Effect of Heat Treatment on the Microstructure and Mechanical Properties of 18Ni-300 Maraging Steel Produced by Additive–Subtractive Hybrid Manufacturing

Abstract

:1. Introduction

| Heat Treatment Conditions at Peak Properties | Process | Hardness | UTS (MPa) | El. (%) | Ref. |

|---|---|---|---|---|---|

| STA (816 °C for 0.5 h + aging 482 °C for 3 h) | Wrought | - | 1944 | 7 | [29] |

| STA (820 °C for 1 h + aging 490 °C for 6 h) | 656 HV0.5 | 2102 | 2 | [10] | |

| STA (820 °C for 1 h + aging 500 °C for 6 h) | 1906 | - | [5] | ||

| STA (750 °C for 2 h + aging 450 °C for 6 h) DA (450 °C for 6 h) | LPBF | 595 HV0.1 598 HV0.1 | 1812 2060 | 1.7 2.6 | [17] |

| STA (820 °C for 1 h + aging 460 °C for 5 h) DA (460 °C for 5 h) | 618 HV2 609 HV2 | 2033 - | 5.27 - | [16] | |

| STA (820 °C for 1 h + aging 500 °C for 6 h) DA (500 °C for 6 h) | - - | 1970 1858 | - - | [5] | |

| STA (840 °C for 2 h + aging 490 °C for 2 h) DA (490 °C for 2 h) | 543 HV0.5 523 HV0.5 | 1790 1820 | 3.5 2 | [18] | |

| STA (840 °C for 1 h + aging 490 °C for 6 h) DA (490 °C for 6 h) | 53.5 HRC 54.6 HRC | 1943 2014 | 5.6 3.3 | [14] | |

| STA (900 °C for 1 h + aging 520 °C for 6 h) DA (520 °C for 6 h) | 665 HV0.2 654 HV0.2 | 2080 2126 | 5.3 6.5 | [31] | |

| STA (1000 °C for 1 h + aging 480 °C for 6 h) DA (480 °C for 6 h) | - - | 1996 2021 | 1.7 3.7 | [7] | |

| DA (500 °C for 3 h) | ASHM | 56.2 HRC | - | - | [28] |

2. Experimental Procedure

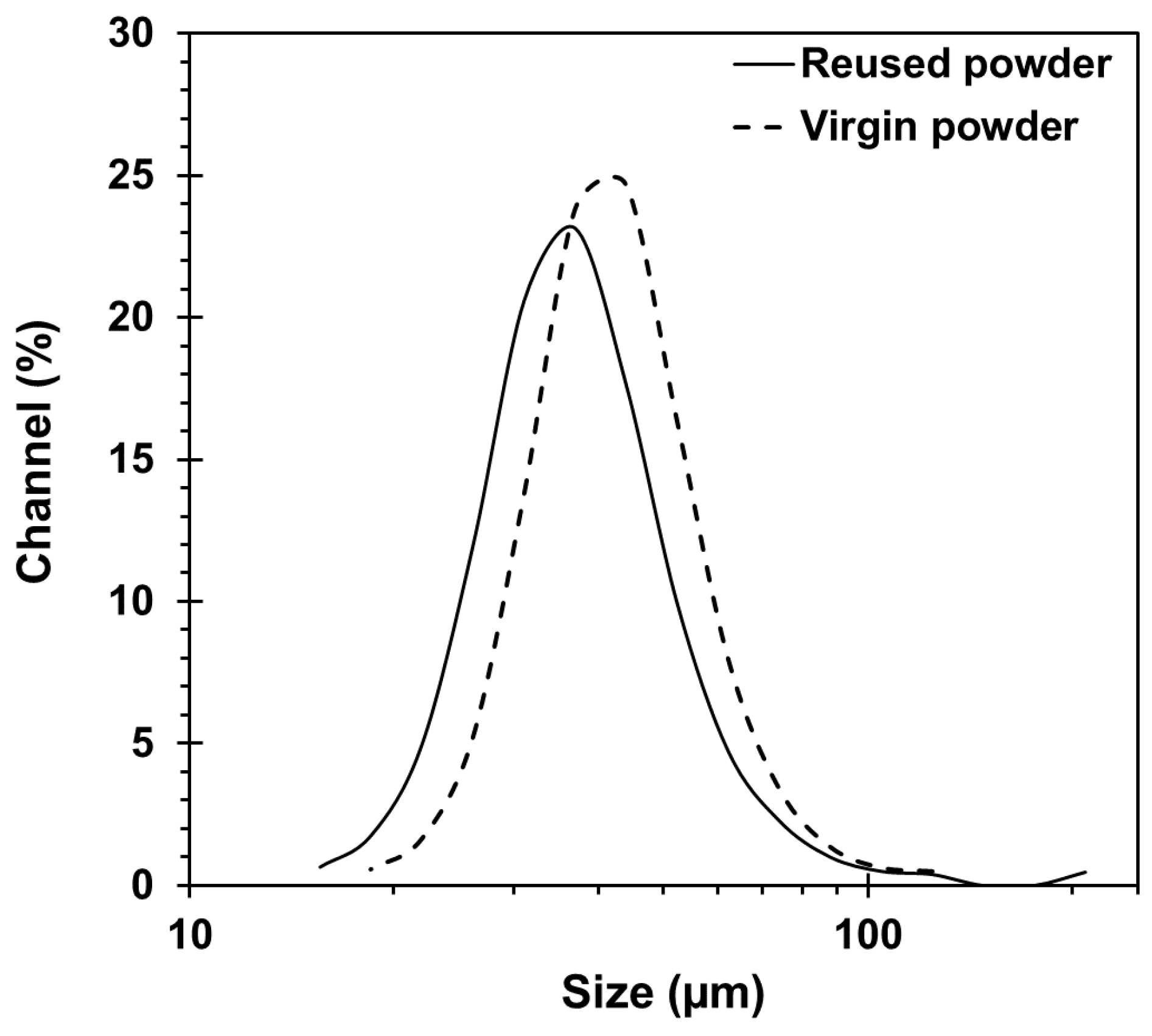

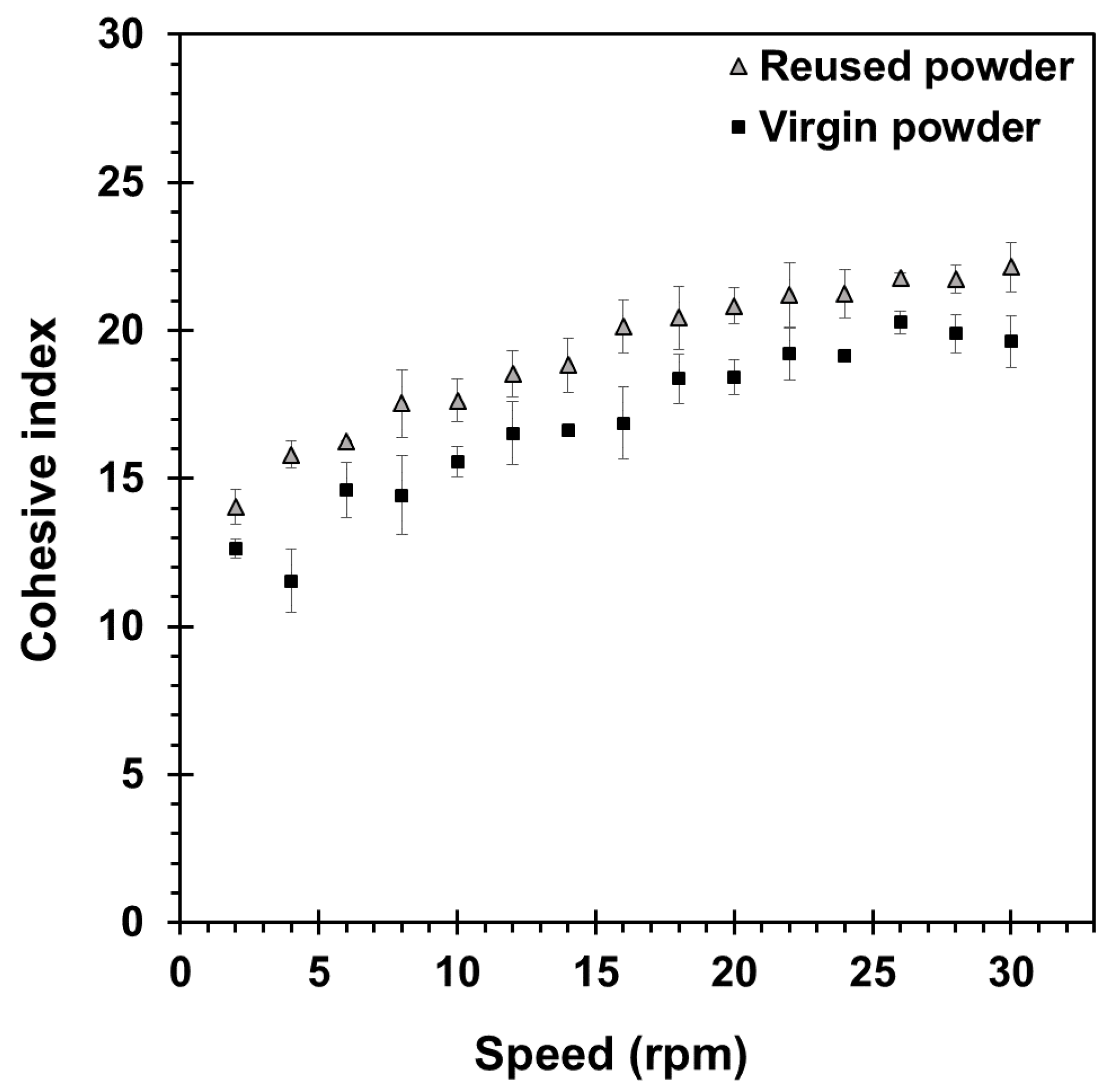

2.1. Powder Characterization

2.2. Sample Fabrication

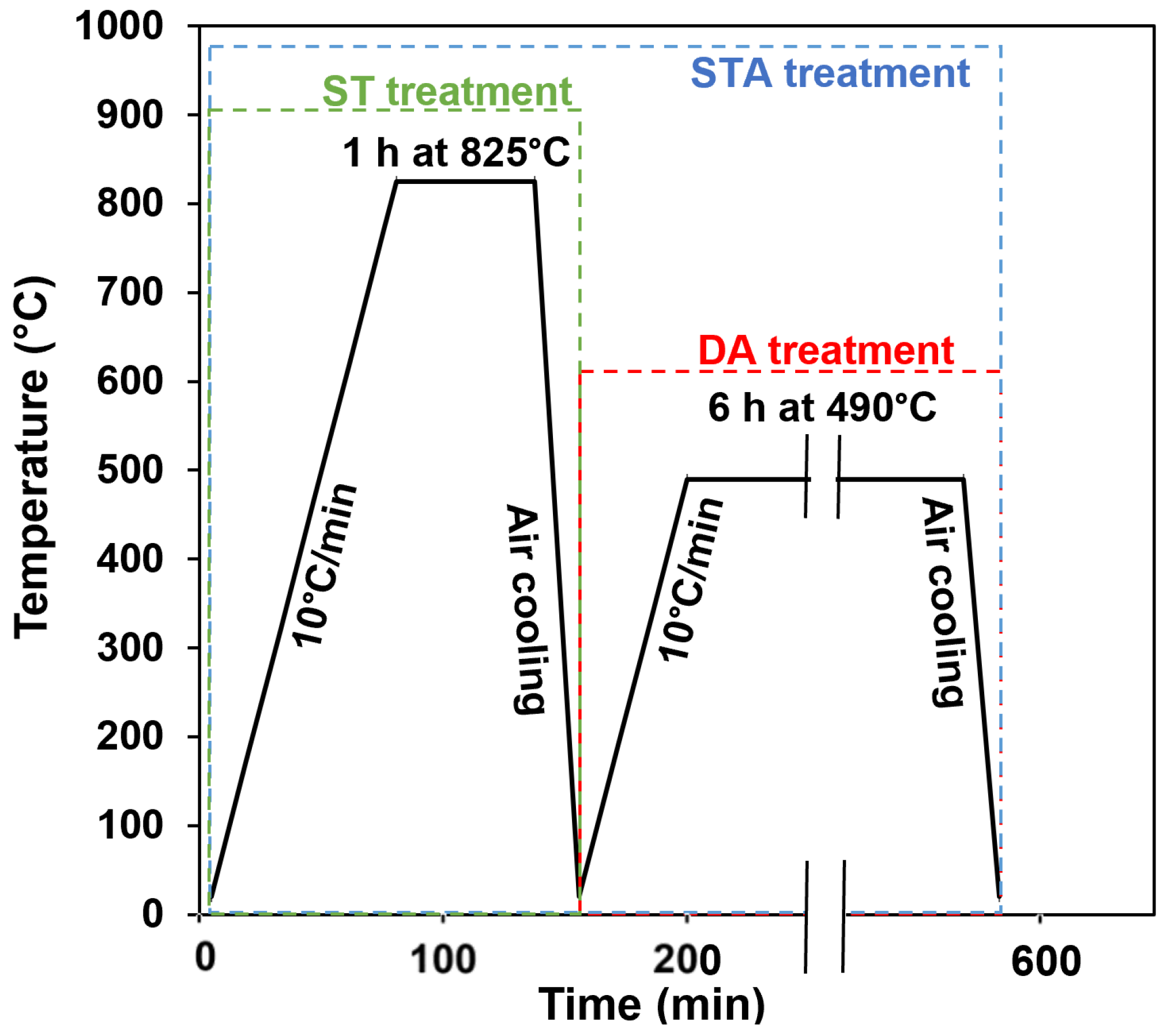

2.3. Heat Treatments

2.4. Materials Characterization and Testing

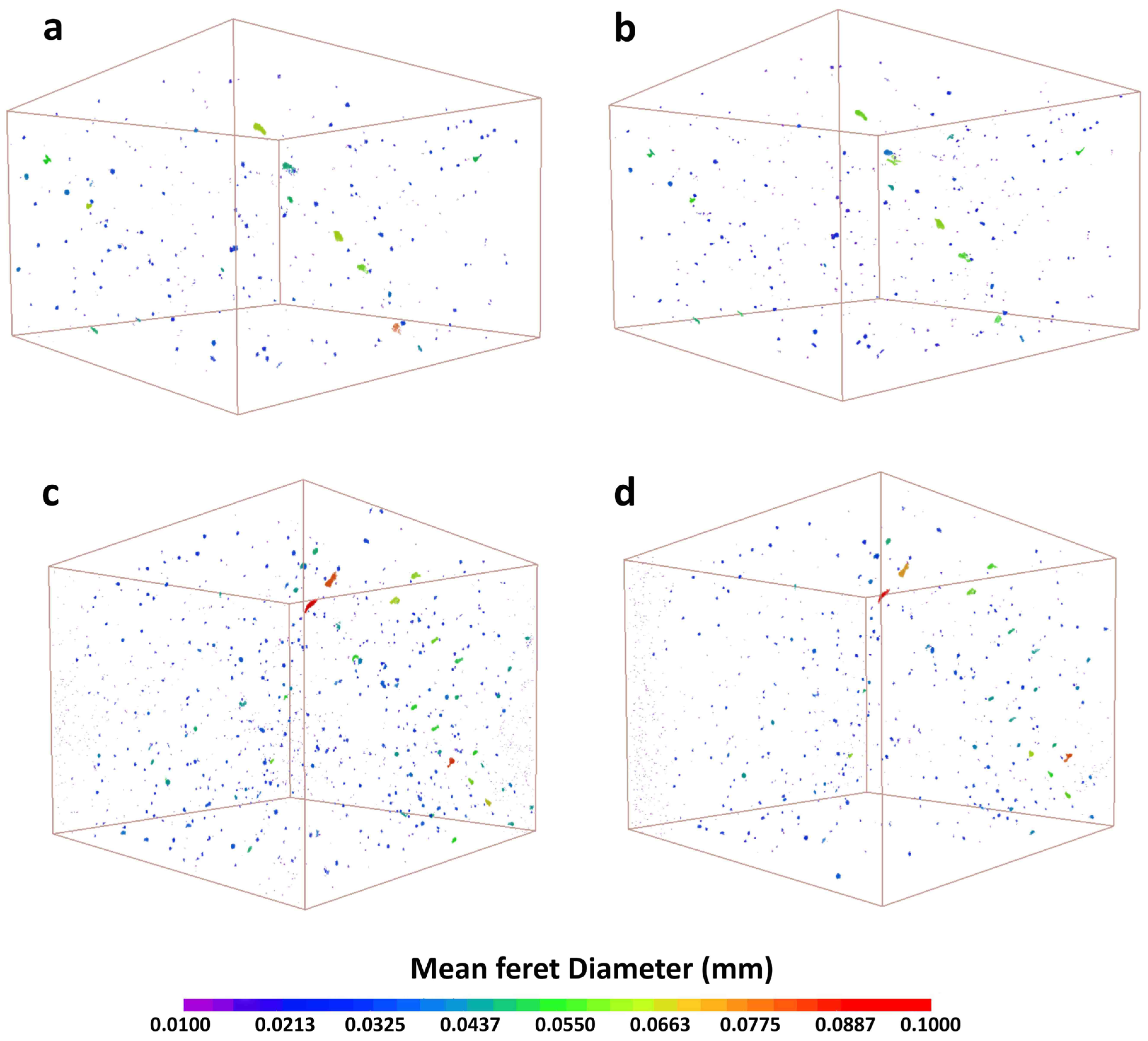

2.4.1. Microporosity Measurements

2.4.2. Microstructural Characterization

2.4.3. Mechanical Testing

3. Results

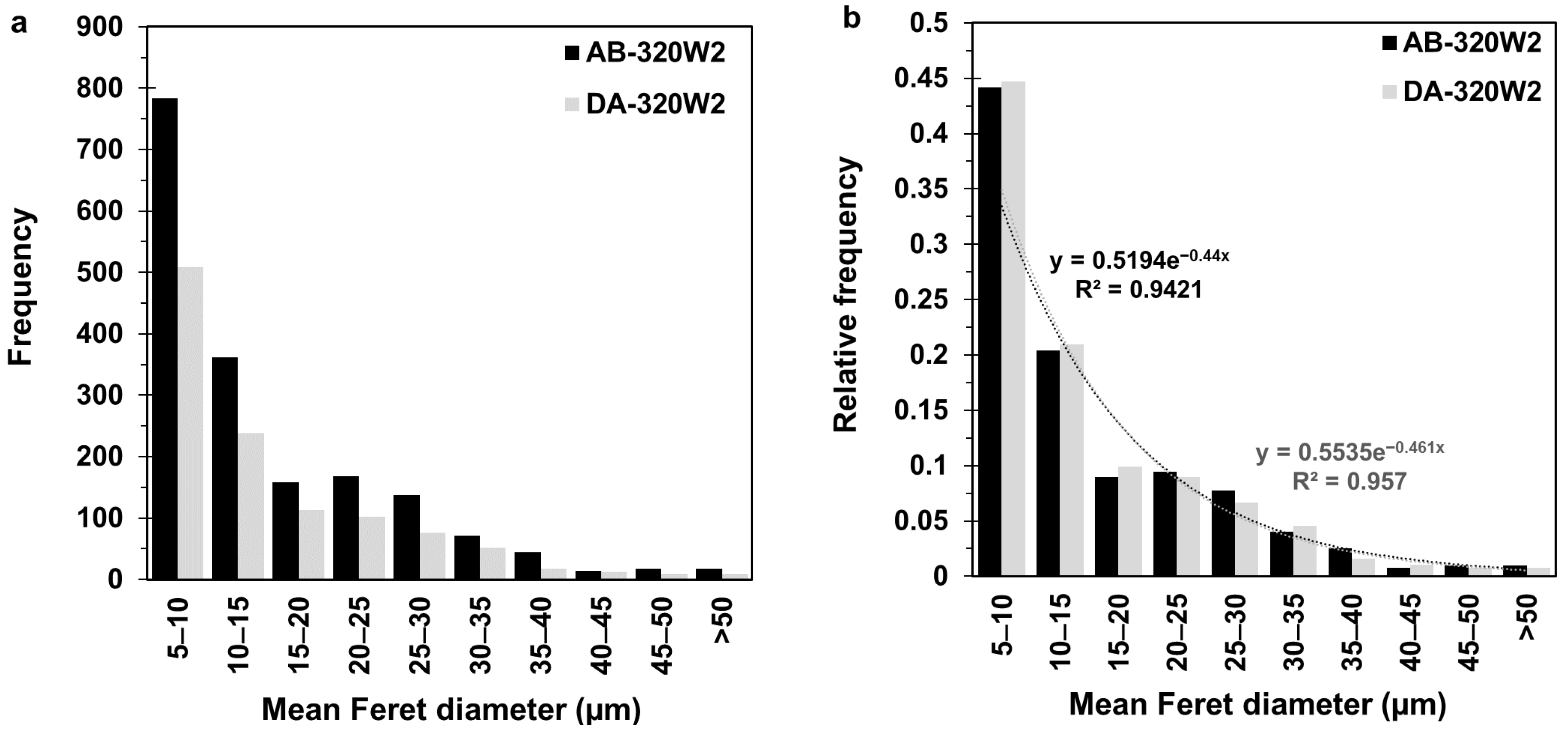

3.1. Microporosity Characterization

3.2. Microstructure Characterization

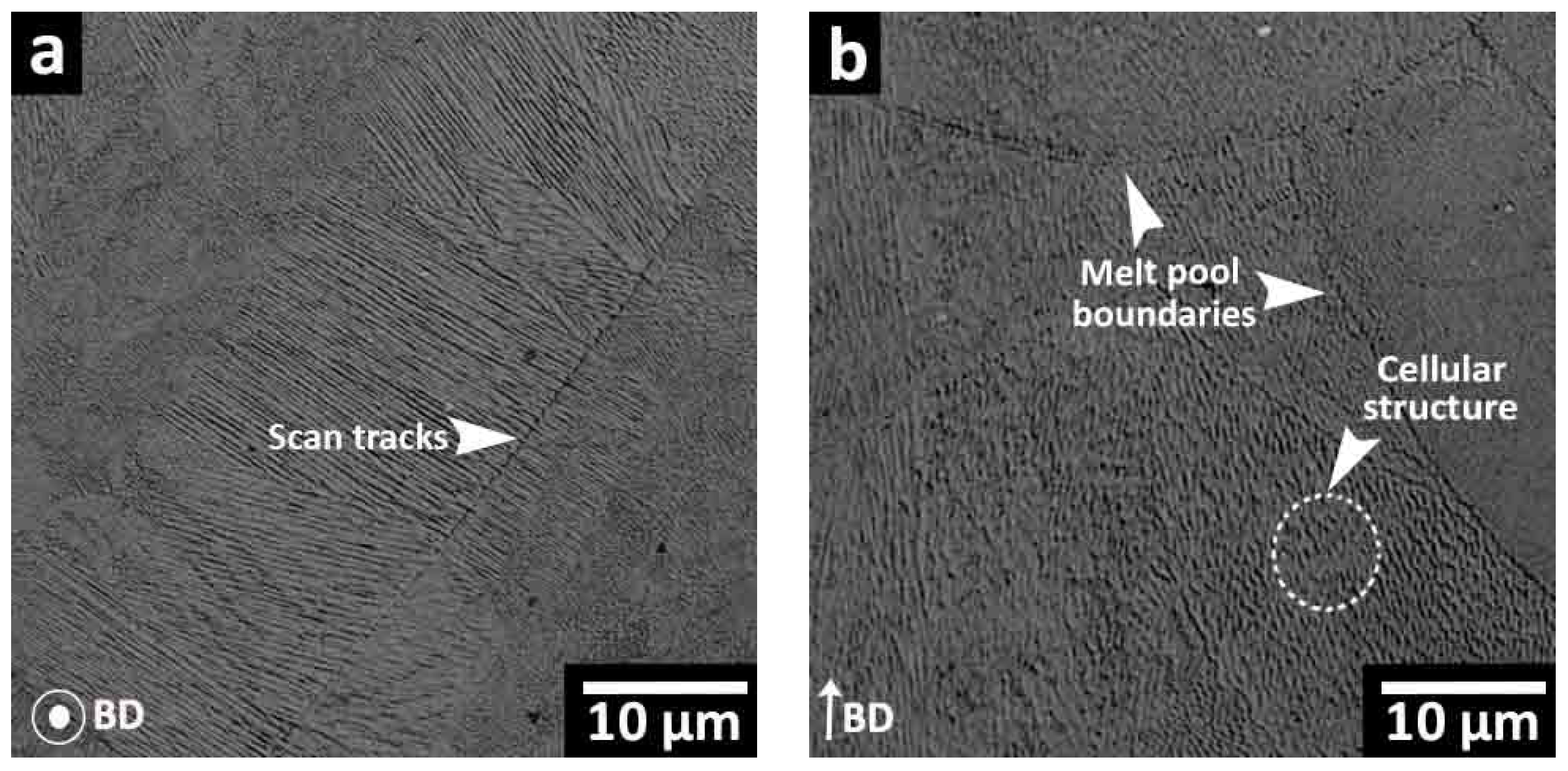

3.2.1. As-Built (AB) Conditions

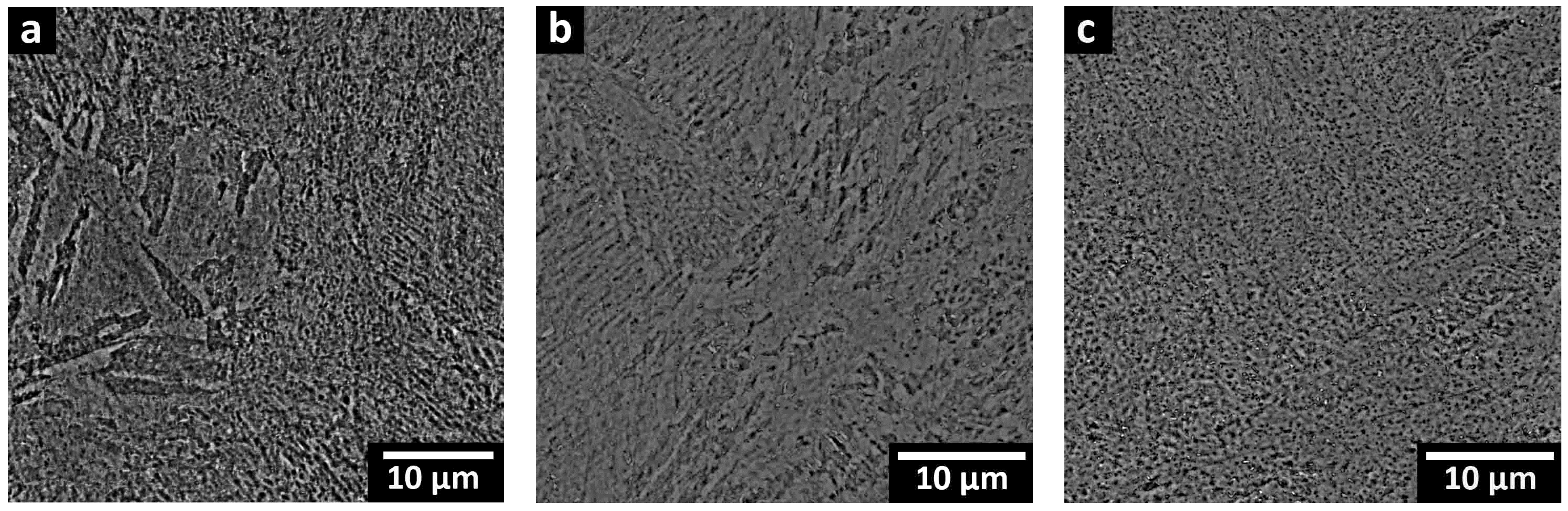

3.2.2. Solution-Treated + Aged (STA) Condition

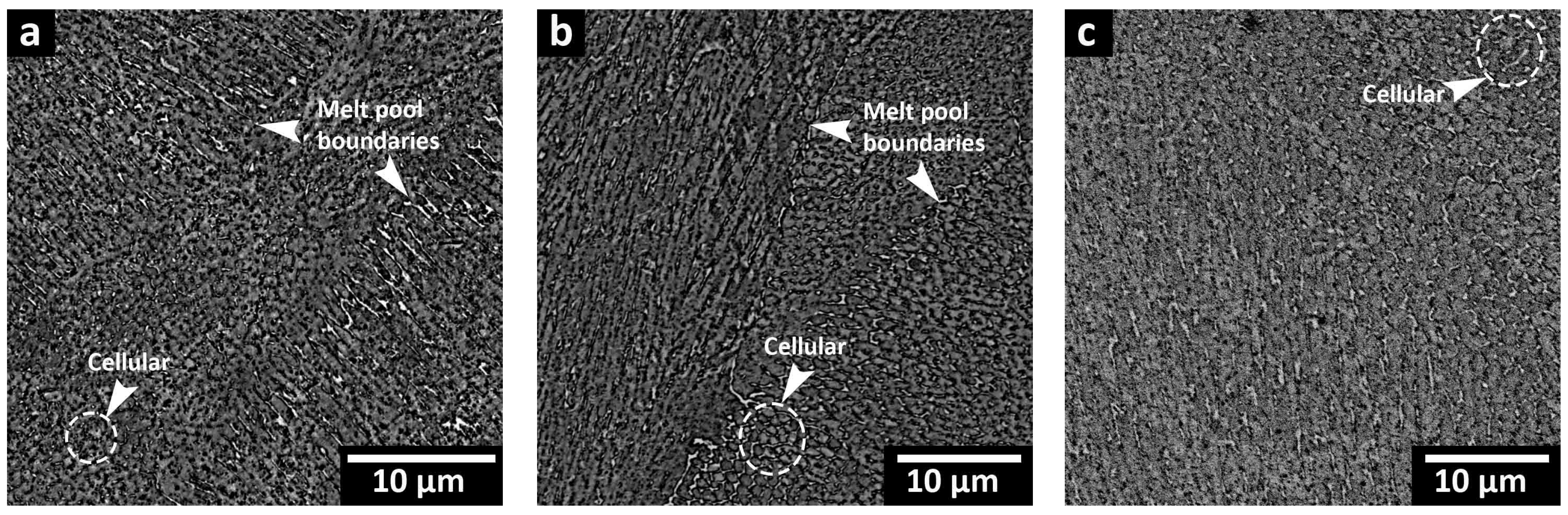

3.2.3. Direct Aging (DA) Condition

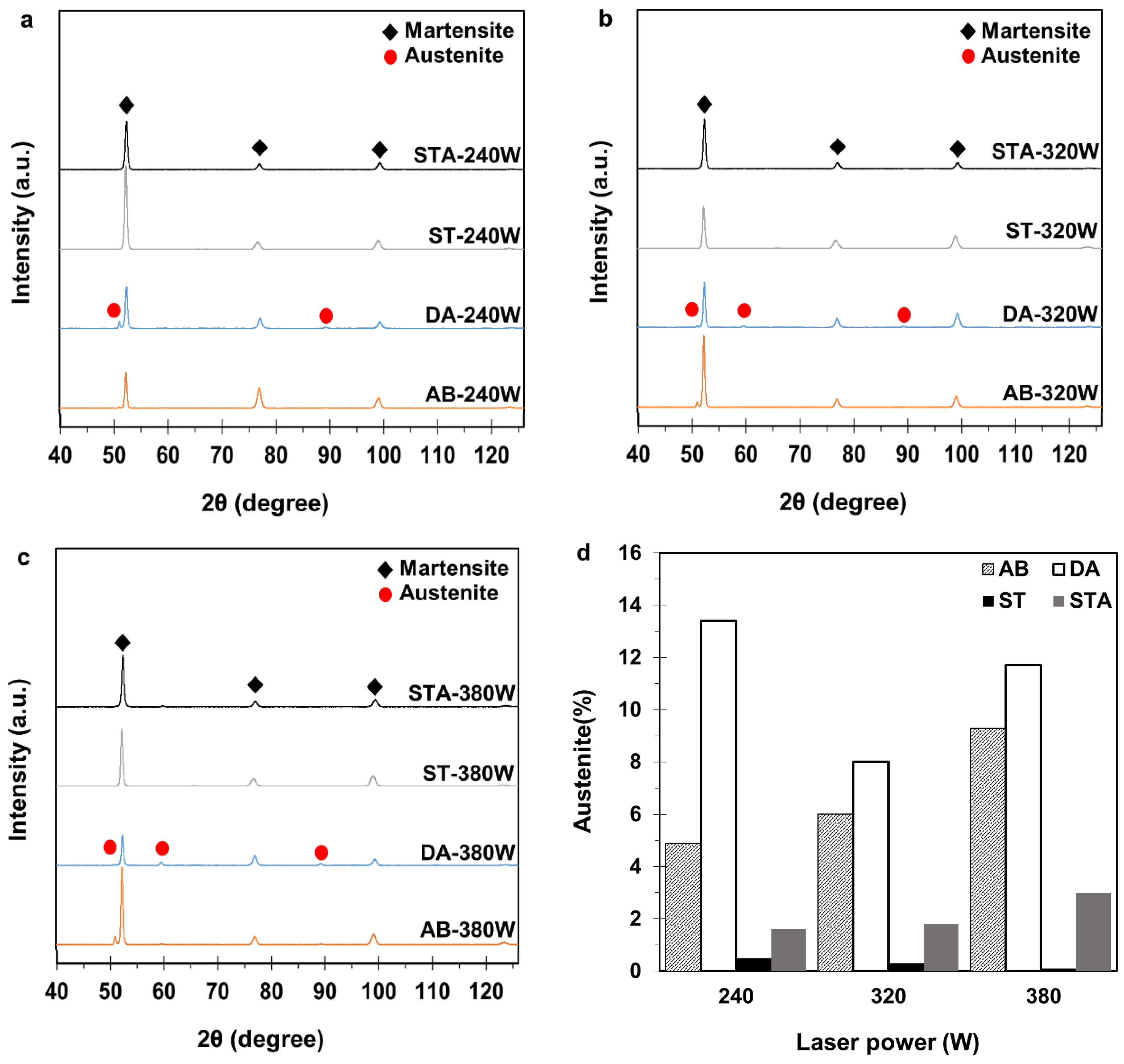

3.3. Phase Analysis

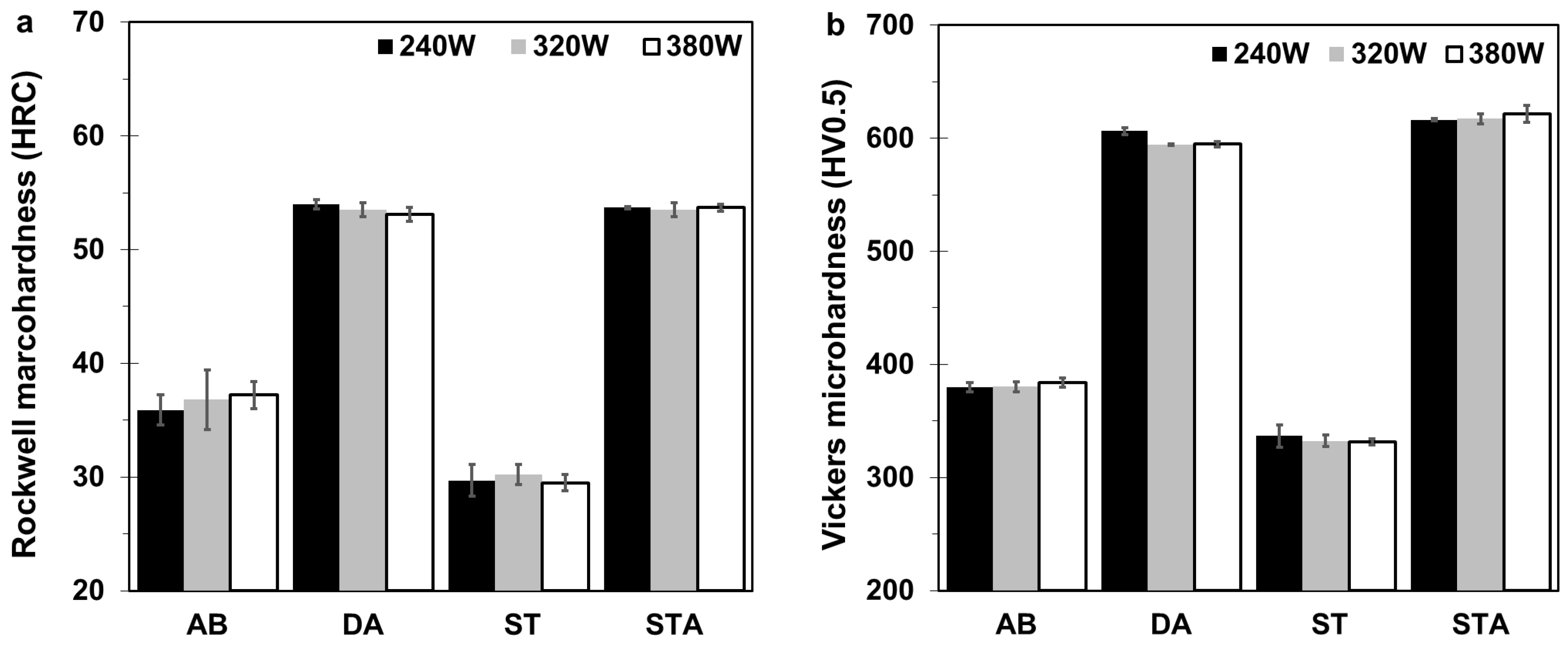

3.4. Macro- and Micro-Hardness

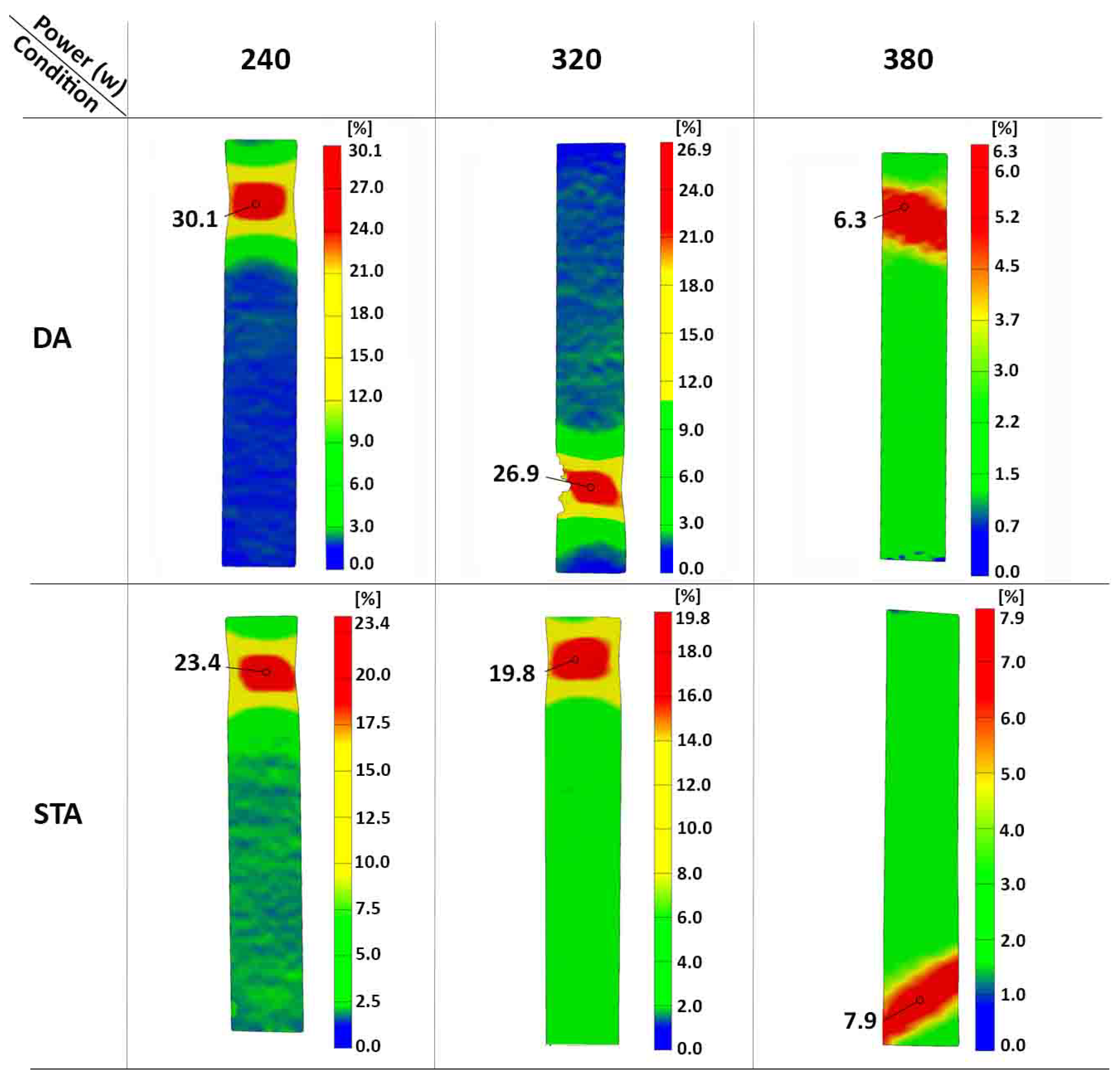

3.5. Tensile Properties

4. Discussion and Future Work

4.1. Microstructural Evolution

4.2. Mechanical Properties

5. Conclusions

- Neither the STA nor DA heat treatments had any significant effect on the porosity of 300 MS produced by ASHM at the different laser powers studied.

- DA at 490 °C for 6 h yielded a similar microstructure to the as-built (AB) samples, with partial dissolution of the cellular substructures into shorter fragments due to the precipitation of Ni intermetallic compounds. ST at 825 °C for 1 h was insufficient for full microstructural homogenization; thus, 300 MS in the STA condition still featured minor traces of cellular substructures within the matrix.

- Compared to the AB samples, DA increased the austenite content up to 13.4% due to the reversion of martensite into austenite, stabilized by Ni micro-segregation in the AB conditions, while ST and STA samples exhibited almost fully martensitic microstructures.

- The macro- and micro-hardness responses of STA (54 HRC and 618 HV0.5) and DA (54 HRC and 606 HV0.5) samples were comparable, where the low fraction of reverted austenite in DA samples did not significantly influence the hardness measurements.

- The reverted austenite in DA samples marginally reduced the YS and UTS by ~7% compared to the STA samples, while enhancing the ductility by up to ~34% through transformation-induced plasticity (TRIP) effects. This ductility enhancement could be triggered at the highest reverted austenite content of ~13.4% in the present study.

- The microstructural and mechanical performance of heat-treated 300 MS produced by ASHM was found to be comparable to those produced by stand-alone additive manufacturing methods (e.g., laser powder bed fusion). This can promote wider applications of 300 MS with ASHM for producing intricate geometries with complex inner features and a high-precision machined surface quality.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Azizi, H.; Ghiaasiaan, R.; Prager, R.; Ghoncheh, M.H.; Samk, K.A.; Lausic, A.; Byleveld, W.; Phillion, A.B. Metallurgical and mechanical assessment of hybrid additively-manufactured maraging tool steels via selective laser melting. Addit. Manuf. 2019, 27, 389–397. [Google Scholar] [CrossRef]

- Du, W.; Bai, Q.; Zhang, B. Machining characteristics of 18Ni-300 steel in additive/subtractive hybrid manufacturing. Int. J. Adv. Manuf. Technol. 2018, 95, 2509–2519. [Google Scholar] [CrossRef]

- Bai, Y.; Zhao, C.; Yang, J.; Hong, R.; Weng, C.; Wang, H. Microstructure and machinability of selective laser melted high-strength maraging steel with heat treatment. J. Mater. Process. Technol. 2021, 288, 116906. [Google Scholar] [CrossRef]

- Wang, M.-M.; Tasan, C.; Ponge, D.; Dippel, A.-C.; Raabe, D. Nanolaminate transformation-induced plasticity–twinning-induced plasticity steel with dynamic strain partitioning and enhanced damage resistance. Acta Mater. 2015, 85, 216–228. [Google Scholar] [CrossRef]

- Kučerová, L.; Burdová, K.; Jeníček, Š.; Chena, I. Effect of solution annealing and precipitation hardening at 250 C–550 C on microstructure and mechanical properties of additively manufactured 1.2709 maraging steel. Mater. Sci. Eng. A 2021, 814, 141195. [Google Scholar] [CrossRef]

- de Oliveira, A.R.; Del Conte, E.G. Concurrent improvement of surface roughness and residual stress of as-built and aged additively manufactured maraging steel post-processed by milling. Int. J. Adv. Manuf. Technol. 2021, 116, 2309–2323. [Google Scholar] [CrossRef]

- Paul, M.J.; Muniandy, Y.; Kruzic, J.J.; Ramamurty, U.; Gludovatz, B. Effect of heat treatment on the strength and fracture resistance of a laser powder bed fusion-processed 18Ni-300 maraging steel. Mater. Sci. Eng. A 2022, 844, 143167. [Google Scholar] [CrossRef]

- Mouritz, A.P. Introduction to Aerospace Materials; American Institute of Aeronautics and Astronautics, Woodhead Publishing in Materials: Cambridge, UK, 2012. [Google Scholar]

- Jägle, E.A.; Sheng, Z.; Kürnsteiner, P.; Ocylok, S.; Weisheit, A.; Raabe, D. Comparison of maraging steel micro-and nanostructure produced conventionally and by laser additive manufacturing. Materials 2016, 10, 8. [Google Scholar] [CrossRef] [Green Version]

- Simson, T.; Koch, J.; Rosenthal, J.; Kepka, M.; Zetek, M.; Zetkova, I.; Wolf, G.; Tomčík, P.; Kulhánek, J. Mechanical Properties of 18Ni-300 maraging steel manufactured by LPBF. Procedia Struct. Integr. 2019, 17, 843–849. [Google Scholar] [CrossRef]

- Casati, R.; Lemke, J.N.; Tuissi, A.; Vedani, M. Aging behaviour and mechanical performance of 18-Ni 300 steel processed by selective laser melting. Metals 2016, 6, 218. [Google Scholar] [CrossRef] [Green Version]

- Damon, J.; Hanemann, T.; Dietrich, S.; Graf, G.; Lang, K.-H.; Schulze, V. Orientation dependent fatigue performance and mechanisms of selective laser melted maraging steel X3NiCoMoTi18-9-5. Int. J. Fatigue 2019, 127, 395–402. [Google Scholar] [CrossRef]

- Chadha, K.; Tian, Y.; Bocher, P.; Spray, J.G.; Aranas, C. Microstructure evolution, mechanical properties and deformation behavior of an additively manufactured maraging steel. Materials 2020, 13, 2380. [Google Scholar] [CrossRef]

- Tan, C.; Zhou, K.; Kuang, M.; Ma, W.; Kuang, T. Microstructural characterization and properties of selective laser melted maraging steel with different build directions. Sci. Technol. Adv. Mater. 2018, 19, 746–758. [Google Scholar] [CrossRef] [Green Version]

- Sun, H.; Chu, X.; Liu, Z.; Azimi, G.; Zou, Y. Selective laser melting of maraging steels using recycled powders: A comprehensive microstructural and mechanical investigation. Metall. Mater. Trans. A 2021, 52, 1714–1722. [Google Scholar] [CrossRef]

- Mutua, J.; Nakata, S.; Onda, T.; Chen, Z.-C. Optimization of selective laser melting parameters and influence of post heat treatment on microstructure and mechanical properties of maraging steel. Mater. Des. 2018, 139, 486–497. [Google Scholar] [CrossRef]

- Kim, D.; Kim, T.; Ha, K.; Oak, J.-J.; Jeon, J.B.; Park, Y.; Lee, W. Effect of heat treatment condition on microstructural and mechanical anisotropies of selective laser melted maraging 18Ni-300 steel. Metals 2020, 10, 410. [Google Scholar] [CrossRef] [Green Version]

- Song, J.; Tang, Q.; Feng, Q.; Ma, S.; Setchi, R.; Liu, Y.; Han, Q.; Fan, X.; Zhang, M. Effect of heat treatment on microstructure and mechanical behaviours of 18Ni-300 maraging steel manufactured by selective laser melting. Opt. Laser Technol. 2019, 120, 105725. [Google Scholar] [CrossRef]

- Yin, S.; Chen, C.; Yan, X.; Feng, X.; Jenkins, R.; O’Reilly, P.; Liu, M.; Li, H.; Lupoi, R. The influence of aging temperature and aging time on the mechanical and tribological properties of selective laser melted maraging 18Ni-300 steel. Addit. Manuf. 2018, 22, 592–600. [Google Scholar] [CrossRef]

- Conde, F.; Escobar, J.; Oliveira, J.; Jardini, A.; Filho, W.B.; Avila, J. Austenite reversion kinetics and stability during tempering of an additively manufactured maraging 300 steel. Addit. Manuf. 2019, 29, 100804. [Google Scholar] [CrossRef]

- Grzesik, W. Hybrid additive and subtractive manufacturing processes and systems: A review. J. Mach. Eng. 2018, 18, 5–24. [Google Scholar] [CrossRef]

- Jiménez, A.; Bidare, P.; Hassanin, H.; Tarlochan, F.; Dimov, S.; Essa, K. Powder-based laser hybrid additive manufacturing of metals. Int. J. Adv. Manuf. Technol. 2021, 114, 63–96. [Google Scholar] [CrossRef]

- Atabay, S.E.; Wanjara, P.; Bernier, F.; Sarafan, S.; Gholipour, J.; Soost, J.; Amos, R.; Patnaik, P.; Brochu, M. In Envelope Additive/Subtractive Manufacturing and Thermal Post-Processing of Inconel 718. Materials 2022, 16, 1. [Google Scholar] [CrossRef] [PubMed]

- Sarafan, S.; Wanjara, P.; Gholipour, J.; Bernier, F.; Osman, M.; Sikan, F.; Soost, J.; Amos, R.; Patnaik, P.; Brochu, M. Benchmarking of 316L Stainless Steel Manufactured by a Hybrid Additive/Subtractive Technology. J. Manuf. Mater. Process. 2022, 6, 30. [Google Scholar] [CrossRef]

- Enemuoh, E.U.; Carrillo, J.; Klein, J.; Cash, A.; Bergstrom, D. Characterization of Maraging Steel Fabricated with Metal Laser Sintering Hybrid Milling. In Proceedings of the Midwest Regional Conference, American Society for Engineering Education ASEE, Salt Lake City, UT, USA, 24–27 June 2018. [Google Scholar]

- Wüst, P.; Edelmann, A.; Hellmann, R. Areal surface roughness optimization of maraging steel parts produced by hybrid additive manufacturing. Materials 2020, 13, 418. [Google Scholar] [CrossRef] [Green Version]

- Sarafan, S.; Wanjara, P.; Gholipour, J.; Bernier, F.; Osman, M.; Sikan, F.; Molavi-Zarandi, M.; Soost, J.; Brochu, M. Evaluation of maraging steel produced using hybrid additive/subtractive manufacturing. J. Manuf. Mater. Process. 2021, 5, 107. [Google Scholar] [CrossRef]

- Du, W.; Bai, Q.; Zhang, B. A novel method for additive/subtractive hybrid manufacturing of metallic parts. Procedia Manuf. 2016, 5, 1018–1030. [Google Scholar] [CrossRef] [Green Version]

- Hall, A.M.; Slunder, C. The Metallurgy, Behavior, and Application of the 18-Percent Nickel Maraging Steels; National Aeronautics and Space Administration: Washington, DC, USA, 1968.

- Tamura, S.; Matsumura, T.; Ezura, A.; Mori, K. Anisotropic cutting force characteristics in milling of maraging steel processed through selective laser melting. J. Manuf. Sci. Eng. 2022, 144, 031012. [Google Scholar] [CrossRef]

- Bai, Y.; Wang, D.; Yang, Y.; Wang, H. Effect of heat treatment on the microstructure and mechanical properties of maraging steel by selective laser melting. Mater. Sci. Eng. A 2019, 760, 105–117. [Google Scholar] [CrossRef]

- Yablokova, G.; Speirs, M.; Van Humbeeck, J.; Kruth, J.-P.; Schrooten, J.; Cloots, R.; Boschini, F.; Lumay, G.; Luyten, J. Rheological behavior of β-Ti and NiTi powders produced by atomization for SLM production of open porous orthopedic implants. Powder Technol. 2015, 283, 199–209. [Google Scholar] [CrossRef] [Green Version]

- Leary, M.; Mazur, M.; Elambasseril, J.; McMillan, M.; Chirent, T.; Sun, Y.; Qian, M.; Easton, M.; Brandt, M. Selective laser melting (SLM) of AlSi12Mg lattice structures. Mater. Des. 2016, 98, 344–357. [Google Scholar] [CrossRef]

- Nguyen, Q.B.; Nai, M.L.S.; Zhu, Z.; Sun, C.-N.; Wei, J.; Zhou, W. Characteristics of inconel powders for powder-bed additive manufacturing. Engineering 2017, 3, 695–700. [Google Scholar] [CrossRef]

- Sames, W.J.; List, F.A.; Pannala, S.; Dehoff, R.R.; Babu, S.S. The metallurgy and processing science of metal additive manufacturing. Int. Mater. Rev. 2016, 61, 315–360. [Google Scholar] [CrossRef]

- Totten, G.E.; Xie, L.; Funatani, K. Handbook of Mechanical Alloy Design; CRC Press: Boca Raton, FL, USA, 2003; Volume 164. [Google Scholar]

- Chen, P.; Zou, T.; Chen, J.Y.; Gao, Z.; Xiong, J. The application of improved PSO algorithm in PMMW image OSTU threshold segmentation. Appl. Mech. Mater. 2015, 721, 779–782. [Google Scholar] [CrossRef]

- Zhu, Q.; Jing, L.; Bi, R. Exploration and improvement of OTSU threshold segmentation algorithm. In Proceedings of the 2010 8th World Congress on Intelligent Control and Automation, Jinan, China, 6–9 July 2010; IEEE: Piscataway, NJ, USA, 2010; pp. 6183–6188. [Google Scholar]

- Jiao, S.; Li, X.; Lu, X. An improved OTSU method for image segmentation. In Proceedings of the 2006 8th International Conference on Signal Processing, Guilin, China, 16–20 November 2006; IEEE: Piscataway, NJ, USA, 2006. [Google Scholar]

- Talonen, J.; Aspegren, P.; Hänninen, H. Comparison of different methods for measuring strain induced α-martensite content in austenitic steels. Mater. Sci. Technol. 2004, 20, 1506–1512. [Google Scholar] [CrossRef]

- ASTM E18-22; Standard Test Methods for Rockwell Hardness of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM E384-22; Standard Test Method for Microindentation Hardness of Materials. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM E8-22; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2022.

- Sarafan, S.; Wanjara, P.; Lévesque, J.-B.; Gholipour, J.; Champliaud, H.; Mathieu, L. Through-thickness residual stresses, microstructure, and mechanical properties of electron beam-welded CA6NM martensitic stainless steel after postweld heat treatment. Adv. Mater. Sci. Eng. 2020, 2020, 7194214. [Google Scholar] [CrossRef] [Green Version]

- Zambrano, O.A.; Gholipour, J.; Wanjara, P.; Jiang, J. Linear Friction Welding of Abrasion Resistant CPM 15V Tool Steel to an Alloyed Carbon Shovel-Tooth Steel. J. Manuf. Mater. Process. 2023, 7, 51. [Google Scholar] [CrossRef]

- Gordon, J.V.; Narra, S.P.; Cunningham, R.W.; Liu, H.; Chen, H.; Suter, R.M.; Beuth, J.L.; Rollett, A.D. Defect structure process maps for laser powder bed fusion additive manufacturing. Addit. Manuf. 2020, 36, 101552. [Google Scholar] [CrossRef]

- Song, J.; Tang, Q.; Chen, H.; Zhang, Z.; Feng, Q.; Zhao, M.; Ma, S.; Setchi, R. Laser powder bed fusion of high-strength maraging steel with concurrently enhanced strength and ductility after heat treatments. Mater. Sci. Eng. A 2022, 854, 143818. [Google Scholar] [CrossRef]

- Kumar, A.; Wilkinson, A.; Roberts, S. Quasi-cleavage fracture planes in spheroidized A533B steel. J. Microsc. 2007, 227, 248–253. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Z.; Dong, C.; Kong, D.; Wang, L.; Ni, X.; Zhang, L.; Wu, W.; Zhu, L.; Li, X. Influence of pore defects on the mechanical property and corrosion behavior of SLM 18Ni300 maraging steel. Mater. Charact. 2021, 182, 111514. [Google Scholar] [CrossRef]

- He, Y.; Zhong, M.; Beuth, J.; Webler, B. A study of microstructure and cracking behavior of H13 tool steel produced by laser powder bed fusion using single-tracks, multi-track pads, and 3D cubes. J. Mater. Process. Technol. 2020, 286, 116802. [Google Scholar] [CrossRef]

- Šafka, J.; Ackermann, M.; Voleský, L. Structural properties of H13 tool steel parts produced with use of selective laser melting technology. J. Phys. Conf. Ser. 2016, 709, 012004. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Liu, S.; Fang, Y.; He, Z. A short review on selective laser melting of H13 steel. Int. J. Adv. Manuf. Technol. 2020, 108, 2453–2466. [Google Scholar] [CrossRef]

- Nandwana, P.; Kannan, R.; Leonard, D.N. Leveraging solute segregation in laser powder bed fusion to achieve superior strength and ductility via single-step heat treatment in Ti-free grade 300 maraging steel. JOM 2020, 72, 4221–4231. [Google Scholar] [CrossRef]

- Wang, M.-X.; Zhu, H.; Yang, G.-J.; Liu, K.; Li, J.-F.; Kong, L.-T. Solid-solution strengthening effects in binary Ni-based alloys evaluated by high-throughput calculations. Mater. Des. 2021, 198, 109359. [Google Scholar] [CrossRef]

- Kadambi, S.B.; Divya, V.D.; Ramamurty, U. Evaluation of Solid-Solution Hardening in Several Binary Alloy Systems Using Diffusion Couples Combined with Nanoindentation. Metall. Mater. Trans. A 2017, 48, 4574–4582. [Google Scholar] [CrossRef] [Green Version]

- Tan, C.; Zhou, K.; Ma, W.; Zhang, P.; Liu, M.; Kuang, T. Microstructural evolution, nanoprecipitation behavior and mechanical properties of selective laser melted high-performance grade 300 maraging steel. Mater. Des. 2017, 134, 23–34. [Google Scholar] [CrossRef]

- Sonderegger, B.; Kozeschnik, E. Particle strengthening in fcc crystals with prolate and oblate precipitates. Scr. Mater. 2012, 66, 52–55. [Google Scholar] [CrossRef]

- Chung, H.; Choi, W.S.; Jun, H.; Do, H.-S.; Lee, B.-J.; Choi, P.-P.; Han, H.N.; Ko, W.-S.; Sohn, S.S. Doubled strength and ductility via maraging effect and dynamic precipitate transformation in ultrastrong medium-entropy alloy. Nat. Commun. 2023, 14, 145. [Google Scholar] [CrossRef]

- Tabor, D. The Hardness of Metals; Oxford University Press: Oxford, UK, 2000. [Google Scholar]

- Sinha, P.; Tharian, K.; Sreekumar, K.; Nagarajan, K.; Sarma, D.S. Effect of aging on microstructure and mechanical properties of cobalt free 18% Ni (250 grade) maraging steel. Mater. Sci. Technol. 1998, 14, 1–9. [Google Scholar] [CrossRef]

- Schnitzer, R.; Zinner, S.; Leitner, H. Modeling of the yield strength of a stainless maraging steel. Scr. Mater. 2010, 62, 286–289. [Google Scholar] [CrossRef]

- Mei, X.; Yan, Y.; Fu, H.; Gao, X.; Huang, S.; Qiao, L. Effect of aging temperature on microstructure evolution and strengthening behavior of L-PBF 18Ni (300) maraging steel. Addit. Manuf. 2022, 58, 103071. [Google Scholar] [CrossRef]

- Jägle, E.A.; Choi, P.-P.; Van Humbeeck, J.; Raabe, D. Precipitation and austenite reversion behavior of a maraging steel produced by selective laser melting. J. Mater. Res. 2014, 29, 2072–2079. [Google Scholar] [CrossRef] [Green Version]

| Elements | Ni | Co | Mo | Ti | Cr | Al | Si | Mn | C | P | S | O | N |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Composition (wt.%) | 17.9 | 8.9 | 5 | 0.8 | 0.2 | 0.11 | 0.08 | 0.06 | 0.01 | 0.008 | 0.006 | 0.04 ppm | 0.02 ppm |

| Condition | Laser Power (W) | Sample Designation |

|---|---|---|

| As-built | 240 | AB-240 W |

| 320 | AB-320 W | |

| 380 | AB-380 W | |

| Solution-treated | 240 | ST-240 W |

| 320 | ST-320 W | |

| 380 | ST-380 W | |

| Solution-treated + aged | 240 | STA-240 W |

| 320 | STA-320 W | |

| 380 | STA-380 W | |

| Direct aging | 240 | DA-240 W |

| 320 | DA-320 W | |

| 380 | DA-380 W |

| Laser Power | Before Heat Treatment | Porosity % | Largest Pore Diameter (µm) | Number of Pores | After Heat Treatment | Porosity % | Largest Pore Diameter (µm) | Number of Pores |

|---|---|---|---|---|---|---|---|---|

| 240 W | AB-240W1 | 0.003 | 86 | 569 | STA-240W1 | 0.003 | 84 | 552 |

| AB-240W2 | 0.001 | 40 | 472 | DA-240W2 | 0.001 | 40 | 441 | |

| 320 W | AB-320W1 | 0.005 | 81 | 386 | STA-320W1 | 0.005 | 63 | 425 |

| AB-320W2 | 0.016 | 99 | 1774 | DA-320W2 | 0.01 | 92 | 1138 | |

| 380 W | AB-380W1 | 0.001 | 85 | 132 | STA-380W1 | 0.0003 | 79 | 41 |

| AB-380W2 | 0.001 | 45 | 242 | DA-380W2 | 0.0003 | 41 | 91 |

| Sample | YS (MPa) | STD | UTS (MPa) | STD | E (GPa) | STD | Fracture Strain (%) | STD | Ref. | |

|---|---|---|---|---|---|---|---|---|---|---|

| Local | Global | |||||||||

| AB-240 W | 1006 | 15 | 1158 | 3 | 169 | 5 | - | 12.8 | 0.7 | Previous study by current authors [27] |

| AB-320 W | 1062 | 14 | 1171 | 5 | 170 | 3 | - | 12.9 | 0.4 | |

| AB-380 W | 1022 | 19 | 1160 | 11 | 161 | 1 | - | 12.5 | 0.8 | |

| STA-240 W | 2030 | 9 | 2080 | 24 | 185 | 9 | 23.4 | 4.4 | 0.1 | Current study |

| STA-320 W | 1983 | 17 | 2066 | 6 | 182 | 2 | 19.8 | 4.3 | 0.2 | |

| STA-380 W | 1973 | 38 | 2073 | 10 | 192 | 7 | 7.9 | 3.5 | 0.7 | |

| DA-240 W | 1884 | 31 | 1950 | 14 | 164 | 3 | 30.1 | 5.9 | 0.5 | |

| DA-320 W | 1895 | 23 | 1943 | 14 | 173 | 8 | 26.9 | 4.2 | 0.1 | |

| DA-380 W | 1860 | 3 | 1923 | 7 | 165 | 4 | 6.3 | 3.2 | 1 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the National Research Council Canada. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Osman, M.; Sarafan, S.; Wanjara, P.; Bernier, F.; Atabay, S.E.; Gholipour, J.; Molavi-Zarandi, M.; Soost, J.; Brochu, M. Effect of Heat Treatment on the Microstructure and Mechanical Properties of 18Ni-300 Maraging Steel Produced by Additive–Subtractive Hybrid Manufacturing. Materials 2023, 16, 4749. https://doi.org/10.3390/ma16134749

Osman M, Sarafan S, Wanjara P, Bernier F, Atabay SE, Gholipour J, Molavi-Zarandi M, Soost J, Brochu M. Effect of Heat Treatment on the Microstructure and Mechanical Properties of 18Ni-300 Maraging Steel Produced by Additive–Subtractive Hybrid Manufacturing. Materials. 2023; 16(13):4749. https://doi.org/10.3390/ma16134749

Chicago/Turabian StyleOsman, Mahmoud, Sheida Sarafan, Priti Wanjara, Fabrice Bernier, Sila Ece Atabay, Javad Gholipour, Marjan Molavi-Zarandi, Josh Soost, and Mathieu Brochu. 2023. "Effect of Heat Treatment on the Microstructure and Mechanical Properties of 18Ni-300 Maraging Steel Produced by Additive–Subtractive Hybrid Manufacturing" Materials 16, no. 13: 4749. https://doi.org/10.3390/ma16134749

APA StyleOsman, M., Sarafan, S., Wanjara, P., Bernier, F., Atabay, S. E., Gholipour, J., Molavi-Zarandi, M., Soost, J., & Brochu, M. (2023). Effect of Heat Treatment on the Microstructure and Mechanical Properties of 18Ni-300 Maraging Steel Produced by Additive–Subtractive Hybrid Manufacturing. Materials, 16(13), 4749. https://doi.org/10.3390/ma16134749