In Situ Microstructure Modification Using a Layerwise Surface-Preheating Laser Scan of Ti-6Al-4V during Laser Powder Bed Fusion

Abstract

1. Introduction

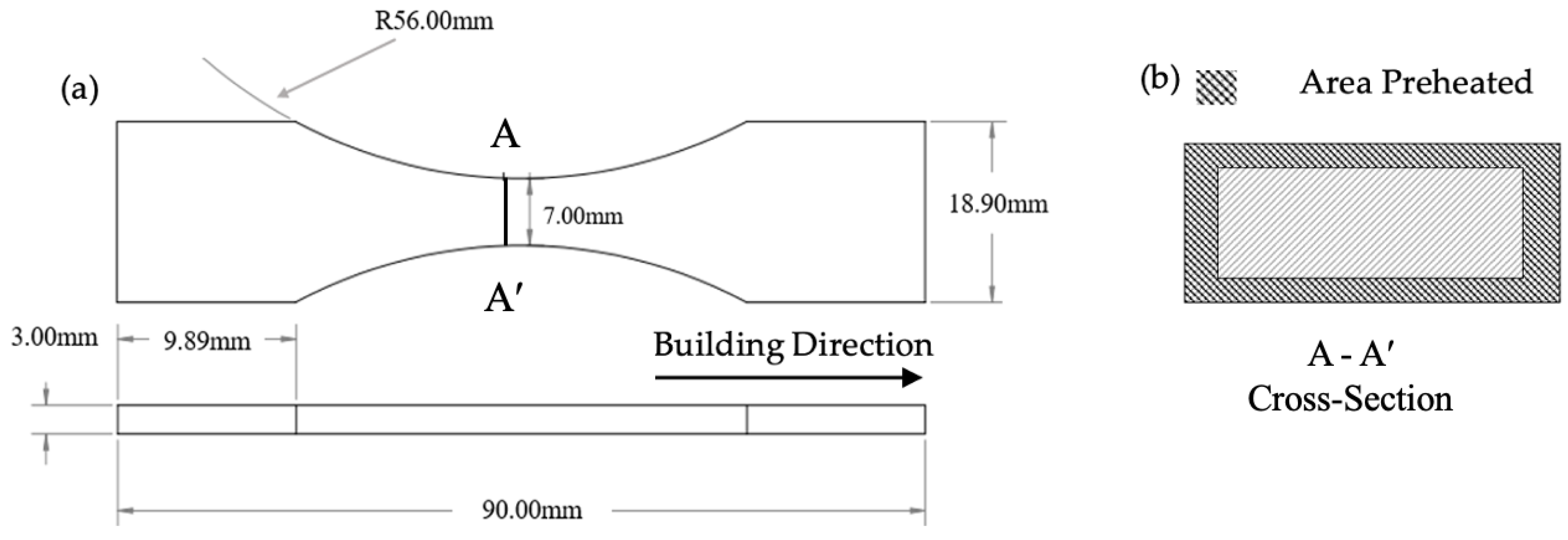

2. Materials and Methods

3. Results

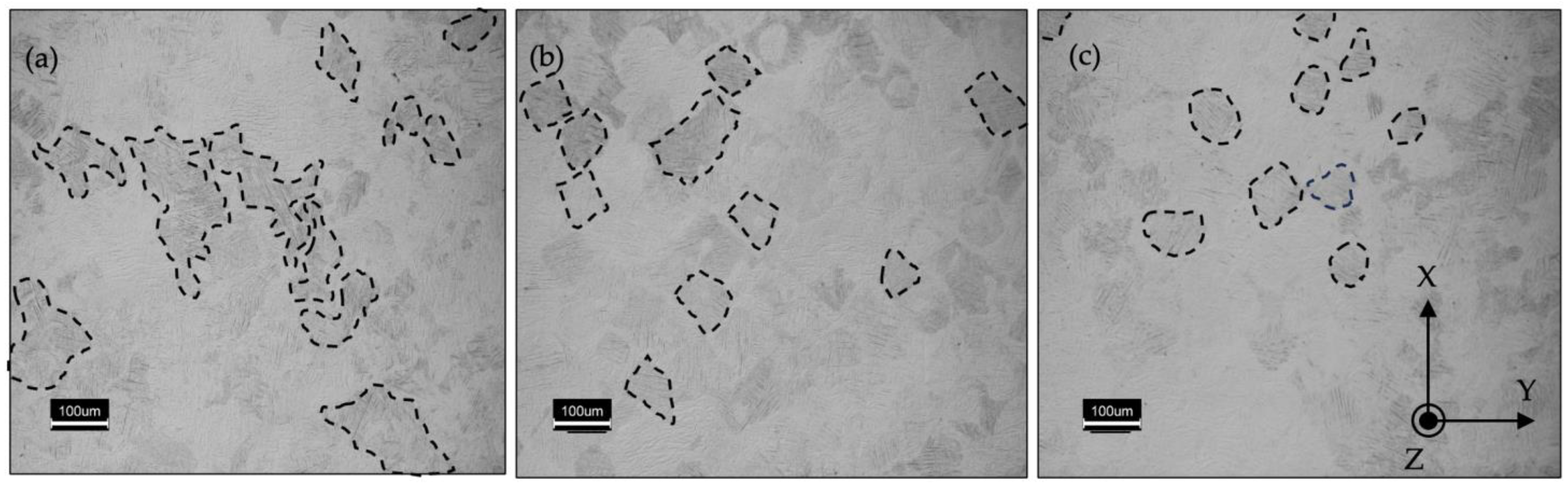

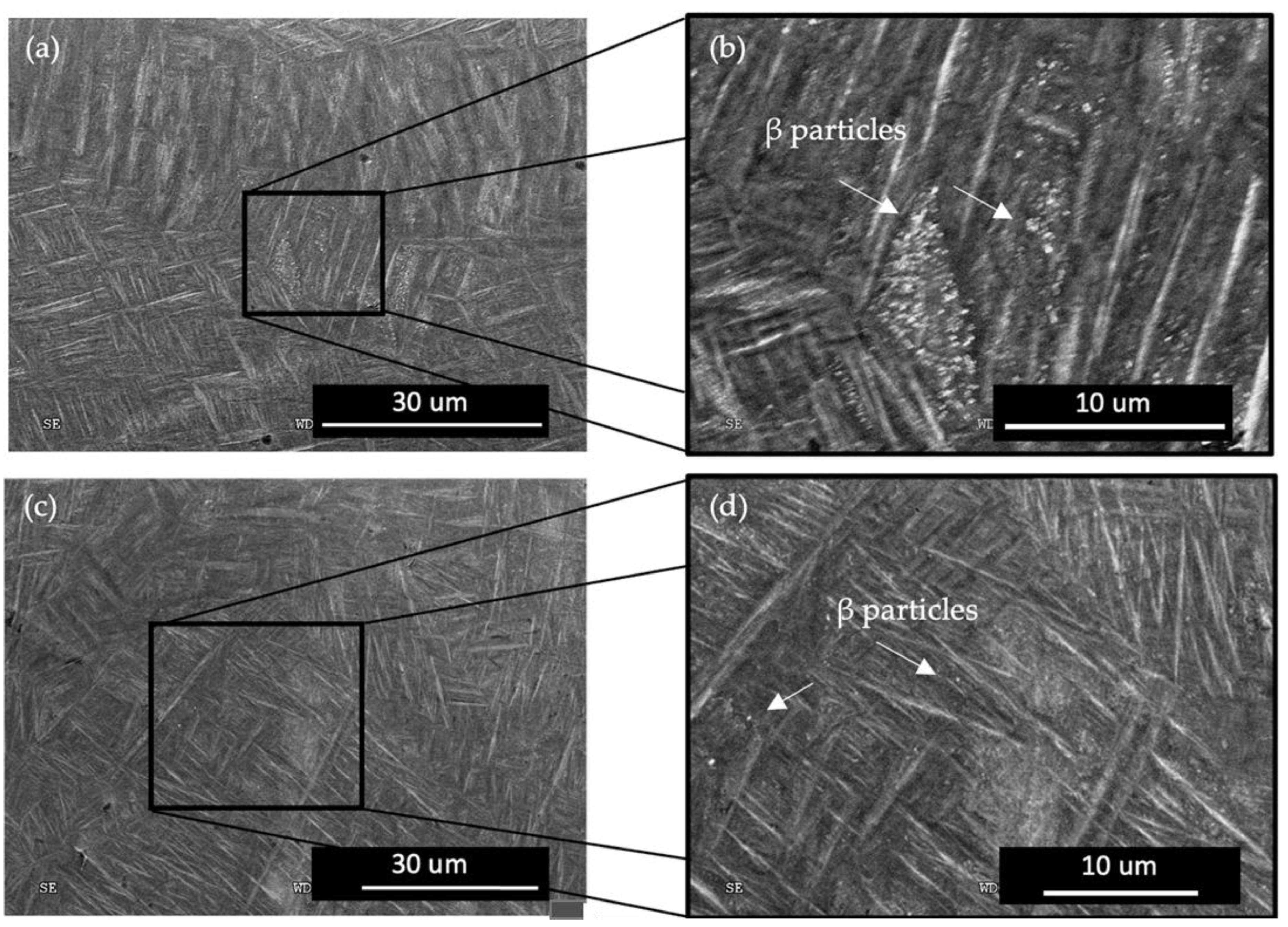

3.1. Microstructure Modification

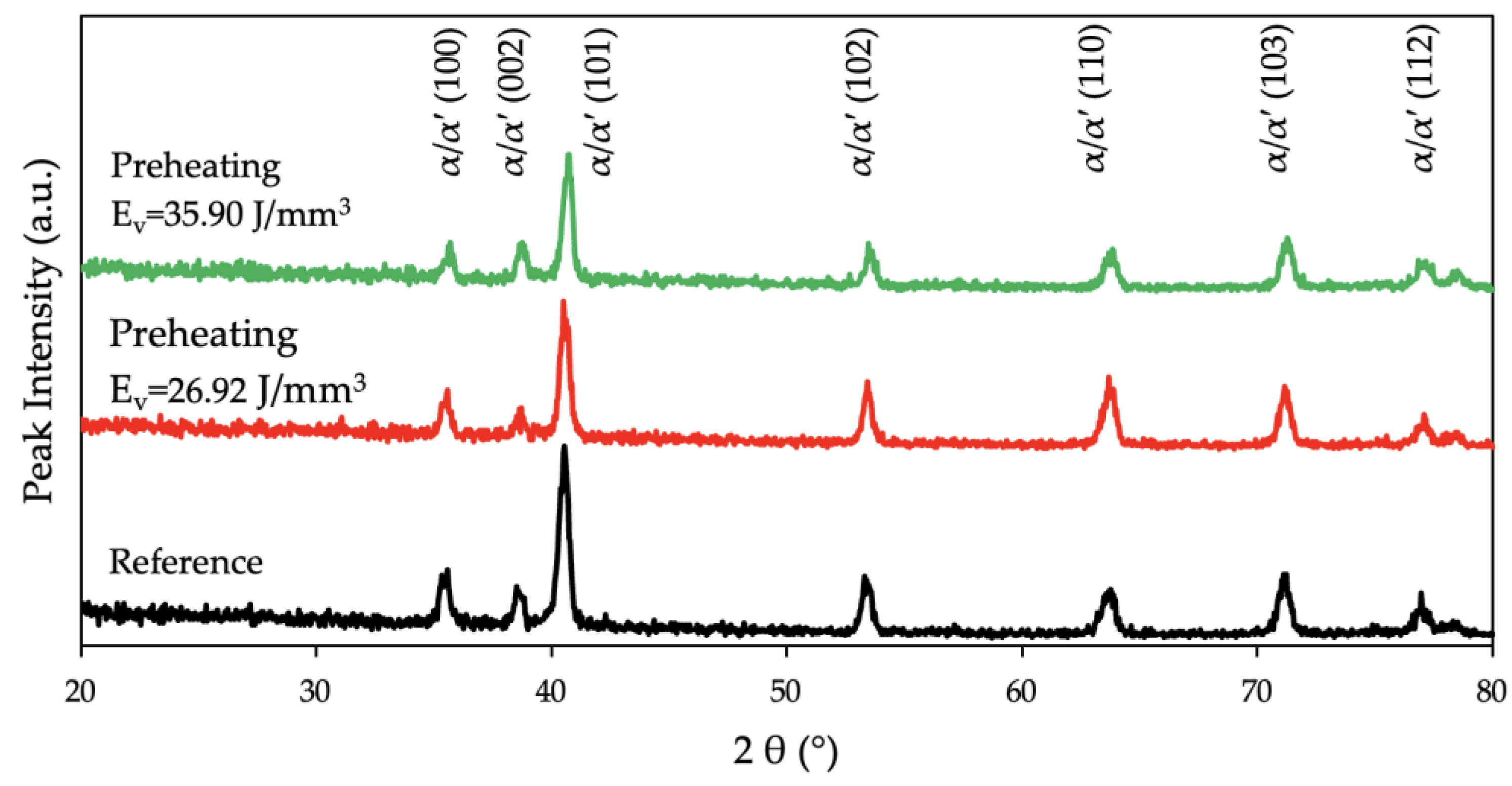

3.2. Crystallography

3.3. Surface Properties

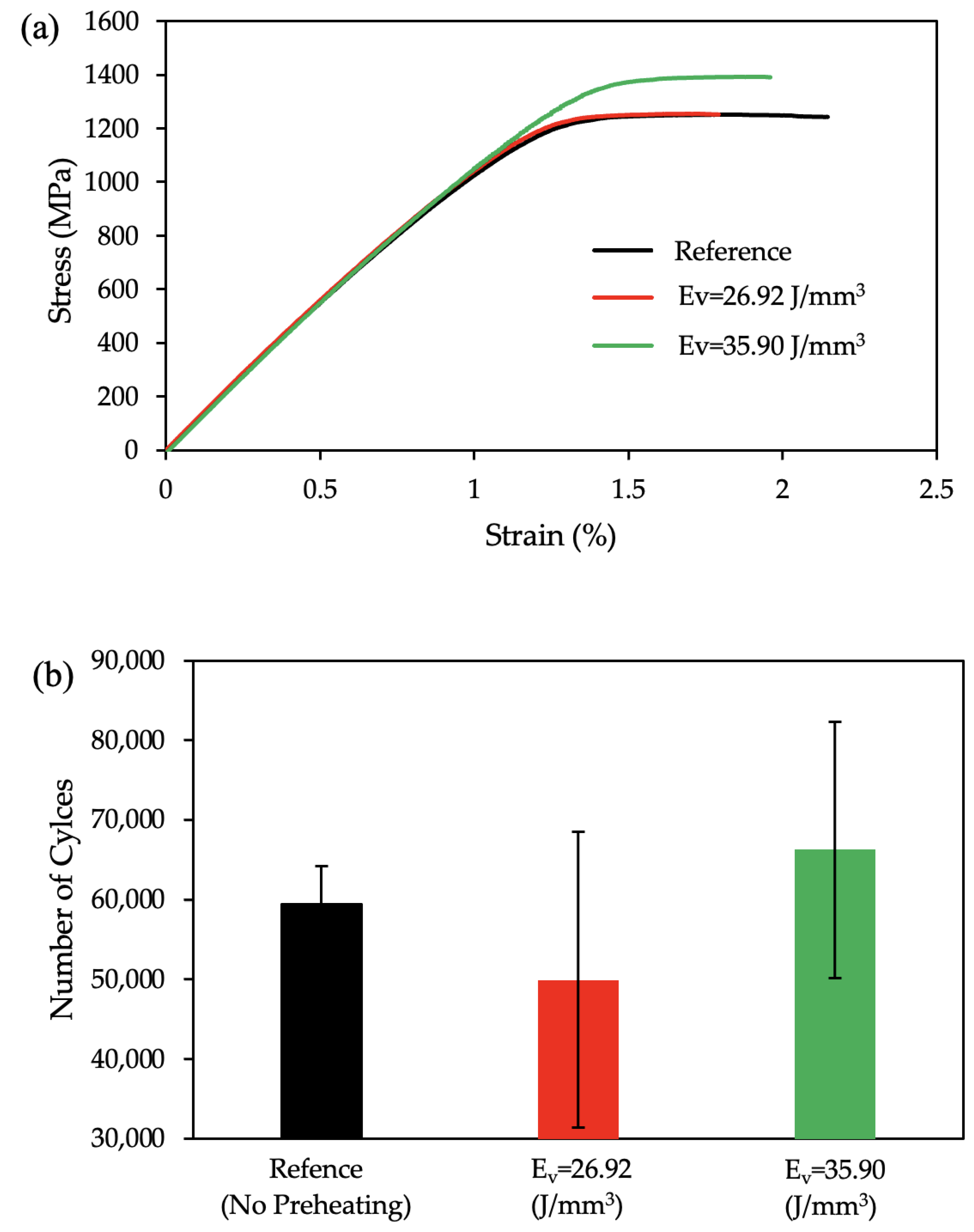

3.4. Mechanical Properties

4. Discussion

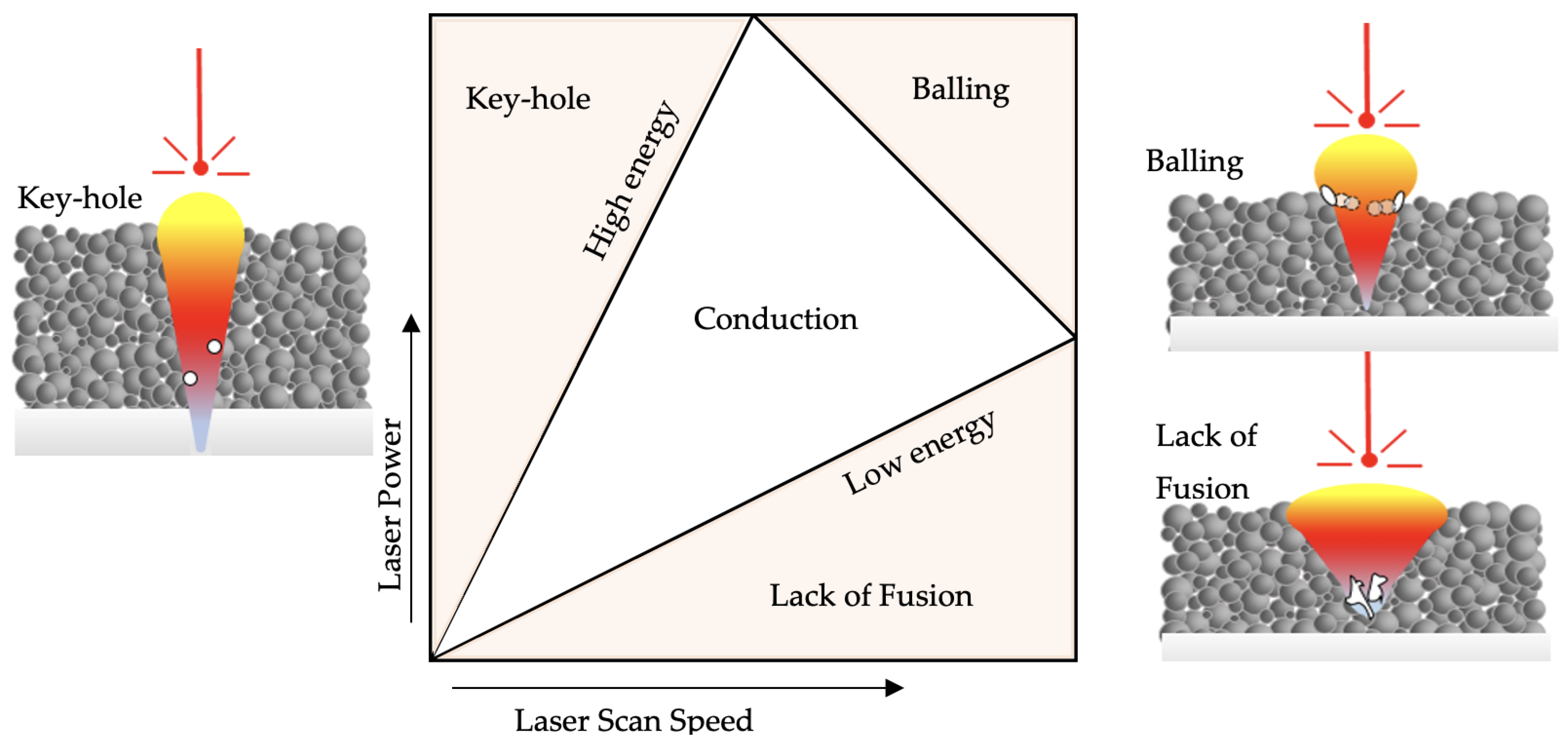

4.1. Preheating Laser Scan Energy Management to Control Defect Formation

4.2. Microstructure Refinement in Ti-6Al-4V Using LPBF

4.3. Functionally Graded Microstructure for the Enhanced Fatigue Behavior of LPBF-Fabricated Ti-6Al-4V

5. Conclusions

- Microstructural analysis demonstrates that the prior β-grain boundaries differ during the LPBF process. By performing preheating, the prior β-grain structure is modified along the XY plane. Low-energy preheating results in a quadratic grain structure and high-energy preheating, on the other hand, produces a circular prior β-grain structure.

- The lath thickness is increased by performing preheating during LPBF. This increment is related to the reduction in the cooling rate resulting from the higher energy input in the preheated samples compared to the reference ones.

- By performing preheating, the decomposition disparity is promoted, and some brighter regions are formed within the microstructure. Furthermore, the number of these brighter regions is enhanced by increasing the energy density in the preheated specimens. Further studies regarding these particles showed that they represent the β phase in the microstructure at RT.

- Results of the W-H analysis assert that the microstrain does not follow any trend between the different preheating regimes; however, its value reveals the presence of the tensile strain within the microstructure. Also, it is worthwhile to note that the lattice parameters of a and c are reduced by performing preheating. Quite contrary to this, the ratio of c/a is enhanced as expected due to the lattice strain relaxation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- He, Y.; Montgomery, C.; Beuth, J.; Webler, B. Melt Pool Geometry and Microstructure of Ti6Al4V with B Additions Processed by Selective Laser Melting Additive Manufacturing. Mater. Des. 2019, 183, 108126. [Google Scholar] [CrossRef]

- Salmi, M. Design and Applications of Additive Manufacturing and 3D Printing. Designs 2022, 6, 6. [Google Scholar] [CrossRef]

- Gong, H.; Rafi, K.; Gu, H.; Janaki Ram, G.D.; Starr, T.; Stucker, B. Influence of Defects on Mechanical Properties of Ti-6Al-4V Components Produced by Selective Laser Melting and Electron Beam Melting. Mater. Des. 2015, 86, 545–554. [Google Scholar] [CrossRef]

- Leuders, S.; Thöne, M.; Riemer, A.; Niendorf, T.; Tröster, T.; Richard, H.A.; Maier, H.J. On the Mechanical Behaviour of Titanium Alloy TiAl6V4 Manufactured by Selective Laser Melting: Fatigue Resistance and Crack Growth Performance. Int. J. Fatigue 2013, 48, 300–307. [Google Scholar] [CrossRef]

- Agius, D.; Kourousis, K.I.; Wallbrink, C. A Review of the As-Built SLM Ti-6Al-4V Mechanical Properties towards Achieving Fatigue Resistant Designs. Metals 2018, 8, 75. [Google Scholar] [CrossRef]

- Prashanth, K.G. Selective Laser Melting: Materials and Applications. J. Manuf. Mater. Process. 2020, 4, 13. [Google Scholar] [CrossRef]

- Liu, S.; Shin, Y.C. Additive Manufacturing of Ti6Al4V Alloy: A Review. Mater. Des. 2019, 164, 107552. [Google Scholar] [CrossRef]

- Gerd Lütjering, J.C.W. Titanium; Engineering Materials, Processes; Springer: Berlin/Heidelberg, Germany, 2007; ISBN 978-3-540-71397-5. [Google Scholar]

- Boyer, R.R. An Overview on the Use of Titanium in the Aerospace Industry. Mater. Sci. Eng. A 1996, 213, 103–114. [Google Scholar] [CrossRef]

- Singh, P.; Pungotra, H.; Kalsi, N.S. On the Characteristics of Titanium Alloys for the Aircraft Applications. Mater. Today Proc. 2017, 4, 8971–8982. [Google Scholar] [CrossRef]

- Liu, J.; Sun, Q.; Zhou, C.; Wang, X.; Li, H.; Guo, K.; Sun, J. Achieving Ti6Al4V Alloys with Both High Strength and Ductility via Selective Laser Melting. Mater. Sci. Eng. A 2019, 766, 138319. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, D.; Guo, Y.; Hu, S.; Wu, X.; Jiang, Y. Microstructural Tailoring of As-Selective Laser Melted Ti6Al4V Alloy for High Mechanical Properties. J. Alloys Compd. 2020, 816, 152536. [Google Scholar] [CrossRef]

- Yan, X.; Yin, S.; Chen, C.; Huang, C.; Bolot, R.; Lupoi, R.; Kuang, M.; Ma, W.; Coddet, C.; Liao, H.; et al. Effect of Heat Treatment on the Phase Transformation and Mechanical Properties of Ti6Al4V Fabricated by Selective Laser Melting. J. Alloys Compd. 2018, 764, 1056–1071. [Google Scholar] [CrossRef]

- Dai, N.; Zhang, L.C.; Zhang, J.; Zhang, X.; Ni, Q.; Chen, Y.; Wu, M.; Yang, C. Distinction in Corrosion Resistance of Selective Laser Melted Ti-6Al-4V Alloy on Different Planes. Corros. Sci. 2016, 111, 703–710. [Google Scholar] [CrossRef]

- Kanganga, M.; du Plessis, A.; Muvunzi, R.; Khodja, M. A Review of the Effects of Laser Shock Peening on Properties of Additively Manufactured Ti6Al4V. In Fatigue in Additive Manufactured Metals; Elsevier: Amsterdam, The Netherlands, 2024; pp. 235–257. [Google Scholar]

- Cao, F.; Zhang, T.; Ryder, M.A.; Lados, D.A. A Review of the Fatigue Properties of Additively Manufactured Ti-6Al-4V. Jom 2018, 70, 349–357. [Google Scholar] [CrossRef]

- Xu, W.; Sun, S.; Elambasseril, J.; Liu, Q.; Brandt, M.; Qian, M. Ti-6Al-4V Additively Manufactured by Selective Laser Melting with Superior Mechanical Properties. JOM 2015, 67, 668–673. [Google Scholar] [CrossRef]

- Sun, C.; Chi, W.; Wang, W.; Duan, Y. Characteristic and Mechanism of Crack Initiation and Early Growth of an Additively Manufactured Ti-6Al-4V in Very High Cycle Fatigue Regime. Int. J. Mech. Sci. 2021, 205, 106591. [Google Scholar] [CrossRef]

- Du, L.; Pan, X.; Qian, G.; Zheng, L.; Hong, Y. Crack Initiation Mechanisms under Two Stress Ratios up to Very-High-Cycle Fatigue Regime for a Selective Laser Melted Ti-6Al-4V. Int. J. Fatigue 2021, 149, 106294. [Google Scholar] [CrossRef]

- Walker, K.F.; Liu, Q.; Brandt, M. Evaluation of Fatigue Crack Propagation Behaviour in Ti-6Al-4V Manufactured by Selective Laser Melting. Int. J. Fatigue 2017, 104, 302–308. [Google Scholar] [CrossRef]

- Syed, A.K.; Ahmad, B.; Guo, H.; Machry, T.; Eatock, D.; Meyer, J.; Fitzpatrick, M.E.; Zhang, X. An Experimental Study of Residual Stress and Direction-Dependence of Fatigue Crack Growth Behaviour in as-Built and Stress-Relieved Selective-Laser-Melted Ti6Al4V. Mater. Sci. Eng. A 2019, 755, 246–257. [Google Scholar] [CrossRef]

- Jesus, J.S.; Borrego, L.P.; Ferreira, J.A.M.; Costa, J.D.; Capela, C. Fatigue Crack Growth Behaviour in Ti6Al4V Alloy Specimens Produced by Selective Laser Melting. Int. J. Fract. 2020, 223, 123–133. [Google Scholar] [CrossRef]

- Boschetto, A.; Bottini, L.; Macera, L.; Veniali, F. Post-Processing of Complex SLM Parts by Barrel Finishing. Appl. Sci. 2020, 10, 1382. [Google Scholar] [CrossRef]

- Liu, R.; Wang, Z.; Sparks, T.; Liou, F.; Newkirk, J. Aerospace Applications of Laser Additive Manufacturing; Elsevier Ltd.: Amsterdam, The Netherlands, 2017; ISBN 9780081004340. [Google Scholar]

- Kadirgama, K.; Harun, W.S.W.; Tarlochan, F.; Samykano, M.; Ramasamy, D.; Azir, M.Z.; Mehboob, H. Statistical and Optimize of Lattice Structures with Selective Laser Melting (SLM) of Ti6AL4V Material. Int. J. Adv. Manuf. Technol. 2018, 97, 495–510. [Google Scholar] [CrossRef]

- Seabra, M.; Azevedo, J.; Araújo, A.; Reis, L.; Pinto, E.; Alves, N.; Santos, R.; Pedro Mortágua, J. Selective Laser Melting (SLM) and Topology Optimization for Lighter Aerospace Componentes. Procedia Struct. Integr. 2016, 1, 289–296. [Google Scholar] [CrossRef]

- Elambasseril, J.; Rogers, J.; Wallbrink, C.; Munk, D.; Leary, M.; Qian, M. Laser Powder Bed Fusion Additive Manufacturing (LPBF-AM): The Influence of Design Features and LPBF Variables on Surface Topography and Effect on Fatigue Properties. Crit. Rev. Solid State Mater. Sci. 2022, 48, 132–168. [Google Scholar] [CrossRef]

- Kahlin, M.; Ansell, H.; Basu, D.; Kerwin, A.; Newton, L.; Smith, B.; Moverare, J.J. Improved Fatigue Strength of Additively Manufactured Ti6Al4V by Surface Post Processing. Int. J. Fatigue 2020, 134, 105497. [Google Scholar] [CrossRef]

- Vayssette, B.; Saintier, N.; Brugger, C.; Elmay, M.; Pessard, E. Surface Roughness of Ti-6Al-4V Parts Obtained by SLM and EBM: Effect on the High Cycle Fatigue Life. Procedia Eng. 2018, 213, 89–97. [Google Scholar] [CrossRef]

- Ge, J.; Huang, J.; Lei, Y.; O’Reilly, P.; Ahmed, M.; Zhang, C.; Yan, X.; Yin, S. Microstructural Features and Compressive Properties of SLM Ti6Al4V Lattice Structures. Surf. Coat. Technol. 2020, 403, 126419. [Google Scholar] [CrossRef]

- Alghamdi, A.; Downing, D.; McMillan, M.; Brandt, M.; Qian, M.; Leary, M. Experimental and Numerical Assessment of Surface Roughness for Ti6Al4V Lattice Elements in Selective Laser Melting. Int. J. Adv. Manuf. Technol. 2019, 105, 1275–1293. [Google Scholar] [CrossRef]

- Aufa, A.N.; Hassan, M.Z.; Ismail, Z.; Harun, N.; Ren, J.; Sadali, M.F. Surface Enhancement of Ti–6Al–4V Fabricated by Selective Laser Melting on Bone-like Apatite Formation. J. Mater. Res. Technol. 2022, 19, 4018–4030. [Google Scholar] [CrossRef]

- Salem, H.; Carter, L.N.; Attallah, M.M.; Salem, H.G. Influence of Processing Parameters on Internal Porosity and Types of Defects Formed in Ti6Al4V Lattice Structure Fabricated by Selective Laser Melting. Mater. Sci. Eng. A 2019, 767, 138387. [Google Scholar] [CrossRef]

- Chastand, V.; Tezenas, A.; Cadoret, Y.; Quaegebeur, P.; Maia, W.; Charkaluk, E. Fatigue Characterization of Titanium Ti-6Al-4V Samples Produced by Additive Manufacturing. Procedia Struct. Integr. 2016, 2, 3168–3176. [Google Scholar] [CrossRef]

- Hartunian, P.; Eshraghi, M. Effect of Build Orientation on the Microstructure and Mechanical Properties of Selective Laser-Melted Ti-6Al-4V Alloy. J. Manuf. Mater. Process. 2018, 2, 69. [Google Scholar] [CrossRef]

- Agius, D.; Kourousis, K.I.; Wallbrink, C.; Song, T. Cyclic Plasticity and Microstructure of As-Built SLM Ti-6Al-4V: The Effect of Build Orientation. Mater. Sci. Eng. A 2017, 701, 85–100. [Google Scholar] [CrossRef]

- Krakhmalev, P.; Fredriksson, G.; Yadroitsava, I.; Kazantseva, N.; Du Plessis, A.; Yadroitsev, I. Deformation Behavior and Microstructure of Ti6Al4V Manufactured by SLM. Phys. Procedia 2016, 83, 778–788. [Google Scholar] [CrossRef]

- Cai, W.; Song, Q.; Ji, H.; Gupta, M.K. Multi-Perspective Analysis of Building Orientation Effects on Microstructure, Mechanical and Surface Properties of Slm Ti6al4v with Specific Geometry. Materials 2021, 14, 4392. [Google Scholar] [CrossRef] [PubMed]

- Kumar, P.; Ramamurty, U. Microstructural Optimization through Heat Treatment for Enhancing the Fracture Toughness and Fatigue Crack Growth Resistance of Selective Laser Melted Ti–6Al–4V Alloy. Acta Mater. 2019, 169, 45–59. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, J.; Li, S.-J.; Hou, W.-T.; Wang, H.; Xu, Q.-S.; Hao, Y.-L.; Yang, R. Effect of HIP Treatment on Fatigue Crack Growth Behavior of Ti–6Al–4V Alloy Fabricated by Electron Beam Melting. Acta Metall. Sin. (Engl. Lett.) 2017, 30, 1163–1168. [Google Scholar] [CrossRef]

- Chastand, V.; Quaegebeur, P.; Maia, W.; Charkaluk, E. Comparative Study of Fatigue Properties of Ti-6Al-4V Specimens Built by Electron Beam Melting (EBM) and Selective Laser Melting (SLM). Mater. Charact. 2018, 143, 76–81. [Google Scholar] [CrossRef]

- De Biasi, R.; Murchio, S.; Sbettega, E.; Carmignato, S.; Luchin, V.; Benedetti, M. Efficient Optimization Framework for L-PBF Fatigue Enhanced Ti6Al4V Lattice Component. Mater. Des. 2023, 230, 111975. [Google Scholar] [CrossRef]

- Bartolomeu, F.; Gasik, M.; Silva, F.S.; Miranda, G. Mechanical Properties of Ti6Al4V Fabricated by Laser Powder Bed Fusion: A Review Focused on the Processing and Microstructural Parameters Influence on the Final Properties. Metals 2022, 12, 986. [Google Scholar] [CrossRef]

- Hosseini, S.M.; Vaghefi, E.; Mirkoohi, E. The Role of Defect Structure and Residual Stress on Fatigue Failure Mechanisms of Ti-6Al-4V Manufactured via Laser Powder Bed Fusion: Effect of Process Parameters and Geometrical Factors. J. Manuf. Process. 2023, 102, 549–563. [Google Scholar] [CrossRef]

- Xu, W.; Lui, E.W.; Pateras, A.; Qian, M.; Brandt, M. In Situ Tailoring Microstructure in Additively Manufactured Ti-6Al-4V for Superior Mechanical Performance. Acta Mater. 2017, 125, 390–400. [Google Scholar] [CrossRef]

- Ali, H.; Ma, L.; Ghadbeigi, H.; Mumtaz, K. In-Situ Residual Stress Reduction, Martensitic Decomposition and Mechanical Properties Enhancement through High Temperature Powder Bed Pre-Heating of Selective Laser Melted Ti6Al4V. Mater. Sci. Eng. A 2017, 695, 211–220. [Google Scholar] [CrossRef]

- Gomez-Gallegos, A.; Mandal, P.; Gonzalez, D.; Zuelli, N.; Blackwell, P. Studies on Titanium Alloys for Aerospace Application. Defect Diffus. Forum 2018, 385, 419–423. [Google Scholar] [CrossRef]

- Niinomi, M. Mechanical Biocompatibilities of Titanium Alloys for Biomedical Applications. J. Mech. Behav. Biomed. Mater. 2008, 1, 30–42. [Google Scholar] [CrossRef] [PubMed]

- ISO 5832-3; Implants for Surgery—Metallic Materials—Part 3: Wrought Titanium 6-Aluminium 4-Vanadium Alloy. The International Organization for Standardization: Geneva, Switzerland, 2021.

- ASTM F1472; Standard Specification for Wrought Titanium-6Aluminum-4Vanadium Alloy for Surgical Implant Applications. American Society for Testing and Materials: West Conshohocken, PA, USA, 2020. [CrossRef]

- ASTM F2924; Standard Specification for Additive Manufacturing Titanium-6 Aluminum-4 Vanadium with Powder Bed Fusion. American Society for Testing and Materials: West Conshohocken, PA, USA, 2021. [CrossRef]

- ASTM E466; Standard Practice for Conducting Force Controlled Constant Amplitude Axial Fatigue Tests of Metallic Materials. American Society for Testing and Materials: West Conshohocken, PA, USA, 2021. [CrossRef]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; Van Humbeeck, J.; Kruth, J.-P. A Study of the Microstructural Evolution during Selective Laser Melting of Ti–6Al–4V. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Farhang, B.; Tanrikulu, A.A.; Ganesh-Ram, A.; Durlov, S.H.; Shayesteh Moghaddam, N. Innovative Fabrication Design for In Situ Martensite Decomposition and Enhanced Mechanical Properties in Laser Powder Bed Fused Ti6Al4V Alloy. J. Manuf. Mater. Process. 2023, 7, 226. [Google Scholar] [CrossRef]

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. NIH Image to ImageJ: 25 Years of Image Analysis. Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef] [PubMed]

- Tanrikulu, A.A.; Ganesh-Ram, A.; Farhang, B.; Amerinatanzi, A. Unveiling the Impact of Layerwise Laser Preheating on Microstructure and Mechanical Response in Laser Powder Bed Fusion. J. Mater. Sci. 2023, 58, 17362–17382. [Google Scholar] [CrossRef]

- Wang, X.; Yu, K.; Wu, S.; Gu, J.; Liu, Y.; Dong, C.; Qiao, Y.; Loy, C.C. ESRGAN: Enhanced Super-Resolution Generative Adversarial Networks. In ECCV 2018: Computer Vision—ECCV 2018 Workshops; Springer: Cham, Switzerland, 2019; pp. 63–79. [Google Scholar]

- Bradski, G. OpenCV Open Source Computer Vision Library 2015. Available online: https://github.com/opencv/opencv/wiki/CiteOpenCV (accessed on 15 January 2008).

- Callister, W.D., Jr. Materials Science and Engineering: An Introduction, 7th ed.; John Wiley & Sons: New York, NY, USA, 2007. [Google Scholar]

- Khorsand Zak, A.; Majid, W.H.A.; Abrishami, M.E.; Yousefi, R. X-ray Analysis of ZnO Nanoparticles by Williamson-Hall and Size-Strain Plot Methods. Solid State Sci. 2011, 13, 251–256. [Google Scholar] [CrossRef]

- Bagasol, A.J.I.; Kaschel, F.R.; Ramachandran, S.; Mirihanage, W.; Browne, D.J.; Dowling, D.P. The Influence of a Large Build Area on the Microstructure and Mechanical Properties of PBF-LB Ti-6Al-4 V Alloy. Int. J. Adv. Manuf. Technol. 2023, 125, 1355–1369. [Google Scholar] [CrossRef] [PubMed]

- Pasang, T.; Tavlovich, B.; Yannay, O.; Jakson, B.; Fry, M.; Tao, Y.; Turangi, C.; Wang, J.C.; Jiang, C.P.; Sato, Y.; et al. Directionally-Dependent Mechanical Properties of Ti6Al4V Manufactured by Electron Beam Melting (EBM) and Selective Laser Melting (SLM). Materials 2021, 14, 3603. [Google Scholar] [CrossRef] [PubMed]

- ISO 21920-2; Geometrical Product Specifications (GPS) Surface Texture: Profile Part 2: Terms, Definitions and Surface Texture Parameters. International Standardization Organization: Geneva, Switzerland, 2021.

- Tenbrock, C.; Fischer, F.G.; Wissenbach, K.; Schleifenbaum, J.H.; Wagenblast, P.; Meiners, W.; Wagner, J. Influence of Keyhole and Conduction Mode Melting for Top-Hat Shaped Beam Profiles in Laser Powder Bed Fusion. J. Mater. Process. Technol. 2020, 278, 116514. [Google Scholar] [CrossRef]

- Pal, S.; Gubeljak, N.; Hudák, R.; Lojen, G.; Rajťúková, V.; Brajlih, T.; Drstvenšek, I. Evolution of the Metallurgical Properties of Ti-6Al-4V, Produced with Different Laser Processing Parameters, at Constant Energy Density in Selective Laser Melting. Results Phys. 2020, 17, 103186. [Google Scholar] [CrossRef]

- Bedmar, J.; de la Pezuela, J.; Riquelme, A.; Torres, B.; Rams, J. Impact of Remelting in the Microstructure and Corrosion Properties of the Ti6Al4V Fabricated by Selective Laser Melting. Coatings 2022, 12, 284. [Google Scholar] [CrossRef]

- Karimi, J.; Suryanarayana, C.; Okulov, I.; Prashanth, K.G. Selective Laser Melting of Ti6Al4V: Effect of Laser Re-Melting. Mater. Sci. Eng. A 2021, 805, 140558. [Google Scholar] [CrossRef]

- Ramosena, L.A.; Dzogbewu, T.C.; du Preez, W. Direct Metal Laser Sintering of the Ti6Al4V Alloy from a Powder Blend. Materials 2022, 15, 8193. [Google Scholar] [CrossRef] [PubMed]

- Wu, S.Q.; Lu, Y.J.; Gan, Y.L.; Huang, T.T.; Zhao, C.Q.; Lin, J.J.; Guo, S.; Lin, J.X. Microstructural Evolution and Microhardness of a Selective-Laser-Melted Ti–6Al–4V Alloy after Post Heat Treatments. J. Alloys Compd. 2016, 672, 643–652. [Google Scholar] [CrossRef]

- Zou, Z.; Simonelli, M.; Katrib, J.; Dimitrakis, G.; Hague, R. Microstructure and Tensile Properties of Additive Manufactured Ti-6Al-4V with Refined Prior-β Grain Structure Obtained by Rapid Heat Treatment. Mater. Sci. Eng. A 2021, 814, 141271. [Google Scholar] [CrossRef]

- Kumar, P.; Prakash, O.; Ramamurty, U. Micro-and Meso-Structures and Their Influence on Mechanical Properties of Selectively Laser Melted Ti-6Al-4V. Acta Mater. 2018, 154, 246–260. [Google Scholar] [CrossRef]

- Lee, E.; Banerjee, R.; Kar, S.; Bhattacharyya, D.; Fraser, H.L. Selection of α Variants during Microstructural Evolution in α/β Titanium Alloys. Philos. Mag. 2007, 87, 3615–3627. [Google Scholar] [CrossRef]

- Antonysamy, A.A.; Meyer, J.; Prangnell, P.B. Effect of Build Geometry on the β-Grain Structure and Texture in Additive Manufacture of Ti6Al4V by Selective Electron Beam Melting. Mater. Charact. 2013, 84, 153–168. [Google Scholar] [CrossRef]

- Etesami, S.A.; Fotovvati, B.; Asadi, E. Heat Treatment of Ti-6Al-4V Alloy Manufactured by Laser-Based Powder-Bed Fusion: Process, Microstructures, and Mechanical Properties Correlations. J. Alloys Compd. 2022, 895, 162618. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, H.; Zhu, L.; Wang, X.; Han, Q.; Li, S.; Wang, Y.; Setchi, R.; Wang, D. Investigation into the Microstructure and Dynamic Compressive Properties of Selective Laser Melted Ti–6Al–4V Alloy with Different Heating Treatments. Mater. Sci. Eng. A 2021, 805, 140561. [Google Scholar] [CrossRef]

- Pantawane, M.V.; Ho, Y.-H.; Joshi, S.S.; Dahotre, N.B. Computational Assessment of Thermokinetics and Associated Microstructural Evolution in Laser Powder Bed Fusion Manufacturing of Ti6Al4V Alloy. Sci. Rep. 2020, 10, 7579. [Google Scholar] [CrossRef]

- Xu, Y.; Lu, Y.; Sundberg, K.L.; Liang, J.; Sisson, R.D. Effect of Annealing Treatments on the Microstructure, Mechanical Properties and Corrosion Behavior of Direct Metal Laser Sintered Ti-6Al-4V. J. Mater. Eng. Perform. 2017, 26, 2572–2582. [Google Scholar] [CrossRef]

- Zhang, Y.S.; Hu, J.J.; Zhao, Y.Q.; Bai, X.F.; Huo, W.T.; Zhang, W.; Zhang, L.C. Microstructure and Mechanical Properties of a High-Oxygen Core-Shell Network Structured Ti6Al4V Alloy. Vacuum 2018, 149, 140–145. [Google Scholar] [CrossRef]

- Muhammad, M.; Pegues, J.W.; Shamsaei, N.; Haghshenas, M. Effect of Heat Treatments on Microstructure/Small-Scale Properties of Additive Manufactured Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2019, 103, 4161–4172. [Google Scholar] [CrossRef]

- Tanrikulu, A.A.; Ganesh-Ram, A.; Farhang, B.; Amerinatanzi, A. Comparison of Layerwise Preheating and Post-Heating Laser Scan on The Microstructure and Mechanical Properties of L-PBF Ti6Al4V. In Proceedings of the 2023 Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 14–16 August 2023. [Google Scholar]

- Senthilkumar, V.; Vickraman, P.; Jayachandran, M.; Sanjeeviraja, C. Structural and Electrical Studies of Nano Structured Sn1−xSbxO2 (x = 0.0, 1, 2.5, 4.5 and 7 at%) Prepared by Co-Precipitation Method. J. Mater. Sci. Mater. Electron. 2010, 21, 343–348. [Google Scholar] [CrossRef]

- Kaschel, F.R.; Vijayaraghavan, R.K.; Shmeliov, A.; McCarthy, E.K.; Canavan, M.; McNally, P.J.; Dowling, D.P.; Nicolosi, V.; Celikin, M. Mechanism of Stress Relaxation and Phase Transformation in Additively Manufactured Ti-6Al-4V via in Situ High Temperature XRD and TEM Analyses. Acta Mater. 2020, 188, 720–732. [Google Scholar] [CrossRef]

- Mahmud, A.; Huynh, T.; Zhou, L.; Hyer, H.; Mehta, A.; Imholte, D.D.; Woolstenhulme, N.E.; Wachs, D.M.; Sohn, Y. Mechanical Behavior Assessment of Ti-6Al-4V ELI Alloy Produced by Laser Powder Bed Fusion. Metals 2021, 11, 1671. [Google Scholar] [CrossRef]

- Goettgens, V.S.; Kaserer, L.; Braun, J.; Busch, R.; Berthold, L.; Patzig, C.; Leichtfried, G. Microstructural Evolution and Mechanical Properties of Ti-6Al-4V in Situ Alloyed with 3.5 Wt.% Cu by Laser Powder Bed Fusion. Materialia 2023, 32, 101928. [Google Scholar] [CrossRef]

- Gu, H.; Wei, C.; Li, L.; Ryan, M.; Setchi, R.; Han, Q.; Qian, L. Numerical and Experimental Study of Molten Pool Behaviour and Defect Formation in Multi-Material and Functionally Graded Materials Laser Powder Bed Fusion. Adv. Powder Technol. 2021, 32, 4303–4321. [Google Scholar] [CrossRef]

- Duan, R.; Li, S.; Cai, B.; Tao, Z.; Zhu, W.; Ren, F.; Attallah, M.M. In Situ Alloying Based Laser Powder Bed Fusion Processing of β Ti–Mo Alloy to Fabricate Functionally Graded Composites. Compos. Part B Eng. 2021, 222, 109059. [Google Scholar] [CrossRef]

- Zhang, J.; Song, B.; Yang, L.; Liu, R.; Zhang, L.; Shi, Y. Microstructure Evolution and Mechanical Properties of TiB/Ti6Al4V Gradient-Material Lattice Structure Fabricated by Laser Powder Bed Fusion. Compos. Part B Eng. 2020, 202, 108417. [Google Scholar] [CrossRef]

- Greitemeier, D.; Dalle Donne, C.; Syassen, F.; Eufinger, J.; Melz, T. Effect of Surface Roughness on Fatigue Performance of Additive Manufactured Ti–6Al–4V. Mater. Sci. Technol. 2016, 32, 629–634. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, K.; Liu, J.; Xu, Y.; Zhang, R.; Zeng, Z.; Zhu, Y.; Huang, A. In-Situ Investigation into the Deformation Behavior of Ti-6Al-4V Processed by Laser Powder Bed Fusion. Mater. Charact. 2022, 194, 112434. [Google Scholar] [CrossRef]

- Khorasani, A.M.; Gibson, I.; Ghasemi, A.; Ghaderi, A. Modelling of Laser Powder Bed Fusion Process and Analysing the Effective Parameters on Surface Characteristics of Ti-6Al-4V. Int. J. Mech. Sci. 2020, 168, 105299. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tanrikulu, A.A.; Farhang, B.; Ganesh-Ram, A.; Hekmatjou, H.; Durlov, S.H.; Amerinatanzi, A. In Situ Microstructure Modification Using a Layerwise Surface-Preheating Laser Scan of Ti-6Al-4V during Laser Powder Bed Fusion. Materials 2024, 17, 1929. https://doi.org/10.3390/ma17081929

Tanrikulu AA, Farhang B, Ganesh-Ram A, Hekmatjou H, Durlov SH, Amerinatanzi A. In Situ Microstructure Modification Using a Layerwise Surface-Preheating Laser Scan of Ti-6Al-4V during Laser Powder Bed Fusion. Materials. 2024; 17(8):1929. https://doi.org/10.3390/ma17081929

Chicago/Turabian StyleTanrikulu, Ahmet Alptug, Behzad Farhang, Aditya Ganesh-Ram, Hamidreza Hekmatjou, Sadman Hafiz Durlov, and Amirhesam Amerinatanzi. 2024. "In Situ Microstructure Modification Using a Layerwise Surface-Preheating Laser Scan of Ti-6Al-4V during Laser Powder Bed Fusion" Materials 17, no. 8: 1929. https://doi.org/10.3390/ma17081929

APA StyleTanrikulu, A. A., Farhang, B., Ganesh-Ram, A., Hekmatjou, H., Durlov, S. H., & Amerinatanzi, A. (2024). In Situ Microstructure Modification Using a Layerwise Surface-Preheating Laser Scan of Ti-6Al-4V during Laser Powder Bed Fusion. Materials, 17(8), 1929. https://doi.org/10.3390/ma17081929