Hardness and Elastic Modulus on Six-Fold Symmetry Gold Nanoparticles

Abstract

:1. Introduction

2. Results and Discussion

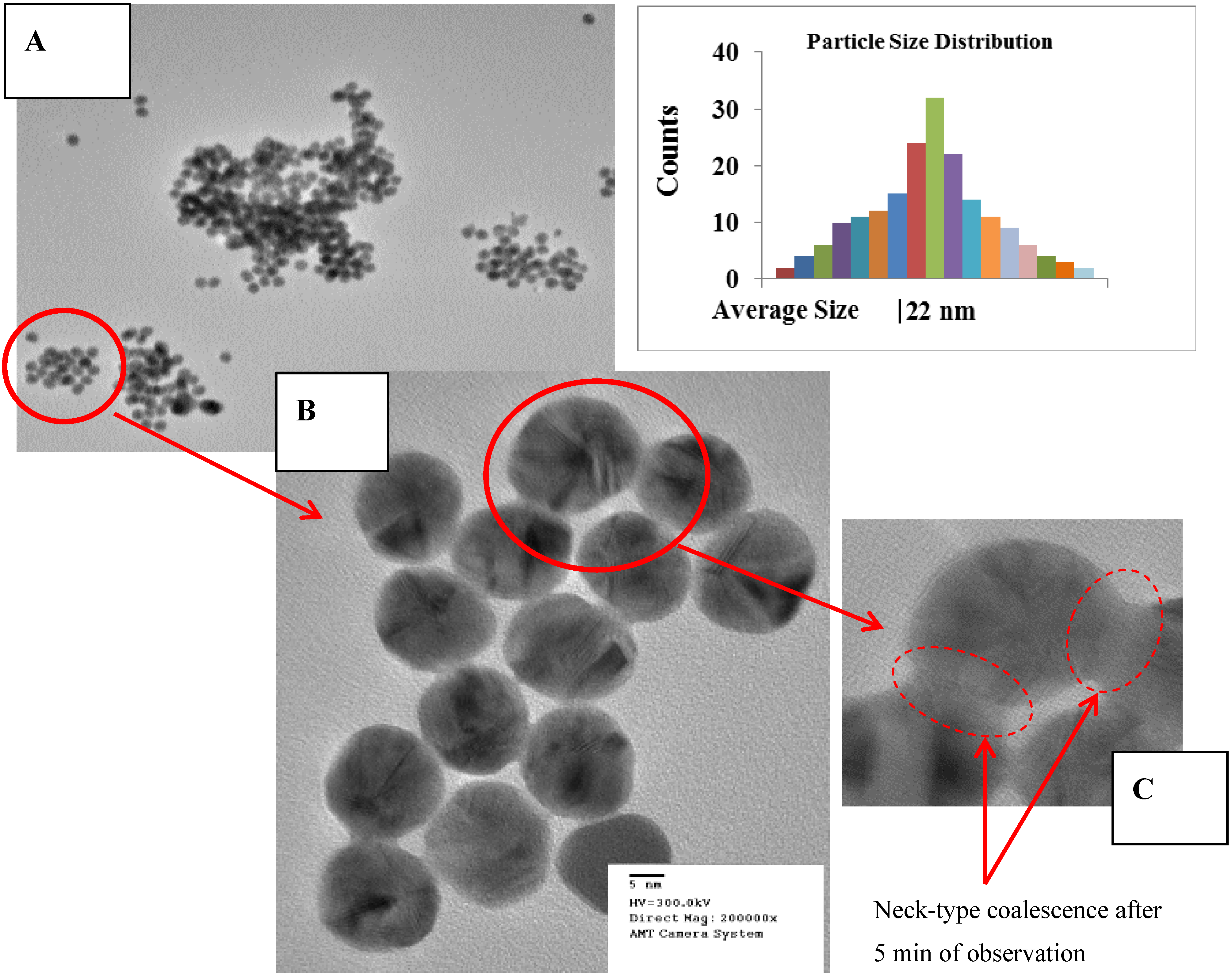

2.1. High Resolution Transmission Electron Microscopy

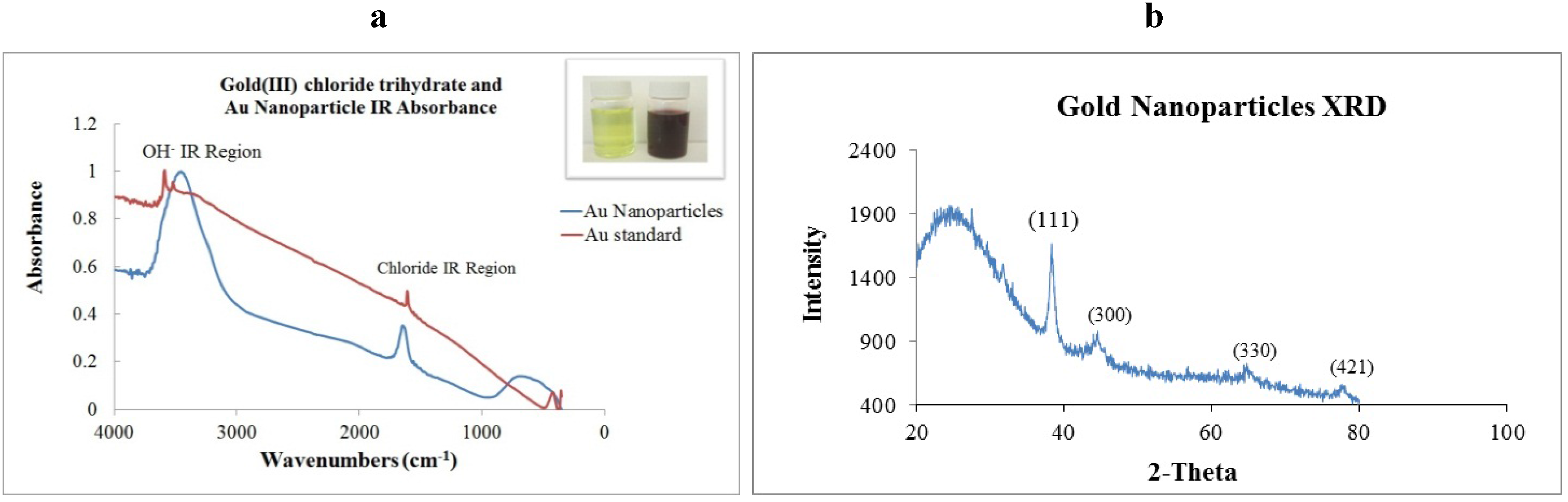

2.2. X-ray Diffraction and Infrared Absorption

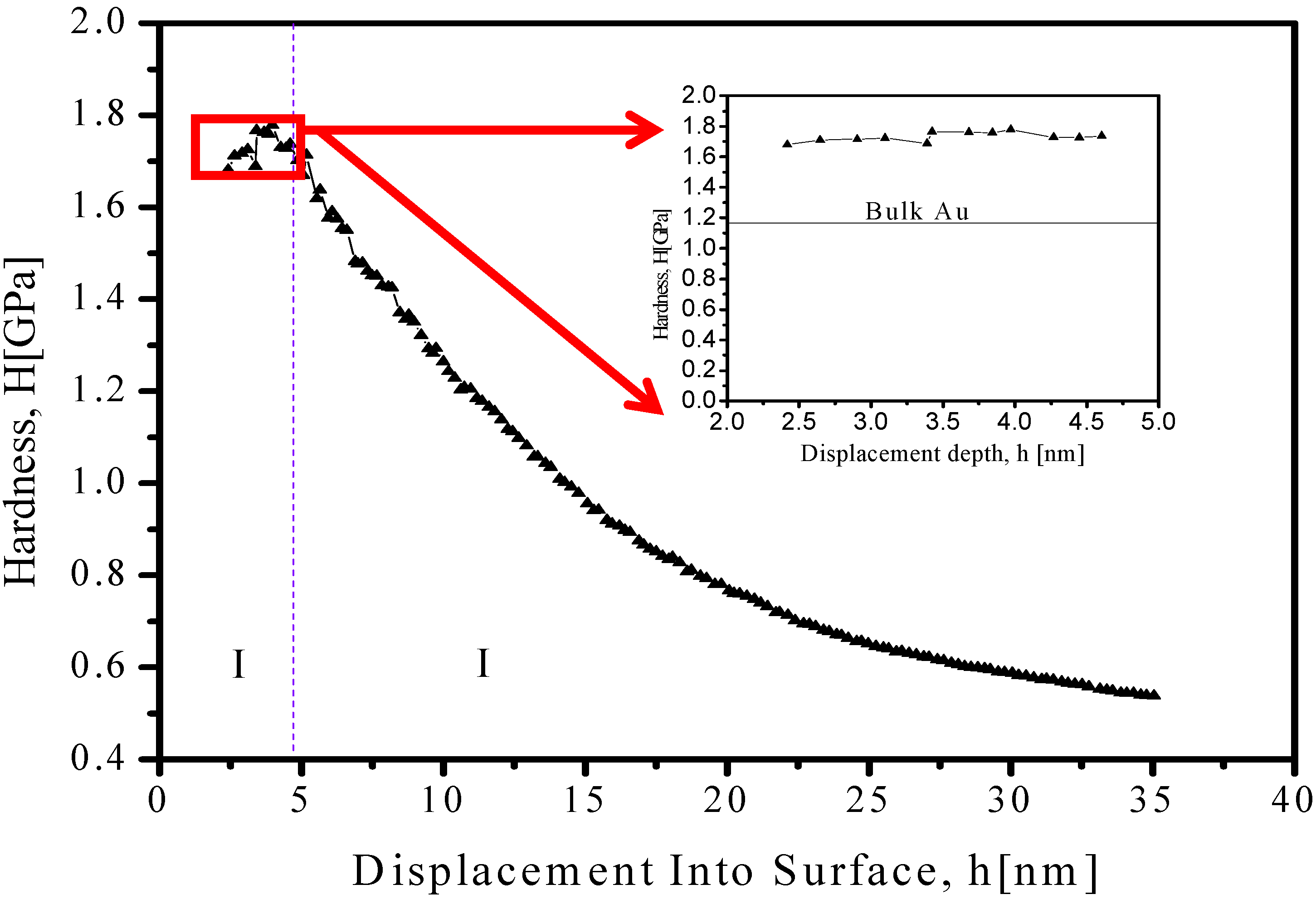

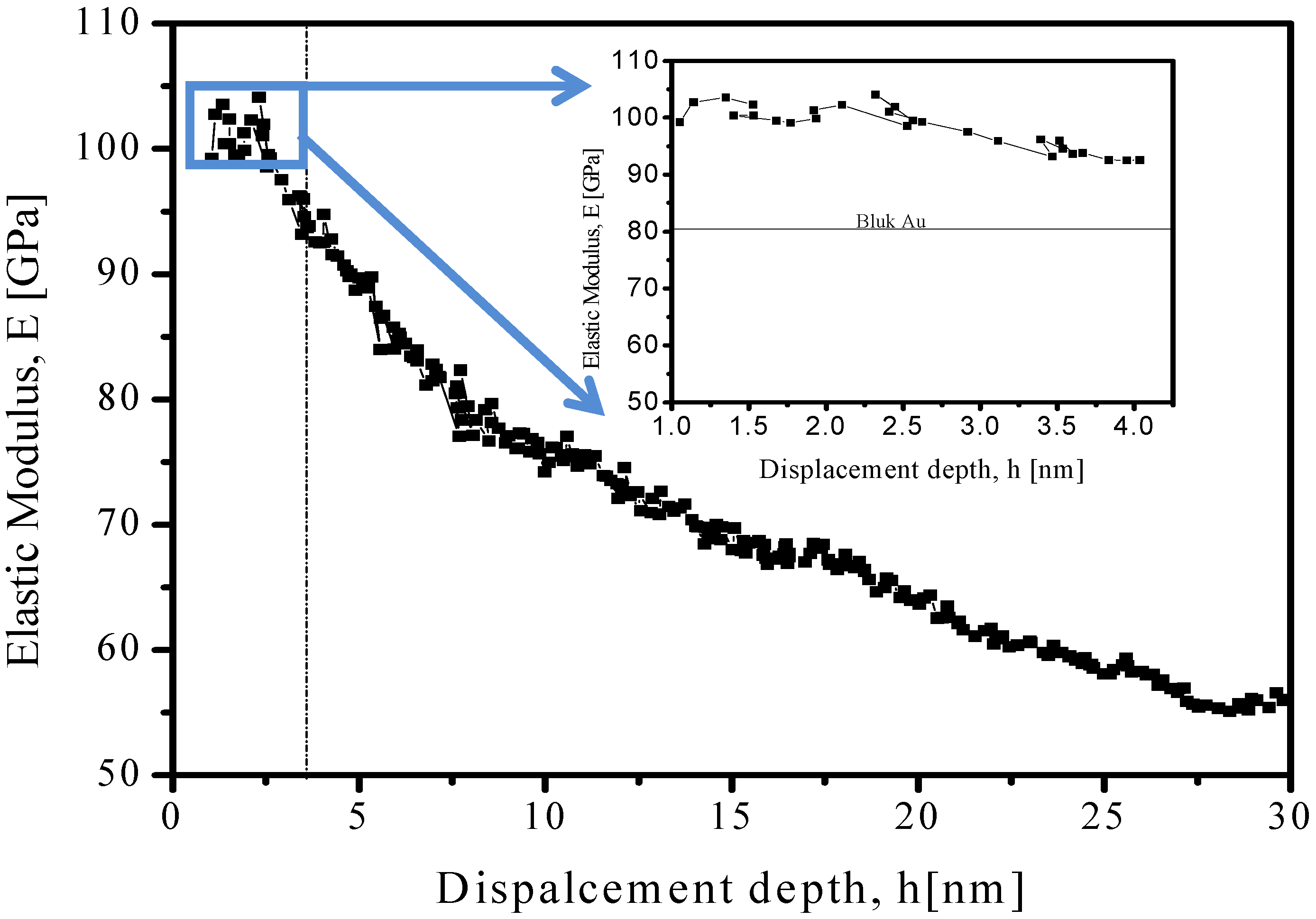

2.3. Mechanical Nanoindentation

3. Experimental Section

4. Conclusions

Acknowledgements

References

- Chen, J.; Wiley, B.; Li, Z.Y.; Campbell, D.; Saeki, F.; Cang, H.; Au, L.; Lee, J.; Li, X.; Xia, Y. Gold nanocages: Engineering their structure for biomedical applications. Adv. Mater. 2005, 17, 2255–2261. [Google Scholar] [CrossRef]

- Thompson, D.T. Using gold nanoparticles for catalysis. Nano Today 2007, 2, 40–43. [Google Scholar] [CrossRef]

- Debouttière, P.-J.; Roux, S.; Vocanson, F.; Billotey, C.; Beuf, O.; Favre-Réguillon, A.; Lin, Y.; Pellet-Rostaing, S.; Lamartine, R.; Perriat, P.; Tillement, O. Design of gold nanoparticles for magnetic resonance imaging. Adv. Funct. Mater. 2006, 16, 2330–2339. [Google Scholar] [CrossRef]

- Lee, P.C.; Meisel, D. Adsorption and surface-enhanced Raman of dyes on silver and gold sols. J. Phys. Chem. 1982, 86, 3391–3395. [Google Scholar] [CrossRef]

- Elechiguerra, J.L.; Reyes-Gasga, J.; José-Yacaman, M. The role of in twinning in shape evolution of anisotropic noble metal nanoparticles. J. Mater. Chem. 2006, 16, 3906–3919. [Google Scholar]

- Montejano-Carrizales, J.M.; Rodriguez-Lopez, J.L.; Gutierrez-Wing, C.; Miki-Yoshida, M.; Jose-Yacaman, M. Encyclopedia of Nanoscience and Nanotechnology.; Nalwa, H.S., Ed.; American Scientific Publishers: Los Angeles, CA, USA, 2004; Volume 2, pp. 237–282. [Google Scholar]

- Casillas, G.; Palomares-Báez, J.P.; Rodríguez-López, J.L.; Luo, J.; Ponce, A.; Esparza, R.; Velázquez-Salazar, J.J.; Hurtado-Macias, A.; González-Hernández, J.; José-Yacaman, M. In situ TEM study of mechanical behaviour of twinned nanoparticles. Philos. Mag. 2012, 92, 4437–4453. [Google Scholar] [CrossRef]

- Carltona, C.E.; Ferreira, P.J. In situ TEM nanoindentation of nanoparticles. Micron 2012, 43, 1134–1139. [Google Scholar] [CrossRef]

- Mook, W.M.; Nowak, J.D.; Perrey, C.R.; Carter, C.B.; Mukherjee, R.; Girshick, S.L.; McMurry, P.H.; Gerberich, W.W. Compressive stress effects on nanoparticle modulus and fracture. Phys. Rev. B 2007, 75, 214112:1–214112:10. [Google Scholar] [CrossRef]

- Gerberich, W.W.; Mook, W.M.; Perrey, C.R.; Carter, C.B.; Baskes, M.I.; Mukherjee, R.; Gidwani, A.; Heberlein, J.; Mc-Murry, P.H.; Girshick, S.L. Superhard silicon nanospheres. J. Mech. Phys. Solids 2003, 51, 979–992. [Google Scholar] [CrossRef]

- Li, X.; Bhushan, B. Development of continuous stiffness measurement technique for composite magnetic tapes. Scr. Mater. 2000, 42, 929–935. [Google Scholar] [CrossRef]

- Li, X.; Bhushan, B. A review of nanoindentation continuous stiffness measurement technique and its applications. Mater. Character. 2002, 48, 11–36. [Google Scholar] [CrossRef]

- José-Yacamán, M.; Gutierrez-Wing, C.; Miki, M.; Yang, D.-Q.; Piyakis, K.N.; Sacher, E. Surface diffusion and coalescence of mobile metal nanoparticles. J. Phys. Chem. B 2005, 109, 9703–9711. [Google Scholar] [CrossRef]

- Deneen, J.; Mook, W.M.; Minor, A.; Gerberich, W.W.; Carter, C.B. In situ deformation of silicon nanospheres. J. Mater. Sci. 2006, 41, 4477–4483. [Google Scholar]

- Deneen, J.; Mook, W.M.; Minor, A.; Gerberich, W.W.; Carter, C.B. Fracturing a nanoparticle. Philos. Mag. 2007, 87, 29–37. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Pethica, J.B.; Oliver, W.C. Tip surface interactions in STM and AFM. Phys. Scr. 1987, 61. [Google Scholar] [CrossRef]

- Volinsky, A.A.; Moody, N.R.; Gerberich, W.W. Nanoindentation of Au and Pt/Cu thin films at elevated temperatures. J. Mater. Res. 2004, 19, 2650–2657. [Google Scholar] [CrossRef]

- Zhang, N.; Deng, Q.; Hong, Y.; Xiong, L.; Li, S.; Strasberg, M.; Yin, W.; Zou, Y.; Taylor, C.R.; Sawyer, G.; Chen, Y. Deformation mechanisms in silicon nanoparticles. J. Appl. Phys. 2011, 109, 063534:1–063534:6. [Google Scholar]

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Ramos, M.; Ortiz-Jordan, L.; Hurtado-Macias, A.; Flores, S.; Elizalde-Galindo, J.T.; Rocha, C.; Torres, B.; Zarei-Chaleshtori, M.; Chianelli, R.R. Hardness and Elastic Modulus on Six-Fold Symmetry Gold Nanoparticles. Materials 2013, 6, 198-205. https://doi.org/10.3390/ma6010198

Ramos M, Ortiz-Jordan L, Hurtado-Macias A, Flores S, Elizalde-Galindo JT, Rocha C, Torres B, Zarei-Chaleshtori M, Chianelli RR. Hardness and Elastic Modulus on Six-Fold Symmetry Gold Nanoparticles. Materials. 2013; 6(1):198-205. https://doi.org/10.3390/ma6010198

Chicago/Turabian StyleRamos, Manuel, Luis Ortiz-Jordan, Abel Hurtado-Macias, Sergio Flores, José T. Elizalde-Galindo, Carmen Rocha, Brenda Torres, Maryam Zarei-Chaleshtori, and Russell R. Chianelli. 2013. "Hardness and Elastic Modulus on Six-Fold Symmetry Gold Nanoparticles" Materials 6, no. 1: 198-205. https://doi.org/10.3390/ma6010198