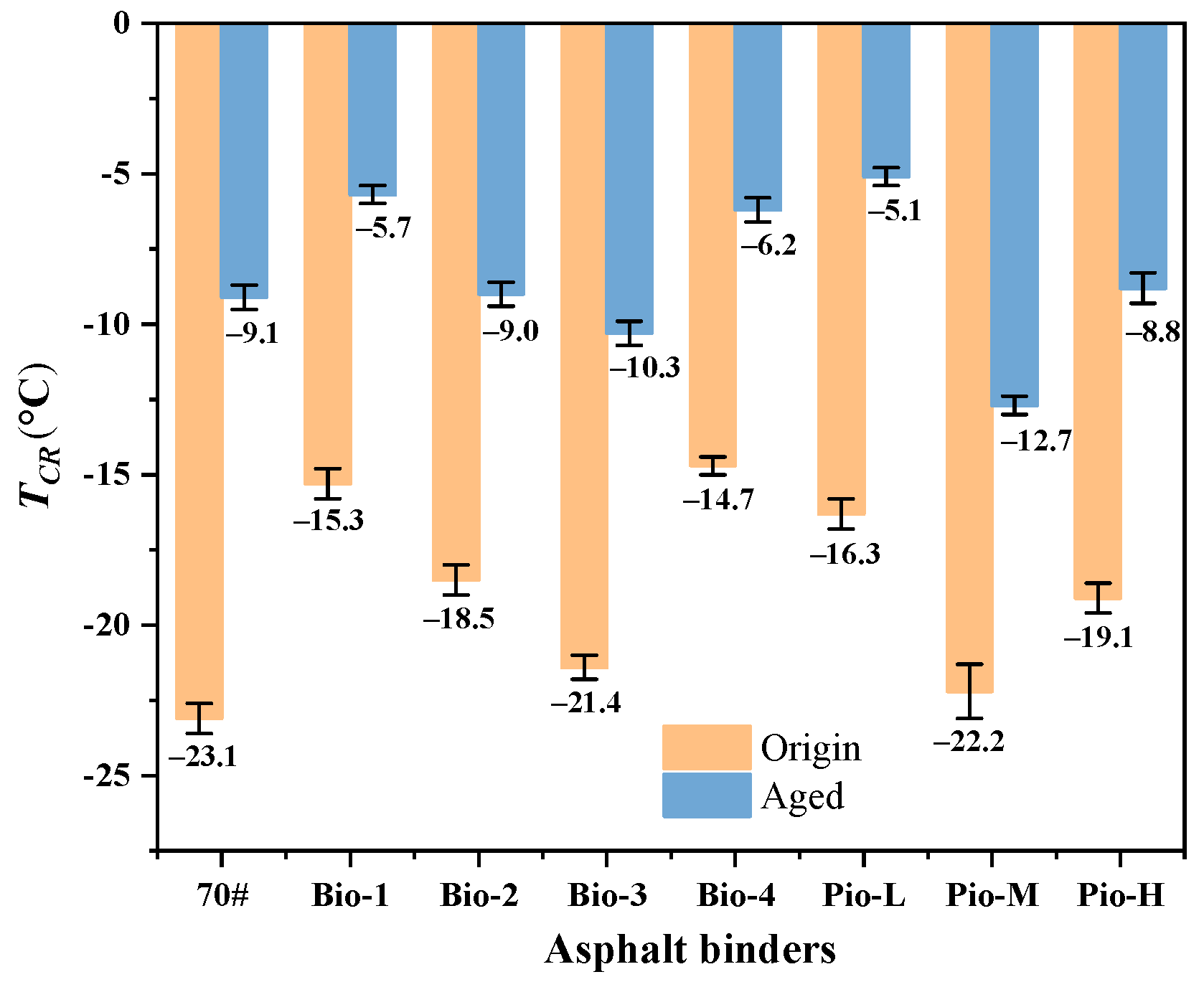

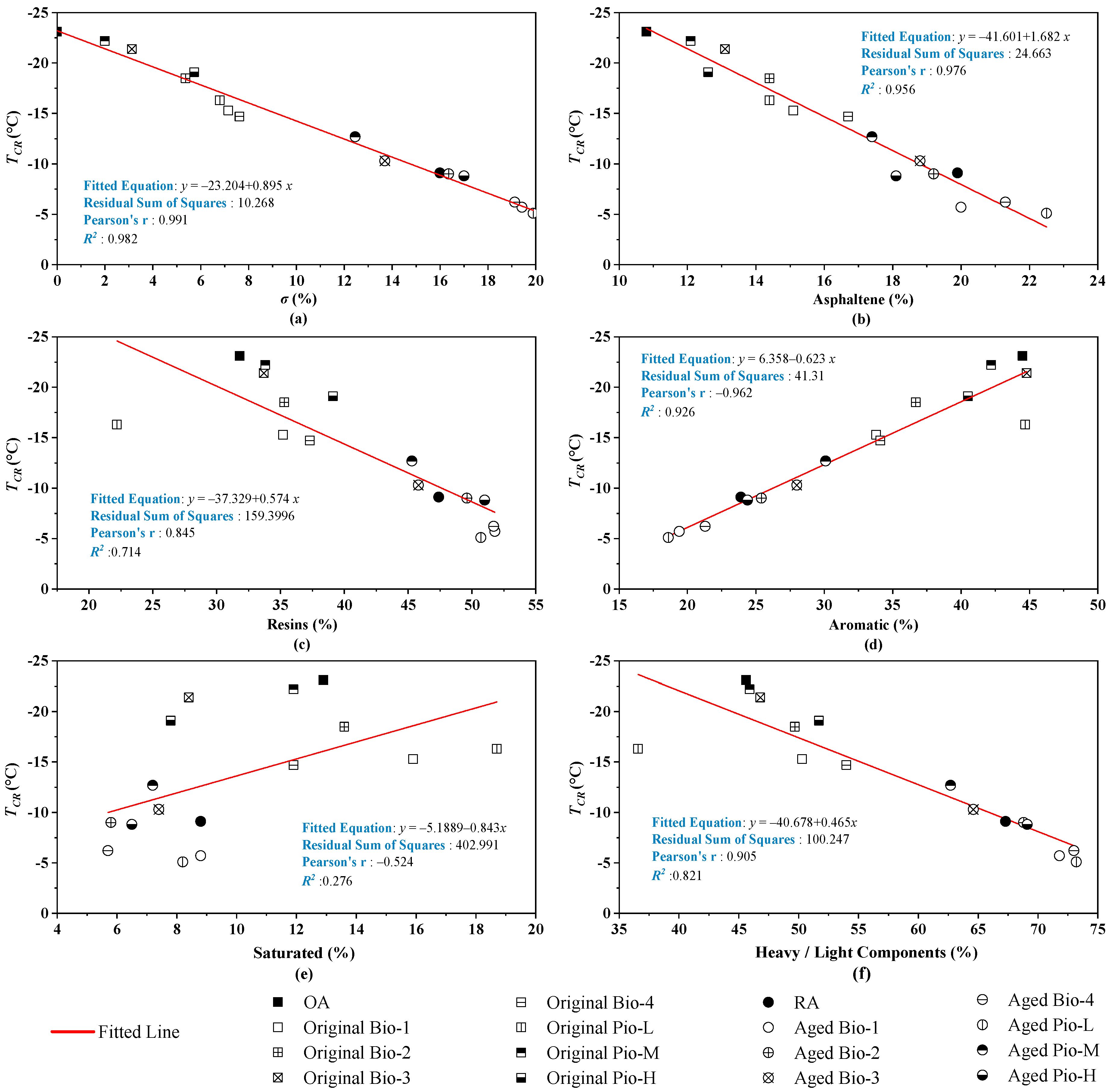

3.2. Cracking Resistance

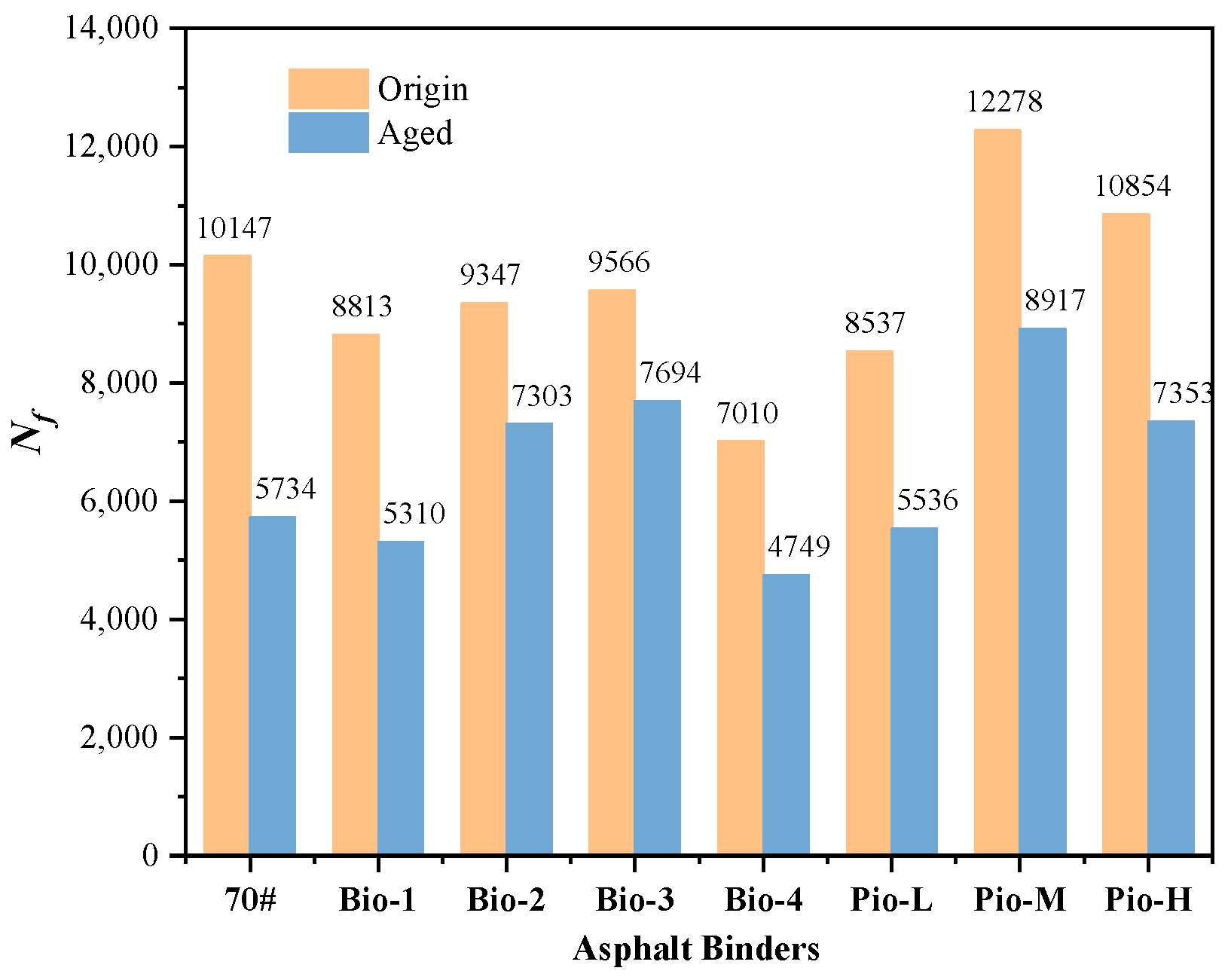

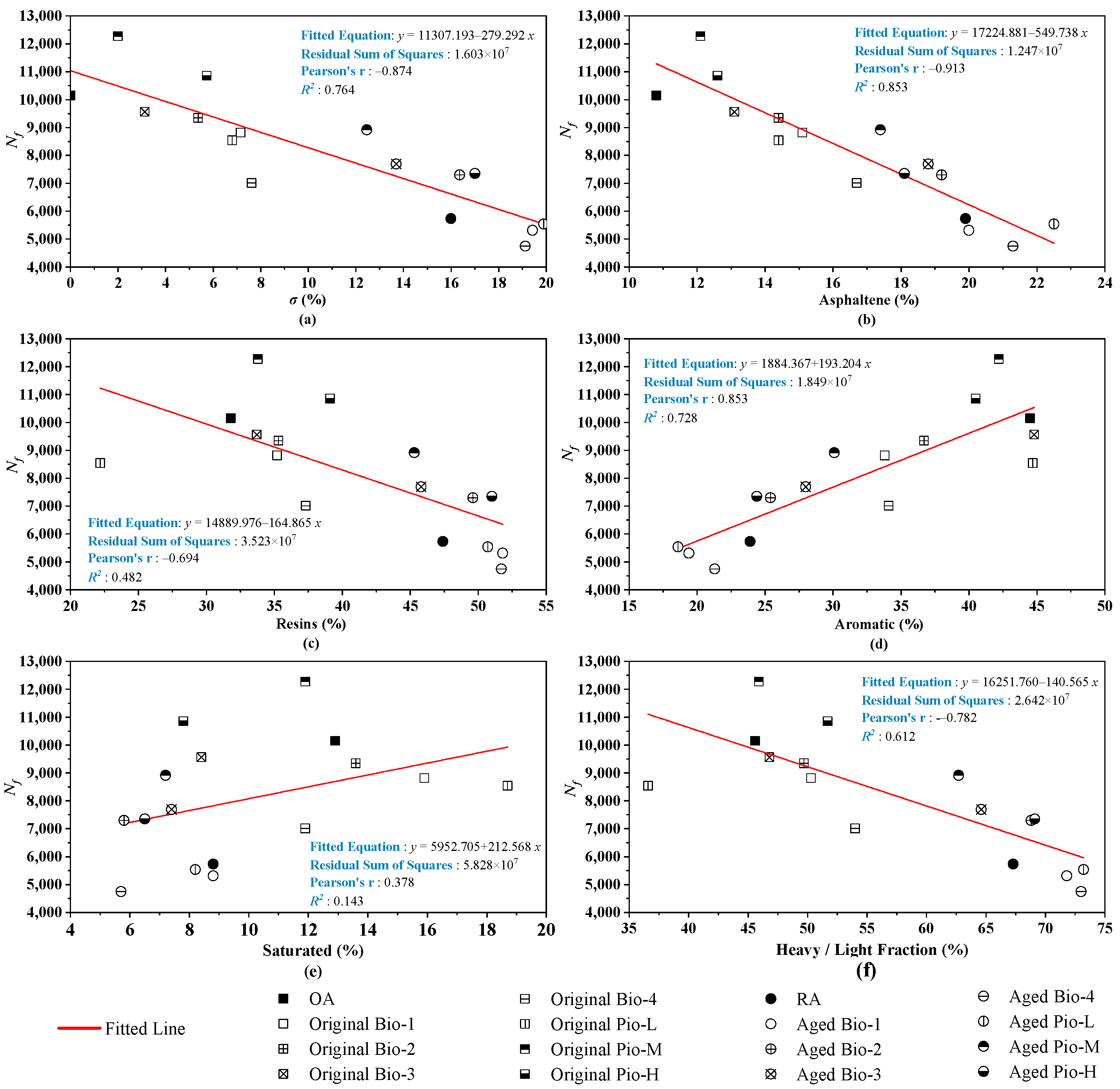

3.3. Fatigue Resistance

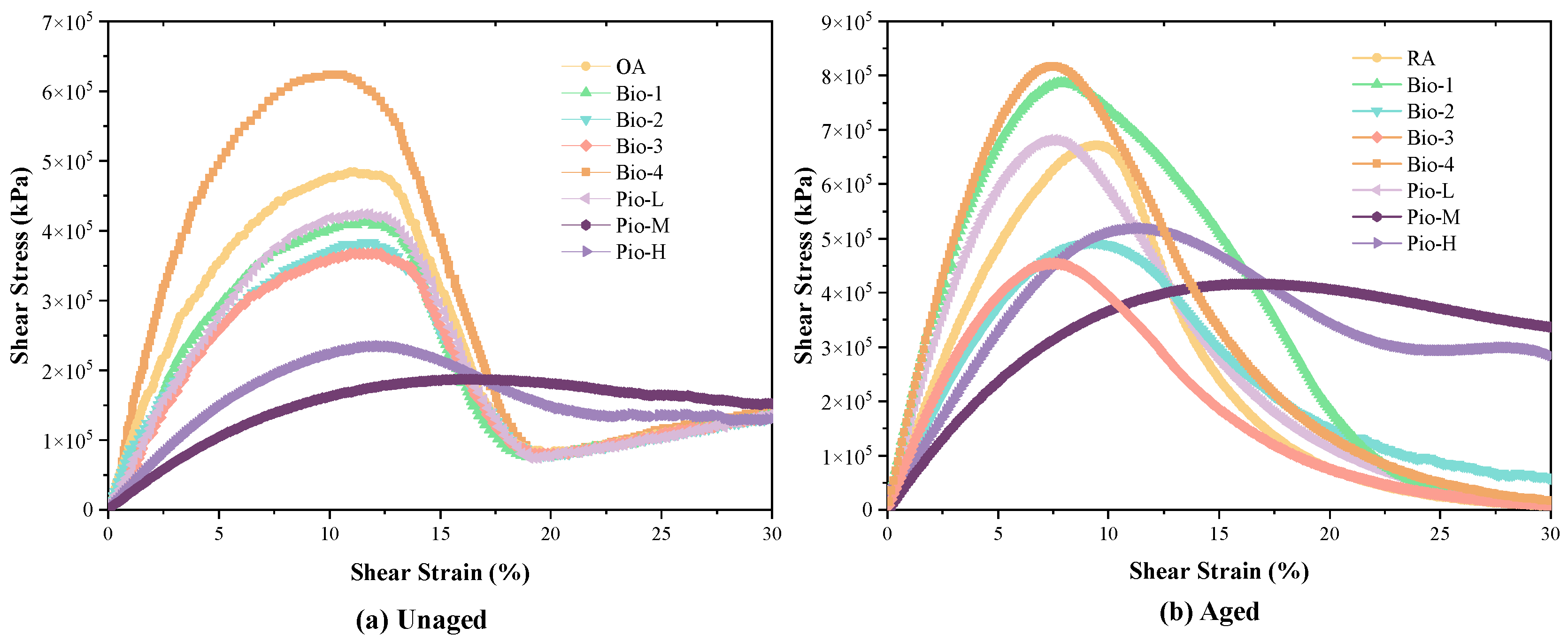

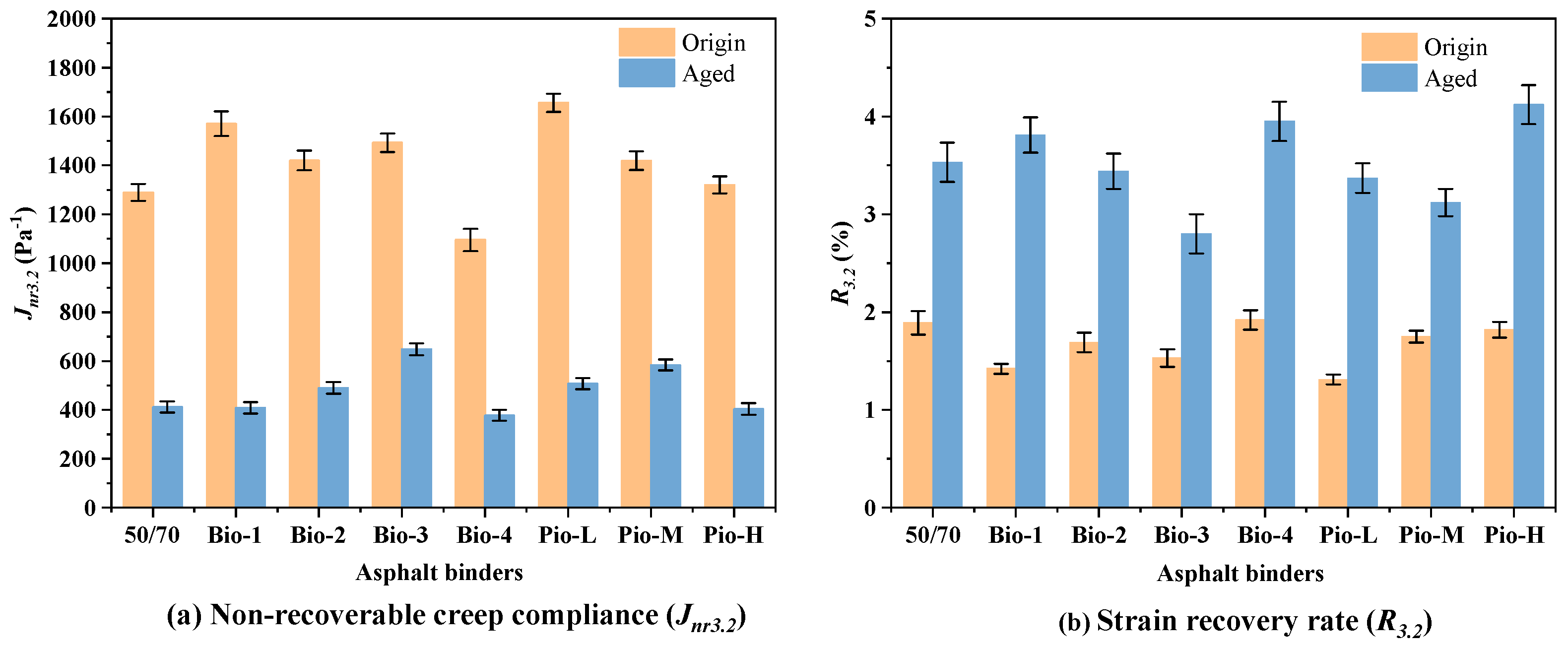

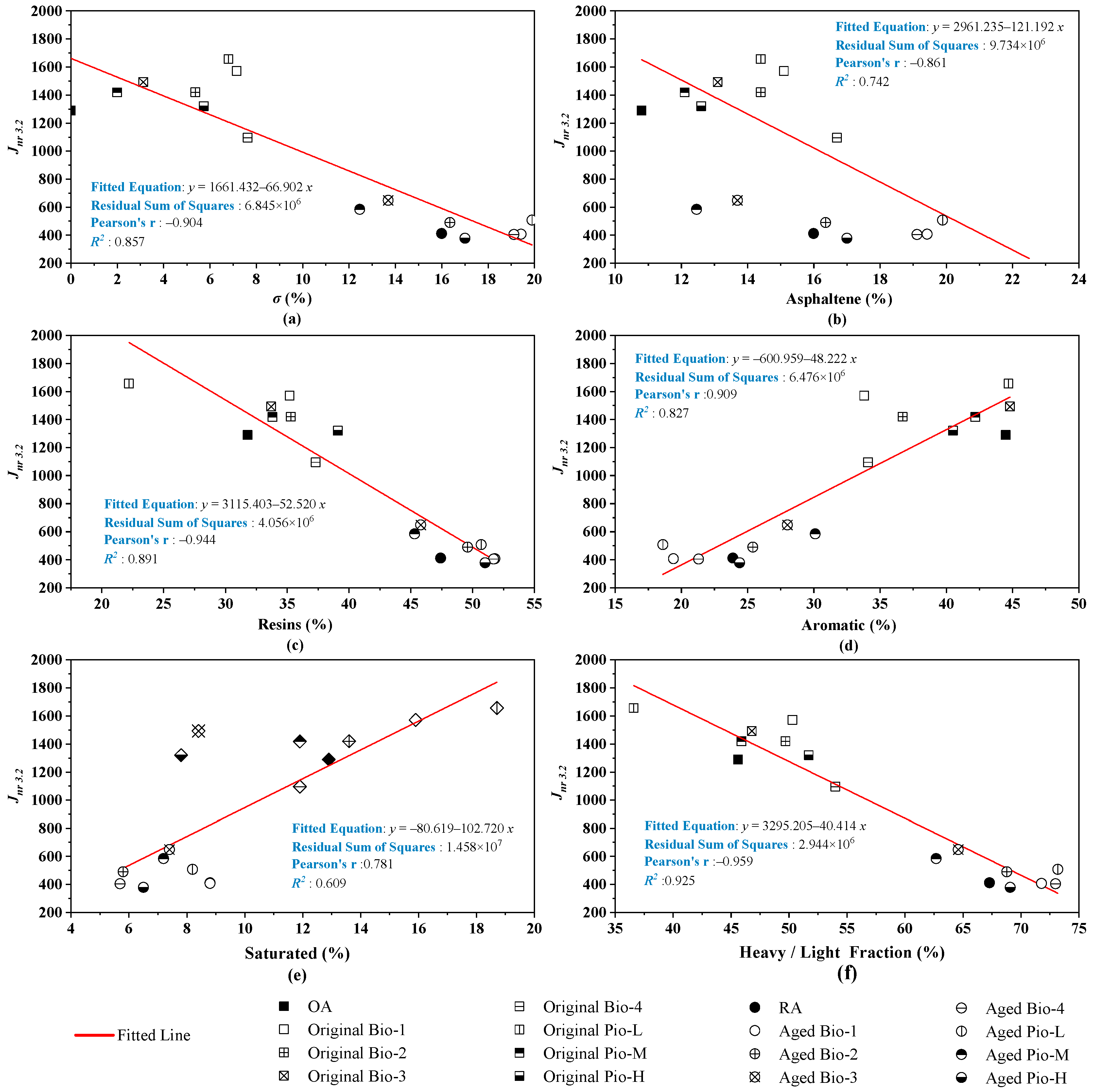

3.4. Rutting Resistance

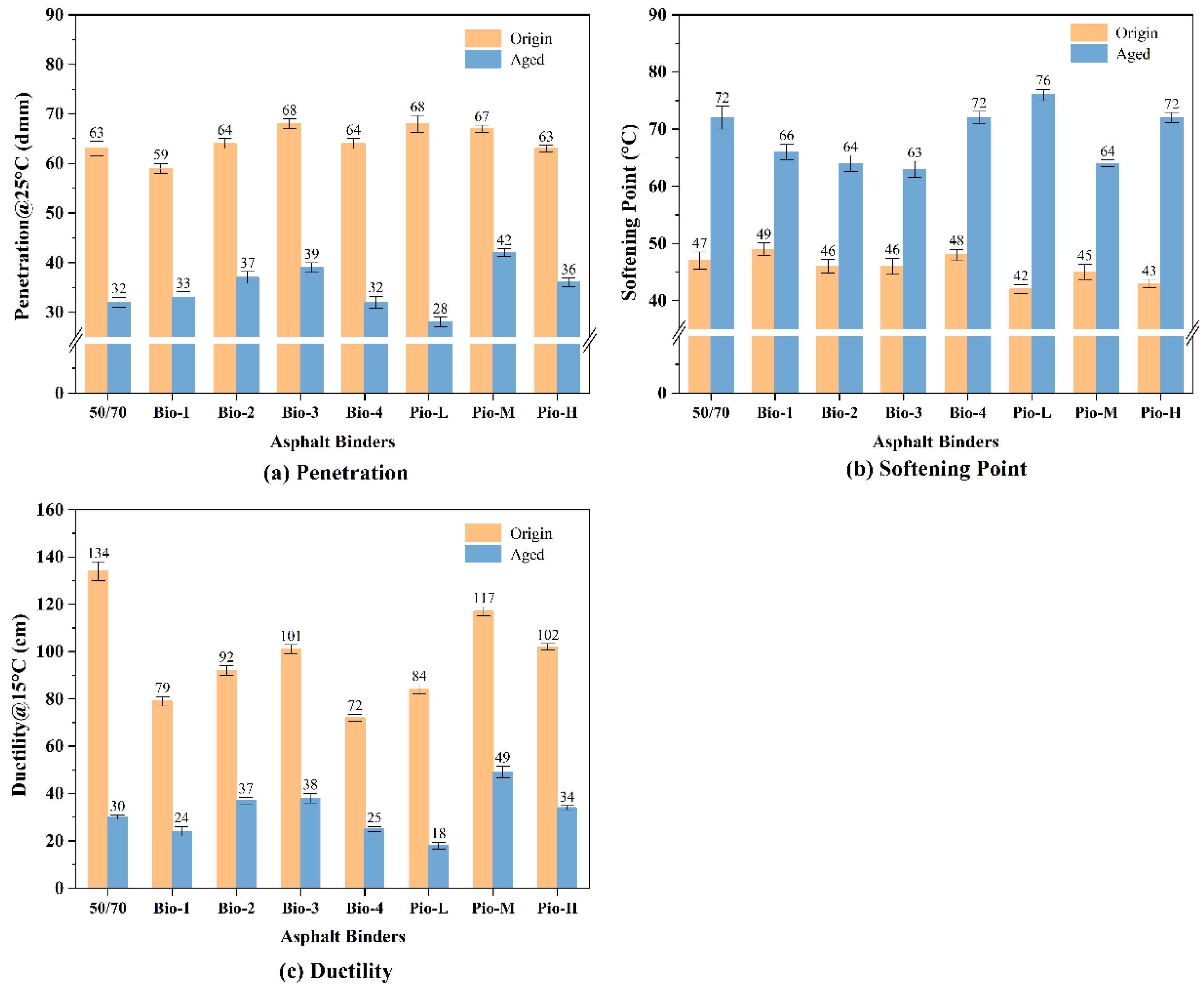

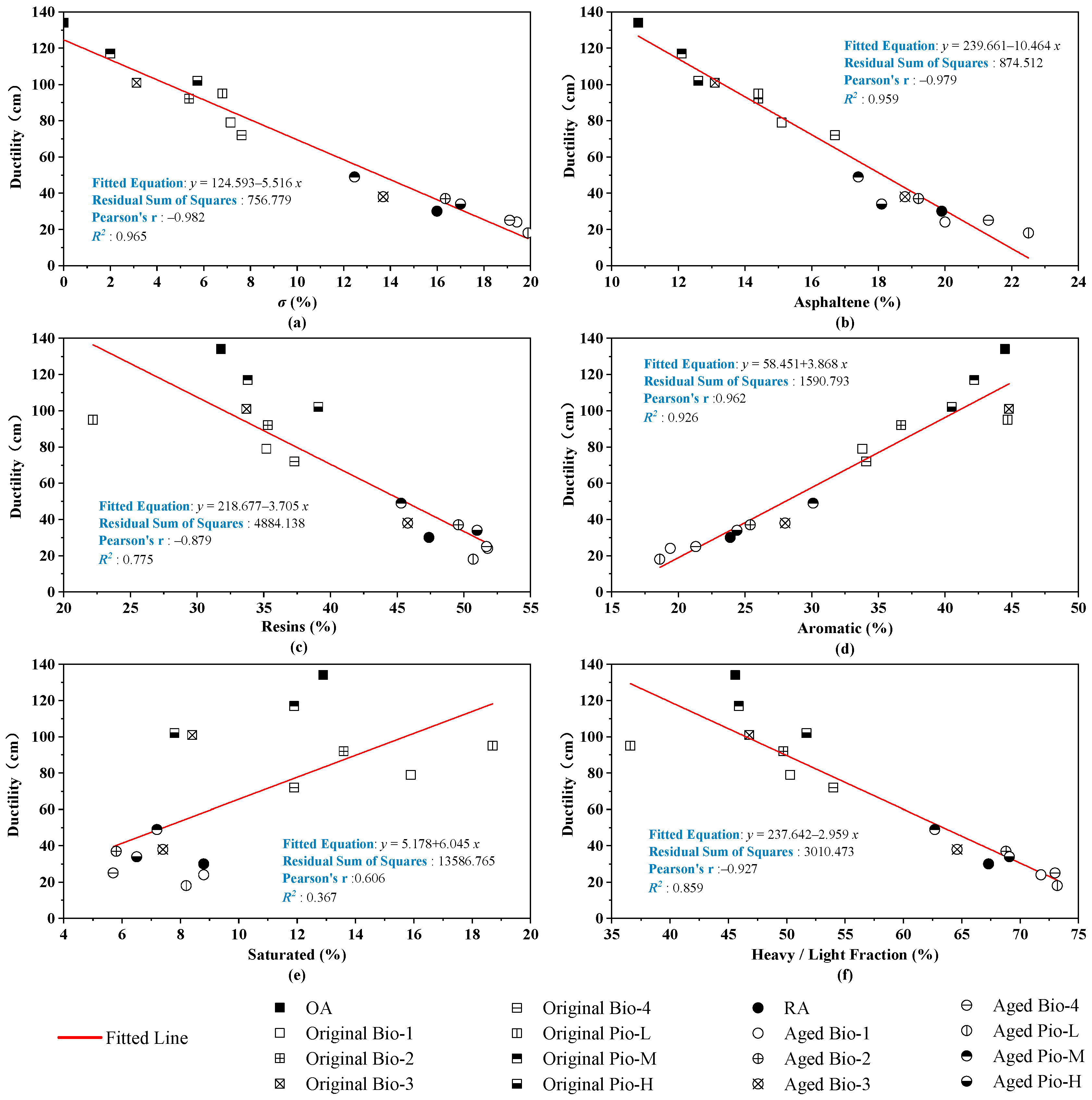

3.5. Penetration, Ductility, and Softening Point

4. Discussion

5. Conclusions

- A new indicator, average deviation of fractions between the given asphalt and its original (marked σ) is proposed to characterize the degree of asphalt aging based on the variations of SARA fractional composition. It normalizes the four simultaneous change indicators (percentage of SARA fractions) during asphalt aging into one indicator. This new indicator has a strong correlation with several mechanical performance indicators of asphalt. Experiments and statistical analysis show that it is strongly correlated (R2 > 0.90) with TCR, ductility, and penetration, has a good correlation (R2 > 0.85) with Jnr3.2, and is correlated with (R2 > 0.75) fatigue life (Nf) and softening point. σ provides a potential approach to further investigate the inner relationship between SARA fraction composition and its mechanical properties of asphalts;

- The correlation between asphalt SARA fractions and their several mechanical indicators is clarified. Asphaltene fraction content is strongly correlated (R2 > 0.95) with low temperature critical cracking temperature (TCR) and ductility. Aromatic fraction content is also strongly correlated (R2 > 0.92) with these two indicators, TCR and ductility. Heavy fraction (asphaltene and resins) content is strongly correlated with (R2 > 0.90) penetration and non-recoverable creep compliance (Jnr3.2 from MSCR test). Resins also have a good correlation (R2 > 0.88) with penetration and non-recoverable creep compliance (Jnr3.2). Saturated fraction is not significantly correlated with these mechanical indicators (all R2 < 0.61);

- Effects of some SARA fractions in asphalt regeneration are evaluated. Asphaltene has a controlling effect on all the mechanical performance of asphalt. The larger the aromatic proportion, the asphalt’s low-temperature cracking resistance and resistance to aging ability are also stronger. The content of saturated fraction should not be too high, otherwise, it may accelerate aging of asphalt. In addition, all the oil-rejuvenators can barely restore the TCR and ductility of the aged asphalt to their original levels because it is difficult to completely reduce the asphaltene content to the original level;

- More currently used mechanical properties indicators, especially those with complex rheology, can be examined for their correlation with fraction composition by the methods presented in this study. This type of work will provide a reference for the directional design of bitumen for applications in complex environments.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xu, J.; Yang, E.; Luo, H.; Ding, H. Effects of warm mix additives on the thermal stress and ductile resistance of asphalt binders. Constr. Build. Mater. 2020, 238, 117746. [Google Scholar] [CrossRef]

- Jamshidi, A.; Hamzah, M.O.; You, Z. Performance of Warm Mix Asphalt containing Sasobit®: State-of-the-art. Constr. Build. Mater. 2013, 38, 530–553. [Google Scholar] [CrossRef]

- Angius, E.; Ding, H.; Hesp, S.A.M. Durability assessment of asphalt binder. Constr. Build. Mater. 2018, 165, 264–271. [Google Scholar] [CrossRef]

- Wang, J.; Wang, T.; Hou, X.; Xiao, F. Modelling of rheological and chemical properties of asphalt binder considering SARA fraction. Fuel 2019, 238, 320–330. [Google Scholar] [CrossRef]

- Martínez-Boza, F.; Partal, P.; Conde, B.; Gallegos, C. Influence of Temperature and Composition on the Linear Viscoelastic Properties of Synthetic Binders. Energy Fuels 2000, 14, 131–137. [Google Scholar] [CrossRef]

- Lian, H.; Lin, J.-R.; Yen, T.F. Peptization studies of asphaltene and solubility parameter spectra. Fuel 1994, 73, 423–428. [Google Scholar] [CrossRef]

- Ding, H.; Hesp, S.A.M. Quantification of crystalline wax in asphalt binders using variable-temperature Fourier-transform infrared spectroscopy. Fuel 2020, 277, 118220. [Google Scholar] [CrossRef]

- Speight, J.G. Petroleum asphaltenes—Part 1: Asphaltenes, resins and the structure of petroleum. Oil Gas Sci. Technol. 2004, 59, 467–477. [Google Scholar] [CrossRef] [Green Version]

- Speight, J.G. The Chemistry and Technology of Petroleum; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar] [CrossRef]

- Yang, C.; Xie, J.; Wu, S.; Amirkhanian, S.; Zhou, X.; Ye, Q.; Yang, D.; Hu, R. Investigation of physicochemical and rheological properties of SARA components separated from bitumen. Constr. Build. Mater. 2020, 235, 117437. [Google Scholar] [CrossRef]

- Branthaver, J.F.; Petersen, J.C.; Robertson, R.E.; Duvall, J.J.; Kim, S.S.; Harnsberger, P.M.; Mill, T.; Ensley, E.K.; Barbour, F.A.; Scharbron, J.F. Binder Characterization and Evaluation. Volume 2: Chemistry. Chromatography 1993, 2, 479. Available online: https://trid.trb.org/view/386723 (accessed on 12 January 2022).

- Speight, J.G.; Koots, J.A. Relation of petroleum resins to asphaltenes. Fuel 1975, 51, 179–184. [Google Scholar] [CrossRef]

- Di Primio, R.; Horsfield, B.; Guzman-Vega, M.A. Determining the temperature of petroleum formation from the kinetic properties of petroleum asphaltenes. Nature 2000, 406, 173–176. [Google Scholar] [CrossRef]

- Pfeiffer, J.P.; Saal, R.N.J. Asphaltic Bitumen as Colloid System. J. Phys. Chem. 1940, 44, 139–149. [Google Scholar] [CrossRef]

- Mangiafico, S.; Di Benedetto, H.; Sauzéat, C.; Olard, F.; Pouget, S.; Planque, L. Effect of colloidal structure of bituminous binder blends on linear viscoelastic behaviour of mixtures containing Reclaimed Asphalt Pavement. Mater. Des. 2016, 111, 126–139. [Google Scholar] [CrossRef]

- Pahlavan, F.; Samieadel, A.; Deng, S.; Fini, E. Exploiting synergistic effects of intermolecular interactions to synthesize hybrid rejuvenators to revitalize aged asphalt. ACS Sustain. Chem. Eng. 2019, 7, 15514–15525. [Google Scholar] [CrossRef]

- Aguiar, J.I.S.; Mansur, C.R.E. Study of the interaction between asphaltenes and resins by microcalorimetry and ultraviolet–visible spectroscopy. Fuel 2015, 140, 462–469. [Google Scholar] [CrossRef]

- Janardhan, A.S.; Mansoori, G.A. Fractal nature of asphaltene aggregation. Jounal Pet. Sci. Eng. 1993, 9, 17–27. [Google Scholar] [CrossRef]

- Luo, H.; Huang, X.; Tian, R.; Huang, J.; Zheng, B.; Wang, D.; Liu, B. Analysis of relationship between component changes and performance degradation of Waste-Oil-Rejuvenated asphalt. Constr. Build. Mater. 2021, 297, 123777. [Google Scholar] [CrossRef]

- Zahoor, M.; Nizamuddin, S.; Madapusi, S.; Giustozzi, F. Sustainable asphalt rejuvenation using waste cooking oil: A comprehensive review. J. Clean. Prod. 2021, 278, 123304. [Google Scholar] [CrossRef]

- Ding, H.; Tetteh, N.; Hesp, S.A.M. Preliminary experience with improved asphalt cement specifications in the City of Kingston, Ontario, Canada. Constr. Build. Mater. 2017, 157, 467–475. [Google Scholar] [CrossRef]

- Al-Saffar, Z.H.; Yaacob, H.; Satar, M.K.I.M.; Kamarudin, S.N.N.; Mahmud, M.Z.H.; Ismail, C.R.; Hassan, S.A.; Mashros, N. A review on the usage of waste engine oil with aged asphalt as a rejuvenating agent. Mater. Today Proc. 2021, 42, 2374–2380. [Google Scholar] [CrossRef]

- Qiu, Y.; Ding, H.; Rahman, A.; Wang, W. Damage characteristics of waste engine oil bottom rejuvenated asphalt binder in the non-linear range and its microstructure. Constr. Build. Mater. 2018, 174, 202–209. [Google Scholar] [CrossRef]

- Paliukaite, M.; Assuras, M.; Hesp, S.A.M. Effect of recycled engine oil bottoms on the ductile failure properties of straight and polymer-modified asphalt cements. Constr. Build. Mater. 2016, 126, 190–196. [Google Scholar] [CrossRef]

- Mamun, A.A.; Al-Abdul Wahhab, H.I. Comparative laboratory evaluation of waste cooking oil rejuvenated asphalt concrete mixtures for high contents of reclaimed asphalt pavement. Int. J. Pavement Eng. 2020, 21, 1297–1308. [Google Scholar] [CrossRef]

- Cai, X.; Zhang, J.; Xu, G.; Gong, M.; Chen, X.; Yang, J. Internal aging indexes to characterize the aging behavior of two bio-rejuvenated asphalts. J. Clean. Prod. 2019, 220, 1231–1238. [Google Scholar] [CrossRef]

- Ahmed, R.B.; Hossain, K. Waste cooking oil as an asphalt rejuvenator: A state-of-the-art review. Constr. Build. Mater. 2020, 230, 116985. [Google Scholar] [CrossRef]

- Bai, T.; Hu, Z.A.; Hu, X.; Liu, Y.; Fuentes, L.; Walubita, L.F. Rejuvenation of short-term aged asphalt-binder using waste engine oil. Can. J. Civ. Eng. 2020, 47, 822–832. [Google Scholar] [CrossRef]

- Lekhaz, D.; Saravanan, K.; Goutham, S. Effect of rejuvenating agents on stone matrix asphalt mixtures incorporating RAP. Constr. Build Mater. 2020, 254, 119298. [Google Scholar]

- Dong, W.; Ma, F.; Li, C.; Fu, Z.; Huang, Y.; Liu, J. Evaluation of Anti-Aging Performance of Biochar Modified Asphalt Binder. Coatings 2020, 10, 1037. [Google Scholar] [CrossRef]

- Elkashef, M.; Williams, R.C.; Cochran, E.W. Physical and chemical characterization of rejuvenated reclaimed asphalt pavement (RAP) binders using rheology testing and pyrolysis gas chromatography-mass spectrometry. Mater. Struct. 2018, 51, 1–9. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, K.; Wu, C.; Liu, K.; Jiang, K. Preparation of bio-oil and its application in asphalt modification and rejuvenation: A review of the properties, practical application and life cycle assessment. Constr. Build. Mater. 2020, 262, 120528. [Google Scholar] [CrossRef]

- Li, R.; Bahadori, A.; Xin, J.; Zhang, K.; Muhunthan, B.; Zhang, J. Characteristics of bioepoxy based on waste cooking oil and lignin and its effects on asphalt binder. Constr. Build. Mater. 2020, 251, 118926. [Google Scholar] [CrossRef]

- Wang, H.; Ma, Z.; Chen, X.; Mohd Hasan, M.R. Preparation process of bio-oil and bio-asphalt, their performance, and the application of bio-asphalt: A comprehensive review. J. Traffic Transp. Eng. 2020, 7, 137–151. [Google Scholar] [CrossRef]

- Li, H.; Feng, Z.; Ahmed, A.T.; Yombah, M.; Cui, C.; Zhao, G.; Guo, P.; Sheng, Y. Repurposing waste oils into cleaner aged asphalt pavement materials: A critical review. J. Clean. Prod. 2022, 334, 130230. [Google Scholar] [CrossRef]

- Baghaee Moghaddam, T.; Baaj, H. The use of rejuvenating agents in production of recycled hot mix asphalt: A systematic review. Constr. Build Mater. 2016, 114, 805–816. [Google Scholar] [CrossRef]

- Haghshenas, H.F.; Rea, R.; Reinke, G.; Yousefi, A.; Haghshenas, D.F.; Ayar, P. Effect of Recycling Agents on the Resistance of Asphalt Binders to Cracking and Moisture Damage. J. Mater. Civ. Eng. 2021, 33, 04021292. [Google Scholar] [CrossRef]

- Ding, H.; Liu, H.; Qiu, Y.; Rahman, A. Effects of crystalline wax and asphaltene on thermoreversible aging of asphalt binder. Int. J. Pavement Eng. 2021, 38, 1–10. [Google Scholar] [CrossRef]

- Shariati, S.; Rajib, A.I.; Fini, E.H. A multifunctional bio-agent for extraction of aged bitumen from siliceous surfaces. J. Ind. Eng. Chem. 2021, 104, 500–513. [Google Scholar] [CrossRef]

- Ding, H.; Zhang, H.; Zheng, X.; Zhang, C. Characterisation of Crystalline Wax in Asphalt Binder by X-Ray Diffraction. Road Mater. Pavement Des. 2022, 259, 1–17. [Google Scholar] [CrossRef]

- Luo, H.; Huang, X. Research on the Change of Performance and Component of Recycled Oil Regenerated Asphalt during Secondary Aging. China J. Highw. Transp. 2021, 34, 98. [Google Scholar] [CrossRef]

- Corbett, L.W. Relationship between composition and physical properties of asphalt and discussion. In Association of Asphalt Paving Technologists Proc; Destech: St Paul, MN, USA, 1970; Volume 39, pp. 481–491. [Google Scholar]

- Redelius, P.; Soenen, H. Relation between bitumen chemistry and performance. Fuel 2015, 140, 34–43. [Google Scholar] [CrossRef]

- Calandra, P.; Caputo, P.; De Santo, M.P.; Todaro, L.; Turco Liveri, V.; Oliviero Rossi, C. Effect of additives on the structural organization of asphaltene aggregates in bitumen. Constr. Build. Mater. 2019, 199, 288–297. [Google Scholar] [CrossRef]

- Thenoux, G.; Bell, C.A.; Wilson, J.E. Evaluation of physical and fractional properties of asphalt and their interrelationship. In Asphalt Materials and Mixtures; SAGE Publications: New York, NY, USA, 1988; pp. 82–97. [Google Scholar]

- Loeber, L.; Muller, G.; Morel, J.; Sutton, O. Bitumen in colloid science: A chemical, structural and rheological approach. Fuel 1998, 77, 1443–1450. [Google Scholar] [CrossRef]

- Ghasemirad, A.; Bala, N.; Hashemian, L. High-Temperature Performance Evaluation of Asphaltenes-Modified Asphalt Binders. Molecules 2020, 25, 3326. [Google Scholar] [CrossRef] [PubMed]

- Qu, X.; Li, T.; Wei, J.; Wang, D.; Oeser, M.; Hao, P. Extraction of polycyclic aromatic compounds (PAC) and the influence on the mechanical and chemical properties of asphalt binder. Constr. Build. Mater. 2019, 23, 228. [Google Scholar] [CrossRef]

- Lesueur, D. The colloidal structure of bitumen: Consequences on the rheology and on the mechanisms of bitumen modification. Adv. Colloid Interface Sci. 2009, 145, 42–82. [Google Scholar] [CrossRef]

- Hofko, B.; Eberhardsteiner, L.; Füssl, J.; Grothe, H.; Handle, F.; Hospodka, M.; Grossegger, D.; Nahar, S.N.; Schmets, A.J.M.; Scarpas, A. Impact of maltene and asphaltene fraction on mechanical behavior and microstructure of bitumen. Mater. Struct. 2016, 49, 829–841. [Google Scholar] [CrossRef] [Green Version]

- Fernandez-Gomez, W.D.; Quintana, H.; Rondon, A.; Daza, C.E.; Ca, L. The effects of environmental aging on Colombian asphalts. Fuel 2014, 115, 321–328. [Google Scholar] [CrossRef]

- Cooper, S.B.; Negulescu, I.; Balamurugan, S.S.; Mohammad, L.; Daly, W.H.; Baumgardner, G.L. Asphalt mixtures containing RAS and/or RAP: Relationships amongst binder composition analysis and mixture intermediate temperature cracking performance. Road Mater. Pavement Des. 2017, 18, 209–234. [Google Scholar] [CrossRef]

- Luo, H.; Leng, H.; Ding, H.; Xu, J.; Lin, H.; Ai, C.; Qiu, Y. Low-temperature cracking resistance, fatigue performance and emission reduction of a novel silica gel warm mix asphalt binder. Constr. Build. Mater. 2020, 78, 1–7. [Google Scholar] [CrossRef]

- Qiu, Y.; Ding, H.; Rahman, A.; Luo, H. Application of dispersant to slow down physical hardening process in asphalt binder. Mater. Struct. 2019, 52, 9. [Google Scholar] [CrossRef]

- Xiao, F.; Amirkhanian, S.N. Effects of liquid antistrip additives on rheology and moisture susceptibility of water bearing warm mixtures. Constr. Build. Mater. 2010, 24, 1649–1655. [Google Scholar] [CrossRef]

- Shi, H.; Xu, T.; Zhou, P.; Jiang, R. Combustion properties of saturates, aromatics, resins, and asphaltenes in asphalt binder. Constr. Build. Mater. 2017, 136, 515–523. [Google Scholar] [CrossRef]

- Sultana, S.; Bhasin, A. Effect of chemical composition on rheology and mechanical properties of asphalt binder. Constr. Build. Mater. 2014, 72, 293–300. [Google Scholar] [CrossRef]

- Petersen, J.C. Chapter 14 Chemical Composition of Asphalt as Related to Asphalt Durability. Dev. Pet. Sci. 2000, 40, 363–399. [Google Scholar] [CrossRef]

- Corbett, L.W. Composition of asphalt based on generic fractionation, using solvent deasphaltening, elution-adsorption chromatography, and densimetric characterization. J Anal. Chem. 1969, 41, 576–579. [Google Scholar] [CrossRef]

- ASTM-D2424; Standard Test Method for Separation of Asphalt into Four Fractions. American Society for Testing Materials: West Conshohocken, PA, USA, 2009.

- Handle, F.; Füssl, J.; Neudl, S.; Grossegger, D.; Eberhardsteiner, L.; Hofko, B.; Hospodka, M.; Blab, R.; Grothe, H. The bitumen microstructure: A fluorescent approach. Mater. Struct. 2016, 49, 167–180. [Google Scholar] [CrossRef] [Green Version]

- ASTM-D5; Standard Test Method for Penetration of Bituminous Materials. American Society for Testing Materials: West Conshohocken, PA, USA, 2013.

- ASTM-D36; Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus). American Society for Testing Materials: West Conshohocken, PA, USA, 2014.

- ASTM-D113; Standard Test Method for Ductility of Asphalt Materials. American Society for Testing Materials: West Conshohocken, PA, USA, 2017.

- ASTM-D4402; Standard Test Method for Viscosity Determination of Asphalt at Elevated Temperatures Using a Rotational Viscometer. American Society for Testing Materials: West Conshohocken, PA, USA, 2015.

- ASTM-D6373; Standard Specification for Performance-Graded Asphalt Binder. American Society for Testing Materials: West Conshohocken, PA, USA, 2021.

- Yan, K.; Peng, Y.; You, L. Use of tung oil as a rejuvenating agent in aged asphalt: Laboratory evaluations. Constr. Build. Mater. 2020, 239, 117783. [Google Scholar] [CrossRef]

- Chen, M.; Xiao, F.; Putman, B.; Leng, B.; Wu, S. High temperature properties of rejuvenating recovered binder with rejuvenator, waste cooking and cotton seed oils. Constr. Build. Mater. 2014, 59, 10–16. [Google Scholar] [CrossRef]

- Ji-lu, Z. Bio-oil from fast pyrolysis of rice husk: Yields and related properties and improvement of the pyrolysis system. J. Anal. Appl. Pyrolysis 2007, 80, 30–35. [Google Scholar] [CrossRef]

- ISO-660; Animal and Vegetable Fats and Oils—Determination of Acid Value and Acidity. International Organization for Standardization: Geneva, Switzerland, 2020.

- ISO-3961; Animal and Vegetable Fats and Oils—Determination of Iodine Value. International Organization for Standardization: Geneva, Switzerland, 2018.

- ISO-3657; Animal and Vegetable Fats and Oils—Determination of Saponification Value. International Organization for Standardization: Geneva, Switzerland, 2020.

- ASTM-D4052; Standard Test Method for Density, Relative Density, and API Gravity of Liquids by Digital Density Meter. American Society for Testing Materials: West Conshohocken, PA, USA, 2019.

- ASTM-D7279; Standard Test Method for Kinematic Viscosity of Transparent and Opaque Liquids by Automated Houillon Viscometer. American Society for Testing Materials: West Conshohocken, PA, USA, 2020.

- ASTM-D56; Standard Test Method for Flash Point by Tag Closed Cup Tester. American Society for Testing Materials: West Conshohocken, PA, USA, 2021.

- AASHTO-M320; Standard Specification for Performance-Graded Asphalt Binder. American Association of State Highway Transportation Officials: West Conshohocken, PA, USA, 2005.

- Roy, S.D.; Hesp, S.A. Low-temperature binder specification development: Thermal stress restrained specimen testing of asphalt binders and mixtures. Transp. Res. Rec. 2001, 1766, 7–14. [Google Scholar] [CrossRef]

- AASHTO-R49; Standard Practice for Determination of Low-Temperature Performance Grade. American Association of State Highway Transportation Officials: West Conshohocken, PA, USA, 2013.

- Shenoy, A. Single-event cracking temperature of asphalt pavements directly from bending beam rheometer data. J. Transp. Eng. 2002, 128, 465–471. [Google Scholar] [CrossRef]

- Bahia, H.U.; Hanson, D.; Zeng, M.; Zhai, H.; Khatri, M.; Anderson, R. Characterization of Modified Asphalt Binders in Superpave Mix Design; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2001. [Google Scholar]

- AASHTO-TP101; Standard Method of Test for Estimating Fatigue Resistance of Asphalt Binders using the Linear Amplitude Sweep. American Association of State Highway Transportation Officials: Washington, DC, USA, 2012.

- ASTM-D7405; Standard Test Method for Multiple Stress Creep and Recovery (MSCR) of Asphalt Binder Using a Dynamic Shear Rheometer. American Society for Testing Materials: West Conshohocken, PA, USA, 2015.

- Hossain, Z.; Ghosh, D.; Zaman, M.; Hobson, K. Use of the multiple stress creep recovery (MSCR) test method to characterize polymer-modified asphalt binders. J. Test. Eval. 2016, 44, 507–520. [Google Scholar] [CrossRef]

- Chen, A.; Liu, G.; Zhao, Y.; Li, J.; Pan, Y.; Zhou, J. Research on the aging and rejuvenation mechanisms of asphalt using atomic force microscopy. Constr. Build. Mater. 2018, 167, 177–184. [Google Scholar] [CrossRef]

- Kuang, D.; Liu, W.; Xiao, Y.; Wan, M.; Yang, L.; Chen, H. Study on the rejuvenating mechanism in aged asphalt binder with mono-component modified rejuvenators. Constr. Build. Mater. 2019, 223, 986–993. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, H.; Zhu, C.; Zhao, B. Rheological examination of aging in bitumen with inorganic nanoparticles and organic expanded vermiculite. Constr. Build. Mater. 2015, 101, 884–891. [Google Scholar] [CrossRef]

- Cong, P.; Guo, X.; Mei, L. Investigation on rejuvenation methods of aged SBS modified asphalt binder. Fuel 2020, 279, 118556. [Google Scholar] [CrossRef]

- Luo, H.; Huang, X.; Rongyan, T.; Ding, H.; Huang, J.; Wang, D.; Liu, Y.; Hong, Z. Advanced method for measuring asphalt viscosity: Rotational plate viscosity method and its application to asphalt construction temperature prediction. Constr. Build. Mater. 2021, 301, 124129. [Google Scholar] [CrossRef]

- Sharma, A.; Rongmei Naga, G.R.; Kumar, P.; Raha, S. Development of an empirical relationship between non-recoverable creep compliance & zero shear viscosity for wide-ranging stiffness of asphalt binders. Constr. Build. Mater. 2022, 326, 126764. [Google Scholar] [CrossRef]

- Haghshenas, H.F.; Kim, Y.-R.; Kommidi, S.R.; Nguyen, D.; Haghshenas, D.F.; Morton, M.D. Evaluation of long-term effects of rejuvenation on reclaimed binder properties based on chemical-rheological tests and analyses. Mater. Struct. 2018, 51, 134. [Google Scholar] [CrossRef]

- Singh, D.; Yenare, C.; Showkat, B. Rheological and Chemical Characteristics of Asphalt Binder Modified with Groundnut Shell Bio-oil. Adv. Civ. Eng. Mater. 2020, 9, 311–339. [Google Scholar] [CrossRef]

- Read, J.; Whiteoak, D. The Shell Bitumen Handbook; Thomas Telford: London, UK, 2003. [Google Scholar]

- Claudy, P.; Letoffe, J.; King, G.; Plancke, J. Characterization of asphalts cements by thermomicroscopy and differential scanning calorimetry: Correlation to classic physical properties. Fuel Sci. Technol. Int. 1992, 10, 735–765. [Google Scholar] [CrossRef]

| Studies | Fractions | Influence on Mechanical Properties |

|---|---|---|

| Corbett, L.W. [42] | Saturates and aromatics | Positive correlation with hardness, temperature susceptibility, softening point |

| Sultana and Bhasin [57] | Saturates and aromatics | Negative correlation with tensile strength |

| Loeber, L. et al. [46] | Asphaltenes | Positively correlated with G* and stiffness |

| Ghasemirad, A. et al. [47] | Asphaltenes | Positively correlated with stiffness, elasticity, and high-performance grade (PG) |

| Hofko, B. et al. [50] | Asphaltenes | Positively correlated with stiffness and elasticity |

| Fernandez et al. [51] | Asphaltenes and resins | Positively correlated with penetration and negative correlation with ductility |

| Cooper et al. [52] | Asphaltenes | Negative correlation with fracture resistance |

| Xin et al. [48] | PAC in Asphaltenes | Positively correlated with elasticity and complex modulus |

| Speight, J.G. [12] | Resins | It is a stabilizer of asphaltene |

| Petersen, J.C. [58] | All the four fractions | Durability |

| Redeliusa, P. et al. [43] | Asphaltenes and aromatics | Respectively positive and negative correlation with viscosity |

| Haibo D. [38] | Asphaltenes | No significant correlation with low temperature performance |

| Raw Materials | Base Oil | Label | Acid Value (mg KOH/g) | Iodine Value (g I/100 g) | Saponification Value (mg KOH/g) | Density @20 °C (cm) | Kinematic Viscosity @60 °C (mm2/s) | Flash Point (°C) | Appearance |

|---|---|---|---|---|---|---|---|---|---|

| Waste edible oil | Bio-oil | Bio-1 | ≤7.1% | 274 | 181 | 0.927 | 61.7 | 316 | Brown, cloudy |

| Tung oil | Bio-2 | ≤0.4% | 76 | 182 | 0.944 | 70.3 | 224 | Yellow, transparent | |

| Biodiesel | Bio-3 | ≤2.9% | 143 | 192 | 0.965 | 68.6 | 251 | Yellow, transparent | |

| Fish oil residue | Bio-4 | ≤3.4% | 173 | 198 | 0.994 | 100.5 | 210 | Yellow, translucent | |

| Light fraction oil | Petroleum extract | Pio-L | - | - | - | 0.893 | 51.2 | 198 | Yellow brown, translucent |

| Middle fraction oil | Pio-M | - | - | - | 0.936 | 88.4 | 224 | Colorless, transparent | |

| Heavy fraction oil | Pio-H | - | - | - | 1.016 | 152.4 | 240 | Black, opaque |

| Asphalt | Aging State | Failure Temperature | LTPG | |

|---|---|---|---|---|

| 50/70 | Unaged | −28.3 | −24.9 | PG XX-22 |

| Aged | −17.2 | −14.5 | PG XX-10 | |

| Bio-1 | Unaged | −21.7 | −17.8 | PG XX-16 |

| Aged | −14.8 | −10.4 | PG XX-10 | |

| Bio-2 | Unaged | −24.0 | −21.1 | PG XX-16 |

| Aged | −18.4 | −13.6 | PG XX-10 | |

| Bio-3 | Unaged | −25.9 | −22.2 | PG XX-22 |

| Aged | −16.3 | −14.6 | PG XX-10 | |

| Bio-4 | Unaged | −21.8 | −16.9 | PG XX-16 |

| Aged | −14.9 | −11.2 | PG XX-10 | |

| Pio-L | Unaged | −23.2 | −17.7 | PG XX-16 |

| Aged | −12.9 | −9.7 | PG XX-04 | |

| Pio-M | Unaged | −28.9 | −24.0 | PG XX-22 |

| Aged | −20.3 | −16.9 | PG XX-16 | |

| Pio-H | Unaged | −25.6 | −21.5 | PG XX-16 |

| Aged | −18.7 | −13.6 | PG XX-10 | |

| Asphalt Samples | Raw Materials of Rejuvenator | Aging State | Ranking of Mechanical Indicators | |||||

|---|---|---|---|---|---|---|---|---|

| Cracking Resistance (TCR) | Fatigue Resistance (Nf) | Rutting Resistance (Jnr3.2 & R3.2) | Penetration | Ductility | Softening Point | |||

| 50/70 | - | Unaged | 1 | 3 | 2 | - | 1 | - |

| Aged | 5 | 5 | 4 | 3 | 5 | 3 | ||

| Bio-1 | Waste edible oil | Unaged | 7 | 6 | 7 | - | 7 | - |

| Aged | 7 | 7 | 3 | 4 | 7 | 5 | ||

| Bio-2 | Tung oil | Unaged | 5 | 5 | 6 | 5 | - | |

| Aged | 3 | 4 | 5 | 6 | 3 | 6 | ||

| Bio-3 | Biodiesel | Unaged | 3 | 4 | 5 | - | 4 | - |

| Aged | 2 | 2 | 8 | 7 | 2 | 8 | ||

| Bio-4 | Fish oil residue | Unaged | 8 | 8 | 1 | - | 8 | - |

| Aged | 6 | 8 | 1 | 2 | 6 | 2 | ||

| Pio-L | Light fraction oil | Unaged | 6 | 7 | 8 | - | 6 | - |

| Aged | 8 | 6 | 6 | 1 | 8 | 1 | ||

| Pio-M | Middle fraction oil | Unaged | 2 | 1 | 4 | 2 | - | |

| Aged | 1 | 1 | 7 | 8 | 1 | 7 | ||

| Pio-H | Heavy fraction oil | Unaged | 4 | 2 | 3 | - | 3 | - |

| Aged | 4 | 3 | 2 | 5 | 4 | 4 | ||

| Mechanical Indicators | Fractions Indicators | |||||

|---|---|---|---|---|---|---|

| σ | Asphaltene Ratio | Resins Ratio | Aromatic Ratio | Saturated Ratio | Heavy/ Light Fraction | |

| TCR | 0.982 *** | 0.956 *** | 0.714 ** | 0.926 *** | 0.276 | 0.821 ** |

| Nf | 0.764 ** | 0.853 ** | 0.482 * | 0.728 ** | 0.143 | 0.612 ** |

| Jnr3.2 | 0.857 ** | 0.742 ** | 0.891 ** | 0.827 ** | 0.609 ** | 0.925 *** |

| Penetration | 0.905 *** | 0.773 ** | 0.889 ** | 0.871 ** | 0.468 * | 0.923 *** |

| Softening Point | 0.778 ** | 0.694 ** | 0.789 ** | 0.777 ** | 0.495 * | 0.831 ** |

| Ductility | 0.965 *** | 0.959 *** | 0.775 ** | 0.926 *** | 0.367 | 0.859 ** |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, R.; Luo, H.; Huang, X.; Zheng, Y.; Zhu, L.; Liu, F. Correlation Analysis between Mechanical Properties and Fractions Composition of Oil-Rejuvenated Asphalt. Materials 2022, 15, 1889. https://doi.org/10.3390/ma15051889

Tian R, Luo H, Huang X, Zheng Y, Zhu L, Liu F. Correlation Analysis between Mechanical Properties and Fractions Composition of Oil-Rejuvenated Asphalt. Materials. 2022; 15(5):1889. https://doi.org/10.3390/ma15051889

Chicago/Turabian StyleTian, Rongyan, Haoyuan Luo, Xiaoming Huang, Yangzezhi Zheng, Leyi Zhu, and Fengyang Liu. 2022. "Correlation Analysis between Mechanical Properties and Fractions Composition of Oil-Rejuvenated Asphalt" Materials 15, no. 5: 1889. https://doi.org/10.3390/ma15051889