Antifungal Susceptibility Assessment of Innovative and Non-Conventional Lime Mortars Incorporating Almond-Shell Powder Bio-Waste Subjected to Particle-Dispersion Technique

Abstract

:1. Introduction

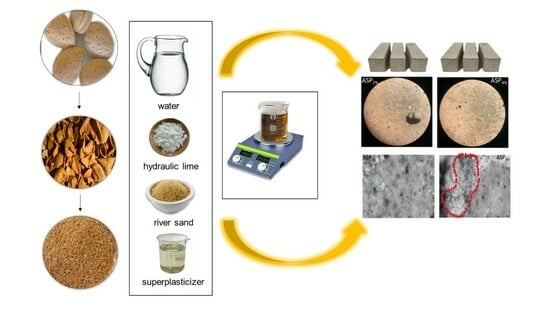

2. Materials and Methods

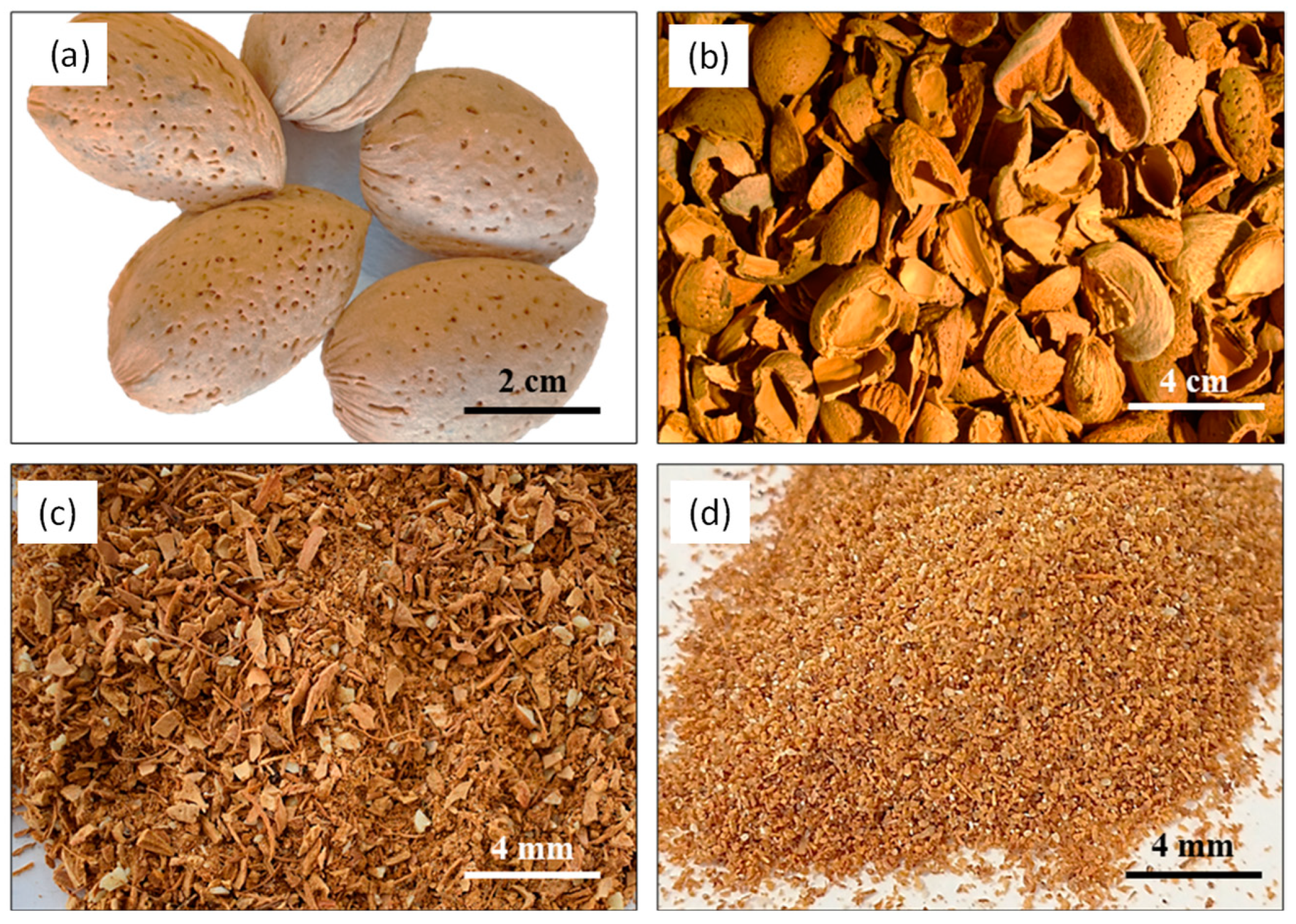

2.1. Materials

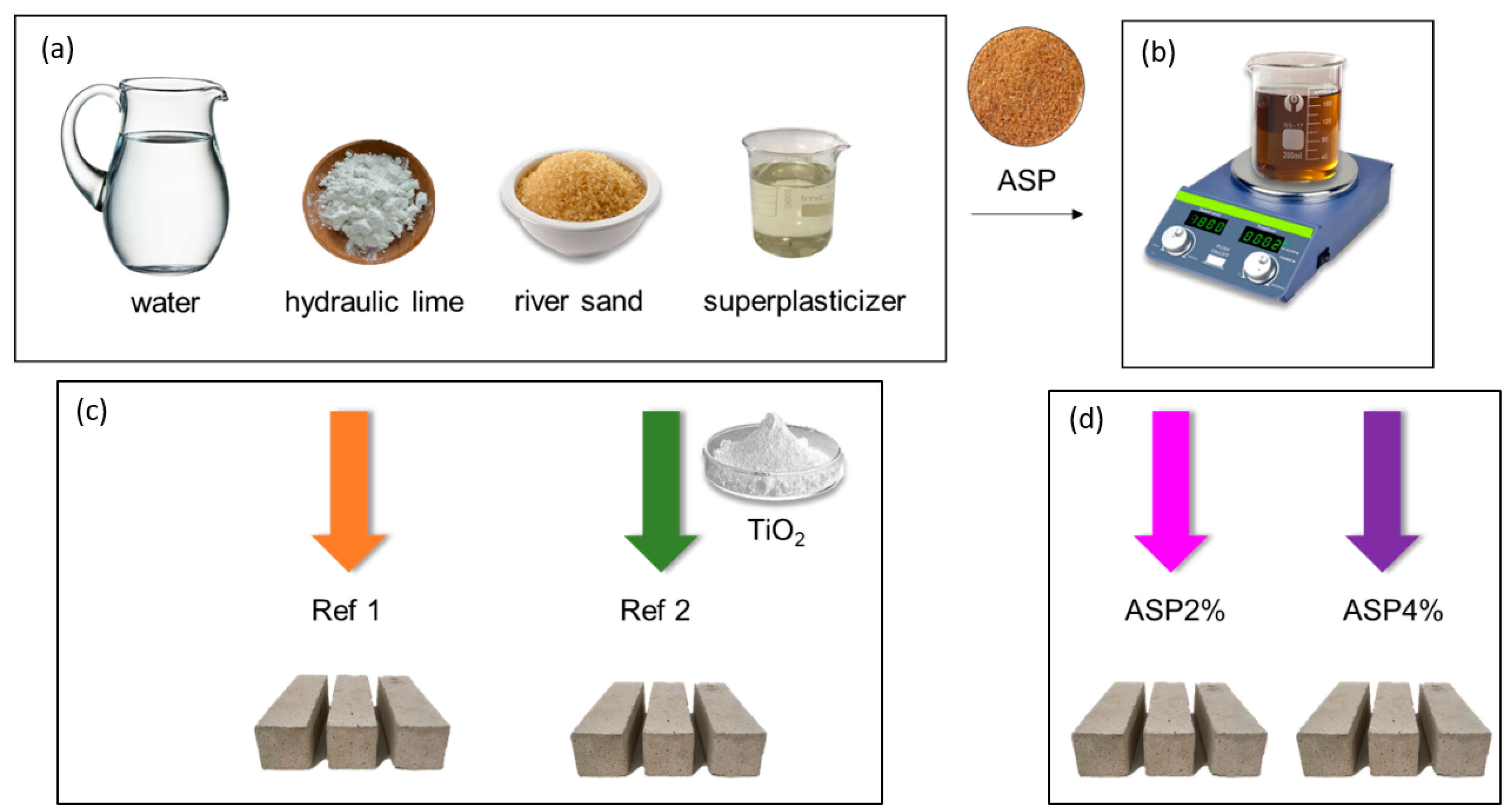

2.2. Samples Preparation

2.3. Compressive and Flexural Strength Tests

2.4. Water Absorption by Capillarity Tests

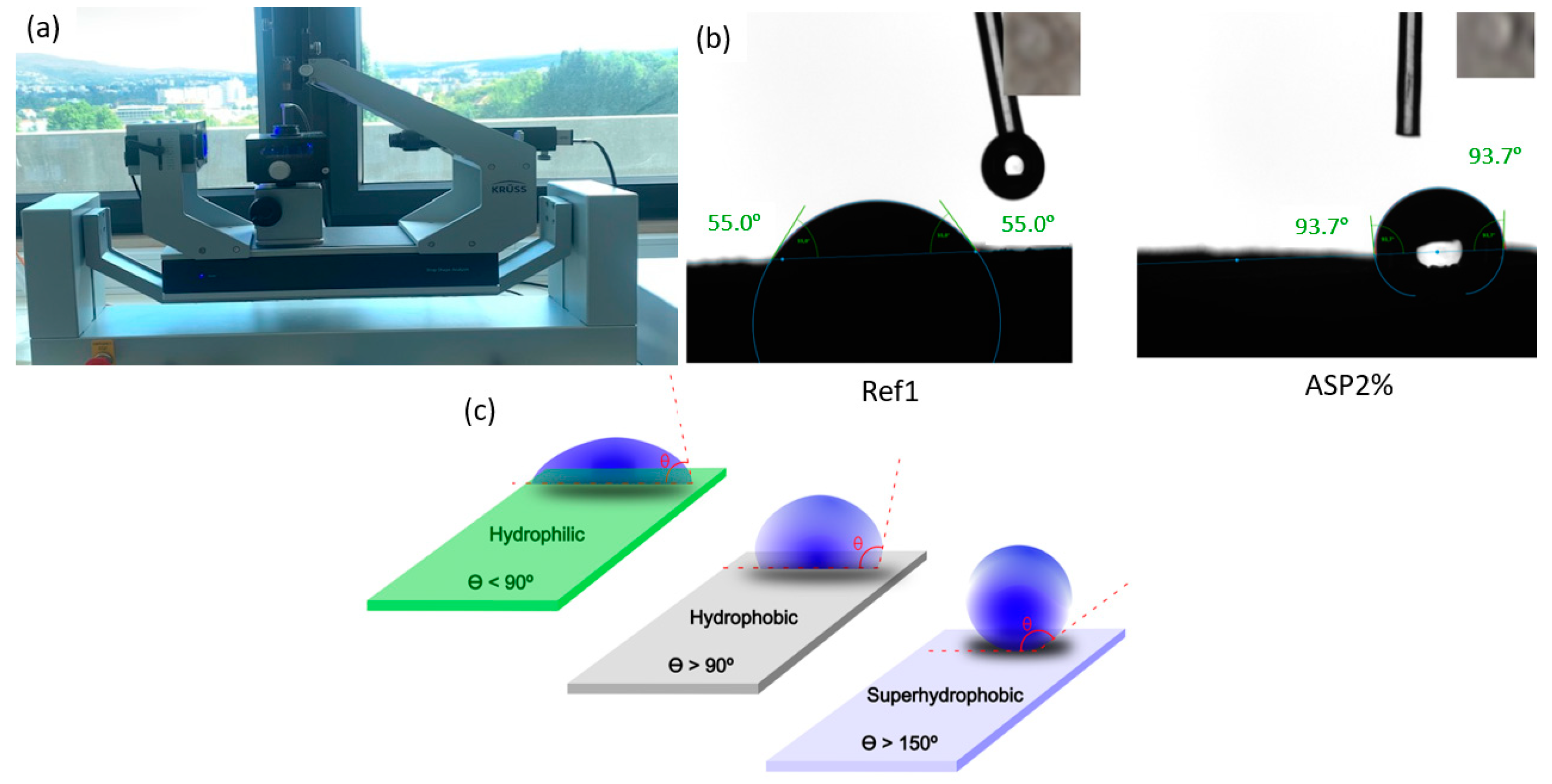

2.5. Contact-Angle Measurements

2.6. Accelerated Biological Susceptibility Evaluation

3. Results and Discussion

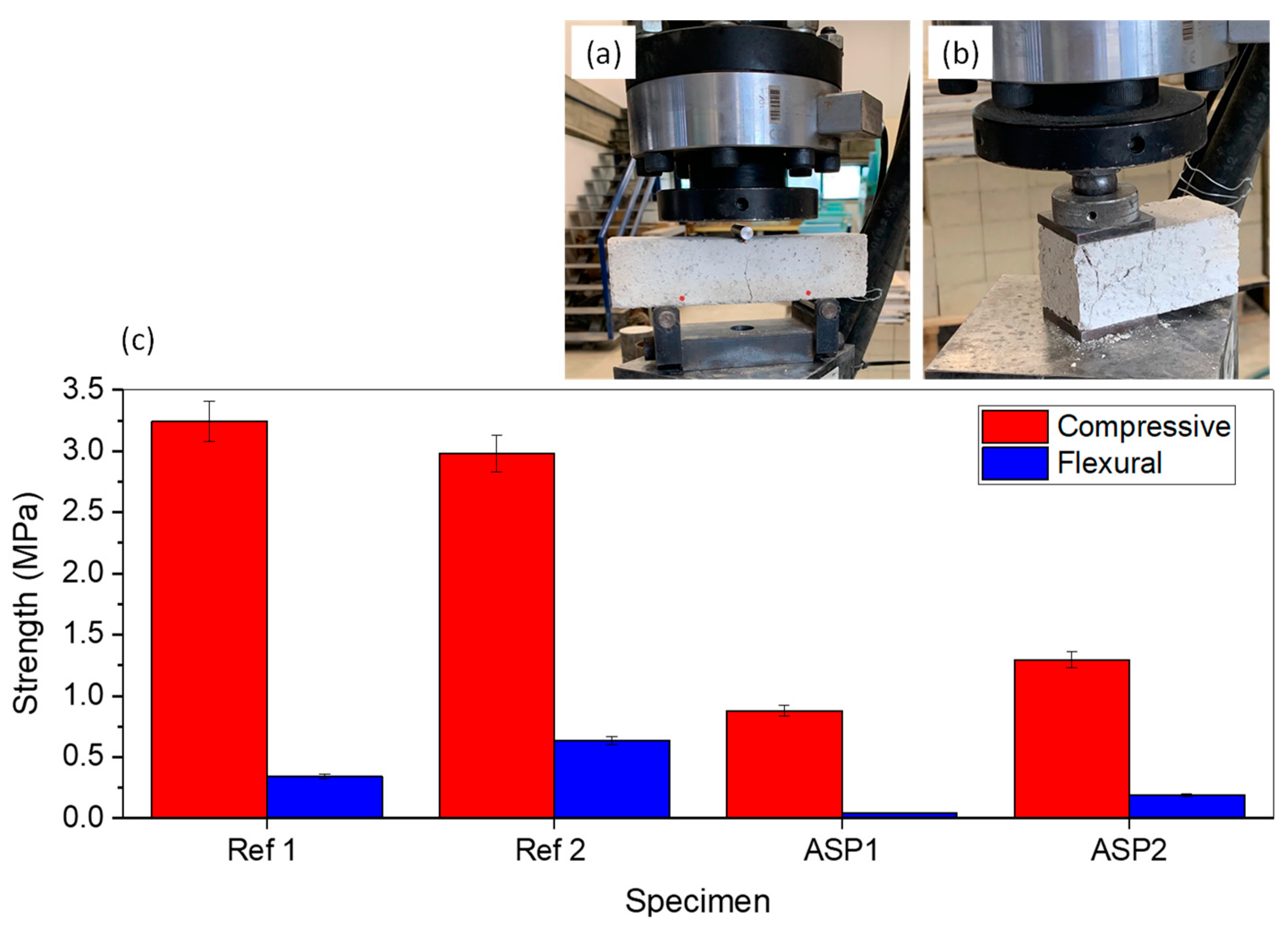

3.1. Flexural and Compressive Strength

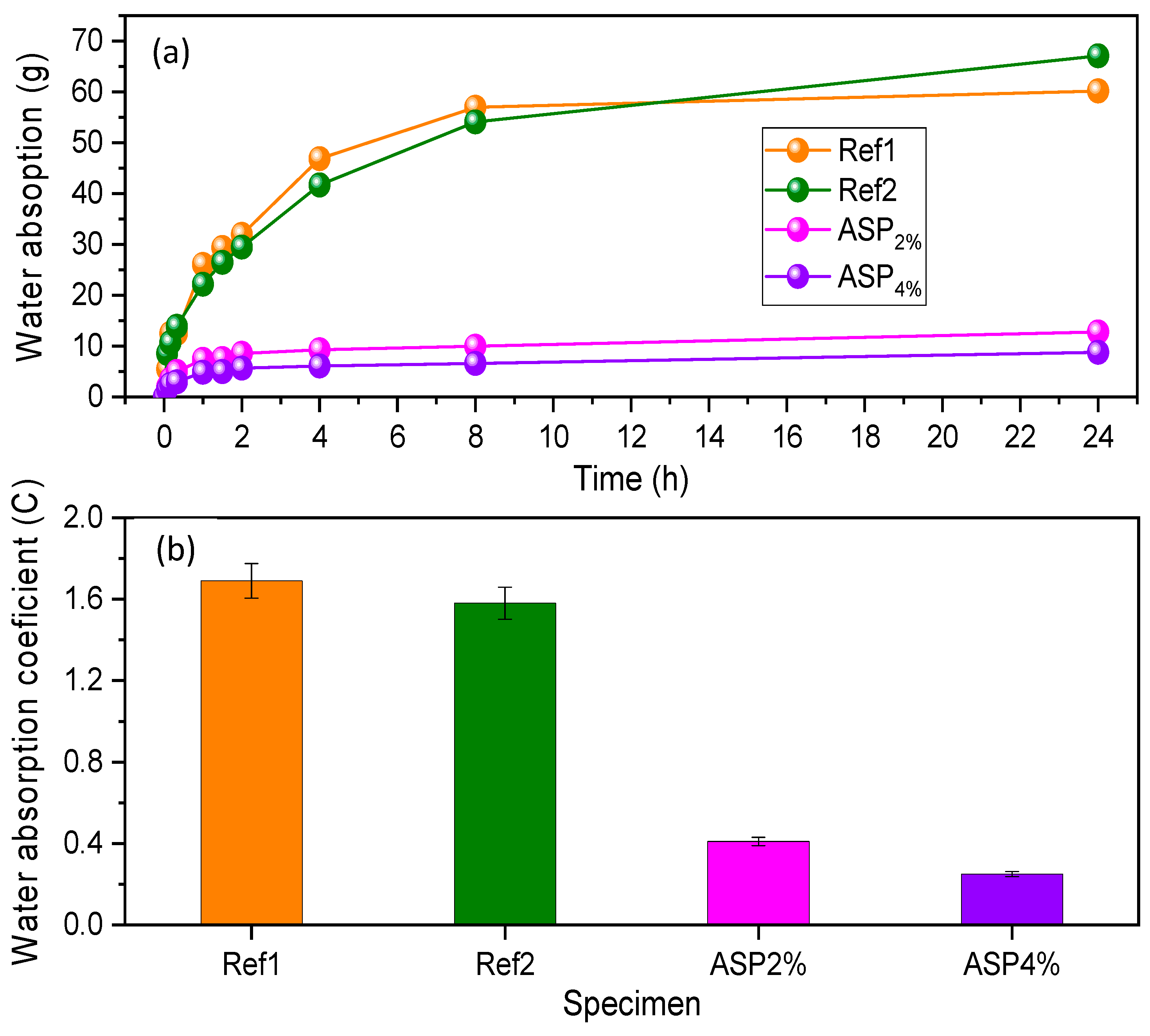

3.2. Water Absorption by Capillarity

3.3. Wettability Studies

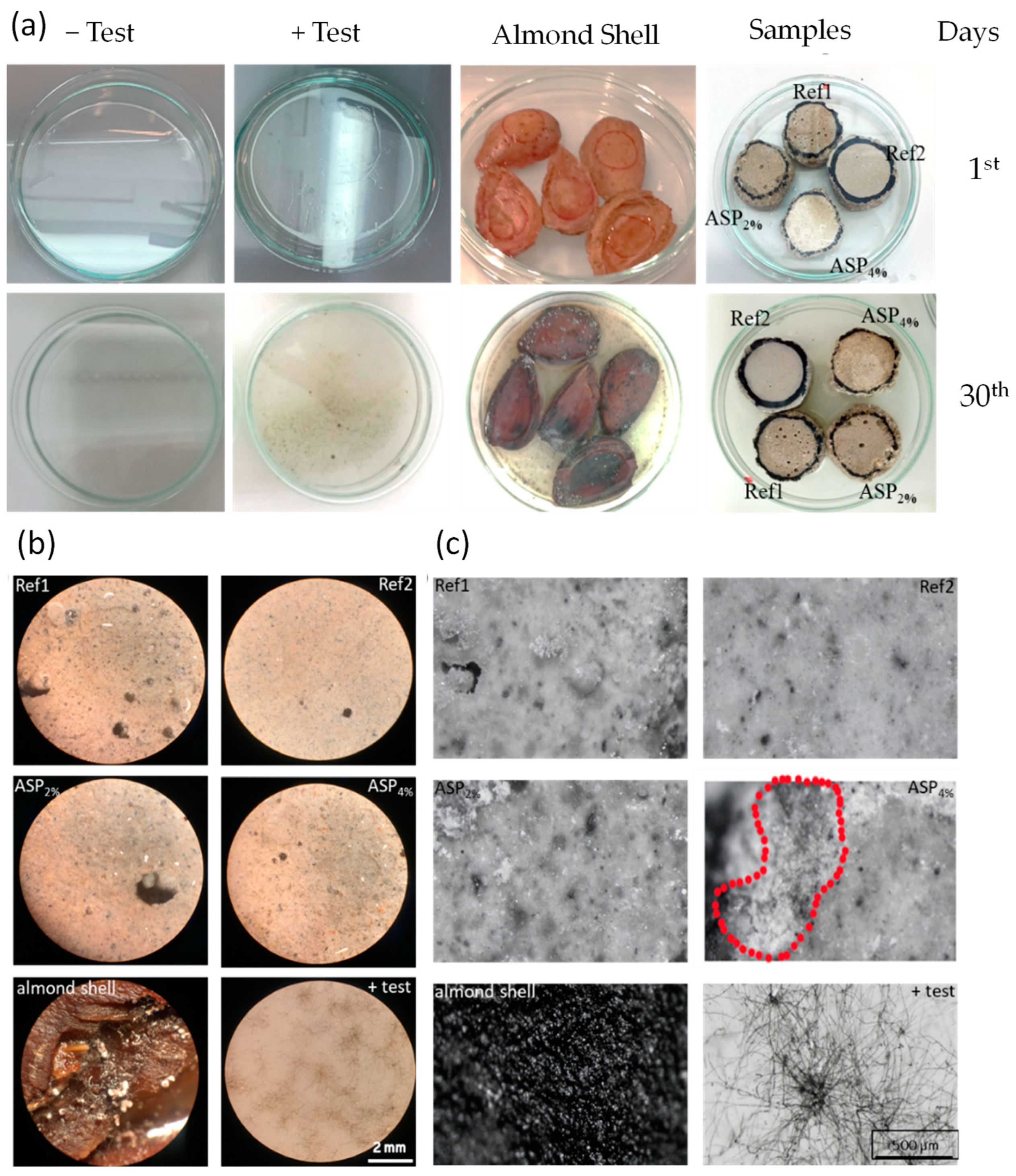

3.4. Accelerated Biological Susceptibility Evaluation

4. Conclusions

- -

- A reduction in the mortars’ mechanical properties is verified when ASP is added to the mixture. However, an increase in compressive and flexural strength is observed for a higher percentage of ASP. The introduction of 4% in the mixture led to an increase in compressive strength of 13% compared to ASP2%, which may be due to the powder’s particle size and its previous dispersion. Furthermore, ASP2% and ASP4% meet the standard requirements for mortars, as far as compressive strength is concerned;

- -

- An increase in ASP content results in better behavior of the mortars to water absorption by capillarity. The reference mortar with no ASP addition absorbed the greatest amount of water, while the mixtures with 2% and 4% of ASP presented a little variation in weight, demonstrating that they both absorbed a small amount of water, which can be an indicator of lower susceptibility to fungi growth. Accordingly, a lower value of the water-absorption coefficient was observed, being reduced as the ASP content increased. These results suggest that changes may occur at the microstructure level, namely at the pore–structure matrix, since when 4% of ASP was added to the mixture, an improvement of the mechanical and water absorption behavior was achieved;

- -

- The mortar with no ASP and the one incorporating n-TiO2 presented a hydrophilic character. When ASP was incorporated in the mortar formulation, less hydrophilic behavior only resulted for the introduction of 2% of ASP. The addition of 4% of ASP led to a contact-angle reduction and, therefore, to an increase in wettability, which may be related to the surface voids increase.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- European Commission. A European Green Deal: Striving to Be the First Climate-Neutral Continent. Available online: https://ec.europa.eu/info/strategy/priorities-2019-2024/european-green-deal_en (accessed on 13 December 2023).

- Hilton, S. Making Construction Materials Greener with Nanotechnology. 2020. Available online: https://blog.agchemigroup.eu/making-construction-materials-greener-with-nanotechnology/ (accessed on 13 December 2023).

- Hogancamp, J.; Grasley, Z. Dispersion of high concentrations of carbon nanofibers in portland cement mortars. J. Nanomater. 2017, 2017, 9375293. [Google Scholar] [CrossRef]

- Huppmann, T.; Yatsenko, S.; Krampe, E.; Kretschmer, K.; Bastian, M. Dióxido de Titânio Aumenta Ação Antimicrobiana em Compostos Plásticos. 2017. Available online: https://www.arandanet.com.br/revista/pi/materia/2017/05/13/dioxido_de_titanio.html (accessed on 13 December 2023). (In Portuguese).

- WNtow-Boahene; Cook, D.; Good, L. Antifungal polymeric materials and nanocomposites. Front. Bioeng. Biotechnol. 2021, 9, 1153. [Google Scholar] [CrossRef] [PubMed]

- Tyagi, P.; Verma, R.K.; Jain, N. Fungal degradation of cultural heritage monuments and management options. Curr. Sci. 2021, 121, 1553–1560. [Google Scholar] [CrossRef]

- Silva, N.C.; Madureira, A.R.; Pintado, M.; Moreira, P.R. Biocontamination and diversity of epilithic bacteria and fungi colonising outdoor stone and mortar sculptures. Appl. Microbiol. Biotechnol. 2022, 106, 3811–3828. [Google Scholar] [CrossRef]

- Szulc, J.; Komar, M.; Kata, I.; Szafran, K.; Gutarowska, B.J.C. Novel Method for Assessing the Protection Lifetime of Building Coatings against Fungi. Coatings 2023, 13, 2026. [Google Scholar] [CrossRef]

- Lobo, F.C.; Franco, A.R.; Fernandes, E.M.; Reis, R.L. An overview of the antimicrobial properties of lignocellulosic materials. Molecules 2021, 26, 1749. [Google Scholar] [CrossRef] [PubMed]

- Jerónimo, A.; Aguiar, B.; Soares, C.; Lima, N. Innovative coating materials to prevent fungi growth. In Viruses, Bacteria and Fungi in the Built Environment; Elsevier: Amsterdam, The Netherlands, 2022; pp. 289–310. [Google Scholar]

- Netregs. Pesticides and Biocides. 2023. Available online: https://www.netregs.org.uk/environmental-topics/materials-fuels-and-equipment/pesticides-and-biocides/ (accessed on 13 December 2023).

- Maltby, L.; Brock, T.C.; Van den Brink, P.J. Fungicide risk assessment for aquatic ecosystems: Importance of interspecific variation, toxic mode of action, and exposure regime. Environ. Sci. 2009, 43, 7556–7563. [Google Scholar] [CrossRef] [PubMed]

- Costerton, J.W.; Lewandowski, Z.; DeBeer, D.; Caldwell, D.; Korber, D.; James, G. Biofilms, the customized microniche. J. Bacteriol. 1994, 176, 2137–2142. [Google Scholar] [CrossRef] [PubMed]

- Foster, A.; Roberto, S.S.; Igari, A.T. Economia circular e resíduos sólidos: Uma revisão sistemática sobre a eficiência ambiental e econômica. In Proceedings of the 18th International Meeting on Business Management and the Environment (ENGEMA 2016), Sao Paulo, Brazil, 5–6 December 2016. (In Portuguese). [Google Scholar]

- Barreca, D.; Nabavi, S.M.; Sureda, A.; Rasekhian, M.; Raciti, R.; Silva, A.S.; Annunziata, G.; Arnone, A.; Tenore, G.C.; Süntar, I.; et al. Almonds (Prunus dulcis Mill. DA webb): A source of nutrients and health-promoting compounds. Nutrients 2020, 12, 672. [Google Scholar] [CrossRef] [PubMed]

- Hassler, M. World Plants. Synonymic Checklist and Distribution of the World Flora. Available online: https://www.worldplants.de/world-plants-complete-list/complete-plant-list/?name=Prunus-dulcis (accessed on 13 December 2023).

- Sottile, F.; Massaglia, S.; Peano, C. Ecological and economic indicators for the evaluation of almond (Prunus dulcis L.) orchard renewal in Sicily. Agriculture 2020, 10, 301. [Google Scholar] [CrossRef]

- Kester, D.E.; Gradziel, T.M.; Grasselly, C. Almonds (Prunus). Genet. Resour. Temp. Fruit Nut Crops 1991, 290, 701–760. [Google Scholar] [CrossRef]

- Doll, D.A.; Freire de Andrade, J.; Serrano, P. Produção de amêndoa em Portugal: Tendências de plantação e desafios de produção num setor em desenvolvimento. Artigo Técnico 2021. (In Portuguese) [Google Scholar]

- BioPOWDER. 2021. Available online: https://www.bio-powder.com/en/almond-shell-powder (accessed on 13 December 2023).

- Li, X.; Liu, Y.; Hao, J.; Wang, W. Study of almond shell characteristics. Materials 2018, 11, 1782. [Google Scholar] [CrossRef] [PubMed]

- Parveen, S.; Rana, S.; Fangueiro, R. A review on nanomaterial dispersion, microstructure, and mechanical properties of carbon nanotube and nanofiber reinforced cementitious composites. J. Nanomater. 2013, 2013, 80. [Google Scholar] [CrossRef]

- De Castro, A.; Pandolfelli, V.C. Revisão: Conceitos de dispersão e empacotamento de partículas para a produção de concretos especiais aplicados na construção civil. Cerâmica 2009, 55, 18–32. (In Portuguese) [Google Scholar] [CrossRef]

- Jain, P.; Gupta, R.; Chaudhary, S.J.M.T.P. A literature review on the effect of using ceramic waste as supplementary cementitious material in cement composites on workability and compressive strength. Mater. Today Proc. 2022, 65, 871–876. [Google Scholar] [CrossRef]

- Mackay, M.E.; Tuteja, A.; Duxbury, P.M.; Hawker, C.J.; Van Horn, B.; Guan, Z.; Chen, G.; Krishnan, R.S. General strategies for nanoparticle dispersion. Science 2006, 311, 1740–1743. [Google Scholar] [CrossRef] [PubMed]

- NP EN 1015-11:2019; Methods of Test for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar. ISO: Geneva, Switzerland, 2019.

- NP EN 1015-18:2002; Methods of Test for Mortar for Mansory—Part 18: Determination of Water Absorption Coefficient Due to Capillary Action of Hardened Mortar. ISO: Geneva, Switzerland, 2002.

- ISO 15148:2002; Hygrothermal Performance of Building Materials and Products—Determination of Water Absorption Coefficient by Partial Immersion. ISO: Geneva, Switzerland, 2002.

- Zhang, P.; Lv, F. A review of the recent advances in superhydrophobic surfaces and the emerging energy-related applications. Energy 2015, 82, 1068–1087. [Google Scholar] [CrossRef]

- Jerónimo, A.; Camões, A.; Aguiar, B.; Lima, N. Hydraulic lime mortars with antifungal properties. Appl. Surf. Sci. 2019, 483, 1192–1198. [Google Scholar] [CrossRef]

- Jerónimo, A.; Soares, C.; Aguiar, B.; Lima, N. Hydraulic lime mortars incorporating micro cork granules with antifungal properties. Constr. Build. Mater. 2020, 255, 119368. [Google Scholar] [CrossRef]

- NP EN 998-1:2013; Specification for Mortar for Masonry—Part 1: Rendering and Plastering Mortar. ISO: Geneva, Switzerland, 2013.

- ASTM G21-15(2021)e1; Standard Practice for Determining Resistance of Synthetic Polymeric Materials to Fungi. ASTM: West Conshohocken, PA, USA, 2015.

| Sample | Composition | NHL5 | Aggregates | SP | ASP | n-TiO2 | Water |

|---|---|---|---|---|---|---|---|

| Ref1 | 0% ASP | 500.00 | 1223.15 | 4.00 | 0.00 | 0.00 | 360.72 |

| Ref2 | 2% n-TiO2 | 500.00 | 1219.24 | 1.50 | 0.00 | 10.00 | 360.72 |

| ASP2% | 2% ASP | 500.00 | 1195.06 | 6.00 | 10.00 | 0.00 | 360.72 |

| ASP4% | 4% ASP | 500.00 | 1166.96 | 8.00 | 20.00 | 0.00 | 360.72 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jerónimo, A.; Loureiro, M.; Fernandes, M.; De Zea Bermudez, V.; Briga-Sá, A. Antifungal Susceptibility Assessment of Innovative and Non-Conventional Lime Mortars Incorporating Almond-Shell Powder Bio-Waste Subjected to Particle-Dispersion Technique. Materials 2024, 17, 1426. https://doi.org/10.3390/ma17061426

Jerónimo A, Loureiro M, Fernandes M, De Zea Bermudez V, Briga-Sá A. Antifungal Susceptibility Assessment of Innovative and Non-Conventional Lime Mortars Incorporating Almond-Shell Powder Bio-Waste Subjected to Particle-Dispersion Technique. Materials. 2024; 17(6):1426. https://doi.org/10.3390/ma17061426

Chicago/Turabian StyleJerónimo, Alexandre, Mafalda Loureiro, Mariana Fernandes, Verónica De Zea Bermudez, and Ana Briga-Sá. 2024. "Antifungal Susceptibility Assessment of Innovative and Non-Conventional Lime Mortars Incorporating Almond-Shell Powder Bio-Waste Subjected to Particle-Dispersion Technique" Materials 17, no. 6: 1426. https://doi.org/10.3390/ma17061426