The Effect of the Addition of Coal Fly Ash (CFA) on the Control of Water Movement within the Structure of the Concrete

Abstract

:1. Introduction

- Capillary porosity;

- The distribution of the size of capillary pores;

- The phase composition of the cement matrix.

- The water/cement or water/binder ratio;

- The type of cement;

- The degree of cement hydration;

- The content of mineral additives.

- Evaluation of the influence of the CFA additive in the amounts of 0%, 20%, and 30% on the level of water absorption of concretes and their compressive strength after 28 days of curing;

- Analysis of the microstructure of the cement matrix of the tested concretes;

- Linking the results obtained in the macroscopic tests with observations of the structures of the analyzed composites in order to prepare recommendations helpful in the development of concrete mix compositions with the addition of CFA in an amount of up to 30% with increased durability.

2. Materials and Methods

2.1. Materials

2.1.1. Aggregates

2.1.2. Binders

- Bogue’s method in the case of OPC;

- Rietvield quantitative analysis in the case of CFA.

2.1.3. Water

2.1.4. Admixture

2.2. Mix Proportions

- Constant: the total amount of the binder, the amount of coarse and fine aggregate, water, and the water–binder ratio: w/b = 0.4;

- Different series of concrete containing CFA amounts by weight: 0% (CFA-00), 20% (CFA-20), and 30% (CFA-30).

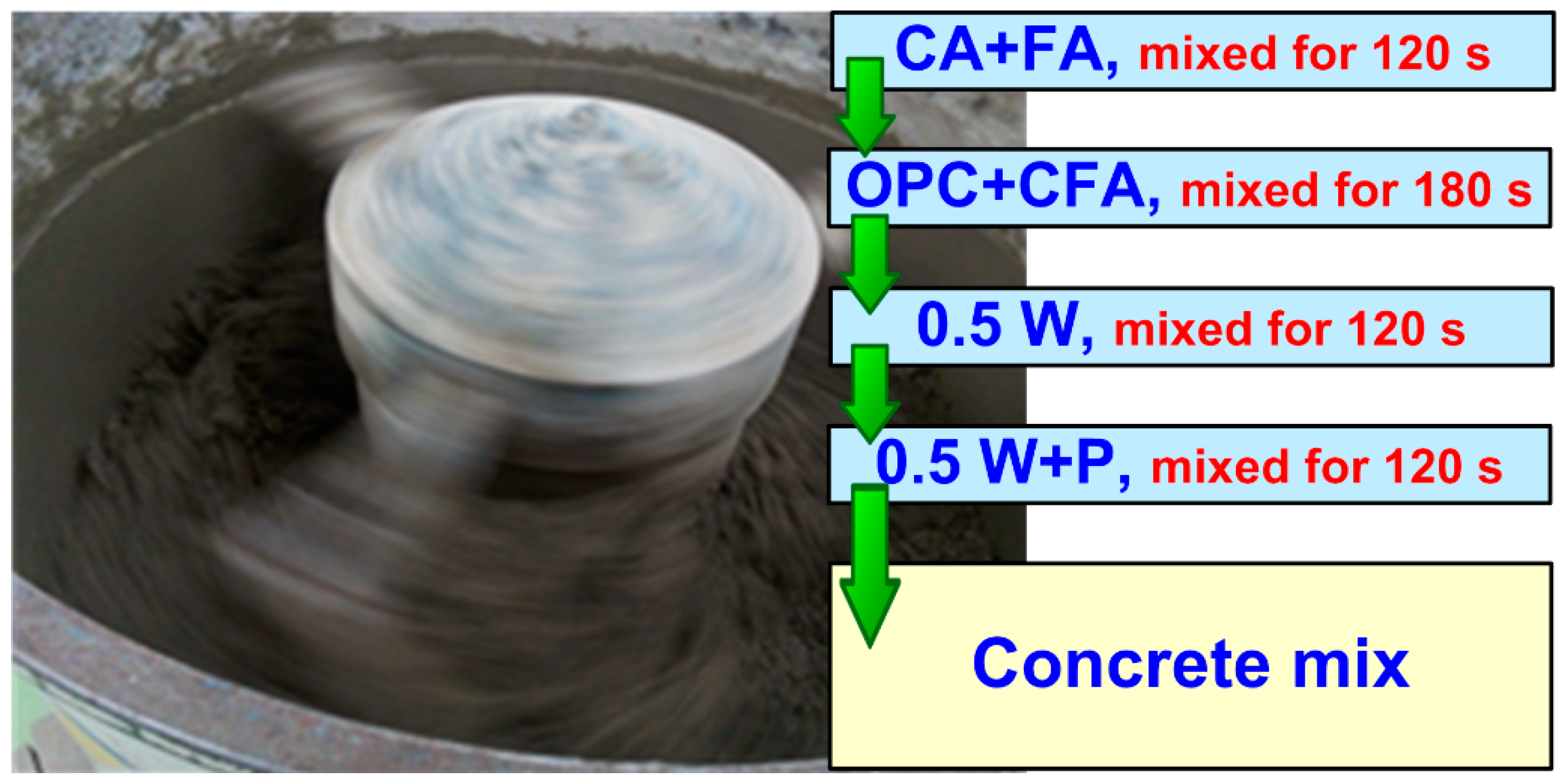

2.3. Mixing, Casting, and Curing of the Specimens

2.4. Experimental Procedures

2.4.1. Compressive Strength Tests

2.4.2. Determination of Water Absorption

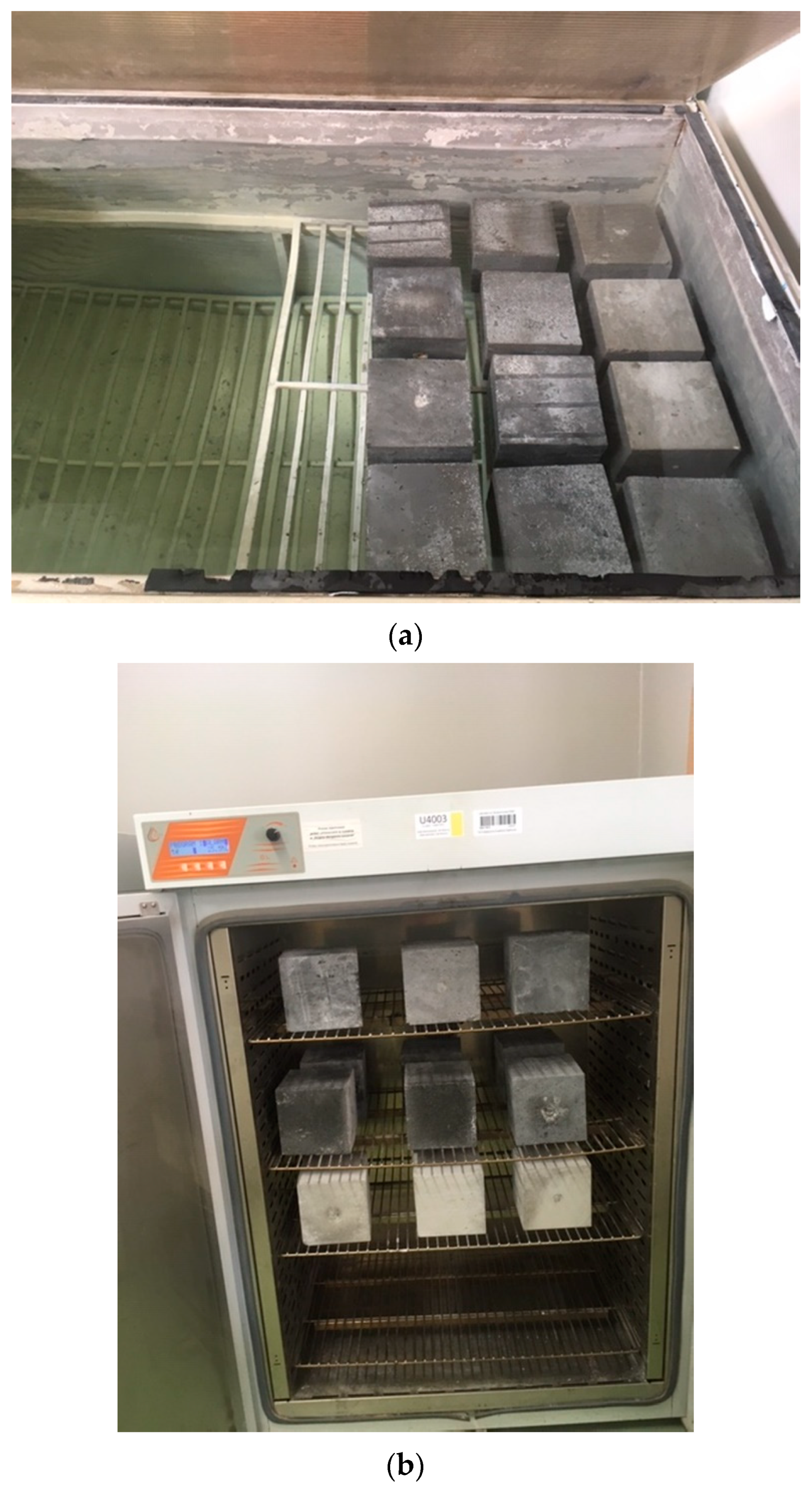

- Initially, the samples were placed in a bath vessel on washers with a thickness of about 10 mm so that the distance between the samples was at least 15 mm;

- The bath was filled with water at a temperature of 18 ± 2 °C to half the height of the samples;

- After 24 h, water was added to the bath to a level 10 mm higher than the level of the samples; this level was maintained until the end of sample saturation;

- After another 24 h, the samples were removed from the water, dried to remove excess water, and weighed with an accuracy of 0.2%;

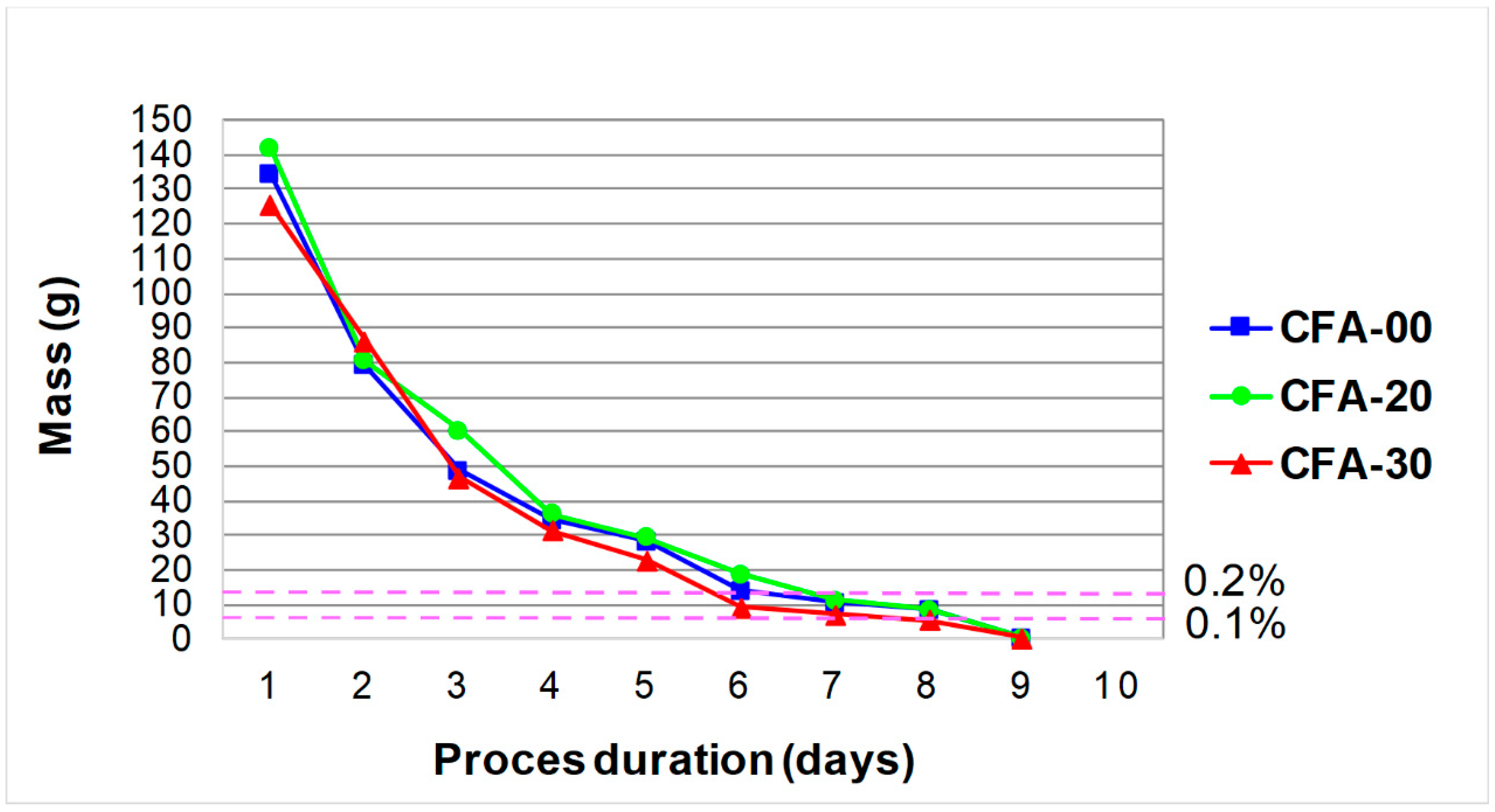

- The saturation of the samples lasted for the following days until two subsequent weighings showed no increase in mass (Figure 3a);

- After the samples were completely saturated, their mass was recorded, and then samples were placed in a dryer with hot air circulation in a Pol-Eko SLW 400 at 105 ± 5 °C (Figure 3b).

2.4.3. Microstructural Study

- Find the influence of the effect of CFA particles on the water absorption of the analyzed composites;

- Evaluate the air voids of the cement matrixes including CFA;

- Determine the degree of the homogenization of individual materials;

- Assess the degree of reaction of CFA grains;

- Evaluate the Interfacial Transition Zone (ITZ) areas between the coarse aggregate and the paste.

- The shape of the samples—rectangular concrete cube;

- Sample dimensions—10 × 10 × 3 mm;

- Preparation of the samples—taken as raw, i.e., the samples before the test were not polished or prepared in any other way;

- Number of samples—6 for each series of concrete;

- Number of photos per sample—30 photos were taken for each sample, from which the representative photos were selected;

- Magnifications used—200 to 80,000 times;

- Presentations—significant observed details like phases, pores, microcrack width in the ITZ area, and unreacted CFA particles were marked on the selected representative photos.

3. Results and Discussion

3.1. Mechanical Characterization and the Rate of Water Absorption

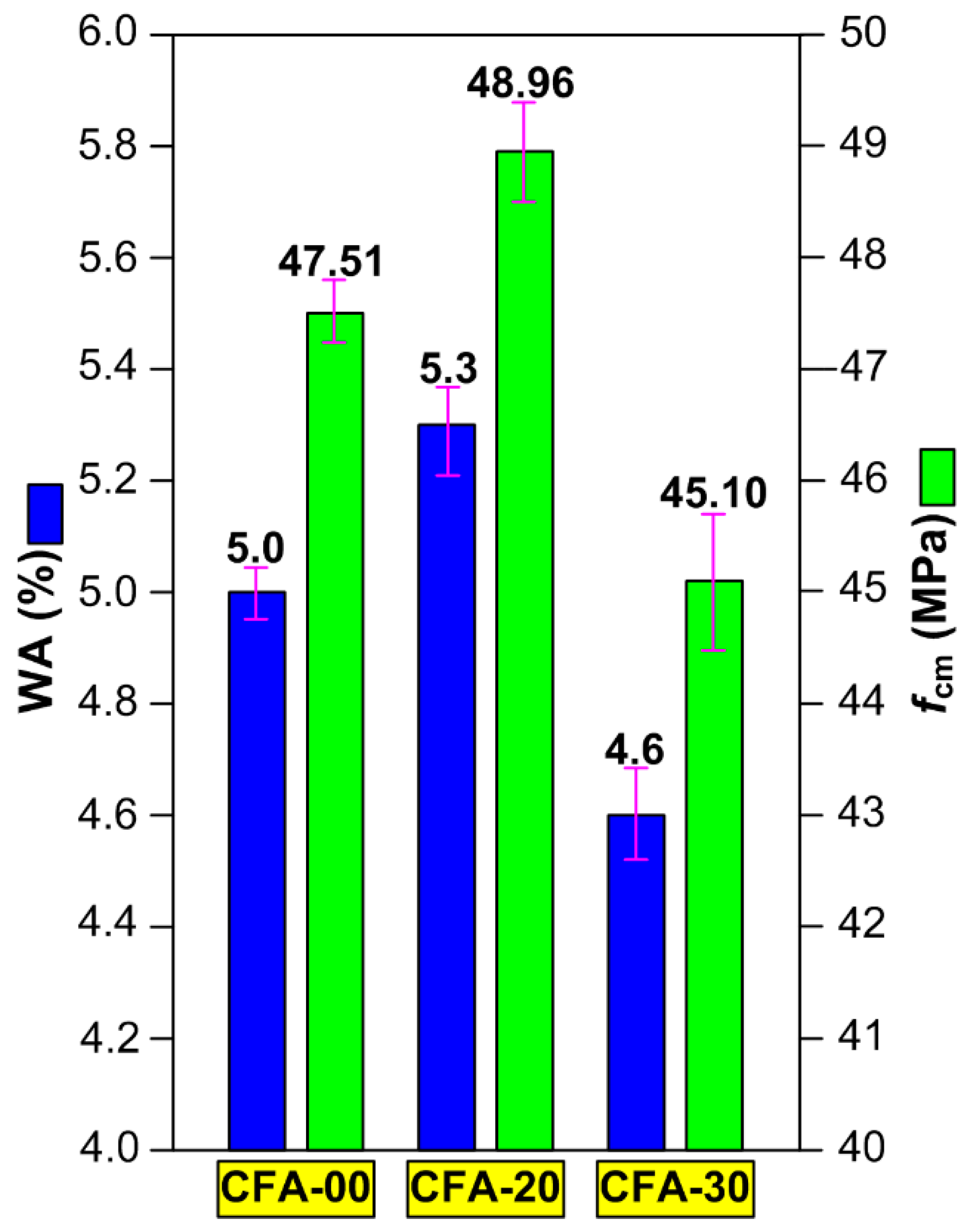

- The highest compressive strength had concrete CFA-20, while the lowest had CFA-30;

- When the content of CFA increased, the eater absorption of the composites with this waste clearly decreased (Figure 6);

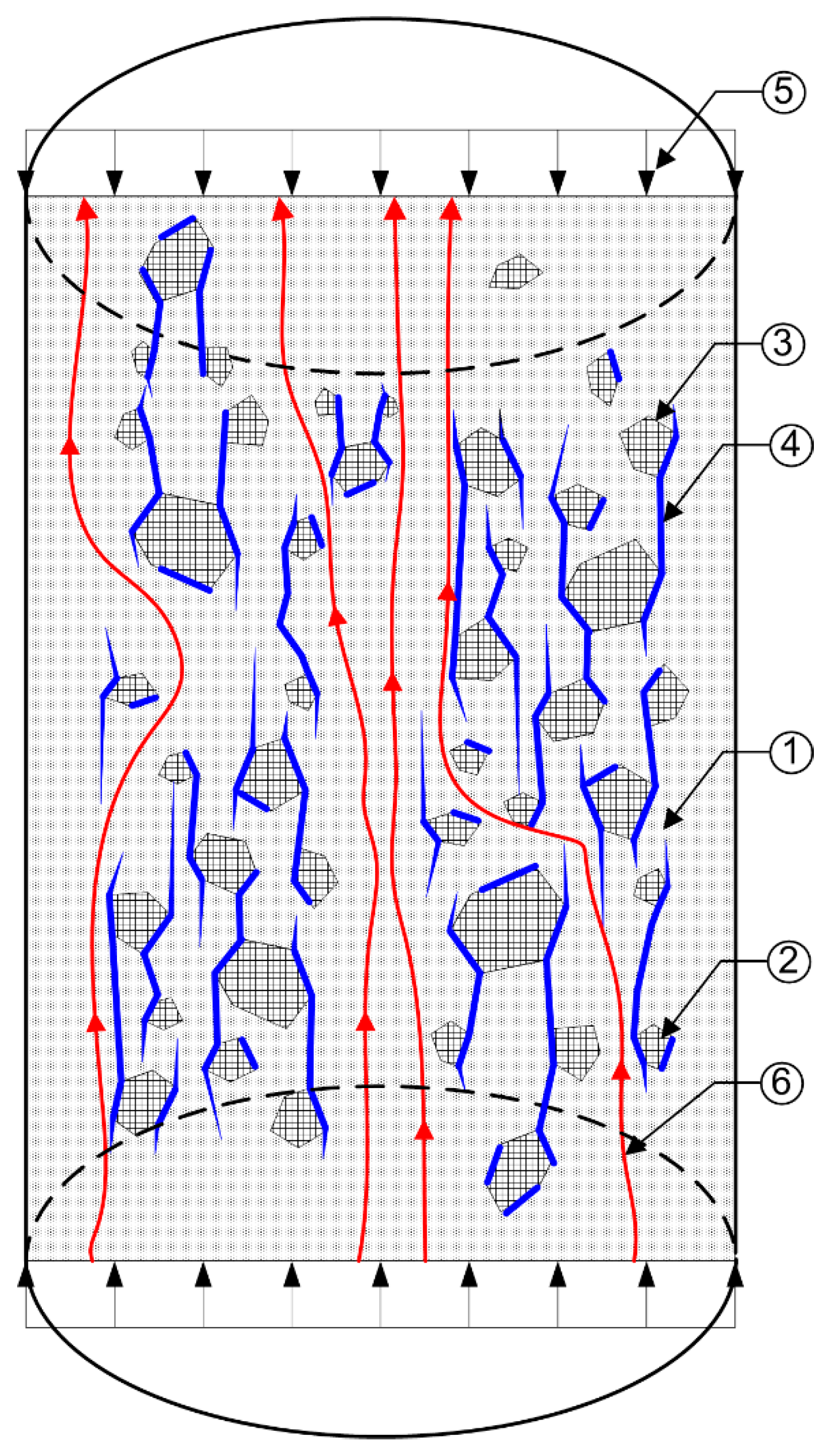

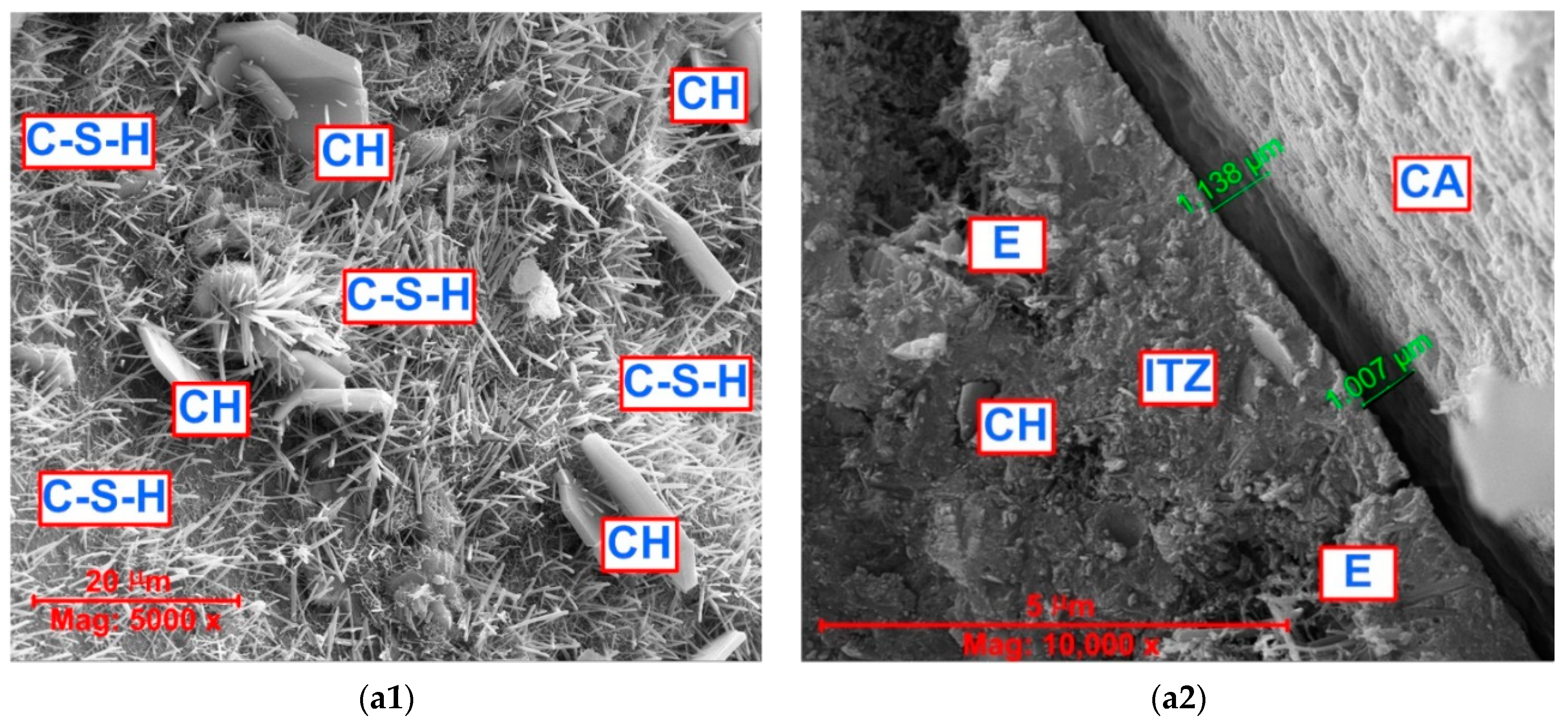

3.2. SEM Analysis

- Presented the typical microstructure of unmodified concrete and contained mainly the continuously developing phases of calcium silicate hydrate (C-S-H) and calcium hydroxide (CH);

- Clearly porous;

- Have loose clusters of the C-S-H phase;

- Include a few unreacted CFA grains.

- Compact and dense;

- The unhydrated CFA particles and cavities created after separating the CFA grains still existed.

- The rate of water absorption decreased with an increase in CFA level due to the reduction in the pore size with the incorporation of CFA [64];

- At low water-to-binder ratios, CFA leads to significantly smaller capillary absorption rates regardless of curing age [116];

- The pozzolanic reaction of CFA progresses significantly and consumes large amounts of CH, producing additional secondary C-S-H gels and resulting in denser and more compact microstructures, thus decreasing the amount of water absorption by immersion [82].

- Both the compressive strength of the concrete with the addition of CFA and its water absorption depend on the percentage of waste used;

- Both analyzed parameters are closely related to the structure of the cement matrix and ITZ areas in between the coarse aggregate grains and the paste.

- Reducing the content of large pores;

- Changing in the structure of the pores, i.e., a reduction in the share of large open capillary pores and the appearance of closed micropores of very small size;

- Reducing the CH content in the paste;

- Increasing the C-S-H phase content.

- At a content of 20% CFA in the binder composition, an increase in the compressive strength of the material is observed, with a simultaneous increase in its water absorption;

- Addition of 30% CFA results in a significant decrease in both the strength of the composite and its water absorption.

4. Conclusions

- (1)

- Compressive strength increased in concrete containing 20% CFA, i.e., in CFA-20, and decreased with an increase in CFA content up to 30%, i.e., in CFA-30;

- (2)

- Coal fly ash concrete made with up to a 30% replacement level showed better absorption behavior than reference concrete;

- (3)

- Both the compressive strength of concrete with the addition of CFA and its water absorption depend on the percentage of waste used, whereas both analyzed parameters are closely related to the structure of the cement matrix and ITZ areas between the coarse aggregate grains and paste;

- (4)

- At a content of 20% CFA in the binder composition, an increase in the compressive strength of the material is observed, with a simultaneous increase in its water absorption. On the other hand, the addition of 30% CFA results in a significant decrease in both the strength of the composite and its water absorption. Therefore, the compressive strength in concretes containing CFA behaved proportionally to the absorption by immersion;

- (5)

- The hydration products of concrete mixed with 20% CFA showed a loose and porous microstructure, and its water absorption increased accordingly;

- (6)

- The concrete composites including 30% CFA may increase the durability of reinforced concrete structures subjected to immersion conditions;

- (7)

- Finally, more investigations are needed on other parameters such as porosity, permeability, and depth of water penetration aspects of concrete made with CFA in order to better understand the influence of this waste on these specific and significant properties of concrete affecting the durability of these composites. The results of these studies will be the subject of subsequent publications.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, W.; Ye, X.; Li, R.; Yang, J. Effect of Stray Current on Corrosion and Calcium Ion Corrosion of Concrete Reinforcement. Materials 2022, 15, 7287. [Google Scholar] [CrossRef] [PubMed]

- Wardach, M.; Krentowski, J.R.; Mackiewicz, M. Evaluation of Precast Beam Deflections Resulting in Cracks in Curtain Walls. Eng. Fail. Anal. 2022, 140, 106568. [Google Scholar] [CrossRef]

- Golewski, G.L. The Specificity of Shaping and Execution of Monolithic Pocket Foundations (PF) in Hall Buildings. Buildings 2022, 12, 192. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, C.; Gao, Z.; Wang, F. A review on Fracture Properties of Steel Fiber Reinforced Concrete. J. Build. Eng. 2023, 67, 105975. [Google Scholar] [CrossRef]

- Golewski, G.; Sadowski, T. Fracture Toughness at Shear (Mode II) of Concretes Made of Natural and Broken Aggregates. Brittle Matrix Compos. 2006, 8, 537–546. [Google Scholar]

- Ma, Z.; Yue, Q.; Chen, Z. A Beam Test Study on the Bond Performance Between Epoxy-Coated Reinforcement and Geopolymer Concrete. Buildings 2023, 13, 430. [Google Scholar] [CrossRef]

- Liu, F.; Zou, Y.; Wang, B.; Yuan, X. The Effect of Stray Current on Calcium Leaching of Cement-Based Materials. Materials 2022, 15, 2279. [Google Scholar] [CrossRef]

- Golewski, G.L. Mechanical Properties and Brittleness of Concrete Made by Combined Fly Ash, Silica Fume and Nanosilica with ordinary Portland cement. AIMS Mater. Sci. 2023, 10, 390–404. [Google Scholar] [CrossRef]

- Amran, M.; Onaizi, A.M.; Qader, D.N.; Murali, G. Innovative Use of Fly Ash-Finely Powdered Glass Cullet as a Nano Additives for a Sustainable Concrete: Strength and Microstructure and Cost Analysis. Case Stud. Constr. Mater. 2022, 17, e01688. [Google Scholar] [CrossRef]

- Gil, D.M.; Golewski, G.L. Potential of Siliceous Fly Ash and Silica Fume as a Substitute of Binder in Cementitious Concrete. E3S Web Conf. 2018, 49, 00030. [Google Scholar] [CrossRef] [Green Version]

- Hashemmoniri, S.; Fatemi, A. Optimization of Lightweight Foamed Concrete Using Fly Ash Based on Mechanical Properties. Innov. Infrastruct. Solut. 2023, 8, 59. [Google Scholar] [CrossRef]

- Reis, J.M.L.; Chianelli-Junior, R.; Cardoso, J.L.; Marinho, F.J.V. Effect of Recycled PET in the Fracture Mechanics of Polymer Mortar. Constr. Build. Mater. 2011, 25, 2799–2804. [Google Scholar] [CrossRef] [Green Version]

- Golewski, G.L. Fracture Performance of Cementitious Composites Based on Quaternary Blended Cements. Materials 2022, 15, 6023. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Sun, X. Synergistic Effects of Nano-Silica and Fly Ash on the Mechanical Properties and Durability of Internal-Cured Concrete Incorporating Artificial Shale Ceramsite. J. Build. Eng. 2023, 66, 105905. [Google Scholar] [CrossRef]

- Golewski, G.L. Determination of Fracture Toughness in Concretes Containing Siliceous Fly Ash During Mode III Loading. Struct. Eng. Mech. 2017, 62, 1–9. [Google Scholar] [CrossRef]

- Wang, H.; Feng, G.; Qi, T.; Gao, X.; Wang, C.; Wang, L.; Zhang, Z. Influence of the Use of Corn Straw Fibers to Connect the Interfacial Transition Zone with the Mechanical Properties of Cemented Coal Gangue Backfill. Constr. Build. Mater. 2023, 367, 130334. [Google Scholar] [CrossRef]

- Zhang, B.; Zhu, H.; Lu, F. Fracture Properties of Slag-Based Alkali-Activated Seawater Coral Aggregate. Theor. Appl. Fract. Mech. 2019, 115, 103071. [Google Scholar] [CrossRef]

- Golewski, G.L.; Sadowski, T. Macroscopic Evaluation of Fracture Processes in Fly Ash Concrete. Solid State Phenom. 2016, 254, 188–193. [Google Scholar] [CrossRef]

- Chen, L.; Huang, L.; Hua, J.; Chen, Z.; Wei, L.; Osman, A.I.; Fawzy, S.; Rooney, D.W.; Dong, L.; Yap, P.-S. Green Construction for Low-Carbon Cities: A Review. Env. Chem. Lett. 2023, 21, 1627–1657. [Google Scholar] [CrossRef]

- Lata, P.; Kaur, I. Thermomechanical Interactions in Transversely Isotropic Magneto Thermoelastic Solid with Two Temperatures and without Energy Dissipation. Steel Compos. Struct. 2019, 32, 779–793. [Google Scholar]

- Golewski, G.L. Comparative Measurements of Fracture Toughness Combined with Visual Analysis of Cracks Propagation Using the DIC Technique of Concretes Based on Cement Matrix with a Highly Diversified Composition. Theor. Appl. Fract. Mech. 2022, 121, 103553. [Google Scholar] [CrossRef]

- Bicer, A. Effect of Production Temperature on Thermal and Mechanical Properties of Polystyrene-Fly Ash Composites. Adv. Compos. Lett. 2020, 29, 2633366X20917988. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Mao, T.; Xia, Y.; Li, X.; Yi, X. Macro-Meso Fatigue Failure of Bimrocks with Various Block Content Subjected to Multistage Fatigue Triaxial Loads. Int. J. Fatigue 2022, 281, 163107014. [Google Scholar] [CrossRef]

- Peride, N.; Carabineanu, A.; Craciun, E.M. Mathematical Modelling of the Interface Crack Propagation in a Pre-Stressed Fiber Reinforced Elastic Composite. Comp. Mater. Sci. 2009, 45, 684–692. [Google Scholar] [CrossRef]

- Golewski, G.L. Studies of natural radioactivity of concrete with siliceous fly ash addition. Cem. Wapno Beton 2015, 2, 106–114. [Google Scholar]

- Brahma Chari, K.J.; Ranga Rao, V. Durability and Microstructure Characteristics of Concrete with Supplementary Cementitious Materials. Civ. Eng. J. 2022, 8, 683–694. [Google Scholar] [CrossRef]

- Golewski, G.L. On the Special Construction and Materials Conditions Reducing the Negative Impact of Vibrations on Concrete Structures. Mater. Today Proc. 2020, 45, 4344–4348. [Google Scholar] [CrossRef]

- Nodehi, M.; Ozbakkaloglu, T.; Gholampour, A. Effect of Supplementary Cementitious Materials on Properties of 3D Printed Conventional and Alkali-Activated Concrete: A Review. Autom. Constr. 2022, 138, 104215. [Google Scholar] [CrossRef]

- Craciun, E.M.; Carabineanu, A.; Peride, N. Antiplane Interface Crack in a Pre-Stressed Fiber-Reinforced Elastic Composite. Comp. Mater. Sci. 2008, 43, 184–189. [Google Scholar] [CrossRef]

- Wang, J.; Li, J.; Hi, Z.S.; Chen, J. Energy Evolution and Failure Characteristics of Red Sandstone under Discontinuous Multilevel Fatigue Loading. Int. J. Fatigue 2022, 160, 106830. [Google Scholar] [CrossRef]

- Golewski, G.L. Green Concrete Based on Quaternary Binders with Significant Reduced of CO2 Emissions. Energies 2021, 14, 4558. [Google Scholar] [CrossRef]

- Golewski, G.L.; Sadowski, T. A Study on Mode III Fracture Toughness in Young and Mature Concrete with Fly Ash Additive. Solid State Phenom. 2016, 254, 120–125. [Google Scholar] [CrossRef]

- Li, Y.; Wu, B.; Wang, R. Critical Review and Gap Analysis on the use of High-Volume Fly Ash as a Substitute Constituent in Concrete. Constr. Build. Mater. 2022, 341, 127889. [Google Scholar] [CrossRef]

- Aminul Haque, M.; Chen, B.; Faisal Javed, M.; Jalal, F.E. Evaluating the Mechanical Strength Prediction Performances of Fly Ash Based MPC Mortar with Artificial Intelligence Approaches. J. Clean. Prod. 2022, 355, 131815. [Google Scholar] [CrossRef]

- Li, X.; Zhang, Q. Influence Behavior of Phosphorus Slag and Fly Ash on the Interface Transition Zone in Concrete Prepared by Cement-Red Mud. J. Build. Eng. 2021, 49, 104017. [Google Scholar] [CrossRef]

- Biricik, H.; Sarier, N. Comparative Study of the Characteristics of Nanosilica–, Silica fume– and Fly Ash–Incorporated Cement Mortars. Mater. Res. 2014, 17, 570–582. [Google Scholar] [CrossRef]

- Al-Mansour, A.; Chow, C.L.; Feo, L.; Penna, R.; Lau, D. Green Concrete: By-Products Utilization and Advanced Approaches. Sustainability 2019, 11, 5145. [Google Scholar] [CrossRef] [Green Version]

- Golewski, G.L. An Analysis of Fracture Toughness in Concrete with Fly Ash Addition, Considering All Models of Cracking. IOP Conf. Ser. Mater. Sci. Eng. 2018, 416, 012029. [Google Scholar] [CrossRef] [Green Version]

- Szostak, B.; Golewski, G.L. Effect of Nano Admixture of CSH on Selected Strength Parameters of Concrete Including Fly Ash. IOP Conf. Ser. Mater. Sci. Eng. 2018, 416, 012105. [Google Scholar] [CrossRef]

- Karim, M.R.; Zain, M.F.M.; Jamil, M.; Lai, F.C. Development of a Zero-Cement Binder Using Slag, Fly Ash, and Rice Husk Ash with Chemical Activator. Adv. Mater. Sci. Eng. 2015, 2015, 247065. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Zhang, P.; Golewski, G.L.; Guan, J. Editorial: Fabrication and Properties of Concrete Containing Industrial Waste. Front. Mater. 2023, 10, 1169715. [Google Scholar] [CrossRef]

- Golewski, G.L.; Szostak, B. Strength and Microstructure of Composites with Cement Matrixes Modified by Fly Ash and Active Seeds of C-S-H Phase. Struct. Eng. Mech. 2022, 82, 543–556. [Google Scholar]

- Fu, Q.; Zhang, Z.; Wang, Z.; He, J.; Niu, D. Erosion behavior of Ions in Lining Concrete Incorporating Fly Ash and Silica Fume under the Combined Action of Load and Flowing Groundwater Containing Composite Salt. Case Stud. Constr. Mater. 2022, 17, e01659. [Google Scholar] [CrossRef]

- Wu, C.-H.; Huang, C.-H.; Kan, Y.-C.; Yen, T. Effect of Fineness and Dosage of Fly aAh on the Fracture Properties and Strength of Concrete. Appl. Sci. 2019, 9, 2266. [Google Scholar] [CrossRef] [Green Version]

- Wong, L.S.; Chandran, S.M.; Rajasekar, R.R.; Kong, S.Y. Pozzolanic Characterization of Waste Newspaper Ash as a Supplementary Cementing Material of Concrete Cylinders. Case Stud. Constr. Mater. 2022, 17, e01342. [Google Scholar] [CrossRef]

- Golewski, G.L. An Extensive Investigations on Fracture Parameters of Concretes Based on Quaternary Binders (QBC) by Means of the DIC Technique. Constr. Build. Mater. 2022, 351, 128823. [Google Scholar] [CrossRef]

- Liu, C.; Yang, L.; Li, Z.; Nie, S.; Hu, C.; Wang, F. Imrove the Long-Term Property of Heat-Cured Mortars Blended with Fly Ash by Internal Curing. J. Build. Eng. 2022, 54, 104624. [Google Scholar] [CrossRef]

- Pathak, S.S.; Vesmawala, G.R. Influence of TiO2 and Fly Ash on Fracture Parameters of Concrete Notched Beams. J. Adv. Concr. Technol. 2022, 20, 624–639. [Google Scholar] [CrossRef]

- Golewski, G.L.; Sadowski, T. Experimental Investigation and Numerical Modelling Fracture Processes in Fly Ash Concrete at Early Age. Solid State Phenom. 2012, 188, 158–163. [Google Scholar] [CrossRef]

- Golewski, G.L. Study of Strength and Microstructure of a New Sustainable Concrete Incorporating Pozzolanic Materials. Struct. Eng. Mech. 2023, 86, 431–441. [Google Scholar]

- Lyratzakis, A.; Tsompanakis, Y.; Psarropoulos, P.N. Efficient Mitigation of High-Speed Train Vibrations on Adjacent Reinforced Concrete Buildings. Constr. Build. Mater. 2022, 314, 125653. [Google Scholar] [CrossRef]

- Golewski, G.L. The Phenomenon of Cracking in Cement Concretes and Reinforced Concrete Structures: The Mechanism of Cracks Formation, Causes of Their Initiation, Types and Places of Occurrence, and Methods of Detection—A Review. Buildings 2023, 13, 765. [Google Scholar] [CrossRef]

- Park, S.; Beak, J.; Kim, K.; Park, Y.-J. Study on Reduction Effect of Vibration Propagation Due to Internal Explosion Using Composite Materials. Int. J. Concr. Struct. Mater. 2021, 15, 30. [Google Scholar] [CrossRef]

- El-Chabib, H.; Ibrahim, A. The Performance of High-Strength Flowable Concrete Made with Binary, Ternary, or Quaternary Binder in Hot Climate. Constr. Build. Mater. 2013, 47, 245–253. [Google Scholar] [CrossRef]

- Golewski, G.L. Combined Effect of Coal Fly Ash (CFA) and Nanosilica (Ns) on the Strength Parameters and Microstructural Properties of Eco-Friendly Concrete. Energies 2023, 16, 452. [Google Scholar] [CrossRef]

- Sun, H.; Zou, H.; Li, X.; Ali Memon, S.; Yuan, B.; Xing, F.; Zhang, X.; Ren, J. Combined Effects of Sulfate and Chloride Attack on Steel Reinforced Mortar under Drying–Immersion Cycles. Buildings 2022, 12, 1252. [Google Scholar] [CrossRef]

- Sun, D.; Cao, Z.; Huang, C.; Wu, K.; De Schutter, G.; Zhang, L. Degradation of Concrete in Marine Environment under Coupled Chloride and Sulfate Attack: A Numerical and Experimental Study. Case Stud. Constr. Mater. 2022, 17, e01218. [Google Scholar] [CrossRef]

- Yin, R.; Zhang, C.; Wu, Q.; Li, B.; Xie, H. Damage on Lining Concrete in Highway Tunnels under Combined Sulfate and Chloride Attack. Front. Struct. Civ. Eng. 2018, 12, 331–340. [Google Scholar] [CrossRef]

- Czarnecki, L.; Geryło, R.; Kuczyński, K. Concrete Repair Durability. Materials 2020, 13, 4535. [Google Scholar] [CrossRef]

- Kewalramani, M.; Khartabil, A. Porosity Evaluation of Concrete Containing Supplementary Cementitious Materials for Durability Assessment Through Volume of Permeable Voids and Water Immersion Conditions. Buildings 2021, 11, 378. [Google Scholar] [CrossRef]

- Mehta, P.K. Durability—Critical Issues for the Future. Concr. Int. 1997, 19, 27–33. [Google Scholar]

- Aparna, S.; Sathyanb, D.; Anand, K.B. Microstructural and Rate of Water Absorption Study on Fly-Ash Incorporated Cement Mortar. Mater. Today Proc. 2018, 5, 23692–23701. [Google Scholar] [CrossRef]

- Śliwiński, J. Basic Properties of Concrete and its Durability. Cem. Wapno Beton 2009, 5, 245–354. [Google Scholar]

- Sinkhonde, D.; Ocharo Onchiri, R. Odhiambo Oyawa, W.; Nyiro Mwero, J. Durability and Water Absorption Behaviour of Rubberised Concrete Incorporating Burnt Clay Brick Powder. Clean Mater. 2022, 4, 100084. [Google Scholar] [CrossRef]

- Raghav, M.; Karthick, S.; Park, T.; Lee, H.-S. Assessment of Corrosion Performance of Steel Rebar in Snail Shell Ash Blended Cements under Marine Environments. Materials 2021, 14, 7286. [Google Scholar] [CrossRef]

- De Schutter, G.; Audenaert, K. Evaluation of Water Absorption of Concrete as a Measure for Resistnace Against Carbonation and Chloride Migration. Mater. Struct. 2004, 37, 591–596. [Google Scholar] [CrossRef]

- Tracz, T.; Śliwiński, J. Effect of Cement Paste Content and w/c Ratio on Concrete Water Absorption. Cem. Wapno Beton 2012, 3, 131–137. [Google Scholar]

- Folagbade, S.O. Absorption Characteristics of Cement Combination Concrete Containing Portland Cement, Fly Ash, and Metakaolin. Civ. Eng. Dimens. 2016, 18, 57–64. [Google Scholar]

- Glinicki, M.A. Methods of Qualitative and Quantitative Assessment of Concrete Air Entrainment. Cem. Wapno Beton 2014, 6, 359–369. [Google Scholar]

- Golda, A.; Kaszuba, S. Concrete Absorbality—Requirements and Measuring Methods. Cem. Wapno Beton 2009, 6, 308–313. [Google Scholar]

- McCarter, W.J.; Ezirim, H.; Emerson, M. Absorption of Water and Chloride into Concrete. Mag. Concr. Res. 1992, 44, 31–37. [Google Scholar] [CrossRef]

- Willson, M.L.; Tennis, P. Design and Control of Concreto Mixtures, 17th ed.; PCA: Washington, DC, USA, 2021. [Google Scholar]

- Razak, A.B.; Chai, H.K.; Wong, H.S. Near Surface Characteristics of Concrete Containing Supplementary Cementing Materials. Cem. Concr. Compos. 2004, 26, 883–889. [Google Scholar] [CrossRef]

- Abdrazakov, F.; Pankova, T.; Orlova, S.; Mikheeva, O.; Mirkina, E.; Mizyurova, E. Hydrotechnical structures. IOP Conf. Ser. Mater. Sci. Eng. 2020, 1001, 012097. [Google Scholar] [CrossRef]

- Abdrazakov, F.; Orlova, S.; Pankova, T.; Mirkina, E.; Fedyunina, T. The Monitoring of Condition of Hydraulic Structures. J. Adv. Res. Dyn. Control Syst. 2018, 10, 1952–1958. [Google Scholar]

- Ehsani, A.; Nili, M.; Shaabani, K. Effect of Nanosilica on the Compressive Strength Development and Water Absorption Properties of Cement Paste and Concrete Containing Fly Ash. KSCE J. Civ. Eng. 2017, 21, 1854–1865. [Google Scholar] [CrossRef]

- Yildirim, H.; Uyan, G.M.; Kemerli, M.K. Effect of Waterproofing Admixtures Types on Permeability of Concreto. In Proceedings of the 5th national Concrete Congress, Istanbul, Turkey, 26–30 May 2003; pp. 123–131. [Google Scholar]

- Dong, Y.; Ma, Y.; Zhu, J.; Qiu, J. Study on Impermeability of Foamed Concrete Containing Municipal Solid Waste Incineration Powder. Materials 2022, 15, 5176. [Google Scholar] [CrossRef]

- Ismail, M.H.; Mohd Rusly, N.S.; Deraman, R. Strength and Water Absorption of Concrete Containing Metakaolin and Nylon Fiber. IJSCET 2020, 11, 230–242. [Google Scholar]

- Salih, M.A. Strength and Durability of High Performance Concrete Containing Fly Ash and Micro Silica. IJCIET 2018, 9, 104–114. [Google Scholar]

- Ranjith, S.; Venkatasubramani, R.; Rreevidya, V.S. Comparative Study on Durability Properties of Engineered Cementitious Composites with Polypropylene Fiber and Glass Fiber. Arch. Civ. Eng. 2017, 63, 83–101. [Google Scholar] [CrossRef] [Green Version]

- Śliwiński, J.; Tracz, T.; Deja, J.; Łagosz, A. Selected Properties of Concretes with an Addition of Fractionated Siliceous and Fluidised Bed Fly Ash. Cem. Wapno Beton 2018, 2, 81–90. [Google Scholar]

- Siddique, R. Compressive Strength, Water Absorption, Sorptivity, Abrasion Resistance and Permeability of Self-Compacting Concrete Containing Coal Bbottom Ash. Constr. Build Mater. 2013, 47, 1444–1450. [Google Scholar] [CrossRef]

- Wilińska, I.; Pacewska, B.; Kubissa, W. Investigation of Portland Cement Composites Containing High Amounts of Different Kinds of Fly Ashes. In Proceedings of the 13th International Conference Modern Building Materials, Structures and Techniques, Vilnius, Lithuania, 16–17 May 2019; pp. 207–216. [Google Scholar]

- da Costa, F.B.P.; Righi, D.P.; Graeff, A.G.; da Silva Filho, L.C.P. Evaluation of Water Absorption on Engineered Cementitious Composites Containing Rice Husk Ash. In Proceedings of the BCCM-3—Brazilian Conference on Composite Materials, Gramado, Brazil, 28–31 August 2016; pp. 207–216. [Google Scholar]

- Gibas, K.; Glinicki, M.A.; Nowowiejski, G. Evaluation of Impermeability of Concrete Containing Calcareous Fly Ash in Respect to Environmental Media. Road Bridges 2013, 12, 159–171. [Google Scholar]

- Piasta, W.; Jaworska, M.; Bucik, A. Influence of High Calcium and Low Calcium Fly Ashes on Strength and Water Absorption of Mortars. Struct. Environ. 2013, 5, 5–10. [Google Scholar]

- Wang, J.; Wang, M. Experimental Study on Water Absorption Proces of Fly Ash Concrete under Sustained Load. IPPTA Q. J. Indian Pulp Pap. Tech. Assoc. 2018, 30, 100–106. [Google Scholar]

- Sun, J.; Zhang, Y.; Shen, X.; Tan, G.; Tanner, J. Water Absorption of High Volume Fly Ash Concrete Prepared by Local Fly Ash. In Proceedings of the 15th International Congress on the Chemistry of Cement, Prague, Czech Republik, 16–20 September 2019. [Google Scholar]

- Karahan, O. Transport Properties of High Volume Fly Ash or Slag Concrete Exposed to High Temperature. Constr. Build. Mater. 2017, 152, 898–906. [Google Scholar] [CrossRef]

- Kurda, R.; de Brito, J.; Silvestre, J.D. Water Absorption and Electrical Resistivity of Concrete with Recycled Concrete Aggregates and Fly Ash. Cem. Concr. Compos. 2019, 95, 169–182. [Google Scholar] [CrossRef]

- Malešev, M.; Radonjanin, V.; Draganić, S.; Šupić, S.; Laban, M. Influence of Fly Ash and Decreasing Water-Powder Ratio on Performance of Recycled Aggregate Concrete. Gradevinar 2017, 69, 811–820. [Google Scholar]

- Ding, Z.; Quy, N.X.; Kim, J.; Hama, Y. Evaluations of Frost and Scaling Resistance of Fly Ash Concrete in Terms of Changes in Water Absorption and Pore Structure under the Accelerated Carbonation Conditions. Constr. Build. Mater. 2022, 345, 128273. [Google Scholar] [CrossRef]

- Gabriel, G.; Surpobo, P.; Irawan, D.; Wahyuniarsih, S.; Asdam, T. Investigation of Water Absorption for Concrete Using Supplementary Materials. IPTEK J. Technol. Sci. 2020, 31, 309–317. [Google Scholar]

- Khatib, J.M.; Mangat, P.S. Absorption Characteristics of Concrete as a Function of Location Relative to Casting Position. Cem. Concr. Res. 1995, 25, 999–1010. [Google Scholar] [CrossRef]

- Golewski, G.L. Effect of Fly Ash Addition on the Fracture Toughness of Plain Concrete at Third Model of Fracture. J. Civ. Eng. Manag. 2017, 23, 613–620. [Google Scholar] [CrossRef] [Green Version]

- Mendes, A.; Sanjayan, J.G.; Gates, W.P.; Collins, F. The Influence of Water Absorption and Porosity on the Deterioration of Cement Paste and Concrete Exposed to Elevated Temperatures, as in a Fire Event. Cem. Concr. Compos. 2012, 34, 1067–1074. [Google Scholar] [CrossRef]

- Nanda, B.; Rout, S. Properties of Concrete Containing Fly Ash and Bottom Ash Mixture as Fine Aggregate. Int. J. Sustain. Eng. 2021, 14, 809–819. [Google Scholar] [CrossRef]

- Foti, D.; Lerna, M.; Sabbà, M.F.; Vacca, V. Mechanical Characteristics and Water Absorption Properties of Blast-Furnace Slag Concretes with Fly Ashes or Microsilica Additions. Appl. Sci. 2019, 9, 1279. [Google Scholar] [CrossRef] [Green Version]

- Golewski, G.L. Generalized Fracture Toughness and Compressive Strength of Sustainable Concrete Including Low Calcium Fly Ash. Materials 2017, 10, 1393. [Google Scholar] [CrossRef] [Green Version]

- Huang, Q.; Zhao, L. Correlation Between Compressive Strength and Water Absorption of Fly Ash Cement Mortar Immersed in Water. Arch. Civ. Eng. 2019, 65, 141–152. [Google Scholar] [CrossRef] [Green Version]

- Demirci, E.E.; Sahin, R. Effect of Strength Class of Concrete and Curing Conditions on Capillary Water Absorption of Self-Compacting and Conventional Concrete. Int. J. Civ. Arch. Struct. Constr. Eng. 2014, 8, 1131–1138. [Google Scholar]

- EN 197-1:2011; Cement–Part 1: Composition, Specifications and Conformity Criteria For Common Cements. NSAI Standard: Dublin, Ireland, 2011.

- ASTM C 618-03; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. Annual Book of ASTM Standard: West Conshohocken, PA, USA, 2008.

- EN 1008; Mixing Water for Concrete—Specification for Sampling, Testing and Assessing the Suitability of Water, including Water Recovered from Processes in the Concrete Industry, as Mixing Water for Concrete. British Standards Institution (BSI): London, UK, 2002.

- EN 12390-3:2011+AC; Testing Hardened Concrete–Part 3: Compressive Strength of Test Specimens. British Standards Institution (BSI): London, UK, 2012.

- PN-B-06250:1988; Beton Zwykły; [Ordinary Concrete]. PKN: Warsaw, Poland, 1988. (In Polish)

- EN 13369:2018-05; Common Rules for Precast Concrete Products. British Standards Institution (BSI): London, UK, 2018.

- Golewski, G.L. The Role of Pozzolanic Aactivity of Siliceous Fly Ash in the Formation of the Structure of Sustainable Cementitious Composites. Sustain. Chem. 2022, 3, 520–534. [Google Scholar] [CrossRef]

- Larbi, J.A. Microstructure of the Interfacial Zone Around Aggregate Particles in Concrete. Heron 1993, 38, 1–69. [Google Scholar]

- Lin, J.; Zhao, Q.; Chen, H.; Li, M.; Yuan, L. A Numerical Study of ITZ Percolation in Polyphase Concrete Systems Considering the Synergetic Effect of Aggregate Shape- and Size-Diversities. Materials 2023, 16, 2515. [Google Scholar] [CrossRef]

- Prokopski, G.; Halbiniak, J. Interfacial Transition Zone in Cementitious Materials. Cem. Concr. Res. 2000, 30, 579–583. [Google Scholar] [CrossRef]

- Diamond, S. Cement Paste Microstructure: An Overview at Several Levels. In Hydraulic Cement Pastes: Their Structure and Properties; Cement and Concrete Association: London, UK, 1977; pp. 2–31. [Google Scholar]

- Nath, P.; Sarker, P. Effect of Fly Ash on the Durability Properties of High Strength Concrete. Proc. Eng. 2011, 14, 1149–1156. [Google Scholar] [CrossRef] [Green Version]

- Golewski, G.L. Concrete Composites Based on Quaternary Blended Cements with a Reduced Width of Initial Microcracks. Appl.Sci. 2023, 13, 7338. [Google Scholar] [CrossRef]

- Zhuang, S.; Wang, Q.; Zhang, M. Water Absorption Behaviour of Concrete: Novel Experimental Findings and Model Characterization. J. Build. Eng. 2022, 53, 104602. [Google Scholar] [CrossRef]

- Sun, Z.; Xiong, J.; Cao, S.; Zhu, J.; Jia, X.; Hu, Z.; Liu, K. Effect of Different Fine Aggregate Characteristics on Fracture Toughness and Microstructure of Sand Concrete. Materials 2023, 16, 2080. [Google Scholar] [CrossRef]

- Kurdowski, W. Cement and Concrete Chemistry; Springer: Dordrecht, The Netherlands; New York, NY, USA, 2014. [Google Scholar]

- Neville, A.M. Properties of Concrete; Pearson Education Limited: Harlow, UK, 2011. [Google Scholar]

- Odler, I. Strength of cement (final report). Mater. Struct. 1991, 24, 143–157. [Google Scholar] [CrossRef]

| Addition of CFA (%) | Age of Samples | Results and the Main Conclusions from the Studies | Reference |

|---|---|---|---|

| 15; 25; 35 | 28 | WA decreased with an increase in the amount of CFA | [64] |

| 25 | 28; 90 | WA ranged from 4.8% after 28 days to 5.1% after 90 days | [82] |

| 40; 55; 70 | 28; 90 | Larger quantities of CFA lead to higher WA after 28 days | [89] |

| After 90 days of curing, the amount of WA decreased | |||

| 30; 50; 70; 90 | 28 | WA ranged from 4.4 to 7.3% The low WA was observed in concrete with 30% CFA Other concretes showed higher WA than the control concrete | [90] |

| 30; 60 | 28 | WA decreased with an increase in the amount of CFA | [91] |

| 30; 50 | 28 | Larger quantities of CFA lead to lower WA | [92] |

| 7.5; 15; 25 | 28 | WA increased with an increase in the amount of CFA | [93] |

| 15 | 28 | The addition of CFA decreased WA | [94] |

| 22 | 90 | WA ranged from 4.3 to 8.0% | [95] |

| Property | Unit | Aggregate Type | |

|---|---|---|---|

| Fine Aggregate (FA) | Coarse Aggregate (CA) | ||

| Specific density | (g/cm3) | 2.60 | 2.65 |

| Bulk density | (g/cm3) | 2.20 | 2.25 |

| Compressive strength | (MPa) | 33 | 34 |

| Modulus of elasticity | (102 MPa) | 330 | 330 |

| Sand point for the aggregate mix | (%) | 40.7 | |

| Material\Constituent | SiO2 | Al2O3 | CaO | MgO | SO3 | Fe2O3 | K2O | P2O5 | TiO2 | Ag2O |

|---|---|---|---|---|---|---|---|---|---|---|

| OPC | 15.00 | 2.78 | 71.06 | 1.38 | 4.56 | 2.72 | 1.21 | - | - | - |

| CFA | 55.27 | 26.72 | 2.35 | 0.81 | 0.47 | 6.66 | 3.01 | 1.92 | 1.89 | 0.10 |

| Phase Type | C3S | C2S | C3A | C4AF |

|---|---|---|---|---|

| Contents | 60.69 | 15.82 | 9.24 | 7.28 |

| Phase Type | Vitreous | Crystalline | |

|---|---|---|---|

| Quartz (SiO2) | Mullite (Al6Si2O13) | ||

| Contents | 71.5 | 19.7 | 8.8 |

| Type | Analyzed Parameter | |||

|---|---|---|---|---|

| Specific Gravity (g/cm3) | Specific Surface Area (m2/g) | Average Particle Diameter (μm) | Color (Visually) | |

| OPC | 3.11 | 0.33 | 40.0 | Light gray |

| CFA | 2.14 | 0.36 | 30.0 | Dark gray |

| Mix | OPC | %OPC | CFA | %CFA | W | P | FA | CA |

|---|---|---|---|---|---|---|---|---|

| CFA-00 | 352 | 100 | 0 | 0 | 141 | 2 | 676 | 1205 |

| CFA-20 | 282 | 80 | 70 | 20 | 141 | 2 | 676 | 1205 |

| CFA-30 | 246 | 70 | 106 | 30 | 141 | 2 | 676 | 1205 |

| Parameter | Date |

|---|---|

| Air circulation | Natural |

| Chamber volume (L) | 400 |

| Chamber material | Acid-proof stainless steel |

| Outline dimensions (mm) width × height depth | 1240 × 1140 × 800 + 60 (handle) |

| Chamber dimensions (mm) width × height × depth | 995 × 790 × 510 |

| Operating temperature range (°C) | 5 °C above ambient temperature up to 250 °C |

| Rated power (kW) | 3500 |

| Temperature regulation (°C) | co 0.1 °C |

| Temperature stability at 105 °C (°C) | ±0.5 °C |

| Number of shelves standard/max | 3/11 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Golewski, G.L. The Effect of the Addition of Coal Fly Ash (CFA) on the Control of Water Movement within the Structure of the Concrete. Materials 2023, 16, 5218. https://doi.org/10.3390/ma16155218

Golewski GL. The Effect of the Addition of Coal Fly Ash (CFA) on the Control of Water Movement within the Structure of the Concrete. Materials. 2023; 16(15):5218. https://doi.org/10.3390/ma16155218

Chicago/Turabian StyleGolewski, Grzegorz Ludwik. 2023. "The Effect of the Addition of Coal Fly Ash (CFA) on the Control of Water Movement within the Structure of the Concrete" Materials 16, no. 15: 5218. https://doi.org/10.3390/ma16155218