Analysis of Influencing Factors of Cementitious Material Properties of Lead–Zinc Tailings Based on Orthogonal Tests

Abstract

:1. Introduction

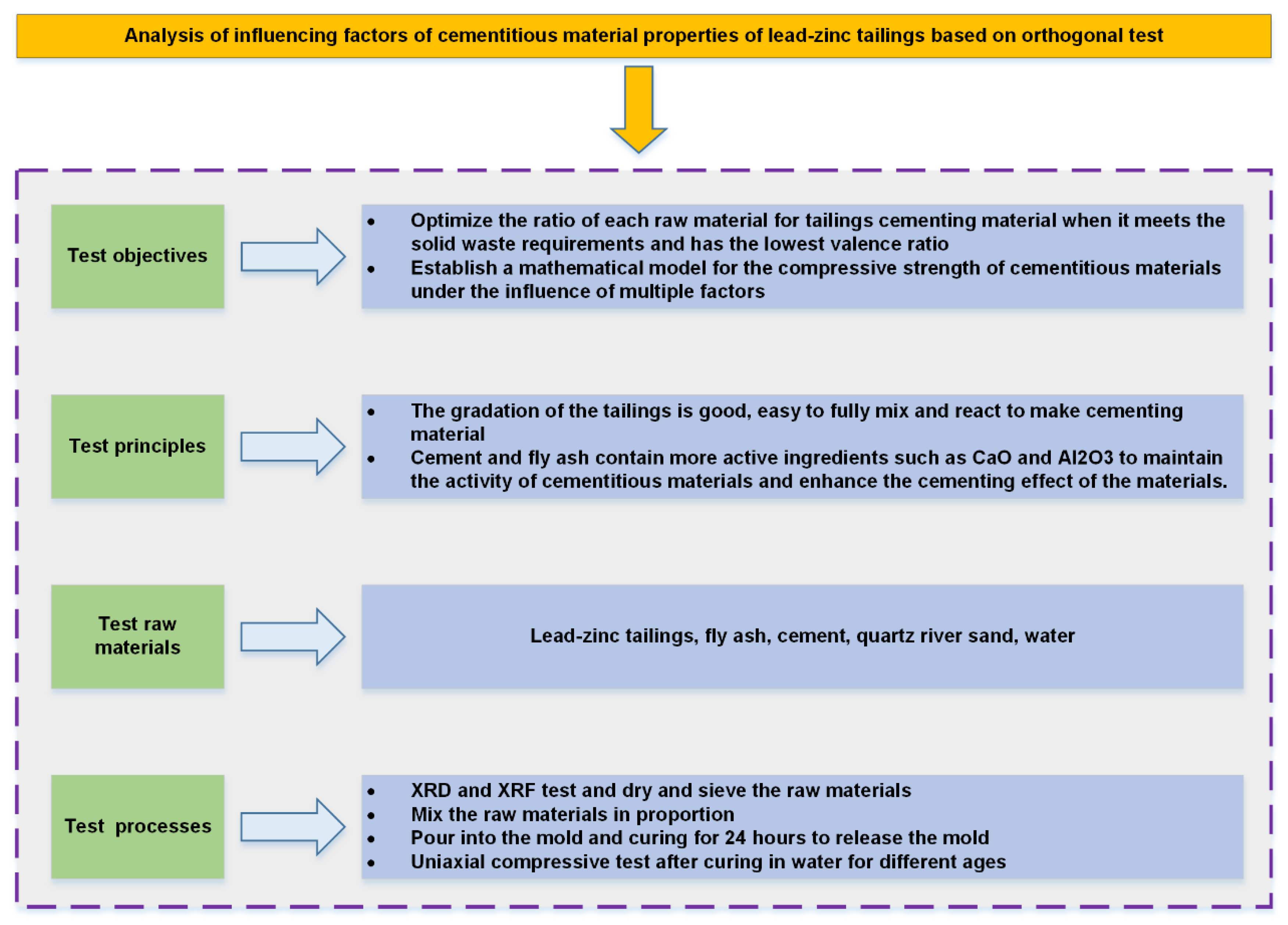

2. Test Method

2.1. Test Materials

2.2. Test Design

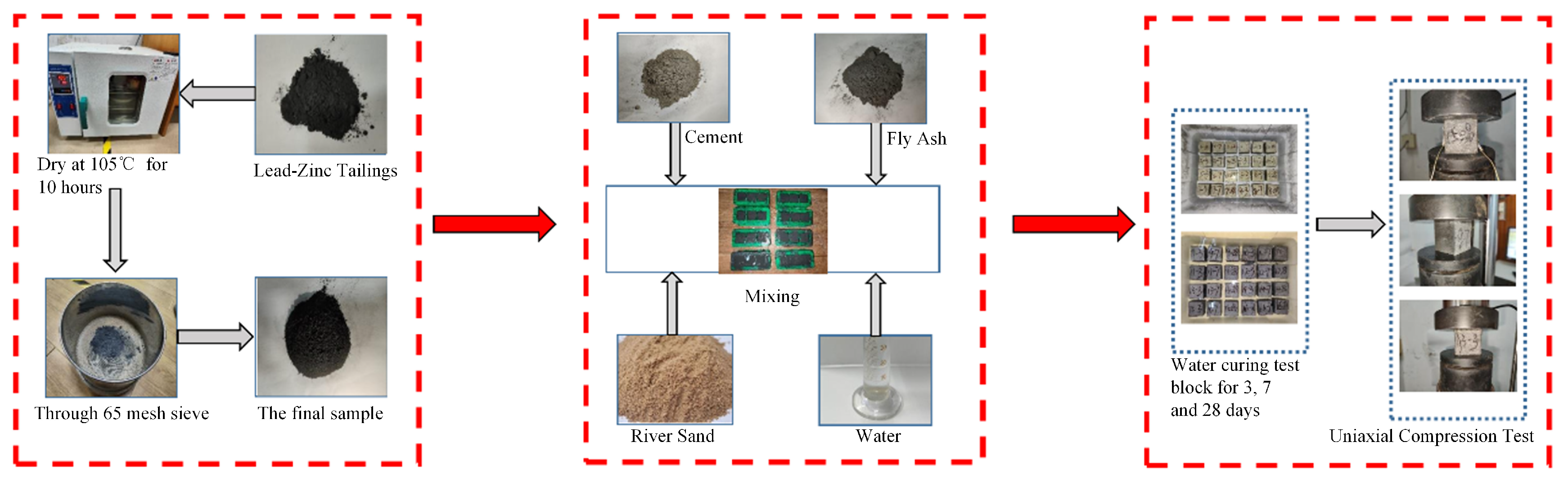

2.3. Test Procedures

3. Results and Discussions

Compression Test Analysis

4. Response Surface Prediction Regression Analysis

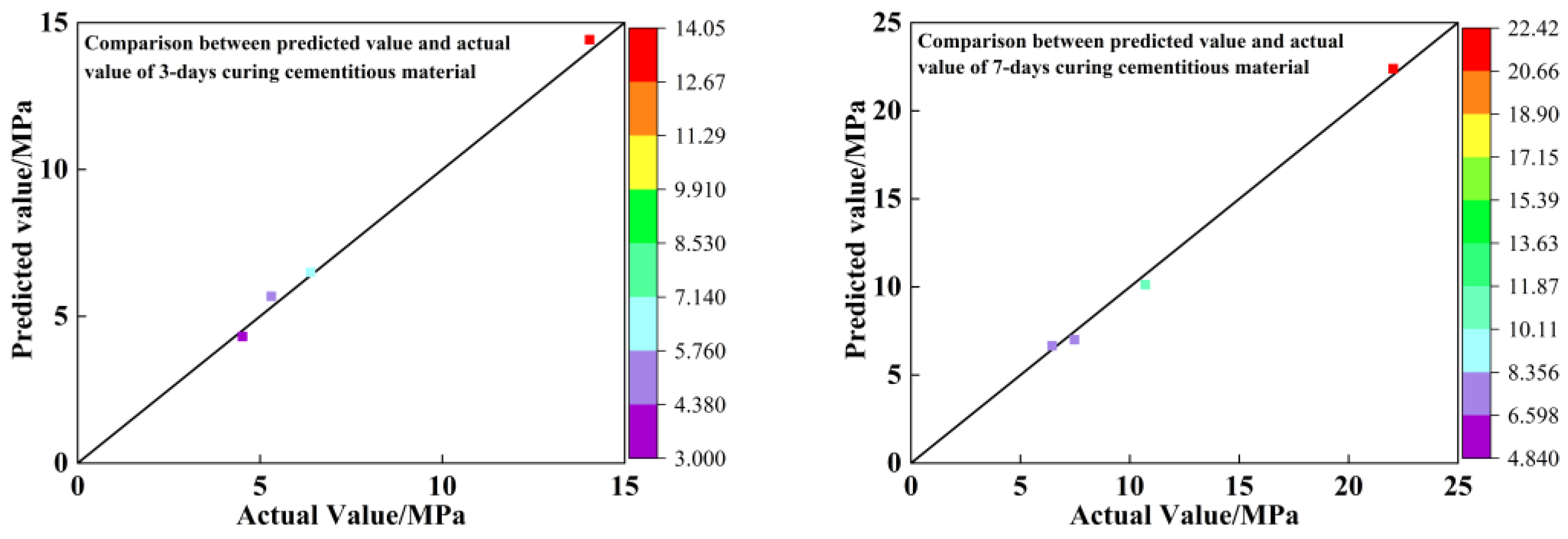

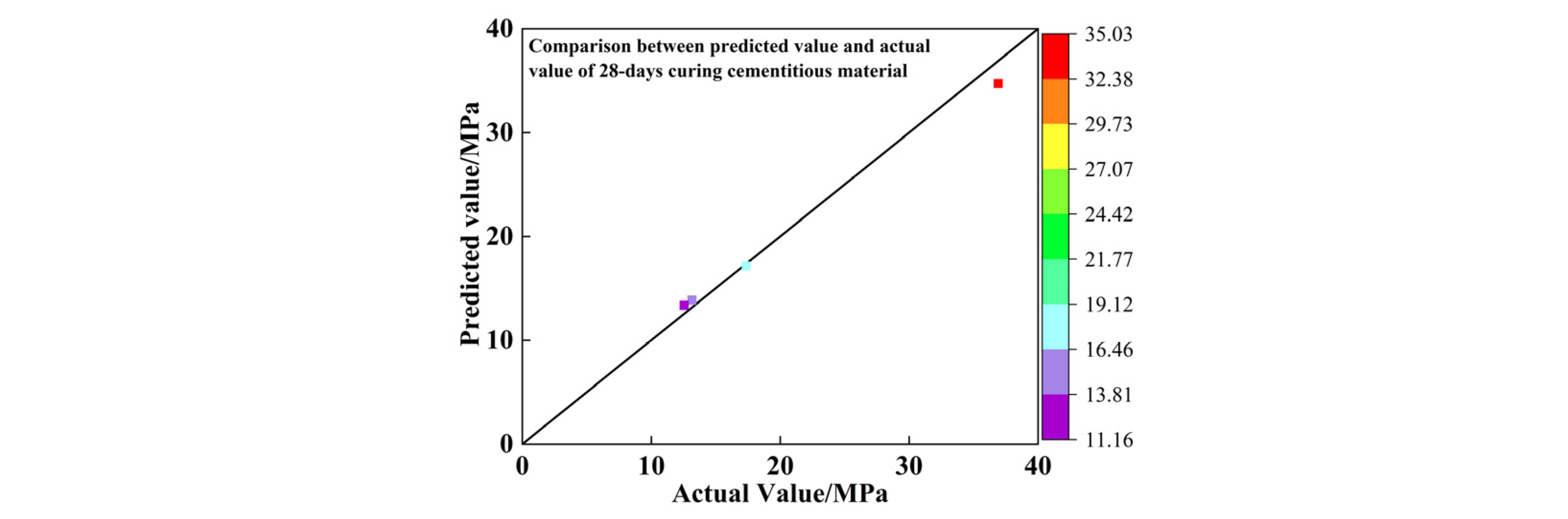

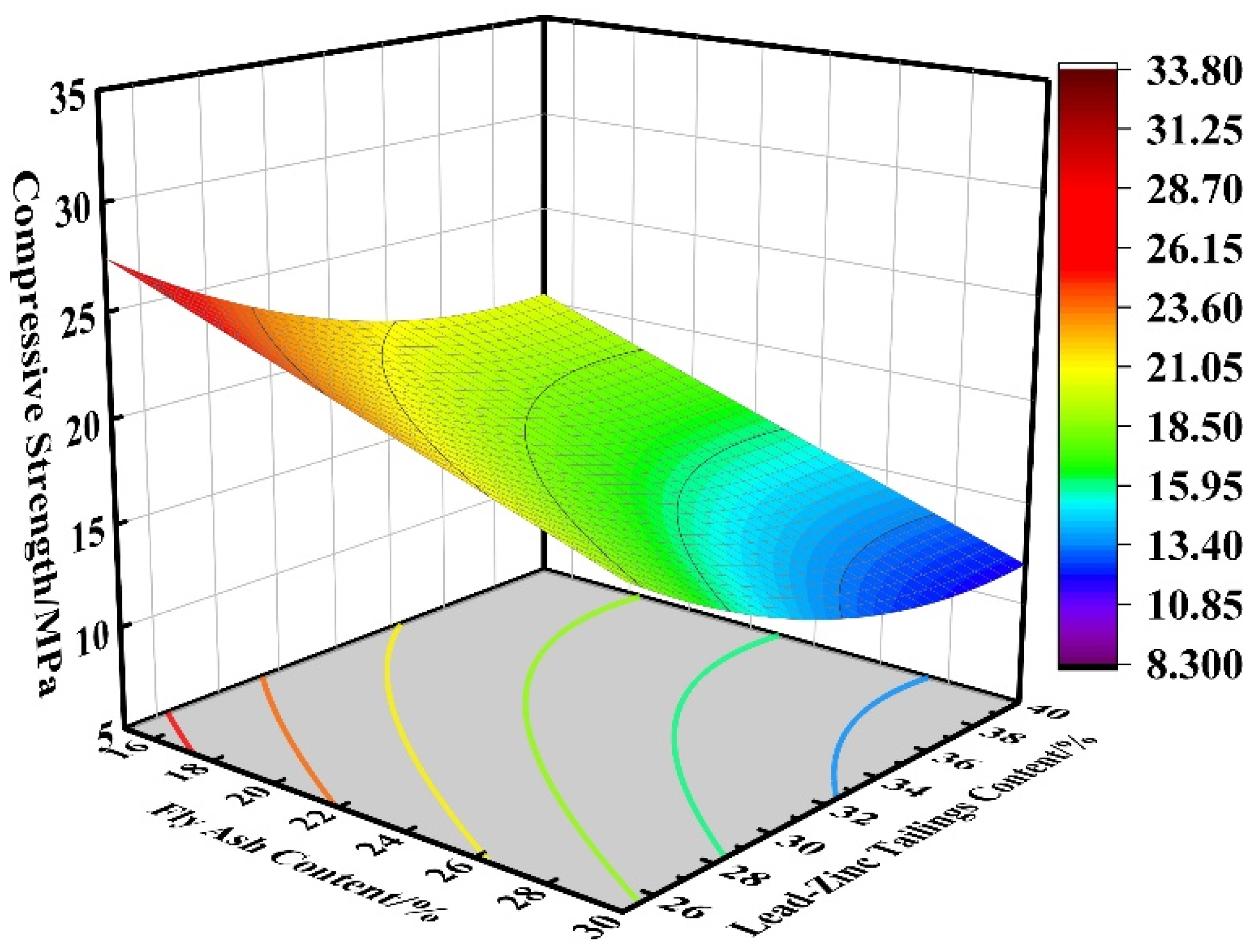

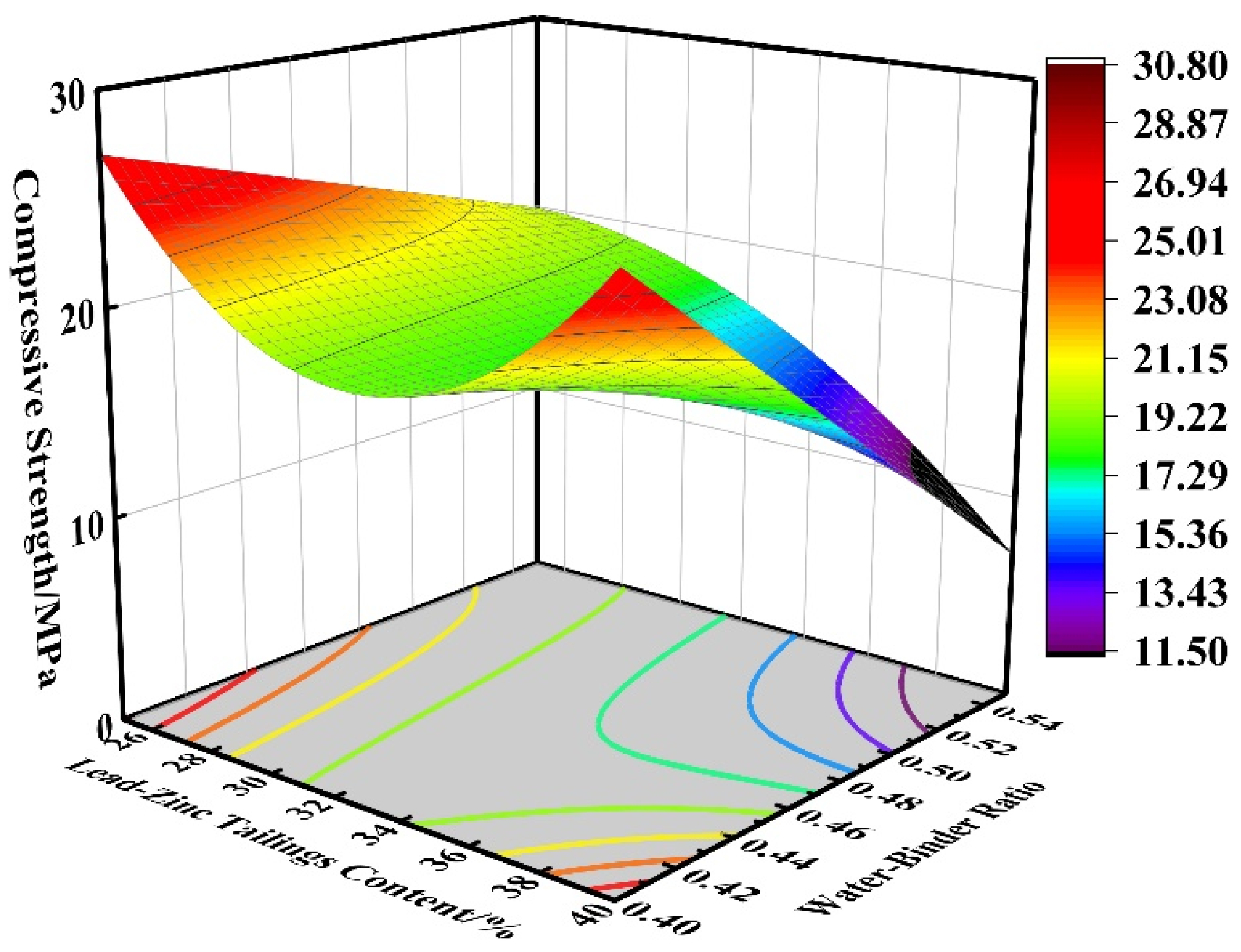

4.1. Regression Analysis

4.2. Optimized Ratios

5. Conclusions

- (1)

- The lead–zinc tailings are well graded and contain mainly quartz, mica, dolomite, chlorite, and other mineral components. The main chemical components are Fe2O3, SiO2, Al2O3, MgO, CaO, etc.

- (2)

- The sensitivity of each factor to strength at 3 days of age is water–binder ratio > lead–zinc tailings content > fly ash content; The sensitivity of each factor to strength at 7 days of age is fly ash content > lead–zinc tailings content > water–binder ratio; The sensitivity of each factor to strength at the age of 28 days is water–binder ratio > lead–zinc tailings content > fly ash content. For specimens under a short curing period (3 d), the most powerful sensitivity parameter is water–binder ratio. The best curing period for specimens is 28 d. With sufficient hydration, the strength is significantly higher than that of the specimen with curing periods of 3 d and 7 d.

- (3)

- For the comprehensive realistic price factors and compressive strength requirements of cementitious materials in the known test group, a water–binder ratio of 0.4 is chosen for the 28-day age cementitious material, and the ratio of fly ash:lead–zinc tailings:cement = 30:40:60, when the valence ratio is 0.38 USD/MPa. In the equation prediction, fly ash:lead–zinc tailings:cement = 30:40:30, with the water–binder ratio of 0.4 is the optimal ratio, when the compressive strength can reach 22.281 MPa.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- The China Mineral Resources Report. 2022. Available online: https://www.mnr.gov.cn/sj/sjfw/kc_19263/zgkczybg/202209/P020220921322252399161.pdf (accessed on 1 September 2022).

- Sun, Y.; Gu, X.; Xu, X. Ecological restoration and mechanical reinforcement effect of slope of tailings reservoir. Environ. Earth Sci. 2021, 80, 80. [Google Scholar] [CrossRef]

- Jiang, P.; Lv, S.; Wang, Y.; Li, N.; Wang, W. Investigation on Direct Shear and Energy Dissipation Characteristics of Iron Tailings Powder Reinforced by Polypropylene Fiber. Appl. Sci. 2019, 9, 5098. [Google Scholar] [CrossRef] [Green Version]

- Che, D.; Liang, A.; Li, X.; Ma, B. Remote Sensing Assessment of Safety Risk of Iron Tailings Pond Based on Runoff Coefficient. Sensors 2018, 18, 4373. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rey, N.J.; Demers, I.; Bussière, B.; Mbonimpa, M.; Gagnon, M. A geochemical evaluation of a monolayer cover with an elevated water table for the reclamation of the Doyon-Westwood tailings ponds, Canada. Environ. Earth Sci. 2020, 79, 58. [Google Scholar] [CrossRef]

- Zhao, X.; Fourie, A.; Qi, C.-C. Mechanics and safety issues in tailing-based backfill: A review. Int. J. Miner. Met. Mater. 2020, 27, 1165–1178. [Google Scholar] [CrossRef]

- Li, X.; Li, Q.; Hu, Y.; Chen, Q.; Peng, J.; Xie, Y.; Wang, J. Study on Three-Dimensional Dynamic Stability of Open-Pit High Slope under Blasting Vibration. Lithosphere 2022, 2021, 6426550. [Google Scholar] [CrossRef]

- Tang, Y.; Lin, H.; Wang, Y.; Zhao, Y. Rock slope stability analysis considering the effect of locked section. Bull. Eng. Geol. Environ. 2021, 80, 7241–7251. [Google Scholar] [CrossRef]

- Peng, J.-S.; Guan, Y.-H.; Lin, X.-J.; Xu, X.-J.; Xiao, L.; Wang, H.-H.; Meng, S. Comparative understanding of metal hyperaccumulation in plants: A mini-review. Environ. Geochem. Health 2020, 43, 1599–1607. [Google Scholar] [CrossRef]

- Li, L.; Sun, J.; Jiang, J.; Wang, J. The effect of environmental regulation competition on haze pollution: Evidence from China’s province-level data. Environ. Geochem. Health 2021, 44, 3057–3080. [Google Scholar] [CrossRef]

- Kun, W.; Peng, Y.; Hudson-Edwards, K.; Wen-sheng, L.; Lei, B. Status and development for the prevention and management of tailings dam failure accidents. Chin. J. Eng. 2018, 40, 526–539. [Google Scholar]

- Luo, X.; Ren, B.; Hursthouse, A.S.; Jiang, F.; Deng, R.-J. Potentially toxic elements (PTEs) in crops, soil, and water near Xiangtan manganese mine, China: Potential risk to health in the foodchain. Environ. Geochem. Health 2019, 42, 1965–1976. [Google Scholar] [CrossRef] [PubMed]

- Jiang, F.; Ren, B.; Hursthouse, A.S.; Zhou, Y. Trace Metal Pollution in Topsoil Surrounding the Xiangtan Manganese Mine Area (South-Central China): Source Identification, Spatial Distribution and Assessment of Potential Ecological Risks. Int. J. Environ. Res. Public Health 2018, 15, 2412. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tang, Z.-E.; Deng, R.-J.; Zhang, J.; Ren, B.-Z.; Hursthouse, A. Regional distribution characteristics and ecological risk assessment of heavy metal pollution of different land use in an antimony mining area—Xikuangshan, China. Hum. Ecol. Risk Assess. Int. J. 2019, 26, 1779–1794. [Google Scholar] [CrossRef]

- Zhou, Y.; Ren, B.; Hursthouse, A.; Zhou, S. Antimony Ore Tailings: Heavy Metals, Chemical Speciation, and Leaching Characteristics. Pol. J. Environ. Stud. 2019, 28, 485–495. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Geng, B.; Hu, X.; Ren, B.; Hursthouse, A.S. Preparation and characterization of iron-copper binary oxide and its effective removal of antimony(III) from aqueous solution. Water Sci. Technol. 2016, 74, 393–401. [Google Scholar] [CrossRef]

- Li, Y.; Zeng, X.; Lin, Z.; Su, J.; Gao, T.; Deng, R.; Liu, X. Experimental study on phosphate rock modified soil-bentonite as cut-off wall materials. Water Sci. Technol. 2022, 22, 1676–1690. [Google Scholar] [CrossRef]

- Zhang, J.; Shi, S.; Lu, Y.; You, B.; Wu, F.; Zhang, L.; Xie, Y.; Zhang, J.; Miao, Z. Coal Mine Gas Abnormal Emission Inducing Factors, Manifestation Emission Mechanism. Fresenius Environ. Bull. 2022, 31, 6569–6575. [Google Scholar]

- Liu, X.; Yang, X. Impact of China’s environmental decentralization on carbon emissions from energy consumption: An empirical study based on the dynamic spatial econometric model. Environ. Sci. Pollut. Res. 2022, 29, 72140–72158. [Google Scholar] [CrossRef]

- Zhang, Y.; Ren, B.; Hursthouse, A.S.; Deng, R.; Hou, B. Study on the Migration Rules of Sb in Antimony Ore Soil Based on HYDRUS-1D. Pol. J. Environ. Stud. 2018, 28, 965–972. [Google Scholar] [CrossRef]

- Deng, Q.Z.; Tian, Y.C. Estimation of Carbon Emission and Identification of Driving Factors in the Circum-Changsha-Zhuzhou-Xiangtan Urban Agglomeration of China. Appl. Ecol. Environ. Res. 2019, 17, 9493–9504. [Google Scholar] [CrossRef]

- Xie, Q.; Ren, B.; Hursthouse, A.; Shi, X. Effects of mining activities on the distribution, controlling factors, and sources of metals in soils from the Xikuangshan South Mine, Hunan Province. Integr. Environ. Assess. Manag. 2021, 18, 748–756. [Google Scholar] [CrossRef] [PubMed]

- He, S.; Lu, Y.; Li, M. Probabilistic risk analysis for coal mine gas overrun based on FAHP and BN: A case study. Environ. Sci. Pollut. Res. 2022, 29, 28458–28468. [Google Scholar] [CrossRef] [PubMed]

- Huang, Z.; Huang, Y.; Yang, Z.; Zhang, J.; Zhang, Y.; Gao, Y.; Shao, Z. Study on the physicochemical characteristics and dust suppression performance of new type chemical dust suppressant for copper mine pavement. Environ. Sci. Pollut. Res. 2021, 28, 59640–59651. [Google Scholar] [CrossRef] [PubMed]

- Huang, Z.; Zhang, L.; Yang, Z.; Zhang, J.; Gao, Y. Preparation and properties of a rock dust suppressant for a copper mine. Atmos. Pollut. Res. 2019, 10, 2010–2017. [Google Scholar] [CrossRef]

- Lei, C.; Yan, B.; Chen, T.; Xiao, X.-M. Recovery of metals from the roasted lead-zinc tailings by magnetizing roasting followed by magnetic separation. J. Clean. Prod. 2017, 158, 73–80. [Google Scholar] [CrossRef]

- Consoli, N.C.; Nierwinski, H.P.; da Silva, A.P.; Sosnoski, J. Durability and strength of fiber-reinforced compacted gold tailings cement blends. Geotext. Geomembr. 2017, 45, 98–102. [Google Scholar] [CrossRef]

- Wang, Q.; Li, J.; Zhu, X.; Yao, G.; Wu, P.; Wang, Z.; Lyu, X.; Hu, S.; Qiu, J.; Chen, P.; et al. Approach to the management of gold ore tailings via its application in cement production. J. Clean. Prod. 2020, 269, 122303. [Google Scholar] [CrossRef]

- Behera, S.K.; Mishra, D.P.; Ghosh, C.N.; Prashant; Mandal, P.K.; Singh, K.M.P.; Buragohain, J.; Singh, P.K. Characterization of lead-zinc mill tailings, fly ash and their mixtures for paste backfilling in underground metalliferous mines. Environ. Earth Sci. 2019, 78, 394. [Google Scholar] [CrossRef]

- Krishna, R.; Shaikh, F.; Mishra, J.; Lazorenko, G.; Kasprzhitskii, A. Mine tailings-based geopolymers: Properties, applications and industrial prospects. Ceram. Int. 2021, 47, 17826–17843. [Google Scholar] [CrossRef]

- Geng, Y.; Peng, C.; Zhou, W.; Huang, S.; Zhou, P.; Wang, Z.; Qin, H.; Li, D. Gradient rise in seepage pollution levels in tailings ponds shapes closer linkages between phytoplankton and bacteria. J. Hazard. Mater. 2022, 437, 129432. [Google Scholar] [CrossRef]

- Yi, Z.-L.; Sun, H.-H.; Wei, X.-Q.; Li, C. Iron ore tailings used for the preparation of cementitious material by compound thermal activation. Int. J. Miner. Met. Mater. 2009, 16, 355–358. [Google Scholar] [CrossRef]

- Cheng, Y.; Huang, F.; Li, W.; Liu, R.; Li, G.; Wei, J. Test research on the effects of mechanochemically activated iron tailings on the compressive strength of concrete. Constr. Build. Mater. 2016, 118, 164–170. [Google Scholar] [CrossRef]

- Burduhos Nergis, D.D.; Vizureanu, P.; Sandu, A.V.; Burduhos Nergis, D.P.; Bejinariu, C. XRD and TG-DTA Study of New Phosphate-Based Geopolymers with Coal Ash or Metakaolin as Aluminosilicate Source and Mine Tailings Addition. Materials 2022, 15, 202. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Ni, W.; Zhang, J.W. Preparation of Cemented Whole Tailings Backfilling Materials by Using Iron and Steel Slag as Major Row Materials of the Cementing Agen. Mod. Min. 2014, 30, 171–174. [Google Scholar]

- Shanshan, X.; Lijie, G. Study on Preparation of New Filling Cementitious Material by Tailings and Smelting Waste. Jiangxi Build. Mater. 2015, 12, 108–113. [Google Scholar]

- Li, C.; Sun, H.; Yi, Z.; Li, L. Innovative methodology for comprehensive utilization of iron ore tailings Part 2: The residues after iron recovery from iron ore tailings to prepare cementitious material. J. Hazard. Mater. 2010, 174, 78–83. [Google Scholar] [CrossRef]

- Liu, W. Experimental Research on Preparation of Cementing Materials with Iron Tailings. Metalmine 2010, 39, 175–178. [Google Scholar]

- Karhu, M.; Lagerbom, J.; Solismaa, S.; Honkanen, M.; Ismailov, A.; Räisänen, M.-L.; Huttunen-Saarivirta, E.; Levänen, E.; Kivikytö-Reponen, P. Mining tailings as raw materials for reaction-sintered aluminosilicate ceramics: Effect of mineralogical composition on microstructure and properties. Ceram. Int. 2018, 45, 4840–4848. [Google Scholar] [CrossRef]

- Lee, J.K.; Shang, J.Q. Micropore Structure of Cement-Stabilized Gold Mine Tailings. Minerals 2018, 8, 96. [Google Scholar] [CrossRef] [Green Version]

- Chonghui, Z.; Junmin, L.; Zenghong, W. Study on the influence of particle gradation on permeability coefficient of coarse-grained soil. Yellow River 2005, 27, 79–81. [Google Scholar]

- Ying, J.; Jun, Z.; Yan-wen, W.; Cheng-cheng, S.; Jin-he, F. Influence of Fly Ash on Void and Compressive Strength of Foam Concrete. Bull. Chin. Ceram. Soc. 2018, 37, 3657–3662. [Google Scholar]

- Kuder, K.; Lehman, D.; Berman, J.; Hannesson, G.; Shogren, R. Mechanical properties of self consolidating concrete blended with high volumes of fly ash and slag. Constr. Build. Mater. 2012, 34, 285–295. [Google Scholar] [CrossRef]

- Noushini, A.; Hastings, M.; Castel, A.; Aslani, F. Mechanical and flexural performance of synthetic fibre reinforced geopolymer concrete. Constr. Build. Mater. 2018, 186, 454–475. [Google Scholar] [CrossRef]

- Li, X.J.; Zhang, H.K.; Bai, Y.F.; Zhang, X.Y. Factor analysis and numerical simulation of rock breaking efficiency of TBM deep rock mass based on orthogonal design. J. Cent. South Univ. 2022, 29, 1345–1362. [Google Scholar] [CrossRef]

- Chen, B.; Shen, X.Y.; Gu, H.M.; Shao, H.M.; Zhai, Y.C.; Ma, P.H. Extracting reaction mechanism analysis of Zn and Si from zinc oxide ore by NaOH roasting method. J. Cent. South Univ. 2017, 24, 2266–2274. [Google Scholar] [CrossRef]

- Zhu, G.; Zhang, S.; Bian, Y.; Hursthouse, A.S. Multi-linear regression model for chlorine consumption by waters. Environ. Eng. Res. 2020, 26, 200402. [Google Scholar] [CrossRef]

- Luo, X.; Ren, B.; Hursthouse, A.S.; Jiang, F.; Deng, R.-J.; Wang, Z. Source identification and risk analysis of potentially toxic elements (PTEs) in rainwater runoff from a manganese mine (south central Hunan, China). Water Supply 2020, 21, 824–835. [Google Scholar] [CrossRef]

- Wang, X.; Ren, B.; Zhou, Y.; Shi, X. Study on the mechanism and kinetics of manganese release from waste manganese ore waste rock under rainfall leaching. Environ. Sci. Pollut. Res. 2021, 29, 5541–5551. [Google Scholar] [CrossRef]

- Zhang, Y.; Ren, B.; Hursthouse, A.S.; Deng, R.; Hou, B. An Improved SWAT for Predicting Manganese Pollution Load at the Soil-Water Interface in a Manganese Mine Area. Pol. J. Environ. Stud. 2018, 27, 2357–2365. [Google Scholar] [CrossRef]

- Cui, W.; Li, X.; Zhou, S.; Weng, J. Investigation on process parameters of electrospinning system through orthogonal experimental design. J. Appl. Polym. Sci. 2006, 103, 3105–3112. [Google Scholar] [CrossRef]

- Zhao, W.; Ji, C.; Sun, Q.; Gu, Q. Preparation and Microstructure of Alkali-Activated Rice Husk Ash-Granulated Blast Furnace Slag Tailing Composite Cemented Paste Backfill. Materials 2022, 15, 4397. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Shi, X.; Zhou, J.; Chen, Q.; Li, E.; Du, X. Compressive behavior and microstructural properties of tailings polypropylene fibre-reinforced cemented paste backfill. Constr. Build. Mater. 2018, 190, 211–221. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, T.-A.; Dreisinger, D.; Lv, C.; Lv, G.; Zhang, W. Recovery of vanadium from calcification roasted-acid leaching tailing by enhanced acid leaching. J. Hazard. Mater. 2019, 369, 632–641. [Google Scholar] [CrossRef]

- Zhao, Y.; Chang, L.; Wang, Y.; Lin, H.; Liao, J.; Liu, Q. Dynamic response of cylindrical thick-walled granite specimen with clay infilling subjected to dynamic loading. Arch. Appl. Mech. 2022, 92, 643–648. [Google Scholar] [CrossRef]

- Chen, Y.; Lin, H.; Li, S.; Cao, R.; Yong, W.; Wang, Y.; Zhao, Y. Shear expression derivation and parameter evaluation of Hoek–Brown criterion. Arch. Civ. Mech. Eng. 2022, 22, 77. [Google Scholar] [CrossRef]

- Xie, S.-J.; Lin, H.; Chen, Y.-F.; Wang, Y.-X. A new nonlinear empirical strength criterion for rocks under conventional triaxial compression. J. Cent. South Univ. 2021, 28, 1448–1458. [Google Scholar] [CrossRef]

- Yang, Z.C. Modeling and Forecasting Monthly Average Water Levels Based on the Elliptic Orbit Model. Nat. Resour. Model. 2015, 28, 109–132. [Google Scholar] [CrossRef]

- Yang, Z.-C. The least-square Fourier-series model-based evaluation and forecasting of monthly average water-levels. Environ. Earth Sci. 2018, 77, 328. [Google Scholar] [CrossRef]

- You, B.; Liang, X.; Liang, K. Study on Non-Coal Mine Wastewater Treatment Based on Response Surface Methodology (RSM). Fresenius Environ. Bull. 2019, 28, 6264–6268. [Google Scholar]

- Zhu, Y.; Zhong, S.; Wang, Y.; Liu, M. Land Use Evolution and Land Ecological Security Evaluation Based on AHP-FCE Model: Evidence from China. Int. J. Environ. Res. Public Heal 2021, 18, 12076. [Google Scholar] [CrossRef]

- Wang, P.; Tian, C.; Liu, R.; Wang, J. Mathematical model for multivariate nonlinear prediction of SMD of X-type swirl pressure nozzles. Process. Saf. Environ. Prot. 2019, 125, 228–237. [Google Scholar] [CrossRef]

- Zhu, G.; Xiong, N.; Wang, C.; Li, Z.; Hursthouse, A. Application of a new HMW framework derived ANN model for optimization of aquatic dissolved organic matter removal by coagulation. Chemosphere 2020, 262, 127723. [Google Scholar] [CrossRef] [PubMed]

- Xie, W.; Ren, B.; Hursthouse, A.S.; Wang, Z.; Luo, X. Simulation of Manganese Transport in Groundwater Using Visual Modflow: A Case Study from Xiangtan Manganese Ore Area in Central China. Pol. J. Environ. Stud. 2021, 30, 1409–1420. [Google Scholar] [CrossRef] [PubMed]

- Hou, B.; Liu, Y.; Peng, T.; Ren, B.; Li, Z.; Hursthouse, A.S. Optimization of The Integration of Fe/C Micro-Electrolysis And Fenton in Treating Coal Chemical Industry Wastewater By Response Surface Methodology. Fresenius Environ. Bull. 2019, 28, 2005–2011. [Google Scholar]

| Material | Chemical Compositions (%) | |||||||

|---|---|---|---|---|---|---|---|---|

| Na2O | SiO2 | Al2O3 | MgO | CaO | P2O5 | K2O | Fe2O3 | |

| Fly Ash | 1.670 | 48.800 | 26.260 | 1.840 | 4.951 | 0.146 | 2.000 | 4.869 |

| Cement | 0.276 | 14.240 | 5.410 | 1.799 | 52.84 | 0.408 | 0.892 | 2.461 |

| Material | Chemical Compositions (%) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| TFe | SiO2 | Al2O3 | MgO | CaO | K2O | MnO2 | TiO2 | Na2O | ZnO | Other | |

| Lead–Zine Tailings | 14.15 | 48.17 | 10.79 | 4.14 | 4.20 | 3.01 | 0.73 | 0.31 | 0.46 | 0.49 | 13.55 |

| Sample No. | Fly Ash/% | Lead–Zinc Tailings/% | Cement/% | Water–Binder Ratio |

|---|---|---|---|---|

| 1 | 15 | 25 | 60 | 0.4 |

| 2 | 15 | 30 | 55 | 0.45 |

| 3 | 15 | 35 | 50 | 0.5 |

| 4 | 15 | 40 | 45 | 0.55 |

| 5 | 20 | 25 | 55 | 0.55 |

| 6 | 20 | 30 | 50 | 0.4 |

| 7 | 20 | 35 | 45 | 0.45 |

| 8 | 20 | 40 | 40 | 0.5 |

| 9 | 25 | 25 | 50 | 0.5 |

| 10 | 25 | 30 | 45 | 0.55 |

| 11 | 25 | 35 | 40 | 0.4 |

| 12 | 25 | 40 | 35 | 0.45 |

| 13 | 30 | 25 | 45 | 0.45 |

| 14 | 30 | 30 | 40 | 0.5 |

| 15 | 30 | 35 | 35 | 0.55 |

| 16 | 30 | 40 | 30 | 0.4 |

| Sample No. | 3 Days | 7 Days | 28 Days |

|---|---|---|---|

| 1 | 14.04 | 22.04 | 36.92 |

| 2 | 11.58 | 17.46 | 22.27 |

| 3 | 8.55 | 13.66 | 21.81 |

| 4 | 5.3 | 8.5 | 12.16 |

| 5 | 7.09 | 12.22 | 20.55 |

| 6 | 10.34 | 15.13 | 21.76 |

| 7 | 6.39 | 10.71 | 17.36 |

| 8 | 4.21 | 6.01 | 12.82 |

| 9 | 8.44 | 13.08 | 23.65 |

| 10 | 5.29 | 7.85 | 15.41 |

| 11 | 6.02 | 9.44 | 17.91 |

| 12 | 4.52 | 6.45 | 13.16 |

| 13 | 7.71 | 9.22 | 19.25 |

| 14 | 5.31 | 7.47 | 12.56 |

| 15 | 3 | 5.08 | 10.59 |

| 16 | 7.39 | 11.24 | 22.91 |

| Mean value | 7.20 | 10.97 | 18.82 |

| Standard deviation | 2.81 | 4.39 | 6.30 |

| Levels | Lead–Zine Tailings (%) | Fly Ash(%) | Water–Binder Ratio |

|---|---|---|---|

| 1 | 25 | 15 | 0.40 |

| 2 | 30 | 20 | 0.45 |

| 3 | 35 | 25 | 0.50 |

| 4 | 40 | 30 | 0.55 |

| Source of Variation | Mean Square | Degrees of Freedom | Quadratic Sum | Value p |

|---|---|---|---|---|

| Model | 63.05 | 7 | 9.01 | 0.0328 |

| A | 21.17 | 1 | 21.17 | 0.0129 |

| B | 14.36 | 1 | 14.36 | 0.0244 |

| C | 25.35 | 1 | 25.35 | 0.0094 |

| AC | 0.91 | 1 | 0.91 | 0.4259 |

| BC | 2.19 | 1 | 2.19 | 0.2407 |

| A2 | 6.55 | 1 | 6.55 | 0.0760 |

| B2 | 0.56 | 1 | 0.56 | 0.5247 |

| Residual | 4.63 | 4 | 1.16 | |

| SUM | 67.68 | 11 |

| Source of Variation | Mean Square | Degrees of Freedom | Quadratic Sum | Value p |

|---|---|---|---|---|

| Model | 140.84 | 6 | 23.47 | 0.0114 |

| A | 71.81 | 1 | 71.81 | 0.0026 |

| B | 54.05 | 1 | 54.05 | 0.0048 |

| C | 26.96 | 1 | 26.96 | 0.0193 |

| AB | 16.61 | 1 | 16.61 | 0.0446 |

| AC | 1.12 | 1 | 1.12 | 0.5190 |

| A2 | 7.97 | 1 | 7.97 | 0.1241 |

| Residual | 11.69 | 5 | 2.34 | |

| SUM | 152.53 | 11 | 0.0114 |

| Source of Variation | Mean Square | Degrees of Freedom | Quadratic Sum | Value p |

|---|---|---|---|---|

| Model | 208.41 | 6 | 34.74 | 0.0214 |

| A | 54.38 | 1 | 54.38 | 0.0186 |

| B | 59.47 | 1 | 59.47 | 0.0157 |

| C | 3.53 | 1 | 3.53 | 0.4218 |

| BC | 27.52 | 1 | 27.52 | 0.0586 |

| B2 | 11.61 | 1 | 11.61 | 0.1737 |

| B2C | 20.44 | 1 | 20.44 | 0.0893 |

| Residual | 23.09 | 5 | 4.62 | |

| SUM | 231.50 | 11 |

| 3 Day Age/MPa | 7 Day Age/MPa | 28 Day Age/MPa | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Test Group Number | Actual Value | Predicted Value | Error Magnitude | Actual Value | Predicted Value | Error Magnitude | Actual Value | Predicted Value | Error Magnitude |

| 1 | 14.04 | 14.42 | 0.38 | 22.04 | 22.38 | 0.34 | 36.92 | 34.72 | −2.2 |

| 7 | 6.39 | 6.50 | 0.11 | 10.71 | 10.12 | −0.59 | 17.36 | 17.15 | −0.21 |

| 12 | 4.52 | 4.31 | −0.21 | 6.45 | 6.66 | 0.21 | 13.16 | 13.85 | 0.69 |

| 14 | 5.31 | 5.68 | 0.37 | 7.47 | 7.00 | −0.47 | 12.56 | 13.36 | 0.8 |

| Test Group Number | Test Cost (USD/ton) | 3 d Price Ratio (USD/MPa) | 7 d Price Ratio (USD/MPa) | 28 d Price Ratio (USD/MPa) |

|---|---|---|---|---|

| 1 | 14.14 | 1.01 | 0.64 | 0.38 |

| 2 | 15.91 | 1.37 | 0.91 | 0.71 |

| 3 | 17.68 | 2.07 | 1.29 | 0.81 |

| 4 | 19.44 | 3.67 | 2.29 | Strength does not match |

| 5 | 19.44 | 2.74 | 1.59 | 0.95 |

| 6 | 14.14 | 1.37 | 0.93 | 0.65 |

| 7 | 15.91 | 2.49 | 1.49 | Strength does not match |

| 8 | 17.68 | 4.20 | 2.94 | Strength does not match |

| 9 | 17.68 | 2.09 | 1.35 | 0.75 |

| 10 | 19.44 | 3.68 | 2.48 | Strength does not match |

| 11 | 14.14 | 2.35 | 1.50 | Strength does not match |

| 12 | 15.91 | 3.52 | 2.47 | Strength does not match |

| 13 | 15.91 | 2.06 | 1.73 | Strength does not match |

| 14 | 17.68 | 3.33 | 2.37 | Strength does not match |

| 15 | 19.44 | Strength does not match | 3.83 | Strength does not match |

| 16 | 14.14 | 1.91 | 1.26 | 0.62 |

| Strength | Grade | Compressive Strength | |

|---|---|---|---|

| General mortar strength | 3 d | 28 d | |

| I | ≥4.0 | ≥20.0 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, Z.; Li, R.; Lin, H.; Chen, Y.; Wang, Y.; Zhao, Y. Analysis of Influencing Factors of Cementitious Material Properties of Lead–Zinc Tailings Based on Orthogonal Tests. Materials 2023, 16, 361. https://doi.org/10.3390/ma16010361

Yin Z, Li R, Lin H, Chen Y, Wang Y, Zhao Y. Analysis of Influencing Factors of Cementitious Material Properties of Lead–Zinc Tailings Based on Orthogonal Tests. Materials. 2023; 16(1):361. https://doi.org/10.3390/ma16010361

Chicago/Turabian StyleYin, Ziyi, Rui Li, Hang Lin, Yifan Chen, Yixian Wang, and Yanlin Zhao. 2023. "Analysis of Influencing Factors of Cementitious Material Properties of Lead–Zinc Tailings Based on Orthogonal Tests" Materials 16, no. 1: 361. https://doi.org/10.3390/ma16010361

APA StyleYin, Z., Li, R., Lin, H., Chen, Y., Wang, Y., & Zhao, Y. (2023). Analysis of Influencing Factors of Cementitious Material Properties of Lead–Zinc Tailings Based on Orthogonal Tests. Materials, 16(1), 361. https://doi.org/10.3390/ma16010361