The Influence of Vibro-Assisted Abrasive Processing on the Surface Roughness and Sub-Surface Microstructure of Inconel 939 Specimen Made by LPBF

Abstract

:1. Introduction

2. Materials and Methods

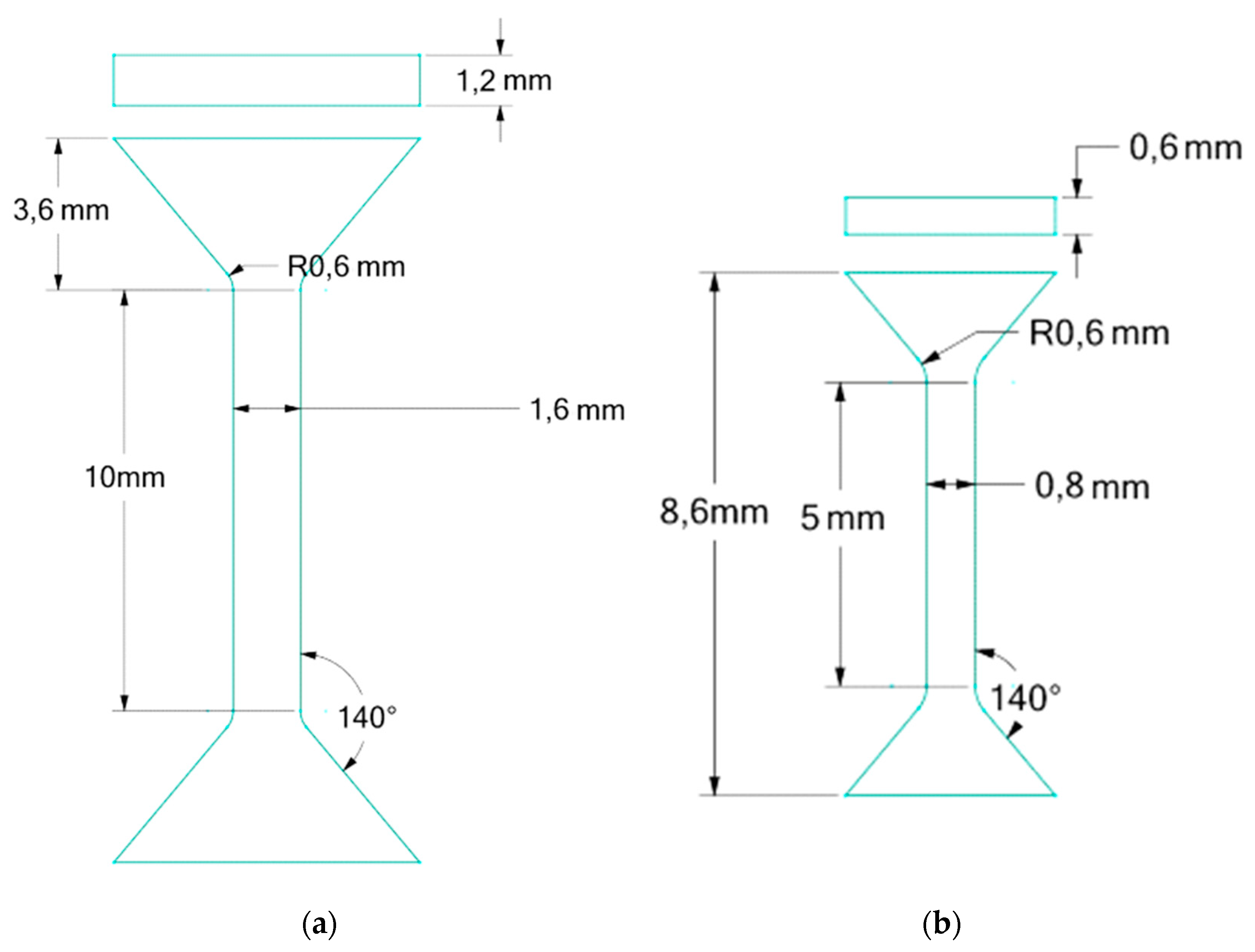

2.1. Samples Preparation

- a rotation between layers of 67 degrees,

- a layer thickness of 20 µm,

- the hatch distance was 50 µm,

- a 5 mm width for scanning stripes with 0.1 mm overlap,

- building direction is along the height of the sample (a laser exposure strategy developed by EOS to improve the quality of the material) [20].

2.2. Experimental Station and Measurements

3. Results and Discussion

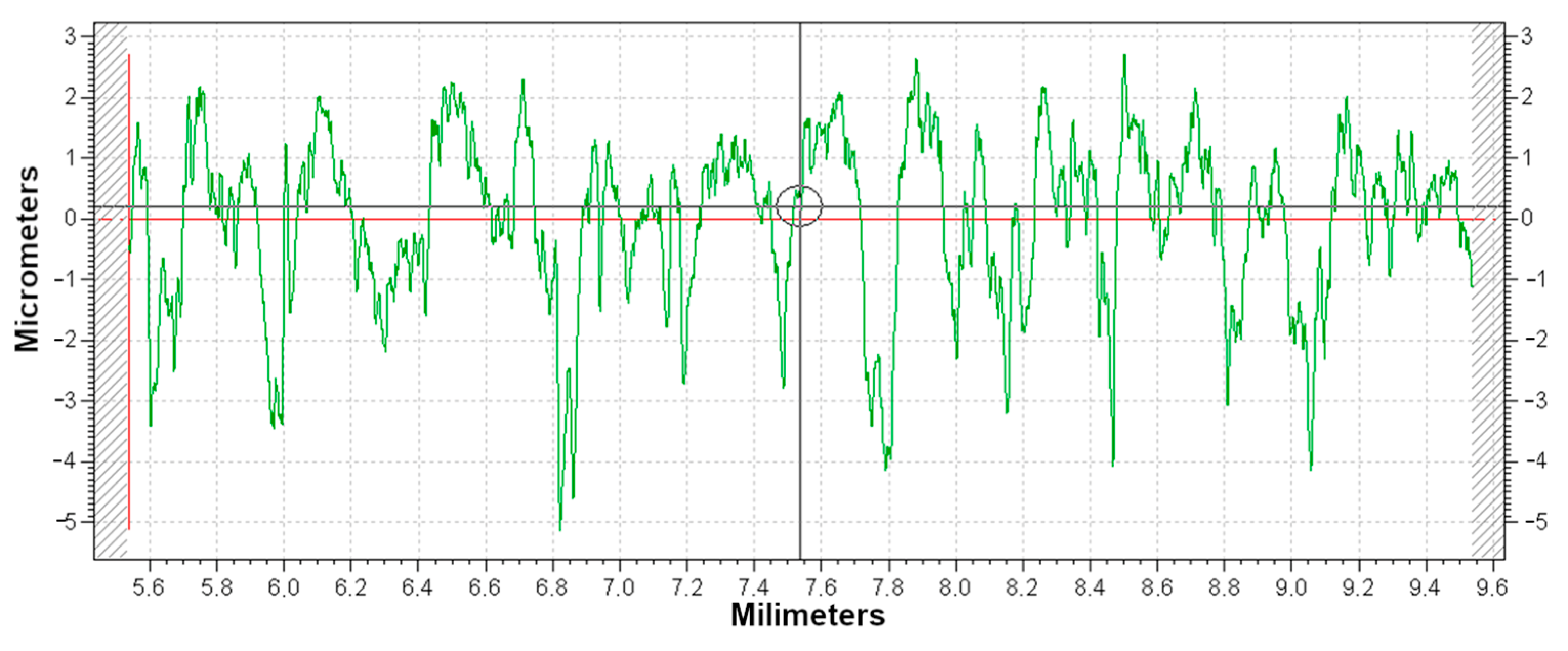

3.1. Vibratory Surface Processing with Fluid

3.2. Vibratory Surface Processing without Fluid

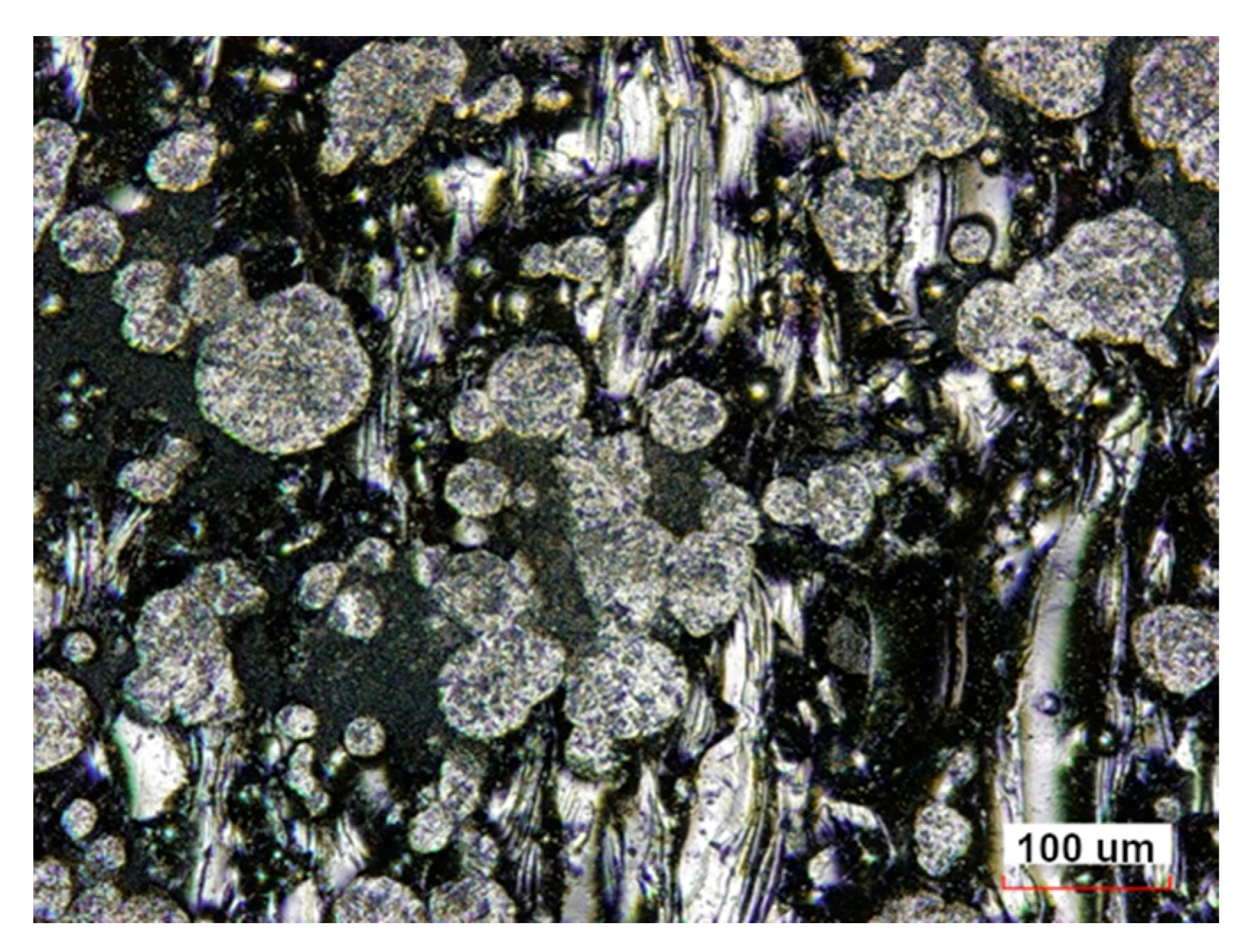

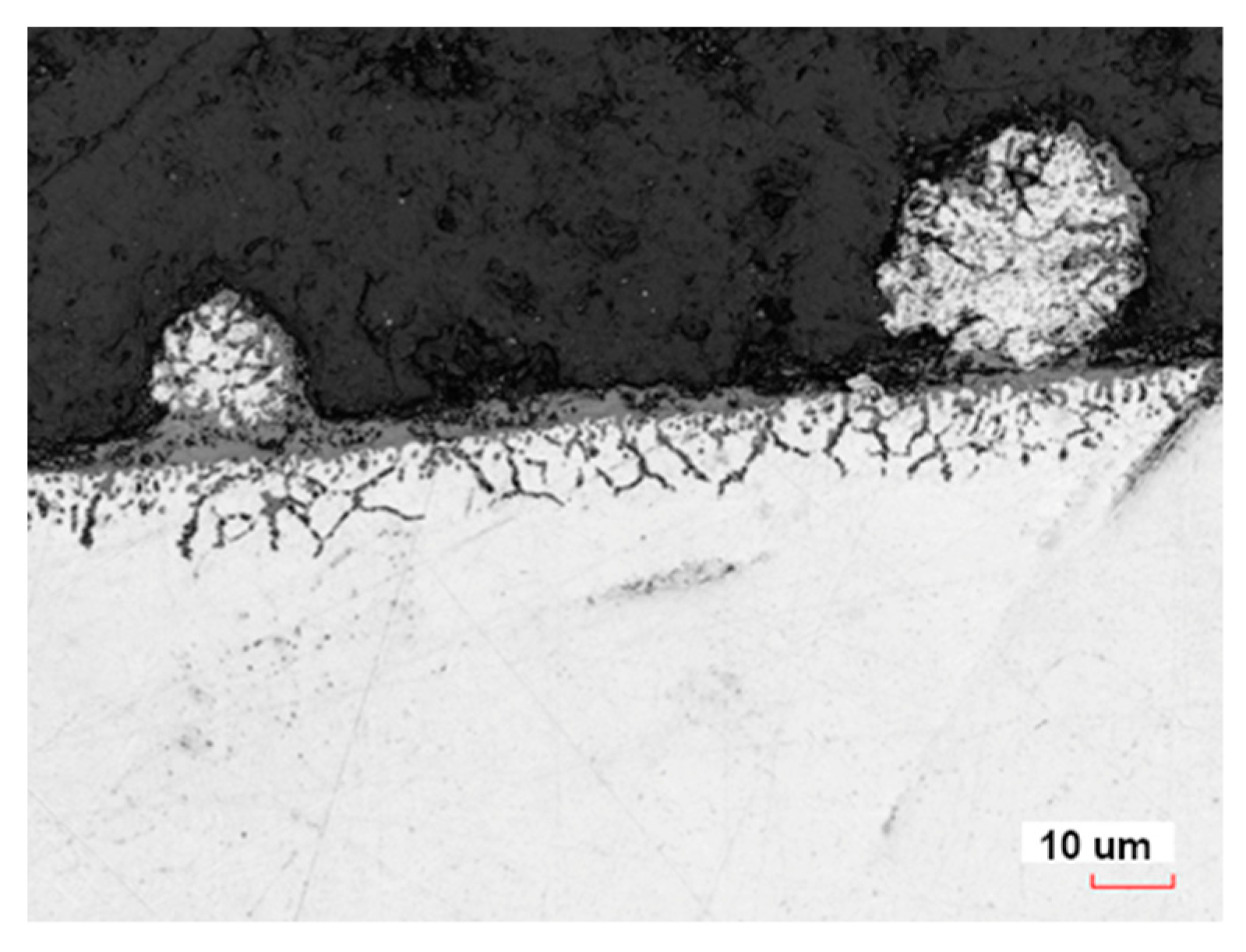

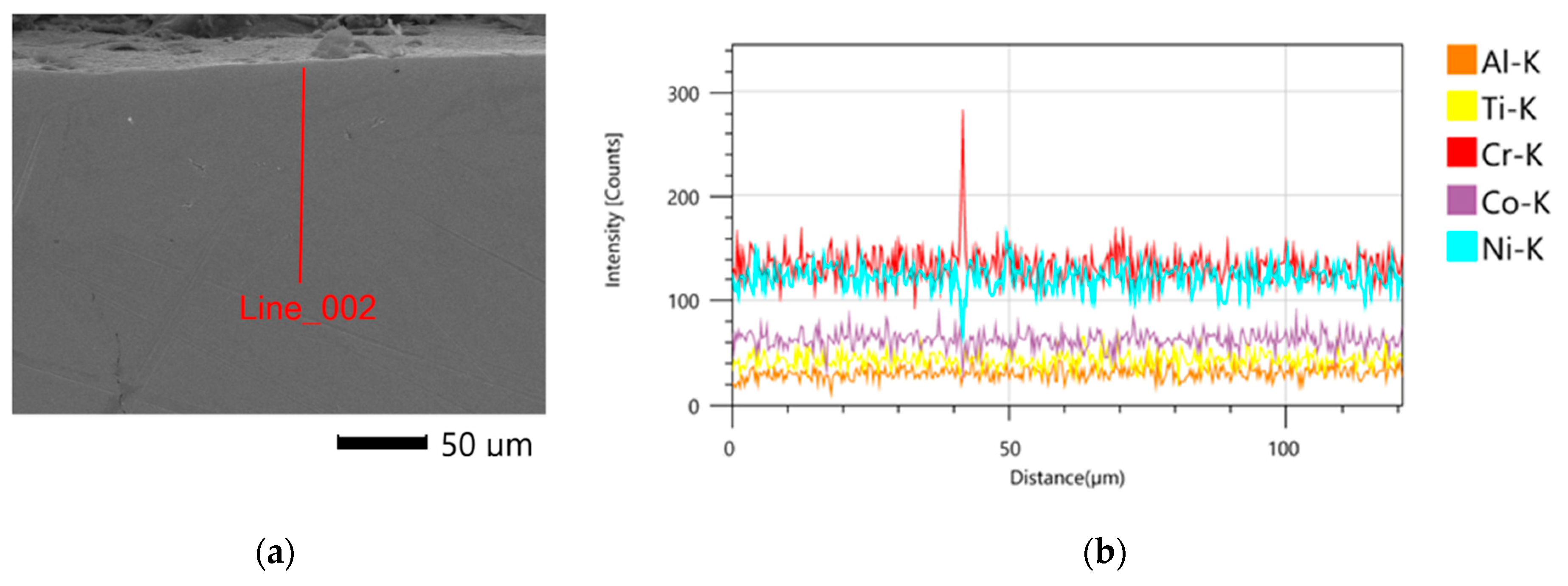

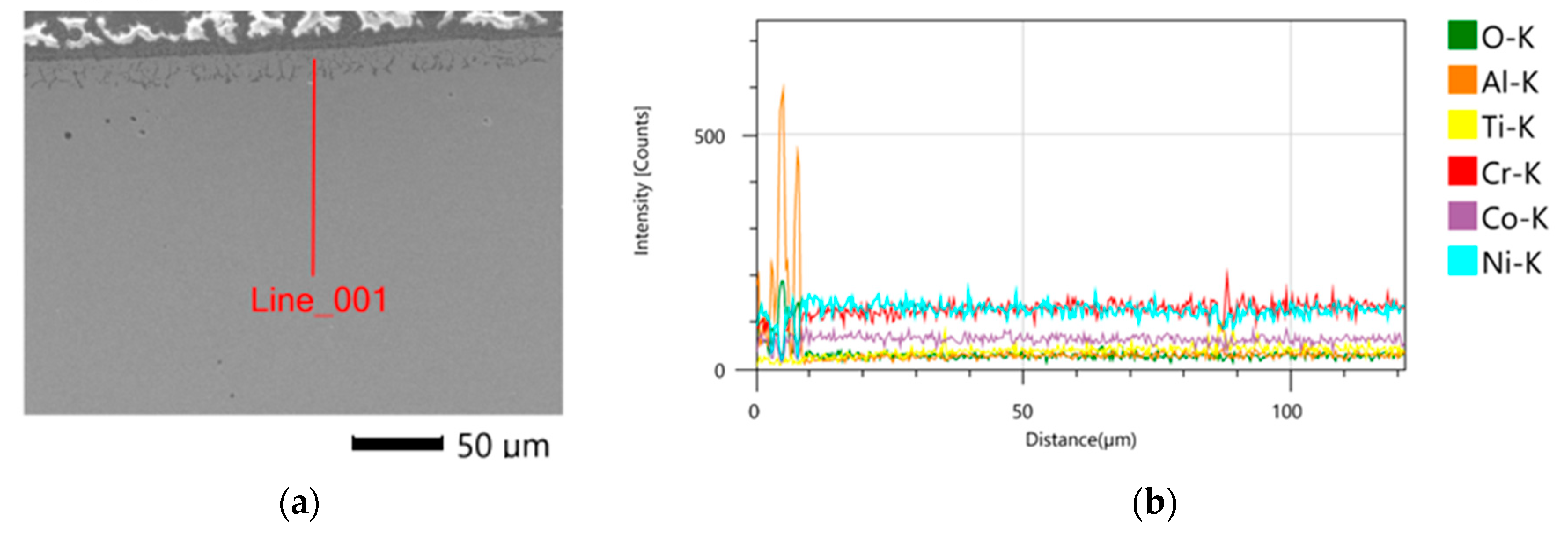

3.3. Analysis of Microstructure and Microhardness

3.4. Discussion

4. Conclusions

- Employing ceramic pellet shapes and machining fluid significantly reduces the average surface roughness Ra, from 6 µm to 1.2 µm.

- The type of abrasive shapes, especially their weight, exerts the most significant influence on the efficiency and surface roughness of the vibratory finishing process.

- It was observed that the impact of cutting fluid presence on machining results is dependent on the abrasive shapes used for ceramic and porcelain rollers. Better process efficiency was achieved without fluid.

- After heat treatment, a continuous layer of oxides several micrometers thick was found on the surface. The presence of oxides was also found in particles on the surface and precipitates in the subsurface layer.

- Microhardness tests demonstrated that following heat treatment, the material’s hardness increases from 500 HV0.01 after LPBF to 680 HV. The presence of sub-surface zones with a different microstructure and lower hardness compared to the core was found for elements after printing, heat treatment and vibration treatment.

- As a result of the diffusion of titanium and aluminum (the main components of the strengthening basic gamma phase) into the precipitates, a reduction in sub-surface hardness was found in the near-surface layer.

- In the sub-surface zone, the occurrence of oxide precipitates rich in aluminum was revealed for Midi and Mini elements after heat and abrasive treatment.

- A favorable balance between hardness and surface roughness was successfully attained in the process, highlighting its potential for utilization in advanced finishing methods for aerospace applications.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Donachie, M.J.; Donachie, S.J. Superalloys: A Technical Guide, 2nd ed.; ASM International: Detroit, MI, USA, 2002; ISBN 978-1-62708-267-9. [Google Scholar]

- Reed, R.C. The Superalloys: Fundamentals and Applications, 1st ed.; Cambridge University Press: Cambridge, UK, 2006; ISBN 978-0-521-85904-2. [Google Scholar]

- Stefan, E.; Talic, B.; Larring, Y.; Gruber, A.; Peters, T.A. Materials Challenges in Hydrogen-Fuelled Gas Turbines. Int. Mater. Rev. 2022, 67, 461–486. [Google Scholar] [CrossRef]

- Thomas, D.S.; Gilbert, S.W. Costs and Cost Effectiveness of Additive Manufacturing; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2014; p. NIST SP 1176. [Google Scholar]

- Shaikh, A.S.; Rashidi, M.; Minet-Lallemand, K.; Hryha, E. On As-Built Microstructure and Necessity of Solution Treatment in Additively Manufactured Inconel 939. Powder Metall. 2023, 66, 3–11. [Google Scholar] [CrossRef]

- Doğu, M.N.; Ozer, S.; Yalçın, M.A.; Davut, K.; Bilgin, G.M.; Obeidi, M.A.; Brodin, H.; Gu, H.; Brabazon, D. Effect of Solution Heat Treatment on the Microstructure and Crystallographic Texture of IN939 Fabricated by Powder Bed Fusion-Laser Beam. J. Mater. Res. Technol. 2023, 24, 8909–8923. [Google Scholar] [CrossRef]

- Marchese, G.; Parizia, S.; Saboori, A.; Manfredi, D.; Lombardi, M.; Fino, P.; Ugues, D.; Biamino, S. The Influence of the Process Parameters on the Densification and Microstructure Development of Laser Powder Bed Fused Inconel 939. Metals 2020, 10, 882. [Google Scholar] [CrossRef]

- Banoth, S.; Li, C.-W.; Hiratsuka, Y.; Kakehi, K. The Effect of Recrystallization on Creep Properties of Alloy IN939 Fabricated by Selective Laser Melting Process. Metals 2020, 10, 1016. [Google Scholar] [CrossRef]

- Wimmer, T.; Mick, Y.; Weigand, B. Experimental Investigation into Capabilities of Laser Powder Bed Fusion to Produce Wavy Macro-Channels from IN939. Addit. Manuf. 2020, 35, 101345. [Google Scholar] [CrossRef]

- Li, Y.; Liang, X.; Yu, Y.; Li, H.; Kan, W.; Lin, F. Microstructures and Mechanical Properties Evolution of IN939 Alloy during Electron Beam Selective Melting Process. J. Alloys Compd. 2021, 883, 160934. [Google Scholar] [CrossRef]

- Kanagarajah, P.; Brenne, F.; Niendorf, T.; Maier, H.J. Inconel 939 Processed by Selective Laser Melting: Effect of Microstructure and Temperature on the Mechanical Properties under Static and Cyclic Loading. Mater. Sci. Eng. A 2013, 588, 188–195. [Google Scholar] [CrossRef]

- Zhang, B.; Ding, H.; Meng, A.C.; Nemati, S.; Guo, S.; Meng, W.J. Crack Reduction in Inconel 939 with Si Addition Processed by Laser Powder Bed Fusion Additive Manufacturing. Addit. Manuf. 2023, 72, 103623. [Google Scholar] [CrossRef]

- Gradl, P.; Tinker, D.C.; Park, A.; Mireles, O.R.; Garcia, M.; Wilkerson, R.; Mckinney, C. Robust Metal Additive Manufacturing Process Selection and Development for Aerospace Components. J. Mater. Eng. Perform. 2022, 31, 6013–6044. [Google Scholar] [CrossRef]

- Khanna, N.; Zadafiya, K.; Patel, T.; Kaynak, Y.; Rahman Rashid, R.A.; Vafadar, A. Review on Machining of Additively Manufactured Nickel and Titanium Alloys. J. Mater. Res. Technol. 2021, 15, 3192–3221. [Google Scholar] [CrossRef]

- Boschetto, A.; Bottini, L.; Macera, L.; Veniali, F. Post-Processing of Complex SLM Parts by Barrel Finishing. Appl. Sci. 2020, 10, 1382. [Google Scholar] [CrossRef]

- Lesyk, D.A.; Martinez, S.; Mordyuk, B.N.; Dzhemelinskyi, V.V.; Lamikiz, A.; Prokopenko, G.I. Post-Processing of the Inconel 718 Alloy Parts Fabricated by Selective Laser Melting: Effects of Mechanical Surface Treatments on Surface Topography, Porosity, Hardness and Residual Stress. Surf. Coat. Technol. 2020, 381, 125136. [Google Scholar] [CrossRef]

- Damon, J.; Dietrich, S.; Vollert, F.; Gibmeier, J.; Schulze, V. Process Dependent Porosity and the Influence of Shot Peening on Porosity Morphology Regarding Selective Laser Melted AlSi10Mg Parts. Addit. Manuf. 2018, 20, 77–89. [Google Scholar] [CrossRef]

- Metal Solutions EOS NickelAlloy IN939 Material Data Sheet Metal Solutions. Available online: https://www.eos.info/03_system-related-assets/material-related-contents/metal-materials-and-examples/metal-material-datasheet/nickelalloy-inconel/material_datasheet_eos_nickelalloy_in939_premium_en_web.pdf (accessed on 5 July 2023).

- ISO 6508-3; Rockwell Hardness Test. International Organization for Standardization: Geneva, Switzerland, 2015. Available online: www.iso.org (accessed on 5 July 2023).

- Laser Exposure Strategy by EOS. Available online: https://www.eos.info/en/blog/reimagining-3d-printing~b~11457 (accessed on 5 July 2023).

- Harte, A.; Atkinson, M.; Smith, A.; Drouven, C.; Zaefferer, S.; Quinta Da Fonseca, J.; Preuss, M. The Effect of Solid Solution and Gamma Prime on the Deformation Modes in Ni-Based Superalloys. Acta Mater. 2020, 194, 257–275. [Google Scholar] [CrossRef]

- Arhami, F.; Mirsalehi, S.E. The Effect of Heat Treatment Sequence on Microstructure and Mechanical Properties of Diffusion Brazed IN-939 Superalloy. J. Mater. Process. Technol. 2019, 266, 351–362. [Google Scholar] [CrossRef]

- Zeng, C.; Ding, H.; Bhandari, U.; Guo, S.M. Design of Crack-Free Laser Additive Manufactured Inconel 939 Alloy Driven by Computational Thermodynamics Method. MRS Commun. 2022, 12, 844–849. [Google Scholar] [CrossRef]

- González, M.A.; Martínez, D.I.; Pérez, A.; Guajardo, H.; Garza, A. Microstructural Response to Heat Affected Zone Cracking of Prewelding Heat-Treated Inconel 939 Superalloy. Mater. Charact. 2011, 62, 1116–1123. [Google Scholar] [CrossRef]

| Element | Cr | Co | Ti | Al | C | Nb | Ta | W | Ni |

|---|---|---|---|---|---|---|---|---|---|

| Chemical composition [%] | 22 | 19 | 4 | 2 | 0.2 | 1 | 1.4 | 1.9 | Balance |

| Heat Treated Condition | As-Manufactured | |||

|---|---|---|---|---|

| Vertical | Horizontal | Vertical | Horizontal | |

| Yield strength Rp0.2 [MPa] | 1100 | 1130 | 740 | 880 |

| Ultimate tensile strength Rm [MPa] | 1500 | 1520 | 1090 | 1160 |

| Elongation | 13 | 11 | 28 | 24 |

| Hardness at room temperature ISO 6508 [19] | 48 | 33 | ||

| Average density [g/cm3] | 8.15 | |||

| Used for Samples | Abrasives | |||

|---|---|---|---|---|

| Type | Photo | Size [mm] | Mass [g] | |

| Midi 1 Mini 1 | Ceramic cubes |  | Irregular | 3.8 |

| Midi 2 Mini 2 | Ceramic rods |  | ⌀4.1 × 14.5 | 0.5 |

| Midi 3 Mini 3 | Porcelain rods EB 0410 VZ |  | ⌀9.5 | 0.37 |

| Midi 4 Mini 4 | Ceramic rods CB 0410 VH |  | ⌀4.1 × 11.5 | 0.31 |

| Midi 5 Mini 5 | Resin cones |  | ⌀11 × 11 | 0.75 |

| Midi 6 Mini 6 | Ceramic pellets |  | ⌀6 | 1.0 |

| Sample | Time [h] | Relative Difference [%] | ||||

|---|---|---|---|---|---|---|

| 0 | 1 | 2 | 3 | 4 | ||

| Midi 1 | 0.5206 | 0.517 | 0.5158 | 0.5139 | 0.5129 | 1.5 |

| Midi 2 | 0.5181 | 0.5167 | 0.5153 | 0.5134 | 0.5127 | 1.0 |

| Midi 3 | 0.5178 | 0.5154 | 0.5146 | 0.5139 | 0.5129 | 0.9 |

| Midi 4 | 0.5182 | 0.5155 | 0.5155 | 0.514 | 0.5135 | 0.9 |

| Midi 5 | 0.5161 | 0.5147 | 0.5136 | 0.5118 | 0.5116 | 0.9 |

| Midi 6 | 0.5109 | 0.5073 | 0.5062 | 0.5044 | 0.5032 | 1.5 |

| Mini 1 | 0.0607 | 0.0595 | 0.0594 | 0.0594 | 0.0594 | 2.1 |

| Mini 2 | 0.0615 | 0.0609 | 0.0609 | 0.0605 | 0.0604 | 1.8 |

| Mini 3 | 0.0620 | 0.0613 | 0.0612 | 0.0611 | 0.0610 | 1.6 |

| Mini 4 | 0.0600 | 0.0594 | 0.0595 | 0.0590 | 0.0591 | 1.5 |

| Mini 5 | 0.0617 | 0.0613 | 0.0611 | 0.0608 | 0.0603 | 2.3 |

| Mini 6 | 0.0616 | 0.0610 | 0.0603 | 0.0602 | 0.0598 | 2.9 |

| Sample | Cubes | Ceramic Pellets | ||||

|---|---|---|---|---|---|---|

| Before | After | Relative Difference [%] | Before | After | Relative Difference [%] | |

| Midi | 0.5129 | 0.5045 | 1.6 | 0.5140 | 0.5087 | 1.0 |

| Mini | 0.06145 | 0.05982 | 2.6 | 0.06147 | 0.06055 | 1.5 |

| Sample | Midi | Mini | ||

|---|---|---|---|---|

| Roughness Parameters | Mean Value | SD | Mean Value | SD |

| Ra [µm] | 6.62 | 0.90 | 6.38 | 0.24 |

| Rsk | 0.95 | 0.19 | 0.57 | 0.27 |

| Rp [µm] | 27.01 | 1.83 | 14.42 | 6.13 |

| Rda [°] | 17.74 | 0.96 | 9.35 | 0.24 |

| RS [µm] | 87.42 | 1.47 | 44.45 | 9.19 |

| Rq [µm] | 8.33 | 1.01 | 4.67 | 0.58 |

| Rku | 3.52 | 0.48 | 2.00 | 1.11 |

| Rv [µm] | 14.10 | 2.63 | 8.36 | 1.67 |

| Rt [µm] | 46.25 | 3.85 | 25.05 | 6.45 |

| Rz [µm] | 41.11 | 4.32 | 22.71 | 6.45 |

| RSm [µm] | 215.98 | 14.26 | 115.12 | 6.74 |

| Sample | Time [h] | Relative Difference [%] | ||||

|---|---|---|---|---|---|---|

| 0 | 1 | 2 | 3 | 4 | ||

| Midi 1 | 6.623 | 3.061 | 2.773 | 2.412 | 2.342 | 64.6 |

| Midi 2 | 6.623 | 4.832 | 2.650 | 2.216 | 2.018 | 69.5 |

| Midi 3 | 6.623 | 3.544 | 3.035 | 2.665 | 2.598 | 60.8 |

| Midi 4 | 6.623 | 3.690 | 2.842 | 2.846 | 2.486 | 62.5 |

| Midi 5 | 6.623 | 2.847 | 2.804 | 2.167 | 2.238 | 66.2 |

| Midi 6 | 6.623 | 2.086 | 1.739 | 1.958 | 1.811 | 72.7 |

| Mini 1 | 6.380 | 1.457 | 1.595 | 1.375 | 1.563 | 75.5 |

| Mini 2 | 6.623 | 2.726 | 1.582 | 2.147 | 1.150 | 82.0 |

| Mini 3 | 6.623 | 1.146 | 2.892 | 2.373 | 2.273 | 64.4 |

| Mini 4 | 6.623 | 2.880 | 1.029 | 1.362 | 1.042 | 83.7 |

| Mini 5 | 6.623 | 3.374 | 3.162 | 0.965 | 2.721 | 57.4 |

| Mini 6 | 6.623 | 1.534 | 1.713 | 1.624 | 1.209 | 81.1 |

| Sample | Time [h] | Relative Difference [%] | ||||

|---|---|---|---|---|---|---|

| 0 | 1 | 2 | 3 | 4 | ||

| Midi 1 | 0.904 | 0.266 | 0.136 | 0.188 | 0.125 | 86.2 |

| Midi 2 | 0.904 | 0.466 | 0.159 | 0.078 | 0.173 | 80.9 |

| Midi 3 | 0.904 | 0.171 | 0.318 | 0.211 | 0.137 | 84.8 |

| Midi 4 | 0.904 | 0.171 | 0.070 | 0.338 | 0.637 | 29.5 |

| Midi 5 | 0.904 | 0.107 | 0.257 | 0.185 | 0.242 | 73.3 |

| Midi 6 | 0.904 | 0.216 | 0.193 | 0.195 | 0.120 | 86.8 |

| Mini 1 | 0.241 | 0.061 | 0.243 | 0.137 | 0.229 | 4.9 |

| Mini 2 | 0.241 | 0.194 | 0.200 | 0.205 | 0.044 | 81.9 |

| Mini 3 | 0.241 | 0.257 | 0.643 | 0.148 | 0.102 | 57.5 |

| Mini 4 | 0.241 | 0.300 | 0.137 | 0.255 | 0.254 | −5.3 |

| Mini 5 | 0.241 | 0.221 | 0.124 | 0.093 | 0.264 | −9.2 |

| Mini 6 | 0.241 | 0.053 | 0.096 | 0.229 | 0.076 | 68.4 |

| Sample | Time [h] | Relative Difference [%] | ||||

|---|---|---|---|---|---|---|

| 0 | 1 | 2 | 3 | 4 | ||

| Midi 1 | 41.111 | 18.576 | 16.412 | 14.182 | 13.718 | 66.6 |

| Midi 2 | 41.111 | 32.465 | 17.404 | 13.168 | 12.642 | 69.2 |

| Midi 3 | 41.111 | 22.299 | 17.889 | 15.400 | 15.016 | 63.5 |

| Midi 4 | 41.111 | 22.153 | 17.689 | 16.836 | 15.526 | 62.2 |

| Midi 5 | 41.111 | 21.466 | 17.609 | 13.809 | 14.604 | 64.5 |

| Midi 6 | 41.111 | 12.168 | 10.634 | 12.170 | 11.460 | 72.1 |

| Mini 1 | 41.458 | 7.978 | 7.610 | 7.443 | 8.442 | 79.5 |

| Mini 2 | 41.458 | 15.078 | 7.725 | 10.858 | 6.506 | 84.2 |

| Mini 3 | 41.458 | 6.677 | 17.286 | 12.310 | 11.185 | 72.8 |

| Mini 4 | 41.458 | 15.136 | 6.548 | 7.657 | 6.326 | 84.6 |

| Mini 5 | 41.458 | 19.792 | 17.190 | 5.872 | 13.797 | 66.4 |

| Mini 6 | 41.458 | 8.743 | 8.951 | 9.118 | 7.298 | 82.2 |

| Sample | Midi 6 | Mini 6 | ||

|---|---|---|---|---|

| Roughness Parameters | Mean Value | SD | Mean Value | SD |

| Ra [µm] | 1.81 | 0.12 | 1.21 | 0.08 |

| Rsk | −0.16 | 0.15 | −0.41 | 0.06 |

| Rp [µm] | 5.21 | 0.32 | 3.18 | 0.23 |

| Rda [µm] | 5.21 | 0.16 | 5.96 | 0.34 |

| RS [µm] | 68.75 | 1.01 | 35.05 | 3.73 |

| Rq [µm] | 2.23 | 0.11 | 1.54 | 0.10 |

| Rku | 2.78 | 0.40 | 3.07 | 0.34 |

| Rv [µm] | 6.25 | 0.76 | 4.11 | 0.52 |

| Rt [µm] | 13.56 | 0.71 | 8.62 | 1.20 |

| Rz [µm] | 11.46 | 0.60 | 7.30 | 0.73 |

| RSm [µm] | 237.14 | 12.95 | 171.50 | 13.71 |

| Sample | Time [h] | Relative Difference [%] | ||||

|---|---|---|---|---|---|---|

| 0 | 1 | 2 | 3 | 4 | ||

| Midi 1 | 0.5177 | 0.5114 | 0.5111 | 0.5081 | 0.5059 | 2.30 |

| Midi 2 | 0.5181 | 0.5167 | 0.5153 | 0.5134 | 0.5127 | 1.04 |

| Midi 3 | 0.5178 | 0.5154 | 0.5146 | 0.5139 | 0.5129 | 0.95 |

| Midi 4 | 0.5182 | 0.5155 | 0.5155 | 0.5140 | 0.5135 | 0.91 |

| Midi 5 | 0.5161 | 0.5147 | 0.5136 | 0.5118 | 0.5116 | 0.87 |

| Midi 6 | 0.5109 | 0.5073 | 0.5062 | 0.5044 | 0.5032 | 1.51 |

| Sample | Time [h] | Relative Difference [%] | ||||

|---|---|---|---|---|---|---|

| 0 | 1 | 2 | 3 | 4 | ||

| Midi 1 | 6.62 | 4.21 | 2.02 | 1.7 | 1.19 | 80.0 |

| Midi 2 | 6.62 | 2.88 | 1.83 | 1.65 | 1.64 | 71.1 |

| Midi 3 | 6.62 | 3.74 | 1.79 | 1.72 | 1.87 | 67.0 |

| Midi 4 | 6.62 | 3.02 | 2.48 | 2.22 | 1.92 | 66.1 |

| Midi 5 | 6.62 | 5.63 | 3.65 | 3.81 | 3.18 | 47.3 |

| Midi 6 | 6.62 | 4.13 | 1.71 | 1.34 | 1.07 | 85.4 |

| No | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| O | 16.6 | 21.1 | 19.6 | 21.2 | 19.9 |

| Al | 29.6 | 33.2 | 31.1 | 35.7 | 31.4 |

| Cr | 11.2 | 9.9 | 10.4 | 9.4 | 10.6 |

| Co | 12.5 | 10.5 | 11.5 | 9.9 | 11.1 |

| Ni | 30.2 | 25.3 | 27.4 | 23.6 | 27.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Radziejewska, J.; Marczak, M.; Maj, P.; Głowacki, D. The Influence of Vibro-Assisted Abrasive Processing on the Surface Roughness and Sub-Surface Microstructure of Inconel 939 Specimen Made by LPBF. Materials 2023, 16, 7429. https://doi.org/10.3390/ma16237429

Radziejewska J, Marczak M, Maj P, Głowacki D. The Influence of Vibro-Assisted Abrasive Processing on the Surface Roughness and Sub-Surface Microstructure of Inconel 939 Specimen Made by LPBF. Materials. 2023; 16(23):7429. https://doi.org/10.3390/ma16237429

Chicago/Turabian StyleRadziejewska, Joanna, Michał Marczak, Piotr Maj, and Dominik Głowacki. 2023. "The Influence of Vibro-Assisted Abrasive Processing on the Surface Roughness and Sub-Surface Microstructure of Inconel 939 Specimen Made by LPBF" Materials 16, no. 23: 7429. https://doi.org/10.3390/ma16237429