Cryogenic Reliability Evaluation of Glass Fabric–Reinforced Composites Using Novel Slip-Prevention Method

Abstract

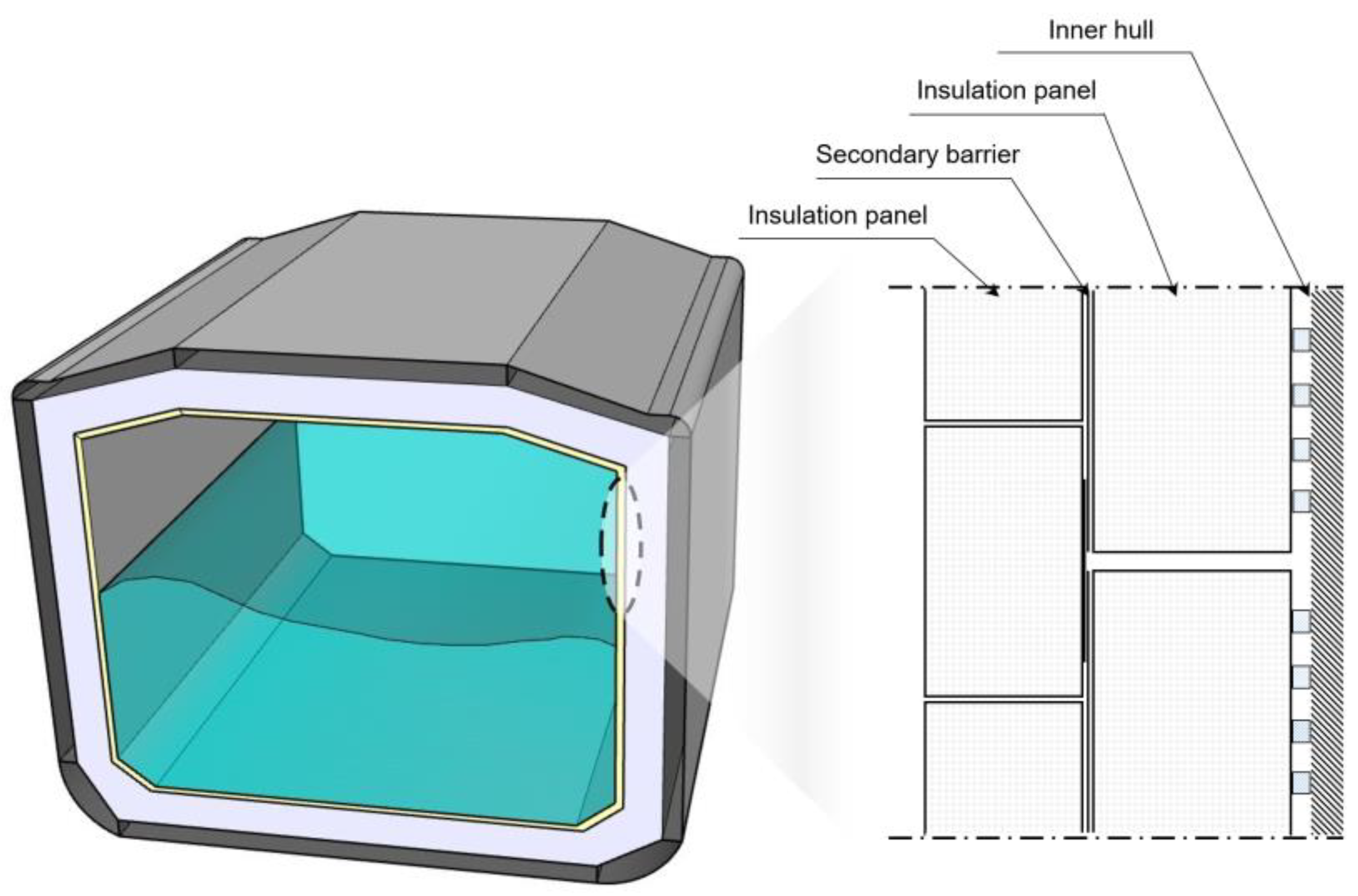

:1. Introduction

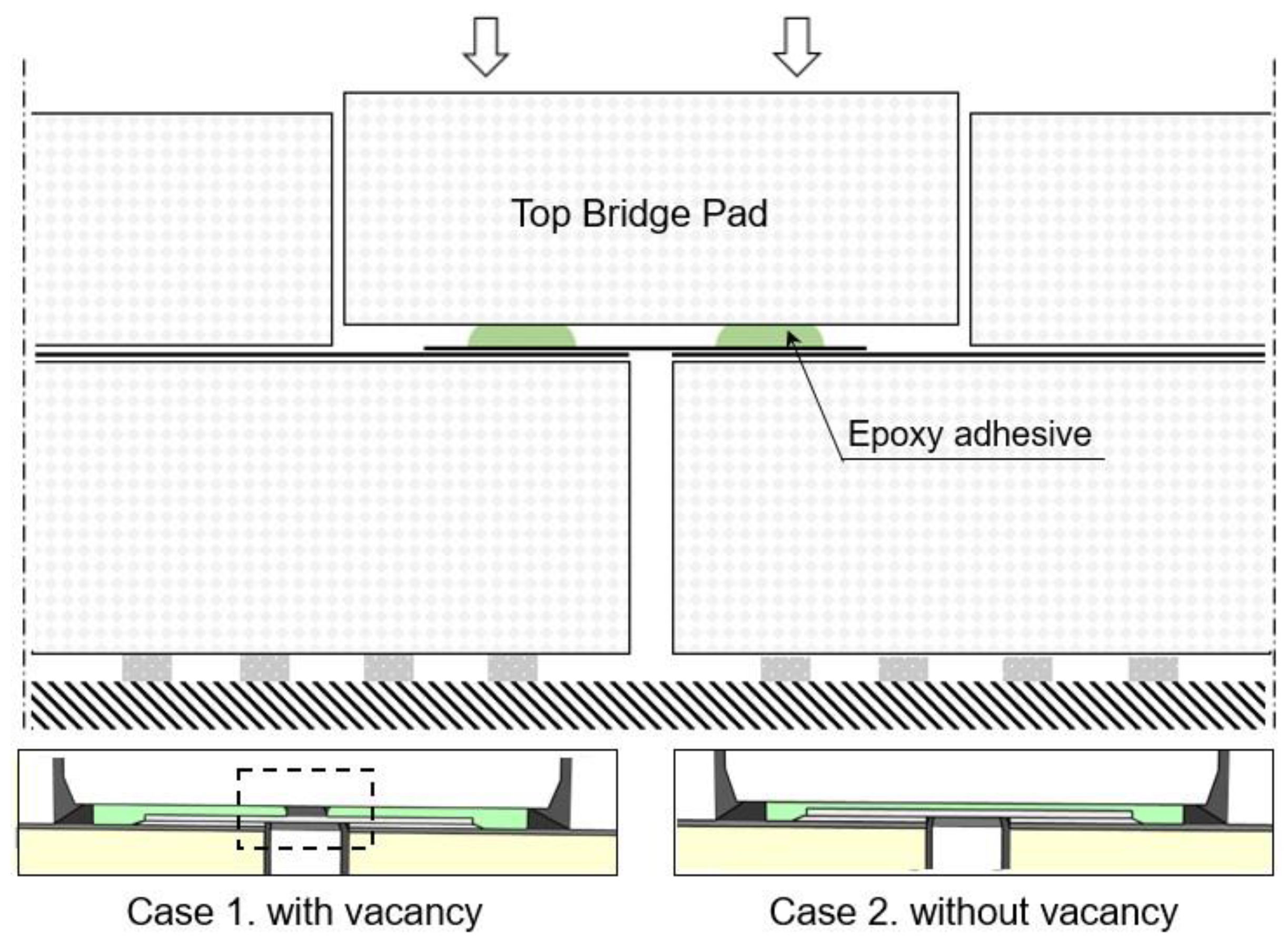

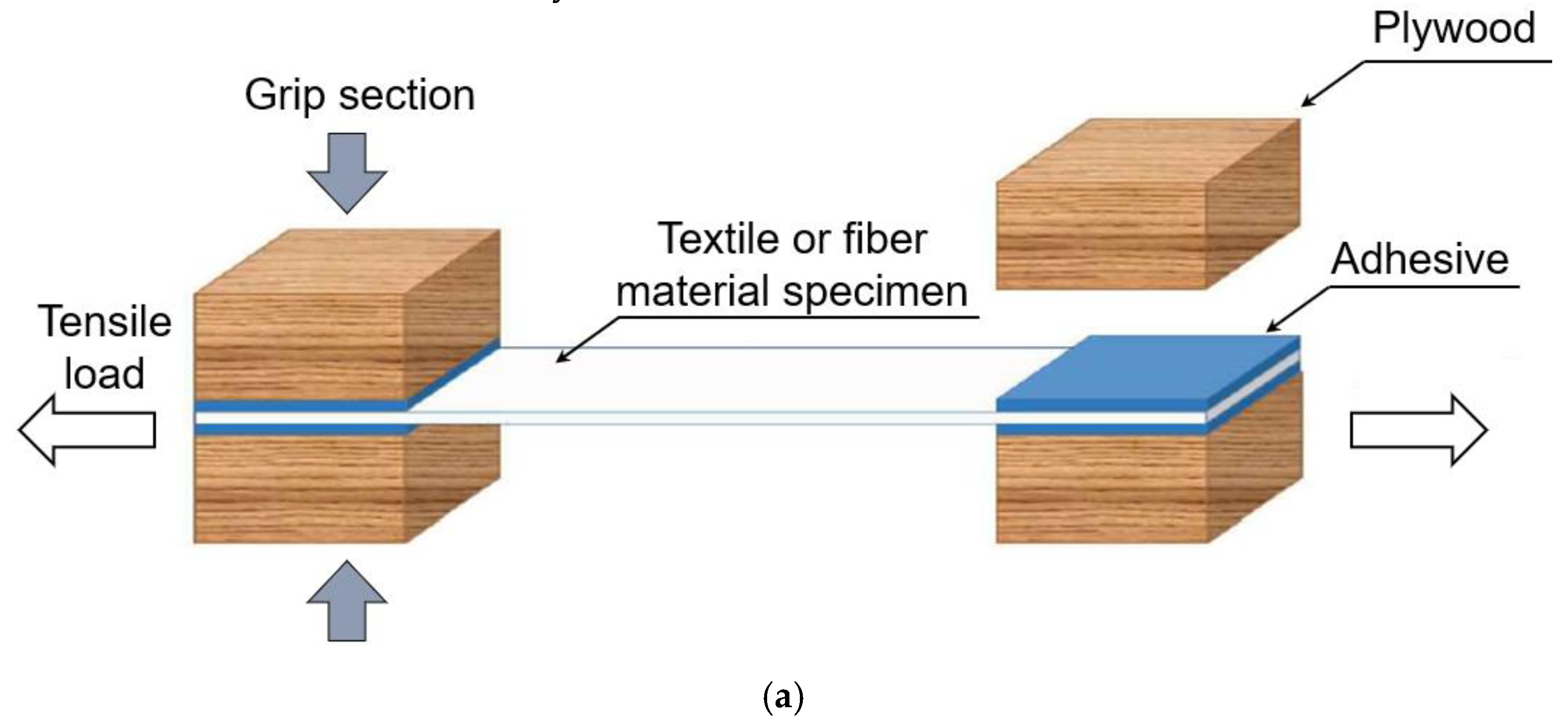

2. Experimental Section

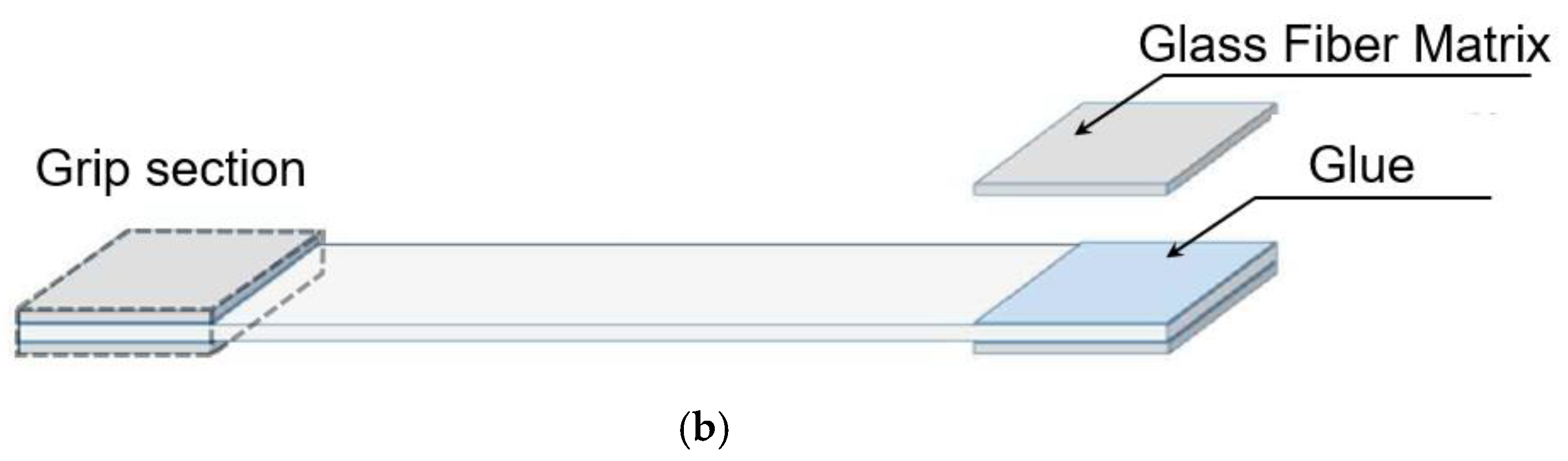

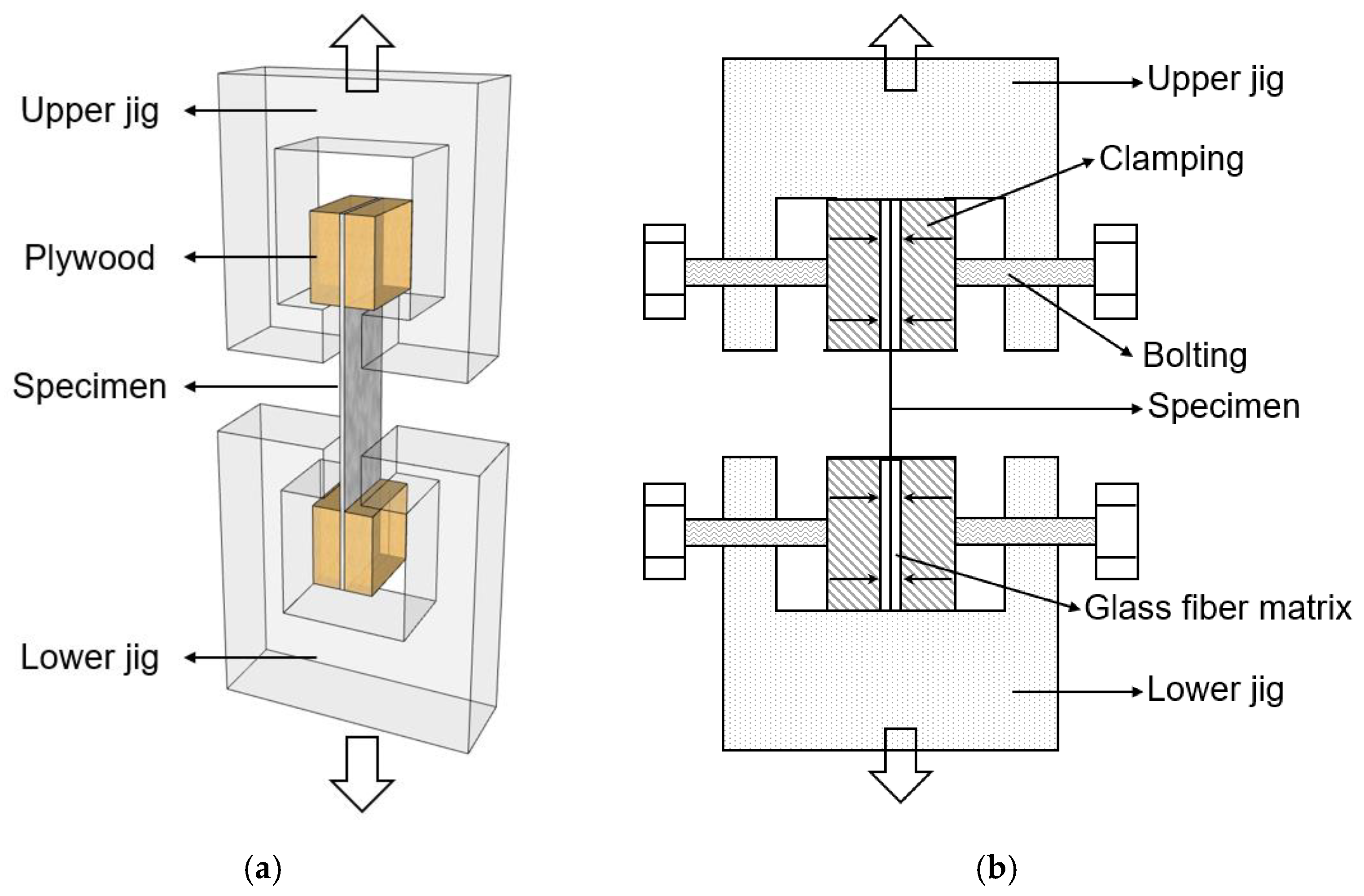

Proposed Mechanical Test Method

3. Results and Discussion

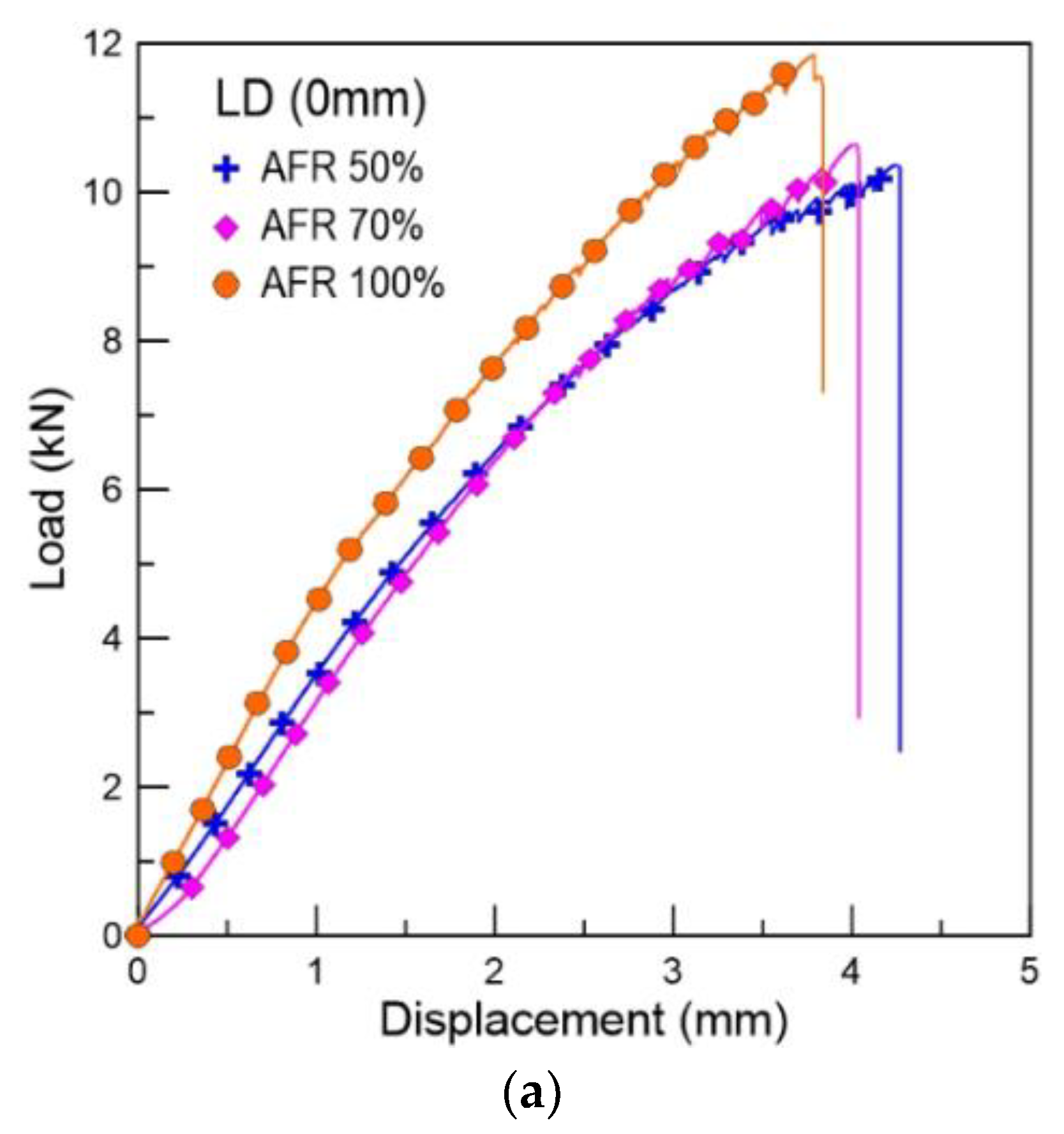

3.1. Maximum Tensile Load and Reliability

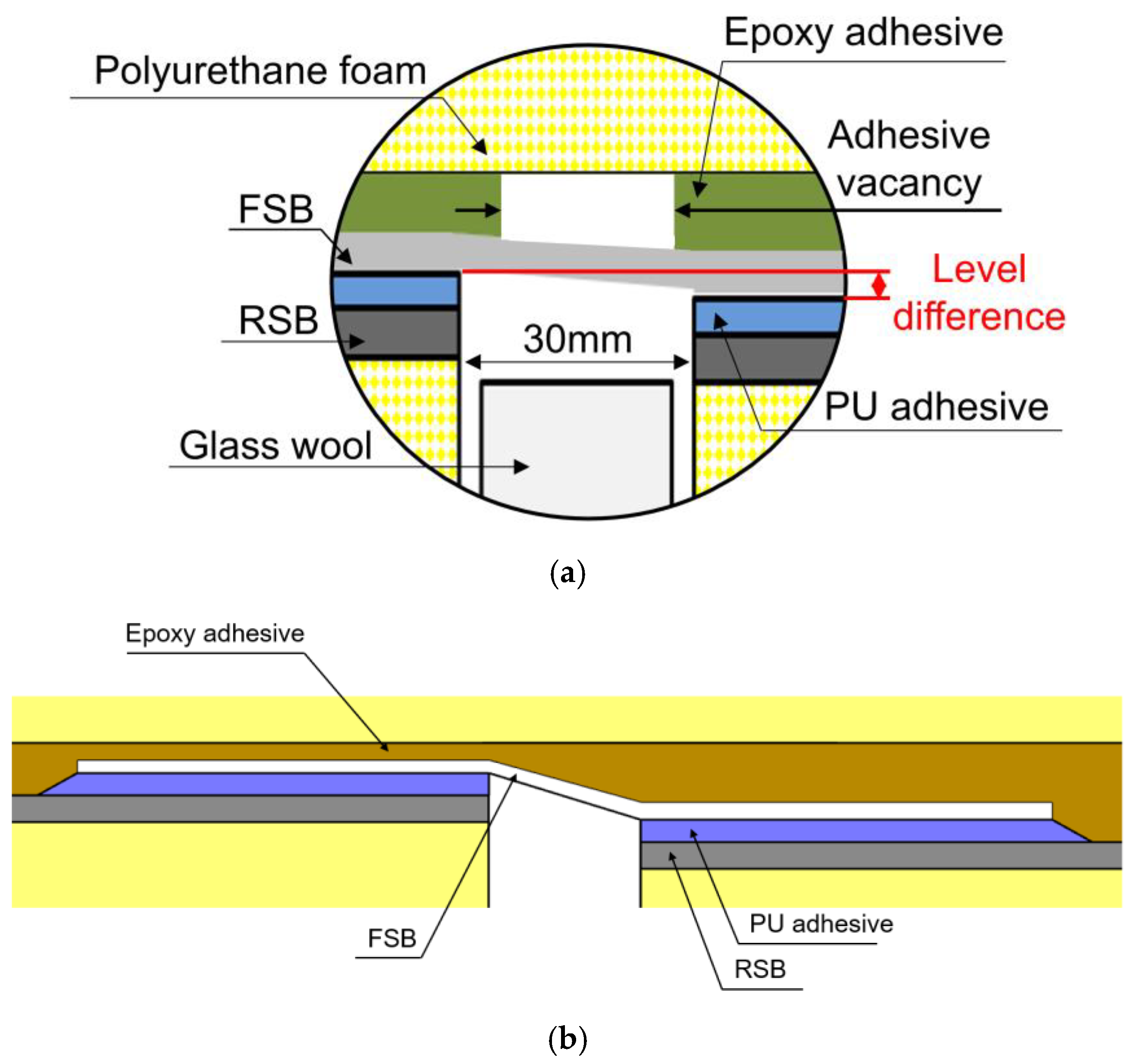

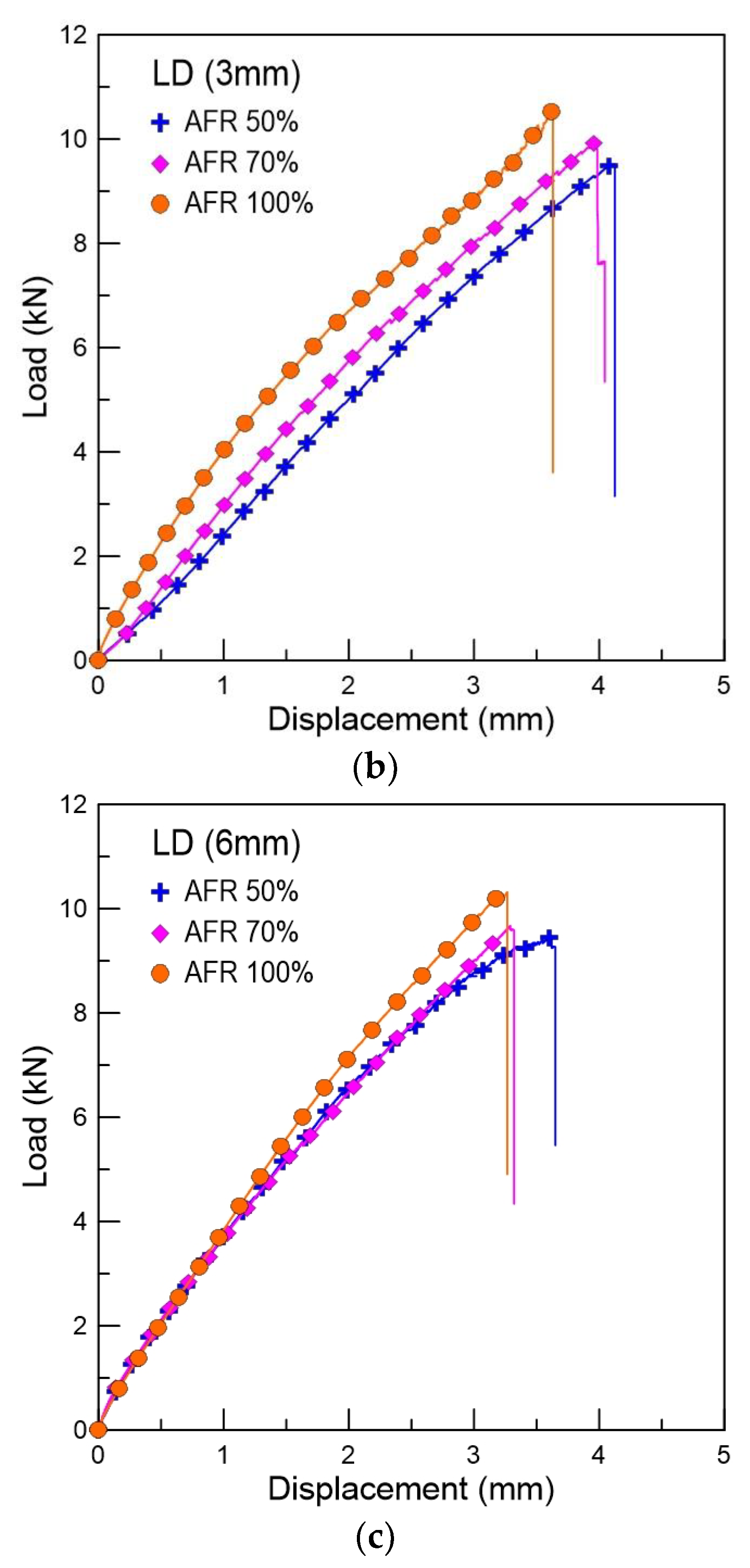

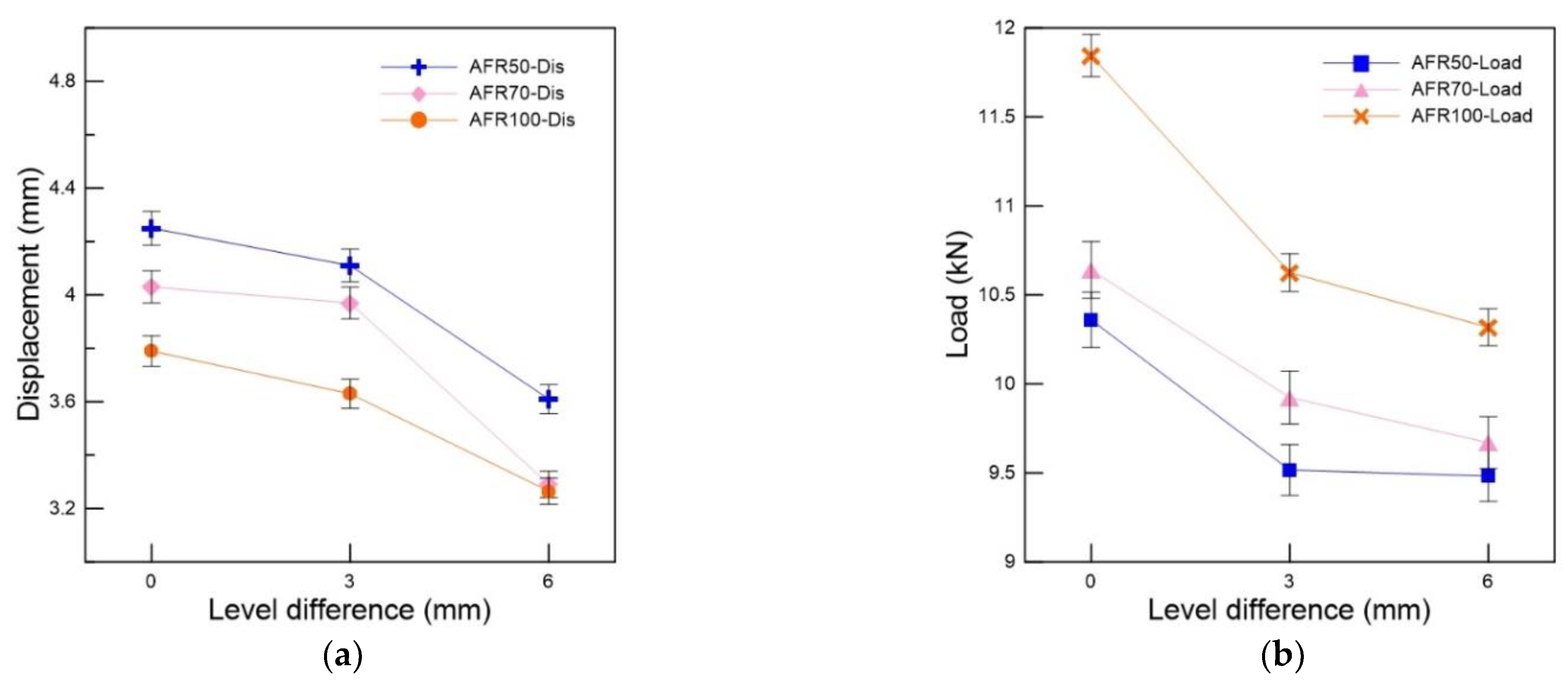

3.2. Effect of the Level Difference

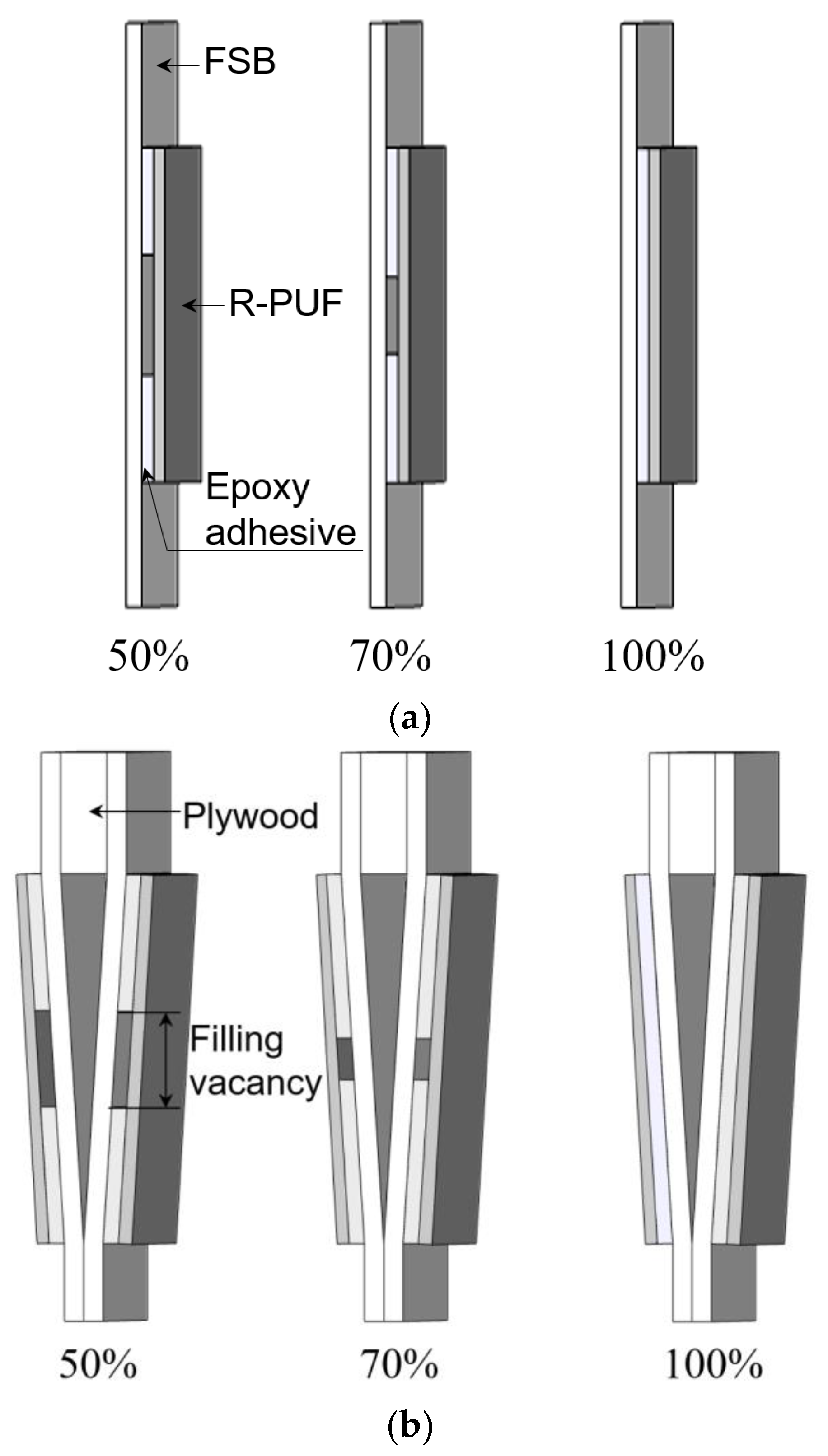

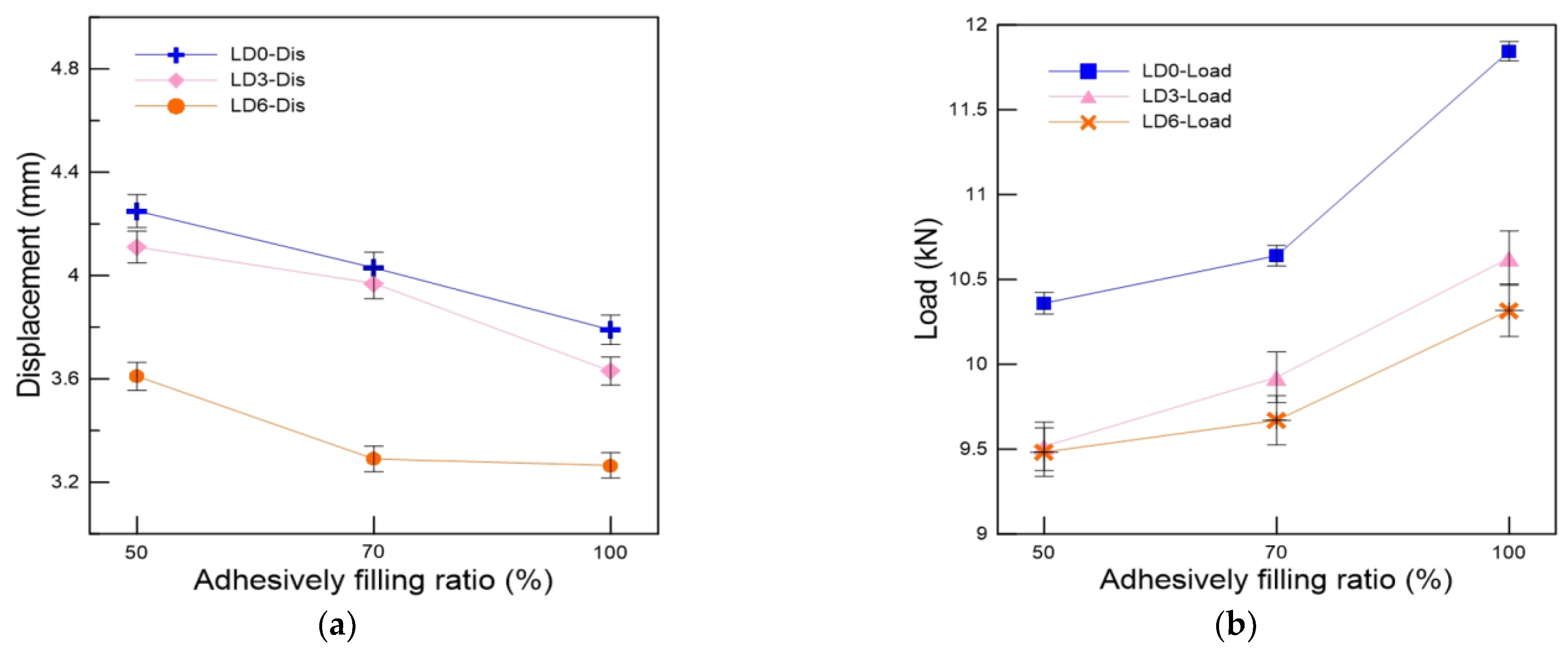

3.3. Effect of the Adhesive Filling Ratio

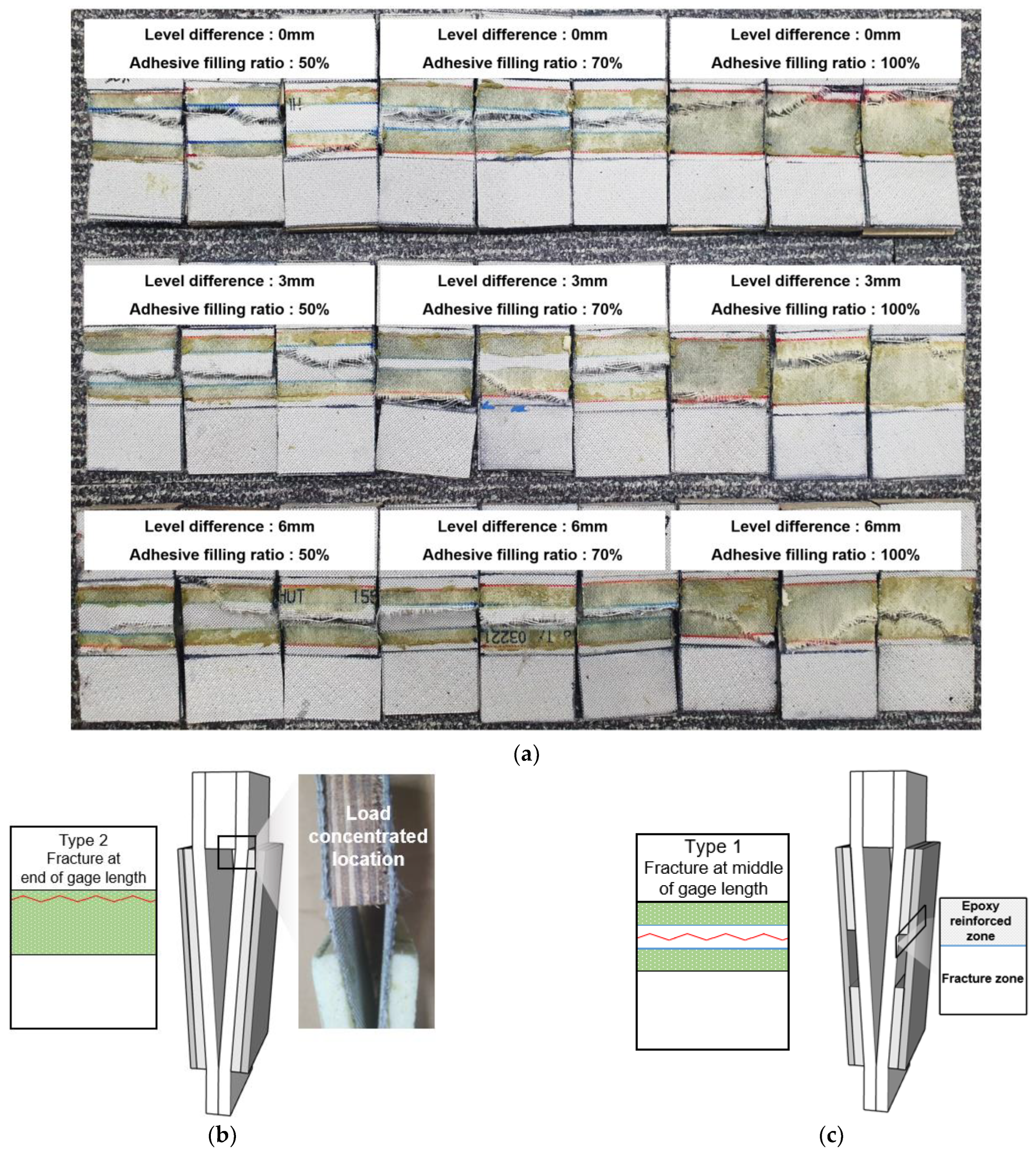

3.4. Fracture Location within Specimens

4. Conclusions

- We proposed a mechanical test method for textile and glass fiber–reinforced materials under cryogenic conditions. The jig was machined bolted and clamped with the specimen, preventing the rotation of the grip section of the specimen.

- Slippage and the premature fracture of the adhesive joints prior to the specimen were prevented by using our newly proposed test method. The curing time was reduced to 1 day, and the rate of experimental failure decreased to 20%.

- As a result of the tensile test with the proposed jig and specimen, fracturing was more likely to occur at the end of the gauge length in specimens with a level difference. Parallelly, the maximum tensile load and displacement decreased with the increasing level difference.

- Fracturing was more likely to occur at the middle of the gauge length in specimens with adhesive vacancies because of the general load concentration. Concurrently, the maximum tensile load and displacement increased and decreased, respectively, with the increasing adhesive filling ratio.

- A microstructural analysis revealed that the fracture load increased with the increasing adhesive filling ratio because the impregnated epoxy adhesive absorbed the tensile load rather than the FSB and hardened the glass fibers on the surface.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- De Carvalho, J.R.; Arnaldo, V. Natural gas and other alternative fuels for transportation purposes. Energy 1985, 10, 187–215. [Google Scholar] [CrossRef]

- Cha, S.J.; Kim, J.D.; Kim, S.K.; Kim, J.H.; Oh, H.K.; Kim, Y.T.; Park, S.B.; Lee, J.M. Effect of temperature on the mechanical performance of plywood used in membrane-type LNG carrier insulation systems. J. Wood Sci. 2020, 66, 28. [Google Scholar] [CrossRef] [Green Version]

- International Code for the Construction and Equipment of Ships Carrying Liquefied Gases in Bulk (I.G.C. Code); International Maritime Organization (IMO) Publications: London, UK, 1986.

- Bae, J.H.; Hwang, B.K.; Kim, J.H.; Kim, S.K.; Lee, J.M. Cumulative damage of hollow glass microsphere weight fraction in polyurethane foam in response to cryogenic temperatures and repeated impact loading. Cryogenics 2020, 107, 103057. [Google Scholar] [CrossRef]

- Kim, J.H.; Choi, S.W.; Park, D.H.; Park, S.B.; Kim, S.K.; Park, K.J.; Lee, J.M. Effects of cryogenic temperature on the mechanical and failure characteristics of melamine-urea-formaldehyde adhesive plywood. Cryogenics 2018, 91, 36–46. [Google Scholar] [CrossRef]

- Kim, B.C.; Soon, H.Y. Pressure resistance of the corrugated stainless steel membranes of LNG carriers. Ocean. Eng. 2011, 38, 592–608. [Google Scholar] [CrossRef]

- Jeong, Y.J.; Kim, H.T.; Kim, S.K.; Kim, J.H.; Kim, Y.T.; Heo, W.S.; Lee, J.M. Evaluation of the pressure-resisting capability of membrane-type corrugated sheet under hydrodynamic load. Thin-Walled Struct. 2021, 162, 107388. [Google Scholar] [CrossRef]

- Lee, D.H.; Bae, J.H.; Hwang, B.K.; Kim, J.H.; Kim, S.K.; Lee, J.M. Impact behavior of hollow glass bubble reinforced foam core LNG insulation panel in cryogenic temperature. J. Compos. Mater. 2021, 55, 1995–2010. [Google Scholar] [CrossRef]

- Kim, S.K.; Kim, J.D.; Lee, D.H.; Kim, J.H.; Lee, J.M. Characteristics of pre-strained polyisocyanurate foam: Deformation recovery and compressive mechanical behavior at cryogenic temperature. J. Cell. Plast. 2021, 58, 357–376. [Google Scholar] [CrossRef]

- Kim, K.H.; Yoon, S.H. Vibration isolation of LNG containment systems due to sloshing with glass fiber composite. Compos. Struct. 2012, 94, 469–476. [Google Scholar] [CrossRef]

- Kim, J.H.; Park, D.H.; Lee, C.S.; Park, K.J.; Lee, J.M. Effects of cryogenic thermal cycle and immersion on the mechanical characteristics of phenol-resin bonded plywood. Cryogenics 2015, 72, 90–102. [Google Scholar] [CrossRef]

- Bang, C.S.; Kim, J.G.; Lee, D.G. Performance improvement by glass fiber of adhesively bonded metal joints at the cryogenic temperature. Compos. Struct. 2013, 96, 321–331. [Google Scholar] [CrossRef]

- Yoon, S.H.; Lee, D.G. Design of the composite sandwich panel of the hot pad for the bonding of large area adhesive films. Compos. Struct. 2011, 94, 102–113. [Google Scholar] [CrossRef]

- Karthik, K.; Rajamani, D.; Manimaran, A.; Udayaprakash, J. Evaluation of tensile properties on Glass/Carbon/Kevlar fiber reinforced hybrid composites. Mater. Today Proc. 2021, 39, 1655–1660. [Google Scholar] [CrossRef]

- Maciel, N.D.; Ferreira, J.B.; da Silva Vieira, J.; Ribeiro, C.G.; Lopes, F.P.; Margem, F.M.; Monteiro, S.N.; Vieira, C.M.F.; da Silva, L.C. Comparative tensile strength analysis between epoxy composites reinforced with curaua fiber and glass fiber. J. Mater. Res. Technol. 2018, 7, 561–565. [Google Scholar] [CrossRef]

- Rahmanian, S.; Thean, K.S.; Suraya, A.R.; Shazed, M.A.; Salleh, M.M.; Yusoff, H.M. Carbon and glass hierarchical fibers: Influence of carbon nanotubes on tensile, flexural and impact properties of short fiber reinforced composites. Mater. Des. 2013, 43, 10–16. [Google Scholar] [CrossRef]

- Tamaki, N.; Kimiyoshi, N.; Junro, K.; Yutaka, K. Influence of prepreg conditions on the void occurrence and tensile properties of woven glass fiber-reinforced polyimide composites. Compos. Sci. Technol. 2009, 69, 2428–2433. [Google Scholar] [CrossRef]

- Oh, D.J.; Lee, J.M.; Chun, M.S.; Kim, M.H. Reliability evaluation of a LNGC insulation system with a metallic secondary barrier. Compos. Struct. 2017, 171, 43–52. [Google Scholar] [CrossRef]

- Bang, C.S.; Park, C. Optimum glass fiber volume fraction in the adhesive for the Al-SUS adhesively bonded joints at cryogenic temperatures. Compos. Struct. 2014, 108, 119–128. [Google Scholar] [CrossRef]

- Ribeiro, F.M.; Campilho, R.D.; Carbas, R.J.; Da Silva, L.F. Strength and damage growth in composite bonded joints with defects. Compos. Part B Eng. 2016, 100, 91–100. [Google Scholar] [CrossRef]

- Lee, C.S.; Chun, M.S.; Kim, M.H.; Lee, J.M. Debonding failure characteristics of multi-laminated bonding system under cryogenic temperature. Int. J. Adhes. Adhes. 2011, 31, 226–237. [Google Scholar] [CrossRef]

- Yoon, S.H.; Kim, K.H.; Lee, D.Y. Cryogenic strength of adhesive bridge joints for thermal insulation sandwich constructions. Compos. Struct. 2014, 111, 1–12. [Google Scholar] [CrossRef]

- Yoon, S.H.; Kim, K.H. Improvement of the adhesive peel strength of the secondary barrier with level difference for LNG containment system. Compos. Struct. 2013, 95, 528–538. [Google Scholar] [CrossRef]

- Stefanov, T.; Ryan, B.; Ivankovic, A.; Myrphy, N. Dynamic mechanical analysis of carbon black filled, elastomer-oughened ethyl cyanoacrylate adhesive bulk films. Int. J. Adhes. Adhes. 2020, 101, 102630. [Google Scholar] [CrossRef]

- ISO P 1421; Rubber-or Plastics-Coated Fabrics–Determination of Tensile Strength and Elongation at Break. ISO: Geneva, Switzerland, 2016.

- Wang, B.; Shin, Y.S.; Eric, N. Hull Deformation Effect on Membrane-Type LNG Containment Systems. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Busan, Republic of Korea, 19–24 June 2016; p. 49941. [Google Scholar] [CrossRef]

- Lu, J.; Xu, S.; Deng, J.; Wu, W.; Wu, H.; Yang, Z. Numerical prediction of temperature field for cargo containment system (CCS) of LNG carriers during pre-cooling operations. J. Nat. Gas Sci. Eng. 2016, 29, 382–391. [Google Scholar] [CrossRef]

- Chen, P.; Wang, Y.; Li, J.; Wang, H.; Zhang, L. Adhesion and erosion properties of epoxy resin composite coatings reinforced with fly ash cenospheres and short glass fibers. Prog. Org. Coat. 2018, 125, 489–499. [Google Scholar] [CrossRef]

- Botelho, E.C.; Silva, R.A.; Pardini, L.C.; Rezende, M.C. Evaluation of adhesion of continuous fiber–epoxy composite/aluminum laminates. J. Adhes. Sci. Technol. 2004, 18, 1799–1813. [Google Scholar] [CrossRef]

- Rajak, D.K.; Wagh, P.H.; Moustabchir, H.; Pruncu, C.I. Improving the Tensile and Flexural Properties of Reinforced Epoxy Composites by using Cobalt Filled and Carbon/Glass Fiber. Forces Mech. 2021, 4, 100029. [Google Scholar] [CrossRef]

| Material | Temperature | Level Difference | Filling Ratio |

|---|---|---|---|

| FSB | −120 °C | 0 mm | 50% |

| 70% | |||

| 100% | |||

| 3 mm | 50% | ||

| 70% | |||

| 100% | |||

| 6 mm | 50% | ||

| 70% | |||

| 100% |

| Material | Temp (°C) | Level Difference (mm) | Filling Ratio (%) | Fracture Load (kN) | Displacement (mm) |

|---|---|---|---|---|---|

| FSB with epoxyadhesive | −120 | 0 | 50 | 10.36 | 4.25 |

| 70 | 10.64 | 4.03 | |||

| 100 | 11.84 | 3.79 | |||

| 3 | 50 | 9.51 | 4.11 | ||

| 70 | 9.92 | 3.97 | |||

| 100 | 10.63 | 3.63 | |||

| 6 | 50 | 9.48 | 3.61 | ||

| 70 | 9.67 | 3.29 | |||

| 100 | 10.32 | 3.27 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeong, Y.-C.; Lee, D.-H.; Kim, S.-K.; Kim, J.-H.; Lee, J.-M. Cryogenic Reliability Evaluation of Glass Fabric–Reinforced Composites Using Novel Slip-Prevention Method. Materials 2023, 16, 121. https://doi.org/10.3390/ma16010121

Jeong Y-C, Lee D-H, Kim S-K, Kim J-H, Lee J-M. Cryogenic Reliability Evaluation of Glass Fabric–Reinforced Composites Using Novel Slip-Prevention Method. Materials. 2023; 16(1):121. https://doi.org/10.3390/ma16010121

Chicago/Turabian StyleJeong, Yong-Cheol, Dong-Ha Lee, Seul-Kee Kim, Jeong-Hyeon Kim, and Jae-Myung Lee. 2023. "Cryogenic Reliability Evaluation of Glass Fabric–Reinforced Composites Using Novel Slip-Prevention Method" Materials 16, no. 1: 121. https://doi.org/10.3390/ma16010121