High-Temperature Mechanical and Dynamical Properties of γ-(U,Zr) Alloys

Abstract

:1. Introduction

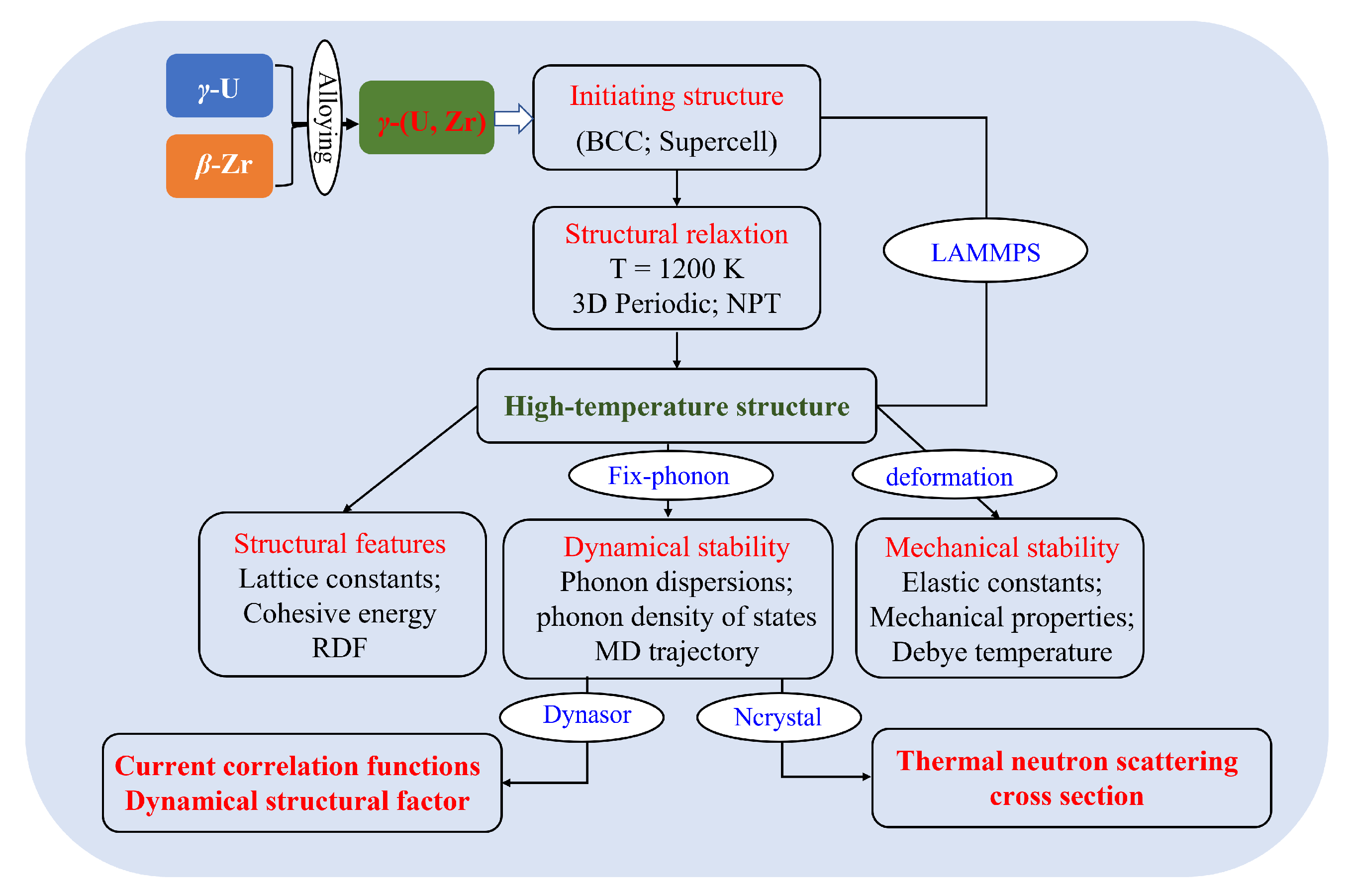

2. Computational Methods

3. Results

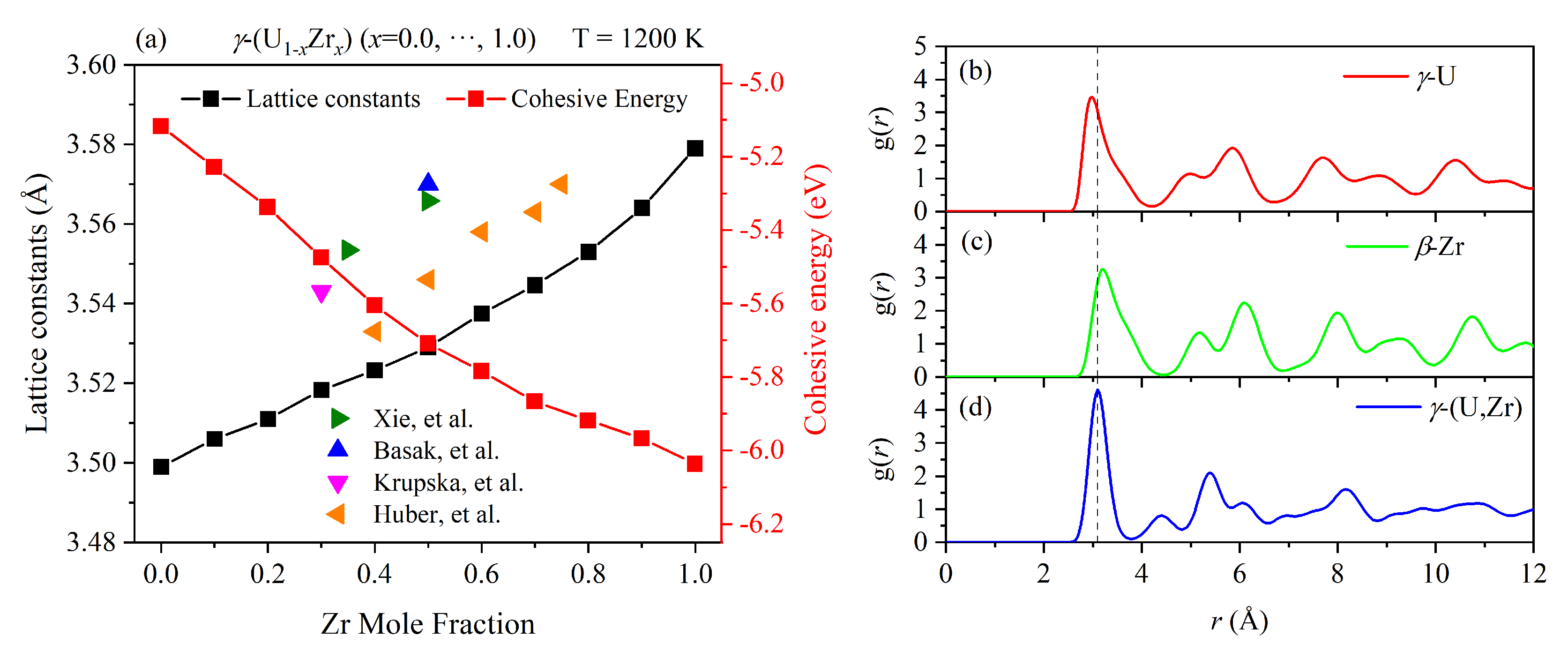

3.1. Crystal Structure

3.2. Mechanical Stability and Properties

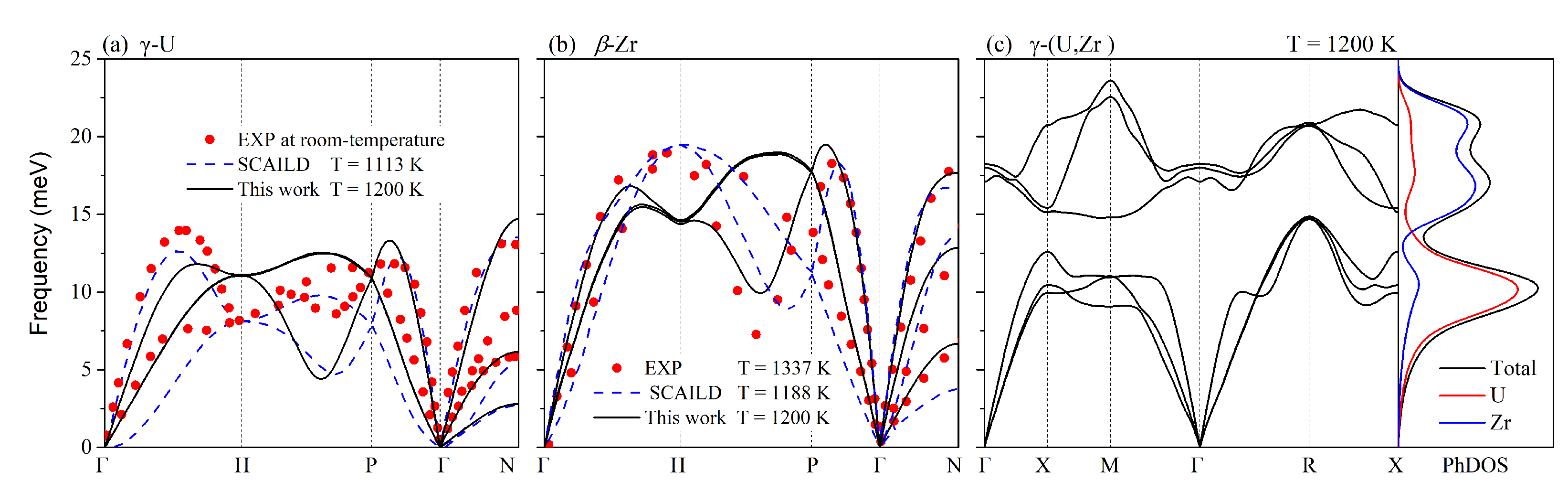

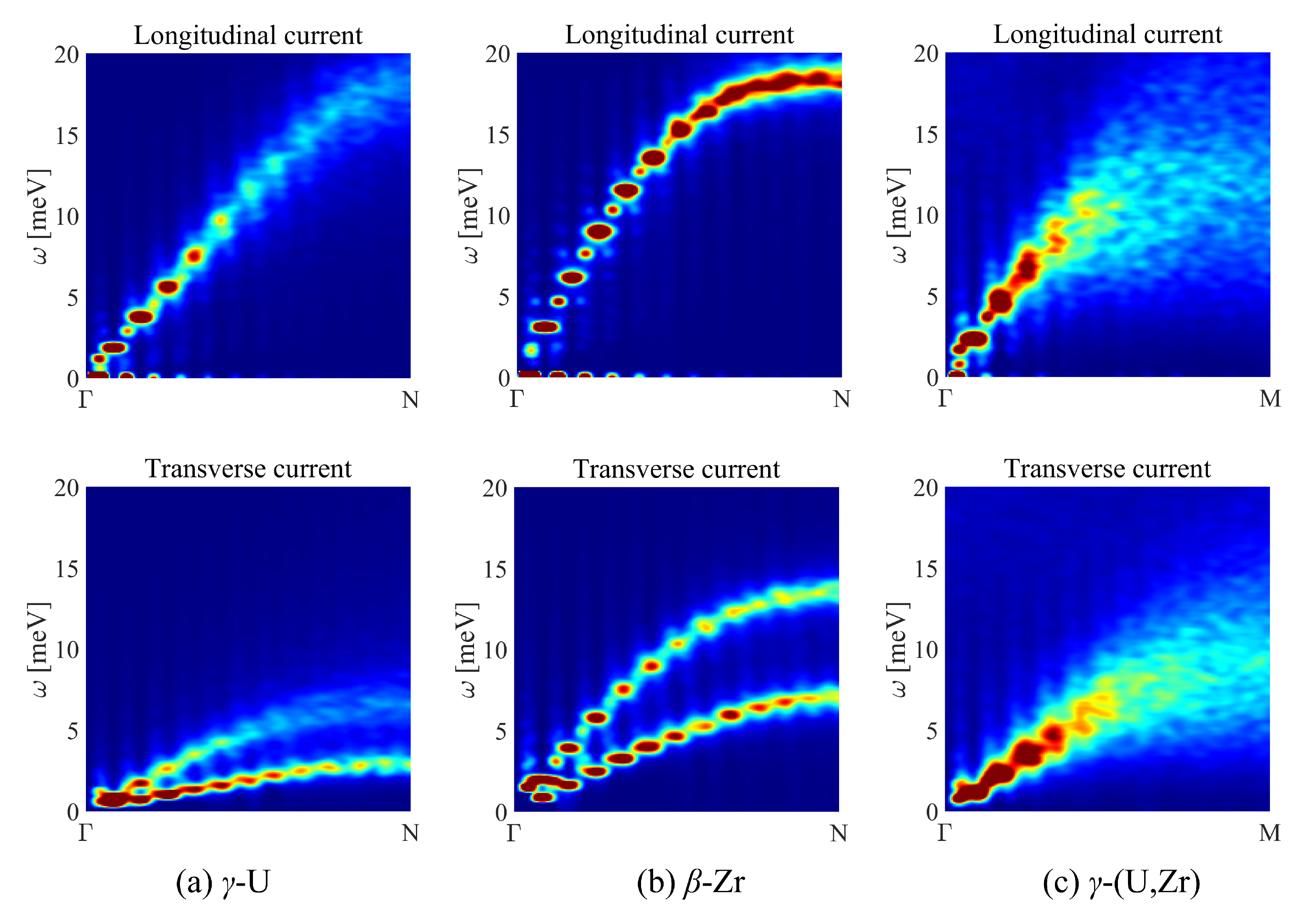

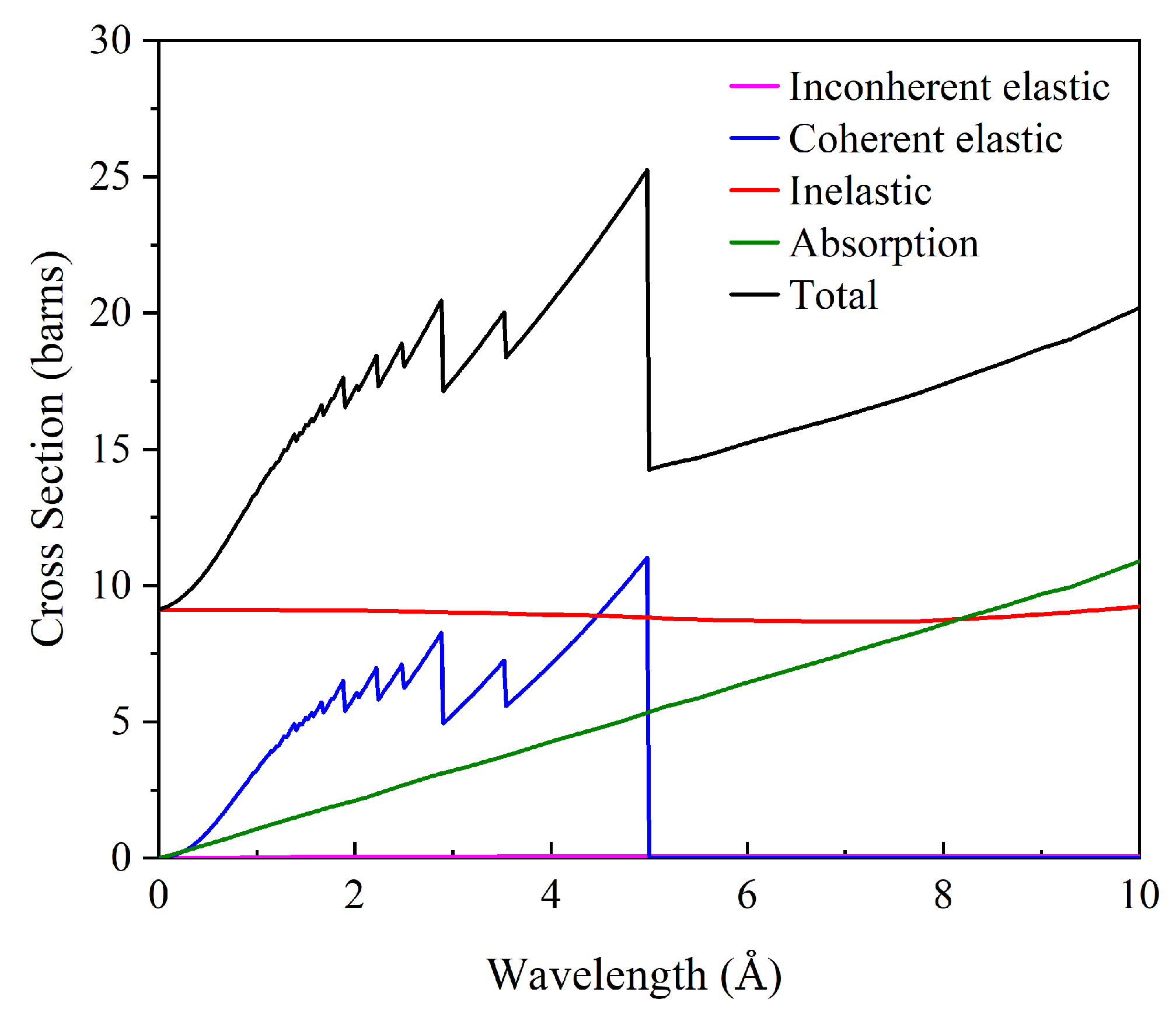

3.3. Dynamical Stability and Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sen, A.; Bachhav, M.; Pu, X.; Teng, F.; Yao, T.; Wharry, J.P. Irradiation Effects on Stability of δ-UZr2 phase in U-50 wt% Zr Alloy. J. Nucl. Mater. 2023, 576, 154251. [Google Scholar] [CrossRef]

- Williams, W.; Vogel, S.; Okuniewski, M. Phase Transformations and Thermal Expansion Coefficients of Unirradiated UX wt.% Zr (X= 6, 10, 20, 30) Measured via Neutron Diffraction. J. Nucl. Mater. 2023, 579, 154380. [Google Scholar] [CrossRef]

- Hofman, G.L.; Walters, L.C.; Bauer, T. Metallic fast reactor fuels. Prog. Nucl. Energy 1997, 31, 83–110. [Google Scholar] [CrossRef]

- Xiong, W.; Xie, W.; Shen, C.; Morgan, D. Thermodynamic modeling of the U-Zr system-A revisit. J. Nucl. Mater. 2013, 443, 331–341. [Google Scholar] [CrossRef]

- Watkins, J.K.; Gonzales, A.; Wagner, A.R.; Sooby, E.S.; Jaques, B.J. Challenges and opportunities to alloyed and composite fuel architectures to mitigate high uranium density fuel oxidation: Uranium mononitride. J. Nucl. Mater. 2021, 553, 153048. [Google Scholar] [CrossRef]

- Watkins, J.K.; Wagner, A.R.; Gonzales, A.; Jaques, B.J.; Sooby, E.S. Challenges and opportunities to alloyed and composite fuel architectures to mitigate high uranium density fuel oxidation: Uranium diboride and uranium carbide. J. Nucl. Mater. 2022, 560, 153502. [Google Scholar] [CrossRef]

- Lawson, A.; Olsen, C.; Richardson, J.; Mueller, M.; Lander, G. Structure of β-uranium. Acta Crystallogr. Sect. B Struct. Sci. 1988, 44, 89–96. [Google Scholar] [CrossRef]

- Meyer, M.; Gan, J.; Jue, J.; Keiser, D.; Perez, E.; Robinson, A.; Wachs, D.; Woolstenhulme, N.; Hofman, G.; Kim, Y. Irradiation performance of U-Mo monolithic fuel. Nucl. Eng. Technol. 2014, 46, 169–182. [Google Scholar] [CrossRef] [Green Version]

- Konovalov, I.; Stetsky, Y. Development Status of Metallic, Dispersion and Non-Oxide Advanced and Alternative Fuels for Power and Research Reactors; Technical report, IAEA-TECDOC-1374; International Atomic Agency: Vienna, Austria, 2003. [Google Scholar]

- Sheldon, R.; Peterson, D. The U-Zr (uranium-zirconium) system. Bull. Alloy. Phase Diagrams 1989, 10, 165–171. [Google Scholar] [CrossRef]

- Moore, A.; Beeler, B.; Deo, C.; Baskes, M.; Okuniewski, M. Atomistic modeling of high temperature uranium-zirconium alloy structure and thermodynamics. J. Nucl. Mater. 2015, 467, 802–819. [Google Scholar] [CrossRef]

- Khanolkar, A.; Yao, T.; Hua, Z.; Dennett, C.A.; Reese, S.J.; Schley, R.S.; He, L.; Kennedy, J.; Hurley, D.H. In situ monitoring of microstructure evolution during thermal processing of uranium-zirconium alloys using laser-generated ultrasound. J. Nucl. Mater. 2021, 553, 153005. [Google Scholar] [CrossRef]

- Xie, Y.; Vogel, S.C.; Harp, J.M.; Benson, M.T.; Capriotti, L. Microstructure Evolution of U-Zr System in A Thermal Cycling Neutron Diffraction Experiment: Extruded U–10Zr (wt.%). J. Nucl. Mater. 2021, 544, 152665. [Google Scholar] [CrossRef]

- Williams, W.; Okuniewski, M.; Vogel, S.; Zhang, J. In situ neutron diffraction study of crystallographic evolution and thermal expansion coefficients in U-22.5 at.% Zr during annealing. JOM 2020, 72, 2042–2050. [Google Scholar] [CrossRef]

- Okamoto, H. U-Zr (Uranium-Zirconium). J. Phase Equilibria Diffus. 2007, 28, 499. [Google Scholar] [CrossRef]

- Chevalier, P.Y.; Fischer, E.; Cheynet, B. Progress in the thermodynamic modelling of the O-U-Zr ternary system. Calphad 2004, 28, 15–40. [Google Scholar] [CrossRef]

- Chen, W.; Bai, X.M. Temperature and composition dependent thermal conductivity model for U-Zr alloys. J. Nucl. Mater. 2018, 507, 360–370. [Google Scholar] [CrossRef]

- Xie, W.; Xiong, W.; Marianetti, C.A.; Morgan, D. Correlation and relativistic effects in U metal and U-Zr alloy: Validation of ab initio approaches. Phys. Rev. B 2013, 88, 235128. [Google Scholar] [CrossRef]

- Xie, W.; Marianetti, C.A.; Morgan, D. Response to letter “Electron correlation and relativity of the 5f electrons in the UZr alloy system”. J. Nucl. Mater. 2016, 476, 110–112. [Google Scholar] [CrossRef] [Green Version]

- Söderlind, P.; Sadigh, B.; Lordi, V.; Landa, A.; Turchi, P. Electron correlation and relativity of the 5f electrons in the U-Zr alloy system. J. Nucl. Mater. 2014, 444, 356–358. [Google Scholar] [CrossRef] [Green Version]

- Zhou, S.; Jacobs, R.; Xie, W.; Tea, E.; Hin, C.; Morgan, D. Combined ab initio and empirical model of the thermal conductivity of uranium, uranium-zirconium, and uranium-molybdenum. Phys. Rev. Mater. 2018, 2, 083401. [Google Scholar] [CrossRef]

- Zhou, S.; Zhang, Y.; Morgan, D. An ab-initio based semi-empirical thermal conductivity model for multiphase uranium-zirconium alloys. J. Nucl. Mater. 2021, 553, 153044. [Google Scholar] [CrossRef]

- Ghosh, P.; Arya, A.; Basak, C.; Poswal, A.; Banerjee, S. Chemical ordering as a precursor to formation of ordered δ-UZr2 phase: A theoretical and experimental study. J. Phys. Condens. Matter 2021, 33, 254003. [Google Scholar] [CrossRef] [PubMed]

- Huang, S.; Ma, J.J.; Lai, K.; Zhang, C.B.; Yin, W.; Qiu, R.; Zhang, P.; Wang, B.T. Point Defects Stability, Hydrogen Diffusion, Electronic Structure, and Mechanical Properties of Defected Equiatomic γ-(U,Zr) from First-Principles. Materials 2022, 15, 7452. [Google Scholar] [CrossRef]

- Zhang, C.B.; Li, X.P.; Li, W.D.; Zhang, P.; Yin, W.; Wang, F.; Wang, B.T. Structural, electronic, and elastic properties of equiatomic UZr alloys from first-principles. J. Nucl. Mater. 2017, 496, 333–342. [Google Scholar] [CrossRef]

- Kong, L.T. Phonon dispersion measured directly from molecular dynamics simulations. Comput. Phys. Commun. 2011, 182, 2201–2207. [Google Scholar] [CrossRef]

- Fransson, E.; Slabanja, M.; Erhart, P.; Wahnström, G. dynasor—A Tool for Extracting Dynamical Structure Factors and Current Correlation Functions from Molecular Dynamics Simulations. Adv. Theory Simulations 2021, 4, 2000240. [Google Scholar] [CrossRef]

- Zhao, S. Role of chemical disorder and local ordering on defect evolution in high-entropy alloys. Phys. Rev. Mater. 2021, 5, 103604. [Google Scholar] [CrossRef]

- Miracle, D.B.; Senkov, O.N. A critical review of high entropy alloys and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef] [Green Version]

- Gludovatz, B.; Hohenwarter, A.; Catoor, D.; Chang, E.H.; George, E.P.; Ritchie, R.O. A fracture-resistant high-entropy alloy for cryogenic applications. Science 2014, 345, 1153–1158. [Google Scholar] [CrossRef] [Green Version]

- Basak, C.B.; Prabhu, N.; Krishnan, M. On the formation mechanism of UZr2 phase. Intermetallics 2010, 18, 1707–1712. [Google Scholar] [CrossRef]

- Krupska, M.; Kim-Ngan, N.T.; Sowa, S.; Paukov, M.; Tkach, I.; Drozdenko, D.; Havela, L.; Tarnawski, Z. Structure, electrical resistivity and superconductivity of low-alloyed γ-U phase retained to low temperatures by means of rapid cooling. Acta Metall. Sin. 2016, 29, 388–398. [Google Scholar] [CrossRef] [Green Version]

- Huber, J.; Ansari, P. The superconductivity of BCC U-Zr alloys. Physica B+ C 1985, 135, 441–444. [Google Scholar] [CrossRef]

- Xie, Y.; Vogel, S.C.; Benson, M.T.; Harp, J.M. Phase evolution of U-Zr system in a thermal cycling neutron diffraction experiment: As-cast U-35Zr and U-50Zr. J. Nucl. Mater. 2022, 564, 153681. [Google Scholar] [CrossRef]

- Steiner, M.; Garlea, E.; Creasy, J.; DeMint, A.; Agnew, S. Temperature dependent elastic properties of γ-phase U–8 wt% Mo. J. Nucl. Mater. 2018, 500, 184–191. [Google Scholar] [CrossRef]

- Beeler, B.; Deo, C.; Baskes, M.; Okuniewski, M. First principles calculations of the structure and elastic constants of α, β and γ uranium. J. Nucl. Mater. 2013, 433, 143–151. [Google Scholar] [CrossRef]

- Mouhat, F.; Coudert, F.X. Necessary and sufficient elastic stability conditions in various crystal systems. Phys. Rev. B 2014, 90, 224104. [Google Scholar] [CrossRef] [Green Version]

- Hill, R. The elastic behaviour of a crystalline aggregate. Proc. Phys. Soc. Sect. A 1952, 65, 349. [Google Scholar] [CrossRef]

- Dudarev, S.; Castell, M.; Botton, G.; Savrasov, S.; Muggelberg, C.; Briggs, G.; Sutton, A.; Goddard, D. Understanding STM images and EELS spectra of oxides with strongly correlated electrons: A comparison of nickel and uranium oxides. Micron 2000, 31, 363–372. [Google Scholar] [CrossRef]

- Dudarev, S.; Manh, D.N.; Sutton, A. Effect of Mott-Hubbard correlations on the electronic structure and structural stability of uranium dioxide. Philos. Mag. B 1997, 75, 613–628. [Google Scholar] [CrossRef]

- Tian, Y.; Xu, B.; Zhao, Z. Microscopic theory of hardness and design of novel superhard crystals. Int. J. Refract. Met. Hard Mater. 2012, 33, 93–106. [Google Scholar] [CrossRef]

- Ibrahim, A. Ion beam mixing of metals and Debye temperature. Nucl. Instruments Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 1988, 34, 135–136. [Google Scholar] [CrossRef]

- Anderson, O.L. A simplified method for calculating the Debye temperature from elastic constants. J. Phys. Chem. Solids 1963, 24, 909–917. [Google Scholar] [CrossRef]

- Feng, J.; Xiao, B.; Zhou, R.; Pan, W.; Clarke, D.R. Anisotropic elastic and thermal properties of the double perovskite slab-rock salt layer Ln2SrAl2O7 (Ln= La, Nd, Sm, Eu, Gd or Dy) natural superlattice structure. Acta Mater. 2012, 60, 3380–3392. [Google Scholar] [CrossRef]

- Brubaker, Z.E.; Ran, S.; Said, A.; Manley, M.E.; Söderlind, P.; Rosas, D.; Idell, Y.; Zieve, R.J.; Butch, N.P.; Jeffries, J. Phonon dispersion of Mo-stabilized γ-U measured using inelastic X-ray scattering. Phys. Rev. B 2019, 100, 094311. [Google Scholar] [CrossRef] [Green Version]

- Heiming, A.; Petry, W.; Trampenau, J.; Alba, M.; Herzig, C.; Schober, H.; Vogl, G. Phonon dispersion of the bcc phase of group-IV metals. II. bcc zirconium, a model case of dynamical precursors of martensitic transitions. Phys. Rev. B 1991, 43, 10948. [Google Scholar] [CrossRef] [PubMed]

- Söderlind, P.; Grabowski, B.; Yang, L.; Landa, A.; Björkman, T.; Souvatzis, P.; Eriksson, O. High-temperature phonon stabilization of γ-uranium from relativistic first-principles theory. Phys. Rev. B 2012, 85, 060301. [Google Scholar] [CrossRef] [Green Version]

- Souvatzis, P.; Eriksson, O.; Katsnelson, M.; Rudin, S. Entropy driven stabilization of energetically unstable crystal structures explained from first principles theory. Phys. Rev. Lett. 2008, 100, 095901. [Google Scholar] [CrossRef]

- Bouchet, J.; Bottin, F. High-temperature and high-pressure phase transitions in uranium. Phys. Rev. B 2017, 95, 054113. [Google Scholar] [CrossRef]

- Qian, X.; Yang, R. Temperature effect on the phonon dispersion stability of zirconium by machine learning driven atomistic simulations. Phys. Rev. B 2018, 98, 224108. [Google Scholar] [CrossRef] [Green Version]

- Cheng, Y.; Daemen, L.L.; Kolesnikov, A.I.; Ramirez-Cuesta, A. Simulation of inelastic neutron scattering spectra using OCLIMAX. J. Chem. Theory Comput. 2019, 15, 1974–1982. [Google Scholar] [CrossRef]

- Squires, G.L. Introduction to the Theory of Thermal Neutron Scattering; Courier Corporation: North Chelmsford, MA, USA, 1996. [Google Scholar]

- Cai, X.X.; Kittelmann, T. NCrystal: A library for thermal neutron transport. Comput. Phys. Commun. 2020, 246, 106851. [Google Scholar] [CrossRef]

- Cai, X.X.; Kittelmann, T.; Klinkby, E.; Damián, J.M. Rejection-based sampling of inelastic neutron scattering. J. Comput. Phys. 2019, 380, 400–407. [Google Scholar] [CrossRef] [Green Version]

| -U (%) | -(UZr) | -(UZr) | -(UZr) | -U [35] | -U [36] | -UZr [25] | |

|---|---|---|---|---|---|---|---|

| 112.5 (18.2%) | 144.5 | 157.4 | 176.4 | 137.6 | 86 | 57.5 | |

| 77.2 (7.4%) | 76.2 | 68.5 | 44.8 | 83.4 | 155 | 78.2 | |

| 34.4 (53.2%) | 26.9 | 59.3 | 69.1 | 16.2 | 37 | 64.7 | |

| 88.9 | 98.9 | 98.1 | 88.7 | 77.8 | |||

| 26.3 | 50.1 | 52.8 | 67.7 | ||||

| 71.9 | 128.5 | 134.4 | 162.0 | ||||

| 2.338 | 6.769 | 7.549 | 13.407 | ||||

| 1195.4 | 1801.5 | 2054.8 | 2667.3 | ||||

| 2594.2 | 3277.5 | 3670.4 | 4335.3 | ||||

| 1346.8 | 2008.1 | 2287.2 | 2943.2 | ||||

| 144.3 | 214.4 | 243.6 | 311.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, J.-J.; Han, X.-F.; Cai, X.-X.; Qiu, R.; Eriksson, O.; Zhang, P.; Wang, B.-T. High-Temperature Mechanical and Dynamical Properties of γ-(U,Zr) Alloys. Materials 2023, 16, 2623. https://doi.org/10.3390/ma16072623

Ma J-J, Han X-F, Cai X-X, Qiu R, Eriksson O, Zhang P, Wang B-T. High-Temperature Mechanical and Dynamical Properties of γ-(U,Zr) Alloys. Materials. 2023; 16(7):2623. https://doi.org/10.3390/ma16072623

Chicago/Turabian StyleMa, Jiang-Jiang, Xue-Fen Han, Xiao-Xiao Cai, Ruizhi Qiu, Olle Eriksson, Ping Zhang, and Bao-Tian Wang. 2023. "High-Temperature Mechanical and Dynamical Properties of γ-(U,Zr) Alloys" Materials 16, no. 7: 2623. https://doi.org/10.3390/ma16072623