The Effect of the Extrusion Ratio on Load and Die Wear in the Extrusion Process

Abstract

:1. Introduction

2. Experimental Research

3. Numerical Analysis

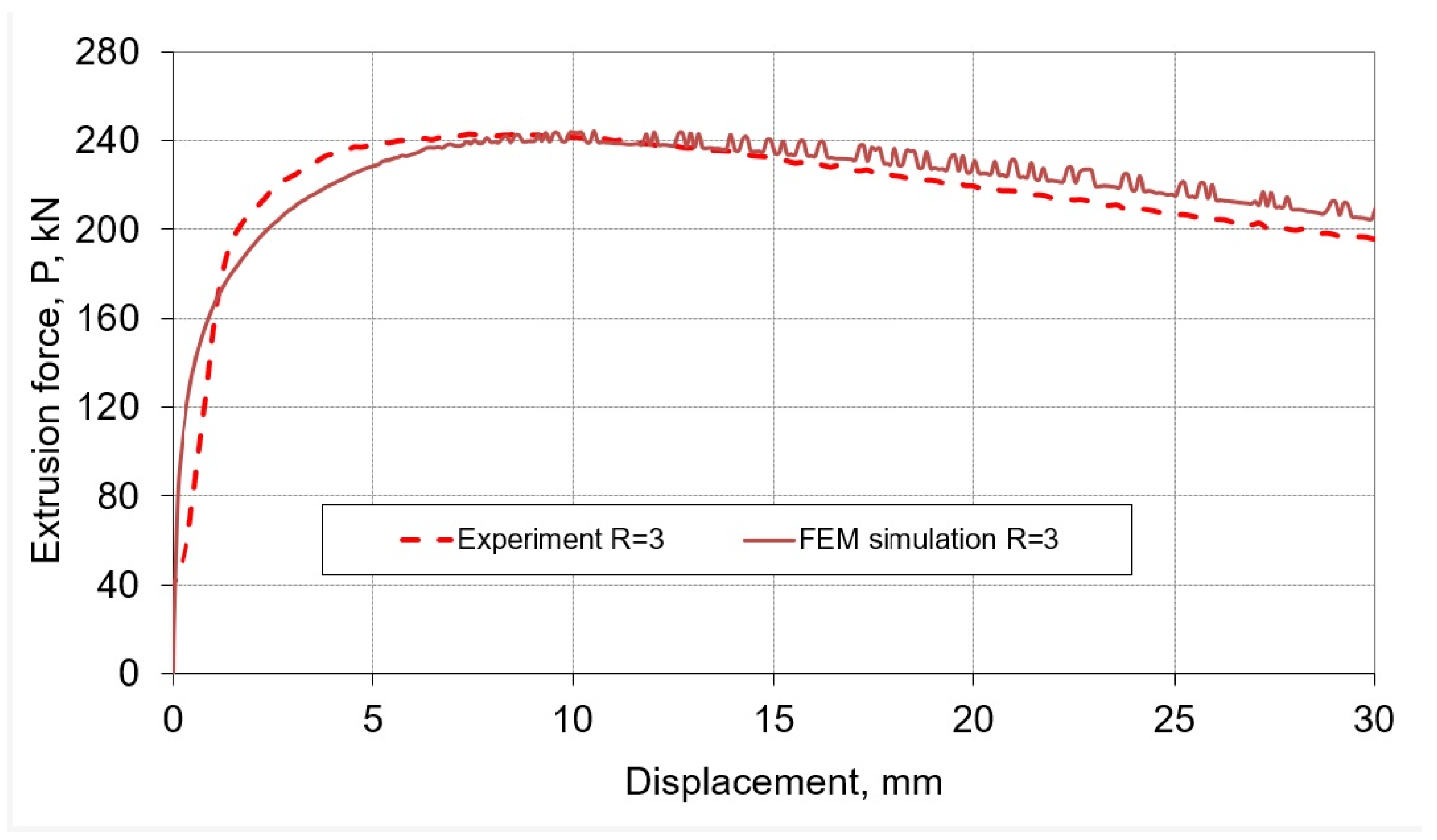

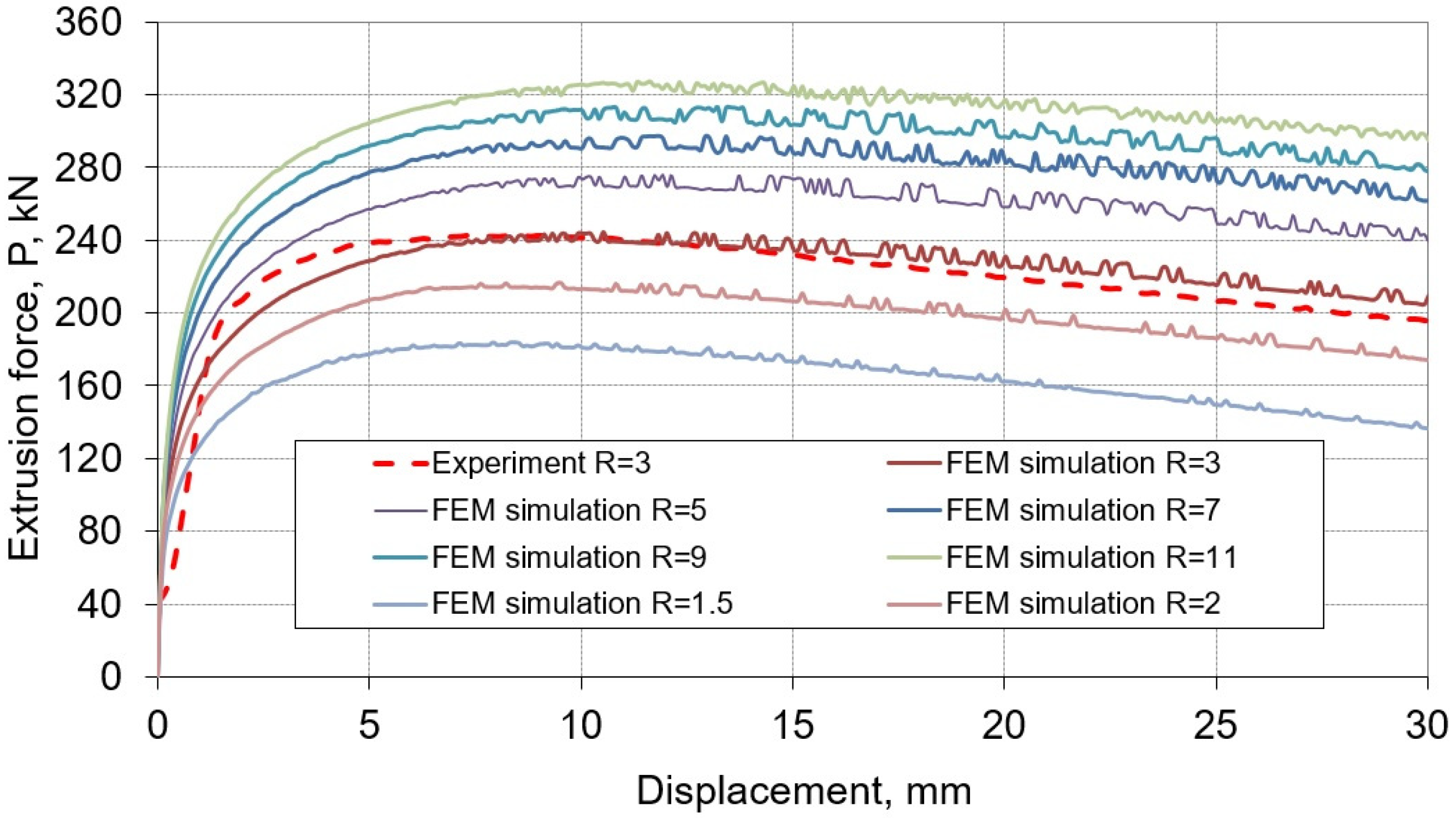

3.1. A Comparative Analysis of the Extrusion Force

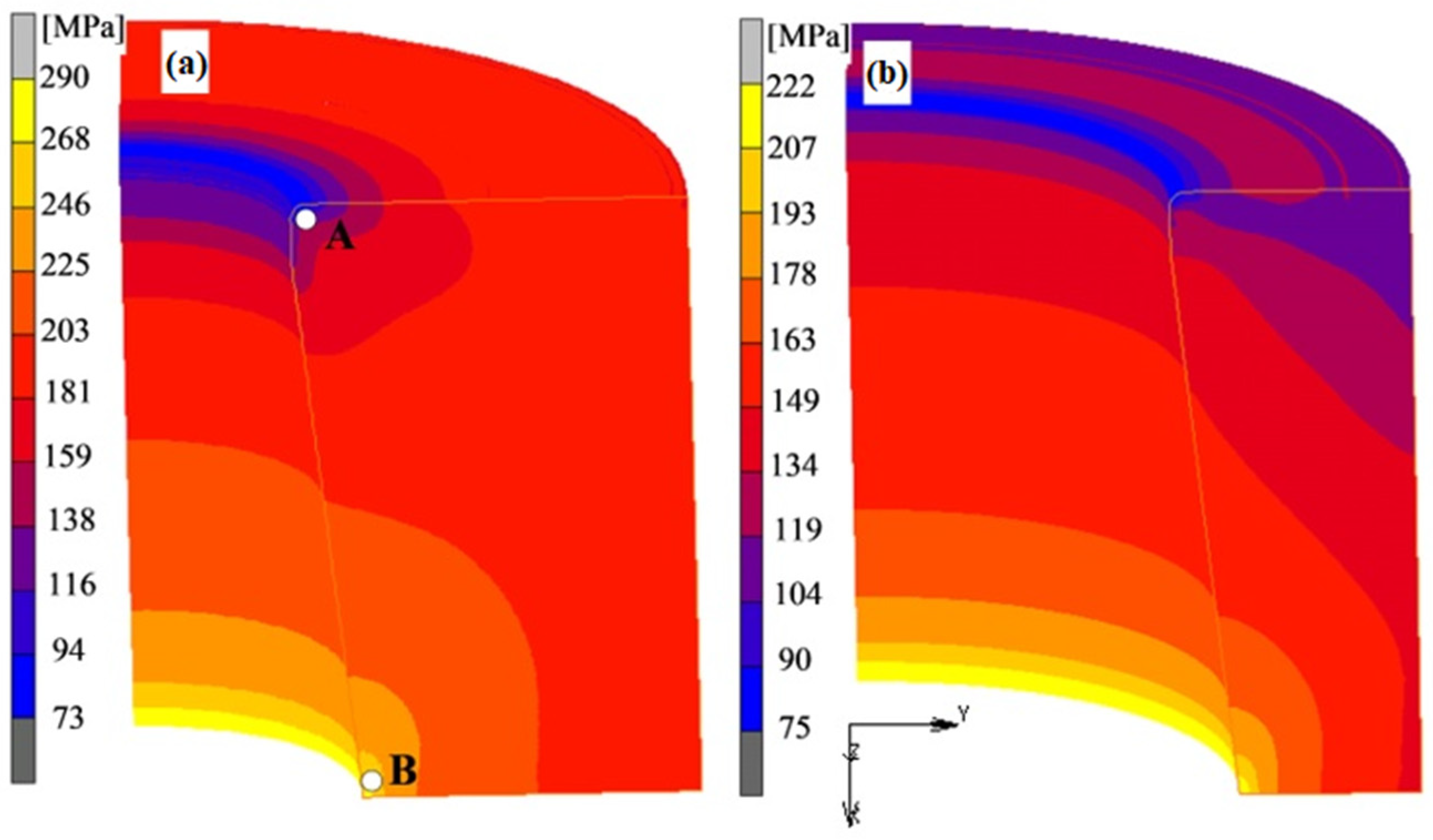

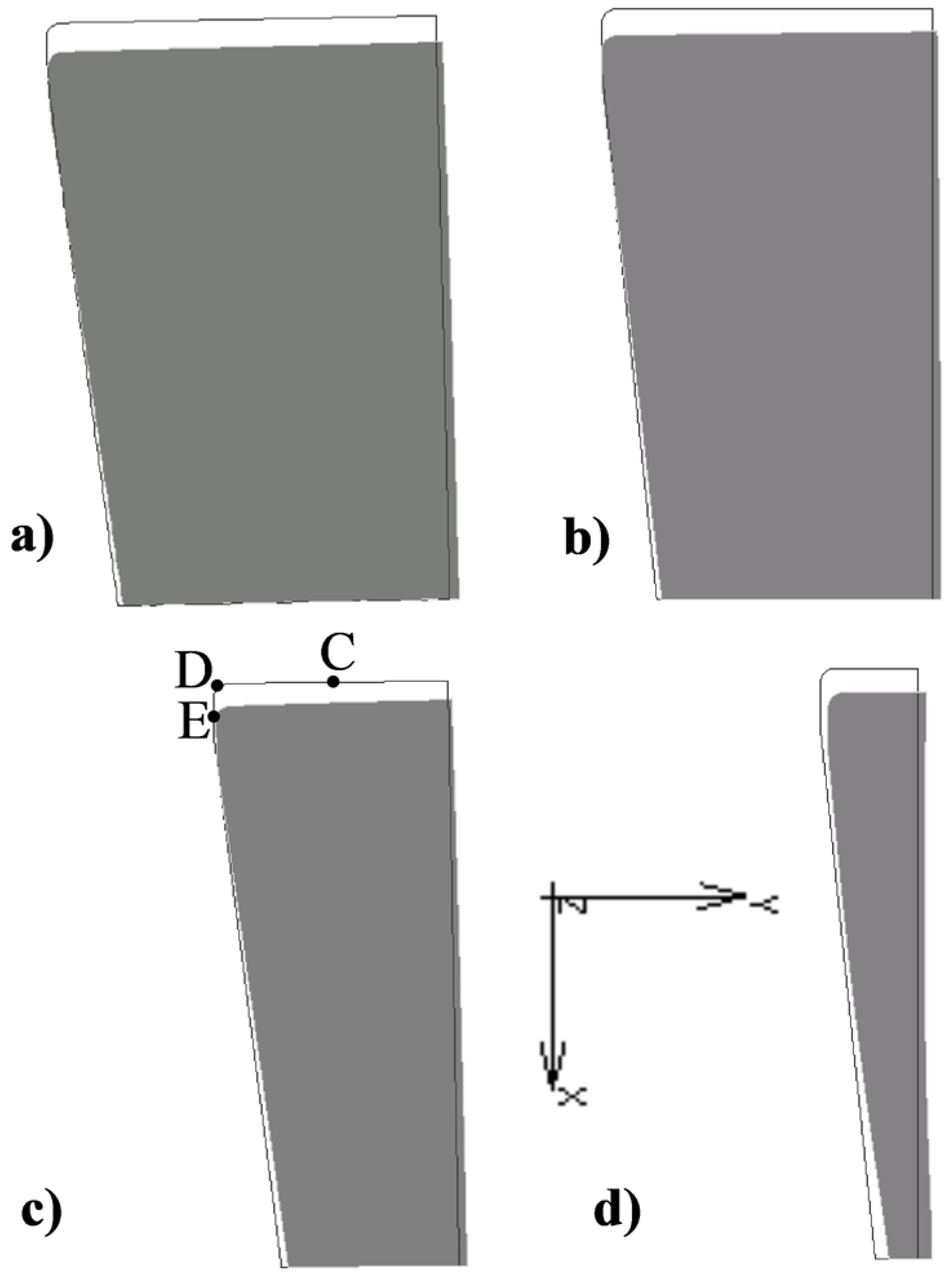

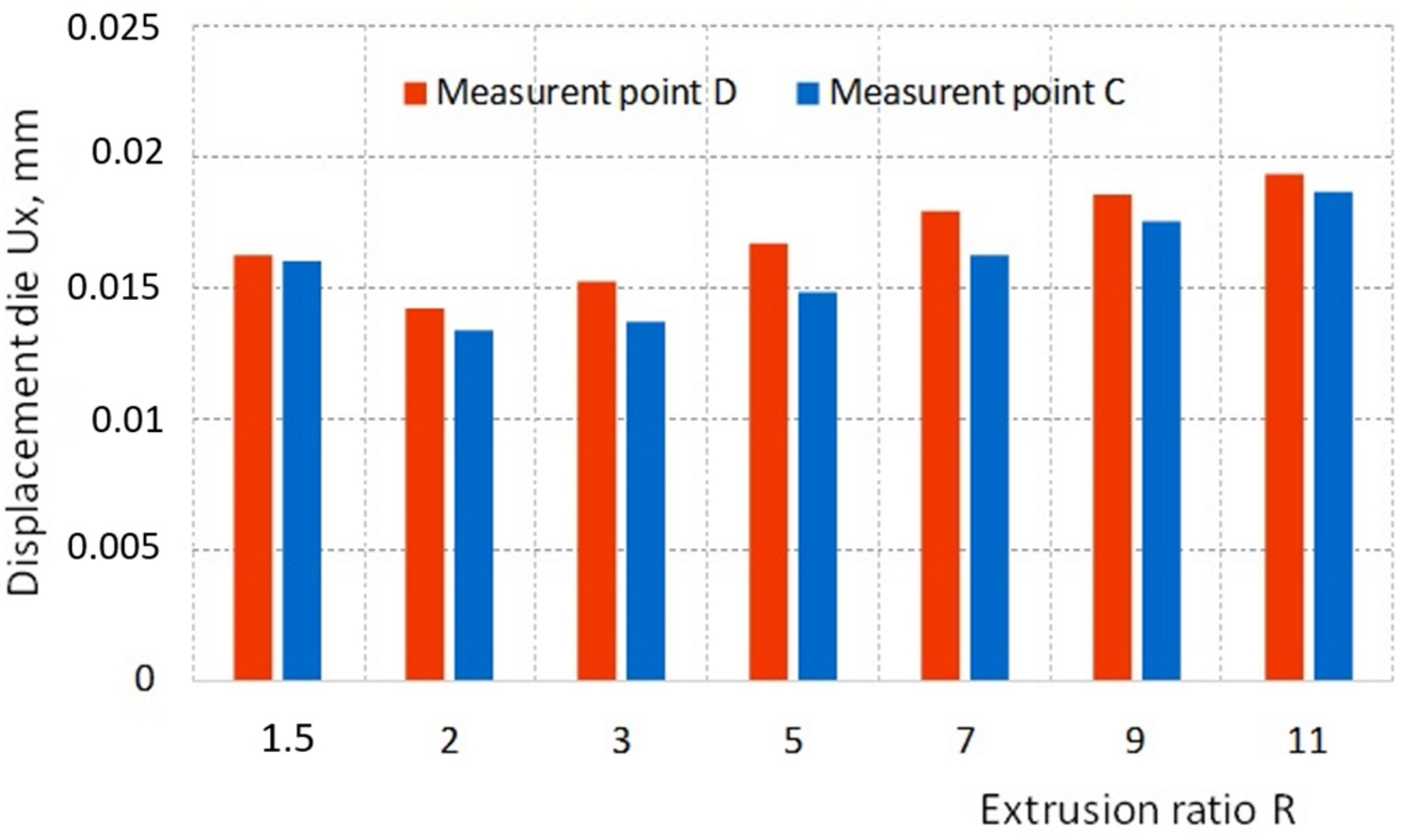

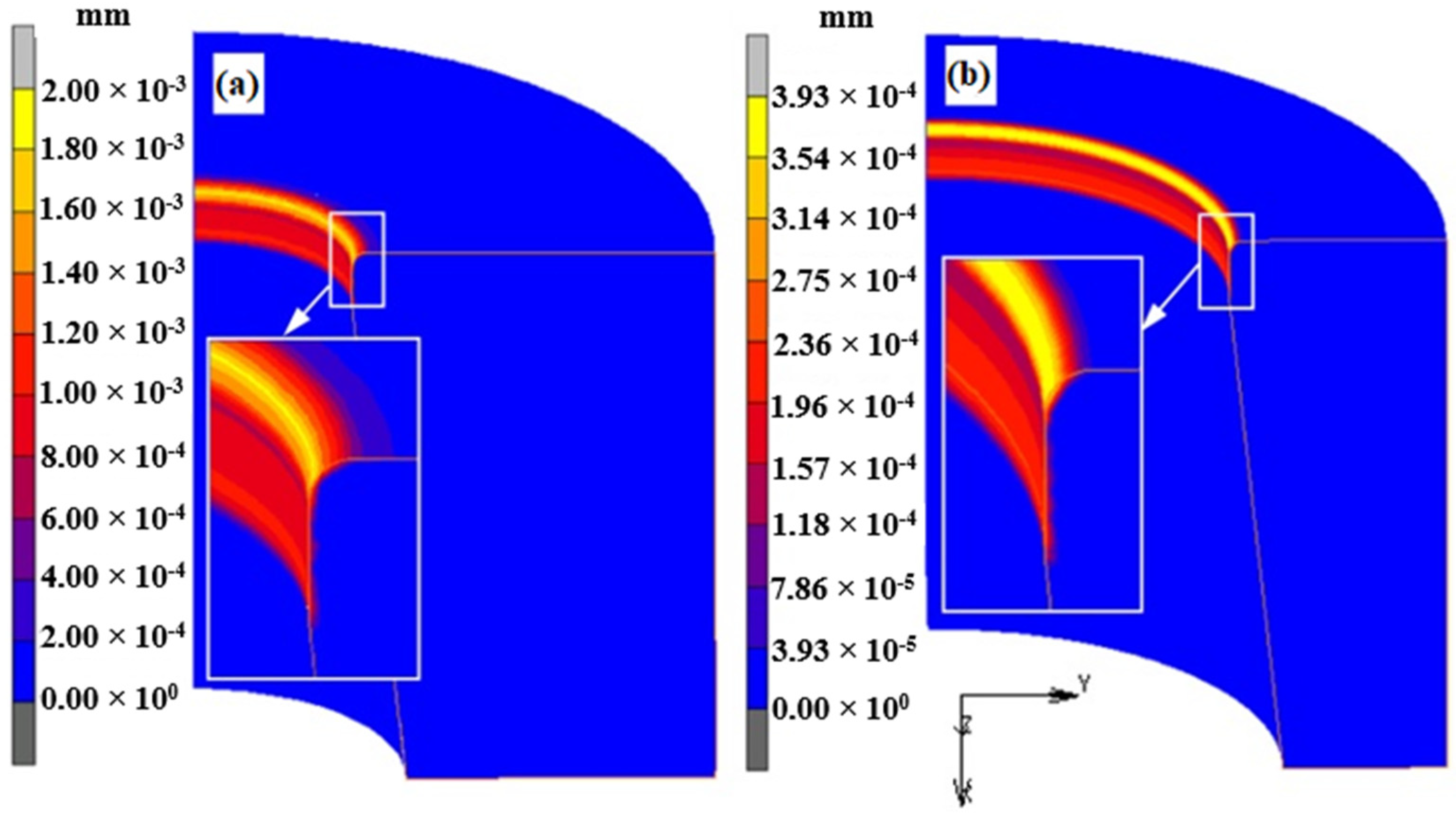

3.2. Stresses and Die Deformation

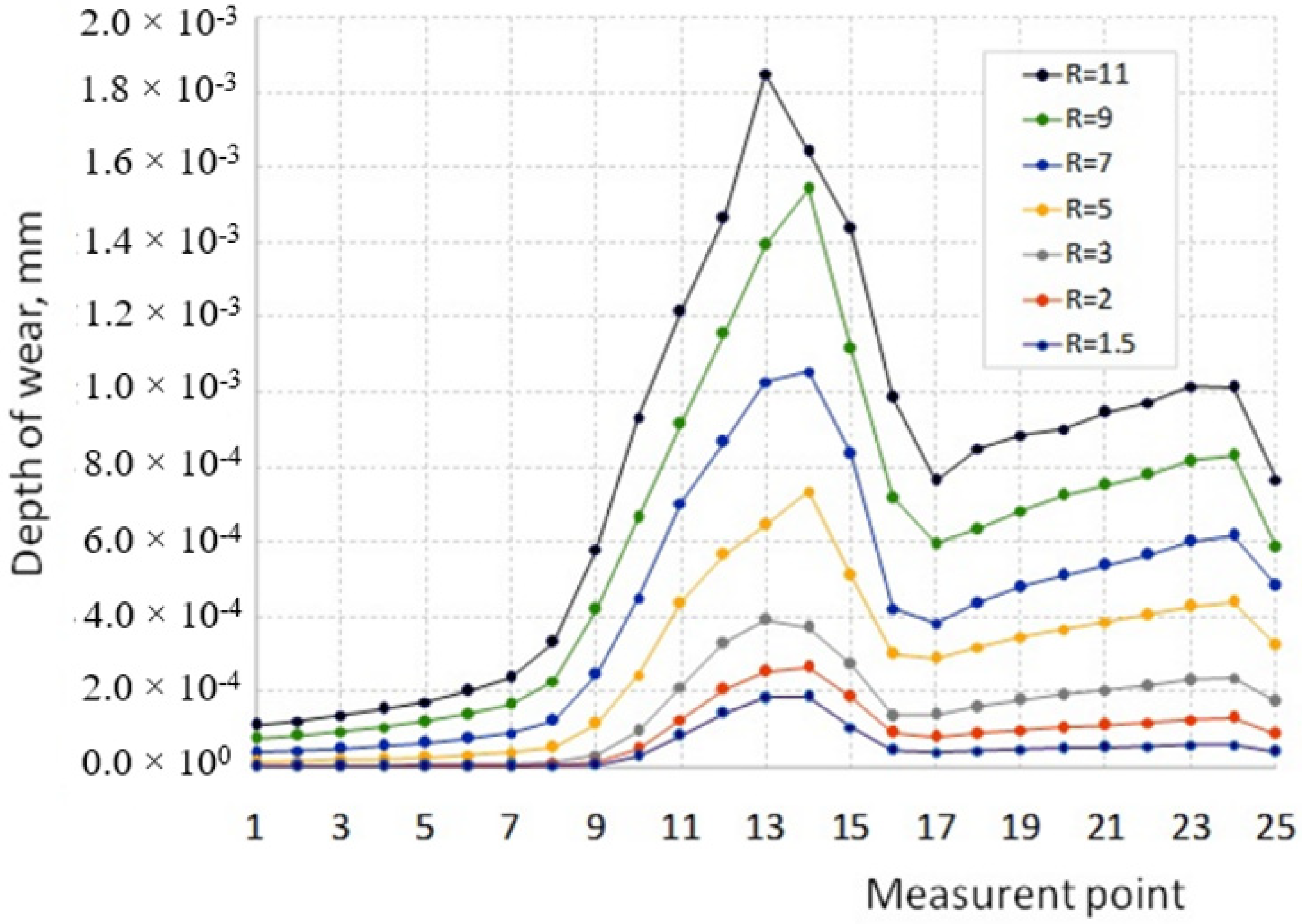

3.3. A Comparative Analysis of Tool Wear

- dV—volume wear

- k—wear coefficient

- dF—normal force

- dL—sliding distance

- H—hardness

- —rate of change of wear in the direction normal to the surface

- σn—normal stress in contact

- vrel—relative sliding velocity

- wn+1—current wear depth

- wn—wear depth amount in the previous computation step

- —incremental wear

- —time in the computation step

4. Conclusions

- (1)

- As the value of the extrusion ratio R increases, the extrusion force grows, while the increase in this force is not proportional to the increase in the R ratio. The most intensive increase in force was observed in the range of small ratios R ≤ 3. Along with a further increase in the value of the R ratio, the intensity of the extrusion force became smaller. It has been shown that the relationship between the extrusion ratio R and the maximum extrusion force Pmax can be described by a logarithmic equation in the form: Pmax = A∙ln(R) + B, in which A and B are constants that can be determined experimentally or on the basis of numerical simulations of the extrusion process.

- (2)

- Assuming a constant outer diameter of the die corresponding to the diameter of the extrusion charge, the most advantageous value due to its deformation is the use of an extrusion ratio R greater than or equal to 3. In the case of smaller values of R ratios, the die cross-section may not provide adequate rigidity. In addition, it was shown that the value of equivalent stresses in the area of the die corner depends relatively little on the value of the extrusion ratio R.

- (3)

- The use of the Archard wear model in the numerical simulation made it possible to conduct a comparative analysis of the impact of the extrusion ratio R on the intensity of the die wear. The die wear was the greatest in the corner radius. The average depth of die wear in the analyzed area largely depends on the R extrusion ratio. An increase in the R ratio value is accompanied by an increase in the die load and an increase in the flow speed extruded through the metal die, which causes an intensive increase in its wear. Based on the results obtained, it can be estimated that, e.g., increasing the R ratio from 3 to 7 causes an over 2.5-fold increase in tool wear. In turn, the implementation of the extrusion process using R = 11 results in an up to 4.5-fold increase in the average depth of die wear compared to its consumption when the extrusion ratio R = 3.

Author Contributions

Funding

Conflicts of Interest

References

- Ma, L.; Wang, Y.; Luo, Y. A method for assessing lifetime of an extrusion container subjected to fatigue-creep interaction. Eng. Fail. Anal. 2020, 118, 104890. [Google Scholar] [CrossRef]

- Hild, R.; Bergs, T.; Mattfeld, P.; Trauth, D.; Klocke, F.; Hoffmann, D.C.; Kruppe, N.C.; Brögelmann, T.; Bobzin, K. Analysis of wear phenomena during forward extrusion under dry friction conditions. Wear 2019, 426–427, 1362–1370. [Google Scholar] [CrossRef]

- Pepelnjak, T.; Milutinović, M.; Plančak, M.; Vilotić, D.; Randjelovic, S.; Movrin, D. The Influence of Extrusion Ratio on Contact Stresses and Die Elastic Deformations in the Case of Cold Backward Extrusion. Mater. Sci. Stroj. Vestn. -J. Mech. Eng. 2016, 62, 41–50. [Google Scholar] [CrossRef] [Green Version]

- Xin, W.; Hong-Fei, S.; Wen-Bin, F. Effect of extrusion ratio on coating extrusion of Pb-GF composite wire by numerical simulation and experimental investigation. Trans. Nonferrous Met. Soc. China 2009, 19, 453–457. [Google Scholar] [CrossRef]

- Kumar, A.V.; Rao, C.S.; Rao, D.N. The Influence of Extrusion ratio on the Properties of Nano SiC reinforced 6061 Aluminum Alloy in cold extrusion. Int. J. Eng. Res. Technol. 2014, 3, 80–86. [Google Scholar]

- Onuh, S.O.; Ekoja, M.; Adeyemi, M.B. Effect of die geometry and extrusion speed on cold extrusion of aluminum and lead alloys. J. Mater. Process. Technol. 2003, 132, 274–285. [Google Scholar] [CrossRef]

- Ajiboye, J.S.; Adeyemi, M.B. Effects of die land on cold extrusion of lead alloy. J. Mater. Process. Technol. 2006, 171, 428–436. [Google Scholar] [CrossRef]

- Ajiboye, J.S.; Adeyemi, M.B. Upper bound analysis for extrusion at various die land lengths and shaped profiles. Int. J. Mech. Sci. 2007, 49, 335–351. [Google Scholar] [CrossRef]

- Lee, J.; Jeong, H.; Park, S. Effect of extrusion ratios on microstructural evolution, textural evolution, and grain boundary character distributions of pure copper tubes during hydrostatic extrusion. Mater. Charact. 2019, 158, 109941. [Google Scholar] [CrossRef]

- Zeng, Z.; Stanford, N.; Davies, C.H.J.; Nie, J.F.; Birbilis, N. Magnesium extrusion alloys: A review of developments and prospects. Int. Mater. Rev. 2018, 64, 27–62. [Google Scholar] [CrossRef]

- Hagihara, K.; Li, Z.X.; Yamasaki, M.; Kawamura, Y.; Nakano, T. Strengthening mechanisms acting in extruded Mg-based long-period stacking ordered (LPSO)-phase alloys. Acta Mater. 2019, 163, 226–239. [Google Scholar] [CrossRef]

- Yu, Z.; Xu, C.; Meng, J.; Liu, K.; Fu, J.L.; Kamado, S. Effects of extrusion ratio and temperature on the mechanical properties and microstructure of as-extruded Mg-Gd-Y-(Nd/Zn)-Zr alloys. Mater. Sci. Eng. A 2019, 762, 138080. [Google Scholar] [CrossRef]

- Yang, Y.; Xiong, X.M.; Su, J.F.; Peng, X.D.; Wen, H.M.; Wei, G.B.; Pan, F.S.; Lavernia, E.J. Influence of extrusion temperature on microstructure and mechanical behavior of duplex Mg-Li-Al-Sr alloy. J. Alloys Compd. 2019, 750, 696–705. [Google Scholar] [CrossRef] [Green Version]

- Tang, W.Q.; Huang, S.Y.; Zhang, S.R.; Li, D.Y.; Peng, Y.H. Influence of extrusion parameters on grain size and texture distributions of AZ31 alloy. J. Mater. Process. Technol. 2011, 211, 1203–1209. [Google Scholar] [CrossRef]

- Zhang, T.L.; Ji, Z.S.; Wu, S.Y. Effect of extrusion ratio on mechanical and corrosion properties of AZ31B alloys prepared by a solid recycling process. Mater. Des. 2011, 32, 2742–2748. [Google Scholar] [CrossRef]

- Wen, L.H.; Ji, Z.S.; Li, X.L. Effect of Extrusion Ratio on Microstructure and Mechanical Properties of Mg–Nd–Zn–Zr Alloys Prepared by a Solid Recycling Process. Mater. Charact. 2008, 59, 1655–1660. [Google Scholar] [CrossRef]

- Feng, S.; Liu, W.C.; Zhao, J.; Wu, G.H.; Zhang, H.H.; Ding, W.J. Effect of extrusion ratio on microstructure and mechanical properties of Mg–8Li–3Al–2Zn–0.5Y alloy with duplex structure. Mater. Sci. Eng. A 2017, 692, 9–16. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, X.Y.; Lu, Y.L.; Li, X.P. Microstructure and mechanical properties of as-extruded Mg-Sn-Zn-Ca alloy with different extrusion ratios. Trans. Nonferrous Met. Soc. China 2018, 28, 2190–2198. [Google Scholar] [CrossRef]

- Tong, L.B.; Zheng, M.Y.; Cheng, L.R.; Kamado, S.; Zhang, H.J. Effect of extrusion ratio on microstructure, texture and mechanical properties of indirectly extruded Mg–Zn–Ca alloy. Mater. Sci. Eng. A 2013, 569, 48–53. [Google Scholar] [CrossRef]

- Guan, K.; Ma, R.; Zhang, J.; Wu, R.; Yang, Q.; Meng, J. Modifying microstructures and tensile properties of Mg-Sm based alloy via extrusion ratio. J. Magnes. Alloy. 2021, 9, 1098–1109. [Google Scholar] [CrossRef]

- Wang, Y.; Li, F.; Wang, Y.; Li, X.; Fang, W. Effect of extrusion ratio on the microstructure and texture evolution of AZ31 magnesium alloy by the staggered extrusion (SE). J. Magnes. Alloy. 2020, 8, 1304–1313. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, Q.; Peng, J.; Zhai, C.; Ding, W. Effects of extrusion ratio on the microstructure and mechanical properties of AZ31 Mg alloy. J. Mater. Process. Technol. 2007, 182, 281–285. [Google Scholar] [CrossRef]

- Shahzad, M.; Wagner, L. Influence of extrusion parameters on microstructure and texture developments, and their effects on mechanical properties of the magnesium alloy AZ80. Mater. Sci. Eng. A 2009, 506, 141–147. [Google Scholar] [CrossRef]

- Huang, X.; Chino, Y.; Yuasa, M.; Ueda, H.; Inoue, M.; Kido, F.; Matsumoto, T. Microstructure and mechanical properties of AZX912 magnesium alloy extruded at different temperatures. Mater. Sci. Eng. A 2017, 679, 162–171. [Google Scholar] [CrossRef]

- Ding, H.; Liu, L.; Kamado, S.; Ding, W.; Kojima, Y. Study of the microstructure, texture and tensile properties of as-extruded AZ91 magnesium alloy. J. Alloys Comp. 2008, 456, 400–406. [Google Scholar] [CrossRef]

- Soltani, N.J.; Nodooshan, H.R.; Bahrami, A.; Pech-Canul, M.I.; Liu, W.; Wu, G. Effect of hot extrusion on wear properties of Al–15 wt.% Mg2Si in situ metal matrix composites. Mater. Des. 2014, 53, 774–781. [Google Scholar] [CrossRef]

- Deaquino-Lara, R.; Soltani, N.; Bahrami, A.; Gutiérrez-Castañeda, E.; García-Sánchez, E.; Hernandez-Rodríguez, M.A.L. Tribological characterization of Al7075–graphite composites fabricated by mechanical alloying and hot extrusion. Mater. Des. 2015, 67, 224–231. [Google Scholar] [CrossRef]

- Soltani, N.; Bahrami, A.; Pech-Canul, M.I. The Effect of Ti on Mechanical Properties of Extruded In-Situ Al-15 pct Mg2Si Composite. Metall. Mater. Trans. A 2013, 44, 4366–4373. [Google Scholar] [CrossRef]

- Bahrami, A.; Razaghian, A.; Emamy, M.; Khorshidi, R. The effect of Zr on the microstructure and tensile properties of hot-extruded Al–Mg2Si composite. Mater. Des. 2012, 36, 323–330. [Google Scholar] [CrossRef]

- Huang, G.; Han, Y.; Guo, X.; Qiu, D.; Wang, L.; Lu, W.; Zhang, D. Effects of extrusion ratio on microstructural evolution and mechanical behavior of in situ synthesized Ti-6Al-4V composites. Mater. Sci. Eng. A 2017, 688, 155–163. [Google Scholar] [CrossRef]

- Ramesh, C.S.; Keshavamurthy, R.; Naveen, G.J. Effect of extrusion ratio on wear behaviour of hot extruded Al6061–SiCp (Ni–P coated) composites. Wear 2011, 271, 1868–1877. [Google Scholar] [CrossRef]

- Krupnik, G.; Grzyb, J.; Oleksy, A.; Libura, W. Jakość prętów ze stopów Al wyciskanych z małym współczynnikiem wydłużenia. Rudy Met. 2007, 52, 728–733. [Google Scholar]

- Karabay, S.; Zeren, M.; Yilmaz, M. Investigation extrusion ratio effect on mechanical behaviour of extruded alloy AA-6063. J. Mater. Process. Technol. 2003, 135, 101–108. [Google Scholar] [CrossRef]

- Tiernan, P.; Draganescu, B. Statistical modeling of surface hardness and roughness in cold extrusion of aluminum. Int. J. Manuf. Res. 2008, 3, 452–470. [Google Scholar] [CrossRef]

- Grzyb, J.; Krupnik, G.; Libura, W.; Rękas, A. Analiza numeryczna i badania struktury prętów AlCu4Mg wyciskanych z małym współczynnikiem wydłużenia. Rudy Met. 2008, 53, 493–497. [Google Scholar]

- Güley, V.; Ben, N.; Khalifa-Tekkaya, A.E. The Effect of Extrusion Ratio and Material Flow on the Mechanical Properties of Aluminum Profiles Solid State Recycled from 6060 Aluminum Alloy Chips. AIP Conf. Proc. 1353, 1609, 2011. [Google Scholar] [CrossRef]

- Nowotyńska, I.; Kut, S. Examining the Effect of the Die Angle on Tool Load and Wear in the Extrusion Process. J. Mater. Eng. Perform. 2014, 23, 1307–1312. [Google Scholar] [CrossRef] [Green Version]

- MSC Software Corporation. Marc Volume B: Element Library; Version 2020; MSC: Newport Beach, CA, USA, 2020. [Google Scholar]

- Giuliano, G. Process Design of the Cold Extrusion of Billet Using, Finite Element Method. Mater. Des. 2007, 28, 726–729. [Google Scholar] [CrossRef]

- Lee, G.A.; Im, Y.T. Finite Element Investigation of the Wear and, Elastic Deformation of Dies in Metal Forming. J. Mater. Process. Technol. 1990, 89–90, 123–127. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Die reduction angle α, degrees | 90 |

| Die external diameter DM, mm | 36 |

| Die height HM, mm | 20 |

| Extrusion ratio, R | 1.5, 2, 3, 5, 7, 9, 11 |

| Length of the calibrating part lk, mm | 2 |

| Rounding radius in the calibrating part r, mm | 0.5 |

| Material | Chemical Composition % | Yield Stress MPa | Brinell Hardness HB |

|---|---|---|---|

| Hard lead | (2.5–5.0) Sb; 0.015 As; 0.04 Cu; 0.0012 Fe; 0.01 Bi | 10 | 8.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kut, S.; Nowotyńska, I. The Effect of the Extrusion Ratio on Load and Die Wear in the Extrusion Process. Materials 2023, 16, 84. https://doi.org/10.3390/ma16010084

Kut S, Nowotyńska I. The Effect of the Extrusion Ratio on Load and Die Wear in the Extrusion Process. Materials. 2023; 16(1):84. https://doi.org/10.3390/ma16010084

Chicago/Turabian StyleKut, Stanisław, and Irena Nowotyńska. 2023. "The Effect of the Extrusion Ratio on Load and Die Wear in the Extrusion Process" Materials 16, no. 1: 84. https://doi.org/10.3390/ma16010084