Modification and Enhancing Contribution of Fiber to Asphalt Binders and Their Corresponding Mixtures: A Study of Viscoelastic Properties

Abstract

:1. Introduction

2. Materials and Methodologies

2.1. Materials

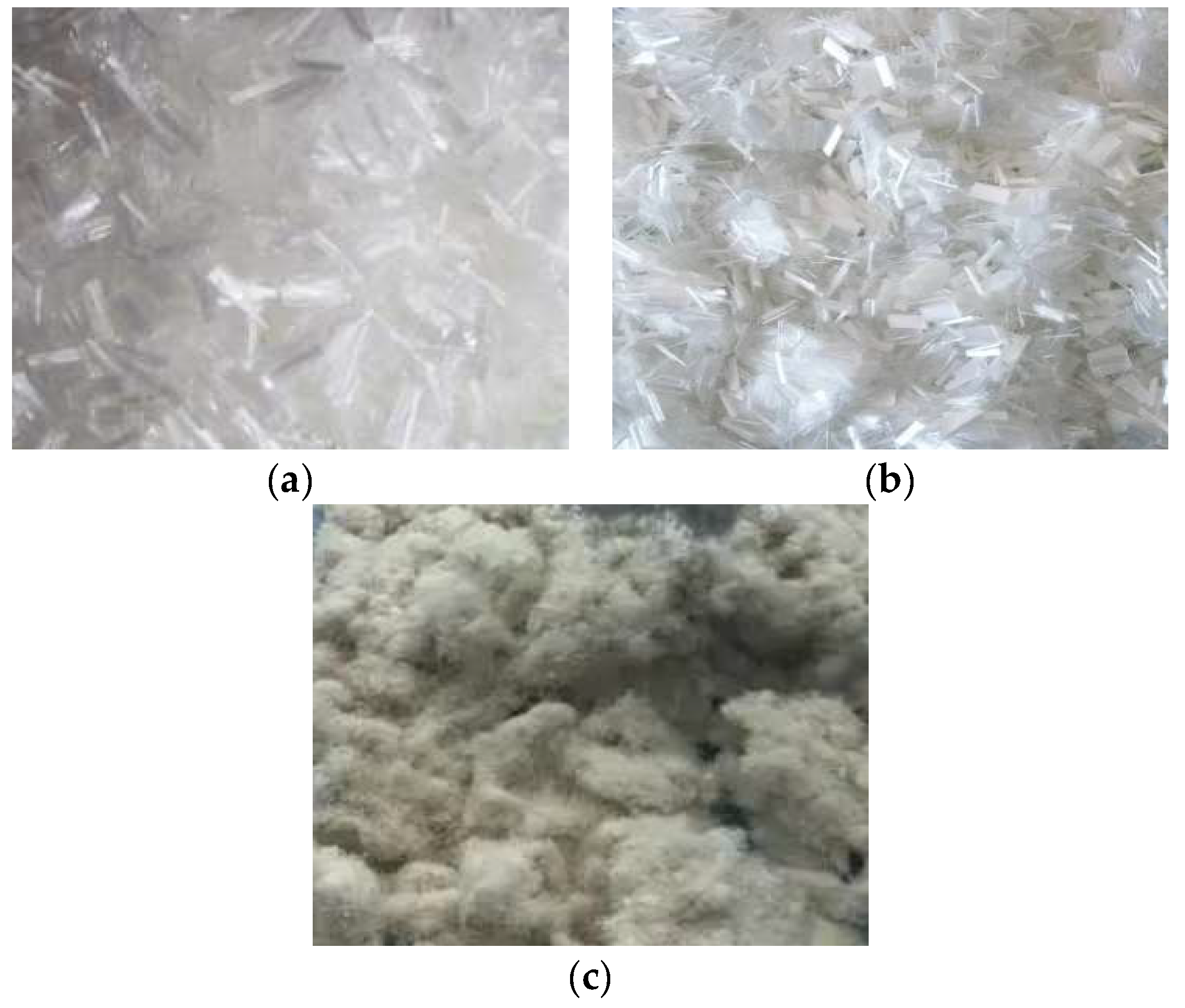

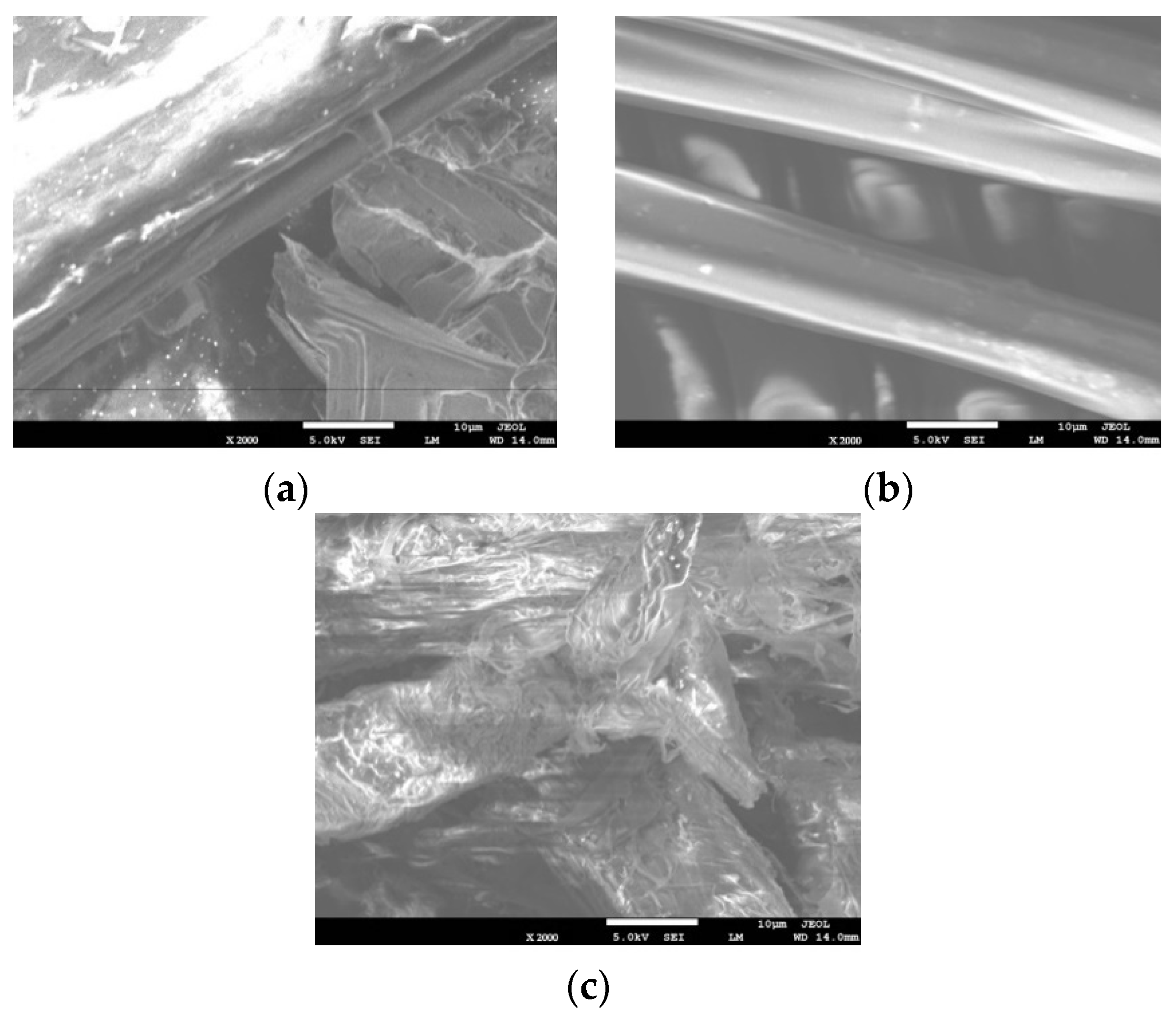

2.1.1. Fibers

2.1.2. Asphalt Binders

2.1.3. Asphalt Mixture

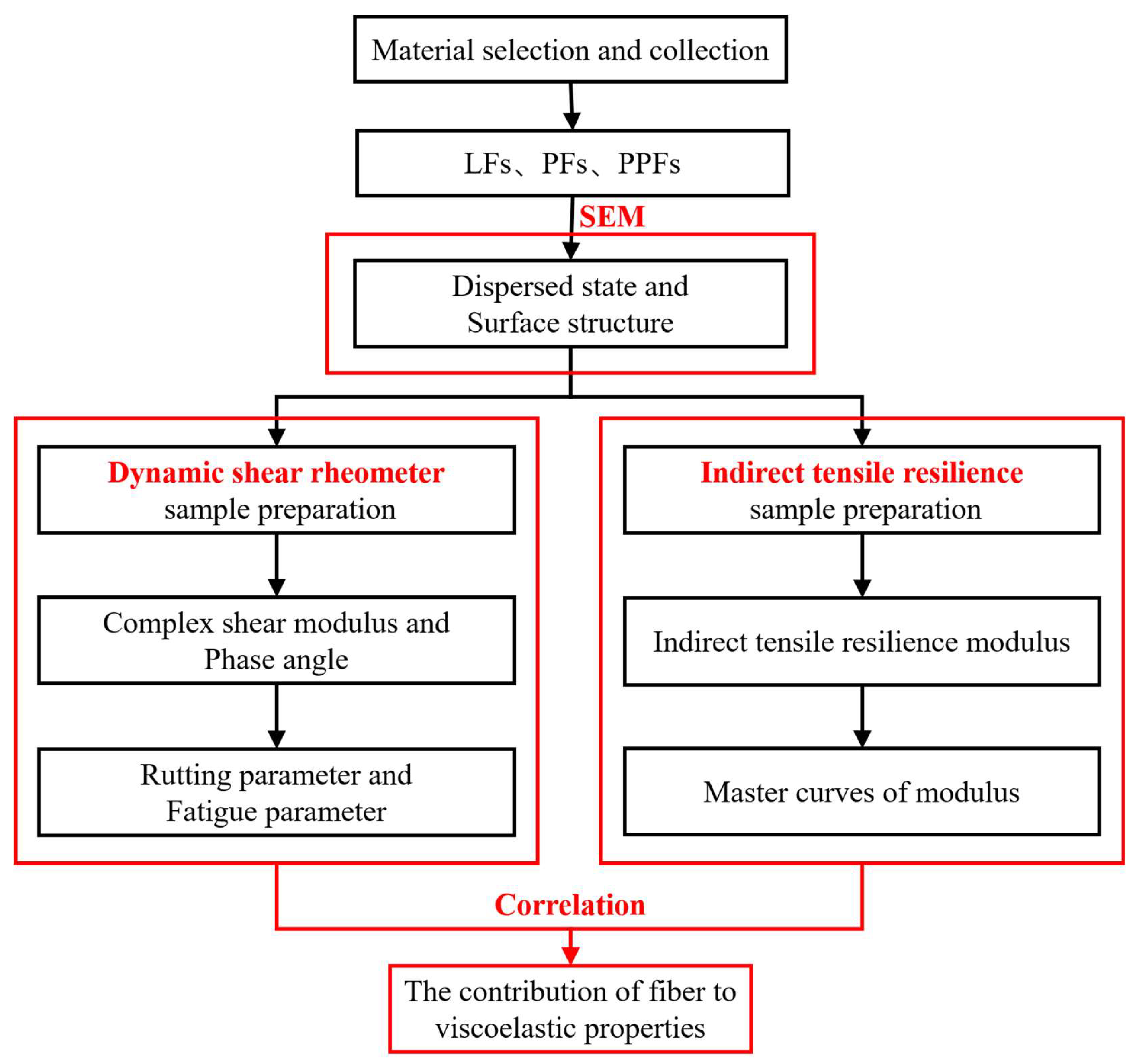

2.2. Methodologies

2.2.1. Dynamic Shear Rheometer

2.2.2. Indirect Tensile Resilience

3. Viscoelastic Properties of Fiber-Reinforced Binders

3.1. Temperature Dependency

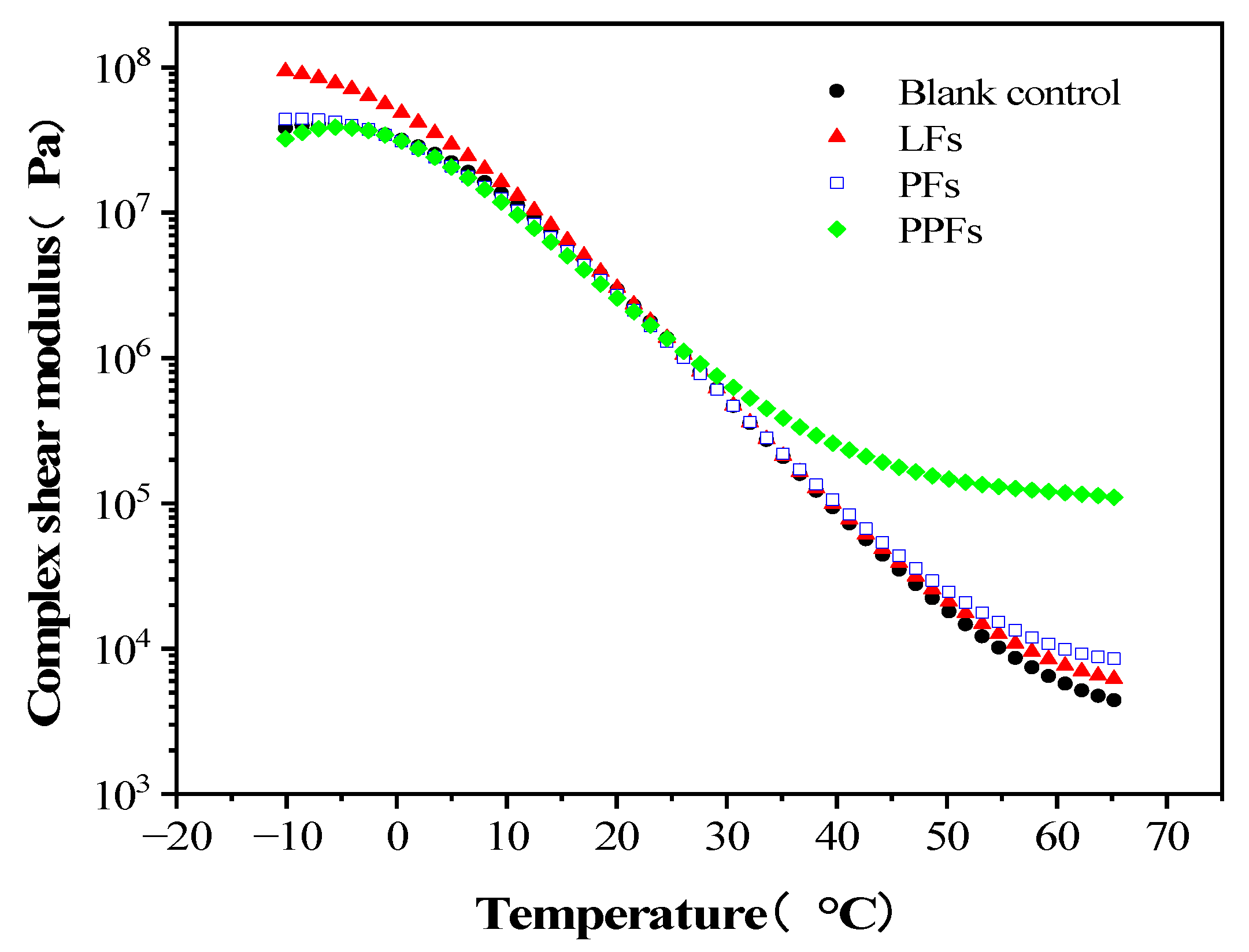

3.1.1. Complex Shear Modulus

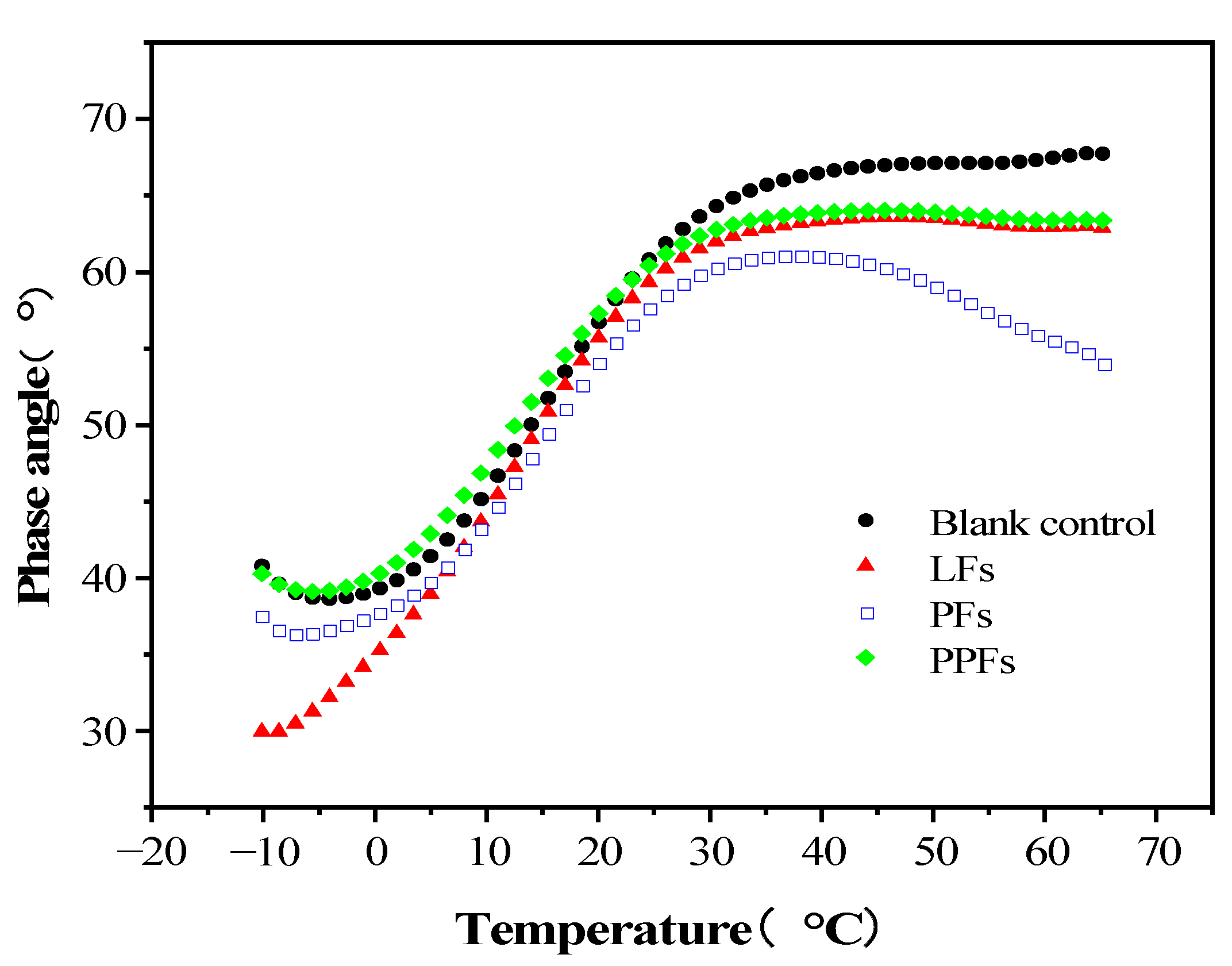

3.1.2. Phase Angle

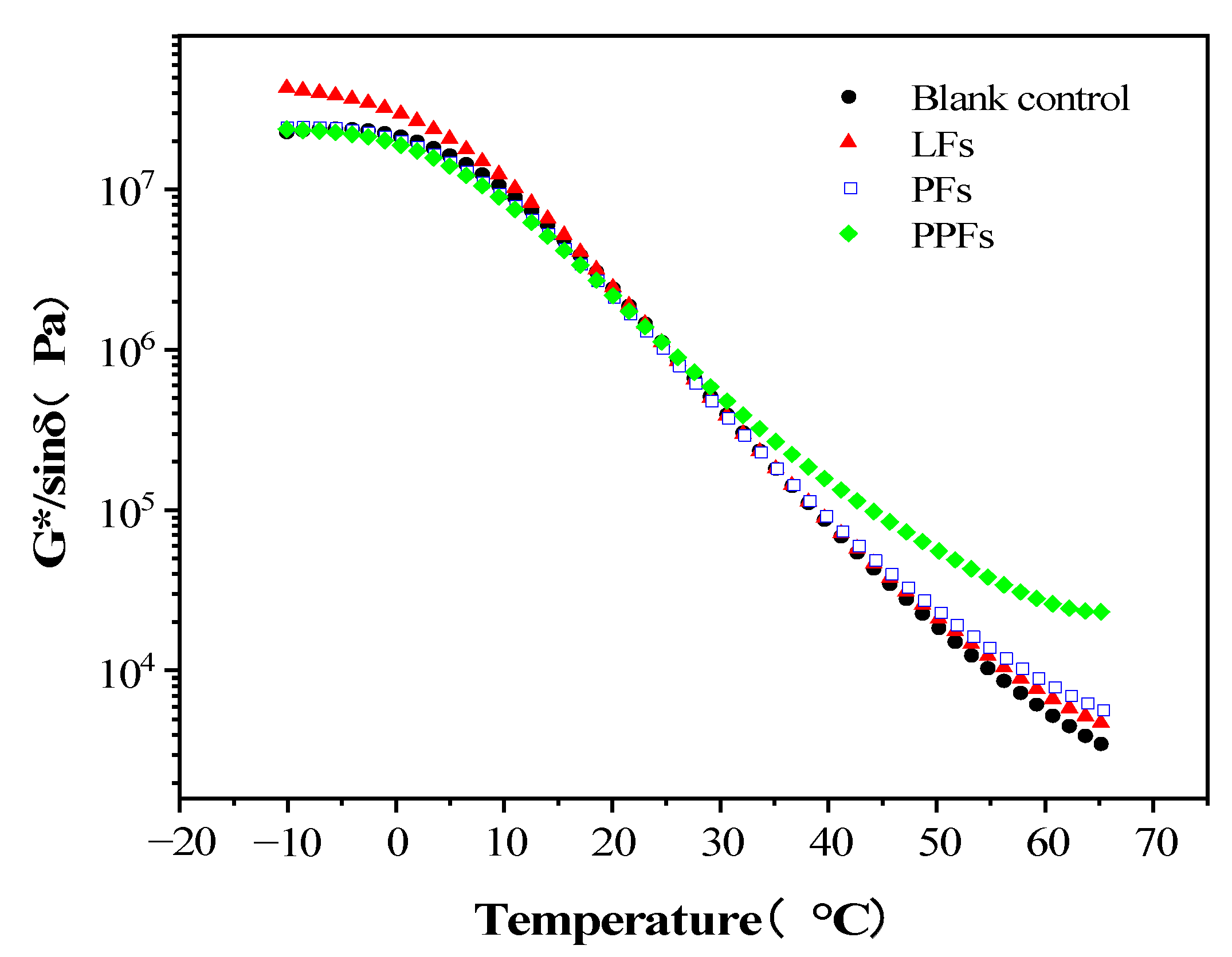

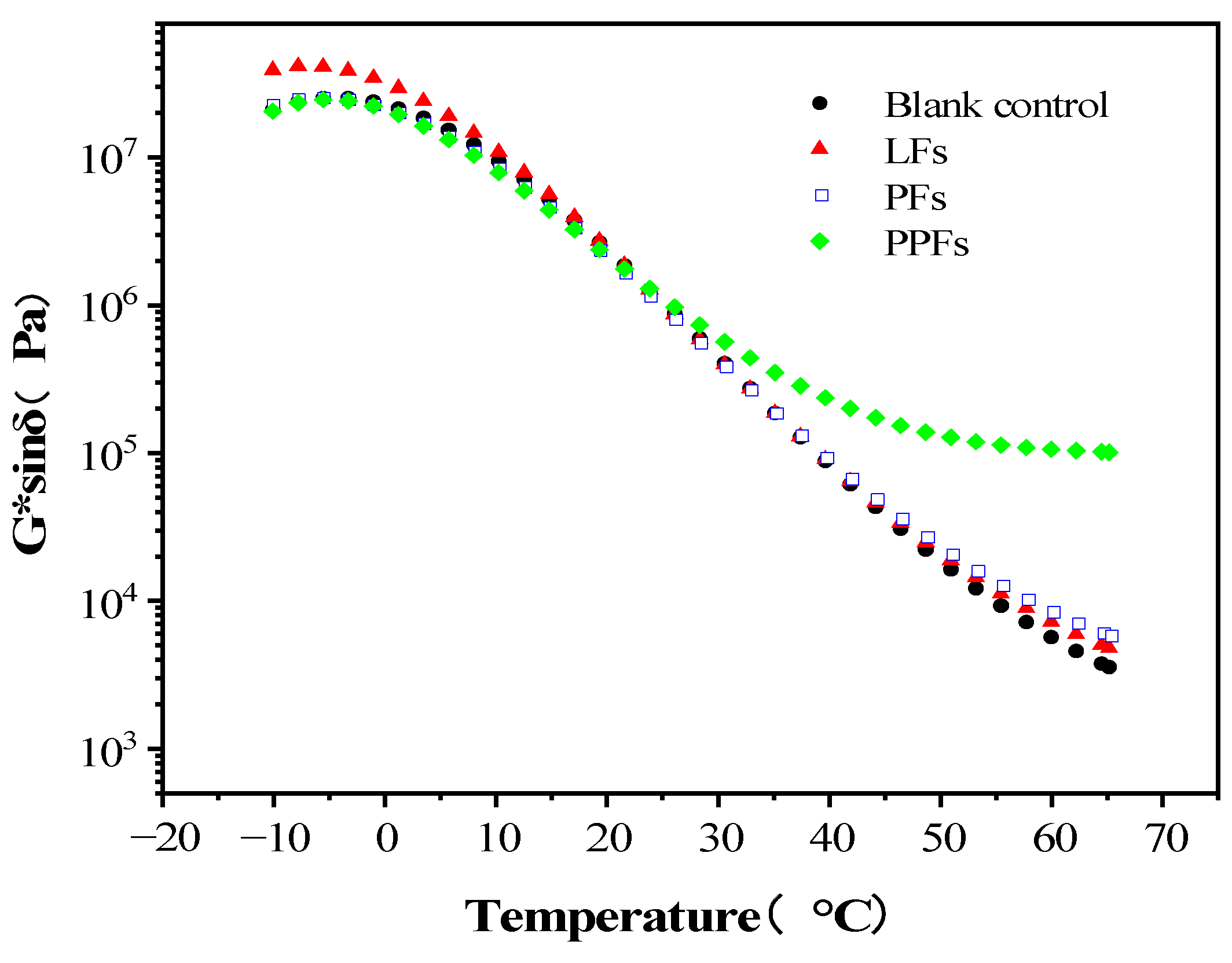

3.2. Rutting Parameter and Fatigue Parameter

3.2.1. Rutting Performance

3.2.2. Fatigue Performance

4. Viscoelastic Properties of Fiber-Reinforced Mixture

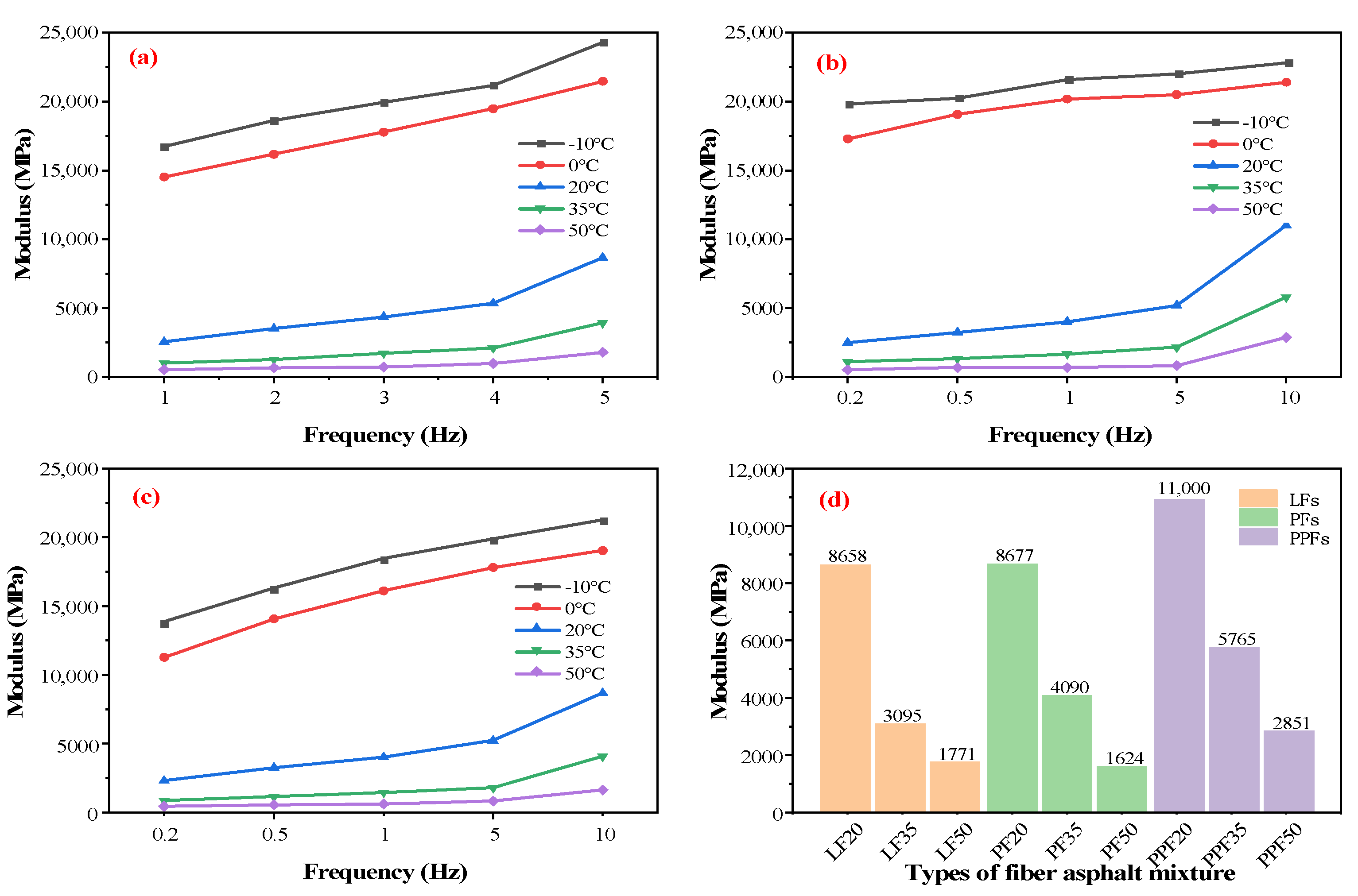

4.1. Indirect Tensile Resilience Modulus

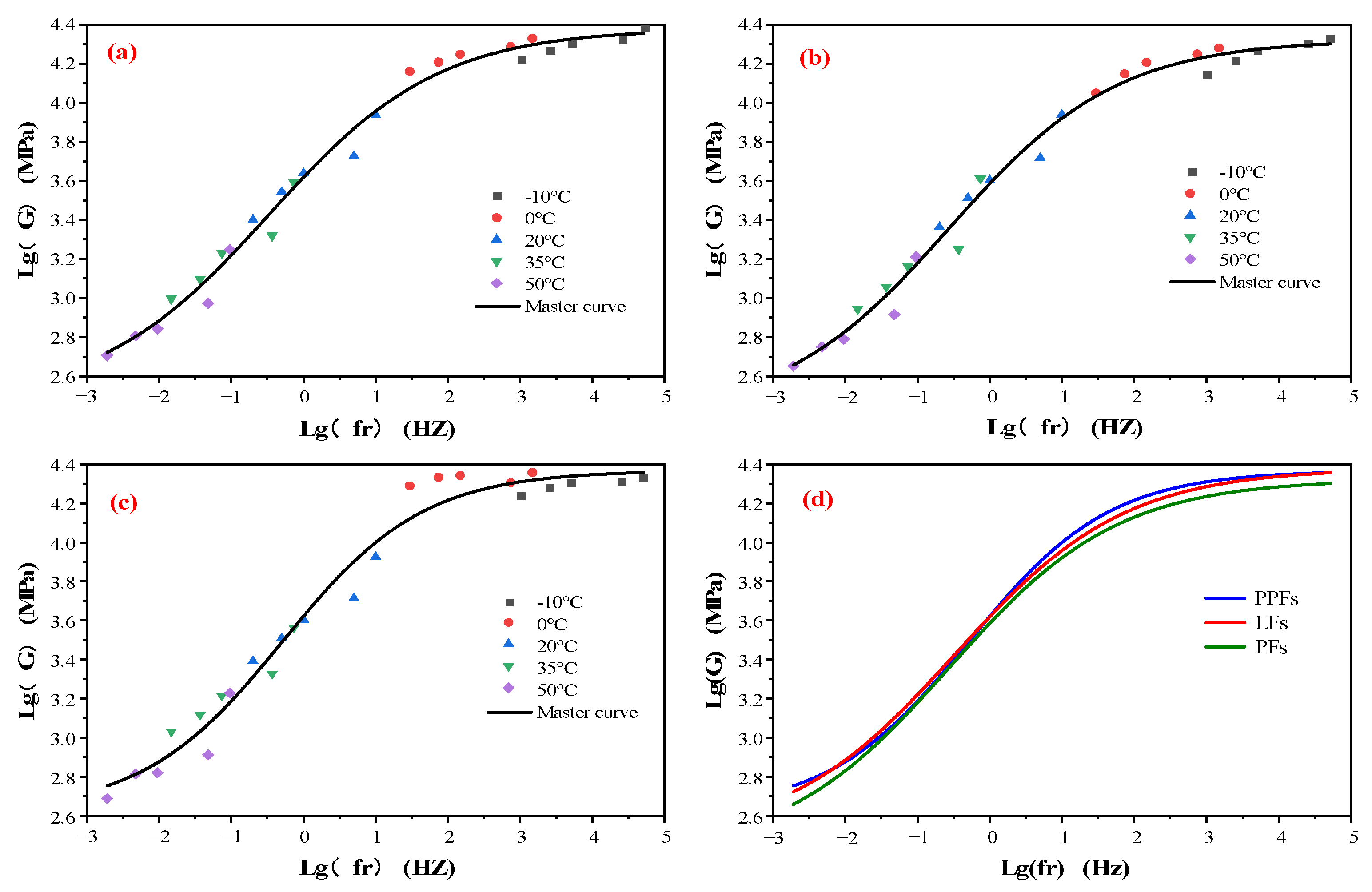

4.2. Master Curves of Modulus

5. Conclusions

- Fiber can improve the high-temperature stability of asphalt binders. The study found that the rutting parameters of the fiber-reinforced asphalt binders were greater than those of the blank control group. Among them, at 25–65 °C, the rutting parameters of PPF-reinforced asphalt binders are much larger than those of LF- and PF-reinforced asphalt binders, and the blank control group.

- The fiber will reduce the anti-fatigue performance of asphalt binders to varying degrees while improving the anti-rutting performance of the asphalt binders. It was found that the fatigue parameters of PPF-reinforced asphalt binders were much larger than those of the other three groups at 25–65 °C. At 15–25 °C, this trend is not obvious.

- The viscoelastic properties of fiber-reinforced asphalt binders have a great relationship with the morphology of fiber. The morphology of PPFs is short columnar, and its surface has an irregular barbed structure. This allows PPFs to be uniformly dispersed in the asphalt binders, and they have the most structural asphalt on their surface. This is the main reason for the best anti-rutting performance of PPF-reinforced asphalt binders. The flocculent morphology of LFs makes it difficult to uniformly disperse in the asphalt binders, so that the viscoelastic properties of LF-reinforced asphalt binders are not prominent.

- From the master curve model of the resilient modulus of the fiber-reinforced asphalt mixture, it can be seen that the change trend of viscoelastic properties of fiber-reinforced asphalt binders and their mixture are basically the same. It is found that the main curves of the PPF-reinforced asphalt mixture are higher at both ends, indicating that the PPF-reinforced asphalt mixture has high stiffness and strong high-temperature stability.

- The study found that the best choice of fiber stabilizer in a fiber asphalt mixture is a fiber with regular columnar morphology on a macro and irregular structure, or a barbed structure on a micro surface.

- Select the best form of fiber to explore the best content of fiber in a fiber-reinforced asphalt mixture.

- The microscopic test method is used to study the combination of fiber and asphalt. The relationship between the fiber–asphalt transition zone and the performance of the fiber-reinforced asphalt mixture was discussed.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tan, R.P.; Liu, K.; Lin, B.Q. Transportation infrastructure development and China’s energy intensive industries—A road development perspective. Energy 2018, 149, 587–596. [Google Scholar] [CrossRef]

- Wan, J.M.; Wu, S.P.; Xiao, Y.; Amirkhanian, S.; Liu, G.; Hu, J.X.; Zhang, D. Using interface shear characteristics to evaluate the residual performance of asphalt pavements. J. Adhes. Sci. Technol. 2018, 32, 2070–2082. [Google Scholar] [CrossRef]

- Arabani, M.; Shabani, A.; Hamedi, G.H. Experimental Investigation of Effect of Ceramic Fibers on Mechanical Properties of Asphalt Mixtures. J. Mater. Civ. Eng. 2019, 31, 04019203. [Google Scholar] [CrossRef]

- Da Costa, L.F.; de Barros, A.G.; Lucena, L.; Lucena, A. Asphalt mixture reinforced with banana fibres. Road Mater. Pavement Des. 2021, 22, 1881–1893. [Google Scholar] [CrossRef]

- Zhao, H.; Guan, B.W.; Xiong, R.; Zhang, A.P. Investigation of the Performance of Basalt Fiber Reinforced Asphalt Mixture. Appl. Sci. 2020, 10, 1561. [Google Scholar] [CrossRef]

- Lou, K.K.; Wu, X.; Xiao, P.; Zhang, C. Investigation on Fatigue Performance of Asphalt Mixture Reinforced by Basalt Fiber. Materials 2021, 14, 5596. [Google Scholar] [CrossRef] [PubMed]

- Hui, Y.; Men, G.; Xiao, P.; Tang, Q.; Han, F.; Kang, A.; Wu, Z. Recent Advances in Basalt Fiber Reinforced Asphalt Mixture for Pavement Applications. Materials 2022, 15, 6826. [Google Scholar] [CrossRef] [PubMed]

- Arabani, M.; Shabani, A. Evaluation of the ceramic fiber modified asphalt binder. Constr. Build. Mater. 2019, 205, 377–386. [Google Scholar] [CrossRef]

- Liu, H.; Li, Y.Y.; Li, J.X.; Wang, F.; Peng, L.F.; Li, C.; Wang, T.L.; Lin, J.T. Fiber-Reinforced Asphalt Mixture Design on Anti-Skid Surfacing for Field Testing High-Speed Vehicles on Pavements. Materials 2023, 16, 549. [Google Scholar] [CrossRef]

- Wei, G.; Mao, X.B. Performance Assessment on Fiberglass-Polyester Paving Mat Being Applied in Asphalt Mixture Complex. Adv. Civ. Eng. 2020, 2020, 8861475. [Google Scholar] [CrossRef]

- Zhang, T.; Wu, J.R.; Hong, R.B.; Ye, S.P.; Jin, A.H. Research on low-temperature performance of steel slag/polyester fiber permeable asphalt mixture. Constr. Build. Mater. 2022, 334, 127214. [Google Scholar] [CrossRef]

- Huang, Y.; Liu, Z.H.; Liu, L.; Zhang, Y.B.; Xu, Q.X. Hybrid Modification of Stone Mastic Asphalt with Cellulose and Basalt Fiber. Adv. Mater. Sci. Eng. 2020, 2020, 5671256. [Google Scholar] [CrossRef]

- Jia, H.C.; Sheng, Y.P.; Lv, H.L.; Kim, Y.R.; Zhao, X.R.; Meng, J.D.; Xiong, R. Effects of bamboo fiber on the mechanical properties of asphalt mixtures. Constr. Build. Mater. 2021, 289, 123196. [Google Scholar] [CrossRef]

- Riccardi, C.; Wang, D.; Wistuba, M.P.; Walther, A. Effects of polyacrylonitrile fibres and high content of RAP on mechanical properties of asphalt mixtures in binder and base layers. Road Mater. Pavement Des. 2023, 24, 2133–2155. [Google Scholar] [CrossRef]

- Wang, X.S.; Zhou, H.Y.; Hu, X.X.; Shen, S.; Dong, B.W. Investigation of the Performance of Ceramic Fiber Modified Asphalt Mixture. Adv. Civ. Eng. 2021, 2021, 8833468. [Google Scholar] [CrossRef]

- Chen, Z.N.; Yi, J.Y.; Chen, Z.G.; Feng, D.C. Properties of asphalt binder modified by corn stalk fiber. Constr. Build. Mater. 2019, 212, 225–235. [Google Scholar] [CrossRef]

- Eltwati, A.S.; Enieb, M.; Al-Saffar, Z.H.; Mohamed, A. Effect of glass fibers and waste engine oil on the properties of RAP asphalt concretes. Int. J. Pavement Eng. 2022, 23, 5227–5238. [Google Scholar] [CrossRef]

- Xia, C.M.; Wu, C.F.; Liu, K.F.; Jiang, K. Study on the Durability of Bamboo Fiber Asphalt Mixture. Materials 2021, 14, 1667. [Google Scholar] [CrossRef]

- Liu, Y.Y.; Zhang, Z.Y.; Tan, L.J.; Xu, Y.; Wang, C.H.; Liu, P.F.; Yu, H.Y.; Oeser, M. Laboratory evaluation of emulsified asphalt reinforced with glass fiber treated with different methods. J. Clean Prod. 2020, 274, 123116. [Google Scholar] [CrossRef]

- Saliani, S.S.; Tavassoti, P.; Baaj, H.; Carter, A. Characterization of asphalt mixtures produced with short Pulp Aramid fiber (PAF). Constr. Build. Mater. 2021, 280, 122554. [Google Scholar] [CrossRef]

- Xing, X.Y.; Chen, S.H.; Li, Y.; Pei, J.Z.; Zhang, J.P.; Wen, Y.; Li, R.; Cui, S.C. Effect of different fibers on the properties of asphalt mastics. Constr. Build. Mater. 2020, 262, 120005. [Google Scholar] [CrossRef]

- Oral, G.; Cetin, A. The Performance Evaluation of Porous Asphalt Mixtures Reinforced by Fibers. Int. J. Civ. Eng. 2023, 21, 445–459. [Google Scholar] [CrossRef]

- Pirmohammad, S.; Amani, B.; Shokorlou, Y.M. The effect of basalt fibres on fracture toughness of asphalt mixture. Fatigue Fract. Eng. Mater. Struct. 2020, 43, 1446–1460. [Google Scholar] [CrossRef]

- Liu, F.; Pan, B.F.; Bian, J.R.; Zhou, C.J. Experimental investigation on the performance of the asphalt mixture with ceramic fiber. J. Clean Prod. 2023, 384, 135585. [Google Scholar] [CrossRef]

- Miao, Y.H.; Wang, T.; Wang, L.B. Influences of Interface Properties on the Performance of Fiber-Reinforced Asphalt Binder. Polymers 2019, 11, 542. [Google Scholar] [CrossRef] [PubMed]

- Hong, R.B.; Wu, J.R.; Cai, H.B. Low-temperature crack resistance of coal gangue powder and polyester fibre asphalt mixture. Constr. Build. Mater. 2020, 238, 117678. [Google Scholar] [CrossRef]

- Wang, F.; Xiao, Y.; Cui, P.D.; Ma, T.; Kuang, D.L. Effect of aggregate morphologies and compaction methods on the skeleton structures in asphalt mixtures. Constr. Build. Mater. 2020, 263, 120220. [Google Scholar] [CrossRef]

- Cui, P.D.; Xiao, Y.; Yan, B.X.; Li, M.L.; Wu, S.P. Morphological characteristics of aggregates and their influence on the performance of asphalt mixture. Constr. Build. Mater. 2018, 186, 303–312. [Google Scholar] [CrossRef]

- Arabani, M.; Pedram, M. Laboratory investigation of rutting and fatigue in glassphalt containing waste plastic bottles. Constr. Build. Mater. 2016, 116, 378–383. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Gu, X.Y.; Lv, J.X. Effect of basalt fiber distribution on the flexural-tensile rheological performance of asphalt mortar. Constr. Build. Mater. 2018, 179, 307–314. [Google Scholar] [CrossRef]

- Liu, G.Q.; Yang, T.; Li, J.; Jia, Y.S.; Zhao, Y.L.; Zhang, J.P. Effects of aging on rheological properties of asphalt materials and asphalt-filler interaction ability. Constr. Build. Mater. 2018, 168, 501–511. [Google Scholar] [CrossRef]

- Xiao, Y.; Chang, X.W.; Yan, B.X.; Zhang, X.S.; Yunusa, M.; Yu, R.E.; Chen, Z.W. SBS morphology characteristics in asphalt binder and their relation with viscoelastic properties. Constr. Build. Mater. 2021, 301, 124292. [Google Scholar] [CrossRef]

- Slebi-Acevedo, C.J.; Lastra-Gonzalez, P.; Pascual-Munoz, P.; Castro-Fresno, D. Mechanical performance of fibers in hot mix asphalt: A review. Constr. Build. Mater. 2019, 200, 756–769. [Google Scholar] [CrossRef]

| Fiber | Length (mm) | Tensile Strength (MPa) | Density (g/cm3) | Melting Point (°C) | Oil Absorption (Times of Own Weight) |

|---|---|---|---|---|---|

| LFs | 5 | - | 1.10 | - | 6.2 |

| PFs | 8 | 508 | 1.38 | 260 | - |

| PPFs | 6 | 450 | 0.91 | 220 | - |

| Standard | 6–12 (LFs < 6) | >270 | - | >220 | 5–9 |

| Characteristics | Experimental Values | Standard | |

|---|---|---|---|

| Penetration@25 °C, 100 g, 5 s (0.1 mm) | 58.6 | 50–60 | |

| Ductility@5 cm/min, 5 °C (1 cm) | 23.8 | ≥20 | |

| Softening point (°C) | 79.1 | ≥60 | |

| Thin film oven test | Ductility@5 cm/min, 5 °C (1 cm) | 17.8 | ≥15 |

| Mass loss rate (%) | +0.016 | ±1.0 | |

| Residual penetration ratio (%) | 75.5 | ≥65 | |

| Solubility (%) | 99.90 | ≥99 | |

| Density (g/cm3) | 1.017 | - | |

| Types | Percentage of Mass (%) through the Following Sieves (mm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 16.0 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 | |

| Upper limit | 100.0 | 100.0 | 75.0 | 34.0 | 26.0 | 24.0 | 20.0 | 16.0 | 15.0 | 12.0 |

| Lower limit | 100.0 | 90.0 | 50.0 | 20.0 | 15.0 | 14.0 | 12.0 | 10.0 | 9.0 | 8.0 |

| Gradation A(35:35:19:11) | 100.0 | 97.3 | 64.0 | 32.1 | 22.3 | 17.5 | 14.9 | 14.0 | 12.7 | 11.2 |

| Gradation | Bitumen Aggregate Ratio (%) | Specimen Gross Density (g/cm3) | Maximum Theoretical Relative Density (g/cm3) | Air Voids (%) | Voids in Mineral Aggregate VMA (%) | Voids Filled with Asphalt VFA (%) | Coarse Aggregate Skeleton Clearance Rate VCAmix (%) |

|---|---|---|---|---|---|---|---|

| A | 6.4 | 2.479 | 2.572 | 3.6 | 18.2 | 80.1 | 40.7 |

| Standard | - | - | - | 3–4 | ≥17.0 | 75–85 | ≤VCADRC |

| Parameter | Requirement |

|---|---|

| Working form | Temperature scan |

| Test temperature | −10 to 35 °C, 20–65 °C |

| Test frequency | 10 rad/s |

| Control mode | Strain control (5%) |

| Sample size | r = 4 mm, h = 2 mm and r = 12.5 mm, h = 1 mm |

| Parameters | Tref | C1 | C2 |

|---|---|---|---|

| - | 20 °C | 8.860 | 101.6 |

| Types | Models | Lg(G)max (MPa) | Lg(G)min (MPa) | Slope | R2 |

|---|---|---|---|---|---|

| LFs | 4.377 | 2.621 | 0.378 | 0.988 | |

| PFs | 4.323 | 2.397 | 0.379 | 0.986 | |

| PPFs | 4.238 | 2.706 | 0.421 | 0.978 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.; Liu, H.; Xiao, Y.; Li, J.; Wang, T.; Peng, L. Modification and Enhancing Contribution of Fiber to Asphalt Binders and Their Corresponding Mixtures: A Study of Viscoelastic Properties. Materials 2023, 16, 5727. https://doi.org/10.3390/ma16165727

Li C, Liu H, Xiao Y, Li J, Wang T, Peng L. Modification and Enhancing Contribution of Fiber to Asphalt Binders and Their Corresponding Mixtures: A Study of Viscoelastic Properties. Materials. 2023; 16(16):5727. https://doi.org/10.3390/ma16165727

Chicago/Turabian StyleLi, Chao, Hao Liu, Yue Xiao, Jixin Li, Tianlei Wang, and Longfan Peng. 2023. "Modification and Enhancing Contribution of Fiber to Asphalt Binders and Their Corresponding Mixtures: A Study of Viscoelastic Properties" Materials 16, no. 16: 5727. https://doi.org/10.3390/ma16165727