Transformation-Induced Creep and Creep Recovery of Shape Memory Alloy

Abstract

:1. Introduction

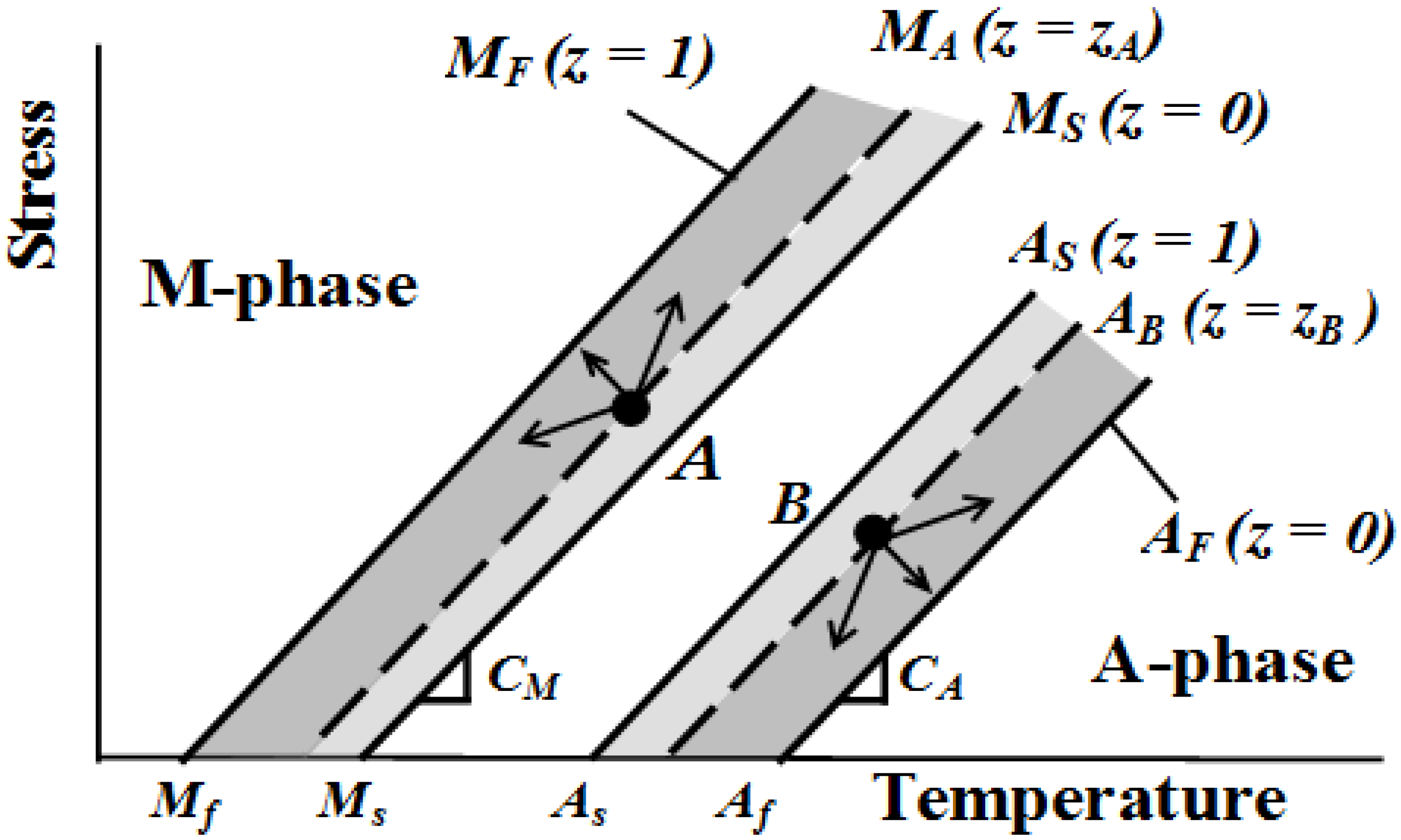

2. Conditions for Progress of Martensitic Transformation

3. Experimental Method

3.1. Materials and Specimens

3.2. Experimental Apparatus

3.3. Experimental Procedure

- (1)

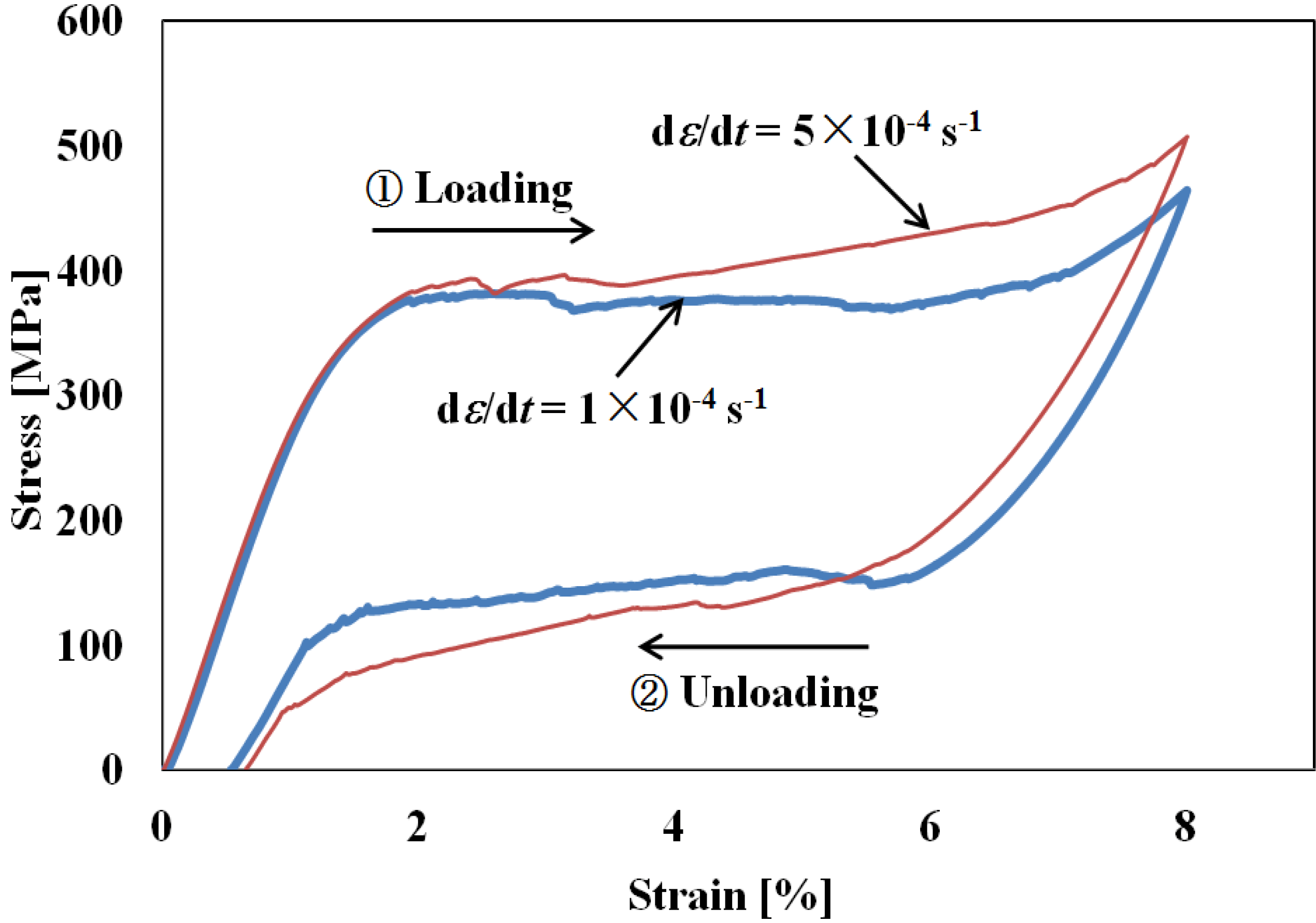

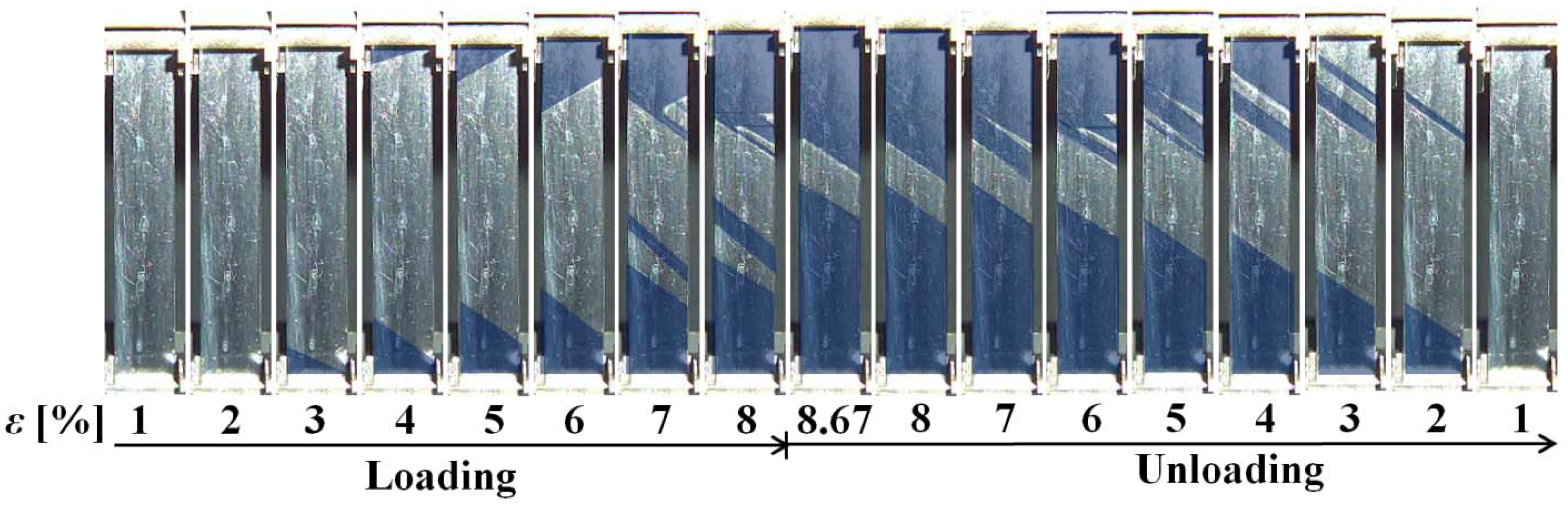

- Subloop loading test at different loading rates: With respect to the maximum strain of 8% at the upper stress plateau of the stress-strain curve, loading and unloading tests were conducted at constant rates of strain and stress and the subloop deformation behaviors were observed for different loading rates.

- (2)

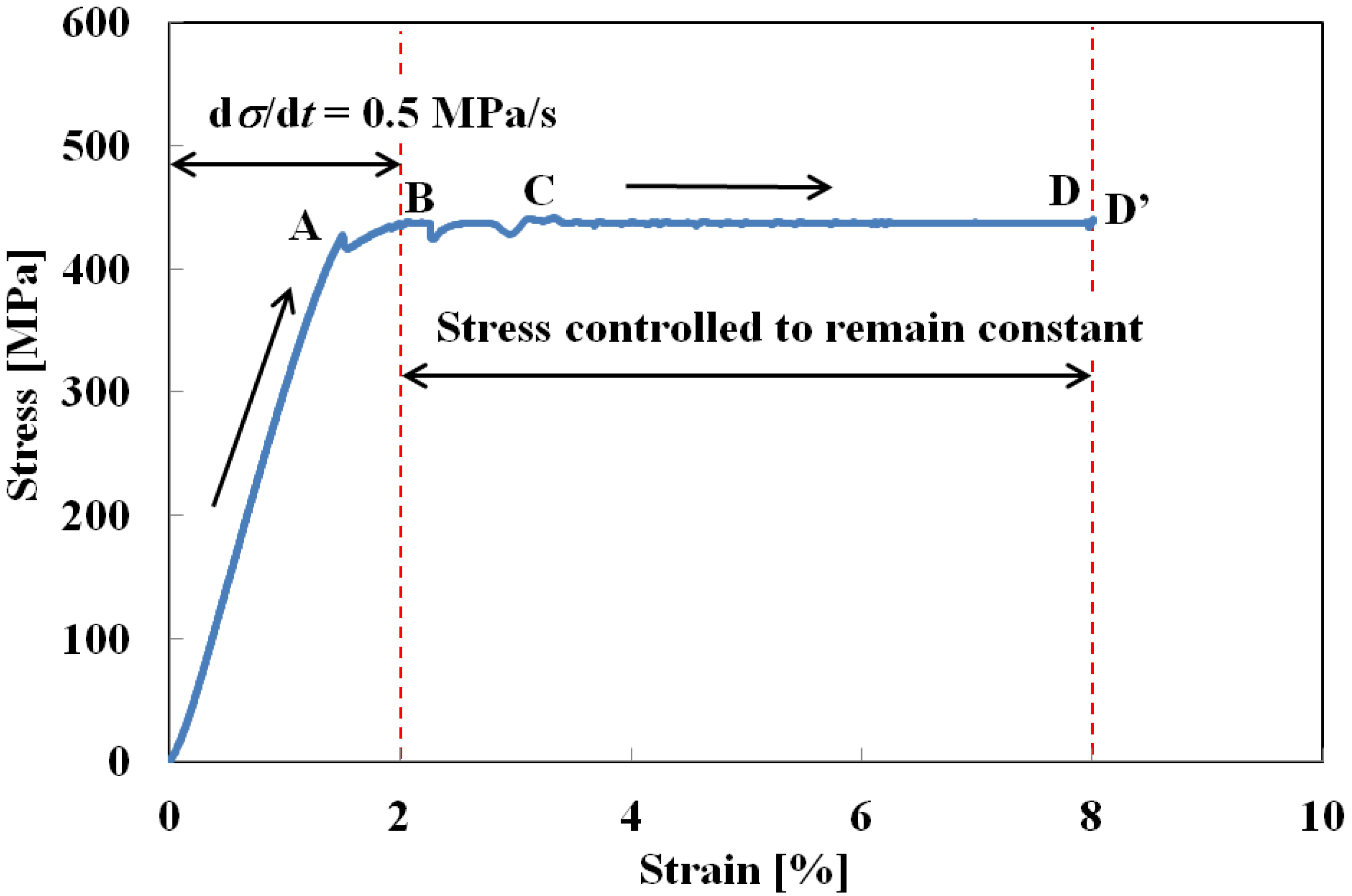

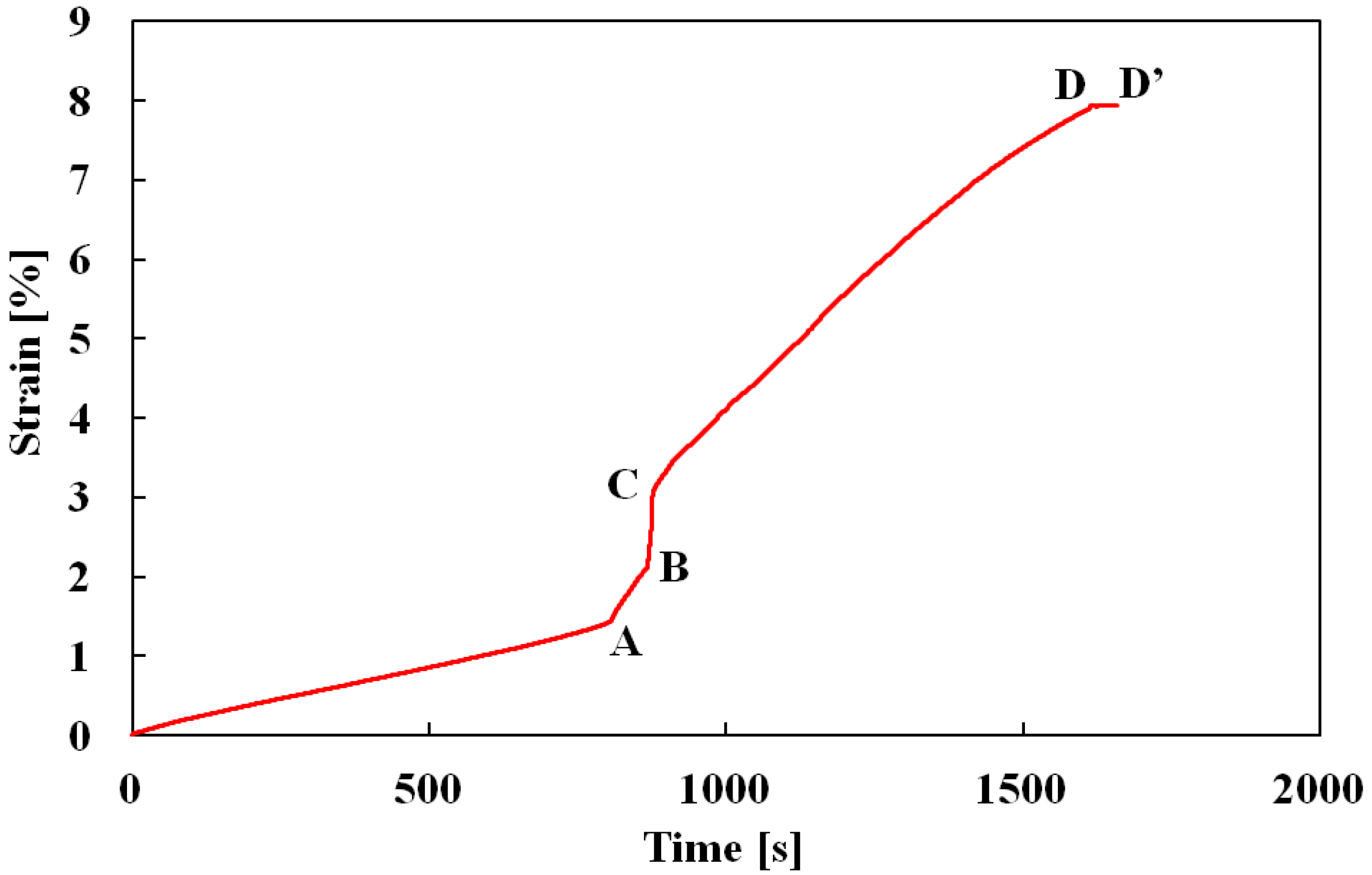

- Creep test: Stress loading was applied at a constant rate up to a level of 2% strain at the upper stress plateau, and stress was then kept constant while the creep deformation behavior was observed.

- (3)

- Creep and creep recovery test: Stress loading was applied at a constant rate up to a strain of 2% at the upper stress plateau, and stress was then kept constant while the creep deformation was observed. After reaching the maximum strain due to the creep deformation, stress was removed at the constant rate down to a decrease in strain of 1.5% from the maximum strain at the lower stress plateau during unloading, and stress was then kept constant while the creep recovery behavior was observed.

4. Superelastic Deformation under Constant Strain Rate

5. Subloop Deformation under Constant Stress Rate

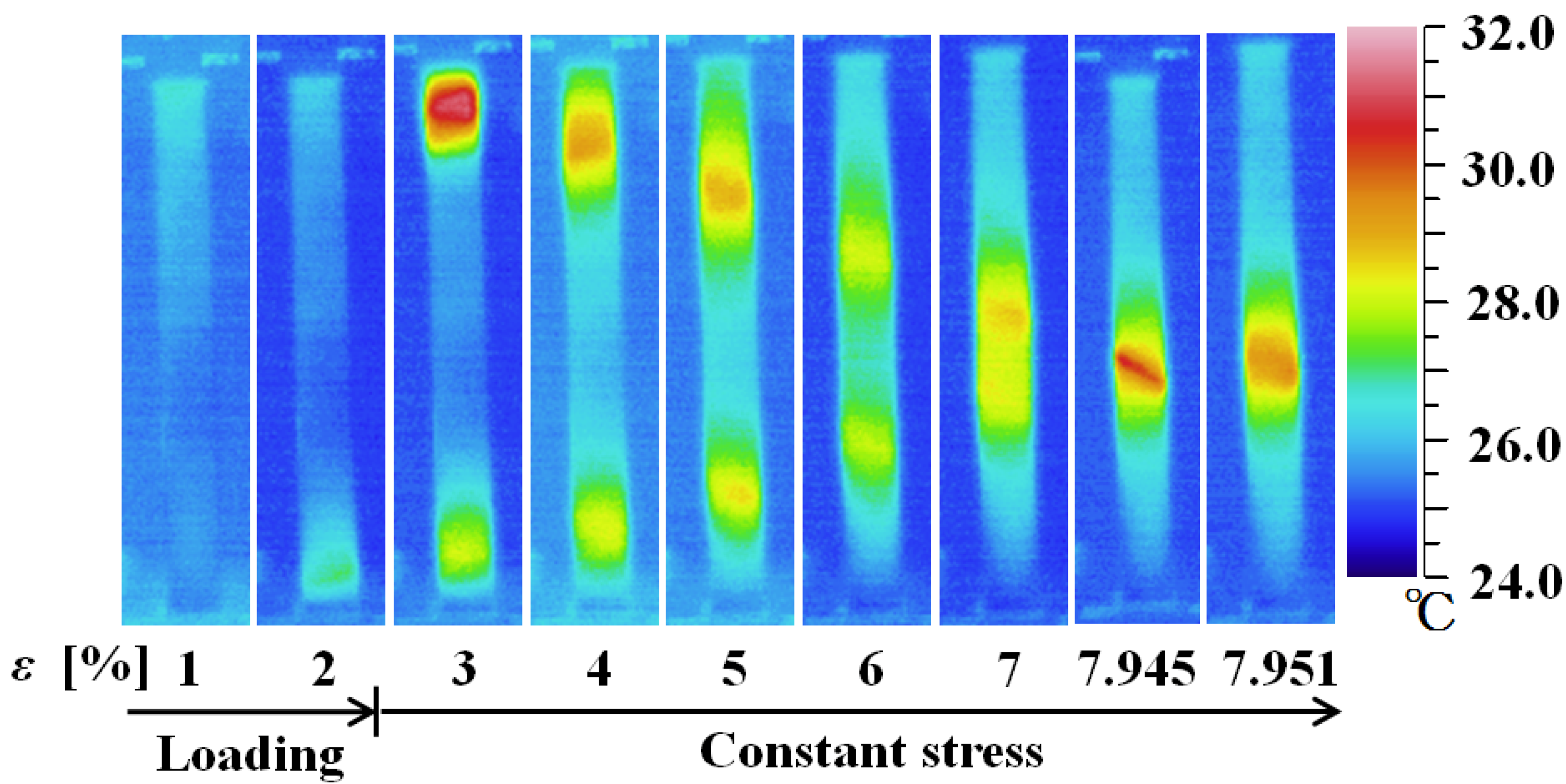

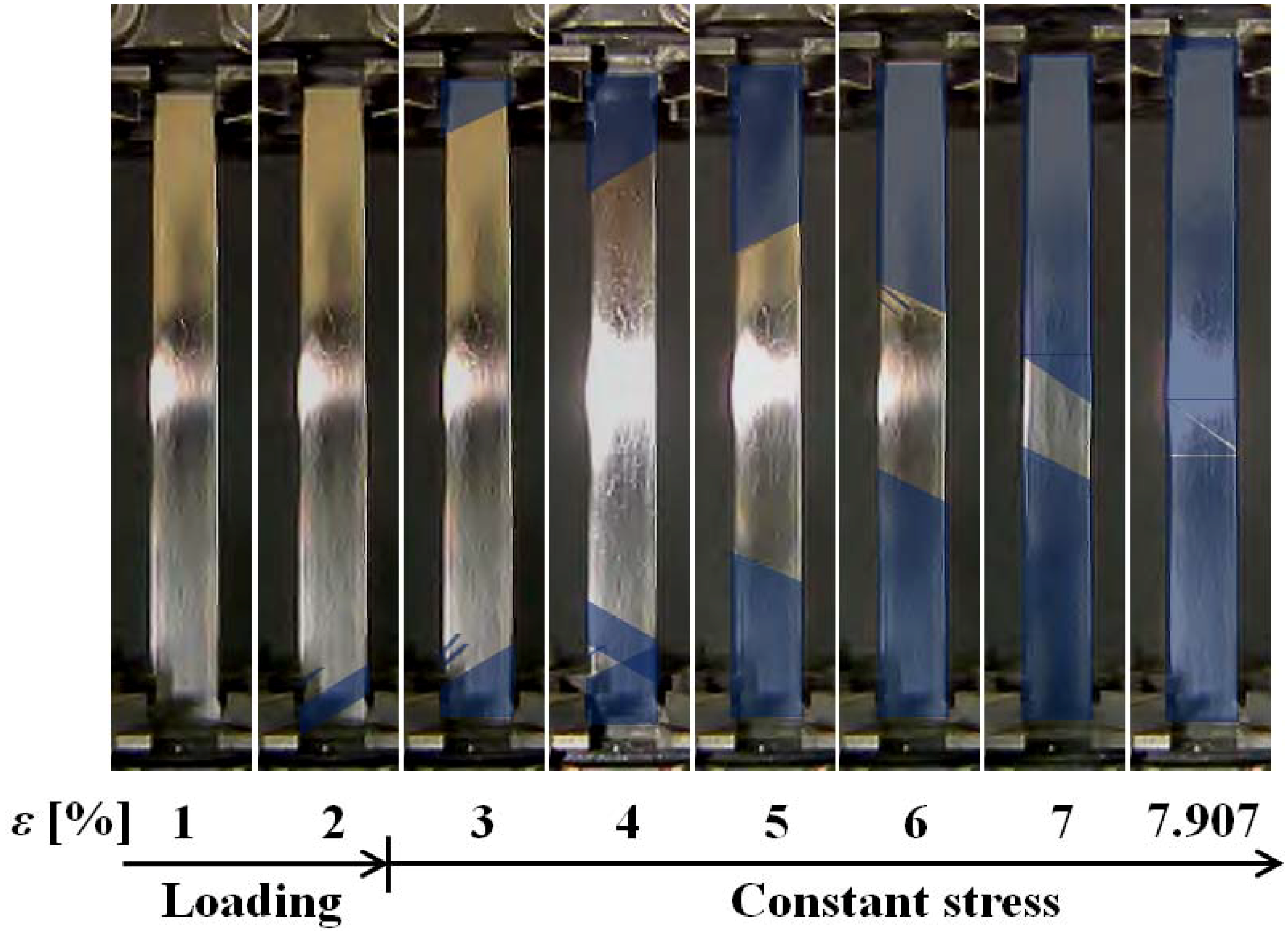

6. Transformation-Induced Creep

6.1. Creep Behavior

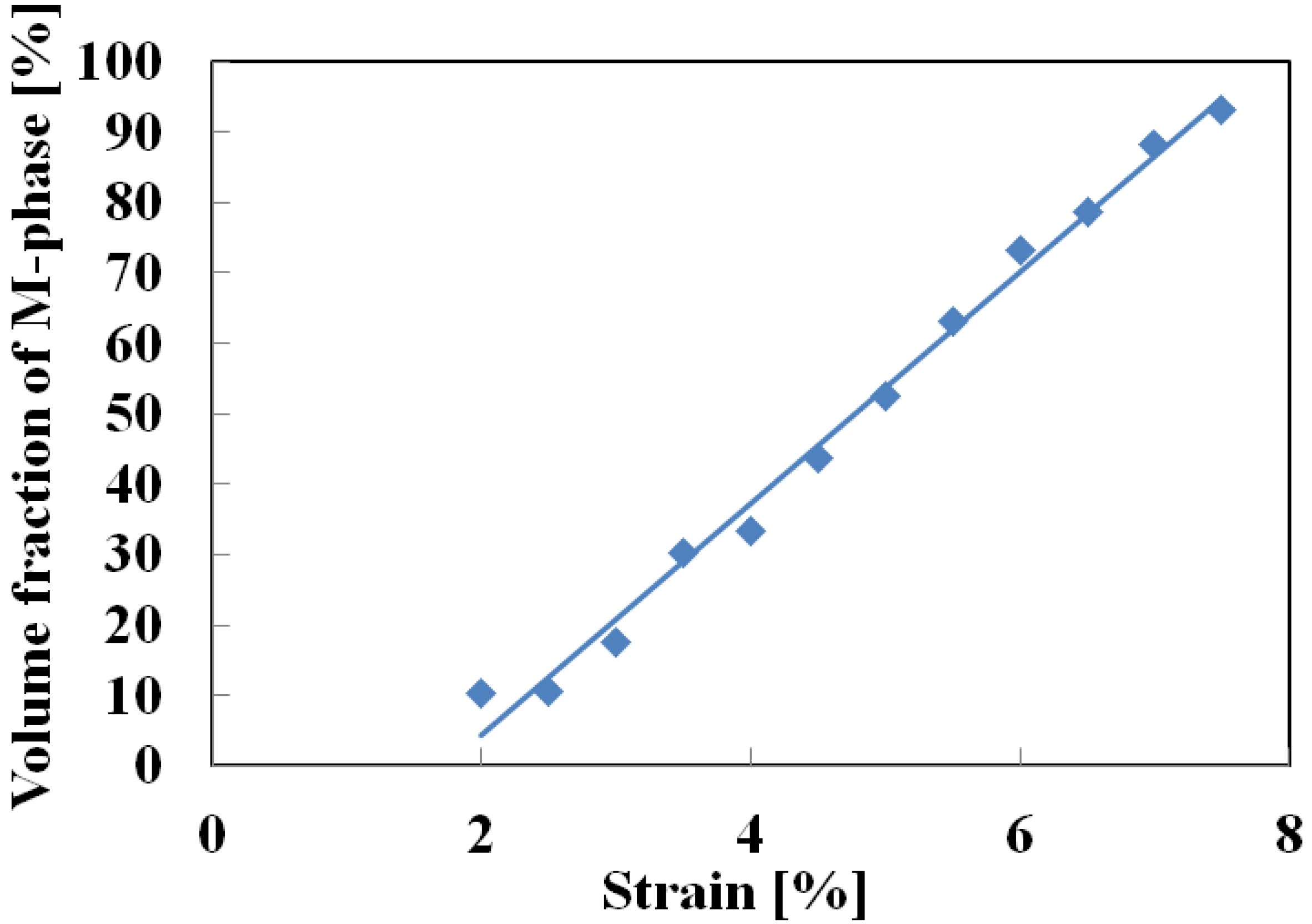

6.2. Progress of Creep

7. Transformation-Induced Creep and Creep Recovery

8. Conclusions

- (1)

- Upper and lower stress plateaus appear in the stress-strain curves during loading and unloading in association with the spreading and shrinking of SIMT bands on the surface of the tape specimens. In the case of unloading from the upper stress plateau under a low stress rate, an increase in strain occurs due to the spreading of the SIMT bands at the start of the unloading.

- (2)

- If stress is held constant at the upper stress plateau after loading up to a strain of 2% under a constant stress rate, creep deformation occurs due to the spread of the SIMT process. The creep strain rate under constant stress is almost constant. It increases in proportion to the increase in the volume fraction of the M-phase.

- (3)

- If stress is held constant at the lower stress plateau after unloading down to a decrease in strain of 1.5% from the maximum strain under a constant stress rate, creep recovery deformation occurs due to reverse transformation.

Acknowledgements

References

- Funakubo, H. Shape Memory Alloys; Gordon and Breach Science: New York, NY, USA, 1987; pp. 1–269. [Google Scholar]

- Otsuka, K.; Wayman, C.M. Shape Memory Materials; Cambridge University Press: Cambridge, UK, 1998; pp. 1–281. [Google Scholar]

- Cismasiu, C. Shape Memory Alloys; Sciyo: Rijeka, Croatia, 2010; pp. 1–209. [Google Scholar]

- Tanaka, K.; Kobayashi, S.; Sato, Y. Thermomechanics of transformation pseudoelasticity and shape memory effect in alloys. Inter. J. Plast. 1986, 2, 59–72. [Google Scholar] [CrossRef]

- Raniecki, B.; Lexcellent, C.; Tanaka, K. Thermodynamic models of pseudoelastic behaviour of shape memory alloys. Arch. Mech. 1992, 44, 261–284. [Google Scholar]

- Tanaka, K.; Nishimura, F.; Tobushi, H. Phenomenological analysis on subloop in shape memory alloys due to incomplete transformations. J. Intell. Mater. Syst. Struct. 1994, 5, 487–493. [Google Scholar] [CrossRef]

- Lin, P.H.; Tobushi, H.; Tanaka, K.; Hattori, T.; Makita, M. Pseudoelastic behaviour of TiNi shape memory alloy subjected to strain variations. J. Intell. Mater. Syst. Struct. 1994, 5, 694–701. [Google Scholar] [CrossRef]

- Tanaka, K.; Nishimura, F.; Hayashi, T.; Tobushi, H.; Lexcellent, C. Phenomenological analysis on subloops and cyclic behavior in shape memory alloys under mechanical and/or thermal loads. Mech. Mater. 1995, 19, 281–292. [Google Scholar] [CrossRef]

- Pieczyska, E.A.; Tobushi, H.; Nowacki, W.K.; Gadaj, S.P.; Sakuragi, T. Subloop deformation behavior of tini shape memory alloy subjected to stress-controlled loadings. Mater. Trans. 2007, 48, 2679–2686. [Google Scholar] [CrossRef]

- Tanaka, K. A thermomechanical sketch of shape memory effect: One-dimensional tensile behavior. Res. Mechanica. 1986, 18, 251–263. [Google Scholar]

- Pieczyska, E.A.; Tobushi, H.; Gadaj, S.P.; Nowacki, W.K. Superelastic deformation behaviors based on phase transformation bands in TiNi shape memory alloy. Mater. Trans. 2006, 47, 670–676. [Google Scholar] [CrossRef]

- He, Y.J.; Yin, H.; Zhou, R.H.; Sun, Q.P. Ambient effect on damping peak of NiTi shape memory alloy. Mater. Lett. 2010, 64, 1483–1486. [Google Scholar] [CrossRef]

- Shaw, J.A.; Kyriakides, S. Thermomechanical aspects of NiTi. J. Mech. Phys. Solids 1995, 43, 1243–1281. [Google Scholar] [CrossRef]

- He, Y.J.; Sun, Q.P. Rate-dependent domain spacing in a stretched NiTi strip. Inter. J. Solids Struct. 2010, 47, 2775–2783. [Google Scholar] [CrossRef]

- Huang, W.M. Transformation front in shape memory alloys. Mater. Sci. Eng. 2005, 392, 121–129. [Google Scholar] [CrossRef]

© 2012 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Takeda, K.; Tobushi, H.; Pieczyska, E.A. Transformation-Induced Creep and Creep Recovery of Shape Memory Alloy. Materials 2012, 5, 909-921. https://doi.org/10.3390/ma5050909

Takeda K, Tobushi H, Pieczyska EA. Transformation-Induced Creep and Creep Recovery of Shape Memory Alloy. Materials. 2012; 5(5):909-921. https://doi.org/10.3390/ma5050909

Chicago/Turabian StyleTakeda, Kohei, Hisaaki Tobushi, and Elzbieta A. Pieczyska. 2012. "Transformation-Induced Creep and Creep Recovery of Shape Memory Alloy" Materials 5, no. 5: 909-921. https://doi.org/10.3390/ma5050909

APA StyleTakeda, K., Tobushi, H., & Pieczyska, E. A. (2012). Transformation-Induced Creep and Creep Recovery of Shape Memory Alloy. Materials, 5(5), 909-921. https://doi.org/10.3390/ma5050909