Preparation and Characterization for the Thermal Stability and Mechanical Property of PLA and PLA/CF Samples Built by FFF Approach

Abstract

:1. Introduction

2. Experiment and Method

2.1. Preparation

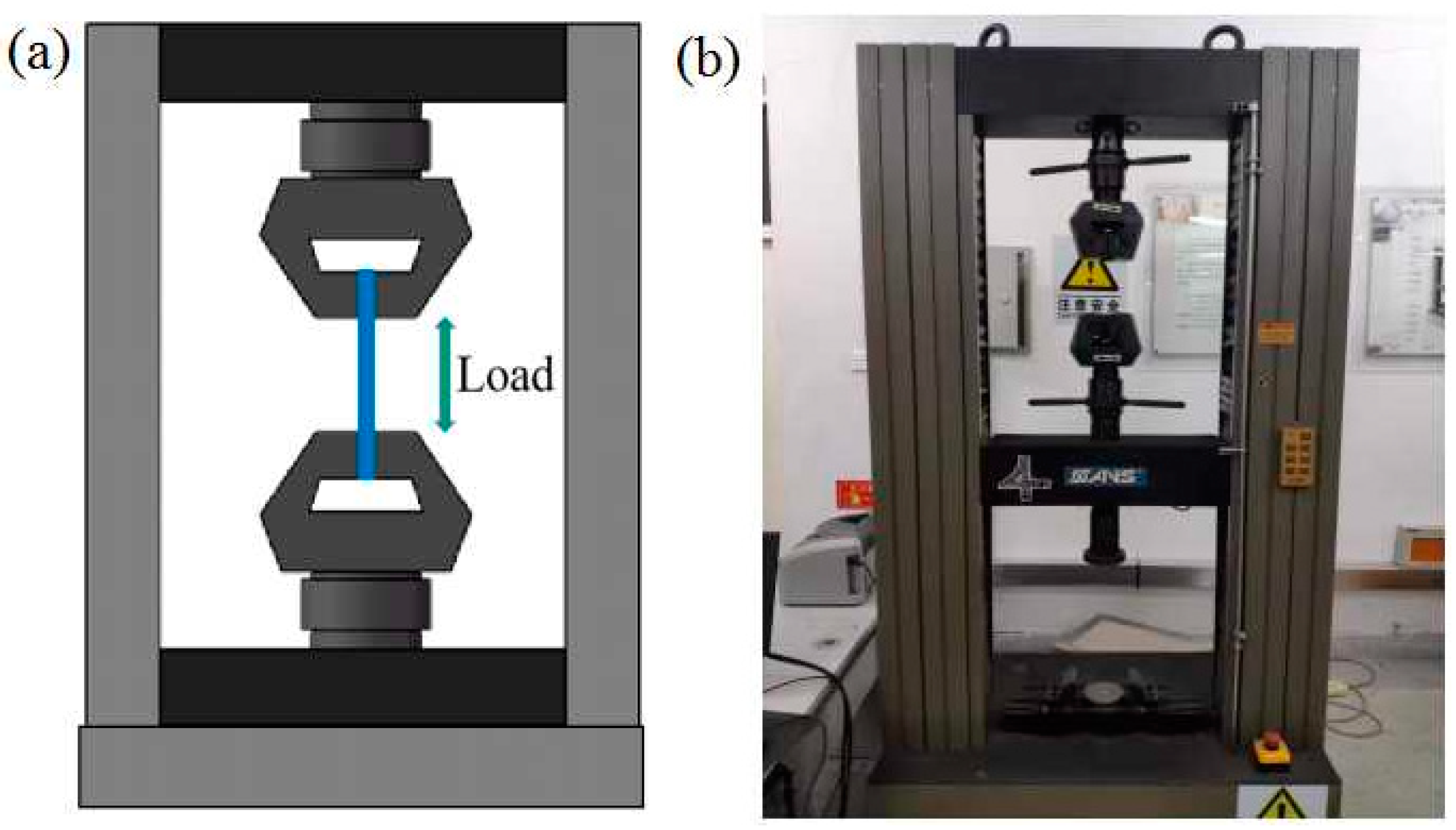

2.2. Characterization

3. Results and Discussion

3.1. XRD Pattern Observation

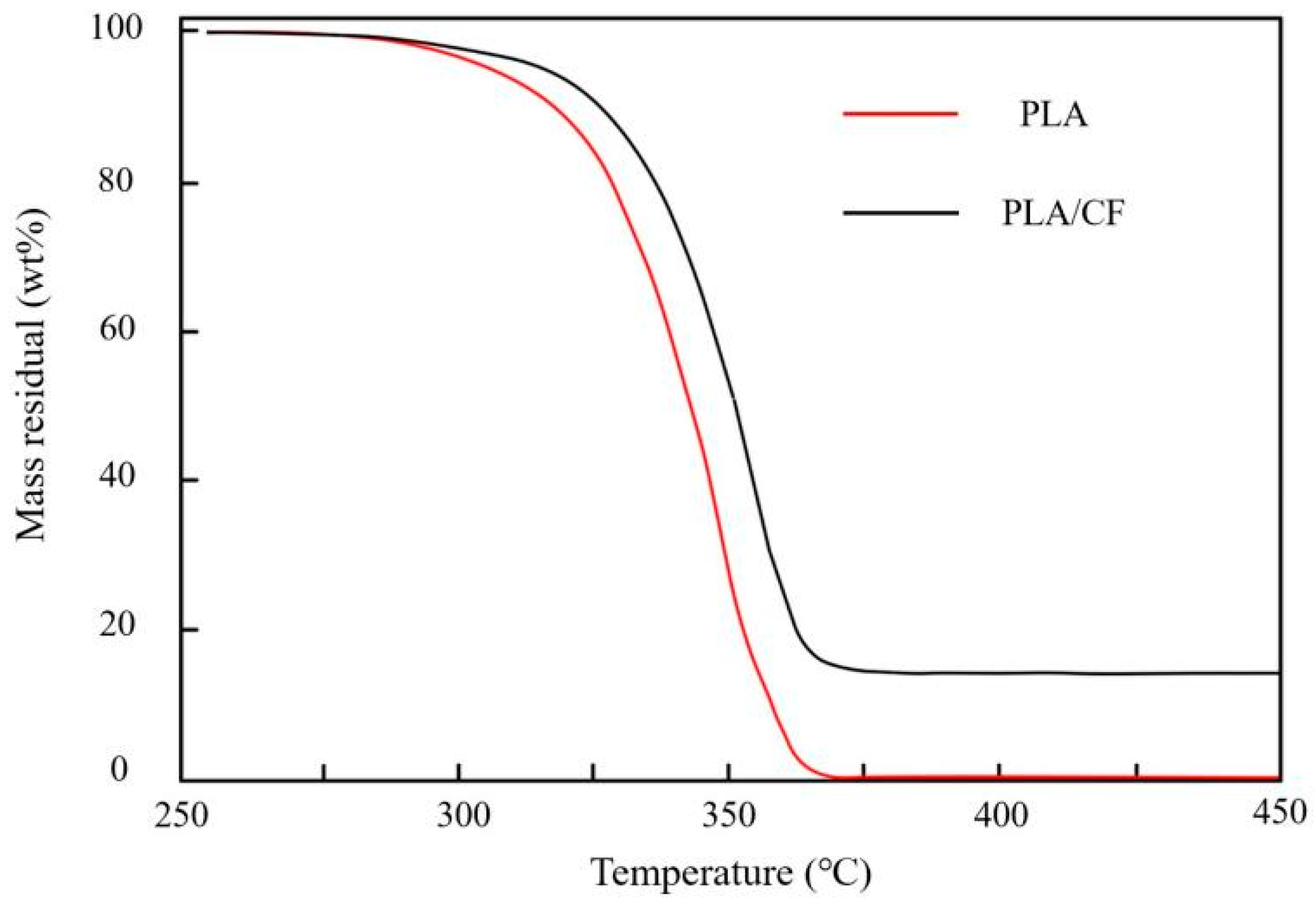

3.2. Thermal Stability Analysis

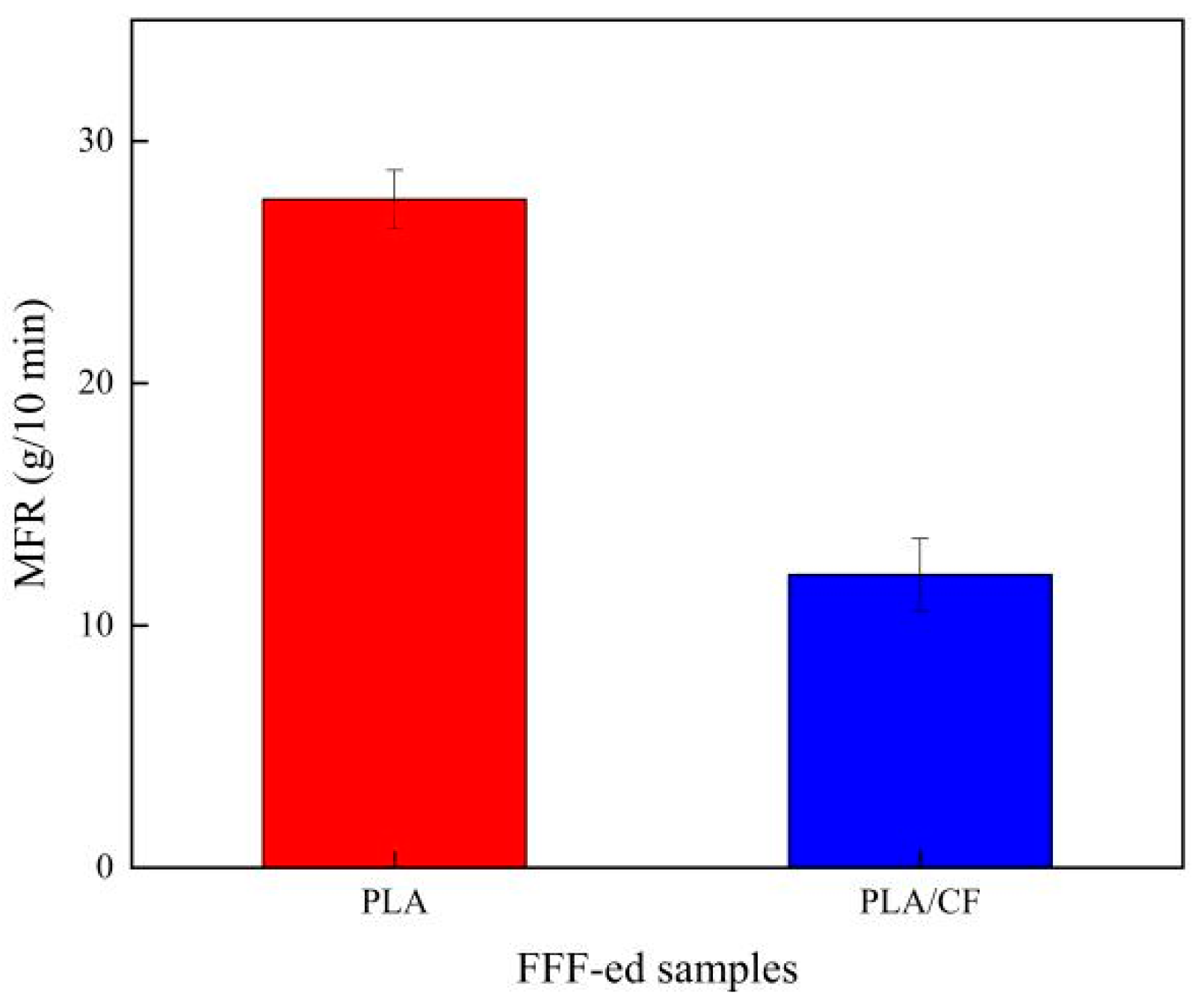

3.3. MFR Investigation

3.4. Mechanical Property Measurement

3.5. Fractured Surface Morphology Detection

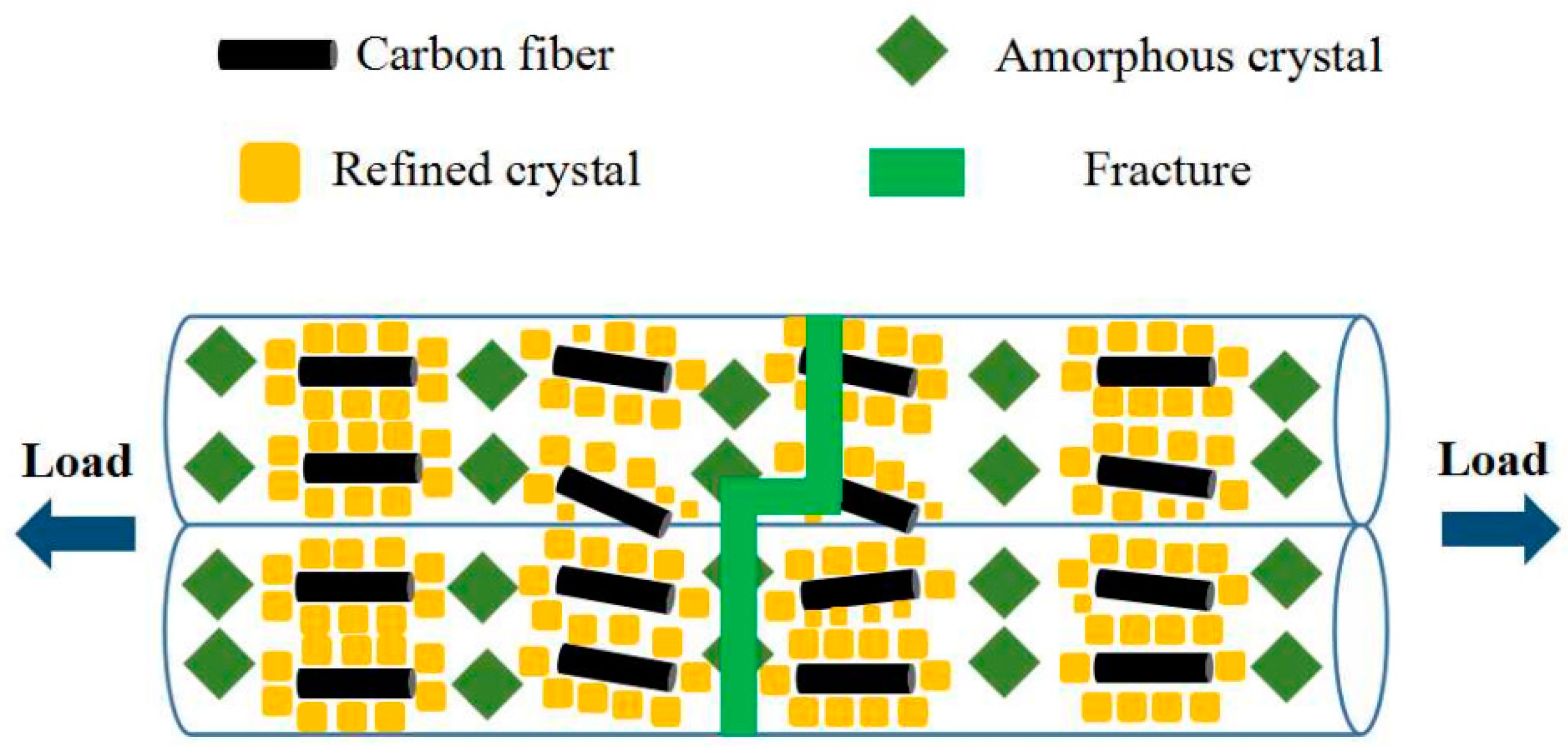

3.6. Reinforcement Mechanism

4. Conclusions

- (1)

- XRD results showed that the diffraction peaks of the PLA and PLA/CF samples were located at 16.6°and 19.1°, corresponding to the crystal planes of (200/110) and (203), respectively. After the introduction of carbon fiber, the crystalline size of PLA was refined.

- (2)

- TGA and DSC curves illustrated that the thermal stability and crystallization degree of the PLA/CF sample were better than those of the PLA sample. In addition, the MFR of the PLA sample decreased from 27.6 g/10 min to 12.1 g/10 min after CF was introduced.

- (3)

- Compared with the PLA sample, the tensile strength of PLA/CF sample increased from 64.27 MPa to 91.58 MPa. SEM images showed that the fractured behavior of the PLA sample varied from brittle fracture to ductile fracture after the CF was introduced.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fico, D.; Rizzo, D.; Casciaro, R.; Corcione, C.E. A Review of Polymer-Based Materials for Fused Filament Fabrication (FFF): Focus on Sustainability and Recycled Materials. Polymers 2022, 14, 465. [Google Scholar] [CrossRef]

- Pratama, J.; Cahyono, S.I.; Suyitno, S.; Muflikhun, M.A.; Salim, U.A.; Mahardika, M.; Arifvianto, B. A Review on Reinforcement Methods for Polymeric Materials Processed Using Fused Filament Fabrication (FFF). Polymers 2021, 13, 4022. [Google Scholar] [CrossRef]

- Buj-Corral, I.; Tejo-Otero, A.; Fenollosa-Artes, F. Development of AM Technologies for Metals in the Sector of Medical Implants. Metals 2020, 10, 686. [Google Scholar] [CrossRef]

- Liu, Z.G.; Wang, Y.Q.; Wu, B.C.; Cui, C.Z.; Guo, Y.; Yan, C. A critical review of fused deposition modeling 3D printing technology in manufacturing polylactic acid parts. Int. J. Adv. Manuf. Technol. 2019, 102, 2877–2889. [Google Scholar] [CrossRef]

- Wu, H.; Fahy, W.P.; Kim, S.; Zhao, N.; Pilato, L.; Kafi, A.; Bateman, S.; Koo, J.H. Recent developments in polymers/polymer nanocomposites for additive manufacturing. Prog. Mater. Sci. 2020, 111, 10638. [Google Scholar] [CrossRef]

- Ahmadifar, M.; Benfriha, K.; Shirinbayan, M.; Tcharkhtchi, A. Additive Manufacturing of Polymer-Based Composites Using Fused Filament Fabrication (FFF): A Review. Appl. Compos. Mater. 2021, 28, 1335–1380. [Google Scholar] [CrossRef]

- Ye, G.Y.; Gu, T.F.; Chen, B.Y.; Bi, H.; Hu, Y. Mechanical, thermal properties and shape memory behaviors of PLA/PCL/PLA-g-GMA blends. Polym. Eng. Sci. 2023, 63, 2084–2092. [Google Scholar] [CrossRef]

- Rajpurohit, S.R.; Dave, H.K. Flexural Strength of fused filament fabricated (FFF) PLA parts on an open-source 3D printer. Adv. Manuf. 2018, 6, 430–441. [Google Scholar] [CrossRef]

- Lee, C.Y.; Liu, C.Y. The influence of forced-air cooling on a 3D printed PLA part manufactured by fused filament fabrication. Addit. Manuf. 2019, 25, 196–203. [Google Scholar] [CrossRef]

- Behzadnasab, M.; Yousefi, A.A.; Ebrahimibagha, D.; Nasiri, F. Effect of processing conditions on mechanical properties of PLA printed parts. Rapid Prototyp. J. 2020, 26, 381–389. [Google Scholar] [CrossRef]

- Dong, J.; Mei, C.; Han, J.; Lee, S.; Wu, Q. 3D printed poly(lactic acid) composites with grafted cellulose nanofibers: Effect of nanofiber and post-fabrication annealing treatment on composite flexural properties. Addit. Manuf. 2019, 28, 621–628. [Google Scholar] [CrossRef]

- Malagutti, L.; Ronconi, G.; Zanelli, M.; Mollica, F.; Mazzanti, V. A Post-Processing Method for Improving the Mechanical Properties of Fused-Filament-Fabricated 3D-Printed Parts. Processes 2022, 10, 2399. [Google Scholar] [CrossRef]

- Liu, Z.B.; Lei, Q.; Xing, S.Q. Mechanical characteristics of wood, ceramic, metal and carbon fiber-based PLA composites fabricated by FDM. J. Mater. Res. Technol.-JMRT 2019, 8, 3741–3751. [Google Scholar] [CrossRef]

- Nevado, P.; Lopera, A.; Bezzon, V.; Fulla, M.R.; Palacio, J.; Zaghete, M.A.; Biasotto, G.; Montoya, A.; Rivera, J.; Robledo, S.M.; et al. Preparation and in vitro evaluation of PLA/biphasic calcium phosphate filaments used for fused deposition modelling of scaffolds. Mater. Sci. Eng. C-Mater. Biol. Appl. 2020, 114, 111013. [Google Scholar] [CrossRef]

- Ghiban, B.; Pascu, N.E.; Antoniac, I.V.; Jiga, G.; Milea, C.; Petre, G.; Gheorghe, C.; Munteanu, C.; Istrate, B. Surface Characterization of Fracture in Polylactic Acid vs. PLA plus Particle (Cu, Al, Graphene) Insertions by 3D Fused Deposition Modeling Technology. Coatings 2021, 11, 633. [Google Scholar] [CrossRef]

- Butt, J.; Oxford, P.; Sadeghi-Esfahlani, S.; Ghorabian, M.; Shirvani, H. Hybrid Manufacturing and Mechanical Characterization of Cu/PLA Composites. Arab. J. Sci. Eng. 2020, 45, 9339–9356. [Google Scholar] [CrossRef]

- Ferreira, I.; Machado, M.; Alves, F.; Marques, A.T. A review on fiber reinforced composite printing via FFF. Rapid Prototyp. J. 2019, 25, 972–988. [Google Scholar] [CrossRef]

- Li, Y.H.; Gao, S.Y.; Dong, R.M.; Ding, X.B.; Duan, X.X. Additive Manufacturing of PLA and CF/PLA Binding Layer Specimens via Fused Deposition Modeling. J. Mater. Eng. Perform. 2018, 27, 492–500. [Google Scholar] [CrossRef]

- Tian, X.Y.; Liu, T.F.; Yang, C.C.; Wang, Q.R.; Li, D.C. Interface and performance of 3D printed continuous carbon fiber reinforced PLA composites. Compos. Part A-Appl. Sci. Manuf. 2016, 88, 198–205. [Google Scholar] [CrossRef]

- Hsieh, C.T.; Pan, Y.J.; Lou, C.W.; Huang, C.L.; Lin, Z.L.; Liao, J.M.; Linm, J.H. Polylactic Acid/Carbon Fiber Composites: Effects of Functionalized Elastomers on Mechanical Properties, Thermal Behavior, Surface Compatibility, and Electrical Characteristics. Fibers Polym. 2016, 17, 615–623. [Google Scholar] [CrossRef]

- Zhu, J.T.; Wu, P.F.; Cui, H.S.; Shi, X.N.; Cui, N.; Li, J.; Huang, Q. Preparation and Structural Properties of 80dtex/72f Stereotactic Composite Polylactic Acid Fibers. Text. Sci. Res. 2023, 220, 45–48. [Google Scholar]

- Sang, L.; Han, S.; Li, Z.; Yang, X.; Hou, W. Development of short basalt fiber reinforced polylactide composites and their feasible evaluation for 3D printing applications. Compos. Part B-Eng. 2019, 164, 629–639. [Google Scholar] [CrossRef]

- Cao, M.; Cui, T.; Yue, Y.; Li, C.; Guo, X.; Jia, X.; Wang, B. Investigation of Carbon Fiber on the Tensile Property of FDM-Produced PLA Specimen. Polymers 2022, 14, 5230. [Google Scholar] [CrossRef]

- Liao, C.G.; Chen, K.; Li, P.; Li, X.G.; Zuo, Y.F. Nano-TiO2 Modified Wheat Straw/Polylactic Acid Composites Based on Synergistic Effect Between Interfacial Bridging and Heterogeneous Nucleation. J. Polym. Environ. 2022, 30, 3021–3030. [Google Scholar] [CrossRef]

- Abu-Jdayil, B.; Barkhad, M.S.; Mourad, A.H.I.; Iqbal, M.Z. Date palm wood waste-based composites for green thermal insulation boards. J. Build. Eng. 2021, 43, 103224. [Google Scholar] [CrossRef]

- Al Zahmi, S.; Alhammadi, S.; ElHassan, A.; Ahmed, W. Carbon Fiber/PLA Recycled Composite. Polymers 2022, 14, 2194. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; He, X.; Zuo, Y.; Wang, S.; Wu, Y. Study on the compatible interface of bamboo fiber/polylactic acid composites by in-situ solid phase grafting. Int. J. Biol. Macromol. 2019, 141, 325–332. [Google Scholar] [CrossRef] [PubMed]

- Lei, Y.Z.; Wang, S.W.; Lv, Q.N.; Li, Z.Z. Crystallization and rheological properties of carbon fiber/poly(lactic acid) composites. Acta Mater. Compos. Sin. 2018, 35, 1402–1406. [Google Scholar]

- Ye, Q.T.; Qian, X.; Zhang, X.H.; Wang, X.F.; Zhang, Y.G.; Shi, X.L. Research progress in thermal conductivity of polymer-basedcomposites based on carbon fiber regulation. China Synth. Fiber Ind. 2022, 45, 61–68. [Google Scholar]

- Klaser, T.; Balen, L.; Skoko, Z.; Pavic, L.; Santic, A. Polylactic Acid-Glass Fiber Composites: Structural, Thermal, and Electrical Properties. Polymers 2022, 14, 4012. [Google Scholar] [CrossRef] [PubMed]

- Siengchin, S. Reinforced Flax Mat/Modified Polylactide (PLA) Composites: Impact, Thermal, and Mechanical Properties. Polym. Mech. 2014, 50, 257–266. [Google Scholar] [CrossRef]

- Adomaviciute, E.; Baltusnikaite, J.; Jonaitiene, V.; Stanys, S. Formation and Properties of Textile Biocomposites with PLA Matrix Reinforced with Flax and Flax/PLA Weft Knitted Fabrics. Fibers Text. East. Eur. 2015, 23, 45–50. [Google Scholar]

- Jin, X.; Chen, X.; Cheng, Q.; Zhang, N.W.; Cai, S.Y.; Ren, J. Non-isothermal crystallization kinetics of ramie fiber-reinforced polylactic acid biocomposite. RSC Adv. 2017, 7, 46014–46021. [Google Scholar] [CrossRef] [Green Version]

- Li, C.Y.; Xia, F.F.; Yao, L.M.; Li, H.X.; Jia, X. Investigation of the mechanical properties and corrosion behaviors of Ni-BN-TiC layers constructed via laser cladding technique. Ceram. Int. 2023, 49, 6671–6677. [Google Scholar] [CrossRef]

- Yang, L.P.; Li, S.J.; Zhou, X.; Liu, J.; Li, Y.; Yang, M.S.; Yuan, Q.L.; Zhang, W. Effects of carbon nanotube on the thermal, mechanical, and electrical properties of PLA/CNT printed parts in the FDM process. Synth. Met. 2019, 253, 122–130. [Google Scholar] [CrossRef]

- Han, X.X.; Huang, L.J.; Wei, Z.H.; Wang, Y.A.; Chen, H.B.; Huang, C.X.; Su, S.Z. Technology and mechanism of enhanced compatibilization of polylactic acid-grafted glycidyl methacrylate. Ind. Crops Prod. 2021, 172, 114065. [Google Scholar] [CrossRef]

- Zhu, Z.W.; He, H.Z.; Xue, B.; Zhan, Z.M.; Wang, G.Z.; Chen, M. Morphology, Thermal, Mechanical Properties and Rheological Behavior of Biodegradable Poly(butylene succinate)/poly(lactic acid) In-Situ Submicrofibrillar Composites. Materials 2019, 11, 2422. [Google Scholar] [CrossRef] [Green Version]

- Kumar Mishra, P.; Senthil, P. Prediction of in-plane stiffness of multi-material 3D printed laminate parts fabricated by FDM process using CLT and its mechanical behaviour under tensile load. Mater. Today Commun. 2020, 23, 100955. [Google Scholar] [CrossRef]

- Qian, K.Y.; Qian, X.; Chen, Y.L.; Zhou, M. Poly(lactic acid)-thermoplastic poly(ether)urethane composites synergistically reinforced and toughened with short carbon fibers for three-dimensional printing. J. Appl. Polym. Sci. 2018, 135, 46483. [Google Scholar] [CrossRef]

- Malagutti, L.; Mazzanti, V.; Mollica, F. Tensile properties of FDM 3D-printed wood flour filled polymers and mathematical modeling through classical lamination theory. Rapid Prototyp. J. 2022, 28, 1834–1842. [Google Scholar] [CrossRef]

- Raj, A.; Prashantha, K.; Samuel, C. Compatibility in biobased poly(L-lactide)/polyamide binary blends: From melt-state interfacial tensions to (thermo)mechanical properties. J. Appl. Polym. Sci. 2019, 137, 48440. [Google Scholar] [CrossRef]

- Caminero, M.A.; Chacón, J.M.; García-Moreno, I.; Rodríguez, G.P. Impact damage resistance of 3D printed continuous fibre reinforced thermoplastic composites using fused deposition modelling. Compos. Part B Eng. 2018, 148, 93–103. [Google Scholar] [CrossRef]

- Nanni, A.; Parisi, M.; Colonna, M.; Messori, M. Thermo-Mechanical and Morphological Properties of Polymer Composites Reinforced by Natural Fibers Derived from Wet Blue Leather Wastes: A Comparative Study. Polymers 2021, 13, 1837. [Google Scholar] [CrossRef]

- Ramesh, P.; Prasad, B.D.; Narayana, K.L. Effect of MMT Clay on Mechanical, Thermal and Barrier Properties of Treated Aloevera Fiber/PLA-Hybrid Biocomposites. Silicon 2019, 12, 1751–1760. [Google Scholar] [CrossRef]

- Xu, H.; Liu, C.Y.; Chen, C.; Hsiao, B.S.; Zhong, G.J.; Li, Z.M. Easy alignment and effective nucleation activity of ramie fibers in injection-molded poly(lactic acid) biocomposites. Biopolymers 2012, 97, 825–839. [Google Scholar] [CrossRef]

| Parameters | Specific |

|---|---|

| Printing speed (mm/s) | 60 |

| Nozzle diameter (mm) | 0.4 |

| Layer thickness (mm) | 0.2 |

| Supplied speed (mm/s) | 60 |

| Raster angle (°) | 0 |

| Print temperature (°C) | 200 |

| Infilled rate | 100% |

| Sample | Tb | Residual Rate |

|---|---|---|

| PLA | 285.6 °C | 0.74% |

| PLA/CF | 291.8 °C | 15.76% |

| Specimen | Tg (°C) | Tcc (°C) | Tm (°C) | (J/g−1) | (J/g−1) | Xc (%) |

|---|---|---|---|---|---|---|

| PLA | 61.32 | 123.68 | 151.91 | 57.3 | 45.2 | 13.01 |

| PLA/CF | 62.13 | 115.63 | 159.87 | 54.6 | 9.5 | 48.49 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, M.; Cui, T.; Yue, Y.; Li, C.; Guo, X.; Jia, X.; Wang, B. Preparation and Characterization for the Thermal Stability and Mechanical Property of PLA and PLA/CF Samples Built by FFF Approach. Materials 2023, 16, 5023. https://doi.org/10.3390/ma16145023

Cao M, Cui T, Yue Y, Li C, Guo X, Jia X, Wang B. Preparation and Characterization for the Thermal Stability and Mechanical Property of PLA and PLA/CF Samples Built by FFF Approach. Materials. 2023; 16(14):5023. https://doi.org/10.3390/ma16145023

Chicago/Turabian StyleCao, Mengyu, Tianqi Cui, Yuhang Yue, Chaoyu Li, Xue Guo, Xin Jia, and Baojin Wang. 2023. "Preparation and Characterization for the Thermal Stability and Mechanical Property of PLA and PLA/CF Samples Built by FFF Approach" Materials 16, no. 14: 5023. https://doi.org/10.3390/ma16145023