Apparent Deterioration Law and Shear Failure Mode of Rock–Mortar Interface Based on Topography-Sensing Technology

Abstract

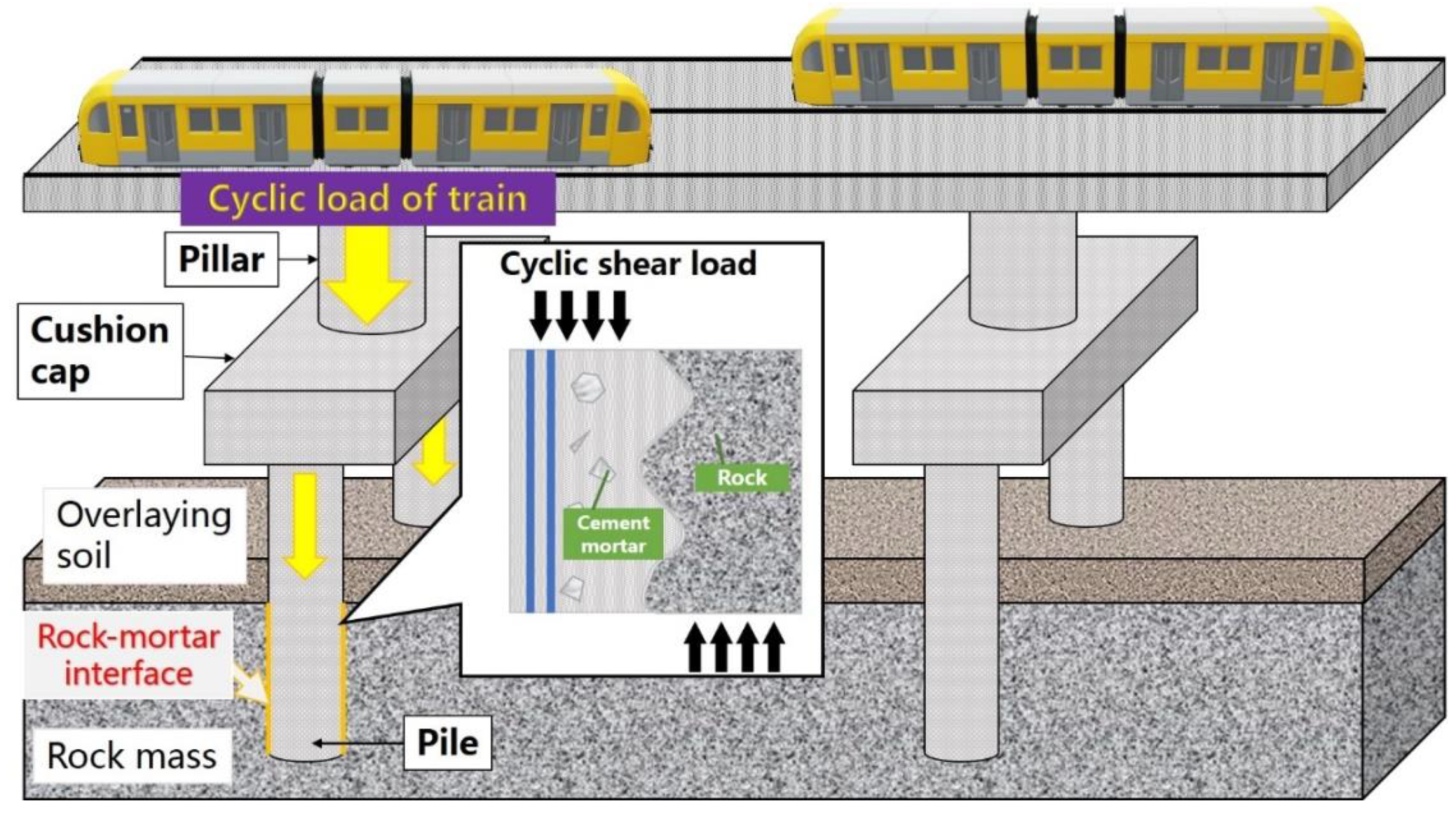

:1. Introduction

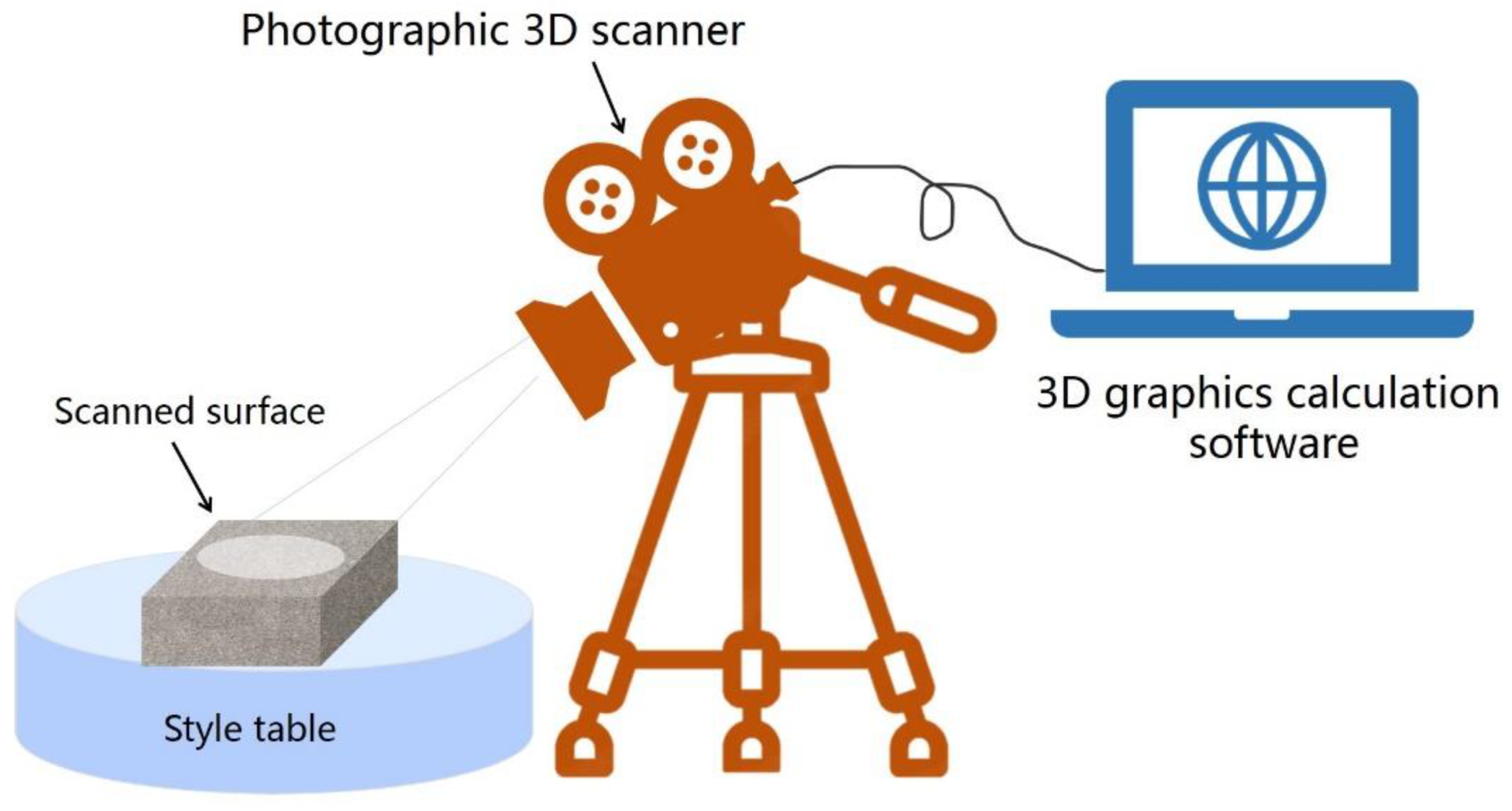

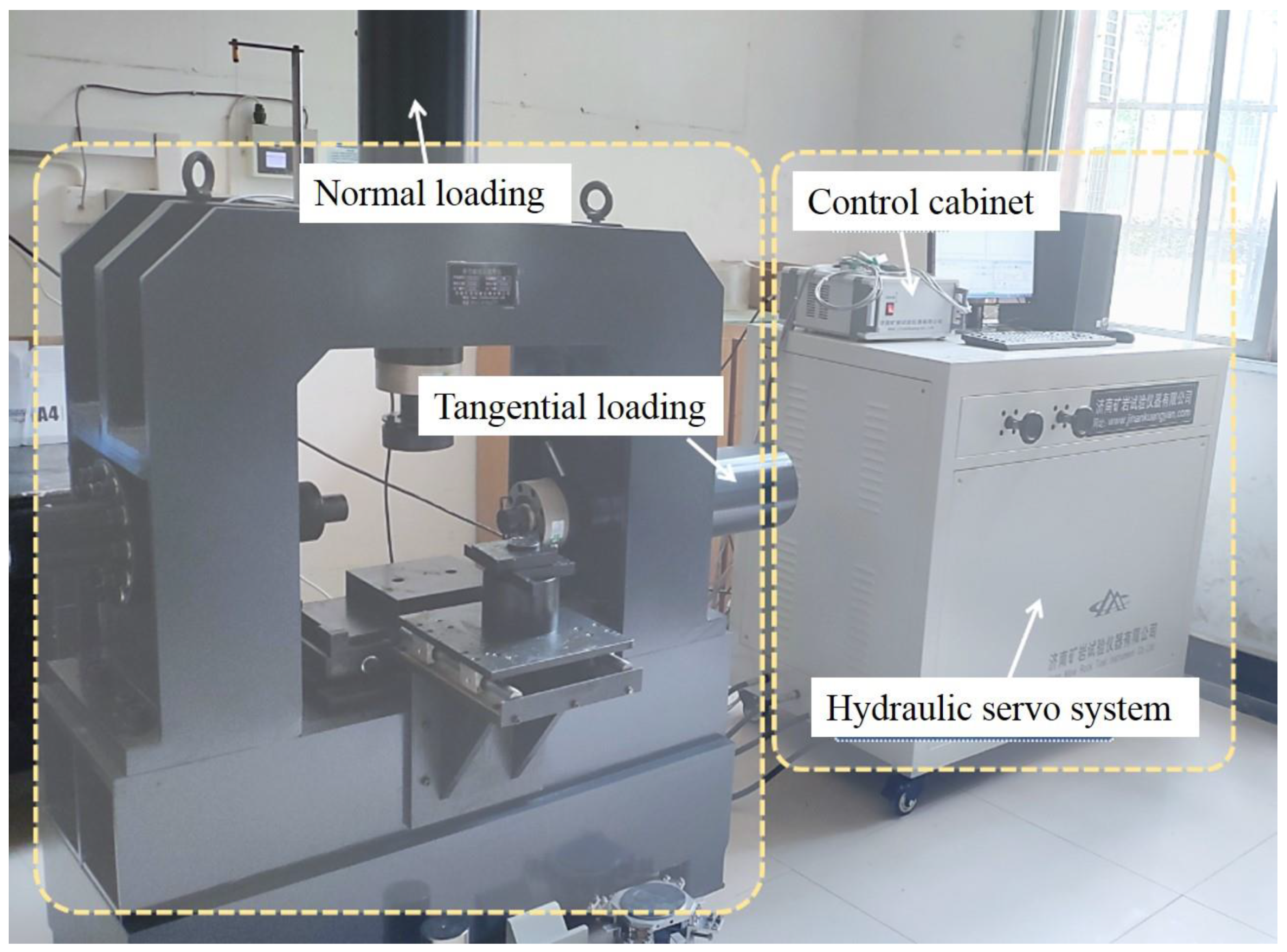

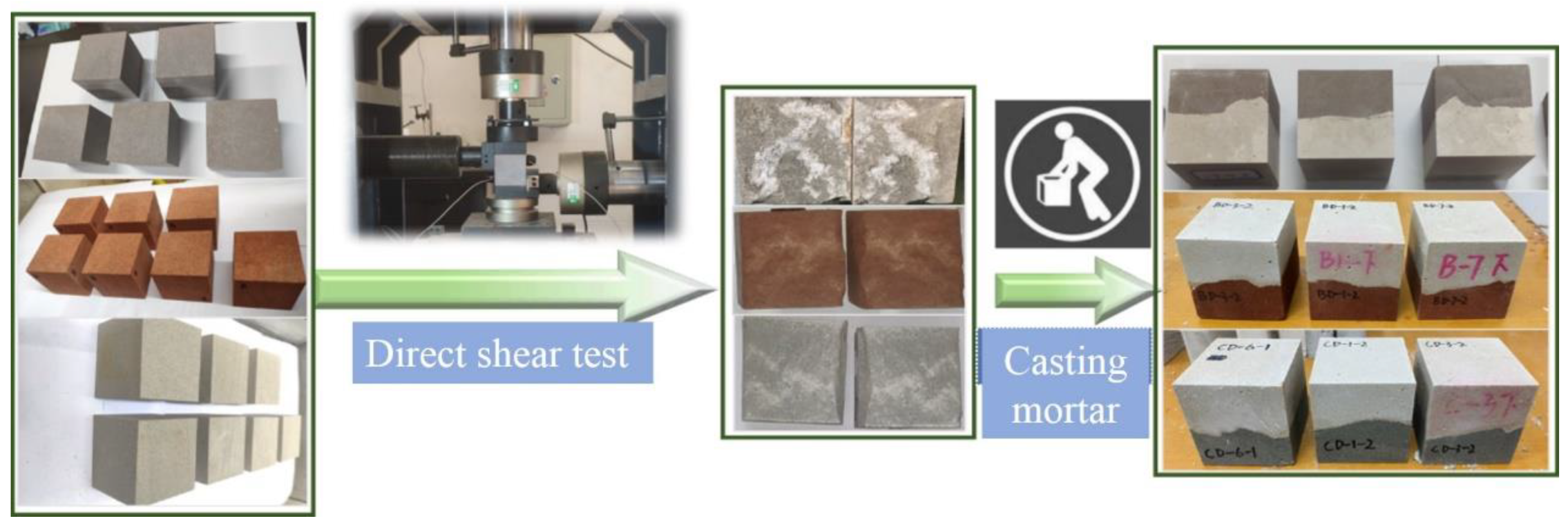

2. Presentation of Test Strategy

2.1. Test Apparatus

- (1)

- Topography-sensing test of rock–mortar interface

- (2)

- Cyclic direct shear tests on rock–mortar interface

- Before loading, the normal and tangential loading devices are moved close to the sample quickly and stopped at approximately 5 mm away from the sample.

- Normal loading is controlled by constant force, and the loading speed is 0.1 kN/s until the target value is reached. Tangential loading begins after the normal force remains stable for 10 s.

- Tangential loading is achieved by constant force and constant displacement: Firstly, tangential force control is adopted at 0.1 kN/s until the tangential force reaches 2 kN. Then, the tangential displacement control is manually started to load at a constant speed of 0.01 mm/s, and it ends when sample failure occurs.

2.2. Rock–Mortar Interface Preparation

2.3. Test Program

3. Strength Deterioration and Dilatancy Characteristics of Rock–Mortar Interface

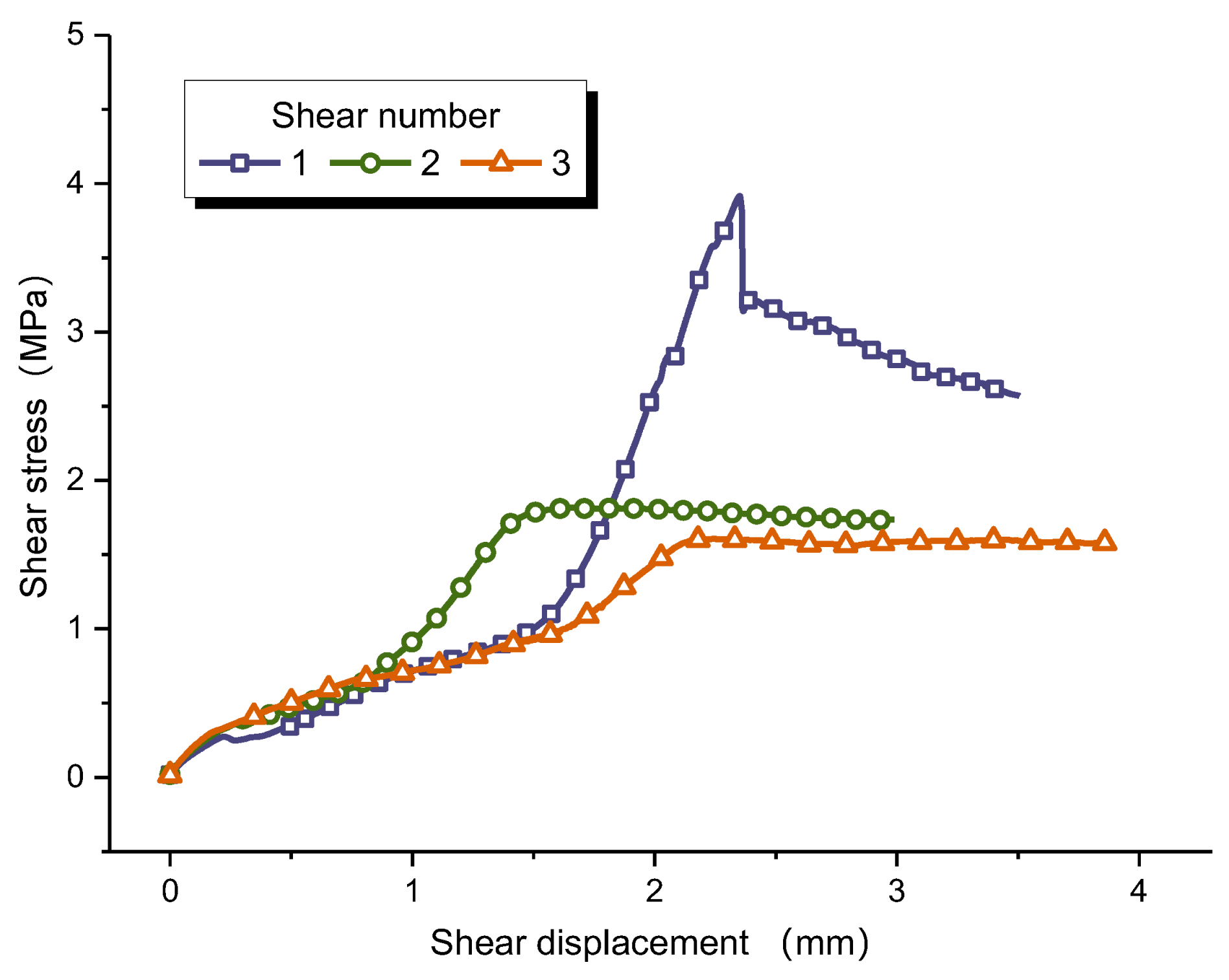

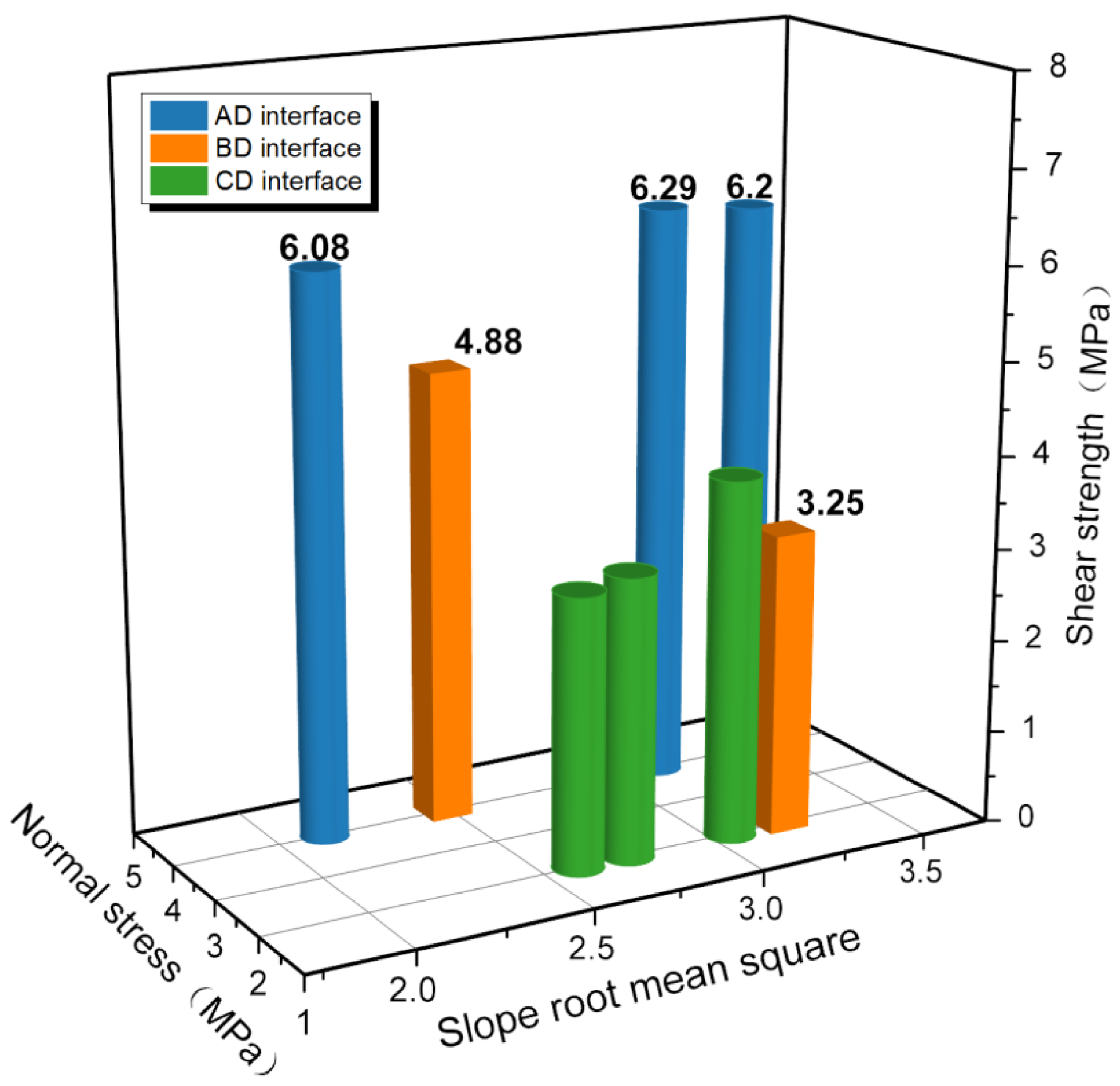

3.1. Deterioration of Interface Strength under Cyclic Shearing

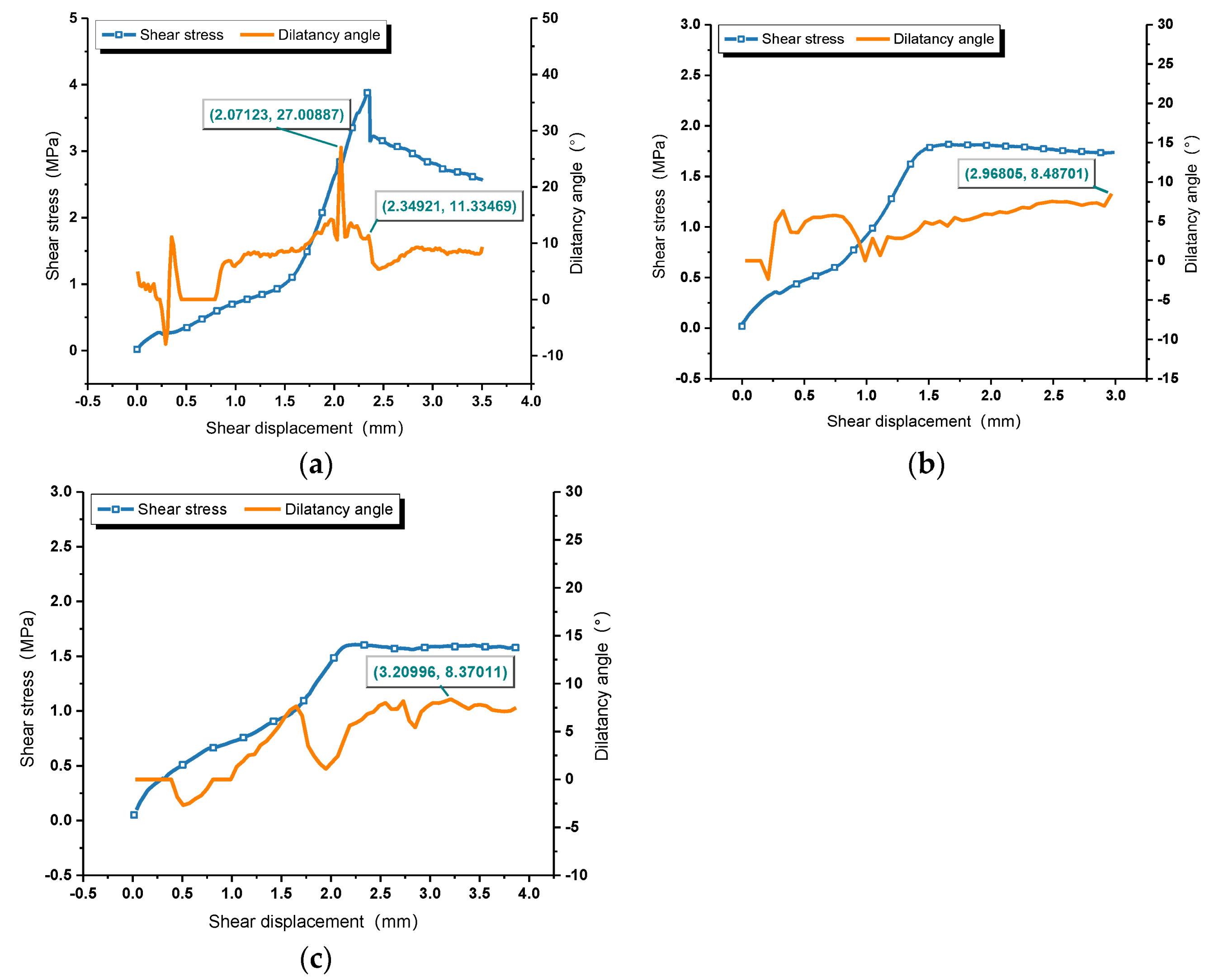

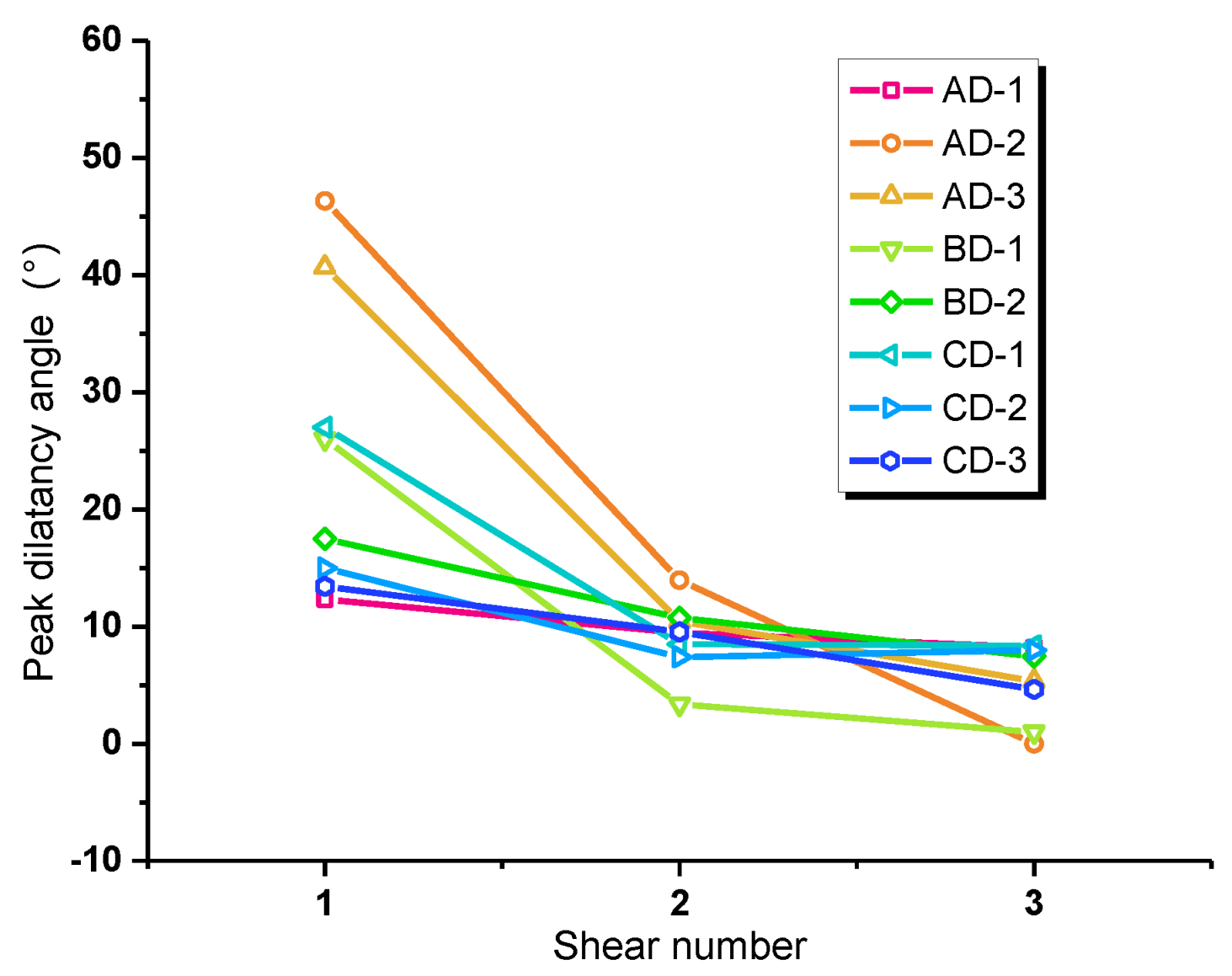

3.2. Dilatancy Characteristics of Interface under Cyclic Shearing

4. Apparent Evolution Characteristics of Rock–Mortar Interface

4.1. Introduction of Three-Dimensional Topography Parameters

- (1)

- Description of height characteristic parameters of surface topography.

- a.

- Maximum interface height Sp: The vertical distance between the lowest point and the highest point of the interface;

- b.

- Interface height root mean square Sq: The square root of the mean distance from each point on the measured surface to the datum. The expression is

- c.

- Arithmetic mean deviation Sa: The arithmetic mean of the distance from each point on the measured surface to the datum in the sampling area, which can be calculated by

- d.

- Skewness coefficient of surface height distribution function Ssk: The ratio of the cubic moment of the height distribution density function to the third power of the root mean square of height. It describes the symmetry of the surface topography and can be expressed by Equation (3).

- e.

- The peak coefficient of the surface height distribution function Sku: Description of the steepness of the interface surface topography. The calculation formula is

- (2)

- Surface morphology texture feature parameters

- a.

- Texture topography ratio Str: Characterizing the degree of interface anisotropy and anisotropy. Its values range from 0 to 1. The larger the value, the greater the degree of isotropy.

- b.

- Texture direction angle Std: Describing the main tilt direction of the surface texture. The value is the angle between the main tilt direction and the tilt direction of the least square surface.

- (3)

- Surface peak morphology characteristics

- a.

- Peak point density Spd: Number of peak points per unit area, which can characterize the complexity of the surface.

- b.

- Arithmetic mean curvature at peak point Spc: Arithmetic mean of curvature of all peaks, which reflects the surface peak’s sharpness or roundness.

- (4)

- Surface topography mixed parameters

- a.

- Fractal dimension Ds: The box-counting method is used to calculate fractal dimension of the surface, and the slope of the regression line is the fractal dimension, which can describe the complexity of the interface.

- b.

- Root mean square of slope of interface Sdq: Characterizing the tilt degree of the interface to a certain extent, which can be obtained by

- c.

- Interface area ratio Sdr: Used to represent the complexity of the interface, the expression of which is

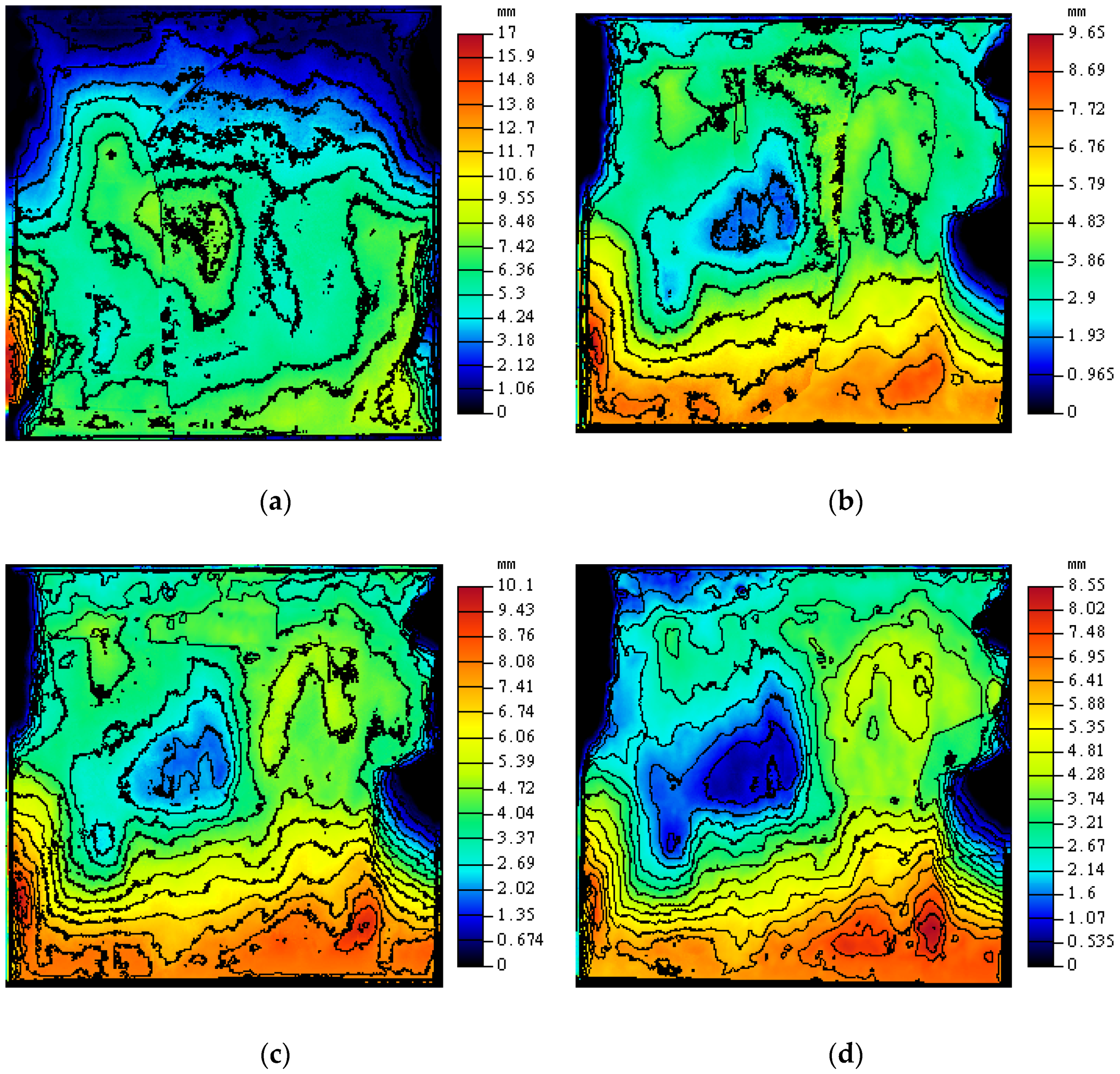

4.2. Morphology Parameter Evolution of Rock–Mortar Interface Subjected to Cyclic Shearing

4.3. Discussions

5. Conclusions

- (1)

- The failure mode of the rock–mortar interface changes from brittle fracture to interfacial friction in cyclic shearing. The shear strength decreases continuously, and the reduction amplitude decreases gradually. The shear performance of malmstone–mortar interface is better than that of red sandstone–mortar interface, and blue sandstone–mortar interface is the lowest. With the increase of shearing times, the peak dilatancy angle decreases. The greater the normal stress, the greater the drop of peak dilatancy angle. The interface dilatancy angle corresponding to malmstone is larger, followed by red sandstone and blue sandstone.

- (2)

- As the time of shearing increases, both maximum interface height Sp and interface height root mean square Sq decrease. The arithmetic mean difference of surface height Sa also decreases only under the 2 Mpa normal stress, and it fluctuates greatly when the normal stress is 4 Mpa. The variation laws of skew coefficient Ssk and peak coefficient Sku are not obvious. For more shearing times, the value of the aspect ratio of texture topography ratio Str is greater, representing the anisotropy of the rock–mortar interface decreases. Meanwhile, texture direction angle Std is reduced, especially in the case of high normal stress.

- (3)

- All the surface topography mixed parameters used in this study, including fractal dimension Ds, root mean square of slope of interface Sdq, and interface area ratio Sdr, decrease with the shearing times, wherein when the normal stress is small, the redution of fractal dimension Ds is greater. The increase in shearing times lowers the surface complexity and the the peak curvature, which produces a more rounded peak. Based on the contour map, the interface steepness decreases and the sag continuously expands. According to the Abbot–Firestone curve, it is judged that the height of bearing shear body gradually decreases.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhu, C.; Long, S.; Zhang, J.; Wu, W.; Zhang, L. Time Series Multi-Sensors of Interferometry Synthetic Aperture Radar for Monitoring Ground Deformation. Front. Environ. Sci. 2022, 10, 929958. [Google Scholar] [CrossRef]

- Zheng, C.; Jiang, B.; Xue, S.; Chen, Z.; Li, H. Coalbed methane emissions and drainage methods in underground mining for mining safety and environmental benefits: A review. Process Saf. Environ. Prot. 2019, 127, 103–124. [Google Scholar] [CrossRef]

- Wu, H.; Jia, Q.; Wang, W.; Zhang, N.; Zhao, Y. Experimental Test on Nonuniform Deformation in the Tilted Strata of a Deep Coal Mine. Sustainability 2021, 13, 13280. [Google Scholar] [CrossRef]

- Tang, Z.C.; Jiao, Y.Y.; Wong, L.; Wang, X. Choosing Appropriate Parameters for Developing Empirical Shear Strength Criterion of Rock Joint: Review and New Insights. Rock Mech. Rock Eng. 2016, 49, 4479–4490. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, C.S.; Wang, Y.X.; Lin, H. Shear-related roughness classification and strength model of natural rock joint based on fuzzy comprehensive evaluation. Int. J. Rock Mech. Min. Sci. 2021, 137, 104550. [Google Scholar] [CrossRef]

- Chen, W.; Wan, W.; Zhao, Y.; Peng, W. Experimental Study of the Crack Predominance of Rock-Like Material Containing Parallel Double Fissures under Uniaxial Compression. Sustainability 2020, 12, 5188. [Google Scholar] [CrossRef]

- Huang, Z.; Zhang, L.; Yang, Z.; Zhang, J.; Gao, Y.; Zhang, Y. Preparation and properties of a rock dust suppressant for a copper mine. Atmos. Pollut. Res. 2019, 10, 2010–2017. [Google Scholar] [CrossRef]

- Liu, S.; Nie, Y.; Hu, W.; Ashiru, M.; Li, Z.; Zuo, J. The Influence of Mixing Degree between Coarse and Fine Particles on the Strength of Offshore and Coast Foundations. Sustainability 2022, 14, 9177. [Google Scholar] [CrossRef]

- Gentier, S.; Riss, J.; Archambault, G.; Flamand, R.; Hopkins, D. Influence of fracture geometry on shear behavior. Int. J. Rock Mech. Min. Sci. 2000, 37, 161–174. [Google Scholar] [CrossRef]

- Barton, N.; Choubey, V. The shear strength of rock joints in theory and practice. Rock Mech. 1977, 10, 1–54. [Google Scholar] [CrossRef]

- Zhao, J. Joint surface matching and shear strength part A: Joint matching coefficient (JMC). Int. J. Rock Mech. Min. Sci. 1997, 34, 173–178. [Google Scholar] [CrossRef]

- Zhao, J. Joint surface matching and shear strength part B: JRC-JMC shear strength criterion. Int. J. Rock Mech. Min. Sci. 1997, 34, 179–185. [Google Scholar] [CrossRef]

- Maksimović, M. New description of the shear strength for rock joints. Rock Mech. Rock Eng. 1992, 25, 275–284. [Google Scholar] [CrossRef]

- Kulatilake, P.; Shou, G.; Huang, T.H.; Morgan, R.M. New peak shear strength criteria for anisotropic rock joints. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1995, 32, 673–697. [Google Scholar] [CrossRef]

- Homand, F.; Belem, T.; Souley, M. Friction and degradation of rock joint surfaces under shear loads. Int. J. Numer. Anal. Methods Geomech. 2010, 25, 973–999. [Google Scholar] [CrossRef]

- Singh, H.K.; Basu, A. Evaluation of existing criteria in estimating shear strength of natural rock discontinuities. Eng. Geol. 2018, 232, 171–181. [Google Scholar] [CrossRef]

- Xia, C.C.; Tang, Z.C.; Xiao, W.M.; Song, Y.L. New Peak Shear Strength Criterion of Rock Joints Based on Quantified Surface Description. Rock Mech. Rock Eng. 2014, 47, 387–400. [Google Scholar] [CrossRef]

- Yang, J.; Rong, G.; Hou, D. Experimental Study on Peak Shear Strength Criterion for Rock Joints. Rock Mech. Rock Eng. 2016, 49, 821–835. [Google Scholar] [CrossRef]

- Liu, D.L.; Hao, S.L.; Liu, X.Z.; Li, B.C.; He, S.F.; Warrington, D.N. Effects of land use classification on landscape metrics based on remote sensing and GIS. Environ. Earth Sci. 2013, 68, 2229–2237. [Google Scholar] [CrossRef]

- Jiang, Q.; Feng, X.T.; Gong, Y.H.; Song, L.B.; Ran, S.G.; Cui, J. Reverse modelling of natural rock joints using 3D scanning and 3D printing. Comput. Geotech. 2016, 73, 210–220. [Google Scholar] [CrossRef]

- Xia, C.C.; Sun, Z.Q. RSP-I type profilometer of rock surface. J. Hydraul. Eng. 1995, 6, 62–66. [Google Scholar]

- Xia, C.; Wang, W.; Ding, Z. Development of threedimensional TJXW– 3D typed portable rock surface topography. Chin. J. Rock Mech. Eng. 2008, 27, 1505–1512. [Google Scholar]

- Cao, P.; Fan, X.; Pu, C.; Chen, R.; Zhang, C. Shear test of joint and analysis of morphology characteristic evolution of joint surface. Chin. J. Rock Mech. Eng. 2011, 30, 480–485. [Google Scholar]

- Grasselli, G.; Wirth, J.; Egger, P. Quantitative three-dimensional description of a rough surface and parameter evolution with shearing. Int. J. Rock Mech. Min. Sci. 2002, 39, 789–800. [Google Scholar] [CrossRef]

- Grasselli, G.; Egger, P. Constitutive law for the shear strength of rock joints based on three-dimensional surface parameters. Int. J. Rock Mech. Min. Sci. 2003, 40, 25–40. [Google Scholar] [CrossRef]

- Grasselli, G. Manuel Rocha Medal recipient—Shear strength of rock joints based on quantified surface description. Rock Mech. Rock Eng. 2006, 39, 295–314. [Google Scholar] [CrossRef]

- Gui, Y.; Xia, C.C.; Ding, W.Q.; Qian, X.; Du, S.G. A New Method for 3D Modeling of Joint Surface Degradation and Void Space Evolution Under Normal and Shear Loads. Rock Mech. Rock Eng. 2017, 50, 2827–2836. [Google Scholar] [CrossRef]

- Gui, Y.; Xia, C.; Ding, W.Q.; Qian, X.; Du, S.G. Modelling Shear Behaviour of Joint Based on Joint Surface Degradation During Shearing. Rock Mech. Rock Eng. 2019, 52, 107–131. [Google Scholar] [CrossRef]

- Vaneghi, R.G.; Ferdosi, B.; Okoth, A.D.; Kuek, B. Strength degradation of sandstone and granodiorite under uniaxial cyclic loading. J. Rock Mech. Geotech. Eng. 2018, 10, 117–126. [Google Scholar] [CrossRef]

- Li, Y.; Zeng, X.; Lin, Z.; Su, J.; Gao, T.; Deng, R.J.; Liu, X. Experimental study on phosphate rock modified soil-bentonite as a cut-off wall material. Water Supply 2021, 22, 1676–1690. [Google Scholar] [CrossRef]

- Peng, Y.; Liu, G.J.; Wu, L.; Zuo, Q.J.; Liu, Y.S.; Zhang, C. Comparative study on tunnel blast-induced vibration for the underground cavern group. Environ. Earth Sci. 2021, 80, 68. [Google Scholar] [CrossRef]

- Han, G.S.; Jing, H.W.; Jiang, Y.J.; Liu, R.C.; Wu, J.Y. Effect of Cyclic Loading on the Shear Behaviours of Both Unfilled and Infilled Rough Rock Joints Under Constant Normal Stiffness Conditions. Rock Mech. Rock Eng. 2020, 53, 31–57. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, Q.; Zhang, C.S.; Liao, J.; Lin, H.; Wang, Y.X. Coupled seepage-damage effect in fractured rock masses: Model development and a case study. Int. J. Rock Mech. Min. Sci. 2021, 144, 104822. [Google Scholar] [CrossRef]

- Asadi, M.S.; Rasouli, V.; Barla, G. A Laboratory Shear Cell Used for Simulation of Shear Strength and Asperity Degradation of Rough Rock Fractures. Rock Mech. Rock Eng. 2013, 46, 683–699. [Google Scholar] [CrossRef]

- Zhao, Z.H.; Peng, H.; Wu, W.; Chen, Y.F. Characteristics of shear-induced asperity degradation of rock fractures and implications for solute retardation. Int. J. Rock Mech. Min. Sci. 2018, 105, 53–61. [Google Scholar] [CrossRef]

- Meng, F.Z.; Zhou, H.; Li, S.J.; Zhang, C.Q.; Wang, Z.Q.; Kong, L.; Zhang, L.M. Shear Behaviour and Acoustic Emission Characteristics of Different Joints Under Various Stress Levels. Rock Mech. Rock Eng. 2016, 49, 4919–4928. [Google Scholar] [CrossRef]

- Li, Y.C.; Wu, W.; Tang, C.A.; Liu, B. Predicting the shear characteristics of rock joints with asperity degradation and debris backfilling under cyclic loading conditions. Int. J. Rock Mech. Min. Sci. 2019, 120, 108–118. [Google Scholar] [CrossRef]

- Lu, Y.; Li, H.; Lu, J.X.; Shi, S.L.; Wang, G.G.X.; Ye, Q.; Li, R.Q.; Zhu, X.N. Clean up water blocking damage in coalbed methane reservoirs by microwave heating: Laboratory studies. Process Saf. Environ. Prot. 2020, 138, 292–299. [Google Scholar] [CrossRef]

- Lee, H.S.; Park, Y.J.; Cho, T.F.; You, K.H. Influence of asperity degradation on the mechanical behavior of rough rock joints under cyclic shear loading. Int. J. Rock Mech. Min. Sci. 2001, 38, 967–980. [Google Scholar] [CrossRef]

- Jafari, M.K.; Hosseini, K.A.; Pellet, F.; Boulon, M.; Buzzi, O. Evaluation of shear strength of rock joints subjected to cyclic loading. Soil Dyn. Earthq. Eng. 2003, 23, 619–630. [Google Scholar] [CrossRef]

- Mirzaghorbanali, A.; Nemcik, J.; Aziz, N. Effects of Shear Rate on Cyclic Loading Shear Behaviour of Rock Joints Under Constant Normal Stiffness Conditions. Rock Mech. Rock Eng. 2014, 47, 1931–1938. [Google Scholar] [CrossRef]

- Mirzaghorbanali, A.; Nemcik, J.; Aziz, N. Effects of Cyclic Loading on the Shear Behaviour of Infilled Rock Joints Under Constant Normal Stiffness Conditions. Rock Mech. Rock Eng. 2014, 47, 1373–1391. [Google Scholar] [CrossRef]

- Niktabar, S.M.M.; Rao, K.S.; Shrivastava, A.K. Automatic Static and Cyclic Shear Testing Machine under Constant Normal Stiffness Boundary Conditions. Geotech. Test. J. 2018, 41, 508–525. [Google Scholar] [CrossRef]

- Liu, Y.; Dai, F.; Dong, L.; Xu, N.W.; Feng, P. Experimental Investigation on the Fatigue Mechanical Properties of Intermittently Jointed Rock Models Under Cyclic Uniaxial Compression with Different Loading Parameters. Rock Mech. Rock Eng. 2018, 51, 47–68. [Google Scholar] [CrossRef]

- Fan, J.; Jiang, D.Y.; Liu, W.; Chen, J.; Daemen, J.J.K. Discontinuous fatigue of salt rock with low-stress intervals. Int. J. Rock Mech. Min. Sci. 2019, 115, 77–86. [Google Scholar] [CrossRef]

- Zhang, H.; Dong, S.; Lu, Z.; Peng, Y.; Hou, W. Shear strength deterioration effect of rock mass joint surface under cyclic shear load. Sci. Rep. 2022, 12, 15034. [Google Scholar] [CrossRef]

- Wu, X.; Jiang, Y.; Gong, B.; Guan, Z.; Deng, T. Shear Performance of Rock Joint Reinforced by Fully Encapsulated Rock Bolt Under Cyclic Loading Condition. Rock Mech. Rock Eng. 2019, 52, 2681–2690. [Google Scholar] [CrossRef]

- Kou, M.; Liu, X.; Tang, S.; Wang, Y. Experimental study of the prepeak cyclic shear mechanical behaviors of artificial rock joints with multiscale asperities. Soil Dyn. Earthq. Eng. 2019, 120, 58–74. [Google Scholar] [CrossRef]

- Dang, W.; Konietzky, H.; Fruehwirt, T.; Herbst, M. Cyclic Frictional Responses of Planar Joints Under Cyclic Normal Load Conditions: Laboratory Tests and Numerical Simulations. Rock Mech. Rock Eng. 2020, 53, 337–364. [Google Scholar] [CrossRef]

- Tang, W.Y.; Lin, H. Influence of Internal Friction Angle and Interface Roughness on Shear Behavior of Mortar-Rock Binary Medium Joint. Geotech. Geol. Eng. 2021, 39, 3917–3929. [Google Scholar] [CrossRef]

- Tang, W.Y.; Lin, H.; Chen, Y.F.; Feng, J.J.; Hu, H.H. Mechanical Characteristics and Acoustic Emission Characteristics of Mortar-Rock Binary Medium. Buildings 2022, 12, 665. [Google Scholar] [CrossRef]

- Lin, H.; Wang, M.; Xu, W.Z. Shear Behaviors of the Binary Structural Plane. Geotech. Geol. Eng. 2018, 36, 939–948. [Google Scholar] [CrossRef]

- Han, L.; Lin, H.; Chen, Y.F.; Lei, D.X. Effects of strength property difference on shear strength of joint of binary media. Environ. Earth Sci. 2021, 80, 712. [Google Scholar] [CrossRef]

- Sun, C.; Sun, M.; Tao, T.; Qu, F.; Wang, G.X.; Zhang, P.; Li, Y.T.; Duan, J.Z. Chloride Binding Capacity and Its Effect on the Microstructure of Mortar Made with Marine Sand. Sustainability 2021, 13, 4169. [Google Scholar] [CrossRef]

- Fan, H.D.; Lu, Y.F.; Hu, Y.L.; Fang, J.; Lv, C.Z.; Xu, C.Q.; Feng, X.Y.; Liu, Y.R. A Landslide Susceptibility Evaluation of Highway Disasters Based on the Frequency Ratio Coupling Model. Sustainability 2022, 14, 7740. [Google Scholar] [CrossRef]

- Yu, W.J.; Li, K.; Liu, Z.; An, B.F.; Wang, P.; Wu, H. Mechanical characteristics and deformation control of surrounding rock in weakly cemented siltstone. Environ. Earth Sci. 2021, 80, 337. [Google Scholar] [CrossRef]

- Feng, T.; Chen, H.S.; Wang, K.L.; Nie, Y.P.; Zhang, X.B.; Mo, H.W. Assessment of underground soil loss via the tapering grikes on limestone hillslopes. Agric. Ecosyst. Environ. 2020, 297, 106935. [Google Scholar] [CrossRef]

- Zhao, Y.; Luo, S.L.; Wang, Y.X.; Wang, W.J.; Zhang, L.Y.; Wan, W. Numerical Analysis of Karst Water Inrush and a Criterion for Establishing the Width of Water-resistant Rock Pillars. Mine Water Environ. 2017, 36, 508–519. [Google Scholar] [CrossRef]

- Yuan, Z.; Zhao, J.; Li, S.; Jiang, Z.; Huang, F. A Unified Solution for Surrounding Rock of Roadway Considering Seepage, Dilatancy, Strain-Softening and Intermediate Principal Stress. Sustainability 2022, 14, 8099. [Google Scholar] [CrossRef]

- Zhao, Y.; Tang, J.; Chen, Y.; Zhang, L.; Wang, W.; Wan, W.; Liao, J. Hydromechanical coupling tests for mechanical and permeability characteristics of fractured limestone in complete stress-strain process. Environ. Earth Sci. 2017, 76, 24. [Google Scholar] [CrossRef]

- Tian, Z.; Zhang, Z.; Deng, M.; Yan, S.; Bai, J. Gob-Side Entry Retained with Soft Roof, Floor, and Seam in Thin Coal Seams: A Case Study. Sustainability 2020, 12, 1197. [Google Scholar] [CrossRef] [Green Version]

- Huang, Z.; Huang, Y.; Yang, Z.; Zhang, J.; Zhang, Y.; Gao, Y.; Shao, Z.; Zhang, L. Study on the physicochemical characteristics and dust suppression performance of new type chemical dust suppressant for copper mine pavement. Environ. Sci. Pollut. Res. 2021, 28, 59640–59651. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Liu, S.; Guo, W.; Yao, X.; Jiang, Z.; Han, Y. Using Remote Sensing Data to Quantify Changes in Glacial Lakes in the Chinese Himalaya. Mt. Res. Dev. 2012, 32, 203–212. [Google Scholar]

- Zhao, X.; Wang, X.; Wei, J.; Jiang, Z.; Zhang, Y.; Liu, S. Spatiotemporal variability of glacier changes and their controlling factors in the Kanchenjunga region, Himalaya based on multi-source remote sensing data from 1975 to 2015. Sci. Total Environ. 2020, 745, 140995. [Google Scholar] [CrossRef]

- Yu, G.; Liao, Y.; Liao, Y.; Zhao, W.; Chen, Q.; Kou, J.; Liu, X. Research on integrated coastal zone management based on remote sensing: A case study of Guangxi Beibu gulf. Reg. Stud. Mar. Sci. 2021, 44, 101710. [Google Scholar] [CrossRef]

- Li, M.; Lv, H.; Lu, Y.; Wang, D.; Shi, S.; Li, R.Q. Instantaneous discharge characteristics and its methane ignition mechanism of coal mine rock damage. Environ. Sci. Pollut. Res. 2022, 29, 62495–62506. [Google Scholar] [CrossRef]

| Type | UCS/Mpa | Cohesion/Mpa | Friction Angle/° |

|---|---|---|---|

| Malmstone (A) | 72.00 | 9.00 | 61.00 |

| Red sandstone (B) | 29.50 | 3.93 | 52.00 |

| Blue sandstone (C) | 33.00 | 2.60 | 51.70 |

| Sample Number | Normal Stress/MPa | Shear Rate/mm × s−1 | Shear Times |

|---|---|---|---|

| AD-1 | 4 | 0.01 | 3 |

| AD-2 | |||

| AD-3 | |||

| BD-1 | |||

| BD-2 | 2 | 0.01 | 3 |

| CD-1 | |||

| CD-2 | |||

| CD-3 |

| Number | First Shearing Stress/MPa | Second Shearing Stress/MPa | Third Shearing Stress/MPa |

|---|---|---|---|

| AD-1 | 6.08 | 4.42 | 4.16 |

| AD-2 | 6.20 | 4.35 | 4.11 |

| AD-3 | 6.29 | 4.43 | 4.32 |

| BD-1 | 4.88 | 2.73 | 2.39 |

| BD-2 | 3.25 | 2.15 | 1.74 |

| CD-1 | 3.91 | 1.82 | 1.61 |

| CD-2 | 3.08 | 1.76 | 1.51 |

| CD-3 | 2.97 | 1.73 | 1.44 |

| Interface Number | Topography Parameters | Before Tests | First Shearing | Second Shearing | Third Shearing |

|---|---|---|---|---|---|

| AD-1 | Sp/mm | 2.41 | 2.36 | 2.99 | 2.38 |

| Sa/mm | 1.16 | 1.19 | 1.22 | 1.22 | |

| Sq/mm | 1.39 | 1.5 | 1.39 | 1.39 | |

| Ssk | −0.837 | −1.45 | 0.13 | 0.22 | |

| Sku | 2.89 | 5.98 | 1.76 | 1.75 | |

| AD-2 | Sp/mm | 3.96 | 4.2 | 4.07 | 4.81 |

| Sa/mm | 1.81 | 2.02 | 1.62 | 1.09 | |

| Sq/mm | 2.21 | 2.71 | 1.85 | 1.82 | |

| Ssk | −0.386 | −1.37 | 0.31 | 0.12 | |

| Sku | 3.09 | 7 | 1.94 | 2.12 | |

| AD-3 | Sp/mm | 4.76 | 4.57 | 4.23 | 4.13 |

| Sa/mm | 2.55 | 1.96 | 1.81 | 1.78 | |

| Sq/mm | 3.51 | 2.32 | 2.12 | 2.07 | |

| Ssk | −1.25 | −0.13 | −0.03 | 0.01 | |

| Sku | 4.11 | 2.06 | 2.06 | 2.01 | |

| BD-1 | Sp/mm | 4.55 | 4.41 | 3.06 | 6.56 |

| Sa/mm | 1.84 | 2.18 | 1.61 | 1.28 | |

| Sq/mm | 2.23 | 2.9 | 1.51 | 1.13 | |

| Ssk | −0.72 | −1.2 | −0.48 | 0.06 | |

| Sku | 3.13 | 3.44 | 2.21 | 1.62 | |

| BD-2 | Sp/mm | 5.68 | 4.16 | 3.69 | 3.28 |

| Sa/mm | 1.72 | 1.5 | 1.43 | 1.38 | |

| Sq/mm | 2.22 | 1.92 | 1.89 | 1.88 | |

| Ssk | −1.41 | −0.62 | 1.14 | 1.80 | |

| Sku | 4.21 | 3.14 | 2.99 | 1.64 | |

| CD-1 | Sp/mm | 5.27 | 4.79 | 4.62 | 3.7 |

| Sa/mm | 1.47 | 1.34 | 1.22 | 1.18 | |

| Sq/mm | 1.82 | 1.6 | 1.52 | 1.4 | |

| Ssk | −0.29 | −0.004 | 0.31 | 1.38 | |

| Sku | 2.81 | 2.18 | 1.97 | 1.18 | |

| CD-2 | Sp/mm | 5.78 | 3.28 | 3.15 | 2.36 |

| Sa/mm | 2.04 | 1.11 | 1.19 | 0.88 | |

| Sq/mm | 2.47 | 1.34 | 1.1 | 0.96 | |

| Ssk | 0.01 | 0.10 | 0.04 | −0.08 | |

| Sku | 2.27 | 2.23 | 1.95 | 1.51 | |

| CD-3 | Sp/mm | 6.88 | 5.67 | 5.61 | 5.06 |

| Sa/mm | 1.75 | 1.58 | 1.48 | 1.24 | |

| Sq/mm | 2.14 | 2.06 | 2.07 | 2.03 | |

| Ssk | −0.52 | 0.08 | 0.08 | 0.24 | |

| Sku | 2.71 | 2.65 | 2.49 | 2.33 |

| Interface Number | Topography Parameters | Before Tests | First Shearing | Second Shearing | Third Shearing |

|---|---|---|---|---|---|

| AD-1 | Str | 0.383 | 0.379 | 0.382 | 0.384 |

| Std/° | 48.6 | 49.6 | 48.2 | 48 | |

| Spd/mm−2 | 0.241 | 0. 207 | 0.187 | 0.176 | |

| Spc/mm−1 | 0.31 | 0.291 | 0.142 | 0.129 | |

| AD-2 | Str | 0.3 | 0.284 | 0.309 | 0.346 |

| Std/° | 44 | 46,2 | 45.7 | 45.6 | |

| Spd/mm−2 | 0.314 | 0.339 | 0.257 | 0.252 | |

| Spc/mm−1 | 0.348 | 0.677 | 0.615 | 0.538 | |

| AD-3 | Str | 0.258 | 0.29 | 0.371 | 0.378 |

| Std/° | 47 | 46.1 | 45.9 | 45.5 | |

| Spd/mm−2 | 0.782 | 0.621 | 0.522 | 0.494 | |

| Spc/mm−1 | 0. 802 | 0.766 | 0.751 | 0.732 | |

| BD-1 | Str | 0.307 | 0.311 | 0.336 | 0.376 |

| Std/° | 36.5 | 36.1 | 35.7 | 35.5 | |

| Spd/mm−2 | 0.491 | 0.392 | 0.321 | 0.301 | |

| Spc/mm−1 | 0.314 | 0.302 | 0.275 | 0.223 | |

| BD-2 | Str | 0.289 | 0.319 | 0.325 | 0.33 |

| Std/° | 51.2 | 51 | 50.7 | 50.6 | |

| Spd/mm−2 | 0.411 | 0.377 | 0.369 | 0.362 | |

| Spc/mm−1 | 0.278 | 0.241 | 0.223 | 0.22 | |

| CD-1 | Str | 0.382 | 0.431 | 0.436 | 0.466 |

| Std/° | 33.3 | 32 | 31.5 | 31.3 | |

| Spd/mm−2 | 0.583 | 0.544 | 0.497 | 0.437 | |

| Spc/mm−1 | 0.254 | 0.196 | 0.127 | 0.126 | |

| CD-2 | Str | 0.192 | 0.197 | 0.263 | 0.291 |

| Std/° | 36.1 | 35.7 | 35.5 | 35 | |

| Spd/mm−2 | 0.732 | 0.724 | 0.688 | 0.685 | |

| Spc/mm−1 | 0.409 | 0.351 | 0.299 | 0.229 | |

| CD-3 | Str | 0.312 | 0.314 | 0.32 | 0.329 |

| Std/° | 40 | 36.2 | 35.6 | 31.1 | |

| Spd/mm−2 | 0.781 | 0.755 | 0.692 | 0.663 | |

| Spc/mm−1 | 0.313 | 0.282 | 0.259 | 0.234 |

| Interface Number | Topography Parameters | Before Tests | First Shearing | Second Shearing | Third Shearing |

|---|---|---|---|---|---|

| AD-1 | Sdq | 2.13 | 2.07 | 1.64 | 1.3 |

| Sdr/% | 22 | 30.6 | 24.17 | 22 | |

| Ds | 2.24 | 2.43 | 2.21 | 2.23 | |

| AD-2 | Sdq | 3.42 | 3.46 | 2.11 | 0.005 |

| Sdr/% | 89.9 | 109 | 87.1 | 86.7 | |

| Ds | 2.28 | 2.29 | 2.22 | 2.19 | |

| AD-3 | Sdq | 3.15 | 3.05 | 1.72 | 0.782 |

| Sdr/% | 70.5 | 84.7 | 76.5 | 70.3 | |

| Ds | 2.21 | 2.26 | 2.29 | 2.26 | |

| BD-1 | Sdq | 2.48 | 1.68 | 1.64 | 1.62 |

| Sdr/% | 76.8 | 56.6 | 49 | 48 | |

| Ds | 2.49 | 2.29 | 2.3 | 2.28 | |

| BD-2 | Sdq | 3.21 | 2.17 | 1.88 | 1.72 |

| Sdr/% | 66 | 57.3 | 52.1 | 50 | |

| Ds | 2.31 | 2.28 | 2.28 | 2.21 | |

| CD-1 | Sdq | 3.06 | 2.57 | 1.62 | 1.39 |

| Sdr/% | 51.2 | 47 | 42.7 | 36 | |

| Ds | 2.59 | 2.32 | 2.23 | 2.21 | |

| CD-2 | Sdq | 2.749 | 2.12 | 0.98 | 1.297 |

| Sdr/% | 31.9 | 26.6 | 16 | 15 | |

| Ds | 2.34 | 2.29 | 2.25 | 2.25 | |

| CD-3 | Sdq | 2.6 | 2.1 | 1.71 | 0.48 |

| Sdr/% | 67 | 61 | 54 | 52 | |

| Ds | 2.36 | 2.3 | 2.28 | 2.22 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, L.; Tang, W.; Lin, H.; Lei, F.; Chen, Y.; Wang, Y.; Zhao, Y. Apparent Deterioration Law and Shear Failure Mode of Rock–Mortar Interface Based on Topography-Sensing Technology. Materials 2023, 16, 763. https://doi.org/10.3390/ma16020763

Xie L, Tang W, Lin H, Lei F, Chen Y, Wang Y, Zhao Y. Apparent Deterioration Law and Shear Failure Mode of Rock–Mortar Interface Based on Topography-Sensing Technology. Materials. 2023; 16(2):763. https://doi.org/10.3390/ma16020763

Chicago/Turabian StyleXie, Linglin, Wenyu Tang, Hang Lin, Fan Lei, Yifan Chen, Yixian Wang, and Yanlin Zhao. 2023. "Apparent Deterioration Law and Shear Failure Mode of Rock–Mortar Interface Based on Topography-Sensing Technology" Materials 16, no. 2: 763. https://doi.org/10.3390/ma16020763

APA StyleXie, L., Tang, W., Lin, H., Lei, F., Chen, Y., Wang, Y., & Zhao, Y. (2023). Apparent Deterioration Law and Shear Failure Mode of Rock–Mortar Interface Based on Topography-Sensing Technology. Materials, 16(2), 763. https://doi.org/10.3390/ma16020763