Electric and Magnetic Properties of the Multiferroic Composites Made Based on Pb(Fe1/2Nb1/2)1−xMnxO3 and the Nickel-Zinc Ferrite

Abstract

:1. Introduction

2. Experiment

3. Results and Discussion

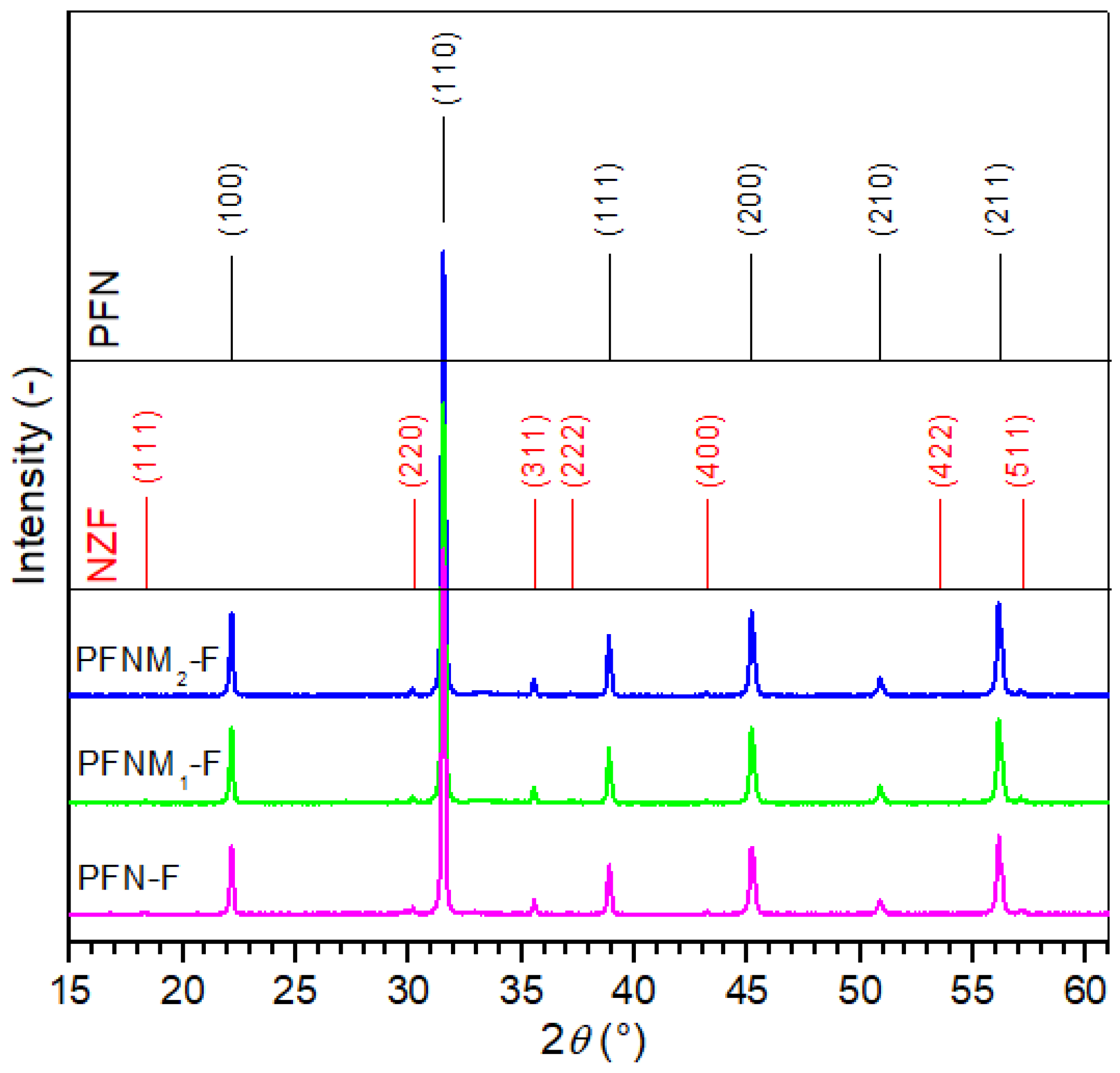

3.1. Crystal Structure

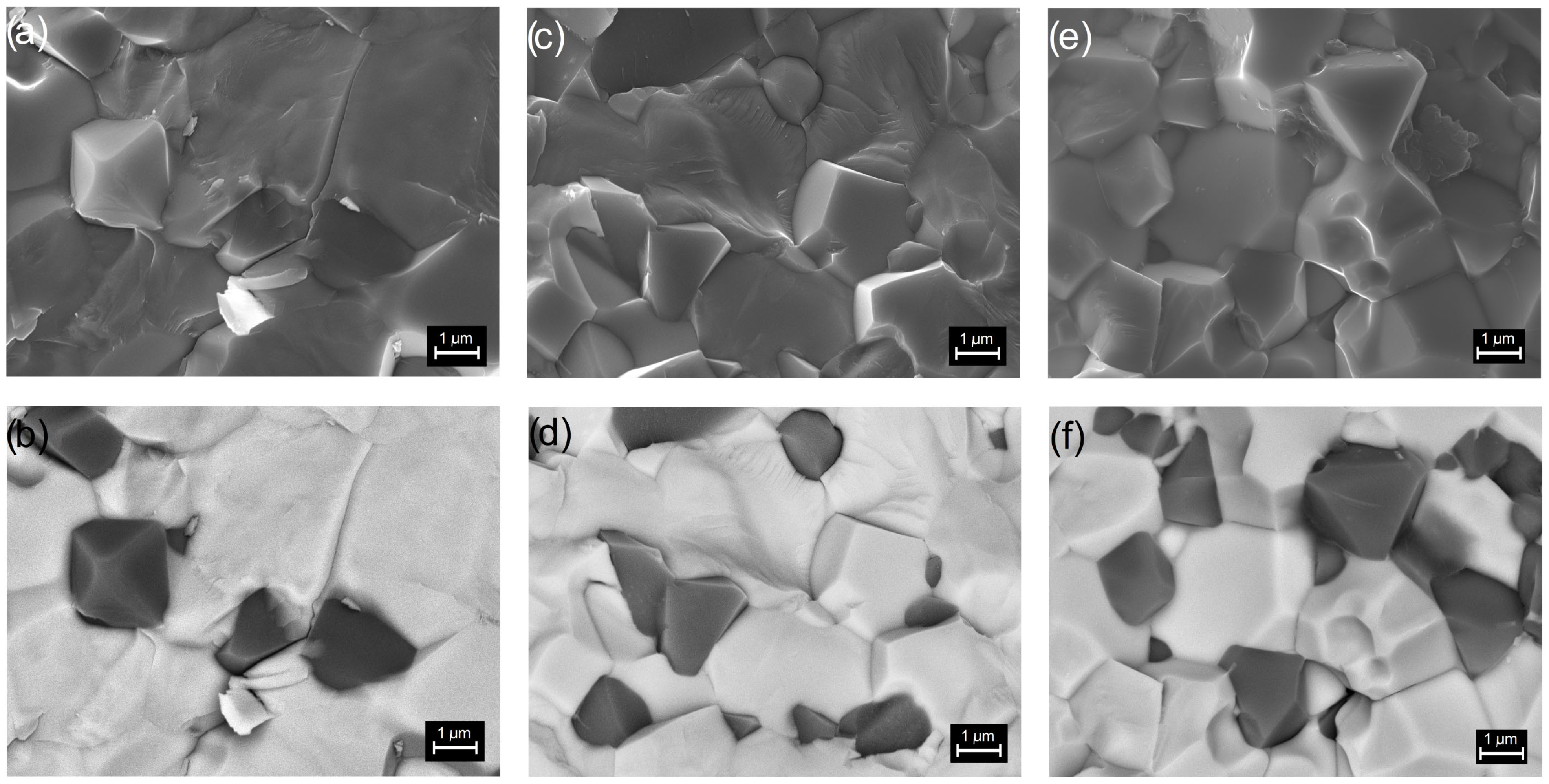

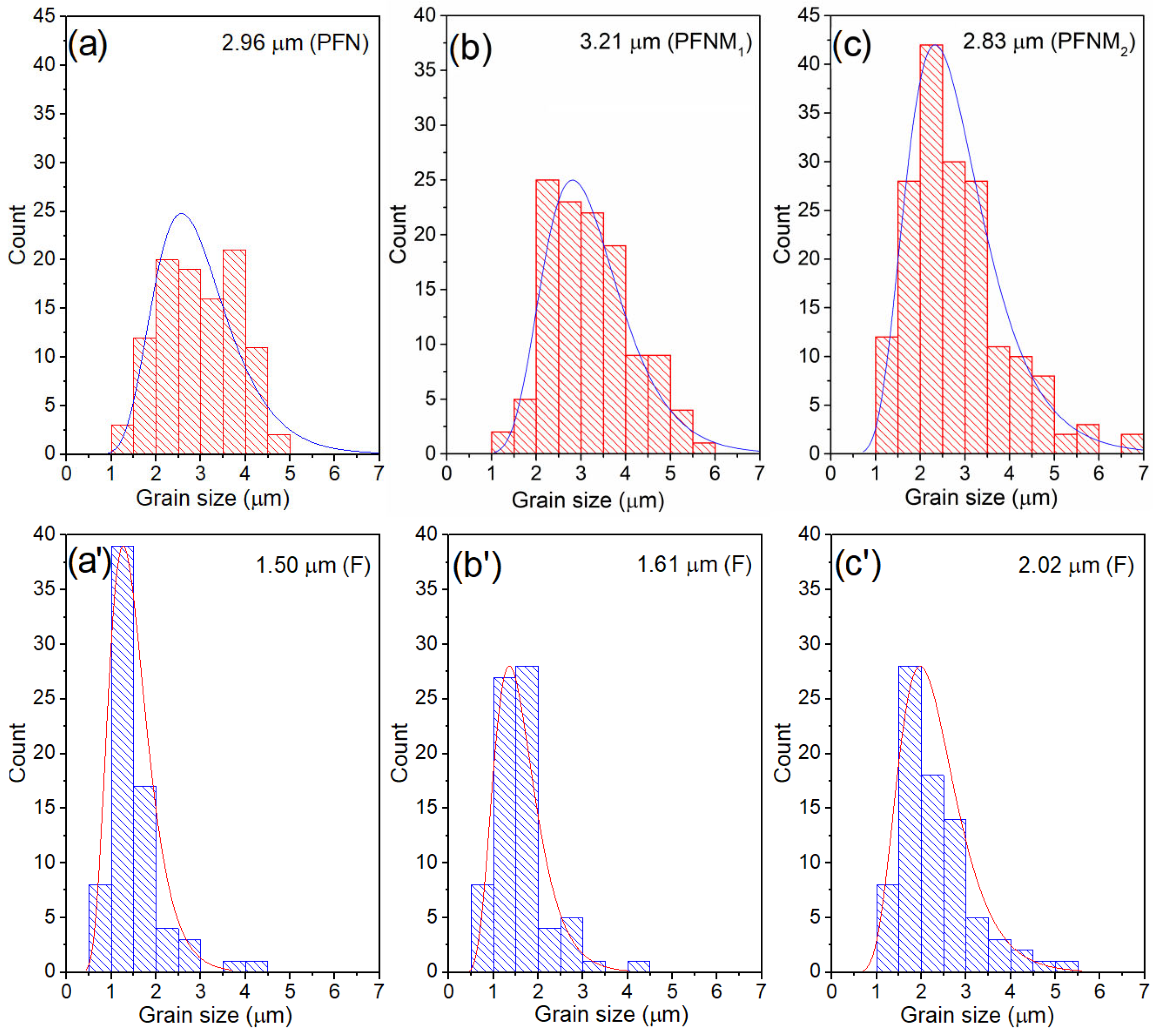

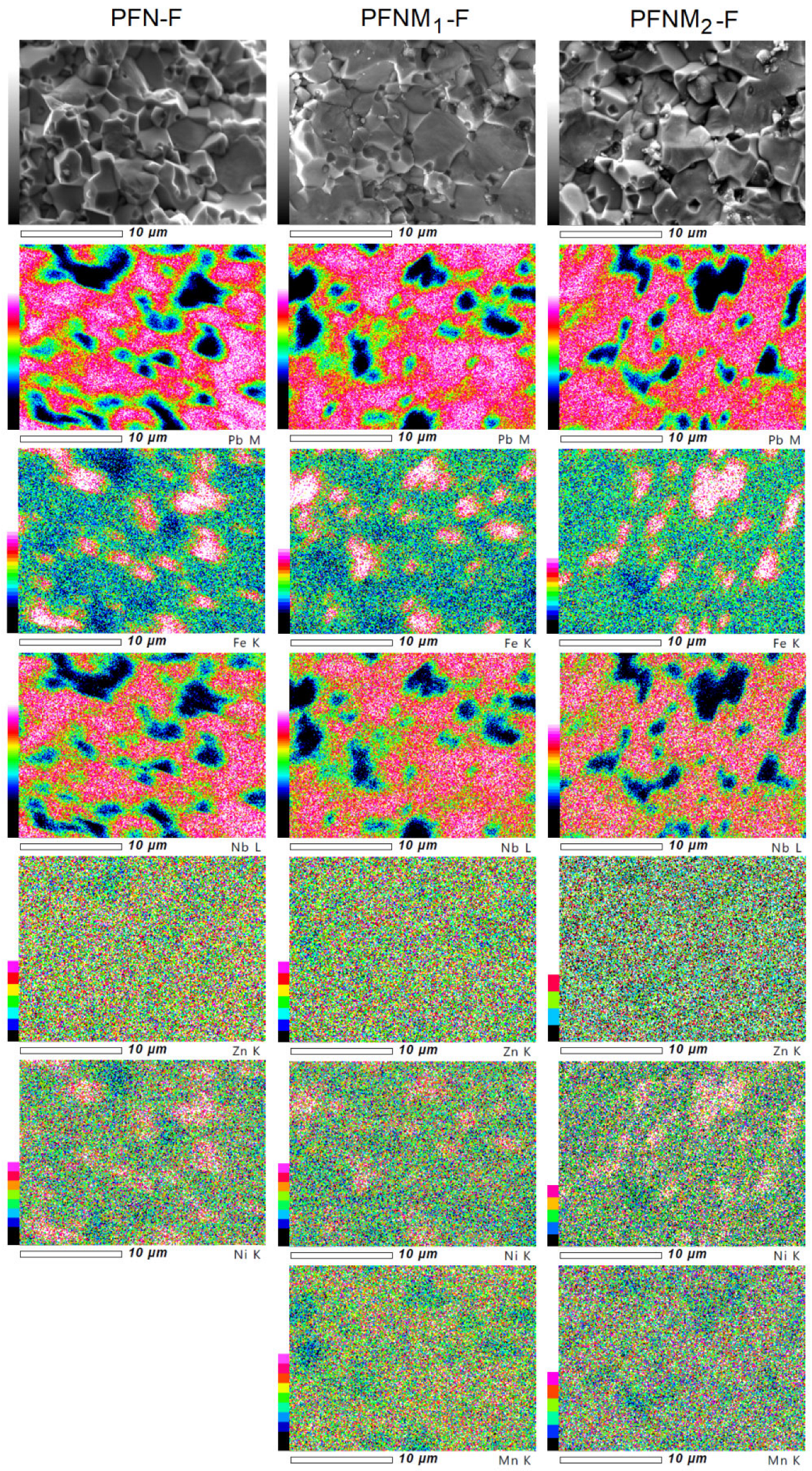

3.2. Microstructure

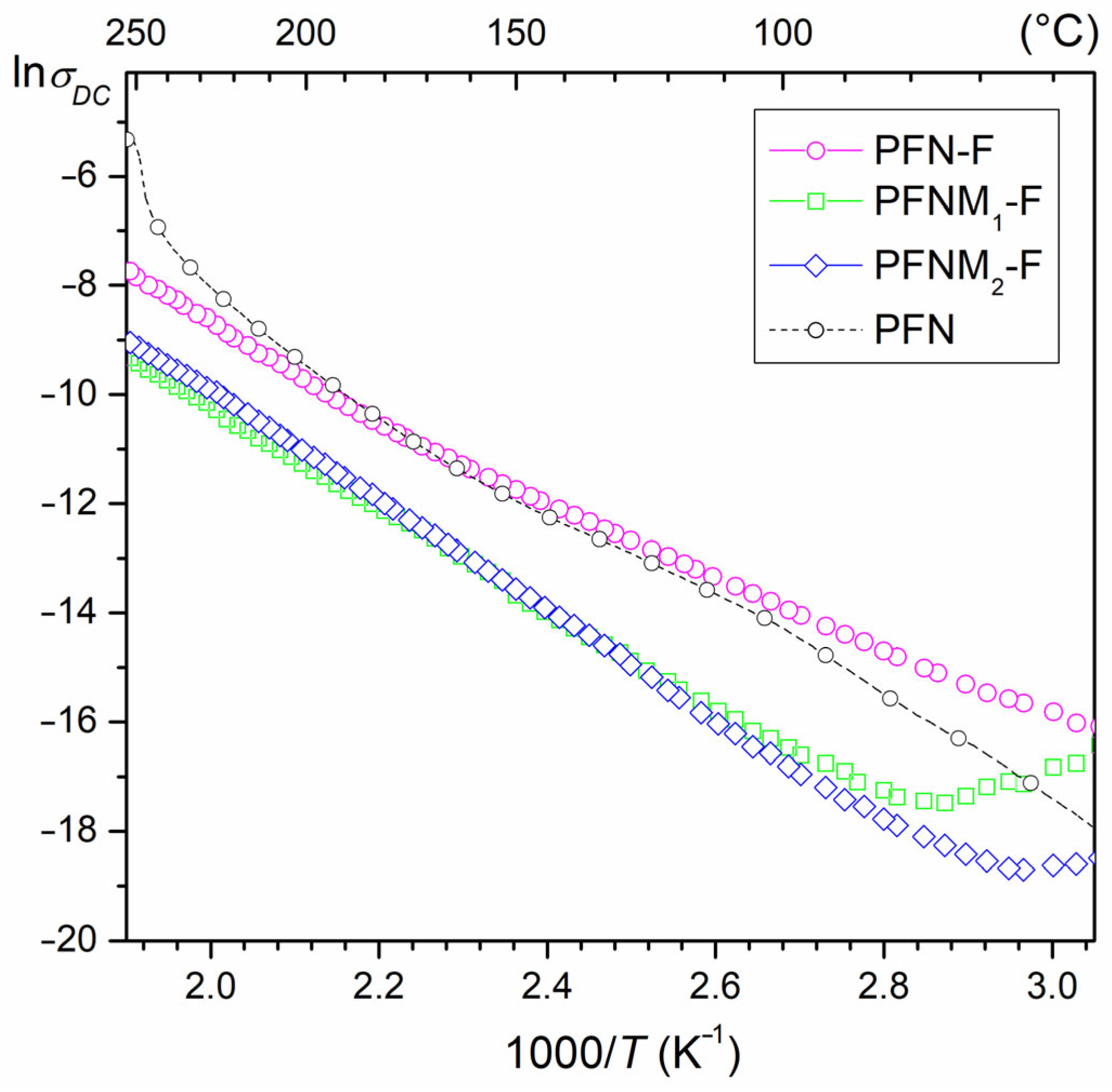

3.3. DC Electric Conductivity

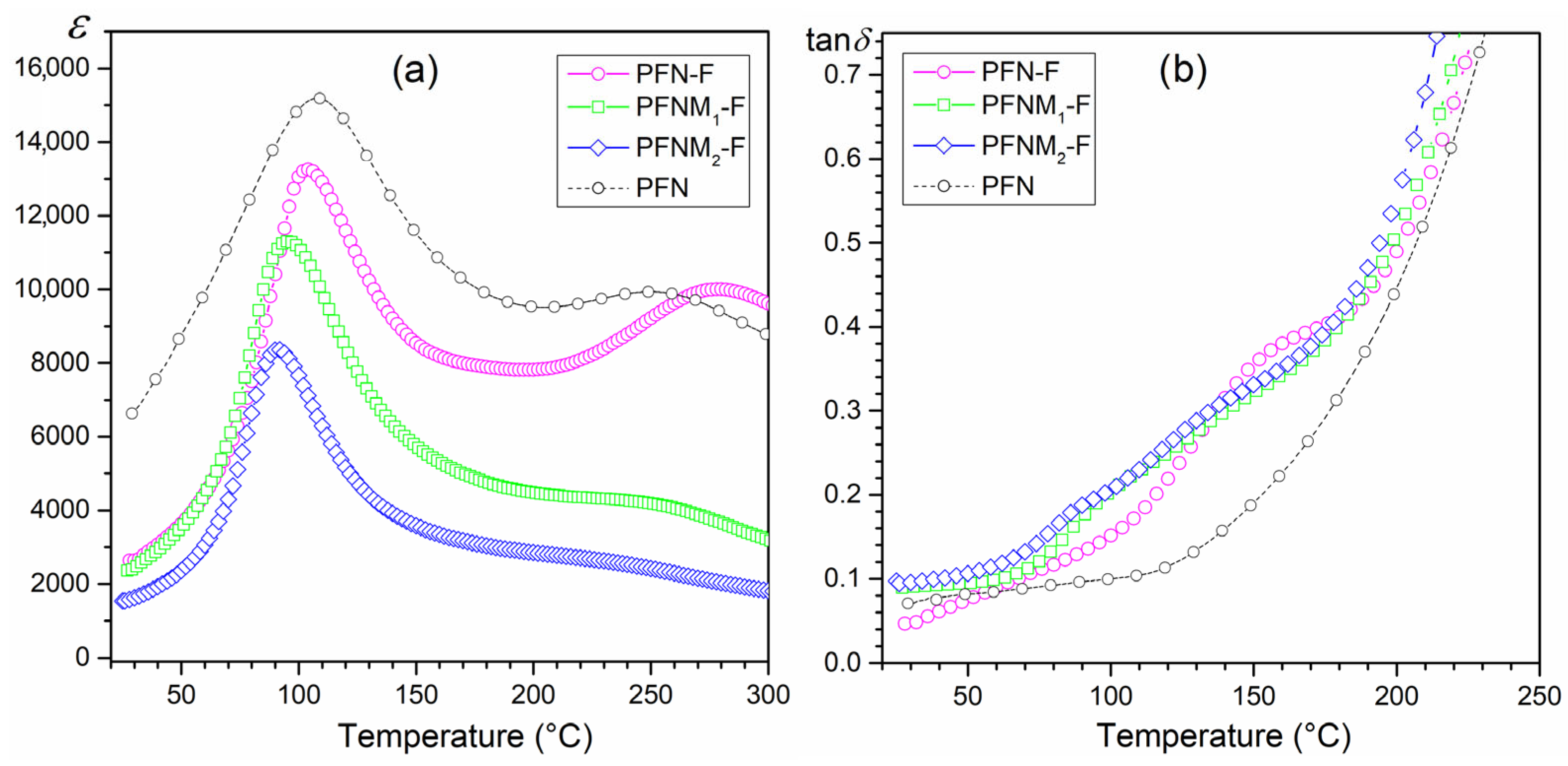

3.4. Dielectric Properties

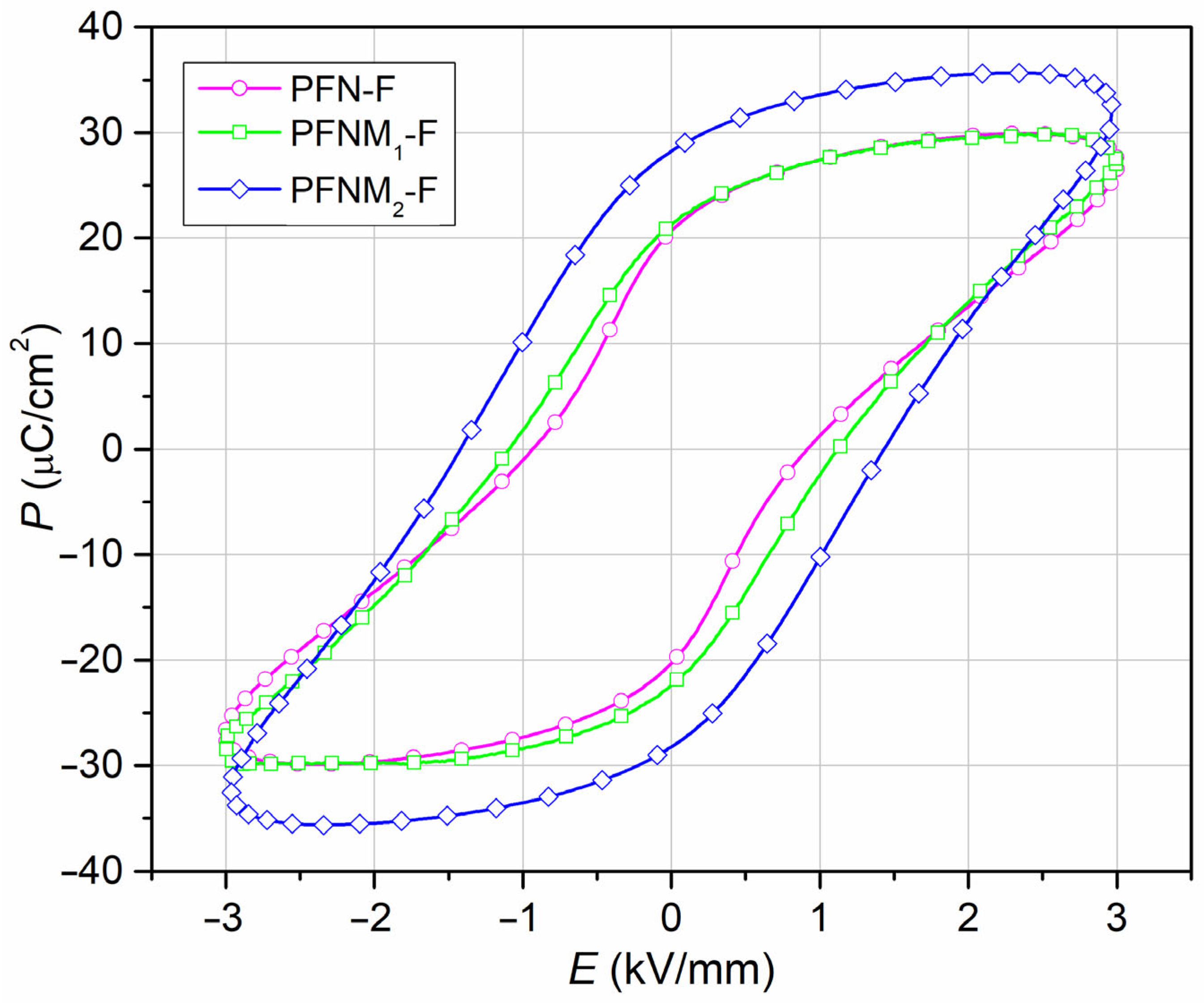

3.5. Ferroelectric Properties

3.6. Magnetic Properties

3.7. Piezoelectric Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kreisel, J.; Kenzelmann, M. Multiferroics—The challenge of coupling magnetism and ferroelectricity. Europhys. News 2009, 40, 17–20. [Google Scholar] [CrossRef]

- Spaldin, N.A. Multiferroics: Past, present, and future. MRS Bull. 2017, 42, 385–389. [Google Scholar] [CrossRef]

- Khomskii, D. Classifying multiferroics: Mechanisms and effects. Physics 2009, 2, 20. [Google Scholar] [CrossRef]

- Gruszka, I.; Kania, A.; Talik, E.; Szubka, M.; Miga, S.; Klimontko, J.; Suchanicz, J. Characterization of multiferroic PbFe0.5Nb0.5O3 and PbFe0.5Ta0.5O3 ceramics derived from citrate polymeric precursors. J. Am. Ceram. Soc. 2019, 102, 1296–1308. [Google Scholar] [CrossRef]

- Nan, C.-W.; Bichurin, M.I.; Dong, S.; Viehland, D.; Srinivasan, G. Multiferroic magnetoelectric composites: Historical perspective, status, and future directions. J. Appl. Phys. 2008, 103, 031101. [Google Scholar] [CrossRef]

- Surowiak, Z.; Bochenek, D.; Korzekwa, J. Ferroic smart materials. Electron. Telecommun. Q. 2007, 53, 193–219. [Google Scholar]

- Fiebig, M.; Lottermoser, T.; Meier, D.; Trassin, M. The evolution of multiferroics. Nat. Rev. 2016, 1, 16046. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, H.; Tan, W.; Huo, D. Magnetization reversal, critical behavior, and magnetocaloric effect in NdMnO3: The role of magnetic ordering of Nd and Mn moments. J. Appl. Phys. 2022, 132, 183907. [Google Scholar] [CrossRef]

- Lorenz, B. Hexagonal Manganites—(RMnO3): Class (I) Multiferroics with Strong Coupling of Magnetism and Ferroelectricity. ISRN Condens. Matter Phys. 2013, 2013, 497073. [Google Scholar] [CrossRef]

- Dong, S.; Liu, J.-M.; Cheong, S.-W.; Ren, Z. Multiferroic materials and magnetoelectric physics: Symmetry, entanglement, excitation, and topology. Adv. Phys. 2015, 64, 519–626. [Google Scholar] [CrossRef]

- Scott, J.F. Data storage: Multiferroic memories. Nat. Mater. 2007, 6, 256–257. [Google Scholar] [CrossRef] [PubMed]

- Bibes, M.; Barthélémy, A. Multiferroics: Towards a magnetoelectric memory. Nat. Mater. 2008, 7, 425–426. [Google Scholar] [CrossRef]

- Gajek, M.; Bibes, M.; Fusil, S.; Bouzehouane, K.; Fontcuberta, J.; Barthélémy, A.; Fert, A. Tunnel junctions with multiferroic barriers. Nat. Mater. 2007, 6, 296. [Google Scholar] [CrossRef] [PubMed]

- Valencia, S.; Crassous, A.; Bocher, L.; Garcia, V.; Moya, X.; Cherifi, R.O.; Deranlot, C.; Bouzehouane, K.; Fusil, S.; Zobelli, A.; et al. Interface-induced room-temperature multiferroicity in BaTiO3. Nat. Mater. 2011, 10, 753–758. [Google Scholar] [CrossRef] [PubMed]

- Kleemann, W.; Borisov, P.; Shvartsman, V.V.; Bedanta, S. Multiferroic and magnetoelectric materials –Developments and perspectives. EPJ Web Conf. 2012, 29, 00046. [Google Scholar] [CrossRef]

- Schmid, H. Multi-ferroic magnetoelectrics. Ferroelectrics 1994, 162, 317–338. [Google Scholar] [CrossRef]

- Hill, N.A. Why are there so few magnetic ferroelectrics? J. Phys. Chem. B 2000, 104, 6694–6709. [Google Scholar] [CrossRef]

- Gupta, A.; Huang, A.; Shannigrahi, S.; Chatterjee, R. Improved magnetoelectric coupling in Mn and Zn doped CoFe2O4–PbZr0.52Ti0.48O3 particulate composite. Appl. Phys. Lett. 2011, 98, 112901. [Google Scholar] [CrossRef]

- Pandya, R.J.; Sengunthar, P.; Zinzuvadiya, S.; Joshi, U.S. Investigation of magnetoelectric coupling effect in strongly ferroic oxide composites. Appl. Phys. A 2019, 125, 614. [Google Scholar] [CrossRef]

- Pradhan, D.K.; Puli, V.S.; Kumari, S.; Sahoo, S.; Das, P.T.; Pradhan, K.; Pradhan, D.K.; Scott, J.F.; Katiyar, R.S. Studies of phase transitions and magnetoelectric coupling in PFN-CZFO multiferroic composites. J. Phys. Chem. C 2016, 120, 1936–1944. [Google Scholar] [CrossRef]

- Sanchez, D.A.; Ortega, N.; Kumar, A.; Sreenivasulu, G.; Katiyar, R.S.; Scott, J.F.; Evans, D.M.; Arredondo-Arechavala, M.; Schilling, A.; Gregg, J.M. Room-temperature single phase multiferroic magnetoelectrics: Pb(Fe,M)x(Zr,Ti)(1−x)O3 [M=Ta, Nb]. J. Appl. Phys. 2013, 113, 074105. [Google Scholar] [CrossRef]

- Venkata Ramana, M.; Ramamanohar Reddy, N.; Siva Kumar, K.V.; Murthy, V.R.K.; Murty, B.S. Magneto-electric effect in multiferroic Ni0.93Co0.02Mn0.05Fe1.95O4−PbZr0.52Ti0.48O3 particulate composites: Dielectric, piezoelectric properties. Mod. Phys. Lett. B 2011, 25, 345–358. [Google Scholar] [CrossRef]

- Duan, C.-G.; Jaswal, S.S.; Tsymbal, E.Y. Predicted magnetoelectric effect in Fe/BaTiO3 multilayers: Ferroelectric control of magnetism. Phys. Rev. Lett. 2006, 97, 047201. [Google Scholar] [CrossRef] [PubMed]

- Trassin, M. Low energy consumption spintronics using multiferroic heterostructures. J. Phys. Condens. Matter 2016, 28, 033001. [Google Scholar] [CrossRef] [PubMed]

- Heron, J.T.; Schlom, D.G.; Ramesh, R. Electric field control of magnetism using BiFeO3-based heterostructures. Appl. Phys. Rev. 2014, 1, 021303. [Google Scholar] [CrossRef]

- Tahmasebi, K.; Barzegar, A. Multiferroic thin film composite of Pb(Zr0:52Ti0:48)O3 and Co-50%Fe alloy. Trans. F Nanotechnol. 2010, 17, 108–112. [Google Scholar]

- Yang, Y.; Infante, I.C.; Dkhil, B.; Bellaiche, L. Strain, effects on multiferroic BiFeO3 films. Comptes Rendus Phys. 2015, 16, 193–203. [Google Scholar] [CrossRef]

- Sando, D.; Barthélémy, A.; Bibes, M. BiFeO3 epitaxial thin films and devices: Past, present and future. J. Phys. Condens. Matter 2014, 26, 473201. [Google Scholar] [CrossRef]

- Bochenek, D.; Niemiec, P. Ferroelectromagnetic properties of the PFN material synthesized by chemical-wet technology. Materials 2018, 11, 2504. [Google Scholar] [CrossRef] [PubMed]

- Gao, X.; Xue, J.; Wang, J.; Yu, T.; Shen, Z.X. Sequential combination of constituent oxides in the synthesis of Pb(Fe1/2Nb1/2)O3 by mechanical activation. J. Am. Ceram. Soc. 2002, 85, 565–572. [Google Scholar] [CrossRef]

- Raymond, O.; Font, R.; Suárez-Almodovar, N.; Portelles, J.; Siqueiros, J.M. Frequency-temperature response of ferroelectromagnetic PbFe1/2Nb1/2O3 ceramics obtained by different precursors. Part I. Structural and thermo-electrical characterization. J. Appl. Phys. 2005, 97, 084107. [Google Scholar] [CrossRef]

- Bochenek, D. Relations between physical properties of the biferroic Pb(Fe1−xNbx)O3 ceramics and their composition change. Eur. Phys. J.-Spec. Top. 2008, 154, 15–18. [Google Scholar] [CrossRef]

- Iwanov, O.N.; Skriptchenko, E.A.; Pryakhina, M.E. Elastic and anelastic properties of the ceramics PbFe0.5Nb0.5O3: Anomalies near TC and TN. Ferroelectrics 2004, 298, 145–151. [Google Scholar] [CrossRef]

- Bochenek, D.; Dudek, J. Influence of the processing conditions on the properties of the biferroic Pb(Fe1/2Nb1/2)O3 ceramics. Eur. Phys. J. Spec. Top. 2008, 154, 19–22. [Google Scholar] [CrossRef]

- Bhat, V.V.; Ramanujachary, K.V.; Lofand, S.E.; Umarji, A.M. Tuning the multiferroic properties of Pb(Fe1/2Nb1/2)O3 by cationic substitution. J. Magn. Magn. Mater. 2004, 280, 221–226. [Google Scholar] [CrossRef]

- Fang, B.-J.; Ding, C.-L.; Liu, W.; Li, L.-Q.; Tang, L. Preparation and electrical properties of high-Curie temperature ferroelectrics. Eur. Phys. J. Appl. Phys. 2009, 45, 20302. [Google Scholar] [CrossRef]

- Raymond, O.; Font, R.; Suarez, N.; Portalles, J.; Siqueiros, J.M. Effects of two kinds of FeNbO4 precursors in the obtainment and dielectric properties of PFN ceramics. Ferroelectrics 2003, 294, 141–154. [Google Scholar]

- Singh, K.; Band, S.A.; Kinge, W.K. Effect of sintering temperature on dielectric properties of Pb(Fe1/2Nb1/2)O3 perovskite material. Ferroelectrics 2004, 306, 179–185. [Google Scholar] [CrossRef]

- Wang, J.T.; Zhang, C. Magnetic field effect on dielectric properties of Pb(Fe1/2Nb1/2)O3 (PFN). Ferroelectrics 2004, 301, 211–214. [Google Scholar] [CrossRef]

- Majumder, S.B.; Bhattacharyya, S.; Katiyar, R.S.; Manivannan, A.; Dutta, P.; Seehra, M.S. Dielectric and magnetic properties of sol-gel-derived lead iron niobate ceramics. J. Appl. Phys. 2006, 99, 024108. [Google Scholar] [CrossRef]

- Raymond, O.; Font, R.; Portelles, J.; Siqueiros, J.M. Magnetoelectric coupling study in multiferroic Pb(Fe0.5Nb0.5)O3 ceramics through small and large electric signal standard measurements. J. Appl. Phys. 2011, 109, 094106. [Google Scholar] [CrossRef]

- Blinc, R.; Cevc, P.; Zorko, A.; Holc, J.; Kosec, M.; Trontelj, Z.; Pirnat, J.; Dalal, N.; Ramachandran, V.; Krzystek, J. Electron paramagnetic resonance of magnetoelectric PbFe1/2Nb1/2O3. J. Appl. Phys. 2007, 101, 033901. [Google Scholar] [CrossRef]

- Lee, B.-H.; Kim, N.-K.; Kim, J.-J.; Cho, S.-H. Dielectric characteristics of Pb[Fe1/2(Ta,Nb)1/2]O3 perovskite ceramic system. J. Korean Phys. Soc. 1998, 32, S978–S980. [Google Scholar]

- Bochenek, D.; Kruk, P.; Skulski, R.; Wawrzała, P. Multiferroic ceramics Pb(Fe1/2Nb1/2)O3 doped by Li. J. Electroceram. 2011, 26, 8–13. [Google Scholar] [CrossRef]

- Kozielski, L.; Bochenek, D. Characterization of energy conversion of multiferroic PFN and PFN:Mn. Process. Appl. Ceram. 2013, 7, 167–173. [Google Scholar] [CrossRef]

- Fang, B.; Shan, Y.; Imoto, H. Charge compensation mechanism decreases dielectric loss in manganese-doped Pb(Fe1/2Nb1/2)O3 ceramics. Jpn. J. Appl. Phys. 2004, 43, 2568–2571. [Google Scholar] [CrossRef]

- Rani, J.; Yadav, K.L.; Prakash, S. Enhanced magnetodielectric effect and optical property of lead-free multiferroic (1-x)(Bi0.5Na0.5)TiO3/xCoFe2O4 composites. Mater. Chem. Phys. 2014, 147, 1184–1190. [Google Scholar] [CrossRef]

- Xu, R.; Wang, Z.; Gao, R.; Zhang, S.; Zhang, Q.; Li, Z.; Li, C.; Chen, G.; Deng, X.; Cai, W.; et al. Effect of molar ratio on the microstructure, dielectric and multiferroic properties of Ni0.5Zn0.5Fe2O4-Pb0.8Zr0.2TiO3 nanocomposite. J. Mater. Sci. Mater. Electron. 2018, 29, 16226–16237. [Google Scholar] [CrossRef]

- Gao, R.; Qin, X.; Zhang, Q.; Xu, Z.; Wang, Z.; Fu, C.; Chen, G.; Deng, X.; Cai, W. Enhancement of magnetoelectric properties of (1-x)Mn0.5Zn0.5Fe2O4-xBa0.85Sr0.15Ti0.9Hf0.1O3 composite ceramics. J. Alloys Compd. 2019, 795, 501–512. [Google Scholar] [CrossRef]

- Zhang, H.; Mak, C.-L. Impedance spectroscopic characterization of fine-grained magnetoelectric Pb(Zr0.53Ti0.47)O3- (Ni0.5Zn0.5)Fe2O4 ceramic composites. J. Alloys Compd. 2012, 513, 165–171. [Google Scholar] [CrossRef]

- Bochenek, D.; Surowiak, Z. Influence of admixtures on the properties of biferroic Pb(Fe0.5Nb0.5)O3 ceramics. Phys. Status Solidi A 2009, 206, 2857–2865. [Google Scholar] [CrossRef]

- Seidel, J.; Martin, L.W.; He, Q.; Zhan, Q.; Chu, Y.-H.; Rother, A.; Hawkridge, M.E.; Maksymovych, P.; Yu, P.; Gajek, M.; et al. Conduction at domain walls in oxide multiferroics. Nat. Mater. 2009, 8, 229–234. [Google Scholar] [CrossRef] [PubMed]

- Ananta, S.; Thomas, N.W. Relationships between sintering conditions, microstructure and dielectric properties of Lead Iron Niobate. J. Eur. Ceram. Soc. 1999, 19, 1873–1881. [Google Scholar] [CrossRef]

- Lee, S.-B.; Yoon, S.-H.; Kim, H. Positive temperature coefficient of resistivity in Pb(Fe1/2Nb1/2)O3 ceramics. J. Eur. Ceram. Soc. 2004, 24, 2465–2470. [Google Scholar] [CrossRef]

- Wójcik, K.; Zieleniec, K.; Milata, M. Electrical properties of Lead Iron Niobate PFN. Ferroelectrics 2003, 289, 107–120. [Google Scholar] [CrossRef]

- Chougule, S.S.; Patil, D.R.; Chougule, B.K. Electrical conduction and magnetoelectric effect in ferroelectric rich (x)Ni0.9Zn0.1Fe2O4-(1-x)PZT ME composites. J. Alloys Compd. 2008, 452, 205–209. [Google Scholar] [CrossRef]

- Chakravarty, R.; Parida, R.K.; Parida, B.N. Dielectric and Impedance study of ‘Ca’ doped BaFe0.5Nb0.5O3 complex perovskite. Appl. Phys. A 2022, 128, 647. [Google Scholar] [CrossRef]

- Bochenek, D.; Niemiec, P.; Skulski, R.; Adamczyk, M.; Brzezińska, D. Electrophysical properties of the multicomponent PBZT-type ceramics doped by Sn4+. J. Electroceram. 2019, 42, 17–30. [Google Scholar] [CrossRef]

- Iqbal, M.J.; Farooq, S. Enhancement of electrical resistivity of Sr0.5Ba0.5Fe12O19 nanomaterials by doping with lanthanum and nickel. Mater. Chem. Phys. 2009, 118, 308–313. [Google Scholar] [CrossRef]

- Gao, Z.; Pu, Y.; Yao, M.; Jin, Q.; Wang, Y.; Zheng, H. Superior electromagnetic properties obtained by enhanced resistivity on multiferroic barium titanate and hexaferrite di-phase composite ceramics. Ceram. Int. 2017, 43, S85–S91. [Google Scholar] [CrossRef]

- Barick, B.K.; Mishra, K.K.; Arora, A.K.; Choudhary, R.N.P.; Pradhan, D.K. Impedance and Raman spectroscopic studies of (Na0.5Bi0.5)TiO3. J. Phys. D Appl. Phys. 2011, 44, 355402. [Google Scholar] [CrossRef]

- Nayak, P.; Badapanda, T.; Singh, A.K.; Panigrahi, S. An approach for correlating the structural and electrical properties of Zr4+- modified SrBi4Ti4O15/SBT ceramic. RSC Adv. 2017, 7, 16319. [Google Scholar] [CrossRef]

- Zhang, T.F.; Tang, X.G.; Liu, Q.X.; Jiang, Y.P.; Huang, X.X.; Zhou, Q.F. Energy-storage properties and high-temperature dielectric relaxation behaviors of relaxor ferroelectric Pb(Mg1/3Nb2/3)O3–PbTiO3 ceramics. J. Phys. D Appl. Phys. 2016, 49, 095302. [Google Scholar] [CrossRef]

- Elissalde, C.; Ravez, J. Ferroelectric ceramics: Defects and dielectric relaxations. J. Mater. Chem. 2001, 11, 1957–1967. [Google Scholar] [CrossRef]

- Natarajan, R.; Dougherty, J.P. Role of Mn in controlling the dielectric loss and ageing effect in Pb(Zn1/3Nb2/3)O3–Pb(Fe2/3W1/3)O3–Pb(Fe1/2Nb1/2)O3. J. Mater. Sci. 1998, 33, 1991–1995. [Google Scholar] [CrossRef]

- Bobić, J.D.; Ivanov, M.; Ilić, N.I.; Dzunuzović, A.S.; Vijatović Petrović, M.M.; Banys, J.; Ribic, A.; Despotovic, Z.; Stojanovic, B.D. PZT-nickel ferrite and PZT-cobalt ferrite comparative study: Structural, dielectric, ferroelectric and magnetic properties of composite ceramics. Ceram. Int. 2018, 44, 6551–6557. [Google Scholar] [CrossRef]

- Kulawik, J.; Szwagierczak, D.; Gröger, B. Investigations of properties of ceramic materials with perovskite structure in chosen electronic applications. Bull. Pol. Acad. Sci. Tech. Sci. 2007, 55, 293–297. [Google Scholar]

- Curecheriu, L.; Postolache, P.; Buscaglia, V.; Horchidan, N.; Alexe, M.; Mitoseriu, L. BaTiO3–ferrite composites with magnetocapacitance and hard/soft magnetic properties. Phase Transit. 2013, 86, 670–680. [Google Scholar] [CrossRef]

- Testino, A.; Mitoseriu, L.; Buscaglia, V.; Buscaglia, M.T.; Pallecchi, I.; Albuquerque, A.S.; Calzona, V.; Marr’e, D.; Siri, A.S.; Nanni, P. Preparation of multiferroic composites of BaTiO3–Ni0.5Zn0.5Fe2O4 ceramics. J. Eur. Ceram. Soc. 2006, 26, 3031–3036. [Google Scholar] [CrossRef]

- Bochenek, D.; Niemiec, P.; Wawrzała, P.; Chrobak, A. Multiferroic ceramic composites based on PZT type ceramic and NiZnFe. Ferroelectrics 2013, 448, 96–105. [Google Scholar] [CrossRef]

- Udeshi, M.; Katba, S.V.; Ravalia, A.; Vagadia, M. Studies on the dielectric behavior of Cu-doped NdMnO3. AIP Conf. Proc. 2014, 1591, 1303–1305. [Google Scholar]

- Somvanshi, A.; Husain, S. Study of structural, dielectric and optical properties of NdMnO3. AIP Conf. Proc. 2018, 3, 030242. [Google Scholar]

- Shankar, S.; Thakur, O.P.; Jayasimhadri, M. Strong enhancement in structural, dielectric, impedance and magnetoelectric properties of NdMnO3-BaTiO3 multiferroic composites. Mater. Chem. Phys. 2021, 270, 124856. [Google Scholar] [CrossRef]

- Ghosh, B.; Sardar, M.; Banerjee, S. Effect of antisite formation on magnetic properties of nickel zinc ferrite particles. J. Appl. Phys. 2013, 114, 183903. [Google Scholar] [CrossRef]

| PFN-F | PFNM1-F | PFNM2-F | |

|---|---|---|---|

| ρ (g/cm3) | 7.62 | 7.64 | 7.66 |

| ρDC at RT (Ωm) | 5.2 × 107 | 1.2 × 108 | 1.8 × 108 |

| MS (Am2/kg) at −268 °C | 6.34 | 6.74 | 7.02 |

| MS (Am2/kg) 1 | 5.71 | 6.01 | 6.32 |

| Mmax | 7.92 | 8.85 | 9.03 |

| ε 1 | 2750 | 2350 | 1530 |

| Tm (°C) | 99 | 96 | 92 |

| εm | 18,570 | 11,220 | 8320 |

| tanδ 1 | 0.065 | 0.089 | 0.097 |

| tanδ at Tm | 0.077 | 0.195 | 0.191 |

| Ea (eV) | 0.58 | 0.87 | 0.80 |

| Pr (µC/cm2) 1,2 | 20.63 | 21.25 | 28.24 |

| Ec (kV/mm) 1,2 | 0.92 | 1.11 | 1.43 |

| d33 (pC/N) 1 | 53 | 78 | 67 |

| kp 1 | 0.28 | 0.33 | 0.34 |

| d31 (pC/N) 1 | 29 | 45 | 42 |

| Qm 1 | 427 | 123 | 72 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bochenek, D.; Chrobak, A.; Ziółkowski, G. Electric and Magnetic Properties of the Multiferroic Composites Made Based on Pb(Fe1/2Nb1/2)1−xMnxO3 and the Nickel-Zinc Ferrite. Materials 2023, 16, 3785. https://doi.org/10.3390/ma16103785

Bochenek D, Chrobak A, Ziółkowski G. Electric and Magnetic Properties of the Multiferroic Composites Made Based on Pb(Fe1/2Nb1/2)1−xMnxO3 and the Nickel-Zinc Ferrite. Materials. 2023; 16(10):3785. https://doi.org/10.3390/ma16103785

Chicago/Turabian StyleBochenek, Dariusz, Artur Chrobak, and Grzegorz Ziółkowski. 2023. "Electric and Magnetic Properties of the Multiferroic Composites Made Based on Pb(Fe1/2Nb1/2)1−xMnxO3 and the Nickel-Zinc Ferrite" Materials 16, no. 10: 3785. https://doi.org/10.3390/ma16103785