Self-Healing Concrete as a Prospective Construction Material: A Review

Abstract

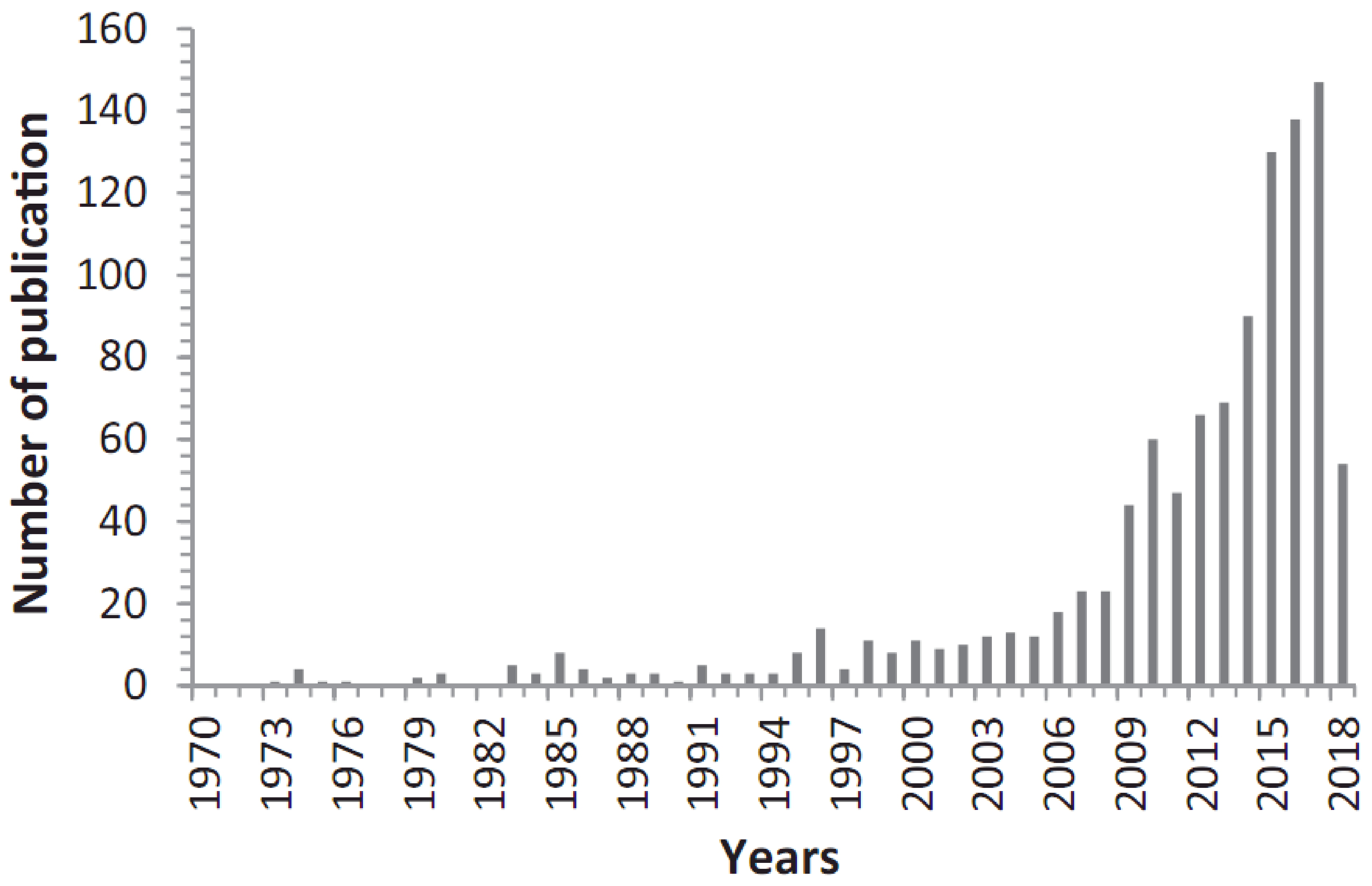

:1. Introduction

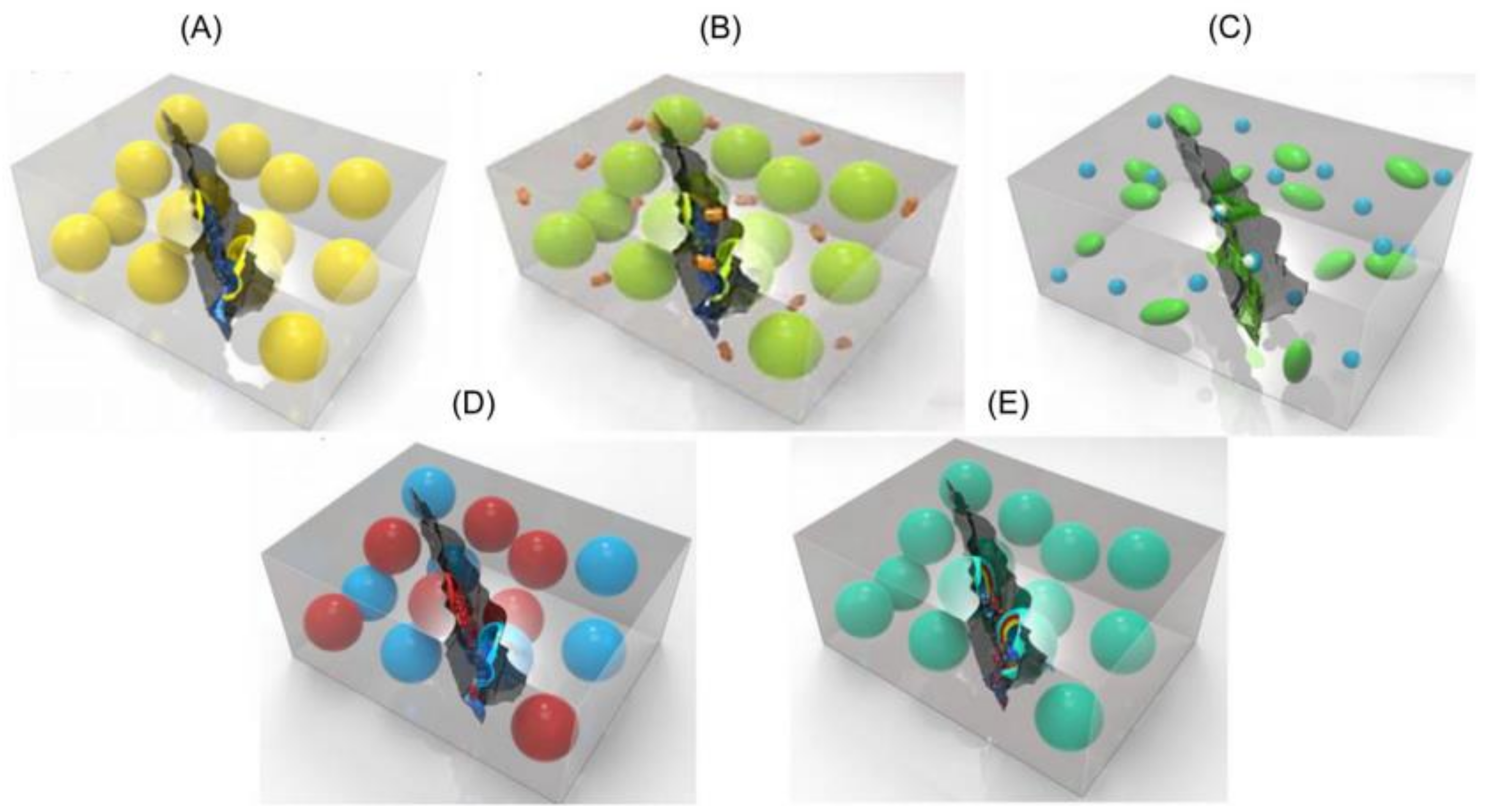

2. Strategies of SHC

3. Influential Factors of Self-Healing

3.1. Moisture Content

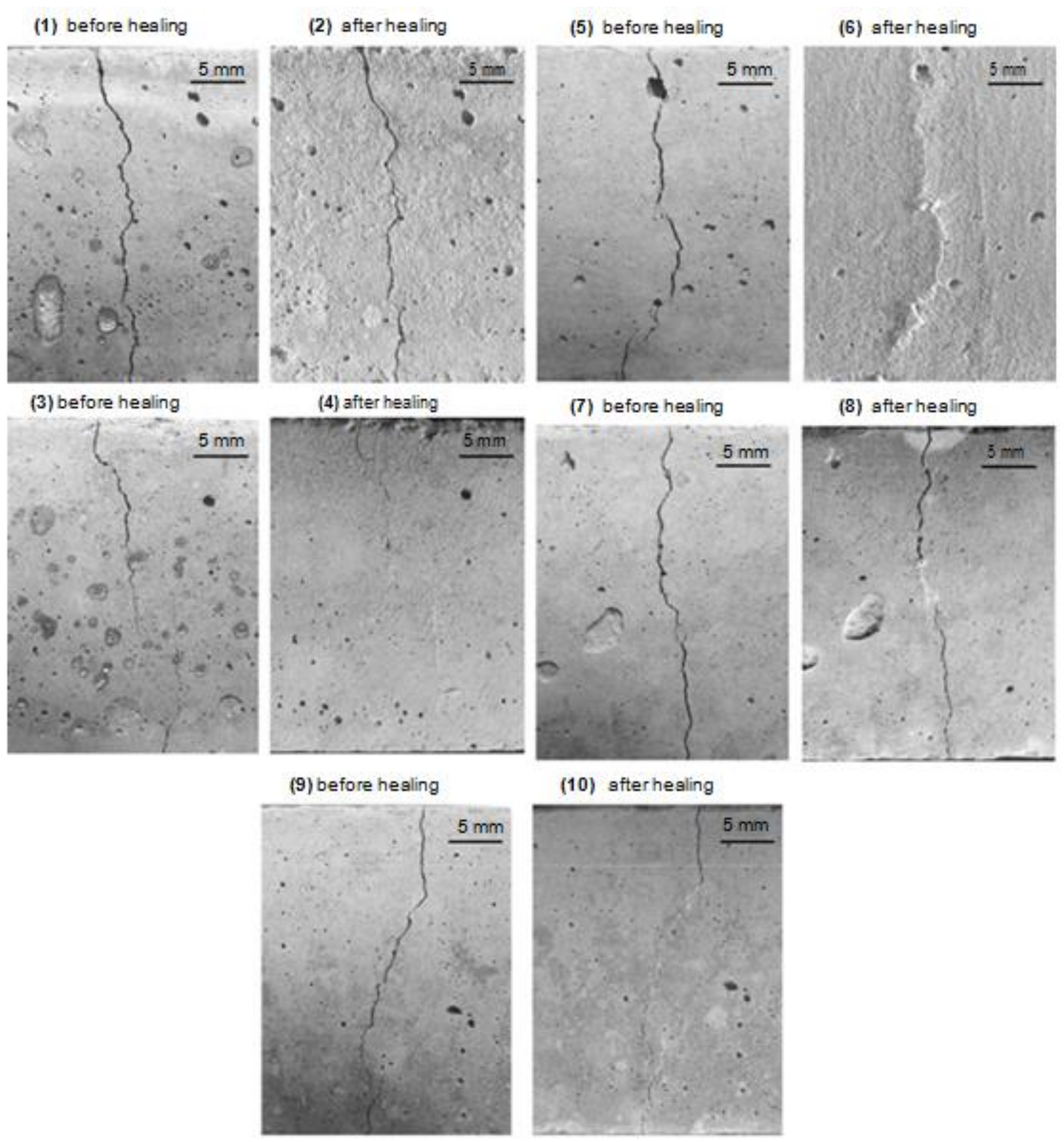

3.2. Crack Width

- -

- Dnssm is the non-steady-state migration coefficient [m2/s];

- -

- U is the absolute value of applied voltage [V];

- -

- T is the average value of the initial and final temperatures in the analyzed solution [K];

- -

- L is the thickness of the specimen [m], and

- -

- xd is the average value of the penetration depth [m]. Further, the following Table 1 summarizes the role of bacteria in crack healing.

| Type of Bacteria | Type of Healing Agent | Embedded | Strength Recovery | Width of Crack, mm | Durability Effect | Refs. |

|---|---|---|---|---|---|---|

| Subtilis | Urea, CaCl2 H2O | Diatomite lam dong | x | 1–1.8 | √ | [63] |

| B. Pseudomycoides | Ureolytic activity | Directly with 100 mL cell | √ | 0.15–0.3 | √ | [64] |

| Subtilis | Urea—2CaCl2 curing | Directly with 2.2 × 106 cells/mL | x | 0.2 | √ | [65] |

| Sporosarcina pasteurii | Urea—CaCl2 curing | Directly with 107 cells/cm3 | √ | 0.28–0.34 | √ | [66] |

| Sphaericus | Urea, yeast extract, Ca(NO3)2, 4H2O | Diatomaceous earth with 109 cell/mL | x | 0.15–0.17 | √ | [67] |

| B. Megaterium | Urea yeast extract, beef extract | Directly with 2.2 × 106 cells/mL | √ | 0.3 | √ | [68] |

| Sphaericus | Urea, yeast extract, Ca(NO3)2, 4H2O | Hydrogelencapsulated spore | x | 0.5 | √ | [69] |

| B. Subtilis | Urea CaCO3 crystals, yeast extracts, NaCl | Steel bar, Hach dr 2400 portable | √ | 1.- | √ | [70] |

| Sphaericus | Urea, Ca(NO3)2, 4H2O | Silica gel, polyurethane | √ | 0.35, 0.25 | √ | [71] |

| Megaterium, licheniformi | Urea-broth culture | Direct with 105 cell/mL of mixing water | x | 0.3 | √ | [72] |

| Sphaericus | Urea, calciumnitrate, yeast extract | Microcapsule | x | 0.97 | √ | [35] |

| B. Sphaericus | Urea Ca2+ ion, CaCl2 usage | Trinocular stereomicroscope | √ | 0.4 | √ | [73] |

| Pasteurii | Mixing water was replaced by urea–yeast extract medium | Direct with 2–6 × 107 cfu/mL | √ | - | x | [74] |

| Sphaericus | Urea, Ca(NO3)2 | Glass tubes with PU foam | √ | 0.3 | - | [75] |

3.3. Time for Hydration

3.4. Pressure Loaded on Cracks

3.5. Water–Cement Ratio

4. Efficiency of Self-Healing

5. Mechanism of Self-Healing

5.1. Autogenic Self-Healing

5.2. Autonomic Bacteria-Based Self-Healing

5.3. Autonomic Capsule-Based Self-Healing

| Encapsulation Techniques | Rate of Sub-Stitution (%) | Material of Encapsulated | Major Findings: (√) Improved Property, and (-) Unknown | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fracture Energy | Strengths and Elastic Modulus | Stiffness and Chloride Resistance | Condenses Index of Damage | Capillary Absorption and Permeability | Sorptivity Coefficient | Crack Width | Porosity and Surface Resistivity | Refs. | ||||

| Poly styrene-divinylbenzene | 0–2 | Epoxy | √ | - | √ | - | √ | - | √ | - | [181] | |

| Poly ureaf-ormaldehyde | 1–4 | Epoxy | - | √ | - | √ | - | - | √ | - | [182] | |

| Urea formaldehyde | 0.25–2 | Ca(NO3)2 | √ | √ | - | - | - | - | √ | √ | [183,184,185] | |

| 0–9 | Epoxy | - | √ | √ | - | √ | √ | |||||

| Urea formaldehyde | 0.5–5 | Sodium silicate | √ | √ | √ | - | [186] | |||||

| Alginate | 10 | Ag+ | - | √ | √ | √ | √ | - | ||||

| Poly-urea | 0.8 | Sodium silicate | - | - | - | - | √ | - | [41] | |||

| Polyurethane | 2.5–5 | Sodium silicate | √ | - | - | - | √ | √ | - | [141] | ||

| Melamine urea–formaldehyde | 1–4 | Epoxy | - | √ | √ | √ | - | - | √ | - | [187] | |

| Polyvinyl alcohol | 10 | Calcium aluminate | - | - | √ | √ | - | - | √ | - | [35] | |

| Silica | 5–10 | Epoxy | √ | - | - | - | √ | √ | √ | √ | [188] | |

| Microcapsules | 1–5 | Bacterial spores | - | √ | - | √ | - | √ | - | [156] | ||

| Poly-urea | 0.25 | Dicyclopenta-diene | - | √ | - | - | - | √ | - | [189] | ||

| Content | Type of material | Øo (µm) | Length (mm) | Øi (µm) | Mixed | Thickness (µm) | ||||||

| Capsule-based approach | Spherical | Cac6h10o6 | Expanded clay | 1000–4000 | – | – | √ | – | [119] | |||

| Bacteria | 1000–4000 | – | – | √ | – | [119] | ||||||

| Na2FPO3 | 4000 | – | – | √ | – | [112] | ||||||

| Tung oil | Gelatin | 50 | – | – | √ | – | [190] | |||||

| Epoxy | 50 | – | – | √ | – | [190] | ||||||

| Acrylic resin | 125–297 | – | – | – | – | [13] | ||||||

| Ca(OH)2 | 50 | – | – | √ | – | [190] | ||||||

| Water | Paraffin | 900 | – | – | – | – | [179] | |||||

| Retarder agent | Wax | 120 | – | – | √ | – | [48] | |||||

| Epoxy | UF | 120 | – | – | √ | 4 | [191] | |||||

| Na2SiO3 | PU | 40–800 | – | – | √ | – | [124] | |||||

| Epoxy | UF | 20–70 | – | – | – | – | [13] | |||||

| Na2SiO3 | Silica | 5000 | – | – | √ | – | [115] | |||||

| Teb | Silica gel | 4.15 | – | – | √ | – | [34] | |||||

| Cylindrical | Ca | Glass | 1000 | 100 | 800 | √ | 100 | [31] | ||||

| Epoxy | 7000 | – | 4000 | – | – | [175] | ||||||

| Pu | Ceramics | 3000–4000 | 15–50 | 2500–3500 | √ | 250 | [115] | |||||

| Epoxy | Glass | 5000 | 250 | 3000 | √ | – | [175] | |||||

| Epoxy | 6000 | 250 | 4000 | √ | – | [175] | ||||||

| Ca | – | 75 | 800 | √ | – | [37] | ||||||

| Bacteria | 2200–3350 | 20–80 | 2000–3000 | √ | 100 | [122] | ||||||

| Ca | 2200–3350 | 20–80 | 2000–3000 | √ | 100 | [192] | ||||||

| Ca | 4000 | 200 | 3200 | √ | 400 | [193] | ||||||

| Poly-acrylate | 2200–3350 | 20–80 | 2000–3000 | √ | 100 | [192] | ||||||

| Ca | – | 100 | 3000 | √ | – | [37] | ||||||

| Ca | Glass | 4000 | 200 | 3200 | √ | 400 | [193] | |||||

| Epoxy | 2200–3350 | 20–80 | 2000–3000 | √ | 100 | [192] | ||||||

| Vascular-based approach | Tubular and cementitious capsules | Epoxy | Glass | – | – | 1500 | √ | – | [194] | |||

| Foam | – | – | 1500 | √ | – | [194] | ||||||

| Ca | 4000 | – | 3000 | √ | 500 | [37] | ||||||

| Epoxy | Porous | 25,000–35,000 | – | – | √ | – | [195] | |||||

| Ca | Glass | 4000 | – | 3200 | √ | 400 | [193] | |||||

| Epoxy | 2000 | – | 800 | √ | 600 | [13] | ||||||

| Alkali silica | 2000 | – | 800 | √ | 600 | [13] | ||||||

| Epoxy | 6000 | – | 4800 | √ | 600 | [196] | ||||||

| Ca | – | – | 1500 | √ | – | [194] | ||||||

| Silicon | – | – | 1500 | √ | – | [194] | ||||||

6. Performance of SHC

| Type of Microbial Agent | Influence on | ||||

|---|---|---|---|---|---|

| Compressive Strength | Durability | Refs. | |||

| Time (Day) | Influence | Water Absorption | Permeability | ||

| Bacillus sphaericus | 28 | √ | – | √ | [207] |

| 7 | √ | ||||

| 7 | √ | √ | – | [206] | |

| 3 | √ | ||||

| 21 | √ | ||||

| – | – | – | √ | [69] | |

| 90 | x | – | √ | [210] | |

| 28 | x | ||||

| – | – | – | √ | [122] | |

| – | – | √ | – | [67] | |

| Bacillus sphaericus | 3 | √ | – | – | [211] |

| 7 | √ | ||||

| 28 | √ | √ | [212] | ||

| B. Pseudomycoides | 7 | √ | – | – | |

| 14 | √ | – | – | [64] | |

| 28 | √ | – | – | ||

| S. pasteurii | 7 | √ | – | – | [208] |

| 28 | √ | ||||

| 28 | √ | √ | – | ||

| Bacillus cohnii | 7 | √ | – | – | [213] |

| 56 | √ | ||||

| 28 | √ | ||||

| Bacillus licheniformis | 3 | √ | – | – | [214] |

| 7 | √ | - | |||

| 28 | √ | √ | |||

| B. subtilis | 3 | √ | – | – | [70] |

| 7 | √ | – | – | ||

| 28 | √ | √ | √ | ||

| Pasteurii bacteria | 28 | √ | √ | √ | [215] |

| 90 | √ | √ | √ | ||

| Diaphorobacter nitroreducens | 28 | √ | – | – | [209] |

| 7 | √ | ||||

| B. megaterium | – | √ | – | – | [68] |

| 28 | √ | – | – | ||

| Bacillus pseudofirmus | 28 | √ | – | – | [119] |

| 7 | √ | ||||

| 3 | √ | ||||

| B. sphaericus | 1 | √ | √ | – | [73] |

| 7 | √ | √ | – | ||

| 28 | √ | √ | – | ||

7. Evaluation of Self-Healing Efficiency

7.1. Rupture Behavior

7.2. Microcapsule and Macrocapsule Shell Robustness and Survivability

7.3. Recovery of Durability

8. Applications of SHC

9. A Preliminary View about the Costs of the SHC Technology

10. Limitations and Hotspot Research Topics for Future Investigations

- − Strategies to enhance bio self-healing and lower costs will bring about a shift in contractors’ acceptance of bio-concrete as a material of choice in the near future [271].

- − Future research should concentrate on the protection of bacteria in their natural habitats and the maintenance of a constant supply of nutrients.

- − The area of study should be extended to include the impact of healing on the return of these BSH materials’ original mechanical characteristics.

- − It is imperative that further study be done to see how these BSH systems perform in real environmental conditions, such as when the concrete is older, when it has many cracks, or when it is subjected to varied sustained loads.

- − There is still a shortage of large-scale meaningful commercial experience, where BSH strategies have not been employed in practical engineering projects till now.

- − A comprehensive evaluation of whether healed BSH concrete elements will achieve a similar or equivalent lifetime performance when compared to uncracked conventional concrete elements would require long-term durability tests to be conducted.

- − Further research is needed to determine how to cheaply scale up the various processes involved in the manufacturing of BSH materials.

- − Despite recent advances in the design of protocols for bio-based self-healing concrete, the available research is still hindered by a lack of numerical simulation, which would allow them to minimize experimental costs and time in the early stages of commercial application [273].

- − In addition, it is required to establish methodologies, such as life-cycle assessments, to evaluate the cradle-to-gate sustainability of various BSH options.

- − Further research is needed to expand the available bacterial isolates for case-specific bespoke solutions.

- − In order to improve our understanding of the precise determinants underpinning an ideal bacterium, it could be better to use genetically modified microorganisms to aid in the focused selection of the most appropriate species.

- − Despite this, SHC’s application to the concrete industry is still a while away.

- − The feasibility of applying a healing agent during the mixing process and the persistence of bacteria in cured concrete require more investigation [44].

- − It is critical that future research be directed toward the creation of capsules that are capable of surviving the concrete mixing and manufacturing processes without affecting the mechanical qualities of the resulting concrete.

11. Future Prospects

- − Autogenous healing is still limited to small cracks, and its reliability still is lower because it is dependent on the matrix composition at the time of crack development, which determines the possible reaction mechanisms.

- − It should also consider the chance of a fracture reaching a capsule, the release efficiency, and the healable crack volume.

- − Because tubular capsules must be manually inserted, this method is only suitable to precast concrete elements.

12. The Role and Potential of Nanotechnologies as Innovative Solutions for Future Building Applications

- -

- The manufacturing of low-cost corrosion-free steel.

- -

- The use of nanoparticles, carbon nanotubes, and nanofibers to boost the strength and durability of cement materials on the SHC capability of high-performance concrete, as well as to reduce pollution [280].

- -

- The creation of coatings and thin films with self-cleaning and self-coloring properties to reduce energy usage.

- -

- The production of thermal insulating materials with ten times the performance of current market choices.

- -

- The creation of nanosensors and nanomaterials with sensing and SHC capabilities.

- -

- Further study in the realm of nanotoxicity is also required; nevertheless, significant caution should be utilized while employing nanoparticles [277].

13. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| SHC | Self-healing concrete |

| ASH | Autogenic self-healing |

| BSH | Bacteria-based self-healing |

| Ca(OH)2 | Carbonation of calcium hydroxide |

| C-S-H | Calcium silicate hydrates |

| ECC | Engineered cementitious composite |

| HPC | High-performance concrete |

| PET | Polyethylene terephthalate |

| SAP | Superabsorbent polymer |

| SCM | Supplementary cementitious material |

| UHPC | Ultra-high-performance concrete |

| UHPFRC | Ultra-high-performance fiber-reinforced concrete |

References

- Rajczakowska, M.; Habermehl-Cwirzen, K.; Hedlund, H.; Cwirzen, A. Self-Healing Potential of Geopolymer Concrete. Proceedings 2019, 34, 6. [Google Scholar] [CrossRef] [Green Version]

- Dry, C. Matrix cracking repair and filling using active and passive modes for smart timed release of chemicals from fibers into cement matrices. Smart Mater. Struct. 1994, 3, 118–123. [Google Scholar] [CrossRef]

- Jonkers, H.M. Self Healing Concrete: A Biological Approach. In Springer Series in Materials Science; Springer: Dordrecht, The Netherlands, 2007; Volume 100, pp. 195–204. [Google Scholar]

- Qureshi, T.; Al-Tabbaa, A. Self-Healing Concrete and Cementitious Materials. In Advanced Functional Materials; IntechOpen: London, UK, 2020. [Google Scholar]

- Khitab, A.; Anwar, W.; Ul-Abdin, Z.; Tayyab, S.; Ibrahim, O.A. Applications of self healing nano concretes. In Smart Nanoconcretes and Cement-Based Materials: Properties, Modelling and Applications; Elsevier: Amsterdam, The Netherlands, 2019; pp. 501–524. ISBN 9780128178553. [Google Scholar]

- Šavija, B.; Schlangen, E. Autogeneous healing and chloride ingress in cracked concrete. Heron 2016, 61, 15–32. [Google Scholar]

- Van Tittelboom, K.; De Belie, N. Self-healing in cementitious materials—A review. Materials 2013, 6, 2182–2217. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lesovik, V.; Fediuk, R.; Amran, M.; Vatin, N.; Timokhin, R. Self-healing construction materials: The geomimetic approach. Sustainability 2021, 13, 9033. [Google Scholar] [CrossRef]

- Sangadji, S.; Schlangen, E.; Milenkovic, A. Porous network concrete: Novel concept of healable concrete structures. In Concrete Repair, Rehabilitation and Retrofitting III, Proceedings of the 3rd International Conference on Concrete Repair, Rehabilitation and Retrofitting, ICCRRR 2012, Cape Town, South Africa, 3–5 September 2012; CRC Press: Boca Raton, FL, USA, 2012; pp. 228–233. [Google Scholar]

- Han, B.; Yu, X.; Ou, J. Challenges of Self-Sensing Concrete. In Self-Sensing Concrete in Smart Structures; Butterworth Heinemann: Oxford, UK, 2014; pp. 361–376. [Google Scholar]

- Sumathi, A.; Murali, G.; Gowdhaman, D.; Amran, M.; Fediuk, R.; Vatin, N.I.; Laxme, R.D.; Gowsika, T.S. Development of bacterium for crack healing and improving properties of concrete under wet–dry and full-wet curing. Sustainability 2020, 12, 10346. [Google Scholar] [CrossRef]

- Jiang, Z.; Xing, F.; Sun, Z.; Wang, P. Healing effectiveness of cracks rehabilitation in reinforced concrete using electrodeposition method. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2008, 23, 917–922. [Google Scholar] [CrossRef]

- Mihashi, H.; Kaneko, Y.; Nishiwaki, T.; Otsuka, K. Fundamental study on development of intelligent concrete characterized by self-healing capability for strength. Trans. Jpn. Concr. Inst. 2000, 22, 441–450. [Google Scholar] [CrossRef]

- Justo-Reinoso, I.; Heath, A.; Gebhard, S.; Paine, K. Aerobic non-ureolytic bacteria-based self-healing cementitious composites: A comprehensive review. J. Build. Eng. 2021, 42, 102834. [Google Scholar] [CrossRef]

- Joseph, C.; Gardner, D.; Jefferson, T.; Isaacs, B.; Lark, B. Self-healing cementitious materials: A review of recent work. Proc. Inst. Civ. Eng. Constr. Mater. 2011, 164, 29–41. [Google Scholar] [CrossRef]

- Jonkers, H.M.; Thijssen, A.; Muyzer, G.; Copuroglu, O.; Schlangen, E. Application of bacteria as self-healing agent for the development of sustainable concrete. Ecol. Eng. 2010, 36, 230–235. [Google Scholar] [CrossRef]

- Li, H.; Liu, Z.Q.; Ou, J.P. Behavior of a simple concrete beam driven by shape memory alloy wires. Smart Mater. Struct. 2006, 15, 1039–1046. [Google Scholar] [CrossRef]

- Li, V.C.; Yang, E.H. Self Healing in Concrete Materials. In Springer Series in Materials Science; Springer: Dordrecht, The Netherlands, 2007; Volume 100, pp. 161–193. [Google Scholar]

- Roig-Flores, M.; Serna, P. Concrete early-age crack closing by autogenous healing. Sustainability 2020, 12, 4476. [Google Scholar] [CrossRef]

- Yang, Y.; Lepech, M.D.; Yang, E.H.; Li, V.C. Autogenous healing of engineered cementitious composites under wet-dry cycles. Cem. Concr. Res. 2009, 39, 382–390. [Google Scholar] [CrossRef]

- Sabapathy, L.; Mohammed, B.S.; Al-Fakih, A.; Wahab, M.M.A.; Liew, M.S.; Amran, Y.H.M. Acid and sulphate attacks on a rubberized engineered cementitious composite containing graphene oxide. Materials 2020, 13, 3125. [Google Scholar] [CrossRef]

- Teall, O.; Pilegis, M.; Davies, R.; Sweeney, J.; Jefferson, T.; Lark, R.; Gardner, D. A shape memory polymer concrete crack closure system activated by electrical current. Smart Mater. Struct. 2018, 27, 075016. [Google Scholar] [CrossRef]

- Qureshi, T.S.; Al-Tabbaa, A. Self-healing of drying shrinkage cracks in cement-based materials incorporating reactive MgO. Smart Mater. Struct. 2016, 25, 084004. [Google Scholar] [CrossRef]

- Ahn, T.H.; Kishi, T. Crack self-healing behavior of cementitious composites incorporating various mineral admixtures. J. Adv. Concr. Technol. 2010, 8, 171–186. [Google Scholar] [CrossRef] [Green Version]

- Sisomphon, K.; Copuroglu, O.; Koenders, E.A.B. Self-healing of surface cracks in mortars with expansive additive and crystalline additive. Cem. Concr. Compos. 2012, 34, 566–574. [Google Scholar] [CrossRef]

- Jiang, Z.; Li, W.; Yuan, Z. Influence of mineral additives and environmental conditions on the self-healing capabilities of cementitious materials. Cem. Concr. Compos. 2015, 57, 116–127. [Google Scholar] [CrossRef]

- Van Tittelboom, K.; Gruyaert, E.; Rahier, H.; De Belie, N. Influence of mix composition on the extent of autogenous crack healing by continued hydration or calcium carbonate formation. Constr. Build. Mater. 2012, 37, 349–359. [Google Scholar] [CrossRef]

- Antiohos, S.K.; Papageorgiou, A.; Papadakis, V.G.; Tsimas, S. Influence of quicklime addition on the mechanical properties and hydration degree of blended cements containing different fly ashes. Constr. Build. Mater. 2008, 22, 1191–1200. [Google Scholar] [CrossRef]

- Qureshi, T.; Kanellopoulos, A.; Al-Tabbaa, A. Autogenous self-healing of cement with expansive minerals-I: Impact in early age crack healing. Constr. Build. Mater. 2018, 192, 768–784. [Google Scholar] [CrossRef] [Green Version]

- Qureshi, T.S.; Al-Tabbaa, A. Influence of Expansive minerals on the Self-healing of Cement Paste and Mortar Systems. Smart Mater. Struct. 2015, 73, 1–4. [Google Scholar]

- Li, V.C.; Lim, Y.M.; Chan, Y.W. Feasibility study of a passive smart self-healing cementitious composite. Compos. Part B Eng. 1998, 29, 819–827. [Google Scholar] [CrossRef]

- Liang, F.; Liu, S.; Wang, C. Editorial (Thematic Issue: Recent Progress on Molecular Recognition and Supramolecular Devices). Curr. Org. Chem. 2014, 18, 1935–1936. [Google Scholar] [CrossRef]

- De Rooij, M.; Schlangen, E.; Joseph, C. Self-Healing Phenomena in Cement-Based Materials; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013; Volume 1, ISBN 9789400766235. [Google Scholar]

- Yang, Z.; Hollar, J.; He, X.; Shi, X. A self-healing cementitious composite using oil core/silica gel shell microcapsules. Cem. Concr. Compos. 2011, 33, 506–512. [Google Scholar] [CrossRef]

- Wang, J.Y.; Soens, H.; Verstraete, W.; De Belie, N. Self-healing concrete by use of microencapsulated bacterial spores. Cem. Concr. Res. 2014, 56, 139–152. [Google Scholar] [CrossRef]

- Siddique, R.; Chahal, N.K. Effect of ureolytic bacteria on concrete properties. Constr. Build. Mater. 2011, 25, 3791–3801. [Google Scholar] [CrossRef]

- Joseph, C.; Jefferson, A.D.; Isaacs, B.; Lark, R.; Gardner, D. Experimental investigation of adhesive-based self-healing of cementitious materials. Mag. Concr. Res. 2010, 62, 831–843. [Google Scholar] [CrossRef] [Green Version]

- Qureshi, T.S.; Kanellopoulos, A.; Al-Tabbaa, A. Encapsulation of expansive powder minerals within a concentric glass capsule system for self-healing concrete. Constr. Build. Mater. 2016, 121, 629–643. [Google Scholar] [CrossRef]

- Alghamri, R.; Kanellopoulos, A.; Litina, C.; Al-Tabbaa, A. Preparation and polymeric encapsulation of powder mineral pellets for self-healing cement based materials. Constr. Build. Mater. 2018, 186, 247–262. [Google Scholar] [CrossRef] [Green Version]

- De Belie, N.; Gruyaert, E.; Al-Tabbaa, A.; Antonaci, P.; Baera, C.; Bajare, D.; Darquennes, A.; Davies, R.; Ferrara, L.; Jefferson, T.; et al. A Review of Self-Healing Concrete for Damage Management of Structures. Adv. Mater. Interfaces 2018, 5, 1800074. [Google Scholar] [CrossRef]

- Giannaros, P.; Kanellopoulos, A.; Al-Tabbaa, A. Sealing of cracks in cement using microencapsulated sodium silicate. Smart Mater. Struct. 2016, 25, 084005. [Google Scholar] [CrossRef]

- Amran, M.; Murali, G.; Khalid, N.H.A.; Fediuk, R.; Ozbakkaloglu, T.; Lee, Y.H.; Haruna, S.; Lee, Y.Y. Slag uses in making an ecofriendly and sustainable concrete: A review. Constr. Build. Mater. 2021, 272, 121942. [Google Scholar] [CrossRef]

- Guzlena, S.; Sakale, G. Self-healing concrete with crystalline admixture—A review. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 660. [Google Scholar]

- Seifan, M.; Samani, A.K.; Berenjian, A. Bioconcrete: Next generation of self-healing concrete. Appl. Microbiol. Biotechnol. 2016, 100, 2591–2602. [Google Scholar] [CrossRef] [Green Version]

- Xu, J.; Wang, X. Self-healing of concrete cracks by use of bacteria-containing low alkali cementitious material. Constr. Build. Mater. 2018, 167, 1–14. [Google Scholar] [CrossRef]

- Mauludin, L.M.; Oucif, C. Modeling of self-healing concrete: A review. J. Appl. Comput. Mech. 2019, 5, 526–539. [Google Scholar]

- Nijland, T.G.; Larbi, J.A.; van Hees, R.P.; Lubelli, B.; de Rooij, M. Self Healing Phenomena in Concretes and Masonry Mortars: A Microscopic Study. In Proceedings of the First International Conference on Self Healing Materials, Noordwijk Aan Zee, The Netherlands, 18–20 April 2007; 2007; pp. 1–9. [Google Scholar]

- Han, B.; Wang, Y.; Dong, S.; Zhang, L.; Ding, S.; Yu, X.; Ou, J. Smart concretes and structures: A review. J. Intell. Mater. Syst. Struct. 2015, 26, 1303–1345. [Google Scholar] [CrossRef]

- Sun, L.; Liang, D.; Gao, Q.; Zhou, J. Analysis on factors affecting the self-repair capability of SMA wire concrete beam. Math. Probl. Eng. 2013, 2013, 138162. [Google Scholar] [CrossRef]

- Yildirim, G.; Sahmaran, M.; Ahmed, H.U. Influence of Hydrated Lime Addition on the Self-Healing Capability of High-Volume Fly Ash Incorporated Cementitious Composites. J. Mater. Civ. Eng. 2015, 27, 4014187. [Google Scholar] [CrossRef]

- Yang, Y.; Yang, E.H.; Li, V.C. Autogenous healing of engineered cementitious composites at early age. Cem. Concr. Res. 2011, 41, 176–183. [Google Scholar] [CrossRef]

- Luo, M.; Qian, C.X.; Li, R.Y. Factors affecting crack repairing capacity of bacteria-based self-healing concrete. Constr. Build. Mater. 2015, 87, 1–7. [Google Scholar] [CrossRef]

- Zhong, W.; Yao, W. Influence of damage degree on self-healing of concrete. Constr. Build. Mater. 2008, 22, 1137–1142. [Google Scholar] [CrossRef]

- Fediuk, R.S.; Yevdokimova, Y.G.; Smoliakov, A.K.; Stoyushko, N.Y.; Lesovik, V.S. Use of geonics scientific positions for designing of building composites for protective (fortification) structures. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017; Volume 221. [Google Scholar]

- Xu, J.; Wang, X.; Zuo, J.; Liu, X. Self-Healing of Concrete Cracks by Ceramsite-Loaded Microorganisms. Adv. Mater. Sci. Eng. 2018, 2018, 5153041. [Google Scholar] [CrossRef] [Green Version]

- Tziviloglou, E.; Wiktor, V.; Jonkers, H.M.; Schlangen, E. Bacteria-based self-healing concrete to increase liquid tightness of cracks. Constr. Build. Mater. 2016, 122, 118–125. [Google Scholar] [CrossRef]

- Wang, W.; Zhong, T.; Wang, X.; He, Z. Research Status of Self-healing Concrete. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2019; Volume 218. [Google Scholar]

- Qian, C.; Chen, H.; Ren, L.; Luo, M. Self-healing of early age cracks in cement-based materials by mineralization of carbonic anhydrase microorganism. Front. Microbiol. 2015, 6, 1225. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zabanoot, M.S.S. Review of autogenous and autonomous self-healing concrete technologies for marine environments. In High Performance and Optimum Design of Structures and Materials IV; WIT Press: Ashurst, UK, 2020; pp. 31–38. [Google Scholar]

- Maes, M.; Van Tittelboom, K.; De Belie, N. The efficiency of self-healing cementitious materials by means of encapsulated polyurethane in chloride containing environments. Constr. Build. Mater. 2014, 71, 528–537. [Google Scholar] [CrossRef]

- Amenta, M.; Metaxa, Z.S.; Papaioannou, S.; Katsiotis, M.S.; Kilikoglou, V.; Kourkoulis, S.K.; Karatasios, I. Quantitative evaluation of self-healing capacity in cementitious materials. Mater. Des. Process. Commun. 2021, 3, e152. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, T.H.; Ghorbel, E.; Fares, H.; Cousture, A. Bacterial self-healing of concrete and durability assessment. Cem. Concr. Compos. 2019, 104, 103340. [Google Scholar] [CrossRef]

- Huynh, N.N.T.; Phuong, N.M.; Toan, N.P.A.; Son, N.K. Bacillus Subtilis HU58 Immobilized in Micropores of Diatomite for Using in Self-healing Concrete. Procedia Eng. 2017, 171, 598–605. [Google Scholar] [CrossRef]

- Algaifi, H.A.; Bakar, S.A.; Alyousef, R.; Mohd Sam, A.R.; Ibrahim, M.H.W.; Shahidan, S.; Ibrahim, M.; Salami, B.A. Bio-inspired self-healing of concrete cracks using new B. pseudomycoides species. J. Mater. Res. Technol. 2021, 12, 967–981. [Google Scholar] [CrossRef]

- Kalhori, H.; Bagherpour, R. Application of carbonate precipitating bacteria for improving properties and repairing cracks of shotcrete. Constr. Build. Mater. 2017, 148, 249–260. [Google Scholar] [CrossRef]

- Jafarnia, M.S.; Khodadad Saryazdi, M.; Moshtaghioun, S.M. Use of bacteria for repairing cracks and improving properties of concrete containing limestone powder and natural zeolite. Constr. Build. Mater. 2020, 242, 118059. [Google Scholar] [CrossRef]

- Wang, J.Y.; De Belie, N.; Verstraete, W. Diatomaceous earth as a protective vehicle for bacteria applied for self-healing concrete. J. Ind. Microbiol. Biotechnol. 2012, 39, 567–577. [Google Scholar] [CrossRef] [PubMed]

- Krishnapriya, S.; Babu, D.V. Isolation and identification of bacteria to improve the strength of concrete. Microbiol. Res. 2015, 174, 48–55. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.Y.; Snoeck, D.; Van Vlierberghe, S.; Verstraete, W.; De Belie, N. Application of hydrogel encapsulated carbonate precipitating bacteria for approaching a realistic self-healing in concrete. Constr. Build. Mater. 2014, 68, 110–119. [Google Scholar] [CrossRef]

- Khushnood, R.A.; Qureshi, Z.A.; Shaheen, N.; Ali, S. Bio-mineralized self-healing recycled aggregate concrete for sustainable infrastructure. Sci. Total Environ. 2020, 703, 135007. [Google Scholar] [CrossRef]

- Signorini, C.; Volpini, V. Mechanical performance of fiber reinforced cement composites including fully-recycled plastic fibers. Fibers 2021, 9, 16. [Google Scholar] [CrossRef]

- Jefferson, A.; Joseph, C.; Lark, R.; Isaacs, B.; Dunn, S.; Weager, B. A new system for crack closure of cementitious materials using shrinkable polymers. Cem. Concr. Res. 2010, 40, 795–801. [Google Scholar] [CrossRef]

- Chaerun, S.K.; Syarif, R.; Wattimena, R.K. Bacteria incorporated with calcium lactate pentahydrate to improve the mortar properties and self-healing occurrence. Sci. Rep. 2020, 10, 17873. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Bundur, Z.B.; Zhu, J.; Ferron, R.D. Evaluation of self-healing of internal cracks in biomimetic mortar using coda wave interferometry. Cem. Concr. Res. 2016, 83, 70–78. [Google Scholar] [CrossRef]

- Wang, J.Y.; Van Tittelboom, K.; De Belie, N.; Verstraete, W. Potential of applying bacteria to heal cracks in concrete. In Proceedings of the 2nd International Conference on Sustainable Construction Materials and Technologies, Ancona, Italy, 28–30 June 2010; pp. 1807–1818. [Google Scholar]

- Xu, J.; Yao, W. Multiscale mechanical quantification of self-healing concrete incorporating non-ureolytic bacteria-based healing agent. Cem. Concr. Res. 2014, 64, 1–10. [Google Scholar] [CrossRef]

- Chernysheva, N.; Lesovik, V.; Fediuk, R.; Vatin, N. Improvement of Performances of the Gypsum-Cement Fiber Reinforced Composite (GCFRC). Materials 2020, 13, 3847. [Google Scholar] [CrossRef] [PubMed]

- Amick, H.; Monteiro, P.J.M. A “toolbox” of damping treatments for concrete structures. In Proceedings of the Structures Congress and Exposition, New York, NY, USA, 20–24 April 2005; pp. 1691–1702. [Google Scholar]

- Lin, F.; Meyer, C. Hydration kinetics modeling of Portland cement considering the effects of curing temperature and applied pressure. Cem. Concr. Res. 2009, 39, 255–265. [Google Scholar] [CrossRef]

- Burduhos Nergis, D.D.; Vizureanu, P.; Ardelean, I.; Sandu, A.V.; Corbu, O.C.; Matei, E. Revealing the influence of microparticles on geopolymers’ synthesis and porosity. Materials 2020, 13, 3211. [Google Scholar] [CrossRef] [PubMed]

- Jozwiak-Niedzwiedzka, D. Microscopic observations of self-healing products in calcareous fly ash mortars. Microsc. Res. Tech. 2015, 78, 22–29. [Google Scholar] [CrossRef]

- Siad, H.; Alyousif, A.; Keskin, O.K.; Keskin, S.B.; Lachemi, M.; Sahmaran, M.; Hossain, K.M.A. Influence of limestone powder on mechanical, physical and self-healing behavior of Engineered Cementitious Composites. Constr. Build. Mater. 2015, 99, 1–10. [Google Scholar] [CrossRef]

- Zamorowski, W. The phenomenon of self-regeneration of concrete. Int. J. Cem. Compos. Light. Concr. 1985, 7, 199–201. [Google Scholar] [CrossRef]

- Tomczak, K.; Jakubowski, J. The effects of age, cement content, and healing time on the self-healing ability of high-strength concrete. Constr. Build. Mater. 2018, 187, 149–159. [Google Scholar] [CrossRef]

- Yıldırım, G.; Khiavi, A.H.; Yeşilmen, S.; Şahmaran, M. Self-healing performance of aged cementitious composites. Cem. Concr. Compos. 2018, 87, 172–186. [Google Scholar] [CrossRef]

- Hosoda, A.; Higuchi, T.; Eguchi, M.; Yoshida, H.; Aoki, H. Self Healing of Longitudinal Cracks in Utility Concrete Pole. J. Adv. Concr. Technol. 2012, 10, 278–284. [Google Scholar] [CrossRef] [Green Version]

- Hearn, N.; Morley, C.T. Self-sealing property of concrete—Experimental evidence. Mater. Struct. Constr. 1997, 30, 404–411. [Google Scholar] [CrossRef]

- Svintsov, A.P.; Shchesnyak, E.L.; Galishnikova, V.V.; Fediuk, R.S.; Stashevskaya, N.A. Effect of nano-modified additives on properties of concrete mixtures during winter season. Constr. Build. Mater. 2020, 237, 117527. [Google Scholar] [CrossRef]

- Rashed, A.; Rogowsky, D.M.; Elwi, A.E. Tests on Reinforced Partially Prestressed Concrete Tank Walls. J. Struct. Eng. 2000, 126, 675–683. [Google Scholar] [CrossRef]

- Hooshmand, A.; Kianoush, R.; Siad, H.; Lachemi, M.; Moslemi, M. Investigation of leakage and self-healing of direct tension cracks under sustained loading and high-water pressure. Constr. Build. Mater. 2021, 267, 120879. [Google Scholar] [CrossRef]

- Yang, E.H.; Yang, Y.; Li, V.C. Use of high volumes of fly ash to improve ECC mechanical properties and material greenness. ACI Mater. J. 2007, 104, 620–628. [Google Scholar] [CrossRef]

- Zhou, J.; Qian, S.; Beltran, M.G.S.; Ye, G.; Van Breugel, K.; Li, V.C. Development of engineered cementitious composites with limestone powder and blast furnace slag. Mater. Struct. Constr. 2010, 43, 803–814. [Google Scholar] [CrossRef] [Green Version]

- Özbay, E.; Şahmaran, M.; Yücel, H.E.; Erdem, T.K.; Lachemi, M.; Li, V.C. Effect of sustained flexural loading on self-healing of engineered cementitious composites. J. Adv. Concr. Technol. 2013, 11, 167–179. [Google Scholar] [CrossRef] [Green Version]

- Jun, P.; Mechtcherine, V. Behaviour of strain-hardening cement-based composites (SHCC) under monotonic and cyclic tensile loading: Part 1—Experimental investigations. Cem. Concr. Compos. 2010, 32, 801–809. [Google Scholar] [CrossRef]

- Schlangen, E.; Heide, N.T.; Breugel, K.V. Crack Healing of Early Age Cracks in Concrete. In Measuring, Monitoring and Modeling Concrete Properties; Springer: Dordrecht, The Netherlands, 2007; pp. 273–284. [Google Scholar]

- Sidiq, A.; Gravina, R.; Giustozzi, F. Is concrete healing really efficient? A review. Constr. Build. Mater. 2019, 205, 257–273. [Google Scholar] [CrossRef]

- Rajczakowska, M.; Habermehl-Cwirzen, K.; Hedlund, H.; Cwirzen, A. Autogenous Self-Healing: A Better Solution for Concrete. J. Mater. Civ. Eng. 2019, 31, 3119001. [Google Scholar] [CrossRef]

- Fediuk, R.; Smoliakov, A.; Stoyushko, N. Increase in composite binder activity. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2016; Volume 156. [Google Scholar]

- Neville, A. Autogenous healing: A concrete miracle? Concr. Int. 2002, 24, 76–82. [Google Scholar]

- Zwaag, S. Self-Healing Materials: An Alternative Approach to 20 Centuries of Materials Science; Springer Science+ Business Media BV: Dordrecht, The Netherlands, 2014; Volume 30. [Google Scholar] [CrossRef] [Green Version]

- Talaiekhozani, A.; Abd Majid, M.Z. A review of self-healing concrete research development. J. Environ. Treat. Tech. 2014, 2, 1–11. [Google Scholar]

- Griño, A.A.; Daly, M.K.M.; Ongpeng, J.M.C. Bio-influenced self-healing mechanism in concrete and its testing: A review. Appl. Sci. 2020, 10, 5161. [Google Scholar] [CrossRef]

- Powers, P.A. A Working Hypothesis for Further Studies of Frost Resistance of Concrete. ACI J. Proc. 1945, 41, 245–272. [Google Scholar] [CrossRef]

- de Azevedo, A.R.; Klyuev, S.; Marvila, M.T.; Vatin, N.; Alfimova, N.; de Lima, T.E.; Fediuk, R.; Olisov, A. Investigation of the Potential Use of Curauá Fiber for Reinforcing Mortars. Fibers 2020, 8, 69. [Google Scholar] [CrossRef]

- Jacobsen, S.; Sellevold, E.J. Self healing of high strength concrete after deterioration by freeze/thaw. Cem. Concr. Res. 1996, 26, 55–62. [Google Scholar] [CrossRef]

- Sukhotskaya, S.S.; Mazhorova, V.P.; Terekhin, Y.N. Effect of autogenous healing of concrete subjected to periodic freeze-thaw cycles. Hydrotech. Constr. 1983, 17, 294–296. [Google Scholar] [CrossRef]

- Jamshidi, R.J.; Lake, C.B.; Gunning, P.; Hills, C.D. Effect of Freeze/Thaw Cycles on the Performance and Microstructure of Cement-Treated Soils. J. Mater. Civ. Eng. 2016, 28, 4016162. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Y.; Yang, Y.; Yao, Y. Autogenous self-healing of engineered cementitious composites under freeze-thaw cycles. Constr. Build. Mater. 2012, 34, 522–530. [Google Scholar] [CrossRef]

- Jacobsen, S.; Marchand, J.; Hornain, H. Sem observations of the microstructure of frost deteriorated and self-healed concretes. Cem. Concr. Res. 1995, 25, 1781–1790. [Google Scholar] [CrossRef]

- Jacobsen, S.; Sellevold, E.J.; Matala, S. Frost durability of high strength concrete: Effect of internal cracking on ice formation. Cem. Concr. Res. 1996, 26, 919–931. [Google Scholar] [CrossRef]

- Homma, D.; Mihashi, H.; Nishiwaki, T. Self-healing capability of fibre reinforced cementitious composites. J. Adv. Concr. Technol. 2009, 7, 217–228. [Google Scholar] [CrossRef] [Green Version]

- Sisomphon, K.; Copuroglu, O.; Fraaij, A. Application of encapsulated lightweight aggregate impregnated with sodium monofluorophosphate as a self-healing agent in blast furnace slag mortar. Heron 2011, 56, 17–36. [Google Scholar]

- Nishiwaki, T.; Koda, M.; Yamada, M.; Mihashi, H.; Kikuta, T. Experimental study on self-healing capability of FRCC using different types of synthetic fibers. J. Adv. Concr. Technol. 2012, 10, 195–206. [Google Scholar] [CrossRef] [Green Version]

- Sisomphon, K.; Copuroglu, O. Self healing mortars by using different cementitious materials. In Proceedings of the International Conference on Advances in Construction Materials through Science and Engineering, Hong Kong, China, 5–7 September 2011; pp. 5–7. [Google Scholar]

- Van Tittelboom, K.; De Belie, N.; Van Loo, D.; Jacobs, P. Self-healing efficiency of cementitious materials containing tubular capsules filled with healing agent. Cem. Concr. Compos. 2011, 33, 497–505. [Google Scholar] [CrossRef]

- Anju, T.R.; Ramamurthy, K.; Dhamodharan, R. Biochar 101: An Introduction to an Ancient Product Offering Modern Opportunities. Constr. Build. Mater. 2016, 9, 1–6. [Google Scholar]

- El-Newihy, A.; Azarsa, P.; Gupta, R.; Biparva, A. Effect of polypropylene fibers on self-healing and dynamic modulus of elasticity recovery of fiber reinforced concrete. Fibers 2018, 6, 9. [Google Scholar] [CrossRef] [Green Version]

- Yuan, X.Z.; Sun, W.; Zuo, X.B. Study of feasibility of heat melt adhesive being used in crack self-healing of cement-based materials. In Applied Mechanics and Materials; Trans Tech Publications Ltd.: Frienbach, Switzerland, 2011; Volume 99–100, pp. 1087–1091. [Google Scholar]

- Wiktor, V.; Jonkers, H.M. Quantification of crack-healing in novel bacteria-based self-healing concrete. Cem. Concr. Compos. 2011, 33, 763–770. [Google Scholar] [CrossRef]

- Edvardsen, C. Water permeability and autogenous healing of cracks in concrete. ACI Mater. J. 1999, 96, 448–454. [Google Scholar] [CrossRef]

- Jonkers, H.M. Bacteria-based self-healing concrete. Heron 2011, 56, 5–16. [Google Scholar]

- Wang, J.; Van Tittelboom, K.; De Belie, N.; Verstraete, W. Use of silica gel or polyurethane immobilized bacteria for self-healing concrete. Constr. Build. Mater. 2012, 26, 532–540. [Google Scholar] [CrossRef]

- Şahmaran, M.; Li, V.C. Durability properties of micro-cracked ECC containing high volumes fly ash. Cem. Concr. Res. 2009, 39, 1033–1043. [Google Scholar] [CrossRef]

- Pelletier, M.M.; Brown, R.; Shukla, A.; Bose, A. Self-Healing Concrete with a Microencapsulated Healing Agent; University of Rhode Island: Kingston, RI, USA, 2010. [Google Scholar]

- Sisomphon, K.; Opurolu, O.; Fraaij, A.L.A. Durability of blast-furnace slag mortars subjected to sodium monofluorophosphate application. Constr. Build. Mater. 2011, 25, 823–828. [Google Scholar] [CrossRef]

- Reinhardt, H.W.; Jooss, M. Permeability and self-healing of cracked concrete as a function of temperature and crack width. Cem. Concr. Res. 2003, 33, 981–985. [Google Scholar] [CrossRef]

- Kunieda, M.; Shimizu, K.; Eguchi, T.; Ueda, N.; Nakamura, H. Fundamental Properties of Ultra High Performance-Strain Hardening Cementitious Composites and Usage for Repair. J. Jpn. Soc. Civ. Eng. Ser. E2 Mater. Concr. Struct. 2011, 67, 508–521. [Google Scholar] [CrossRef] [Green Version]

- Danish, A.; Mosaberpanah, M.A.; Salim, M.U. Past and present techniques of self-healing in cementitious materials: A critical review on efficiency of implemented treatments. J. Mater. Res. Technol. 2020, 9, 6883–6899. [Google Scholar] [CrossRef]

- Van Tittelboom, K.; Snoeck, D.; Vontobel, P.; Wittmann, F.H.; De Belie, N. Use of neutron radiography and tomography to visualize the autonomous crack sealing efficiency in cementitious materials. Mater. Struct. Constr. 2013, 46, 105–121. [Google Scholar] [CrossRef]

- Lee, H.X.D.; Wong, H.S.; Buenfeld, N. Self-sealing cement-based materials using superabsorbent polymers. In Proceedings of the International RILEM Conference on Use of Superabsorbent Polymers and Other New Additives in Concrete, Lyngby, Denmark, 15–18 August 2010. [Google Scholar]

- Termkhajornkit, P.; Nawa, T.; Yamashiro, Y.; Saito, T. Self-healing ability of fly ash-cement systems. Cem. Concr. Compos. 2009, 31, 195–203. [Google Scholar] [CrossRef]

- Granger, S.; Loukili, A.; Pijaudier-Cabot, G.; Chanvillard, G. Experimental characterization of the self-healing of cracks in an ultra high performance cementitious material: Mechanical tests and acoustic emission analysis. Cem. Concr. Res. 2007, 37, 519–527. [Google Scholar] [CrossRef] [Green Version]

- Ferraro, L.; Caggiano, A.; Krelani, V.; Etse, G. Self-Healing Capacity of Cementitious Composites: Experiments and Modeling. Mecánica Comput. 2014, 33, 1323–1338. [Google Scholar]

- Kim, S.; Kim, M.J.; Yoon, H.; Yoo, D.Y. Effect of cryogenic temperature on the flexural and cracking behaviors of ultra-high-performance fiber-reinforced concrete. Cryogenics 2018, 93, 75–85. [Google Scholar] [CrossRef]

- Lesovik, V.S.; Zagorodnyuk, L.K.; Babaev, Z.K.; Dzhumaniyazov, Z.B. Analysis of the Causes of Brickwork Efflorescence in the Aral Sea Region. Glas. Ceram. 2020, 77, 277–279. [Google Scholar] [CrossRef]

- Kwon, S.; Nishiwaki, T.; Kikuta, T.; Mihashi, H. Experimental study on self-healing capability of cracked ultra-high-performance hybrid-fiber-reinforced cementitious composites. Cem. Sci. Concr. Technol. 2013, 66, 552–559. [Google Scholar]

- Rose, J.; Grasley, Z.; Tang, M.; Edwards, M.; Wang, F. Accelerated Autogenous Healing of Concrete Pipe Sections with Crack and Decalcification Damage. J. Mater. Civ. Eng. 2018, 30, 4018308. [Google Scholar] [CrossRef]

- Tolstoy, A.D.; Lesovik, V.S.; Glagolev, E.S.; Krymova, A.I. Synergetics of hardening construction systems. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; Volume 327. [Google Scholar]

- Orlov, M.V. Materials Microencapsulation Applications in Oil Drilling and Production. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2021; Volume 1942. [Google Scholar]

- Ferrara, L.; Van Mullem, T.; Alonso, M.C.; Antonaci, P.; Borg, R.P.; Cuenca, E.; Jefferson, A.; Ng, P.L.; Peled, A.; Roig-Flores, M.; et al. Experimental characterization of the self-healing capacity of cement based materials and its effects on the material performance: A state of the art report by COST Action SARCOS WG2. Constr. Build. Mater. 2018, 167, 115–142. [Google Scholar] [CrossRef] [Green Version]

- Li, W.; Jiang, Z.; Yang, Z.; Zhao, N.; Yuan, W. Self-healing efficiency of cementitious materials containing microcapsules filled with healing adhesive: Mechanical restoration and healing process monitored by water absorption. PLoS ONE 2013, 8, e81616. [Google Scholar] [CrossRef] [PubMed]

- Huang, H.; Ye, G.; Damidot, D. Effect of blast furnace slag on self-healing of microcracks in cementitious materials. Cem. Concr. Res. 2014, 60, 68–82. [Google Scholar] [CrossRef]

- Fediuk, R.; Mosaberpanah, M.A.; Lesovik, V. Development of fiber reinforced self-compacting concrete (FRSCC): Towards an efficient utilization of quaternary composite binders and fibers. Adv. Concr. Constr. 2020, 9, 387–395. [Google Scholar]

- Palin, D.; Jonkers, H.M.; Wiktor, V. Autogenous healing of sea-water exposed mortar: Quantification through a simple and rapid permeability test. Cem. Concr. Res. 2016, 84, 1–7. [Google Scholar] [CrossRef]

- Maes, M.; Snoeck, D.; De Belie, N. Chloride penetration in cracked mortar and the influence of autogenous crack healing. Constr. Build. Mater. 2016, 115, 114–124. [Google Scholar] [CrossRef]

- De Nardi, C.; Cecchi, A.; Ferrara, L.; Benedetti, A.; Cristofori, D. Effect of age and level of damage on the autogenous healing of lime mortars. Compos. Part B Eng. 2017, 124, 144–157. [Google Scholar] [CrossRef] [Green Version]

- Sherir, M.A.A.; Hossain, K.M.A.; Lachemi, M. The influence of MgO-type expansive agent incorporated in self-healing system of Engineered cementitious Composites. Constr. Build. Mater. 2017, 149, 164–185. [Google Scholar] [CrossRef]

- Saleh Salem Beshr, B.; Abdul Mohaimen, I.M.; Noor Azline, M.N.; Nor Azizi, S.; Nabilah, A.B.; Farah Nora Aznieta, A.A. Feasibility assessment on self-healing ability of cementitious composites with MgO. J. Build. Eng. 2021, 34, 101914. [Google Scholar] [CrossRef]

- Hosoda, A.; Komatsu, S.; Ahn, T.; Kishi, T.; Ikeno, S.; Kobayashi, K. Self healing properties with various crack widths under continuous water leakage. In Concrete Repair, Rehabilitation and Retrofitting II, Proceedings of the 2nd International Conference on Concrete Repair, Rehabilitation and Retrofitting, ICCRRR, Cape Town, South Africa, 24–26 November 2008; CRC Press: Boca Raton, FL, USA, 2009; pp. 121–122. [Google Scholar]

- Snoeck, D.; De Belie, N. Autogenous healing in strain-hardening cementitious materials with and without superabsorbent polymers: An 8-year study. Front. Mater. 2019, 6, 48. [Google Scholar] [CrossRef]

- Zhou, Z.; Li, Z.; Xu, D.; Yu, J. Influence of slag and fly ash on the self-healing ability of concrete. In Advanced Materials Research; Trans Tech Publications Ltd.: Frienbach, Switzerland, 2011; Volume 306–307, pp. 1020–1023. [Google Scholar]

- Watanabe, T.; Fujiwara, Y.; Hashimoto, C.; Ishimaru, K. Evaluation of self healing effect in fly-ash concrete by ultrasonic test method. Int. J. Mod. Phys. B 2011, 25, 4307–4310. [Google Scholar] [CrossRef]

- Qian, S.Z.; Zhou, J.; Schlangen, E. Influence of curing condition and precracking time on the self-healing behavior of Engineered Cementitious Composites. Cem. Concr. Compos. 2010, 32, 686–693. [Google Scholar] [CrossRef]

- Alazhari, M.S.A. The Effect of Microbiological Agents on the Efficiency of Bio-Based Repair Systems for Concrete. Ph.D. Thesis, University of Bath, Bath, UK, 2017. Volume 294. [Google Scholar]

- Tolstoy, A.; Lesovik, V.; Fediuk, R.; Amran, M.; Gunasekaran, M.; Vatin, N.; Vasilev, Y. Production of greener high-strength concrete using russian quartz sandstone mine waste aggregates. Materials 2020, 13, 5575. [Google Scholar] [CrossRef]

- Lee, Y.S.; Ryou, J.S. Self healing behavior for crack closing of expansive agent via granulation/film coating method. Constr. Build. Mater. 2014, 71, 188–193. [Google Scholar] [CrossRef]

- Pang, B.; Zhou, Z.; Hou, P.; Du, P.; Zhang, L.; Xu, H. Autogenous and engineered healing mechanisms of carbonated steel slag aggregate in concrete. Constr. Build. Mater. 2016, 107, 191–202. [Google Scholar] [CrossRef]

- Ferrara, L.; Krelani, V.; Moretti, F. On the use of crystalline admixtures in cement based construction materials: From porosity reducers to promoters of self healing. Smart Mater. Struct. 2016, 25, 084002. [Google Scholar] [CrossRef]

- Cailleux, E.; Pollet, V. Investigations on the development of self-healing properties in protective coatings for concrete and repair mortars. In Proceedings of the 2nd International Conference on Self-Healing Materials, Chicago, IL, USA, 28 June–1 July 2009; Volume 32, pp. 1–4. [Google Scholar]

- Da Silva, F.B.; De Belie, N.; Boon, N.; Verstraete, W. Production of non-axenic ureolytic spores for self-healing concrete applications. Constr. Build. Mater. 2015, 93, 1034–1041. [Google Scholar] [CrossRef]

- Palin, D.; Wiktor, V.; Jonkers, H.M. A bacteria-based self-healing cementitious composite for application in low-temperature marine environments. Biomimetics 2017, 2, 13. [Google Scholar] [CrossRef] [Green Version]

- Fookes, P.G.; Simm, J.D.; Barr, J.M. Marine Concrete Performance in Different Climatic Environments; ReCAP Project Management Unit, Cardno Emerging Market: London, UK, 1986; pp. 115–130. [Google Scholar]

- Mors, R.M.; Jonkers, H.M. Feasibility of lactate derivativ e based agent as additive for concrete for regain of crack water tightness by bacterial metabolism. Ind. Crops Prod. 2017, 106, 97–104. [Google Scholar] [CrossRef]

- Volodchenko, A.A.; Lesovik, V.S.; Cherepanova, I.A.; Volodchenko, A.N.; Zagorodnjuk, L.H.; Elistratkin, M.Y. Peculiarities of non-autoclaved lime wall materials production using clays. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018. [Google Scholar]

- Wang, J.; Mignon, A.; Snoeck, D.; Wiktor, V.; Van Vliergerghe, S.; Boon, N.; De Belie, N. Application of modified-alginate encapsulated carbonate producing bacteria in concrete: A promising strategy for crack self-healing. Front. Microbiol. 2015, 6, 1088. [Google Scholar] [CrossRef] [Green Version]

- Palin, D.; Wiktor, V.; Jonkers, H.M. A bacteria-based bead for possible self-healing marine concrete applications. Smart Mater. Struct. 2016, 25, 084008. [Google Scholar] [CrossRef]

- Wang, C.; Bu, Y.; Zhao, L. Properties and self-healing behavior of oil absorbent microspheres modified cement. Smart Mater. Struct. 2017, 26, 095010. [Google Scholar] [CrossRef]

- Chernyshova, N.; Lesovik, V.; Fediuk, R.; Timokhin, R. Enhancement of fresh properties and performances of the eco-friendly gypsum-cement composite (EGCC). Constr. Build. Mater. 2020, 260, 120462. [Google Scholar] [CrossRef]

- Blaiszik, B.J.; Kramer, S.L.B.; Olugebefola, S.C.; Moore, J.S.; Sottos, N.R.; White, S.R. Self-healing polymers and composites. Annu. Rev. Mater. Res. 2010, 40, 179–211. [Google Scholar] [CrossRef]

- Zhu, D.Y.; Rong, M.Z.; Zhang, M.Q. Self-healing polymeric materials based on microencapsulated healing agents: From design to preparation. Prog. Polym. Sci. 2015, 49–50, 175–220. [Google Scholar] [CrossRef]

- Kosarli, M.; Bekas, D.; Tsirka, K.; Paipetis, A.S. Capsule-based self-healing polymers and composites. In Self-Healing Polymer-Based Systems; Elsevier: Amsterdam, The Netherlands, 2020; pp. 259–278. [Google Scholar]

- Dry, C.; Corsaw, M. A comparison of bending strength between adhesive and steel reinforced concrete with steel only reinforced concrete. Cem. Concr. Res. 2003, 33, 1723–1727. [Google Scholar] [CrossRef]

- Hilloulin, B.; Van Tittelboom, K.; Gruyaert, E.; De Belie, N.; Loukili, A. Design of polymeric capsules for self-healing concrete. Cem. Concr. Compos. 2015, 55, 298–307. [Google Scholar] [CrossRef] [Green Version]

- Dry, C.M. Smart earthquake-resistant materials: Using time-released adhesives for damping, stiffening, and deflection control. In Proceedings of the 3rd International Conference on Intelligent Materials and 3rd European Conference on Smart Structures and Materials, Lyon, France, 3–5 June 1996; Volume 2779, p. 958. [Google Scholar]

- Thao, T.D.P.; Johnson, T.J.S.; Tong, Q.S.; Dai, P.S. Implementation of self-healing in concrete–Proof of concept. IES J. Part A Civ. Struct. Eng. 2009, 2, 116–125. [Google Scholar] [CrossRef]

- Lesovik, V.; Popov, D.; Fediuk, R.; Glagolev, E.; Yoo, D.Y. Improvement of Mechanical and Durability Behaviors of Textile Concrete: Effect of Polymineral Composite Binders and Superabsorbent Polymers. J. Mater. Civ. Eng. 2020, 32, 04020315. [Google Scholar] [CrossRef]

- Dry, C.M. Smart multiphase composite materials that repair themselves by a release of liquids that become solids. In Smart Structures and Materials 1994: Smart Materials; International Society for Optics and Photonics: Bellingham, WA, USA, 1994; Volume 2189, pp. 62–70. [Google Scholar]

- Dry, C.M. Smart materials which sense, activate and repair damage; hollow porous fibers in composites release chemicals from fibers for self-healing, damage prevention, and/or dynamic control. In Proceedings of the First European Conference on Smart Structures and Materials, Glasgow, UK, 12–14 May 1992. [Google Scholar]

- Janssen, D. Water Encapsulation to Initiate Self-Healing in Cementitious Materials. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, 2011. [Google Scholar]

- Clear, C.A. Effects of Autogenous Healing upon the Leakage of Water through Cracks in Concrete; Cement and Concrete Association: Camberley, UK, 1985. [Google Scholar]

- Lstiburek, J.W. Concrete solutions. ASHRAE J. 2020, 62, 76–85. [Google Scholar]

- Li, W.; Jiang, Z.; Yang, Z. Acoustic characterization of damage and healing of microencapsulation-based self-healing cement matrices. Cem. Concr. Compos. 2017, 84, 48–61. [Google Scholar] [CrossRef]

- Souza, L.; Al-Tabbaa, A. Microfluidic fabrication of microcapsules tailored for self-healing in cementitious materials. Constr. Build. Mater. 2018, 184, 713–722. [Google Scholar] [CrossRef]

- Wang, X.; Sun, P.; Han, N.; Xing, F. Experimental study on mechanical properties and porosity of organic microcapsules based self-healing cementitious composite. Materials 2017, 10, 20. [Google Scholar] [CrossRef] [Green Version]

- Katoueizadeh, E.; Zebarjad, S.M.; Janghorban, K. Investigating the effect of synthesis conditions on the formation of urea-formaldehyde microcapsules. J. Mater. Res. Technol. 2019, 8, 541–552. [Google Scholar] [CrossRef]

- Milla, J.; Hassan, M.M.; Rupnow, T.; Al-Ansari, M.; Arce, G. Effect of self-healing calcium nitrate microcapsules on concrete properties. Transp. Res. Rec. 2016, 2577, 69–77. [Google Scholar] [CrossRef]

- Li, W.; Zhu, X.; Zhao, N.; Jiang, Z. Preparation and properties of melamine urea-formaldehyde microcapsules for self-healing of cementitious materials. Materials 2016, 9, 152. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- García Calvo, J.L.; Pérez, G.; Carballosa, P.; Erkizia, E.; Gaitero, J.J.; Guerrero, A. Development of ultra-high performance concretes with self-healing micro/nano-additions. Constr. Build. Mater. 2017, 138, 306–315. [Google Scholar] [CrossRef]

- Xiong, W.; Tang, J.; Zhu, G.; Han, N.; Schlangen, E.; Dong, B.; Wang, X.; Xing, F. A novel capsule-based self-recovery system with a chloride ion trigger. Sci. Rep. 2015, 5, 10866. [Google Scholar] [CrossRef] [Green Version]

- Malinskii, Y.M.; Prokopenko, V.V.; Ivanova, N.A.; Kargin, V.A. Investigation of self-healing of cracks in polymers. Polym. Mech. 1973, 6, 240–244. [Google Scholar] [CrossRef]

- Xing, F.; Ni, Z.; Han, N.X.; Dong, B.Q.; Du, X.X.; Huang, Z.; Zhang, M. Self-Healing Mechanism of a Novel Cementitious Composite Using Microcapsules. Adv. Concr. Struct. Durab. Proc. Icdcs 2008, 12, 195–204. [Google Scholar]

- De Belie, N.; Van Tittelboom, K. Self-healing concrete: Suitability of different healing agents. Int. J. 3R’s 2010, 1, 12–21. [Google Scholar]

- Sun, L.; Yu, W.Y.; Ge, Q. Experimental research on the self—Healing performance of micro—Cracks in concrete bridge. In Advanced Materials Research; Trans Tech Publications Ltd.: Frienbach, Switzerland, 2011; Volume 250–253, pp. 28–32. [Google Scholar]

- Dry, C.; Corsaw, M.; Bayer, E. A comparison of internal self-repair with resin injection in repair of concrete. J. Adhes. Sci. Technol. 2003, 17, 79–89. [Google Scholar] [CrossRef]

- Sangadji, S.; Schlangen, E. Self healing of concrete structures—Novel approach using porous network concrete. J. Adv. Concr. Technol. 2012, 10, 185–194. [Google Scholar] [CrossRef] [Green Version]

- Kuang, Y.; Ou, J. Self-repairing performance of concrete beams strengthened using superelastic SMA wires in combination with adhesives released from hollow fibers. Smart Mater. Struct. 2008, 17, 025020. [Google Scholar] [CrossRef]

- Al-Fakih, A.; Mohammed, B.S.; Wahab, M.M.A.; Liew, M.S.; Mugahed Amran, Y.H.; Alyousef, R.; Alabduljabbar, H. Characteristic compressive strength correlation of rubberized concrete interlocking masonry wall. Structures 2020, 26, 169–184. [Google Scholar] [CrossRef]

- Onaizi, A.M.; Lim, N.H.A.S.; Huseien, G.F.; Amran, M.; Ma, C.K. Effect of the addition of nano glass powder on the compressive strength of high volume fly ash modified concrete. Mater. Today Proc. 2022, 48, 1789–1795. [Google Scholar] [CrossRef]

- Avudaiappan, S.; Amran, M.; Aepuru, R.; Fediuk, R.; Vatin, N. Prediction of Pore Volume Dispersion and Microstructural Characteristics of Concrete Using Image Processing Technique. Crystals 2021, 11, 1476. [Google Scholar]

- Lesovik, V.; Chernysheva, N.; Fediuk, R.; Amran, M.; Murali, G.; de Azevedo, A.R.G. Optimization of fresh properties and durability of the green gypsum-cement paste. Constr. Build. Mater. 2021, 287, 123035. [Google Scholar] [CrossRef]

- Amran, M.; Al-Fakih, A.; Chu, S.H.; Fediuk, R.; Haruna, S.; Azevedo, A.; Vatin, N. Long-term durability properties of geopolymer concrete: An in-depth review. Case Stud. Constr. Mater. 2021, 15, e00661. [Google Scholar] [CrossRef]

- Amran, M.; Debbarma, S.; Ozbakkaloglu, T. Fly ash-based eco-friendly geopolymer concrete: A critical review of the long-term durability properties. Constr. Build. Mater. 2021, 270, 121857. [Google Scholar] [CrossRef]

- Loganina, V.; Fediuk, R.; Taranov, D.; Amran, Y.H.M. Estimation of the probability of cracking of facade coatings. In Materials Science Forum; Trans Tech Publications Ltd.: Frienbach, Switzerland, 2021; Volume 1037, pp. 675–683. [Google Scholar]

- Pacheco-Torgal, F.; Labrincha, J.A. Biotech cementitious materials: Some aspects of an innovative approach for concrete with enhanced durability. Constr. Build. Mater. 2013, 40, 1136–1141. [Google Scholar] [CrossRef]

- Fediuk, R.S.; Ibragimov, R.A.; Lesovik, V.S.; Akopian, A.K.; Teleshev, A.A.; Khankhabaev, L.R.; Ivanov, A.S. Application of cementitious composites in mechanical engineering. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; Volume 327. [Google Scholar]

- Achal, V.; Mukherjee, A.; Reddy, M.S. Microbial concrete: A way to enhance durability of building structures. In Proceedings of the 2nd International Conference on Sustainable Construction Materials and Technologies, Ancona, Italy, 28–30 June 2010; pp. 23–28. [Google Scholar]

- Achal, V.; Mukerjee, A.; Sudhakara Reddy, M. Biogenic treatment improves the durability and remediates the cracks of concrete structures. Constr. Build. Mater. 2013, 48, 1–5. [Google Scholar] [CrossRef]

- Bang, S.S.; Lippert, J.J.; Yerra, U.; Mulukutla, S.; Ramakrishnan, V. Microbial calcite, a bio-based smart nanomaterial in concrete remediation. Int. J. Smart Nano Mater. 2010, 1, 28–39. [Google Scholar] [CrossRef]

- Erşan, Y.Ç.; Da Silva, F.B.; Boon, N.; Verstraete, W.; De Belie, N. Screening of bacteria and concrete compatible protection materials. Constr. Build. Mater. 2015, 88, 196–203. [Google Scholar] [CrossRef]

- Wang, J.; Dewanckele, J.; Cnudde, V.; Van Vlierberghe, S.; Verstraete, W.; De Belie, N. X-ray computed tomography proof of bacterial-based self-healing in concrete. Cem. Concr. Compos. 2014, 53, 289–304. [Google Scholar] [CrossRef]

- Seifan, M.; Sarmah, A.K.; Samani, A.K.; Ebrahiminezhad, A.; Ghasemi, Y.; Berenjian, A. Mechanical properties of bio self-healing concrete containing immobilized bacteria with iron oxide nanoparticles. Appl. Microbiol. Biotechnol. 2018, 102, 4489–4498. [Google Scholar] [CrossRef]

- Sri Durga, C.S.; Ruben, N.; Sri Rama Chand, M.; Indira, M.; Venkatesh, C. Comprehensive microbiological studies on screening bacteria for self-healing concrete. Materialia 2021, 15, 101051. [Google Scholar] [CrossRef]

- Sierra-Beltran, M.G.; Jonkers, H.M.; Schlangen, E. Characterization of sustainable bio-based mortar for concrete repair. Constr. Build. Mater. 2014, 67, 344–352. [Google Scholar] [CrossRef]

- Chahal, N.; Siddique, R.; Rajor, A. Influence of bacteria on the compressive strength, water absorption and rapid chloride permeability of fly ash concrete. Constr. Build. Mater. 2012, 28, 351–356. [Google Scholar] [CrossRef]

- Tayebani, B.; Mostofinejad, D. Self-healing bacterial mortar with improved chloride permeability and electrical resistance. Constr. Build. Mater. 2019, 208, 75–86. [Google Scholar] [CrossRef]

- Bhaskar, S.; Anwar Hossain, K.M.; Lachemi, M.; Wolfaardt, G.; Otini Kroukamp, M. Effect of self-healing on strength and durability of zeolite-immobilized bacterial cementitious mortar composites. Cem. Concr. Compos. 2017, 82, 23–33. [Google Scholar] [CrossRef]

- Jonkers, H.M.; Schlangen, E. Self-healing of cracked concrete: A bacterial approach. In Proceedings of the 6th International Conference on Fracture Mechanics of Concrete and Concrete Structures, Catania, Italy, 17 June 2007; Volume 3, pp. 1821–1826. [Google Scholar]

- Volodchenko, A.A.; Lesovik, V.S. Effective Composites Employing Fast-Hardening Gypsum Cement Binders for Additive Manufacturing. In Proceedings of the International Conference “Actual Issues of Mechanical Engineering” (AIME), Tomsk, Russia, 27–29 July 2017. [Google Scholar]

- Van Tittelboom, K.; De Belie, N.; De Muynck, W.; Verstraete, W. Use of bacteria to repair cracks in concrete. Cem. Concr. Res. 2010, 40, 157–166. [Google Scholar] [CrossRef]

- Guo, S.; Chidiac, S. Self-healing concrete: A critical review. In Proceedings of the Annual Conference—Canadian Society for Civil Engineering, Montreal, QC, Canada, 12–15 June 2019. [Google Scholar]

- Wang, J. Self-Healing Concrete by Means of Immobilized Carbonate Precipitating Bacteria. Ph.D. Thesis, Ghent University, Ghent, Belgium, 2013. [Google Scholar]

- El-Zeadani, M.; Rashid, R.S.M.; Amran, M.Y.H.; Swi, M.I. Effect of the plate bondstress-slip property on the flexural strength of FRP Plated RC beams using a displacement-based approach. SN Appl. Sci. 2020, 2, 1925. [Google Scholar] [CrossRef]

- Amran, Y.H.M.; Rashid, R.S.M.; Hejazi, F.; Safiee, N.A.; Ali, A.A.A. Response of precast foamed concrete sandwich panels to flexural loading. J. Build. Eng. 2016, 7, 143–158. [Google Scholar] [CrossRef]

- Yip, C.C.; Marsono, A.K.; Wong, J.Y.; Amran, M.Y.H. Flexural strength of special reinforced lightweight concrete beam for Industrialised Building System (IBS). J. Teknol. 2015, 77, 187–196. [Google Scholar] [CrossRef] [Green Version]

- Al-Nini, A.; Nikbakht, E.; Syamsir, A.; Shafiq, N.; Mohammed, B.S.; Al-Fakih, A.; Al-Nini, W.; Amran, Y.H.M. Flexural behavior of double-skin steel tube beams filled with fiber-reinforced cementitious composite and strengthened with CFRP sheets. Materials 2020, 13, 3064. [Google Scholar] [CrossRef] [PubMed]

- Al-Fakih, A.; Mohammed, B.S.; Wahab, M.M.A.; Liew, M.S.; Mugahed Amran, Y.H. Flexural behavior of rubberized concrete interlocking masonry walls under out-of-plane load. Constr. Build. Mater. 2020, 263, 120661. [Google Scholar] [CrossRef]

- Murali, G.; Amran, M.; Fediuk, R.; Vatin, N.; Raman, S.N.; Maithreyi, G.; Sumathi, A. Structural behavior of fibrous-ferrocement panel subjected to flexural and impact loads. Materials 2020, 13, 5648. [Google Scholar] [CrossRef] [PubMed]

- Siddika, A.; Shojib, M.H.H.; Hossain, M.M.; Hossain, M.I.; Al Mamun, M.A.; Alyousef, R.; Amran, Y.H.M. Flexural performance of wire mesh and geotextile-strengthened reinforced concrete beam. SN Appl. Sci. 2019, 1, 1324. [Google Scholar] [CrossRef] [Green Version]

- De Belie, N.; Wang, J.; Bundur, Z.B.; Paine, K. Bacteria-based concrete. In Eco-Efficient Repair and Rehabilitation of Concrete Infrastructures; Woodhead Publishing: Shaston, UK, 2018; pp. 531–567. ISBN 9780081021811. [Google Scholar]

- Talero, R.; Rahhal, V.; Potapov, V.V.; Serdan, A.A.; Kashpura, V.N.; Gorbach, V.A.; Tyurina, N.A.; Zubakha, S.V.; Rahhal, V.; Talero, R.; et al. AN2521 Application Note-19 V–75 W laptop adapter with tracking boost PFC pre-regulator, using the L6563 and L6668. Constr. Build. Mater. 2007, 1, 2–6. [Google Scholar]

- Zemskov, S.V.; Jonkers, H.M.; Vermolen, F.J. Two analytical models for the probability characteristics of a crack hitting encapsulated particles: Application to self-healing materials. Comput. Mater. Sci. 2011, 50, 3323–3333. [Google Scholar] [CrossRef]

- Lv, L.Y.; Zhang, H.; Schlangen, E.; Yang, Z.; Xing, F. Experimental and numerical study of crack behaviour for capsule-based self-healing cementitious materials. Constr. Build. Mater. 2017, 156, 219–229. [Google Scholar] [CrossRef]

- Lv, L.; Yang, Z.; Chen, G.; Zhu, G.; Han, N.; Schlangen, E.; Xing, F. Synthesis and characterization of a new polymeric microcapsule and feasibility investigation in self-healing cementitious materials. Constr. Build. Mater. 2016, 105, 487–495. [Google Scholar] [CrossRef]

- White, S.R.; Sottos, N.R.; Geubelle, P.H.; Moore, J.S.; Kessler, M.R.; Sriram, S.R.; Brown, E.N.; Viswanathan, S. Autonomic healing of polymer composites. Nature 2001, 409, 794–797. [Google Scholar] [CrossRef]

- Gilabert, F.A.; Garoz, D.; Van Paepegem, W. Stress concentrations and bonding strength in encapsulation-based self-healing materials. Mater. Des. 2015, 67, 28–41. [Google Scholar] [CrossRef]

- Kumar, A.; Paul, S.K. Healing of fatigue crack in steel with the application of pulsed electric current. Materialia 2020, 14, 100906. [Google Scholar] [CrossRef]

- Van Mullem, T.; Anglani, G.; Dudek, M.; Vanoutrive, H.; Bumanis, G.; Litina, C.; Kwiecień, A.; Al-Tabbaa, A.; Bajare, D.; Stryszewska, T.; et al. Addressing the need for standardization of test methods for self-healing concrete: An inter-laboratory study on concrete with macrocapsules. Sci. Technol. Adv. Mater. 2020, 21, 661–682. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Zheng, Q.; Ashour, A.; Han, B. Self-healing cement concrete composites for resilient infrastructures: A review. Compos. Part B Eng. 2020, 189, 107892. [Google Scholar] [CrossRef]

- Kanellopoulos, A.; Qureshi, T.S.; Al-Tabbaa, A. Glass encapsulated minerals for self-healing in cement based composites. Constr. Build. Mater. 2015, 98, 780–791. [Google Scholar] [CrossRef]

- Nishiwaki, T.; Mihashi, H.; Jang, B.K.; Miura, K. Development of self-healing system for concrete with selective heating around crack. J. Adv. Concr. Technol. 2006, 4, 267–275. [Google Scholar] [CrossRef] [Green Version]

- Formia, A.; Terranova, S.; Antonaci, P.; Pugno, N.M.; Tulliani, J.M. Setup of extruded cementitious hollow tubes as containing/releasing devices in self-healing systems. Materials 2015, 8, 1897–1923. [Google Scholar] [CrossRef]

- Van den Heede, P.; Van Belleghem, B.; Alderete, N.; Van Tittelboom, K.; De Belie, N. Neutron radiography based visualization and profiling of water uptake in (Un)cracked and autonomously healed cementitious materials. Materials 2016, 9, 311. [Google Scholar] [CrossRef] [Green Version]

- Van Mullem, T.; Van Tittelboom, K.; Gruyaert, E.; Caspeele, R.; De Belie, N. Development of an improved cracking method to reduce the variability in testing the healing efficiency of self-healing mortar containing encapsulated polymers. In Proceedings of the 5th International Conference on Concrete Repair, Rehabilitation and Retrofitting (ICCRRR), Cape Town, South Africa, 19–21 November 2018; Volume 199. [Google Scholar]

- Feiteira, J.; Gruyaert, E.; De Belie, N. Self-healing of moving cracks in concrete by means of encapsulated polymer precursors. Constr. Build. Mater. 2016, 102, 671–678. [Google Scholar] [CrossRef]

- Van Belleghem, B.; Van Tittelboom, K.; De Belie, N. Efficiency of self-healing cementitious materials with encapsulated polyurethane to reduce water ingress through cracks. Mater. Constr. 2018, 68, e159. [Google Scholar] [CrossRef]

- Van Belleghem, B.; Kessler, S.; Van den Heede, P.; Van Tittelboom, K.; De Belie, N. Chloride induced reinforcement corrosion behavior in self-healing concrete with encapsulated polyurethane. Cem. Concr. Res. 2018, 113, 130–139. [Google Scholar] [CrossRef]

- Van Belleghem, B.; Van den Heede, P.; Van Tittelboom, K.; De Belie, N.D. Quantification of the service life extension and environmental benefit of Chloride Exposed Self-Healing Concrete. Materials 2017, 10, 5. [Google Scholar] [CrossRef] [Green Version]

- Van den Heede, P.; Van Belleghem, B.; Araújo, M.A.; Feiteira, J.; De Belie, N. Screening of different encapsulated polymer-based healing agents for chloride exposed self-healing concrete using chloride migration tests. In Key Engineering Materials; Trans Tech Publications Ltd.: Frienbach, Switzerland, 2018; Volume 761, pp. 152–158. [Google Scholar]

- Kuang, Y.C.; Ou, J.P. Passive smart self-repairing concrete beams by using shape memory alloy wires and fibers containing adhesives. J. Cent. South Univ. Technol. 2008, 15, 411–417. [Google Scholar] [CrossRef]

- Chen, H.-J.; Peng, C.-F.; Tang, C.-W.; Chen, Y.-T. Self-Healing Concrete by Biological Substrate. Materials 2019, 12, 4099. [Google Scholar] [CrossRef] [Green Version]

- Jiang, Z.; Li, J.; Li, W. Preparation and characterization of autolytic mineral microsphere for self-healing cementitious materials. Cem. Concr. Compos. 2019, 103, 112–120. [Google Scholar] [CrossRef]

- Dry, C.M. Three designs for the internal release of sealants, adhesives, and waterproofing chemicals into concrete to reduce permeability. Cem. Concr. Res. 2000, 30, 1969–1977. [Google Scholar] [CrossRef]

- Van Tittelboom, K.; Adesanya, K.; Dubruel, P.; Van Puyvelde, P.; De Belie, N. Methyl methacrylate as a healing agent for self-healing cementitious materials. Smart Mater. Struct. 2011, 20, 125016. [Google Scholar] [CrossRef]

- Dry, C.M.; Corsaw, M.J.T. A time-release technique for corrosion prevention. Cem. Concr. Res. 1998, 28, 1133–1140. [Google Scholar] [CrossRef]

- Dong, B.; Fang, G.; Ding, W.; Liu, Y.; Zhang, J.; Han, N.; Xing, F. Self-healing features in cementitious material with urea-formaldehyde/epoxy microcapsules. Constr. Build. Mater. 2016, 106, 608–617. [Google Scholar] [CrossRef]

- Kanellopoulos, A..; Giannaros, P.; Al-Tabbaa, A. The effect of varying volume fraction of microcapsules on fresh, mechanical and self-healing properties of mortars. Constr. Build. Mater. 2016, 122, 577–593. [Google Scholar] [CrossRef]

- Gardner, D.; Lark, R.; Jefferson, T.; Davies, R. A survey on problems encountered in current concrete construction and the potential benefits of self-healing cementitious materials. Case Stud. Constr. Mater. 2018, 8, 238–247. [Google Scholar] [CrossRef]

- Lee, M.W.; Yoon, S.S.; Yarin, A.L. Solution-Blown Core-Shell Self-Healing Nano- and Microfibers. ACS Appl. Mater. Interfaces 2016, 8, 4955–4962. [Google Scholar] [CrossRef] [PubMed]

- Shchukin, D.G.; Lamaka, S.V.; Yasakau, K.A.; Zheludkevich, M.L.; Ferreira, M.G.S.; Möhwald, H. Active anticorrosion coatings with halloysite nanocontainers. J. Phys. Chem. C 2008, 112, 958–964. [Google Scholar] [CrossRef]

- Chen, Y.; Xia, C.; Shepard, Z.; Smith, N.; Rice, N.; Peterson, A.M.; Sakulich, A. Self-Healing Coatings for Steel-Reinforced Concrete. ACS Sustain. Chem. Eng. 2017, 5, 3955–3962. [Google Scholar] [CrossRef]

- Hang, T.T.X.; Truc, T.A.; Olivier, M.G.; Vandermiers, C.; Guérit, N.; Pébre, N. Corrosion protection mechanisms of carbon steel by an epoxy resin containing indole-3 butyric acid modified clay. Prog. Org. Coat. 2010, 69, 410–416. [Google Scholar] [CrossRef] [Green Version]

- Matchar, E. With This Self-Healing Concrete, Buildings Repair Themselves. Available online: https://www.smithsonianmag.com/innovation/with-this-self-healing-concrete-buildings-repair-themselves-180955474/ (accessed on 27 December 2021).

- Freyermuth, C.L. Life-cycle cost analysis for large bridges. Concr. Int. 2001, 23, 89–95. [Google Scholar]

- Cantarelli, C.C.; Flybjerg, B.; Molin, E.J.E.; van Wee, B. Cost Overruns in Large-Scale Transport Infrastructure Projects. Autom. Constr. 2018, 2, 19. [Google Scholar]

- ASCE. ASCE|2013 Report Card for America’s Infrastructure|Overview: Executive Summary; ASCE: Reston, VG, USA, 2013. [Google Scholar]

- Jensen, O.M.; Hansen, P.F. Autogenous deformation and RH-change in perspective. Cem. Concr. Res. 2001, 31, 1859–1865. [Google Scholar] [CrossRef]

- Wu, Z.; Wong, H.S.; Buenfeld, N.R. Influence of drying-induced microcracking and related size effects on mass transport properties of concrete. Cem. Concr. Res. 2015, 68, 35–48. [Google Scholar] [CrossRef] [Green Version]

- Delatte, N. Failure, Distress and Repair of Concrete Structures; Elsevier: Amsterdam, The Netherlands, 2009; ISBN 9781845694081. [Google Scholar]

- Bartlett, F.M. Canadian Standards Association standard A23. 3-04 resistance factor for concrete in compression. Can. J. Civ. Eng. 2007, 34, 1029–1037. [Google Scholar] [CrossRef]

- Vijay, K.; Murmu, M.; Deo, S.V. Bacteria based self healing concrete—A review. Constr. Build. Mater. 2017, 152, 1008–1014. [Google Scholar] [CrossRef]

- Wu, M.; Johannesson, B.; Geiker, M. A review: Self-healing in cementitious materials and engineered cementitious composite as a self-healing material. Constr. Build. Mater. 2012, 28, 571–583. [Google Scholar] [CrossRef]

- Ghaz-Jahanian, M.A.; Khodaparastan, F.; Berenjian, A.; Jafarizadeh-Malmiri, H. Influence of small RNAs on biofilm formation process in bacteria. Mol. Biotechnol. 2013, 55, 288–297. [Google Scholar] [CrossRef]

- Vaghari, H.; Eskandari, M.; Sobhani, V.; Berenjian, A.; Song, Y.; Jafarizadeh-Malmiri, H. Process intensification for production and recovery of biological products. Am. J. Biochem. Biotechnol. 2015, 11, 37–43. [Google Scholar] [CrossRef] [Green Version]

- Litina, C.; Bumanis, G.; Anglani, G.; Dudek, M.; Maddalena, R.; Amenta, M.; Papaioannou, S.; Pérez, G.; Calvo, J.L.G.; Asensio, E.; et al. Evaluation of methodologies for assessing self-healing performance of concrete with mineral expansive agents: An interlaboratory study. Materials 2021, 14, 2024. [Google Scholar] [CrossRef]

- Onaizi, A.M.; Huseien, G.F.; Lim, N.H.A.S.; Amran, M.; Samadi, M. Effect of nanomaterials inclusion on sustainability of cement-based concretes: A comprehensive review. Constr. Build. Mater. 2021, 306, 124850. [Google Scholar] [CrossRef]

- García Calvo, J.L.; Pérez, G.; Carballosa, P.; Erkizia, E.; Gaitero, J.J.; Guerrero, A. The effect of nanoparticles on the self-healing capacity of high performance concrete. In Nanotechnology in Eco-Efficient Construction: Materials, Processes and Applications; Woodhead Publishing: Shaston, UK, 2018; pp. 43–67. ISBN 9780081026410. [Google Scholar]

- Pacheco-Torgal, F.; Jalali, S. Nanotechnology: Advantages and drawbacks in the field of construction and building materials. Constr. Build. Mater. 2011, 25, 582–590. [Google Scholar] [CrossRef] [Green Version]

- Huang, Z.; Cao, F. Effects of Nano-materials on the Performance of UHPC. Mater. Rev. 2012, 26, 136–142. [Google Scholar]

- Bila, S. Strategic priorities of social production digitalization: World experience. Univ. Econ. Bull. 2021, 48, 40–55. [Google Scholar] [CrossRef]

- Rostamiyan, Y.; Fereidoon, A.; Mashhadzadeh, A.H.; Ashtiyani, M.R.; Salmankhani, A. Using response surface methodology for modeling and optimizing tensile and impact strength properties of fiber orientated quaternary hybrid nano composite. Compos. Part B Eng. 2015, 69, 304–316. [Google Scholar] [CrossRef]

- Zhu, R.; Liu, X.N.; Hu, G.K.; Sun, C.T.; Huang, G.L. Negative refraction of elastic waves at the deep-subwavelength scale in a single-phase metamaterial. Nat. Commun. 2014, 5, 5510. [Google Scholar] [CrossRef] [Green Version]

- Ugwu, O.O.; Arop, J.B.; Nwoji, C.U.; Osadebe, N.N. Nanotechnology as a Preventive Engineering Solution to Highway Infrastructure Failures. J. Constr. Eng. Manag. 2013, 139, 987–993. [Google Scholar] [CrossRef]

- Gohardani, O.; Elola, M.C.; Elizetxea, C. Potential and prospective implementation of carbon nanotubes on next generation aircraft and space vehicles: A review of current and expected applications in aerospace sciences. Prog. Aerosp. Sci. 2014, 70, 42–68. [Google Scholar] [CrossRef]

- Malucelli, G.; Carosio, F.; Alongi, J.; Fina, A.; Frache, A.; Camino, G. Materials engineering for surface-confined flame retardancy. Mater. Sci. Eng. R Rep. 2014, 84, 1–20. [Google Scholar] [CrossRef]

- Zhu, W.; Bartos, P.J.M.; Porro, A. Application of nanotechnology in construction Summary of a state-of-the-art report. Mater. Struct. Constr. 2004, 37, 649–658. [Google Scholar] [CrossRef]

| Method | Possibilities | Refs. | |

|---|---|---|---|

| Visualization and determination | X-ray radiography | Imagining release encapsulated agent from embedded capsule | [13] |

| Scanning electron microscopy | Imagining crystal deposition | [16,47,67,111] | |

| Environmental scanning electron microscopy | Imagining breakage of partially embedded capsule | [16] | |

| Thin section analysis | Imagining crystal deposition inside crack | [95,112] | |

| Optical microscopy and image analysis | Imagining crystal deposition and determination of healing rate | [111,113,114] | |

| X-ray tomography | Imagining release encapsulated agent from embedded capsule in 3D | [115] | |

| Release of encapsulated agent | [13,115] | ||

| Environmental scanning electron microscopy | Imagining breakage of partially embedded capsule | [16] | |

| X-ray diffraction analysis | Finding of crystalline materials | [116] | |

| Determination of crystalline materials | [117] | ||

| Infrared analysis | Finding of precipitated products | [118,119] | |

| Raman spectroscopy | Determination chemical composition | [111] | |

| Correlation of digital image | Crack tends to close after treatment | [72] | |

| Micromorphology | Crystals starts to deposit in crack | [95,112] | |

| Image analysis/optical microscopy | Determination of healing rate | [113,114] | |

| Regain tightness | Air permeability | Air flow via crack | [34] |

| Water permeability | Water flow via crack | [90,115,120,121,122] | |

| Capillary water uptake | Capillary water uptake by crack | [112,123] | |

| Corrosion test | Resistance against corrosion | [67,124] | |

| Corrosion resistance | [124] | ||