Open-Cellular Co-Base and Ni-Base Superalloys Fabricated by Electron Beam Melting

Abstract

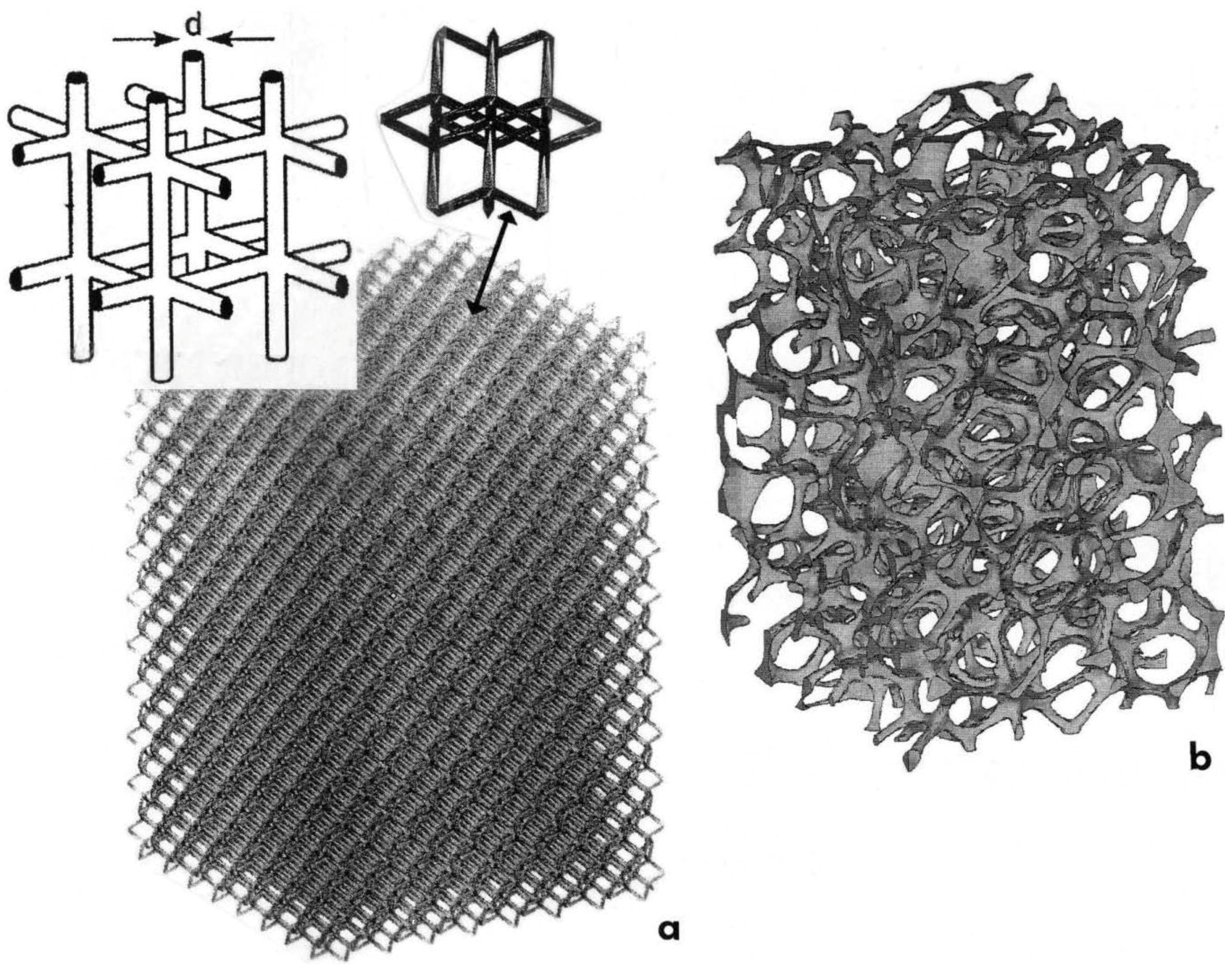

:1. Introduction

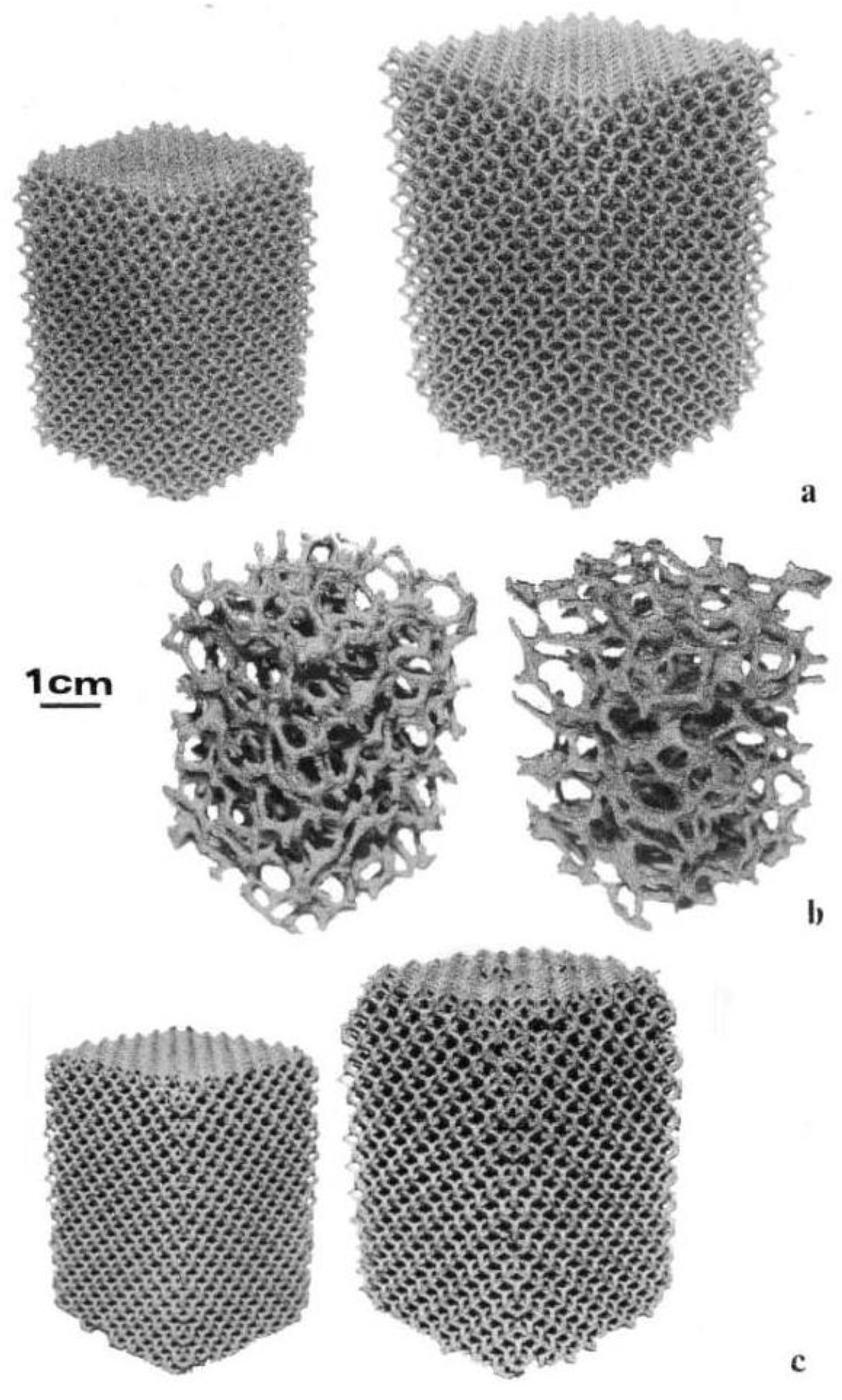

2. Experimental

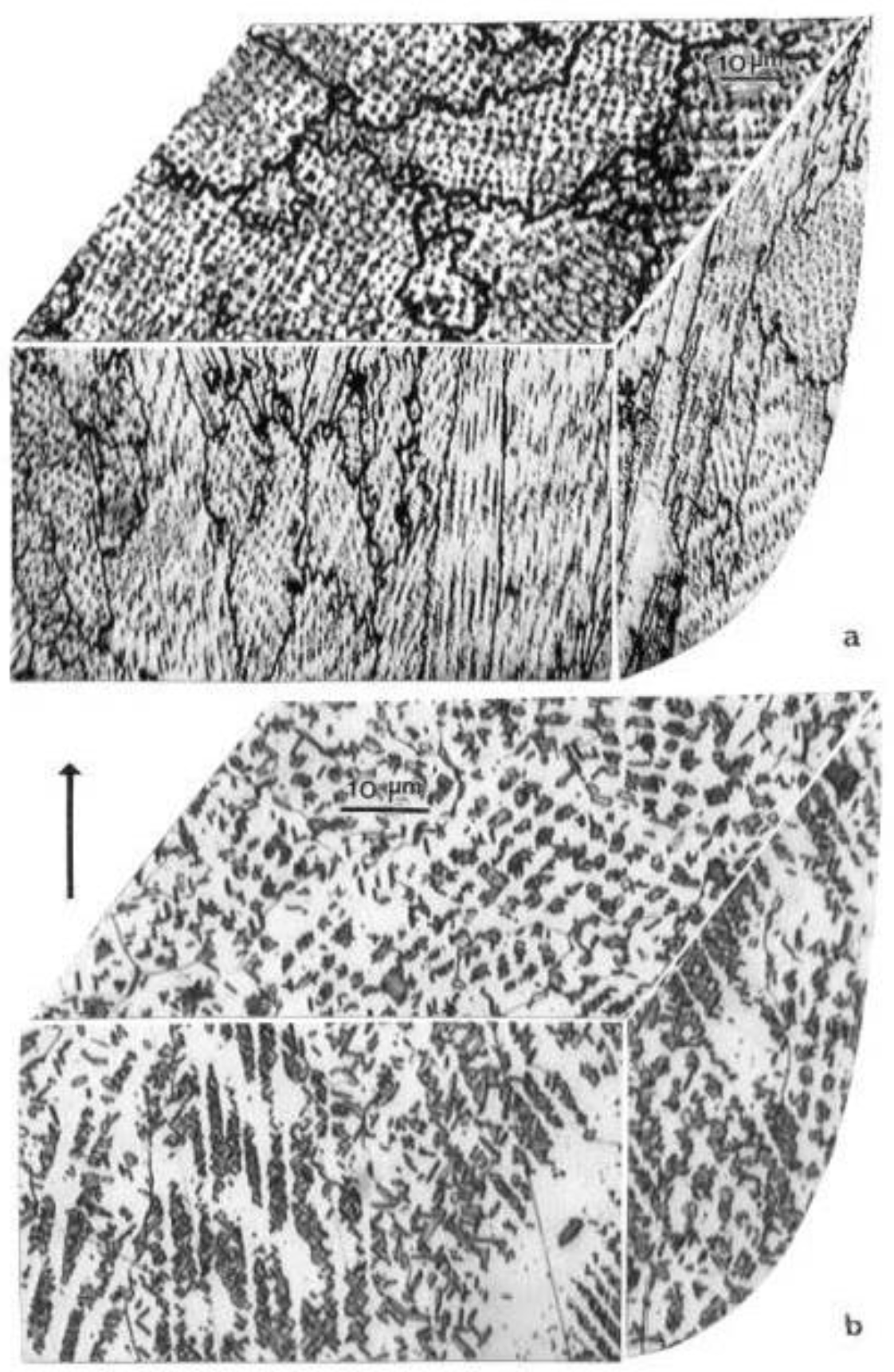

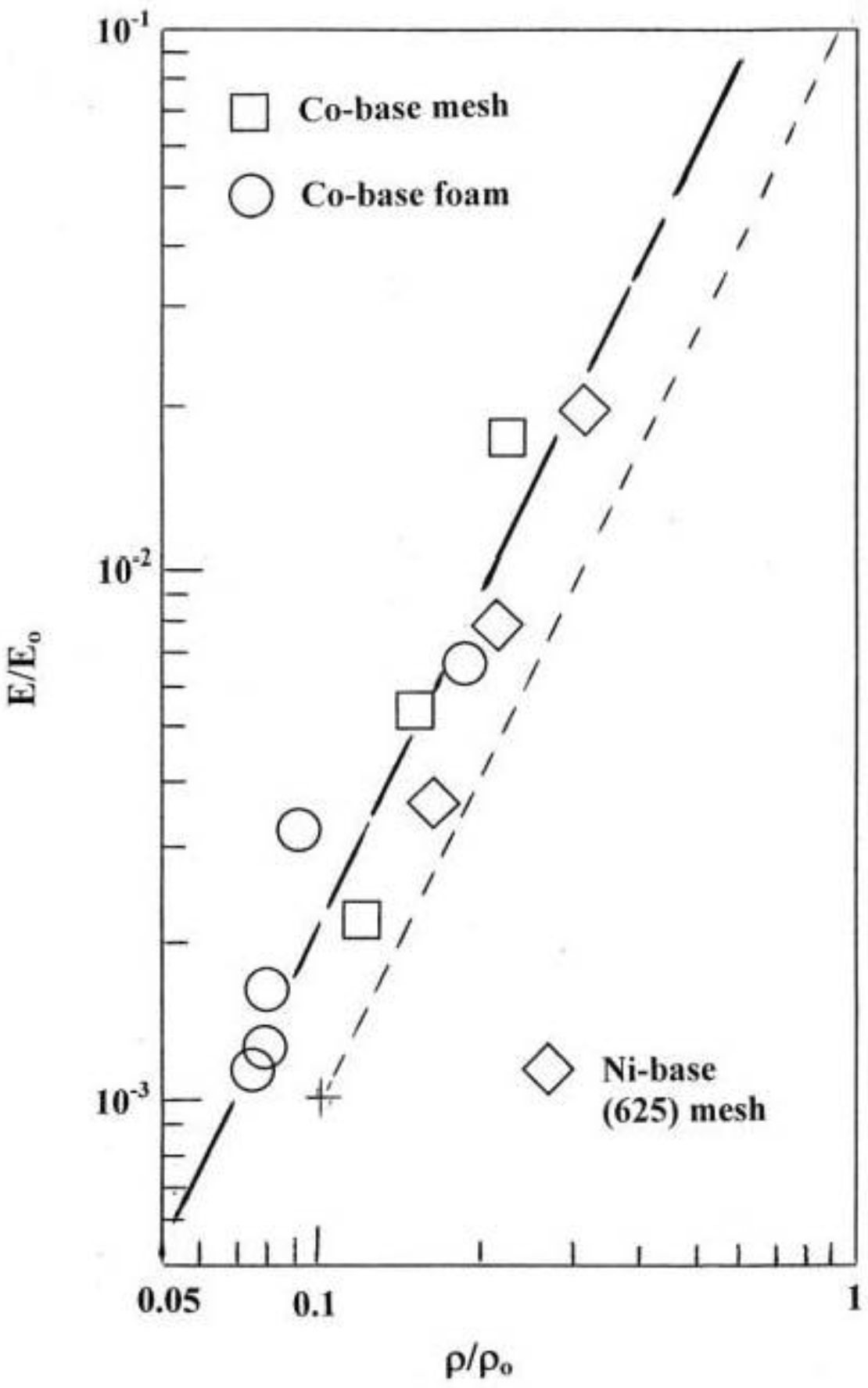

3. Results and Discussion

| MATERIAL | ρa (g/cm3) | Poreh Density (ppi) | ρ/ρob | Ec (GPa) | E/Eod | E/ρe | HVf (GPa) | σ/ρg |

|---|---|---|---|---|---|---|---|---|

| Co-base mesh | 0.98 | 14 | 0.12 | 0.49 | 2.3 | 0.50 | 5.2 | 1.8 |

| Co-base mesh | 1.25 | 17 | 0.15 | 1.16 | 5.5 | 0.93 | - | 1.4 |

| Co-base mesh | 1.85 | 25 | 0.22 | 3.68 | 17.5 | 2.00 | - | 0.9 |

| Co-base foam | 0.63 | 4 | 0.075 | 0.25 | 1.2 | 0.40 | 4.5 | 2.3 |

| Co-base foam | 0.66 | 5 | 0.078 | 0.28 | 1.3 | 0.42 | - | 2.3 |

| Co-base foam | 0.69 | 7 | 0.080 | 0.35 | 1.7 | 0.50 | - | 2.2 |

| Co-base foam | 0.76 | 9 | 0.090 | 0.70 | 3.3 | 0.92 | - | 2.0 |

| Ni-base mesh | 1.37 | 14 | 0.16 | 0.76 | 3.6 | 0.55 | 2.9 | 0.7 |

| Ni-base mesh | 1.80 | 17 | 0.21 | 1.68 | 8.0 | 0.93 | - | 0.5 |

| Ni-base mesh | 2.60 | 22 | 0.31 | 4.17 | 19.9 | 1.60 | - | 0.4 |

4. Conclusions

Acknowledgments

References

- Ashby, M.F.; Medalist, R.F.M. The mechanical properties of cellular solids. Metall. Trans. A 1983, 14A, 1755–1786. [Google Scholar]

- Gibson, L.J.; Ashby, M.F. Cellular Solids: Structure and Properties, 2nd ed.; Cambridge University Press: Cambridge, UK, 1997. [Google Scholar]

- Lu, T.J.; Stone, H.A.; Ashby, M.F. Heat transfer in open-cell metal foams. Acta Mater. 1998, 45, 3619–3635. [Google Scholar] [CrossRef]

- Ashby, M.F.; Evans, A.G.; Fleck, N.A.; Gibson, L.J.; Hutchinson, J.W.; Wadley, H.N.G. Metal Foams: A Design Guide; Butterworth-Heinemann: Boston, MA, USA, 2000. [Google Scholar]

- Barnhart, J. Manufacture, characterization and application of cellular metals and metal foams. Prog. Mater. Res. 2000, 46, 559–632. [Google Scholar] [CrossRef]

- Boomsma, K.; Poulikakou, D.; Zwick, F. Metal foams as compact high performance heat exchangers. Mech. Mater. 2003, 35, 1161–1176. [Google Scholar]

- Kaviany, M. Principles of Heat Transfer in Porous Media; Springer: New York, NY, USA, 1999. [Google Scholar]

- Bhattacharya, A.; Mahajan, R.L. Finned metal foam heat sinks for electronics cooling in forced convection. J. Electronic Pack. 2002, 124, 155–163. [Google Scholar] [CrossRef]

- Ashby, M.F.; Tianjian, L.U. Metal foams: A survey. Sci. China 2003, 46, 521–532. [Google Scholar] [CrossRef]

- Simone, A.E.; Gibson, L.J. Efficient structural components using porous metals. Acta Mater. 1998, 46, 55–62. [Google Scholar]

- Berman, M. Regular-faced convex polyhedral. J. Franklin Institute 1971, 291, 329–351. [Google Scholar] [CrossRef]

- Davies, G.J.; Zhen, S. Metallic foams and their production, properties and applications. J. Mater. Sci. 1983, 18, 1899–1911. [Google Scholar] [CrossRef]

- Keans, M.W.; Blenkinsop, P.A.; Barber, A.C.; Farthing, T.W. Manufacture of a novel porous material. Int. J. Powd. Met. 1988, 24, 59–64. [Google Scholar]

- Lefebvre, L.-P.; Bonhart, J.; Dunand, D.C. Porous metals and metallic foams: Current status and recent developments. Adv. Engr. Mater. 2008, 10, 775–787. [Google Scholar] [CrossRef] [Green Version]

- Li, Q.; Chen, E.Y.; Bice, D.R.; Dunand, D.C. Mechanical properties of cast Ti-6Al-4V lattice block structures. Metall. Mater. Trans. A 2008, 39A, 411–449. [Google Scholar]

- Mullen, L.; Stamp, R.; Brooks, W.; Jones, E.; Sutcliffe, C. Selective laser melting: A regular unit cell approach for the manufacture of porous titanium bone in-growth constructs suitable for orthopaedic applications. J. Biomed. Mater. Res. B 2009, 89B, 325–334. [Google Scholar] [CrossRef]

- Stamp, R.; Fox, P.; O’Neill, W.; Jones, E.; Sutcliffe, C. The development of a scanning strategy for the manufacture of porous biomaterials by selective laser melting. J. Mater. Sci. Mater. Med. 2009, 20, 1839–1848. [Google Scholar] [CrossRef] [PubMed]

- Heinl, L.-P.; Muller, L.; Körner, C.; singer, R.F.; Müller, F.A. Cellular Ti-6Al-4V structures with interconnected macroporosity for bone implants fabricated by selective electron beam melting. Acta Biomater. 2008, 4, 1536–1544. [Google Scholar] [CrossRef]

- Murr, L.E.; Gaytan, S.M.; Medina, F.; Lopez, H.; Martinez, E.; Machado, B.I.; Hernandez, D.H.; Martinez, L.; Lopez, M.I.; Wicker, R.B.; Bracke, J. Next generation biomedical implants using additive manufacturing of complex, cellular and functional mesh arrays. Phil. Trans. Roy Soc. A 2010, 368, 1999–2032. [Google Scholar] [CrossRef]

- Gaytan, S.M.; Murr, L.E.; Martinez, E.; Martinez, J.L.; Machado, B.I.; Ramirez, D.A.; Medina, F.; Collins, S.; Wicker, R.B. Comparison of microstructures and mechanical properties for solid and mesh cobalt-base alloy prototypes fabricated by electron beam melting. Metall. Mater. Trans. A 2010, 41A, 3010–3327. [Google Scholar]

- Murr, L.E.; Martinez, E.; Ramirez, D.A.; Gaytan, S.M.; Machado, B.I.; Shindo, P.W.; Martinez, J.L.; Medina, F.; Wooten, J.; Ciscel, D.; Akelid, U.; Wicker, R.B. Microstructural architecture, microstructures and mechanical properties for a nickel-base superalloy fabricated by electron beam melting. Metall. Mater. Trans. A 2011, in press. [Google Scholar]

- Chalmers, B. The Principles of Solidification; Wiley: New York, NY, USA, 1964. [Google Scholar]

- Woudruff, D.P. The Solid-Liquid Interface; Cambridge University Press: London, UK, 1973. [Google Scholar]

- Thompson, E.R.; Lenkey, F.D. Directionally solidified eutectic superalloys. In Composite Materials; Academic Press: New York, NY, USA, 1974; Volume 4, p. 101. [Google Scholar]

- Hertzberg, R.W. Structure-property relationships in eutectic composites. In Frontiers in Materials Science; Murr, L.E., Stein, C., Eds.; Marcel Dekker, Inc.: New York, NY, USA, 1976; p. 421. [Google Scholar]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; VonHumbeeck, J.; Kruth, J.-P. A study of the microstructural evolution during selective laser melting of Ti-6Al-4V. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Strondl, A.; Fischer, R.; Frommeyer, G.; Schneider, A. Investigations of MX and γ΄/γ΄΄ precipitates in the nickel-based superalloy 718 produced by electron beam melting. Mater. Sci. Engng. A 2008, 480, 138–147. [Google Scholar] [CrossRef]

© 2011 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Murr, L.; Li, S.; Tian, Y.; Amato, K.; Martinez, E.; Medina, F. Open-Cellular Co-Base and Ni-Base Superalloys Fabricated by Electron Beam Melting. Materials 2011, 4, 782-790. https://doi.org/10.3390/ma4040782

Murr L, Li S, Tian Y, Amato K, Martinez E, Medina F. Open-Cellular Co-Base and Ni-Base Superalloys Fabricated by Electron Beam Melting. Materials. 2011; 4(4):782-790. https://doi.org/10.3390/ma4040782

Chicago/Turabian StyleMurr, Lawrence, Shujun Li, Yuxing Tian, Krista Amato, Edwin Martinez, and Frank Medina. 2011. "Open-Cellular Co-Base and Ni-Base Superalloys Fabricated by Electron Beam Melting" Materials 4, no. 4: 782-790. https://doi.org/10.3390/ma4040782