Effects of Hydrolysed Whey Proteins on the Techno-Functional Characteristics of Whey Protein-Based Films

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Film Casting

2.3. Water Vapour Transmission Rate Measurement

2.4. Oxygen Transmission Rate Measurement

2.5. Tensile Property Measurement

2.6. Young’s Modulus Measurement

2.7. Surface Energy Measurement

2.8. Colour Measurement

2.9. Film Thickness

2.10. Residual Water Content Measurement

2.11. Statistical Analysis

3. Results and Discussions

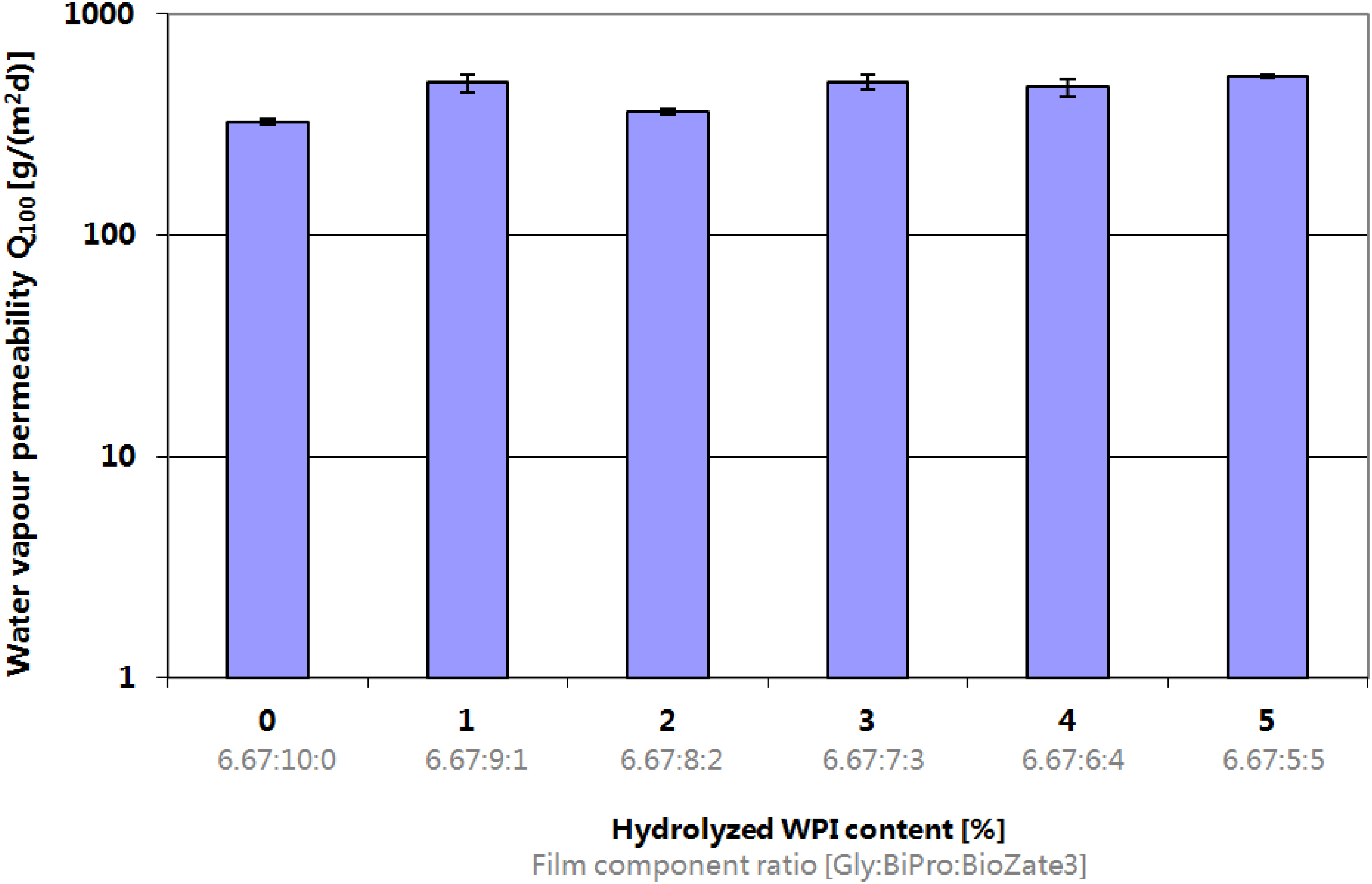

3.1. Water Vapour Transmission Rate

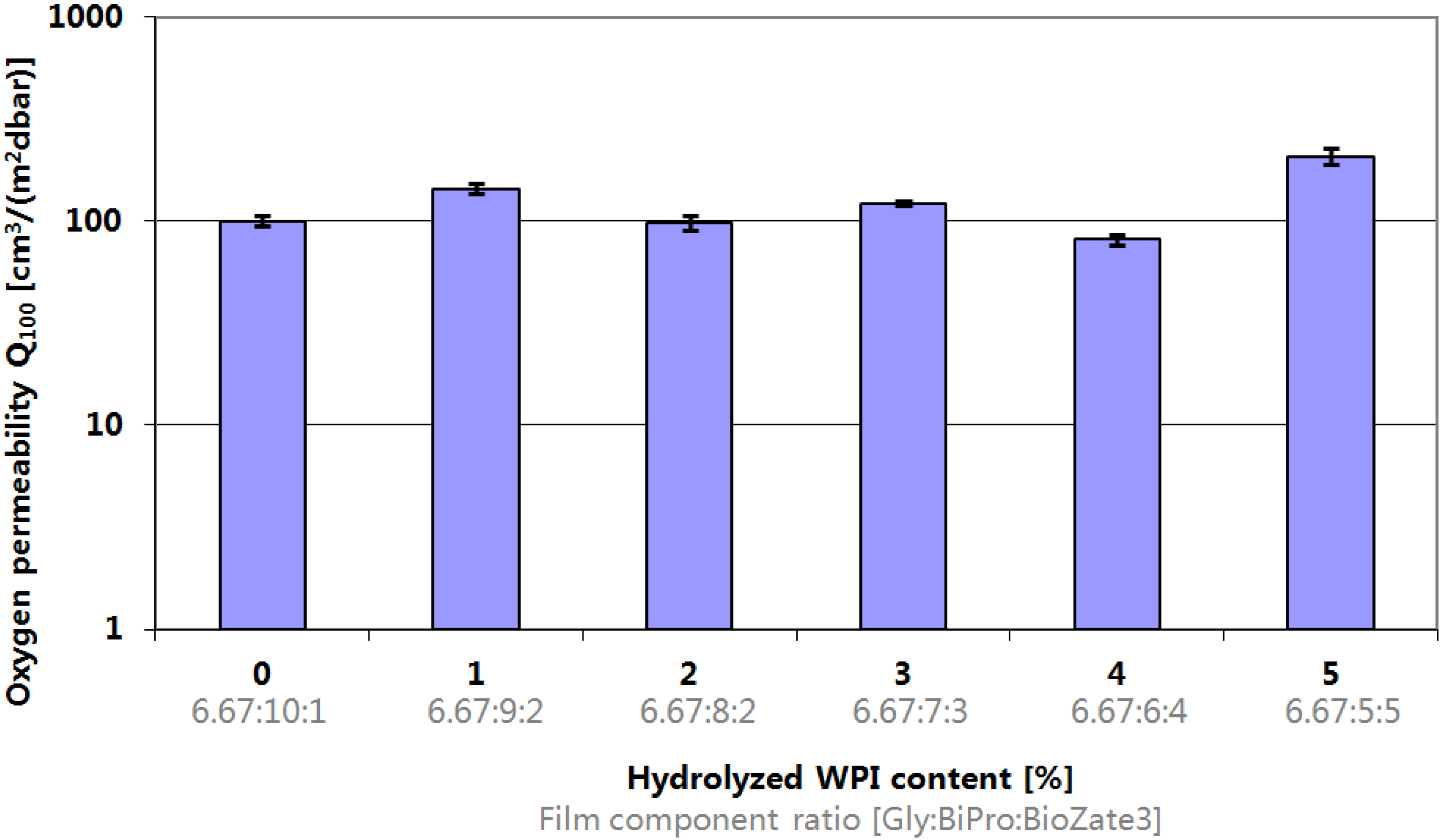

3.2. Oxygen Transmission Rate

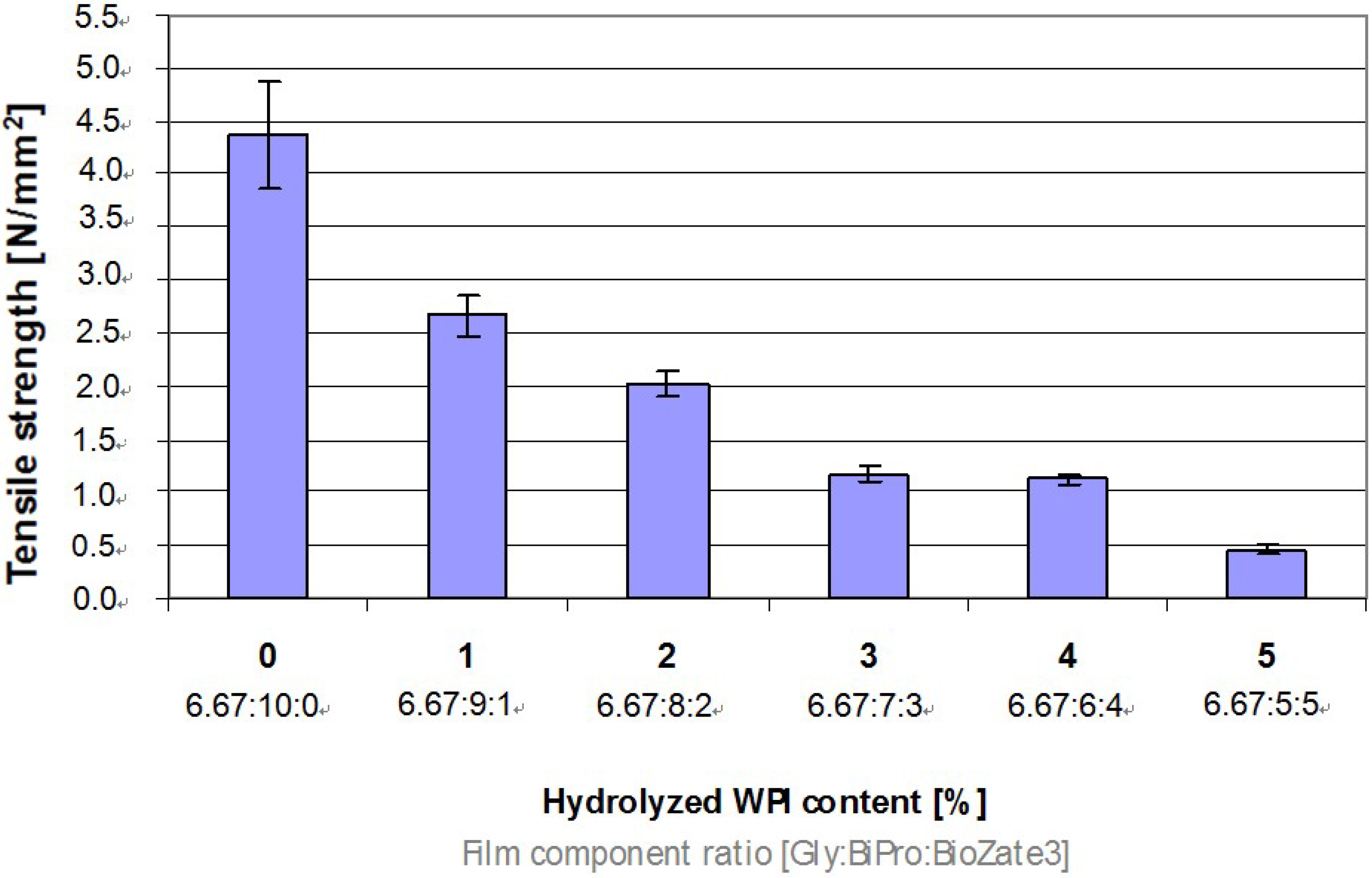

3.3. Tensile Property

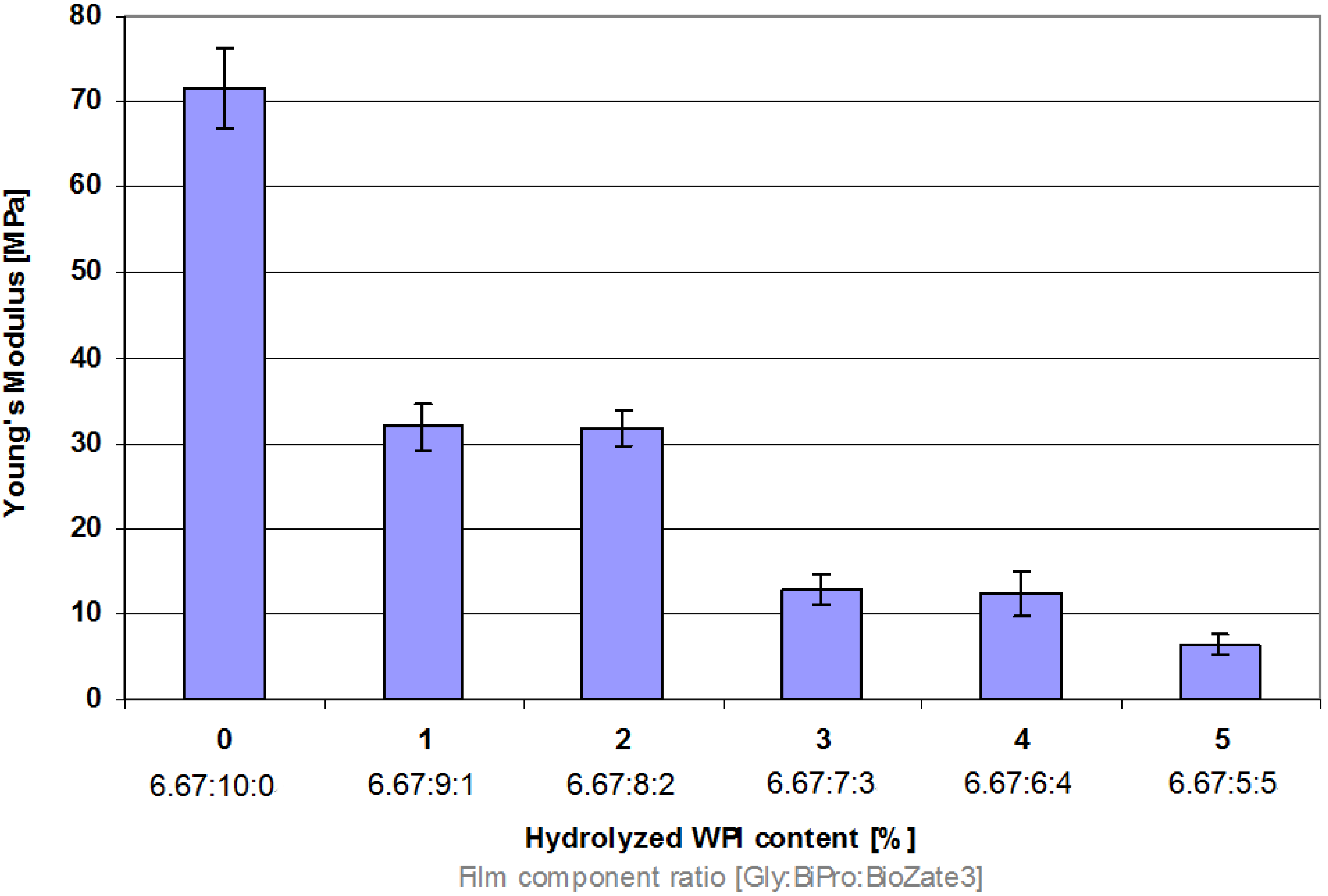

3.4. Elastic Property

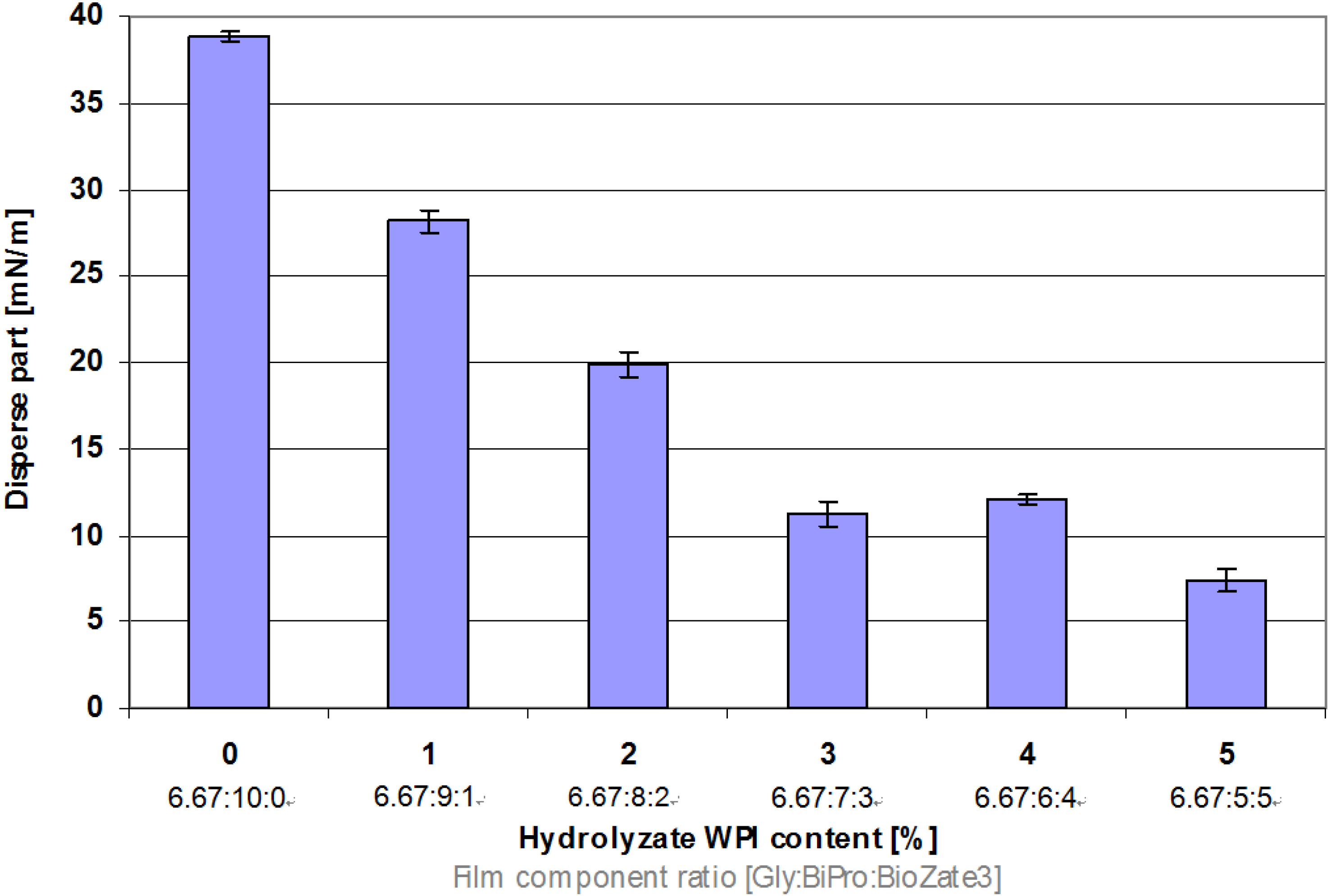

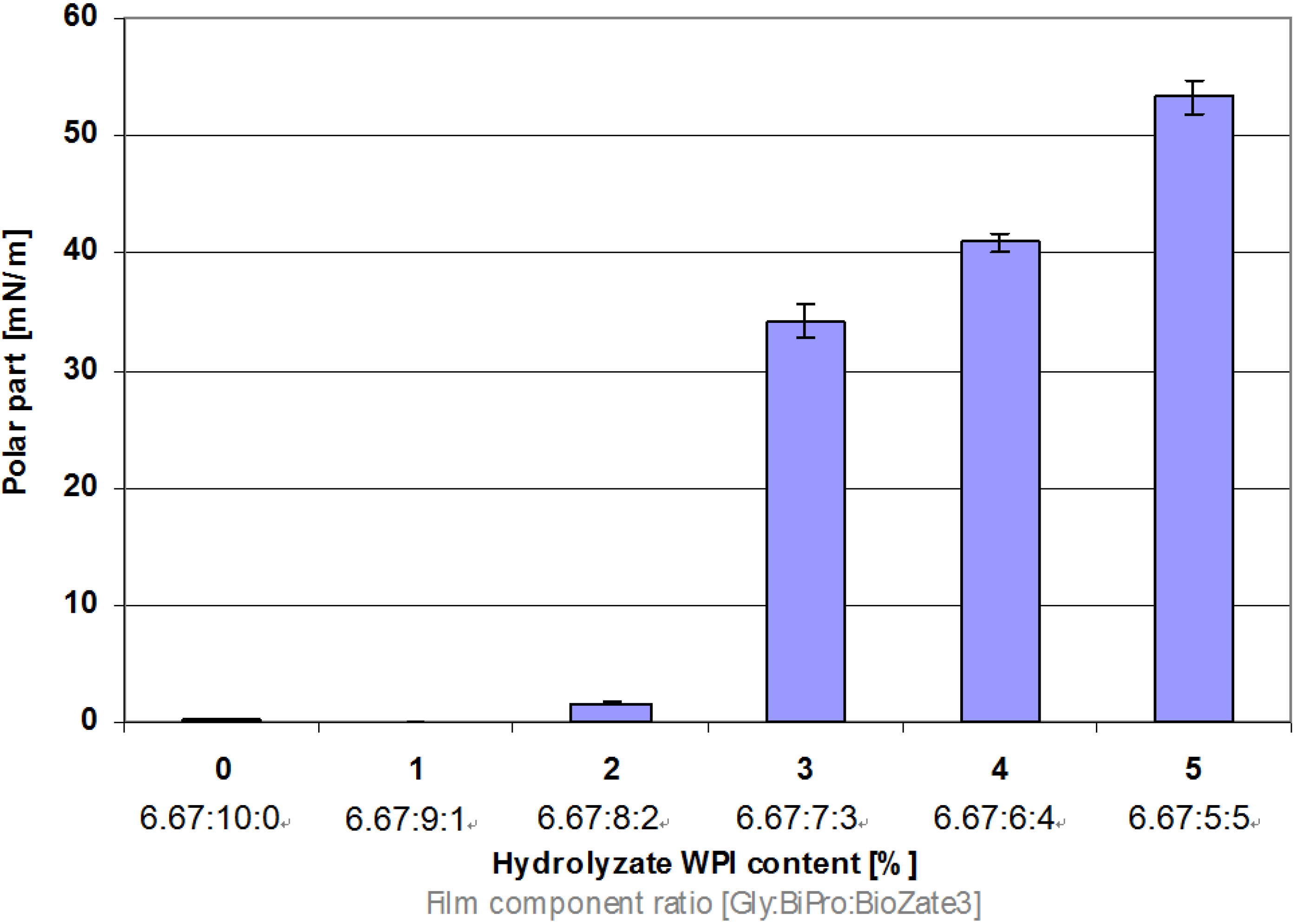

3.5. Surface Energy

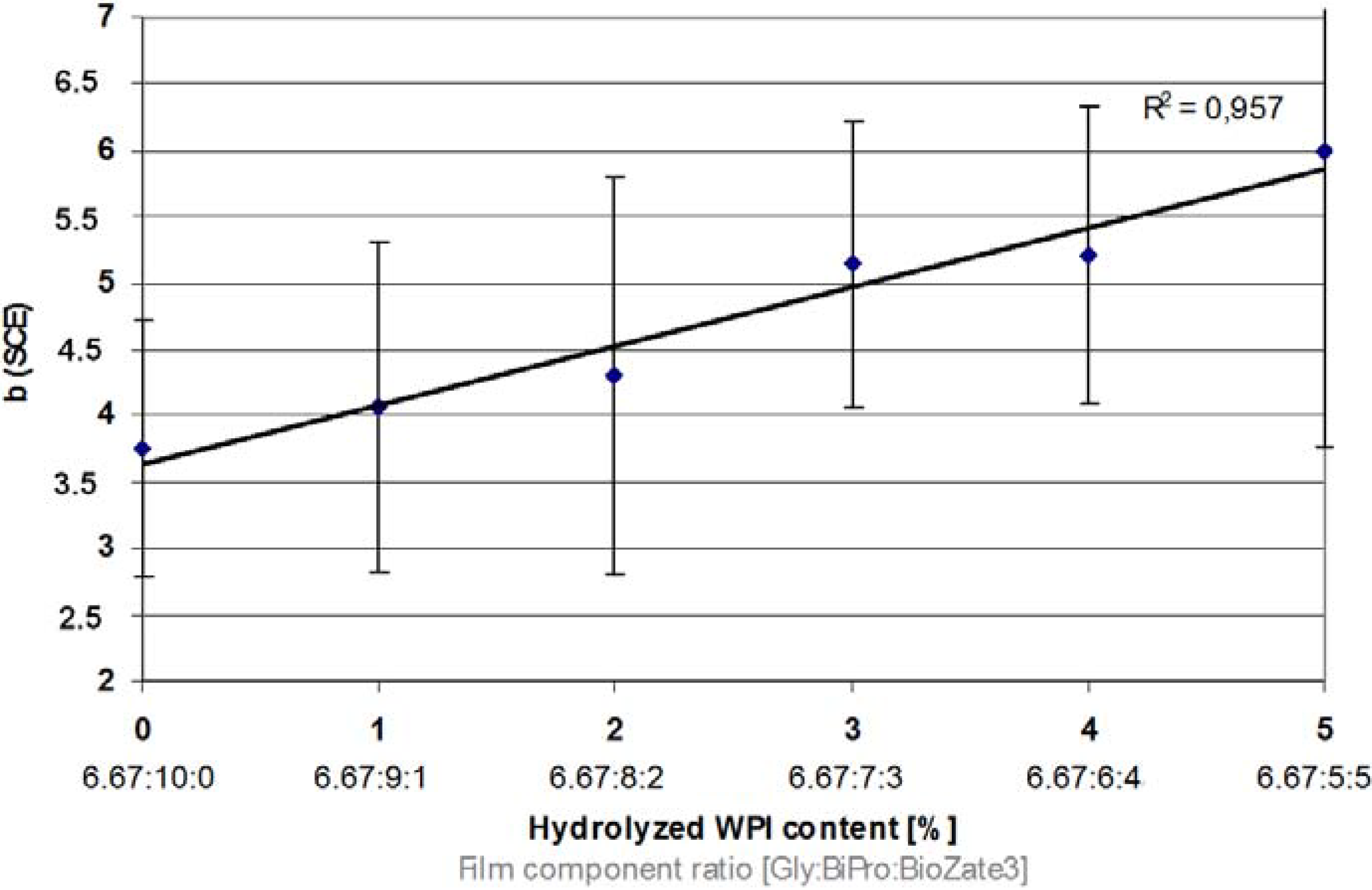

3.6. Yellow Colouration

4. Conclusions

Acknowledgement

References

- Adegboye, T.; Somade, S. 111 Question and Answers in Packaging Technology; iUniverse: Bloomington, IL, USA, 2009. [Google Scholar]

- Schmid, M.; Dallmann, K.; Bugnicourt, E.; Cordoni, D.; Wild, F.; Lazzeri, A.; Noller, K. Properties of whey protein coated films and laminates as novel recyclable food packaging materials with excellent barrier properties. Int. J. Polym. Sci. 2012, 562381:1–562381:7. [Google Scholar]

- Sängerlaub, S.; Gibis, D.; Kirchhoff, E.; Tittjung, M.; Schmid, M.; Müller, K. Compensation of pinhole defects in food packages by application of iron-based oxygen scavenging multilayer films. Packag. Technol. Sci. 2013, 1, 17–30. [Google Scholar] [CrossRef]

- Schmid, M.; Benz, A.; Stinga, C.; Samain, D.; Zeyer, K.P. Fundamental investigations regarding barrier properties of grafted PVOH layers. Int. J. Polym. Sci. 2012, 637837:1–637837:6. [Google Scholar]

- Buchert, J.; Ercili Cura, D.; Ma, H.; Gasparetti, C.; Monogioudi, E.; Faccio, G.; Mattinen, M.; Boer, H.; Partanen, R.; Selinheimo, E.; Lantto, R.; Kruus, K. Crosslinking food proteins for improved functionality. Ann. Rev. Food Sci. Technol. 2010, 1, 113–138. [Google Scholar] [CrossRef]

- de Wit, J.N. Lehrbuch der Molke und Molkenerzeugnisse, 1st ed.; European Whey Products Association: Brüssel, Belgium, 2001; p. 43. [Google Scholar]

- Schmid, M.; Held, J.; Wild, F.; Noller, K. Thermoforming of whey protein-based barrier layers for application in food packaging. Food Sci. Technol. 2011, 25, 34–35. [Google Scholar]

- Schmid, M. Whey protein-based coatings as sustainable barrier material in food packaging applications. In Proceeding of IAPRI World Packaging Conference 2012, San Luis Obispo, CA, USA, 17–21 June 2012; DEStech Publications, Inc.: Lancaster, PA, USA, 2012; pp. 279–286. [Google Scholar]

- Hernandez-Izquierdo, V.M.; Krochta, J.M. Thermal transitions and heat-sealing of glycerol-plasticized whey protein films. Packag. Technol. Sci. 2009, 22, 255–260. [Google Scholar] [CrossRef]

- Whitaker, J.R.; Shahidi, F.; Munguia, A.L.; Yada, R.Y.; Fuller, G. Functional Properties of Protein and Lipids; American Chemical Society: Whasington, DC, USA, 1998. [Google Scholar]

- Bugnicourt, E.; Schmid, M.; Nerney, O.M.; Wildner, J.; Smykala, L.; Lazzeri, A.; Cinelli, P. Processing and validation of whey protein coated films and laminates at semi-industrial scale as novel recyclable food packaging materials with excellent barrier properties. Adv. Mater. Sci. Eng. 2013. in Press. [Google Scholar]

- Hong, S.I.; Krochta, J.M. Oxygen barrier properties of whey protein isolate coatings on polypropylene films. J. Food Sci. 2003, 68, 224–228. [Google Scholar] [CrossRef]

- Sothornvit, R.; Krochta, J.M. Oxygen permeability and mechanical properties of films from hydrolyzed whey protein. J. Agric. Food Chem. 2000, 48, 3913–3916. [Google Scholar] [CrossRef] [PubMed]

- Sothornvit, R.; Krochta, J.M. Water vapor permeability and solubility of films from hydrolyzed whey protein. J. Food Sci. 2000, 65, 700–703. [Google Scholar] [CrossRef]

- McHugh, T.H.; Krochta, J.M. Sorbitol-plasticized vs. glycerol-plasticized whey-protein edible films—Integrated oxygen permeability and tensile property evaluation. J. Agric. Food Chem. 1994, 42, 841–845. [Google Scholar]

- McHugh, T.H.; Aujard, J.F.; Krochta, J.M. Plasticized whey-protein edible films—Water-vapor permeability properties. J. Food Sci. 1994, 59, 416–419. [Google Scholar] [CrossRef]

- Hong, S.I.; Krochta, J.M. Whey protein isolate coating on LDPE film as a novel oxygen barrier in the composite structure. Packag. Technol. Sci. 2004, 17, 13–21. [Google Scholar] [CrossRef]

- Perez-Gago, M.B.; Krochta, J.M. Formation and Properties of Whey Protein Films and Coating. Protein-based Films and Coatings; Gennadios, A., Ed.; CRC Press LLC: Boca Raton, FL, USA, 2002; pp. 162–163, 171, 176. [Google Scholar]

- Onwulata, C.; Huth, P. Whey processing, functionality and health benefits. In Variation: IFT Press Series; Wiley-Blackwell: Ames, IA, USA, 2008; pp. 133–167. [Google Scholar]

- Yoo, S.; Lau, S.H.; Krochta, J.M. Grease penetration and browning resistance of pulpboard and paperboard coated with whey protein. Packag. Technol. Sci. 2012, 25, 259–270. [Google Scholar] [CrossRef]

- McHugh, T.H.; Krochta, J.M. Water-vapor permeability properties of edible whey protein-lipid emulsion films. J. Am. Oil Chem. Soc. 1994, 71, 307–312. [Google Scholar] [CrossRef]

- DIN 53122-1. Bestimmung der Wasserdampfdurchlässigkeit. In Prüfung von Kunststoff-Folien, Elastomerfolien, Papier, Pappe und anderen Flächengebilden; DIN (Deutsches Institut für Normung): Berlin, Germany, 2001; p. 9. [Google Scholar]

- DIN 53380-3. Bestimmung der Gasdurchlässigkeit. In Sauerstoffspezifisches Trägergas-Verfahren zur Messung an Kunststoff-Folien und Kunststoff-Formteilen; DIN (Deutsches Institut für Normung): Berlin, Germany, 1998; p. 9. [Google Scholar]

- DIN EN ISO 527-1. Bestimmung der Zugeigenschaften. In Allgemeine Grundsätze; DIN (Deutsches Institut für Normung): Berlin, Germany, 1996; pp. 3–7. [Google Scholar]

- Davis, J.R. Tensile Testing, 2nd ed.; ASM International: Materials Park, OH, USA, 2004; Volume VII, pp. 3–19. [Google Scholar]

- Beer, F.; Russell, J.E. Mechanics of Materials; McGraw-Hill: New York, NY, USA, 1981; p. 616. [Google Scholar]

- Perez-Gago, M.B.; Nadaud, P.; Krochta, J.M. Water vapor permeability, solubility, and tensile properties of heat-denatured versus native whey protein films. J. Food Sci. 1999, 64, 1034–1037. [Google Scholar] [CrossRef]

- Mate, J.I.; Krochta, J.M. Comparison of oxygen and water vapor permeabilities of whey protein isolate and beta-lactoglobulin edible films. J. Agric. Food Chem. 1996, 44, 3001–3004. [Google Scholar] [CrossRef]

- Perez-Gago, M.B.; Krochta, J.M. Water vapor permeability of whey protein emulsion films as affected by pH. J. Food Sci. 1999, 64, 695–698. [Google Scholar] [CrossRef]

- Endres, H.-J.; Siebert-Raths, A. Engineering Biopolymers: Markets, Manufacturing, Properties and Applications; Hanser-Verlag: Munich, Germany, 2011. [Google Scholar]

- Drummond, C.J.; Chan, D.Y.C. van der Waals interaction, surface free energies, and contact angles: Dispersive polymers and liquids. Langmuir 1997, 13, 3890–3895. [Google Scholar] [CrossRef]

- Pauling, L. General Chemistry; W.H. Freeman: San Francisco, CA, USA, 1988; p. 992. [Google Scholar]

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Schmid, M.; Hinz, L.-V.; Wild, F.; Noller, K. Effects of Hydrolysed Whey Proteins on the Techno-Functional Characteristics of Whey Protein-Based Films. Materials 2013, 6, 927-940. https://doi.org/10.3390/ma6030927

Schmid M, Hinz L-V, Wild F, Noller K. Effects of Hydrolysed Whey Proteins on the Techno-Functional Characteristics of Whey Protein-Based Films. Materials. 2013; 6(3):927-940. https://doi.org/10.3390/ma6030927

Chicago/Turabian StyleSchmid, Markus, Lesley-Virgina Hinz, Florian Wild, and Klaus Noller. 2013. "Effects of Hydrolysed Whey Proteins on the Techno-Functional Characteristics of Whey Protein-Based Films" Materials 6, no. 3: 927-940. https://doi.org/10.3390/ma6030927