Evaluation of Compatibility between Beetle-Killed Lodgepole Pine (Pinus Contorta var. Latifolia) Wood with Portland Cement

Abstract

:1. Introduction

2. Results and Discussion

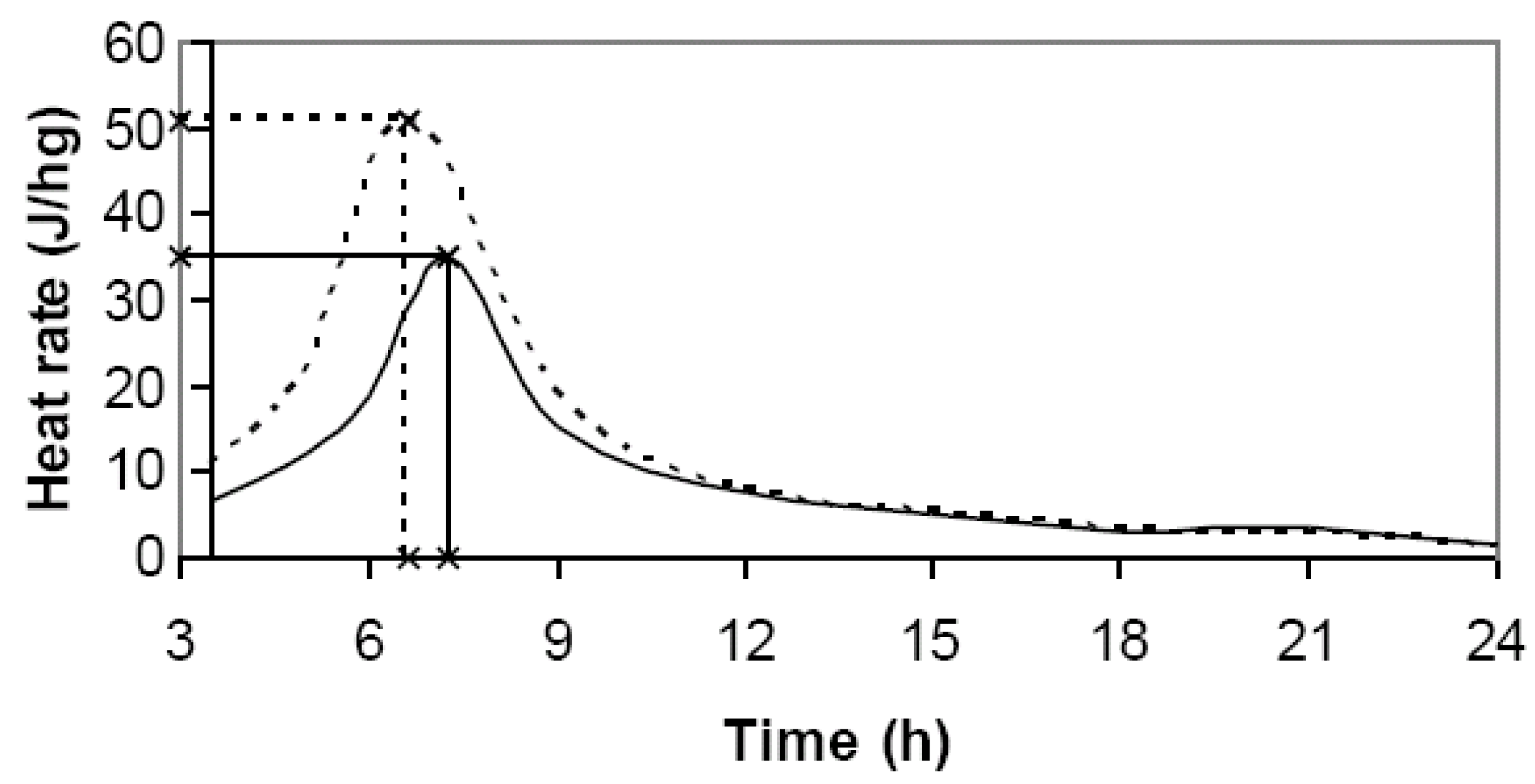

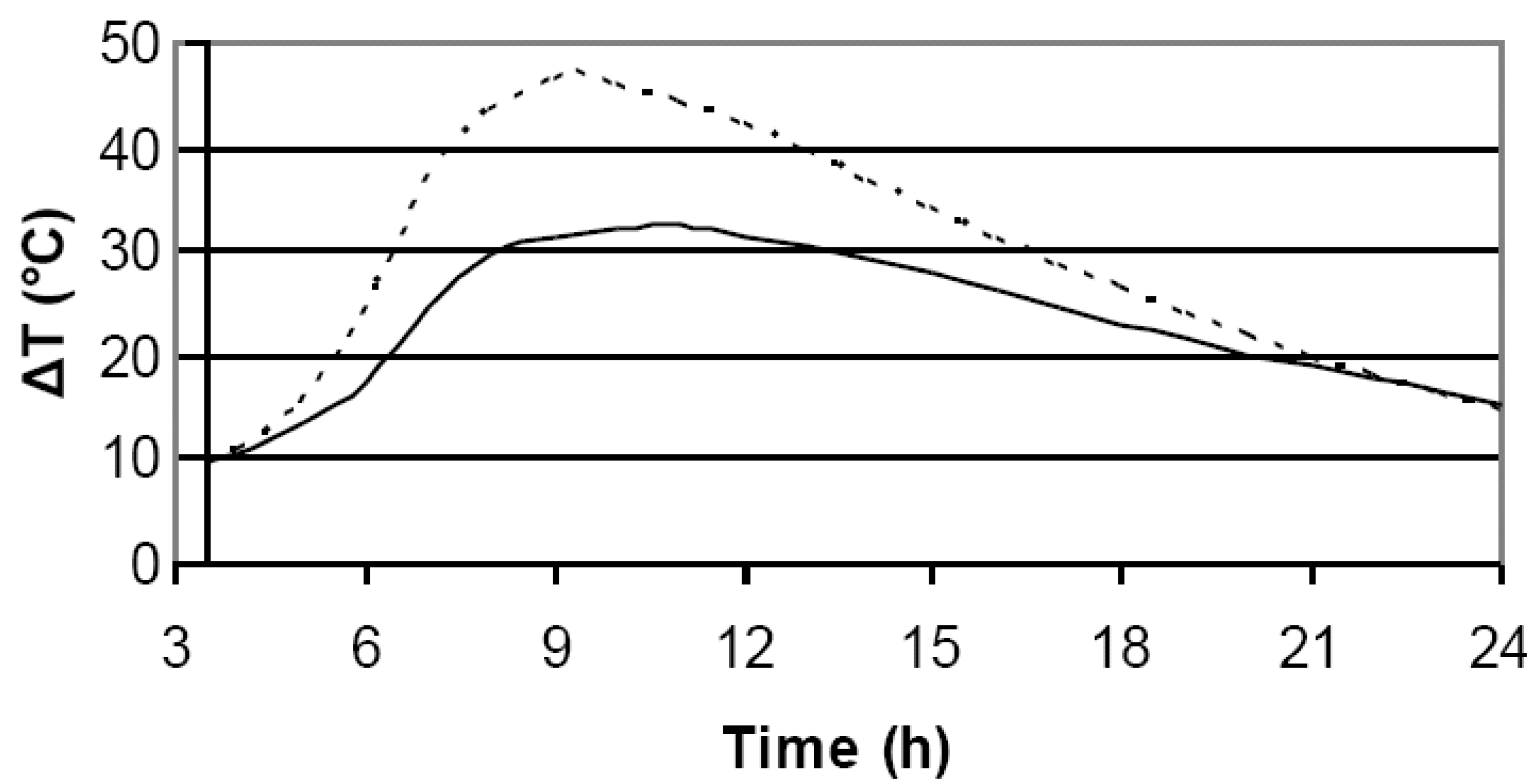

2.1. Development of New Compatibility Index (CX)

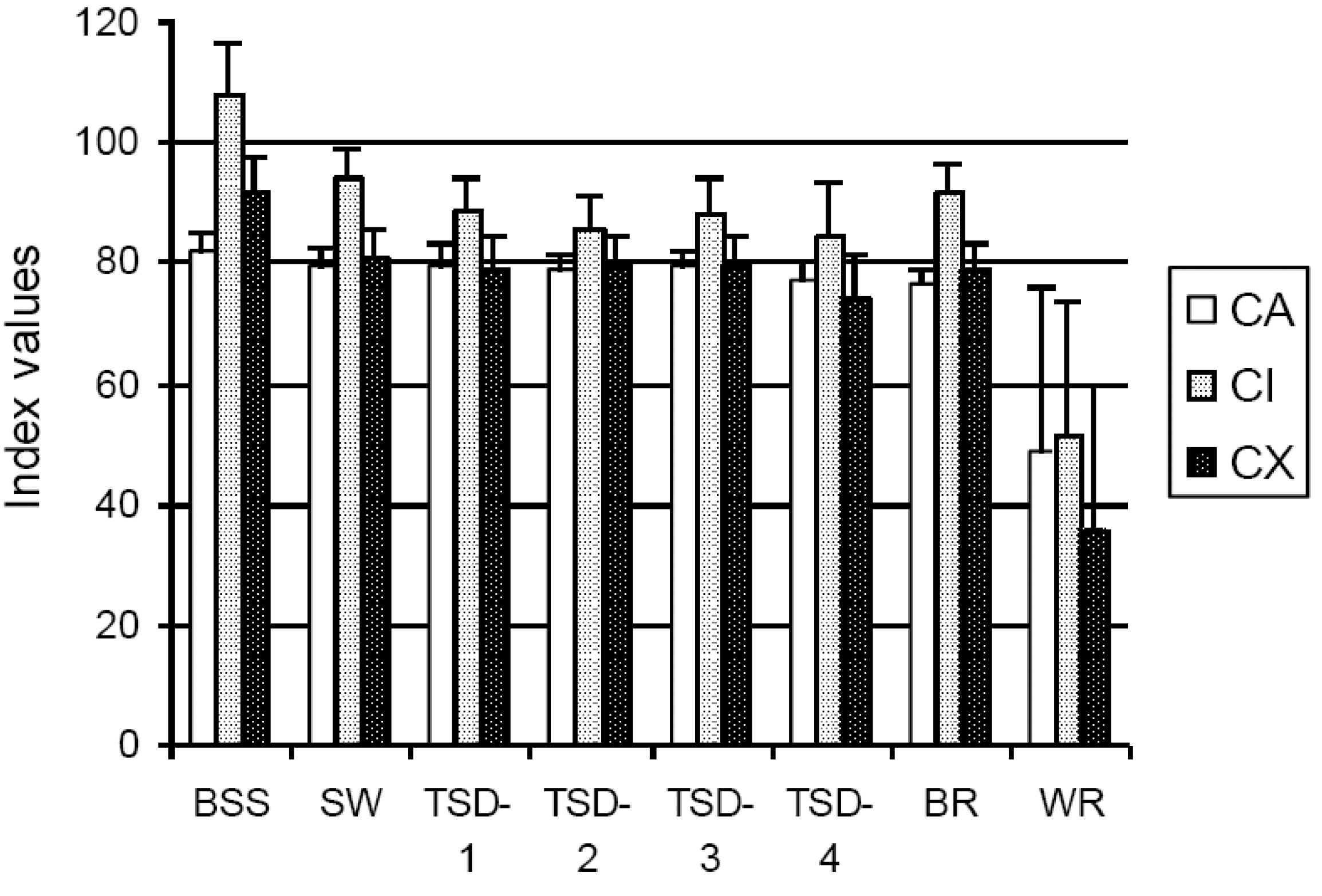

2.2. Assessment of Wood-Cement Compatibility

| Group | CA | CI | CX | |||

|---|---|---|---|---|---|---|

| Blue-stained sapwood (BSS) | 81.8 | a | 108.0 | a | 91.9 | a |

| Sound wood (SW) | 79.8 | a | 94.1 | b | 80.8 | b |

| TSD-1 | 79.4 | a | 88.7 | b | 79.2 | b |

| TSD-2 | 78.9 | a | 85.4 | b | 79.3 | b |

| TSD-3 | 79.5 | a | 87.9 | b | 79.3 | b |

| TSD-4 | 76.9 | a | 84.3 | b | 74.4 | b |

| Brown rot (BR) | 76.4 | a | 91.9 | b | 78.8 | b |

| White rot (WR) | 48.8 | b | 51.2 | c | 40.6 | c |

3. Experimental Section

| Time since death class | Estimated years since death | External tree appearance |

|---|---|---|

| TSD-1 | 1 year | green, yellowish or freshly red needles; no needles loss |

| TSD-2 | 2–3 years | red attack; slight needle loss |

| TSD-3 | 4–5 years | red attack; substantial needle loss |

| TSD-4 | +6 years | gray attack; no needles, loss of fine branches |

4. Conclusions

Acknowledgements

References

- Moslemi, A.A. Emerging technologies in mineral-bonded wood and fiber composites. Adv. Perform. Mater. 1999, 6, 161–179. [Google Scholar] [CrossRef]

- Weatherwax, R.C.; Tarkow, H. Effect of wood on setting of Portland cement. For. Prod. J. 1964, 14, 567–570. [Google Scholar]

- Hofstrand, A.D.; Moslemi, A.A.; Garcia, J.F. Curing characteristics of wood particles from nine northern Rocky Mountain species mixed with Portland cement. For. Prod. J. 1984, 34, 57–61. [Google Scholar]

- Hachmi, M.; Moslemi, A.A.; Campbell, A.G. A new technique to classify the compatibility of wood with cement. Wood Sci. Technol. 1990, 24, 345–354. [Google Scholar] [CrossRef]

- Miller, D.P.; Moslemi, A.A. Wood-cement composites: species and sapwood-heartwood effects on hydration and tensile strength. For. Prod. J. 1991, 41, 9–14. [Google Scholar]

- Lee, W.C.; Hong, Z.; Phillips, D.R.; Hse, C.Y. Effect of cement/wood ratios and wood storage conditions on hydration temperature, hydration time, and compressive strength of wood-cement mixtures. Wood Fiber Sci. 1987, 19, 262–268. [Google Scholar]

- Dinwoodie, J.M.; Paxton, B.H. Wood-cement particleboard: A technical assessment. Appl. Polym. Symp. 1984, 40, 217–227. [Google Scholar]

- Weatherwax, R.C.; Tarkow, H. Decayed wood as an inhibitor. For. Prod. J. 1967, 14, 567–570. [Google Scholar]

- Lewis, K.J.; Hartley, I.D. Rate of degradation, degrade, and fall of trees killed by mountain pine beetle. BC J. Ecosyst. Manag. 2006, 7, 11–19. [Google Scholar]

- Davis, T.C. Effect of blue stain on setting of excelsior-cement mixtures. For. Prod. J. 1966, 16, 49–50. [Google Scholar]

- Karade, S.R.; Irle, M.; Maher, K. Assessment of wood-cement compatibility: A new approach. Holzforschung 2003, 57, 672–680. [Google Scholar] [CrossRef]

- Jorge, F.C.; Pereira, C.; Ferreira, J.M. Wood-cement composites: A review. Holz als Roh- und Werkstoff 2004, I, 370–377. [Google Scholar]

- Defo, M.; Cloutier, A.; Riedl, B. Wood-cement compatibility of some Eastern Canadian woods by isothermal calorimetry. For. Prod. J. 2004, 54, 49–56. [Google Scholar]

- Hachmi, M.; Moslemi, A.A. Correlation between wood-cement compatibility and wood extractives. For. Prod. J. 1989, 39, 55–58. [Google Scholar]

- Woo, K.L.; Watson, P.; Mansfield, S.D. The effects of mountain pine beetle attack on lodgepole pine wood morphology and chemistry: Implications for wood and fiber quality. Wood Fiber Sci. 2005, 37, 112–126. [Google Scholar]

- Watson, P. Impact of the mountain pine beetle in pulp and papermaking. In The Mountain Pine Beetle: A Synthesis of Biology, Management, and Impacts on Lodgepole Pine; Safranyk, L., Wilson, B., Eds.; Natural Resources Canada (Canadian Forest Service): Victoria, British Columbia, Canada, 2006. [Google Scholar]

- Biblis, E.J.; Lo, C.F. Effect on the setting of southern pine-cement mixtures. For. Prod. J. 1968, 18, 28–34. [Google Scholar]

- Semple, K.; Evans, P.D. Properties of wood-wool cement boards manufactured from radiata pine wood. Wood Fiber Sci. 2000, 32, 37–43. [Google Scholar]

- Thrower, J.; Willis, R.; De Jong, R.; Gilbert, D.; Robertson, H. Sample Plan to Measure Tree Characteristics Related to the Shelf Life of Mountain Pine Beetle-Killed Lodgepole Pine Trees in British Columbia; Mountain Pine Beetle Initiative Working Paper 2005-1; Natural Resources Canada (Canadian Forest Service): Victoria, British Columbia, Canada, 2005. [Google Scholar]

- Lewis, K.; Thompson, D.; Hartley, I.D.; Pasca, S. Wood Decay and Degradation in Standing Lodgepole Pine (Pinus contorta var. latifolia Engelm.) Killed by Mountain Pine Beetle (Dendroctonus ponderosa Hopkins: Coleoptera); Mountain Pine Beetle Initiative Working Paper 2006-11-MPBI P.O. #8.10; Natural Resources Canada (Canadian Forest Service): Victoria, British Columbia, Canada, 2006. [Google Scholar]

© 2010 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Pasca, S.A.; Hartley, I.D.; Reid, M.E.; Thring, R.W. Evaluation of Compatibility between Beetle-Killed Lodgepole Pine (Pinus Contorta var. Latifolia) Wood with Portland Cement. Materials 2010, 3, 5311-5319. https://doi.org/10.3390/ma3125311

Pasca SA, Hartley ID, Reid ME, Thring RW. Evaluation of Compatibility between Beetle-Killed Lodgepole Pine (Pinus Contorta var. Latifolia) Wood with Portland Cement. Materials. 2010; 3(12):5311-5319. https://doi.org/10.3390/ma3125311

Chicago/Turabian StylePasca, Sorin A., Ian D. Hartley, Matthew E. Reid, and Ronald W. Thring. 2010. "Evaluation of Compatibility between Beetle-Killed Lodgepole Pine (Pinus Contorta var. Latifolia) Wood with Portland Cement" Materials 3, no. 12: 5311-5319. https://doi.org/10.3390/ma3125311