Eco-Friendly Pavements Manufactured from Mixed Recycled Aggregates Obtained from Construction and Demolition Waste: An Industrial-Scale Validation

Abstract

:1. Introduction

2. Materials and Methods

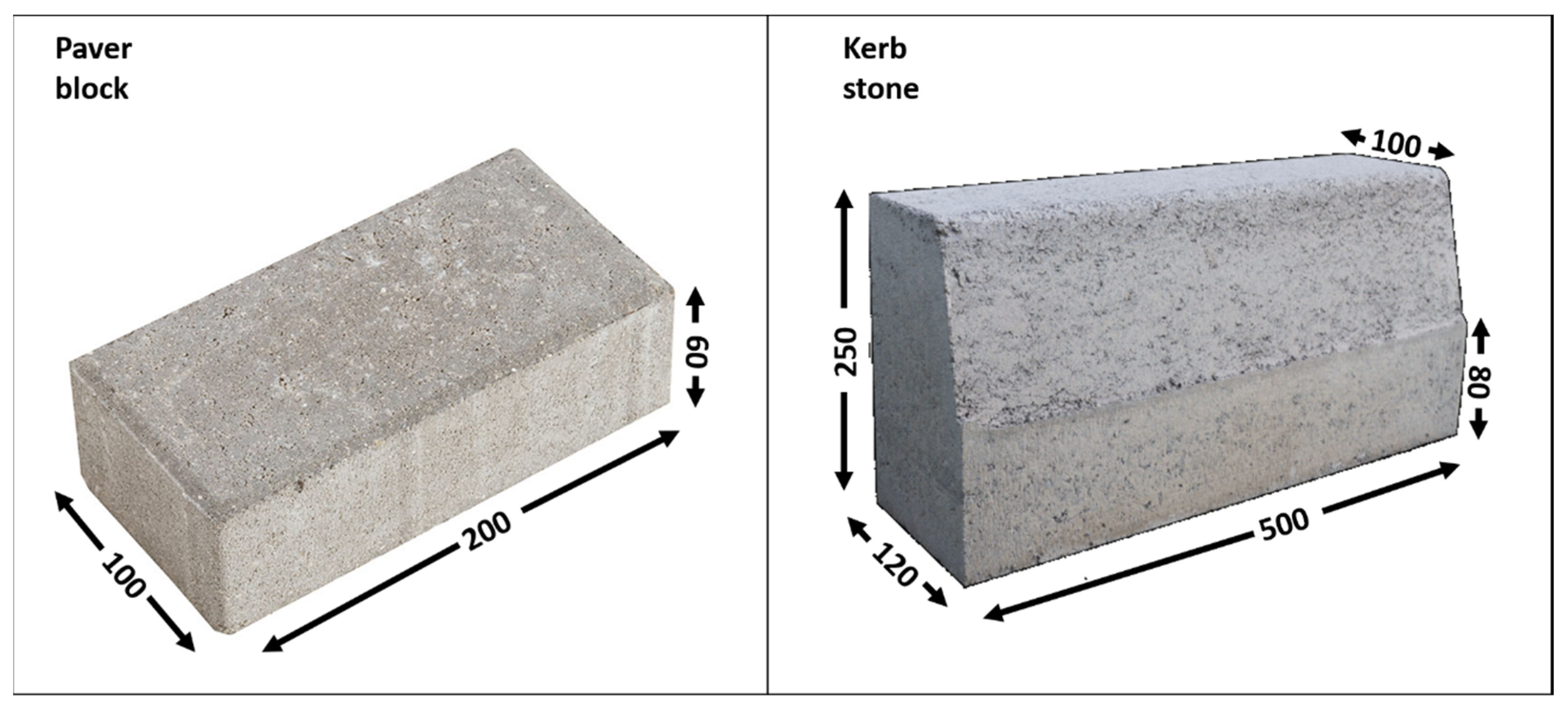

2.1. Materials and Sample Preparation

2.1.1. Materials

2.1.2. Laboratory-Scale Stage

2.1.3. Industrial-Scale Stage

2.1.4. Experimental Methodology

2.2. Methods

3. Results and Discussion

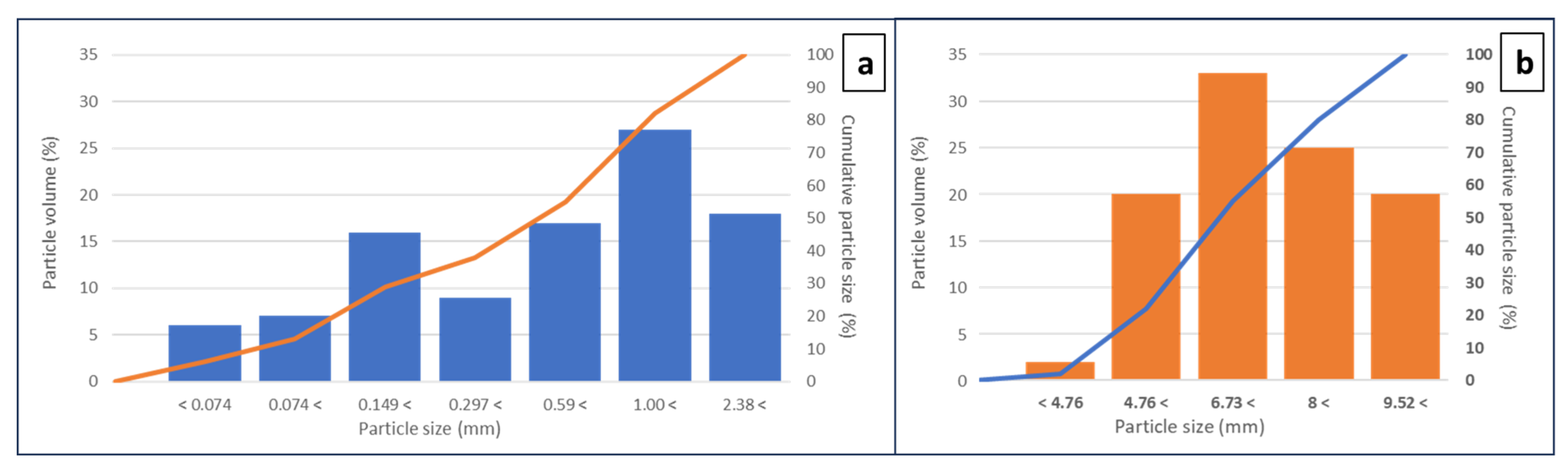

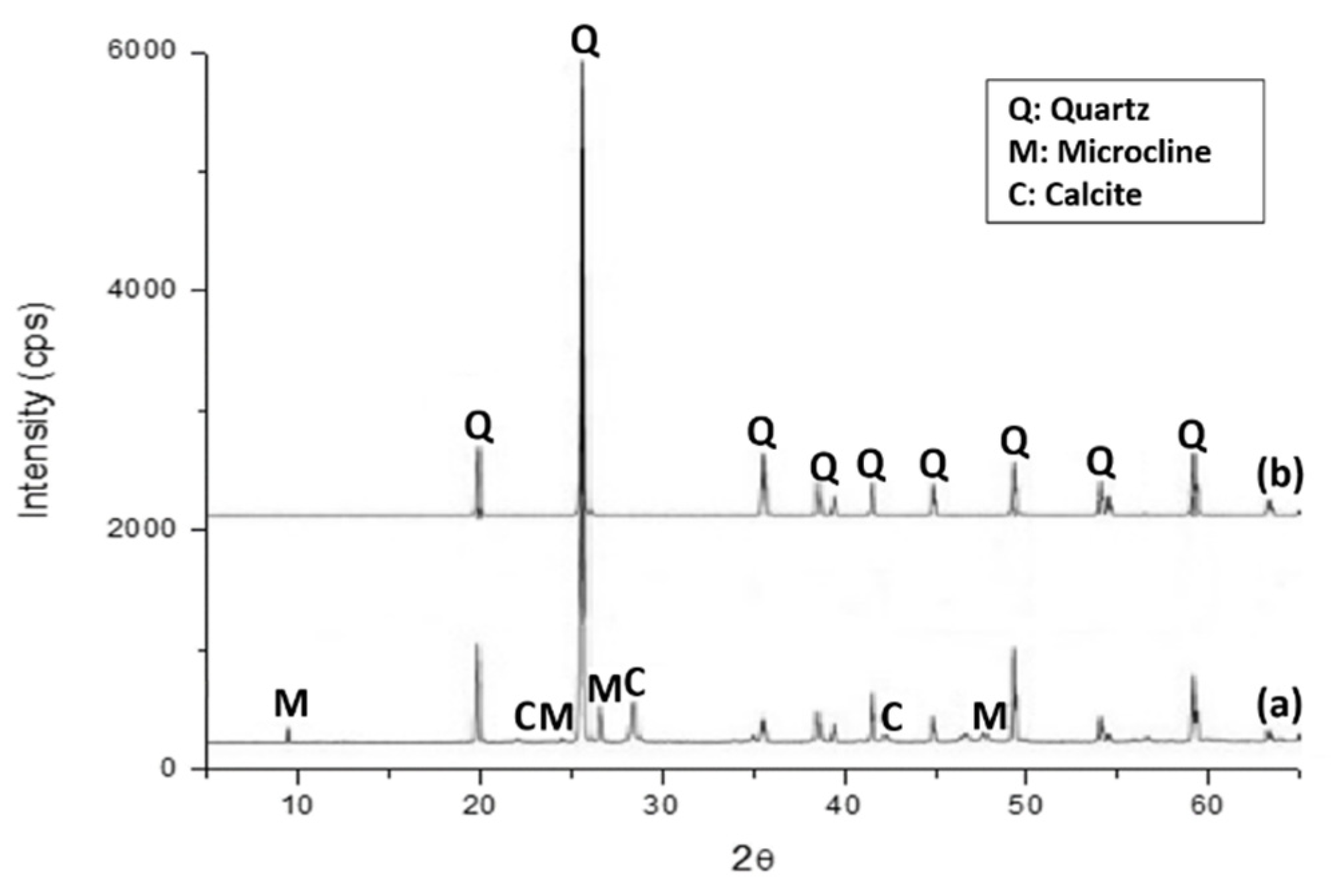

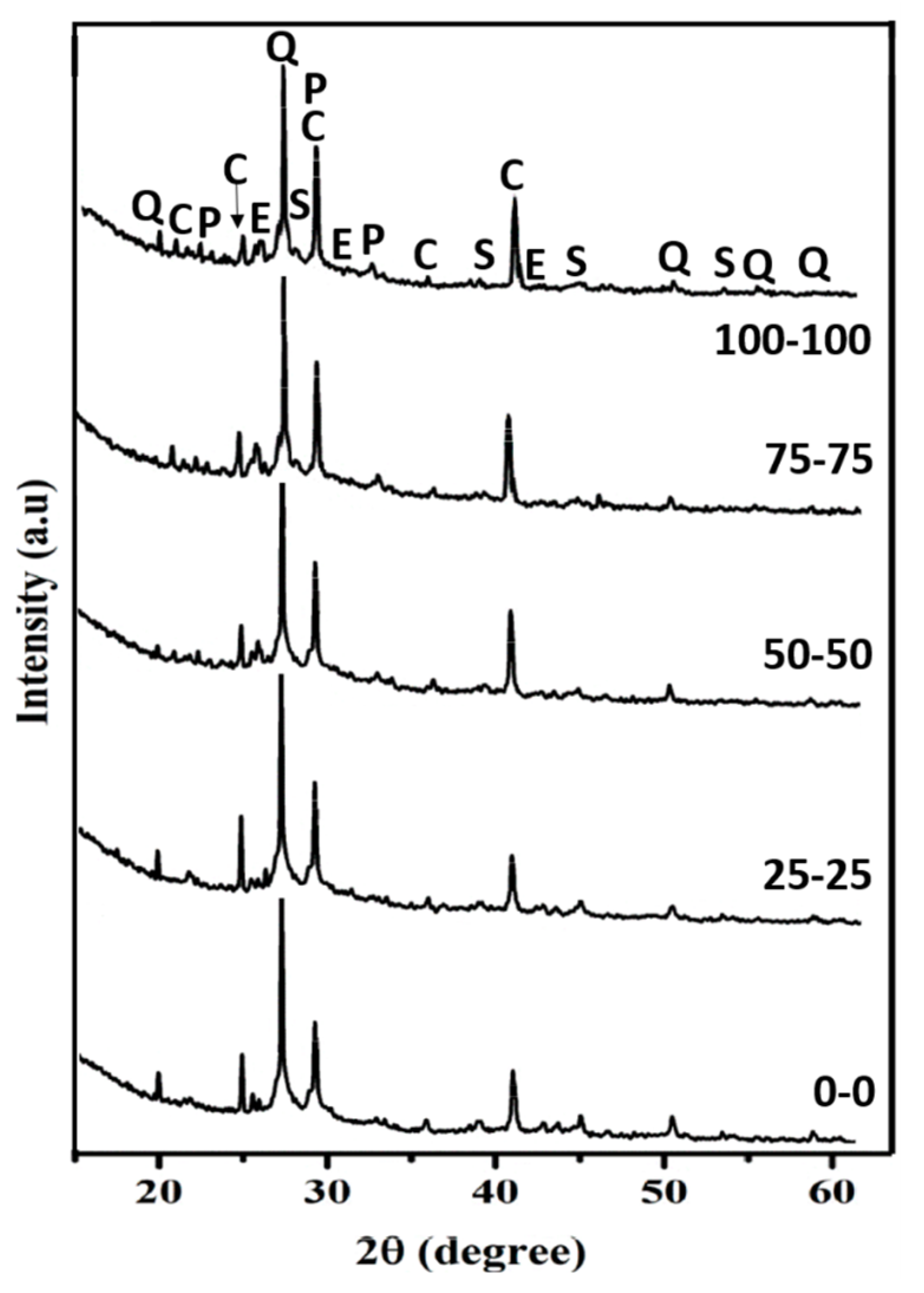

3.1. Characterisation of Raw Materials

3.2. Characterisation of Laboratory-Scale Concrete Specimens

3.3. Characterisation of Laboratory-Scale Precast Pavement Units

3.4. Characterisation of Industrial-Scale Precast Pavement Units

3.5. Environmental Implications

4. Conclusions

- Substituting natural aggregates (NAs) with recycled aggregates (RAs) did not adversely affect cement hydration but led to concretes with lower quartz content and a higher presence of Ca-bearing crystalline phases derived from mortar remains in construction and demolition waste (CDW).

- The addition of RAs increased water absorption (WA) and apparent porosity (AP) of the precast concrete elements while simultaneously decreasing density (D).

- Concrete with up to 75% NA replacement (fine or coarse) could be classified as Class 2 and Mark B, in relation to its resistance to weathering.

- Laboratory-scale pavers with RAs exceed the EN-1338 standard’s minimum-breaking-load values of 250 N mm−1. Moreover, a 50% replacement had no detrimental effect on the mechanical performance of the paver blocks.

- Concrete kerbs manufactured at the laboratory scale with up to 50% replacement could be classified as Class 1 and Mark S (UNE-EN 1340:2004).

- At an industrial scale, prefabricated kerbs with up to 50% fine fraction substitution (50-0) or up to 25% and 10% fine and coarse fraction substitution (25-10) met the requirements concerning bending strength, water absorption, and abrasion wear established in UNE-EN 1340:2004 [39]. Precast paver blocks with up to 50% FRA and 20% CRA (50-20) also met UNE-EN 1338:2004 requirements [38].

- The replacement of NAs with RAs at an industrial scale enabled a reduction in cement content of up to 13 wt.%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- European Commission. Directive 2018/851 on Waste (Waste Framework Directive), Brussels, Belgium. 2018. Available online: https://eur-lex.europa.eu/legal-content/ES/TXT/?uri=celex%3A32008L0098 (accessed on 10 July 2023).

- Deydier, E.; Guilet, R.; Sarda, S.; Sharrock, P. Physical and chemical characterization of crude meat and bone meal combustion residue: Waste or raw material? J. Hazard. Mater. 2005, 121, 141–148. [Google Scholar] [CrossRef] [PubMed]

- Gázquez, M.J.; Bolívar, J.P.; García-Tenorio, R.; Caparros, A. Evaluation of the use of TiO2 industry red gypsum waste in cement production. Cem. Concr. Compos. 2013, 37, 76–81. [Google Scholar] [CrossRef]

- Rosales, J.; Pérez-Moreno, S.M.; Cabrera, M.; Gázquez-González, M.J.; Bolívar-Raya, J.P.; De Brito, J.; Agrela-Sainz, F. Treated phosphogypsum as an alternative set regulator and mineral addition in cement production. J. Clean. Prod. 2020, 244, 118752. [Google Scholar] [CrossRef]

- Contreras, M.; Teixeira, S.R.; Santos, G.T.A.; Gázquez, M.J.; Romero, M.; Bolívar, J.P. Influence of the addition of phosphogypsum on some properties of ceramic tiles. Constr. Build. Mater. 2018, 175, 588–600. [Google Scholar] [CrossRef]

- Farzampour, A. Temperature and humidity effects on behavior of grouts. Adv. Concr. Constr. 2017, 5, 659–669. [Google Scholar] [CrossRef]

- Chalangaran, N.; Farzampour, A.; Paslar, N.; Fatemi, H. Experimental investigation of sound transmission loss in concrete containing recycled rubber crumbs. Adv. Concr. Constr. 2021, 11, 447–454. [Google Scholar] [CrossRef]

- Chalangaran, N.; Farzampour, A.; Paslar, N. Nano Silica and Metakaolin Effects on the Behavior of Concrete Containing Rubber Crumbs. CivilEng 2020, 1, 264–274. [Google Scholar] [CrossRef]

- Contreras, M.; Gázquez, M.J.; García-Díaz, I.; Alguacil, F.; López, F.A.; Bolívar, J.P. Valorisation of waste ilmenite mud in the manufacture of Sulphur Polymer Cement. J. Environ. Manag. 2013, 128, 625–630. [Google Scholar] [CrossRef]

- Delgado, M.; Maeso, F.J.; Martín, J.V.; González, M.I.; Martínez, S. Valorization of sludge from the quartz industry as soil amendment and crop production. Soil Tillage Res. 2019, 194, 104320. [Google Scholar] [CrossRef]

- Alp, I.; Deveci, H.; Yazıcı, E.Y.; Türk, T.; Süngün, Y.H. Potential use of pyrite cinders as raw material in cement production: Results of industrial scale trial operations. J. Hazard. Mater. 2009, 166, 144–149. [Google Scholar] [CrossRef]

- European Commission. The European Construction Sector: A Global Partner; European Commission, Joint Research Centre (JRC): Brussels, Belgium, 2016; Available online: https://ec.europa.eu/growth/content/european-construction-sector-global-partner-0_en (accessed on 24 September 2023).

- European Commission. EU Construction and Demolition Waste Protocol and Guidelines. Brussels, Belgium. 2018. Available online: https://ec.europa.eu/growth/content/eu-construction-and-demolition-waste-protocol-0_en (accessed on 12 August 2023).

- U.S. EPA. Construction and Demolition Debris Generation in the United States, 2015. Office of Resource Conservation and Recovery. September 2018. Available online: https://www.epa.gov/sites/production/files/2018-09/documents/construction_and_demolition_debris_generation_in_the_united_states_2015_final.pdf (accessed on 12 September 2023).

- Xiao, S.; Dong, H.; Geng, Y.; Brander, M. An overview of China’s recyclable waste recycling and recommendations for integrated solutions. Resour. Conserv. Recycl. 2018, 134, 112–120. [Google Scholar] [CrossRef]

- Huang, B.; Wang, X.; Kua, H.; Geng, Y.; Bleischwitz, R.; Ren, J. Construction and demolition waste management in China through the 3R principle. Resour. Conserv. Recycl. 2018, 129, 36–44. [Google Scholar] [CrossRef]

- Domínguez, A.; Domínguez, M.I.; Ivanova, S.; Centeno, M.A.; Odriozola, J.A. Recycling of construction and demolition waste generated by building infrastructure for the production of glassy materials. Ceram. Int. 2016, 42, 15217–15223. [Google Scholar] [CrossRef]

- Leite, F.; Dos Santos Motta, R.; Vasconcelos, K.; Bernucci, L. Laboratory evaluation of recycled construction and demolition waste for pavements. Constr. Build. Mater. 2011, 25, 2972–2979. [Google Scholar] [CrossRef]

- Ossa, A.; García, J.L.; Botero, E. Use of recycled construction and demolition waste (CDW) aggregates: A sustainable alternative for the pavement construction industry. J. Clean. Prod. 2016, 135, 379–386. [Google Scholar] [CrossRef]

- Silva, R.V.; De Brito, J.; Dhir, R.K. Properties and composition of recycled aggregates from construction and demolition waste suitable for concrete production. Constr. Build. Mater. 2014, 65, 201–217. [Google Scholar] [CrossRef]

- Sheen, Y.N.; Wang, H.Y.; Juang, Y.P.; Le, D.H. Assessment on the engineering properties of ready-mixed concrete using recycled aggregates. Constr. Build. Mater. 2013, 45, 298–305. [Google Scholar] [CrossRef]

- Kou, S.; Poon, C.; Wan, H. Properties of concrete prepared with low-grade recycled aggregates. Constr. Build. Mater. 2012, 36, 881–889. [Google Scholar] [CrossRef]

- Başaran, B.; Aksoylu, C.; Özkılıç, Y.O.; Karalar, M.; Hakamy, A. Shear behaviour of reinforced concrete beams utilizing waste marble powder. Structures 2023, 54, 1090–1100. [Google Scholar] [CrossRef]

- Basaran, B.; Kalkan, I.; Aksoylu, C.; Özkılıç, Y.O.; Sabri, M.M.S. Effects of Waste Powder, Fine and Coarse Marble Aggregates on Concrete Compressive Strength. Sustainability 2023, 14, 4388. [Google Scholar] [CrossRef]

- Chang, Q.; Liu, L.; Farooqi, M.U.; Thomas, B.; Özkılıç, Y.O. Data-driven based estimation of waste-derived ceramic concrete from experimental results with its environmental assessment. J. Mater. Res. Technol. 2023, 24, 6348–6368. [Google Scholar] [CrossRef]

- Özkılıç, Y.O.; Başaran, B.; Aksoylu, C.; Karalar, M.; Martins, C.H. Mechanical behavior in terms of shear and bending performance of reinforced concrete beam using waste fire clay as replacement of aggregate. Case Stud. Constr. Mater. 2023, 18, e02104. [Google Scholar] [CrossRef]

- Özkılıç, Y.O.; Karalar, M.; Aksoylu, C.; Beskopylny, A.N.; Stel’makh, S.A.; Shcherban, E.M.; Qaidi, S.; Pereira, I.d.S.A.; Monteiro, S.N.; Azevedo, A.R.G. Shear performance of reinforced expansive concrete beams utilizing aluminium waste. J. Mater. Res. Technol. 2023, 24, 5433–5448. [Google Scholar] [CrossRef]

- Arulrajah, A.; Disfani, M.M.; Horpibulsuk, S.; Suksiripattanapong, C.; Prongmanee, N. Physical properties and shear strength responses of recycled construction and demolition materials in unbound pavement base/subbase applications. Constr. Build. Mater. 2014, 58, 245–257. [Google Scholar] [CrossRef]

- Ayan, V.; Limbachiya, M.C.; Omer, J.R.; Azadani, S.M.N. Compaction assessment of recycled aggregates for use in unbound subbase application. J. Civ. Eng. Manag. 2014, 20, 169–174. [Google Scholar] [CrossRef]

- Chen, M.; Lin, J.; Wu, S. Potential of recycled fine aggregates powder as filler in asphalt mixture. Constr. Build. Mater. 2011, 25, 3909–3914. [Google Scholar] [CrossRef]

- Agarwal, M.; Krishan, A. Reusability of Construction & Demolition waste in bricks. Int. Res. J. Eng. Technol. 2017, 4, 147–151. Available online: https://www.irjet.net/archives/V6/i6/IRJET-V6I6100.pdf (accessed on 22 October 2023).

- Contreras, M.; Teixeira, S.R.; Lucas, M.C.; Lima, L.C.N.; Cardoso, D.S.L.; da Silva, G.A.C.; Gregório, G.C.; de Souza, A.E.; dos Santos, A. Recycling of construction and demolition waste for producing new construction material (Brazil case-study). Constr. Build. Mater. 2016, 123, 594–600. [Google Scholar] [CrossRef]

- Leiva, C.; Solís-Guzmán, J.; Marrero, M.; Arenas García, C. Recycled blocks with improved sound and fire insulation containing construction and demolition waste. Waste Manag. 2013, 33, 663–671. [Google Scholar] [CrossRef]

- Soutsos, M.N.; Tang, K.; Millard, S.G. Concrete building blocks made with recycled demolition aggregate. Constr. Build. Mater. 2011, 25, 726–735. [Google Scholar] [CrossRef]

- Sand and Sustainability: 10 Strategic Recommendations to Avert a Crisis. Retrieved from United Nations Environment Programme. Available online: https://www.unep.org/resources/report/sand-and-sustainability-10-strategic-recommendations-avert-crisis (accessed on 2 September 2023).

- Contreras-Llanes, M.; Romero, M.; Gázquez, M.J.; Bolívar, J.P. Recycled Aggregates from Construction and Demolition Waste in the Manufacture of Urban Pavements. Materials 2021, 14, 6605. [Google Scholar] [CrossRef] [PubMed]

- Contreras Llanes, M.; Romero Pérez, M.; Gázquez González, M.J.; Bolívar, J.P. Construction and demolition waste as recycled aggregate for environmentally friendly concrete paving. Environ. Sci. Pollut. Res. 2022, 29, 9826–9840. [Google Scholar] [CrossRef] [PubMed]

- UNE-EN 1338:2004; Concrete Paving Blocks—Requirements and Test Methods. European Standards. European Commission: Brussels, Belgium, 2004.

- UNE-EN 1340:2004; Concrete Kerb Units—Requirements and Test Methods. European Standards. European Commission: Brussels, Belgium, 2004.

- Tam, V.W.Y.; Tam, C.M.; Le, K.N. Removal of cement mortar remains from recycled aggregate using pre-soaking approaches. Resour. Conserv. Recycl. 2007, 50, 82–101. [Google Scholar] [CrossRef]

- Shi, C.; Li, Y.; Zhang, J.; Li, W.; Chong, L.; Xie, Z. Performance enhancement of recycled concrete aggregate—A review. J. Clean. Prod. 2016, 112, 466–472. [Google Scholar] [CrossRef]

- Ferreira, L.; De Brito, J.; Barra, M. Influence of the pre-saturation of recycled coarse concrete aggregates on concrete properties. Mag. Concr. Res. 2011, 63, 617–627. [Google Scholar] [CrossRef]

- García-González, J.; Rodríguez-Robles, D.; Juan-Valdés, A.; Morán-del Pozo, J.; Guerra-Romero, M.I. Pre-Saturation Technique of the Recycled Aggregates: Solution to the Water Absorption Drawback in the Recycled Concrete Manufacture. Materials 2014, 7, 6224–6236. [Google Scholar] [CrossRef]

- UNE-EN 41166; Concrete Units. Definitions, Classification and General Characteristics. European Standards. European Commission: Brussels, Belgium, 2000.

- UNE-EN 1097-2:2021; Tests for Mechanical and Physical Properties of Aggregates—Part 2: Methods for the Determination of Resistance to Fragmentation. European Standards. European Commission: Brussels, Belgium, 2021.

- UNE-EN 146404:2018; Aggregates for Concrete. Determination of the Coefficient of Friability of the Sands. European Standards. European Commission: Brussels, Belgium, 2018.

- UNE-EN 12620:2013; Aggregates for Concrete. European Standards. European Commission: Brussels, Belgium, 2013.

- UNE-EN 933-3:1997; Tests for Geometrical Properties of Aggregates. Part 3: Determination of Particle Shape. Flakiness Index. European Standards. European Commission: Brussels, Belgium, 1997.

- UNE-EN 83980:2014; Concrete Durability. Test Methods. Determination of the Water Absorption, Density and Accessible Porosity for Water in Concrete. European Standards. European Commission: Brussels, Belgium, 2014.

- ISO 5016:1997; Shaped Insulating Refractory Products—Determination of Bulk Density and True Porosity. The International Organization for Standardization (ISO): Geneva, Switzerland, 1997.

- EN 12390-3:2020; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. European Standards. European Commission: Brussels, Belgium, 2020.

- UNE-CEN/TS 12390-9; Testing Hardened Concrete—Part 9: Freeze-Thaw Resistance. European Standards. European Commission: Brussels, Belgium, 2009.

- U.S. EPA SW-846; Test Methods for Evaluating Solid Waste Physical Chemical Methods. U.S. Environmental Protection Agency: Washington, DC, USA, 1997.

- Averardi, A.; Cola, C.; Zeltmann, S.E.; Gupta, N. Effect of particle size distribution on the packing of powder beds: A critical discussion relevant to additive manufacturing. Mater. Today Commun. 2020, 24, 100964. [Google Scholar] [CrossRef]

- Malhotra, V.M.; Mehta, P.K. Puzzolanic and Cementitious Materials; Taylor and Francis: London, UK, 1996. [Google Scholar]

- Menezes, R.R.; Ferreira, H.S.; Neves, G.A.; Ferreira, H.C. The use of granite wastes as ceramic raw materials. Cerâmica 2002, 48, 92–101. [Google Scholar] [CrossRef]

- Saiz-Martínez, P.; González-Cortina, M.; Fernández-Martínez, F.; Rodríguez-Sánchez, A. Comparative study of three types of fine recycled aggregates from construction and demolition waste (CDW), and their use in masonry mortar fabrication. J. Clean. Prod. 2016, 118, 162–169. [Google Scholar] [CrossRef]

- Mangi, S.A.; Ibrahim, M.H.V.; Jamaluddin, N.; Arshad, M.F.; Jaya, R.P. Short-term effects of sulphate and chloride on the concrete containing coal bottom ash as supplementary cementitious material. Eng. Sci. Technol. Int. J. 2019, 22, 515–522. [Google Scholar] [CrossRef]

- Government of Spain. Royal Decree 1247/2008 Of 18 July, Which Approves: The Statement Of Structural Concrete (EHE-08); Government of Spain: Madrid, Spain, 2008.

- Rudnick, R.L.; Gao, S. Composition of the continental crust. In Treatise of Geochemistry; Holland, H.D., Turekian, K.K., Eds.; Elsevier: Amsterdam, The Netherlands, 2003; Volume 3, pp. 1–64. [Google Scholar] [CrossRef]

- Murat, M.; Sorrentina, F. Effect of large additions of Cd, Pb, Cu, Zn to cement raw metal on the composition and the properties of the clinker and cement. Cem. Concr. Res. 1996, 26, 377–385. [Google Scholar] [CrossRef]

- Martínez, I.; Etxeberria, M.; Pavón, E.; Díaz, N. A comparative analysis of the properties of recycled and natural aggregate in masonry mortars. Constr. Build. Mater. 2013, 49, 384–392. [Google Scholar] [CrossRef]

- Raigón-Pichardo, M.; García-Ramos, G.; Sánchez-Soto, P.J. Characterization of a waste washing solid product of mining granitic tin-bearing sands and its application as ceramic raw material. Resour. Conserv. Recycl. 1996, 17, 109–124. [Google Scholar] [CrossRef]

- Moreno-Juez, J.; Vegas, I.J.; Frías Rojas, M.; Vigil de la Villa, R.; Guede-Vázquez, E. Laboratory-scale study and semi-industrial validation of viability of inorganic CDW fine fractions as SCMs in blended cements. Constr. Build. Mater. 2013, 271, 121823. [Google Scholar] [CrossRef]

- Gutteridge, W.A.; Dalziel, J.A. Filler cement: The effect of the secondary component on the hydration of Portland cement: Part 2: Fine hydraulic binders. Cem. Concr. Res. 1990, 20, 853–861. [Google Scholar] [CrossRef]

- Gutteridge, W.A.; Dalziel, J.A. Filler cement: The effect of the secondary component on the hydration of Portland cement: Part I. A fine nonhydraulic filler. Cem. Concr. Res. 1990, 20, 778–782. [Google Scholar] [CrossRef]

- Dolado, J.S.; Ayuela, A.; Gimel, J. Nanoscale texture development of C-S-H gel: A computational model for nucleation and growth. Appl. Phys. Lett. 2013, 103, 234105. [Google Scholar] [CrossRef]

- Frías, M.; Vigil de la Villa, R.; Martínez-Ramírez, S.; Fernández-Carrasco, L.; Villar-Cociña, E.; García-Giménez, R. Multi-Technique Characterization of a Fine Fraction of CDW and Assessment of Reactivity in a CDW/Lime system. Minerals 2020, 10, 590. [Google Scholar] [CrossRef]

- Gonzalez-Corominas, A.; Etxeberria, M. Properties of high performance concrete made with recycled fine ceramic and coarse mixed aggregates. Constr. Build. Mater. 2014, 68, 618–626. [Google Scholar] [CrossRef]

- Nandi, S.; Ransinchung, G.D.R.N. Performance evaluation and sustainability assessment of precast concrete paver blocks containing coarse and fine RAP fractions: A comprehensive comparative study. Constr. Build. Mater. 2021, 300, 124042. [Google Scholar] [CrossRef]

- Rahul, S.D.; Reddy, S.V.; Tarun, N.; Basutkar, S.M.; Wali, R.S.; Renukadevi, M.V. Influence of brick waste and brick waste fines as fine aggregate on the properties of paver blocks—Preliminary investigation. Mater. Today Proc. 2021, 43, 1496–1502. [Google Scholar] [CrossRef]

- López-Gayarre, F.; López-Colina, C.; Serrano, M.A.; López-Martínez, A. Manufacture of concrete kerbs and floor blocks with recycled aggregate from C&DW. Constr. Build. Mater. 2013, 40, 1193–1199. [Google Scholar] [CrossRef]

- Özalp, F.; Yilmaz, H.D.; Kara, M.; Kaya, Ö.; Sahin, A. Effects of recycled aggregates from construction and demolition wastes on mechanical and permeability properties of paving stone, kerb and concrete pipes. Constr. Build. Mater. 2016, 110, 17–23. [Google Scholar] [CrossRef]

- Gastaldi, D.; Canonico, F.; Capelli, L.; Buzzi, L.; Boccaleri, E.; Irico, S. An investigation on the recycling of hydrated cement from concrete demolition waste. Cem. Concr. Compos. 2015, 61, 29–35. [Google Scholar] [CrossRef]

- Pimiento, J.A.; Restrepo, C.E. Comparative Analysis of the Carbon Footprint Necessary for the Assimilation of the Emissions Generated by the Production of the Coarse Sand Stone Aggregate, Using Construction and Demolition Waste (RCD) and Open Pit Extraction; Universidad Pontificia Bolivariana: La Paz, Bolivia, 2018. (In Spanish) [Google Scholar]

- Natesan, M.; Smith, S.; Humphreys, K.; Kaya, Y. The Cement Industry and Global Climate Change: Current and Potential Future Cement Industry CO2 Emissions. In Proceedings of the 6th International Conference on Greenhouse Gas Control Technologies, Kyoto, Japan, 1–4 October 2002; Pergamon: Oxford, UK, 2003; pp. 995–1000. [Google Scholar] [CrossRef]

| Code | Sand | FRA | Gravel | CRA | OPC | SP * |

|---|---|---|---|---|---|---|

| 0-0 | 55.76 | 0 (0) | 37.18 | 0 (0) | 7 | 0.06 |

| 25-0 | 41.82 | 13.94 (25) | 37.18 | 0 (0) | 7 | 0.06 |

| 50-0 | 27.88 | 27.88 (50) | 37.18 | 0 (0) | 7 | 0.06 |

| 75-0 | 13.94 | 41.82 (75) | 37.18 | 0 (0) | 7 | 0.06 |

| 100-0 | 0 | 55.76 (100) | 37.18 | 0 (0) | 7 | 0.06 |

| 0-25 | 55.76 | 0 (0) | 27.88 | 9.30 (25) | 7 | 0.06 |

| 0-50 | 55.76 | 0 (0) | 18.59 | 18.59 (50) | 7 | 0.06 |

| 0-75 | 55.76 | 0 (0) | 9.30 | 27.88 (75) | 7 | 0.06 |

| 0-100 | 55.76 | 0 (0) | 0 | 37.18 (100) | 7 | 0.06 |

| 25-25 | 41.82 | 13.94 (25) | 27.88 | 9.30 (25) | 7 | 0.06 |

| 50-50 | 27.88 | 27.88 (50) | 18.59 | 18.59 (50) | 7 | 0.06 |

| 75-75 | 13.94 | 41.82 (75) | 9.30 | 27.88 (75) | 7 | 0.06 |

| 100-100 | 0 | 55.76 (100) | 0 | 37.18 (100) | 7 | 0.06 |

| Raw Materials | Na2O | MgO | Al2O3 | SiO2 | P2O5 | SO3 | K2O | CaO | TiO2 | Mn2O3 | Fe2O3 | LOI |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CDW | 0.4 ± 0.1 | 1.7 ± 0.3 | 9.8 ± 0.5 | 75.5 ± 7.2 | 0.04 ± 0.01 | 0.2 ± 0.1 | 1.0 ± 0.2 | 6.1 ± 0.5 | 1.1 ± 0.2 | 0.05 ± 0.02 | 3.2 ± 0.4 | 5.1 ± 0.5 |

| CRA | 0.3 ± 0.1 | 1.4 ± 0.2 | 6.8 ± 0.6 | 73.1 ± 6.1 | 0.06 ± 0.02 | 0.2 ± 0.1 | 1.2 ± 0.2 | 6.4 ± 0.6 | 0.4 ± 0.1 | 0.06 ± 0.02 | 2.3 ± 0.2 | 5.7 ± 0.3 |

| FRA | <0.01 | 1.2 ± 0.2 | 5.4 ± 0.5 | 78.4 ± 4.9 | 0.06 ± 0.02 | 1.0 ± 0.2 | 0.8 ± 0.2 | 5.5 ± 0.4 | 0.2 ± 0.1 | 0.05 ± 0.01 | 1.9 ± 0.1 | 4.9 ± 0.4 |

| NG | 1.5± 0.3 | 1.4 ± 0.2 | 4.8 ± 0.5 | 63.2 ± 3.8 | 0.24 ± 0.08 | 0.6 ± 0.2 | 0.8 ± 0.1 | 10.5 ± 0.4 | 0.5 ± 0.1 | 0.05 ± 0.01 | 2.9 ± 0.2 | 1.9 ± 0.3 |

| NS | 0.6 ± 0.2 | 1.3 ± 0.2 | 3.8 ± 0.4 | 90.6 ± 4.2 | <0.01 | <0.01 | 0.4 ± 0.1 | 1.5 ± 0.3 | 0.4 ± 0.1 | 0.20 ± 0.03 | 1.2 ± 0.1 | 0.7 ± 0.1 |

| Cement | 0.2 ± 0.1 | 2.2 ± 0.4 | 5.9 ± 0.5 | 21.5 ± 1.4 | - | 2.0 ± 0.4 | 0.7 ± 0.1 | 59.8 ± 1.1 | - | - | 2.8 ± 0.4 | 3.7 ± 0.3 |

| Raw Materials | Ba | Zr | V | Cr | Y | Rb | Zn | Cu | Sr | Pb | As |

|---|---|---|---|---|---|---|---|---|---|---|---|

| CDW | 483 ± 34 | 385 ± 39 | 81 ± 14 | 58 ± 12 | 12 ± 4 | 32 ± 8 | 88 ± 5 | 80 ± 4 | 177 ± 11 | 28 ± 4 | 3.8 ± 0.3 |

| CRA | 405 ± 49 | 390 ± 24 | 101 ± 12 | 90 ± 21 | 11 ± 2 | 50 ± 6 | 45 ± 9 | 81 ± 6 | 230 ± 16 | 22 ± 3 | 3.9 ± 0.3 |

| FRA | 529 ± 41 | 385 ± 31 | 67 ± 9 | 89 ± 13 | 22 ± 4 | 45 ± 4 | 80 ± 7 | 89 ± 9 | 301 ± 18 | 26 ± 3 | 4.0 ± 0.9 |

| Soil (*) | 584 | 203 | 97 | 92 | 21 | 78 | 67 | 28 | 348 | 17 | 4.8 |

| Raw Materials | LA (%) | Friability | Flakiness (%) | Fines (%) | BD * (kg m−3) | BD ** (kg m−3) | SG (kg m−3) | WA (%) |

|---|---|---|---|---|---|---|---|---|

| NS | - | 20.9 ± 2.8 | - | 4.2 ± 1.3 | 1450 ± 70 | 1660 ± 40 | 2450 ± 180 | 1.1 ± 0.2 |

| NG | 25 ± 1 | - | 15 ± 2 | 0.2 ± 0.1 | 1520 ± 40 | 1620 ± 90 | 2650 ± 110 | 1.7 ± 0.5 |

| CDW | 38 ± 5 | 29.5 ± 5.2 | 35 ± 4 | 12.6 ± 3.1 1.5 ± 0.4 | 1390 ± 180 | 1610 ± 190 | 2200 ± 340 | 7.1 ± 1.9 |

| FRA | - | 24.2 ± 3.5 | - | 6.9 ± 2.0 | 1410 ± 120 | 1590 ± 100 | 2280 ± 290 | 5.0 ± 0.9 |

| CRA | 33 ± 3 | - | 22 ± 4 | 0.3 ± 0.1 | 1490 ± 190 | 1530 ± 90 | 2390 ± 210 | 4.5 ± 1.1 |

| Code | AP (%) | SG (g·cm-3) | WA (%) | σ (MPa) |

|---|---|---|---|---|

| 0-0 | 8.7 ± 0.7 | 2.39 ± 0.22 | 4.8 ± 0.8 | 37 ± 3 |

| 25-0 | 9.1 ± 0.4 | 2.28 ± 0.20 | 5.1 ± 0.5 | 37 ± 4 |

| 50-0 | 9.2 ± 0.5 | 2.19 ± 0.18 | 5.7 ± 0.9 | 33 ± 5 |

| 75-0 | 9.8 ± 0.6 | 2.17 ± 0.23 | 5.8 ± 0.4 | 33 ± 4 |

| 100-0 | 10.0 ± 0.5 | 2.17 ± 0.20 | 6.1 ± 0.7 | 31 ± 3 |

| 0-25 | 9.5 ± 0.4 | 2.32 ± 0.10 | 5.0 ± 0.5 | 35 ± 4 |

| 0-50 | 9.9 ± 0.4 | 2.28 ± 0.24 | 5.4 ± 0.7 | 31 ± 5 |

| 0-75 | 10.5 ± 0.6 | 2.17 ± 0.19 | 5.9 ± 0.4 | 29 ± 4 |

| 0-100 | 11.2 ± 0.5 | 2.14 ± 0.22 | 6.5 ± 0.6 | 29 ± 3 |

| 25-25 | 9.5 ± 0.7 | 2.37 ± 0.25 | 5.9 ± 0.4 | 34 ± 3 |

| 50-50 | 10.1 ± 0.4 | 2.24 ± 0.15 | 6.9 ± 0.6 | 31 ± 4 |

| 75-75 | 10.5 ± 0.7 | 2.16 ± 0.31 | 7.3 ± 0.4 | 30 ± 5 |

| 100-100 | 11.0 ± 0.5 | 2.21 ± 0.21 | 8.2 ± 0.3 | 28 ± 5 |

| Code | AP (%) | SG (g cm−3) | WA (%) | T (MPa) | B (MPa) |

|---|---|---|---|---|---|

| Paver blocks | |||||

| 0-0 | 8.7 ± 0.7 | 2.39 ± 0.22 | 5.0 ± 0.3 | 3.9 ± 0.2 | - |

| 25-0 | 9.1 ± 0.4 | 2.28 ± 0.20 | 5.2 ± 0.4 | 3.9 ± 0.3 | - |

| 50-0 | 9.2 ± 0.5 | 2.19 ± 0.18 | 5.7 ± 0.8 | 3.7 ± 0.2 | - |

| 75-0 | 9.8 ± 0.6 | 2.17 ± 0.23 | 5.8 ± 0.4 | 3.4 ± 0.4 | - |

| 100-0 | 10.0 ± 0.5 | 2.17 ± 0.20 | 6.0 ± 0.6 | 3.1 ± 0.4 | - |

| 0-25 | 9.5 ± 0.4 | 2.32 ± 0.10 | 5.2 ± 0.4 | 3.9 ± 0.3 | - |

| 0-50 | 9.9 ± 0.4 | 2.28 ± 0.24 | 5.3 ± 0.6 | 3.6 ± 0.2 | - |

| 0-75 | 10.5 ± 0.6 | 2.17 ± 0.19 | 5.8 ± 0.3 | 3.1 ± 0.4 | - |

| 0-100 | 11.2 ± 0.5 | 2.14 ± 0.22 | 6.5 ± 0.6 | 2.9 ± 0.4 | - |

| 25-25 | 9.5 ± 0.7 | 2.37 ± 0.25 | 5.9 ± 0.5 | 3.6 ± 0.3 | - |

| 50-50 | 10.1 ± 0.4 | 2.24 ± 0.15 | 6.9 ± 0.6 | 3.5 ± 0.3 | - |

| 75-75 | 10.5 ± 0.7 | 2.16 ± 0.31 | 7.2 ± 0.4 | 3.0 ± 0.5 | - |

| 100-100 | 11.0 ± 0.5 | 2.21 ± 0.21 | 8.1 ± 0.3 | 2.9 ± 0.6 | - |

| Kerb units | |||||

| 0-0 | 8.5 ± 0.5 | 2.37 ± 0.15 | 4.8 ± 0.4 | - | 4.9 ± 0.3 |

| 25-0 | 8.9 ± 0.6 | 2.31 ± 0.17 | 5.1 ± 0.4 | - | 4.9 ± 0.3 |

| 50-0 | 9.0 ± 0.6 | 2.22 ± 0.19 | 5.2 ± 0.8 | - | 4.6 ± 0.3 |

| 75-0 | 9.2 ± 0.6 | 2.19 ± 0.20 | 5.9 ± 0.7 | - | 3.5 ± 0.4 |

| 100-0 | 9.8 ± 0.5 | 2.17 ± 0.21 | 6.1 ± 0.8 | - | 3.3 ± 0.3 |

| 0-25 | 9.3 ± 0.5 | 2.25 ± 0.15 | 5.5 ± 0.5 | - | 4.8 ± 0.3 |

| 0-50 | 9.8 ± 0.6 | 2.25 ± 0.18 | 5.3 ± 0.6 | - | 3.5 ± 0.3 |

| 0-75 | 10.0 ± 0.8 | 2.19 ± 0.17 | 5.9 ± 0.9 | - | 2.9 ± 0.5 |

| 0-100 | 11.1 ± 0.6 | 2.15 ± 0.21 | 6.3 ± 0.5 | - | 2.2 ± 0.7 |

| 25-25 | 9.6 ± 0.6 | 2.35 ± 0.22 | 5.8 ± 0.8 | - | 3.8 ± 0.4 |

| 50-50 | 10.2 ± 0.7 | 2.29 ± 0.17 | 6.4 ± 0.6 | - | 3.3 ± 0.3 |

| 75-75 | 10.9 ± 0.8 | 2.18 ± 0.21 | 7.9 ± 0.4 | - | 2.8 ± 0.4 |

| 100-100 | 11.1 ± 0.8 | 2.19 ± 0.25 | 8.7 ± 0.8 | - | 2.4 ± 0.5 |

| Mechanical Strength (MPa) | WA (%) | Abrasion Wear (mm) | Freeze-Thaw Cycles (kg m−2) | ||

|---|---|---|---|---|---|

| 7 Days | 28 Days | 28 Days | 28 Days | 28 Days | |

| Paver blocks | |||||

| 0-0 | 4.2 ± 0.2 | 5.1 ± 0.2 | 4.1 ± 0.2 | 20.0 ± 0.3 | 0.89 ± 0.50 |

| 25-0 | 4.0 ± 0.3 | 4.8 ± 0.5 | 3.7 ± 0.3 | 20.1 ± 0.1 | 0.90 ± 0.69 |

| 50-0 | 3.2 ± 0.3 | 4.1 ± 0.3 | 3.8 ± 0.5 | 20.0 ± 0.1 | 0.90 ± 0.58 |

| 0-25 | 2.7 ± 0.2 | 4.3 ± 0.3 | 4.3 ± 0.4 | 20.4 ± 0.3 | 0.91 ± 0.10 |

| 0-50 | 2.9 ± 0.5 | 3.9 ± 0.4 | 3.9 ± 0.2 | 20.2 ± 0.4 | 0.98 ± 0.09 |

| 25-10 | 2.6 ± 0.3 | 3.9 ± 0.2 | 4.0 ± 0.2 | 20.3 ± 0.4 | 1.00 ± 0.12 |

| 25-25 | 2.6 ± 0.3 | 3.5 ± 0.2 | 4.5 ± 0.3 | 20.3 ± 0.4 | 1.05 ± 0.15 |

| Requirements * | - | 3.6 | 6 | 23 | 1 |

| Kerb units | |||||

| 0-0 | 4.2 ± 0.2 | 5.9 ± 0.2 | 4.1 ± 0.2 | 20.0 ± 0.3 | - |

| 50-0 | 3.9 ± 0.2 | 5.3 ± 0.3 | 4.6 ± 0.3 | 20.1 ± 0.4 | - |

| 75-0 | 3.0 ± 0.4 | 3.8 ± 0.3 | 4.9 ± 0.3 | 20.4 ± 0.4 | - |

| 0-25 | 3.9 ± 0.4 | 5.4 ± 0.4 | 3.9 ± 0.4 | 20.2 ± 0.4 | - |

| 0-50 | 2.8 ± 0.5 | 3.7 ± 0.3 | 4.1 ± 0.2 | 20.5 ± 0.4 | - |

| 25-10 | 3.6 ± 0.3 | 5.1 ± 0.4 | 4.4 ± 0.4 | 20.3 ± 0.4 | - |

| 25-25 | 3.1 ± 0.3 | 3.4 ± 0.5 | 4.5 ± 0.3 | 20.3 ± 0.4 | - |

| Requirements ** | - | 5 | 6 | 23 | - |

| Cement Reduction (wt.%) | Breaking Strength (MPa) | WA (%) | Abrasion Wear (mm) | ||

|---|---|---|---|---|---|

| 7 Days | 28 Days | 28 Days | 28 Days | ||

| 0-0 | - | 4.2 ± 0.2 | 5.1 ± 0.2 | 4.1 ± 0.2 | 20.0 ± 0.3 |

| 25-0 | 20 | 2.6 ± 0.2 | 2.7 ± 0.2 | 3.6 ± 0.9 | 19.9 ± 0.1 |

| 25-0 | 13 | 2.9 ± 0.2 | 3.6 ± 0.2 | 4.3 ± 0.2 | 20.5 ± 0.5 |

| 50-0 | 20 | 1.7 ± 0.1 | 1.9 ± 0.1 | 3.9 ± 0.8 | 20.0 ± 0.6 |

| 50-0 | 13 | 2.2 ± 0.2 | 2.3 ±0.2 | 3.9 ± 0.3 | 20.4 ± 0.1 |

| 50-0 | 7 | 3.3 ± 0.1 | 3.7 ± 0.1 | 4.2 ± 0.2 | 19.9 ± 0.4 |

| 50-10 | 7 | 3.6 ± 0.1 | 3.8 ± 0.1 | 3.7 ± 0.6 | 20.1 ± 0.3 |

| 50-20 | 7 | 2.6 ± 0.2 | 3.1 ± 0.2 | 3.4 ± 0.2 | 20.4 ± 0.6 |

| Requirements * | - | - | 3.6 | 6 | 20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Contreras-Llanes, M.; Gázquez, M.J.; Romero, M. Eco-Friendly Pavements Manufactured from Mixed Recycled Aggregates Obtained from Construction and Demolition Waste: An Industrial-Scale Validation. Materials 2023, 16, 7544. https://doi.org/10.3390/ma16247544

Contreras-Llanes M, Gázquez MJ, Romero M. Eco-Friendly Pavements Manufactured from Mixed Recycled Aggregates Obtained from Construction and Demolition Waste: An Industrial-Scale Validation. Materials. 2023; 16(24):7544. https://doi.org/10.3390/ma16247544

Chicago/Turabian StyleContreras-Llanes, Manuel, Manuel Jesús Gázquez, and Maximina Romero. 2023. "Eco-Friendly Pavements Manufactured from Mixed Recycled Aggregates Obtained from Construction and Demolition Waste: An Industrial-Scale Validation" Materials 16, no. 24: 7544. https://doi.org/10.3390/ma16247544