Atomic-Scale Structural Properties in NiCo2O4/CuFe2O4 Bilayer Heterostructures on (001)-MgAl2O4 Substrate Regulated by Film Thickness

Abstract

:1. Introduction

2. Materials and Methods

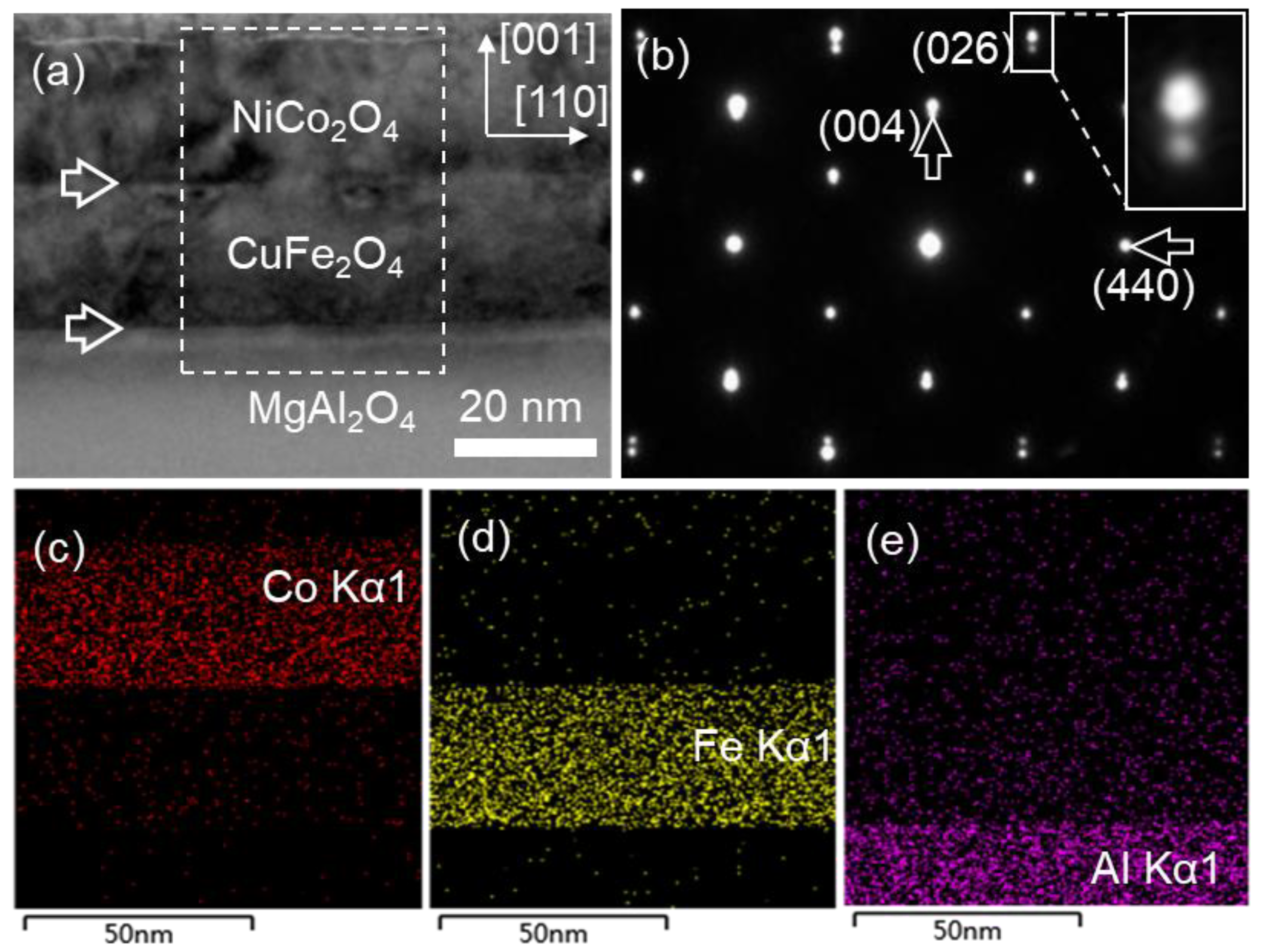

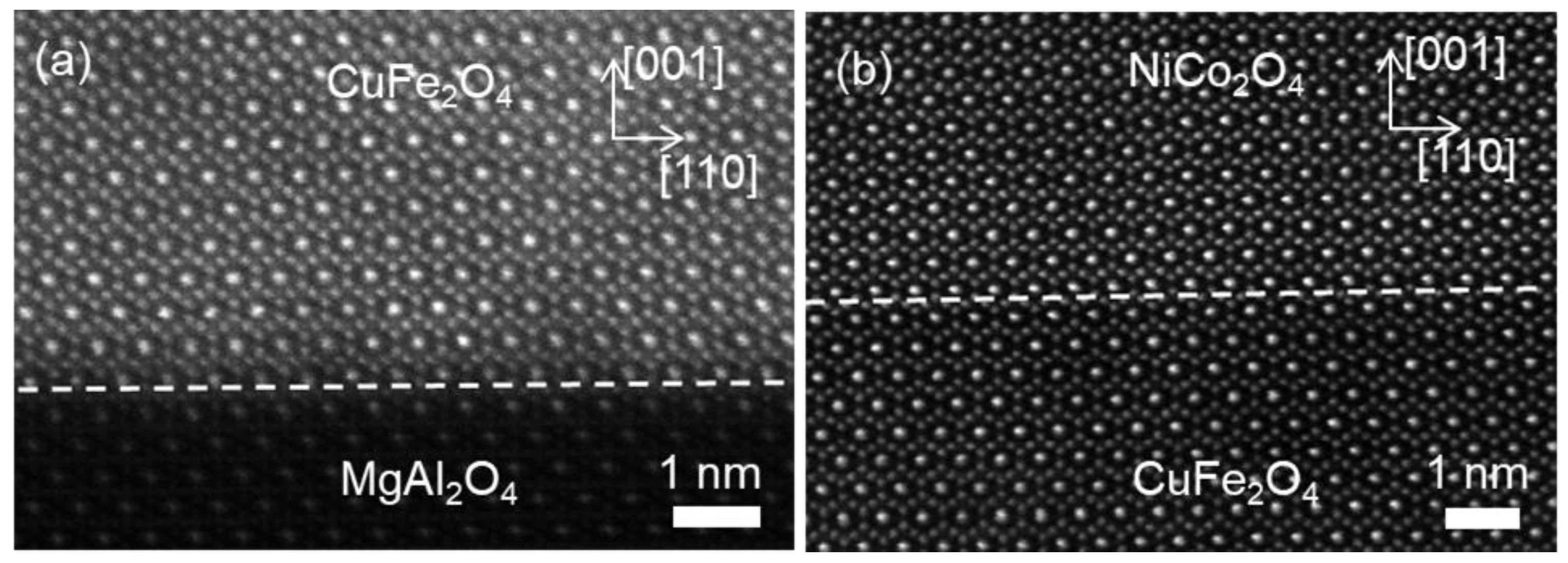

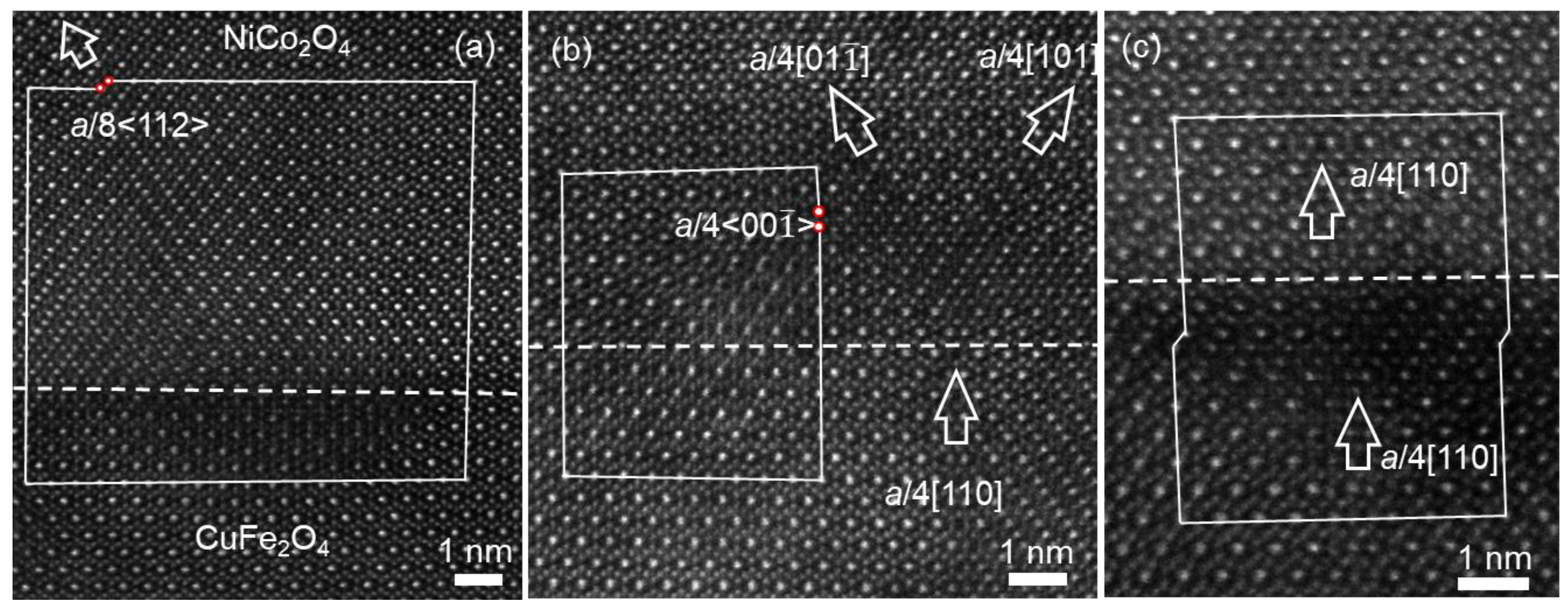

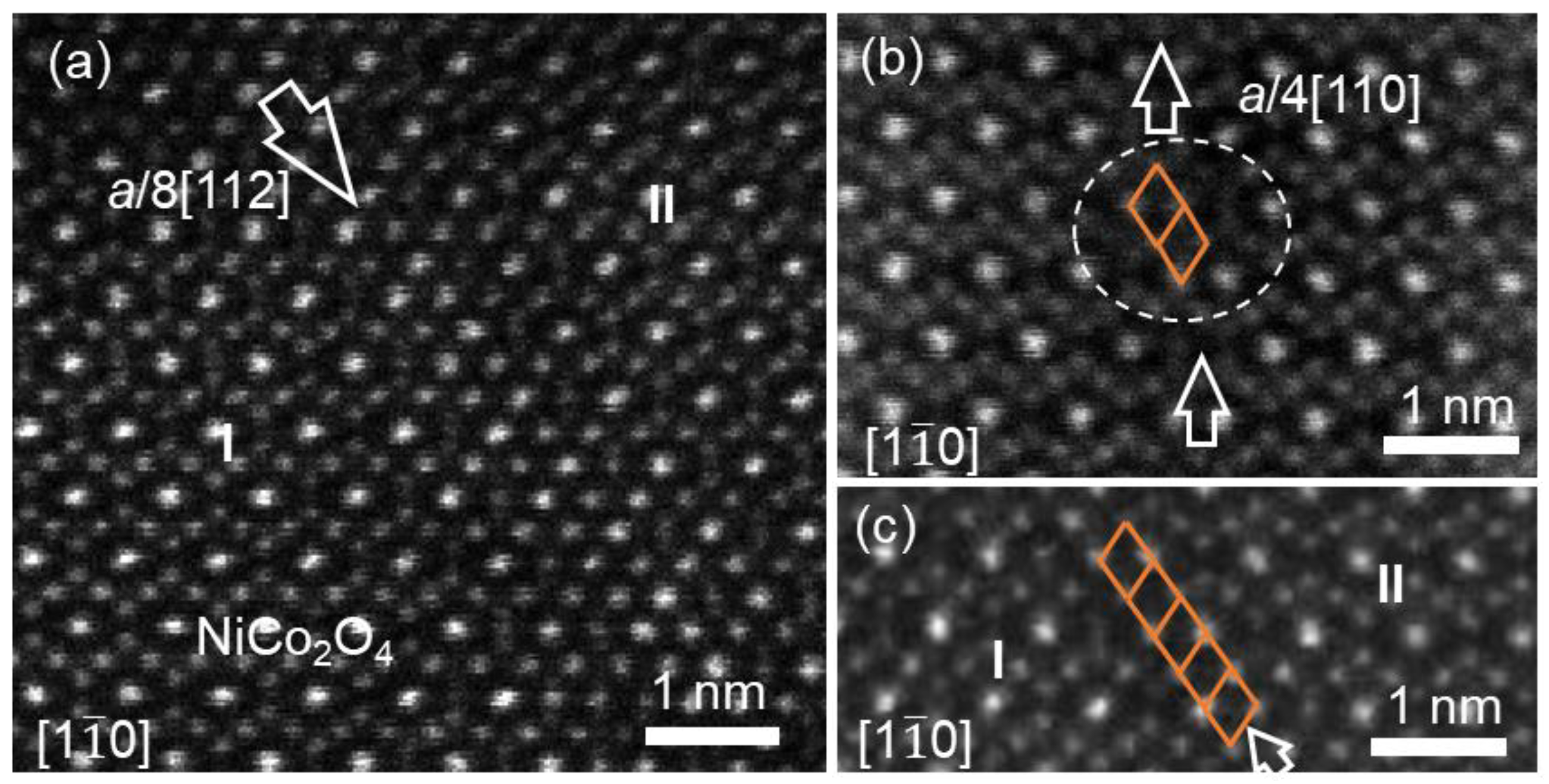

3. Results and Discussions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Suzuki, Y.; VanDover, R.B.; Gyorgy, E.M.; Phillips, J.M.; Korenivski, V.; Werder, D.J.; Chen, C.H.; Cava, R.J.; Krajewski, J.J.; Peck, W.F.; et al. Structure and Magnetic Properties of Epitaxial Spinel Ferrite Thin Films. Appl. Phys. Lett. 1996, 68, 714–716. [Google Scholar] [CrossRef]

- Hcini, S.; Brahmi, M.; Dhaou, M.H.; Khirouni, K.; Mallah, A.; Mashary, F.S.A.; Albadri, A.E. Studies of Structural, Dielectric, and Optical Properties of CuCoFeO4 Spinel for High Frequency, Microwave, and Optoelectronic Applications. J. Mol. Struct. 2023, 1291, 135981. [Google Scholar] [CrossRef]

- Zhang, R.; Qin, C.; Bala, H.; Wang, Y.; Cao, J. Recent Progress in Spinel Ferrite (MFe2O4) Chemiresistive Based Gas Sensors. Nanomaterials 2023, 13, 2188. [Google Scholar] [CrossRef] [PubMed]

- Anandan, S.; Selvamani, T.; Prasad, G.G.; Asiri, A.M.; Wu, J.J. Magnetic and Catalytic Properties of Inverse Spinel CuFe2O4 Nanoparticles. J. Magn. Magn. Mater. 2017, 432, 437–443. [Google Scholar] [CrossRef]

- Yang, A.; Chen, Z.; Islam, S.M.; Vittoria, C.; Harris, V.G. Cation Engineering of Cu-ferrite Films Deposited by Alternating Target Laser Ablation Deposition. J. Appl. Phys. 2008, 103, 07E509. [Google Scholar] [CrossRef]

- Zheng, M.; Guan, P.F.; Fan, H.L. Mechanically Enhanced Magnetism in Flexible Semitransparent CuFe2O4/mica Epitaxial Heterostructures. Appl. Surf. Sci. 2022, 584, 152586. [Google Scholar] [CrossRef]

- Ati, A.A.; Abdalsalam, A.H.; Abbas, H.H. Influence of Annealing on Structural, Morphology, Magnetic and Optical Properties of PLD Deposited CuFe2O4 Thin Films. Inorg. Chem. Commun. 2022, 146, 110072. [Google Scholar] [CrossRef]

- Xu, X.S.; Mellinger, C.; Cheng, Z.G.; Chen, X.G.; Hong, X. Epitaxial NiCo2O4 Film as an Emergent Spintronic Material: Magnetism and Transport Properties. J. Appl. Phys. 2022, 132, 020901. [Google Scholar] [CrossRef]

- Liu, L.; Zhen, C.M.; Xu, L.; Shui, Z.Z.; Ma, L.; Zhao, D.W.; Hou, D.L. Semiconductor-Metal Transition in Vulcanized NiCo2O4 Film. J Phys. Chem. Solids 2023, 174, 111189. [Google Scholar] [CrossRef]

- Bitla, Y.; Chin, Y.Y.; Lin, J.C.; Van, C.N.; Liu, R.R.; Zhu, Y.M.; Liu, H.J.; Zhan, Q.; Lin, H.J.; Chen, C.T.; et al. Origin of Metallic Behavior in NiCo2O4 Ferrimagnet. Sci. Rep. 2015, 5, 15201. [Google Scholar] [CrossRef]

- Kim, J.; Park, Y.J.; Dho, J. Ferrimagnetic and Metallic Properties of (001) NiCo2O4 Films Fabricated at Various Oxygen Pressures. J. Magn. 2023, 28, 102–107. [Google Scholar] [CrossRef]

- Wu, C.F.; Zhen, C.M.; Zhang, X.Z.; Xu, X.S.; Xie, J.T.; Ma, L.; Zhao, D.W.; Hou, D.L. Sensitive Metallic Behavior in Epitaxial NiCo2O4 Films Regulated by the Film Thickness. J Phys. Chem. Solids 2022, 160, 110321. [Google Scholar] [CrossRef]

- Zhen, C.M.; Zhang, X.Z.; Wei, W.G.; Guo, W.Z.; Pant, A.; Xu, X.S.; Shen, J.; Ma, L.; Hou, D.L. Nanostructural Origin of Semiconductivity and Large Magnetoresistance in Epitaxial NiCo2O4/Al2O3 Thin Films. J. Phys. D 2018, 51, 145308. [Google Scholar] [CrossRef]

- Lee, M. Disordered Exchange is Biased. Nat. Phys. 2021, 17, 434–435. [Google Scholar] [CrossRef]

- Hassnain Jaffari, G.; Bah, M.; Ismat Shah, S. Strong Magnetic Coupling Between Antiferromagnetic and Ferromagnetic Phases in Polycrystalline Hollow Nanoparticles Composed of Spinel Solid Solution. J. Alloys Compd. 2021, 857, 157607. [Google Scholar] [CrossRef]

- Muzzi, B.; Albino, M.; Petrecca, M.; Innocenti, C.; de Julián Fernández, C.; Bertoni, G.; Ibarra, M.R.; Christensen, M.; Avdeev, M.; Marquina, C.; et al. Defect-engineering by Solvent Mediated Mild Oxidation as a Tool to Induce Exchange Bias in Metal Doped Ferrites. Small Methods 2023, 7, 2300647. [Google Scholar] [CrossRef]

- Beatriz, R.M.; Martín, T.A.; Skorikov, A.S.; Miguel, C.H.; Bals, S.; Salgueiriño, V. Interfaceless Exchange Vias in CoFe2O4 Nanocrystals. Nano Lett. 2023, 23, 1688–1695. [Google Scholar]

- Díez, J.M.; Cuñado, J.L.F.; Lapa, P.; Solís, R.; Arnay, I.; Pedraz, P.; Perna, P.; Bollero, A.; Miranda, R.; Schuller, I.K.; et al. Interfacial Exchange Phenomena Driven by Ferromagnetic Domains. Adv. Mater. Interfaces 2022, 9, 2200331. [Google Scholar] [CrossRef]

- Kim, J.V.; Stamps, R.L. Defect-modified Exchange Bias. Appl. Phys. Lett. 2001, 79, 2785–2787. [Google Scholar] [CrossRef]

- Khan, A.; Rajput, S.; Anas, M.; Malik, V.K.; Maitra, T.; Nath, T.K.; Taraphder, A. The Effect of Antisite Disorder on Magnetic and Exchange Bias Properties of Gd-substituted Y2CoMnO6 Double Perovskite. J. Phys. Condens. Matter. 2022, 34, 435801. [Google Scholar] [CrossRef] [PubMed]

- McKenna, K.P.; Hofer, F.; Gilks, D.; Lazarov, V.K.; Chen, C.; Wang, Z.; Ikuhara, Y. Atomic-scale Structure and Properties of Highly Stable Antiphase Boundary Defects in Fe3O4. Nat. Commun. 2014, 5, 5740. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Lu, J.; Jin, L.; Rusz, J.; Kocevski, V.; Yanagihara, H.; Kita, E.; Mayer, J.; Dunin-Borkowski, R.E.; Xiang, H.; et al. Atomic Structure and Electron Magnetic Circular Dichroism of Individual Rock Salt Structure Antiphase Boundaries in Spinel Ferrites. Adv. Funct. Mater. 2021, 31, 2008306. [Google Scholar] [CrossRef]

- Mi, S.B.; Zhang, R.Y.; Lu, L.; Liu, M.; Wang, H.; Jia, C.L. Atomic-scale Structure and Formation of Antiphase Boundaries in α-Li0.5Fe2.5O4 Thin Films on MgAl2O4 (001) Substrates. Acta Mater. 2017, 127, 178–184. [Google Scholar] [CrossRef]

- Ahmed, S.; Pokle, A.; Bianchini, M.; Schweidler, S.; Beyer, A.; Brezesinski, T.; Janek, J.; Volz, K. Understanding the Formation of Antiphase Boundaries in Layered Oxide Cathode Materials and Their Evolution Upon Electrochemical Cycling. Matter 2021, 4, 3953–3966. [Google Scholar] [CrossRef]

- Lee, D.; Trang, T.T.T.; Heo, Y.U. Role of Dislocation Climb on Twin Boundary and Antiphase Boundary Formations in Inverse-Spinel MnAl2O4. J. Alloys Compd. 2023, 958, 170526. [Google Scholar] [CrossRef]

- Cao, K.Y.; Tian, F.H.; Huang, S.; Zhang, Y.; Zhao, Q.Z.; Yao, K.K.; Dai, Z.Y.; Li, J.N.; Yu, Z.H.; Zhou, C.; et al. Tuning the Exchange Bias Effect Via Thermal Treatment Temperature in Bulk Ni50Mn42In3Sb5 Heusler Alloys. Appl. Phys. Express 2021, 14, 105502. [Google Scholar] [CrossRef]

- Panigrahi, B.; Raja, M.M.; Murapaka, C.; Halder, A. Bias-field-free Microwave Operation in NiFe/FeMn Exchange Biased Bilayers by Varying FeMn Thickness. J. Supercond. Nov. Magn. 2023, 36, 1075–1083. [Google Scholar] [CrossRef]

- Sun, H.D.; Jing, C.; Su, Y.; Cai, F.Q.; Yang, S.Y.; Zhou, T.; Zhang, Y.L.; Li, Z. Spontaneous Exchange Bias and Magnetic Characteristics in Ni50Mn35Sn10V5 Heusler Alloy. Solid State Commun. 2023, 373–374, 115339. [Google Scholar] [CrossRef]

- Deng, Z.; Wang, X.; Wang, M.; Shen, F.; Zhang, J.; Chen, Y.; Feng, H.L.; Xu, J.; Peng, Y.; Li, W.; et al. Giant Exchange-bias-like Effect at Low Cooling Fields Induced by Pinned Magnetic Domains in Y2NiIrO6 Double Perovskite. Adv. Mater. 2023, 35, 2209759. [Google Scholar] [CrossRef]

- Pal, K.; Das, I. The Impact of Oxygen Deficiency on Giant Exchange Bias in Perovskite Oxide: SrFe0.5Co0.5O3−δ (δ = 0.37). J. Alloys Compd. 2023, 960, 170794. [Google Scholar] [CrossRef]

- Pennycook, S.J.; Nellist, P.D. Z-Contrast Scanning Transmission Electron Microscopy. In Impact of Electron and Scanning Probe Microscopy on Materials Research; Rickerby, D.G., Valdrè, G., Valdrè, U., Eds.; Springer: Berlin, Germany, 1999; pp. 161–207. [Google Scholar]

- Liu, K.; Zhang, R.Y.; Lu, L.; Mi, S.B.; Liu, M.; Wang, H.; Jia, C.L. Formation of Antiphase Boundaries in CuFe2O4 Films Induced by Rough MgAl2O4 (001) Substrates. Thin Solid Films 2019, 680, 55–59. [Google Scholar] [CrossRef]

- Momma, K.; Izumi, F. VESTA 3 for Three-dimensional Visualization of Crystal, Volumetric and Morphology Data. J. Appl. Crystallogr. 2011, 44, 1272–1276. [Google Scholar] [CrossRef]

- Yang, C.P.; Liu, B.; Liu, G.J.; Diao, F.Y.; Yang, H.W.; Wang, Y.Q. Effect of film thickness and strain state on the structure, magnetic and transport properties of La0.9Sr0.1CoO3 films. Solid State Ion 2018, 319, 28–33. [Google Scholar] [CrossRef]

- Wang, Z.; Guo, H.; Shao, S.; Saghayezhian, M.; Li, J.; Fittipaldi, R.; Vecchione, A.; Siwakoti, P.; Zhu, Y.; Zhang, J.; et al. Designing Antiphase Boundaries by Atomic Control of Heterointerfaces. Proc. Natl. Acad. Sci. USA 2018, 115, 9485–9490. [Google Scholar] [CrossRef] [PubMed]

- Joanna, B.G.; Marta, R.; Adam, C.; Edward, K.; Katarzyna, Z. Surface and Interface Properties of TiO2/CuO Thin Film Bilayers Deposited by rf Reactive Magnetron Sputtering. Appl. Surf. Sci. 2023, 616, 156394. [Google Scholar]

- Aouadi, K.; Nouveau, C.; Besnard, A.; Tlili, B.; Montagne, A.; Chafra, M. The Effect of Bilayer Periods and Their Thickness in Magnetron Sputtering Protective Multilayer Coatings for Tribological Applications. J. Mater. Eng. Perform. 2021, 30, 2526–2535. [Google Scholar] [CrossRef]

- Mendil, J.; Trassin, M.; Bu, Q.; Schaab, J.; Baumgartner, M.; Murer, C.; Dao, P.T.; Vijayakumar, J.; Bracher, D.; Bouillet, C.; et al. Magnetic Properties and Domain Structure of Ultrathin Yttrium Iron Garnet/Pt Bilayers. Phys. Rev. Mater. 2019, 3, 034403. [Google Scholar] [CrossRef]

- Feng, M.; Ahlm, N.J.; Kane, A.M.; Chiu, I.; Sasaki, D.Y.; Shafer, P.; Mehta, A.; Takamura, Y. Strain and Thickness-dependent Magnetic Properties of Epitaxial La0.67Sr0.33CoO3/La0.67Sr0.33MnO3 Bilayers. J. Appl. Phys. 2022, 132, 195301. [Google Scholar] [CrossRef]

- Jana, A.K.; Raja, M.M.; Chelvane, J.A.; Ghosal, P.; Jammalamadaka, S.N. Ferromagnetic Thickness Variation Exchange Bias in IrMn (111)/Fe2CoSi Hybrid Structure. J. Supercond. Nov. Magn. 2022, 35, 1313–1319. [Google Scholar] [CrossRef]

- Chen, Z.L.; Liu, X.; Jiang, J.W.; Li, R.; Wang, Y.; Guo, L.; Xu, Y.D.; Mi, W.B. Modulating Exchange Bias, Anisotropic Magnetoresistance, and Planar Hall Resistance of Flexible Co/MnN Epitaxial Bilayers on Mica by Bending Strain. ACS Appl. Mater. Interfaces 2023, 15, 6209–6216. [Google Scholar] [CrossRef]

- Margulies, D.T.; Parker, F.T.; Rudee, M.L.; Spada, F.E.; Chapman, J.N.; Aitchison, P.R.; Berkowitz, A.E. Origin of the Anomalous Magnetic Behavior in Single Crystal Fe3O4 Films. Phys. Rev. Lett. 1997, 79, 5162–5167. [Google Scholar] [CrossRef]

- Eerenstein, W.; Palstra, T.T.M.; Hibma, T.; Celotto, S. Origin of the Increased Resistivity in Epitaxial Fe3O4 Films. Phys. Rev. B 2002, 66, 201101. [Google Scholar] [CrossRef]

- Wu, J.; Guzman, R.; Zhang, Y.; Chen, H.; Chen, Y.; Bao, S.; Yi, D.; Nan, C.-W.; Zhou, W.; Chen, C.; et al. Lateral Magnetic Anisotropy Modulated by Antiphase Domain Boundaries in PrBaCo2O5+δ thin films. Acta Mater. 2023, 247, 118760. [Google Scholar] [CrossRef]

- Vronka, M.; Straka, L.; Graef, M.D.; Heczko, O. Antiphase Boundaries, Magnetic Domains, and Magnetic Vortices in Ni–Mn–Ga Single Crystals. Acta Mater. 2020, 184, 179–186. [Google Scholar] [CrossRef]

- Sarkar, T.; Reddy, V.R.; Elizabeth, S.; Kumar, P.S.A. Antiphase Boundary in Antiferromagnetic Multiferroic LuMn0.5Fe0.5O3: Anomalous Ferromagnetism, Exchange Bias Effect and Large Vertical Hysteretic Shift. J. Phys. Condens. Matter 2018, 30, 315801. [Google Scholar] [CrossRef] [PubMed]

- Arora, S.K.; Sofin, R.G.S.; Nolan, A.; Shvets, I.V. Antiphase Boundaries Induced Exchange Coupling in Epitaxial Fe3O4 Thin Films. J. Magn. Magn. Mater. 2005, 286, 463–467. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, K.; Zhang, R.; Li, J.; Zhang, S. Atomic-Scale Structural Properties in NiCo2O4/CuFe2O4 Bilayer Heterostructures on (001)-MgAl2O4 Substrate Regulated by Film Thickness. Materials 2024, 17, 871. https://doi.org/10.3390/ma17040871

Liu K, Zhang R, Li J, Zhang S. Atomic-Scale Structural Properties in NiCo2O4/CuFe2O4 Bilayer Heterostructures on (001)-MgAl2O4 Substrate Regulated by Film Thickness. Materials. 2024; 17(4):871. https://doi.org/10.3390/ma17040871

Chicago/Turabian StyleLiu, Kun, Ruyi Zhang, Jiankang Li, and Songyou Zhang. 2024. "Atomic-Scale Structural Properties in NiCo2O4/CuFe2O4 Bilayer Heterostructures on (001)-MgAl2O4 Substrate Regulated by Film Thickness" Materials 17, no. 4: 871. https://doi.org/10.3390/ma17040871