1. Introduction

The agromaterials, greatly reviewed by Rouilly and Rigal in 2002 are a very promising field, effective in reducing green-house effect (few or no petroleum use) and producing easily biodegradable products [

1]. Using only agricultural wastes instead of dedicated crops is tomorrow's challenge for producing such materials because of the land-usage competition between food in one hand, and industry in the other hand (fuel, plastic-like materials, solvents,

etc.). Under this consideration, researchers have been working on the molding of natural fiber materials without addition of any glue, binder, or polymeric resin.

The major part of these reports is about binderless particleboards (historically Mobarak

et al. [

2] 1982, Suchsland

et al. [

3] 1987, Suzuki

et al. [

4] 1998, Anglès

et al. [

5] 1999, Okuda and Sato [

6] 2004, Van Dam

et al. [

7] 2004, Widyorini

et al. [

8] 2005 followed by many others) which use low pressure molding (typically around 10 MPa) and thermo-triggered self-binding ability of natural fibers, with help of a steam treatment, or not.

High pressure molding (generally over 100 MPa) in two or three dimensions and extrusion have been more recently studied on pure non modified natural fibers (e.g., Miki

et al. [

9] 2003, Imanishi

et al. [

10] 2005, Yamashita

et al. [

11] 2007, Rouilly

et al. [

12] 2012).

These papers explored the conditions of molding and their effect on the mechanical properties of the resulting materials, but in these cases, since the starting material contains cellulose, hemicelluloses, lignin and also proteins or short polysaccharides, the contribution of each component to the bonding remains unclear. It is widely admitted and reported that the self-binding ability of natural fibers is mostly based on melting/glass transition and degradation products of lignin and hemicelluloses. In addition, for materials that contain protein and sugars, their presence can have a major role. The main component of every plant material is cellulose, it is therefore of major interest to study the self binding ability of pure cellulose to produce agromaterials.

Cellulose can be processed into very high performance films and sheets according to the concepts of “all cellulose composite” and “nanofibers paper”. The first concept uses a sequential exchange of solvent from water to DMAc through ethanol and acetone and the final addition of LiCl to solubilize cellulose. Then removing the solvent by rinsing and casting produces very high performance sheets: e.g., Nishino

et al. [

13] processed a composite made from pre-oriented ramie fibers and Kraft pulp solubilized cellulose matrix which obtained a dynamic storage modulus of 45 GPa and an amazing tensile strength of 480 MPa. Gindl and Keckes [

14] processed micro-crystalline cellulose the same way and obtained an anisotropic all cellulose film which had 13 GPa of Young’s modulus and 243 MPa of tensile strength.

These amazing performances seemed to be possible only with the dissolution of cellulose using hazardous chemicals but Yano

et al. [

15] reported the production of high strength material without solubilization of fibers: working with Kraft pulp, they used repeated high pressure homogenizer treatments to reduce the size of the cellulose microfibrils to a nanometer scale, which was called nanofibers. The suspension was concentrated with cold pressing, followed by an air drying step and a final hot pressing step. They obtained 16 GPa of bending modulus and a high bending strength of 250 MPa. Iwamoto

et al. [

16] reported 8 GPa of Young’s modulus and 90 MPa of tensile strength using a special grinding treatment of cellulose water suspension and a similar process of filtering and drying. Finally, Nogi

et al. [

17] presented an optically transparent material based on the findings of Yano

et al. and the grinding treatment of Abe

et al. [

18] which had a Young’s modulus of 13 GPa and a tensile strength of 223 MPa.

Compression-molding as an alternative method to time consuming air drying process was also studied. Nilsson

et al. [

19] reported the production of compression molded material from wet cellulose disintegrated pulps using a two-stage (Cold, 7 min, 0.6 MPa/Hot, 20 min,−45 MPa) pressing step, their material reached 11 GPa of Young’s modulus and 76 MPa of tensile strength. Also, Rampinelli

et al. [

20] studied the mechanical properties of compression molded highly refined micro-fibrillated cellulose. They produced a material with 180 MPa of tensile strength, 165 MPa of bending strength and a bending modulus of 9.4 GPa with an optimized process using 120 MPa of pressure, for 6 min at 160 °C. Finally, Zhang

et al. [

21] produced ball-milled cellulose material from non treated cotton linters micro-crystalline cellulose using a high shear device usually dedicated to the sintering of metals and reported a bending modulus of 1.84 GPa using DMA measurements.

The pharmaceutical tablet production uses cellulose as excipient, but it uses room temperature to prevent degradation of the active substances and a lot of additives can be used [

22].

This paper examines the possibility of molding purified cellulose under its most current and simple form, α-cellulose, non refined, untreated, unmodified and without the use of a water suspension step. The goal of this project is to produce 3D objects with a fast and eco-friendly yet economically viable process of compression molding of raw lignocellulosic materials. Molding parameters were deeply explored on α-cellulose as the major polymer in lignocellulosic materials. The effects of the parameters on the mechanical properties of the molded samples were investigated. The three-points bending and tensile strengths and moduli, specific density and moisture content of the compression-molded specimen were measured and results were discussed.

3. Discussion

A first statement of this study was the possibility of molding cellulose objects with interesting mechanical properties in a very short time. Yano

et al. [

15] used a days-long drying step and a further 30 min of pressing to obtain very high performance nanofiber sheets. Later, Iwamoto

et al. [

16] suppressed the pressing step but needed 48 h at 55 °C and final drying at 105 °C to obtain the material. Nogi

et al. [

17] confirmed this process when they first introduced their optically transparent nanofibers paper which was obtained by a 72 h drying step. Very long processing times are also observed in the case of solubilization of cellulose for obtaining “all cellulose composites” [

13,

14].

In the case of binderless particleboards, long processing times are expected when directly pressing raw material usually 10 [

6] or 20 min [

26]. When the starting material is pre-treated using steam explosion, molding times can be reduced, e.g., 80 s [

3].

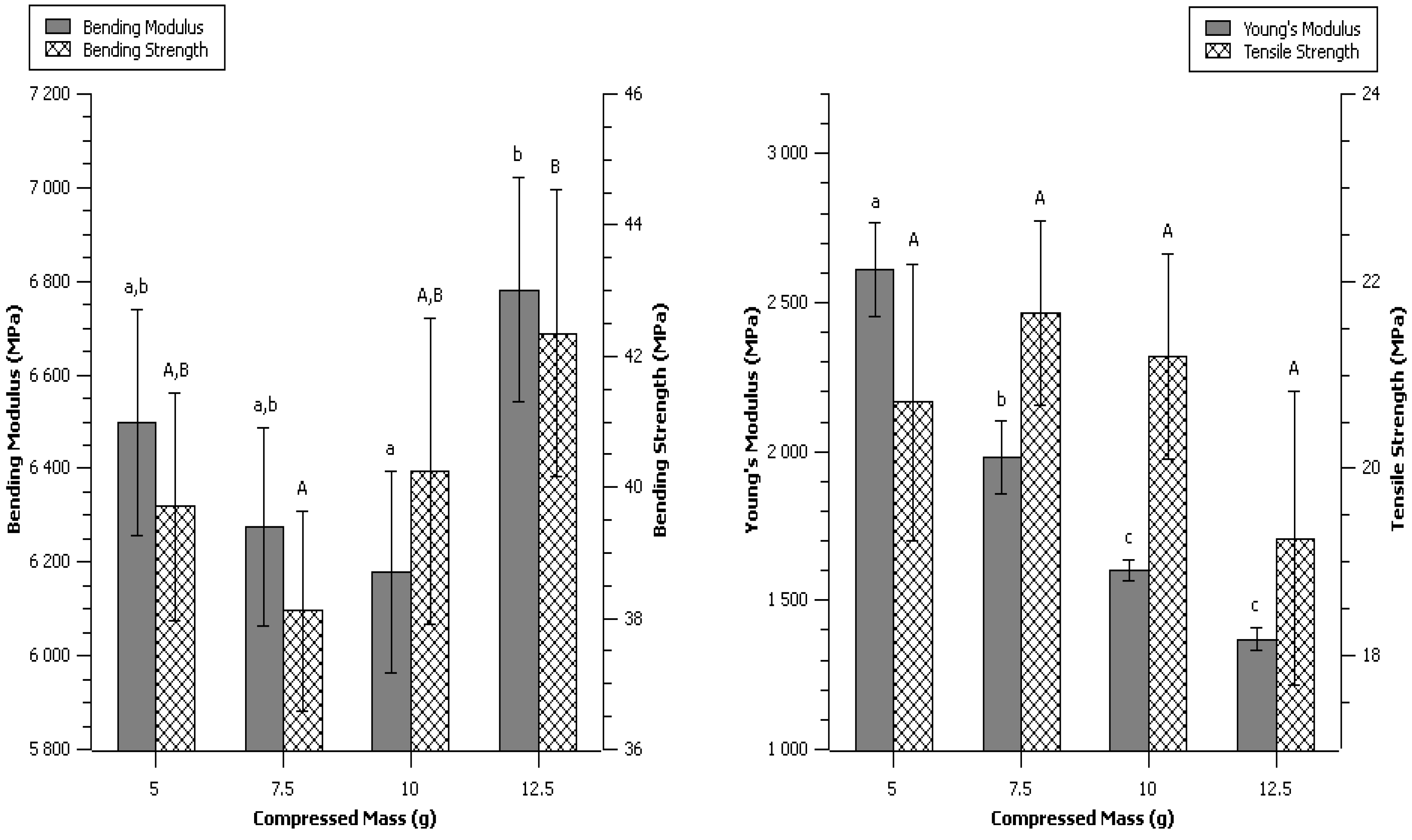

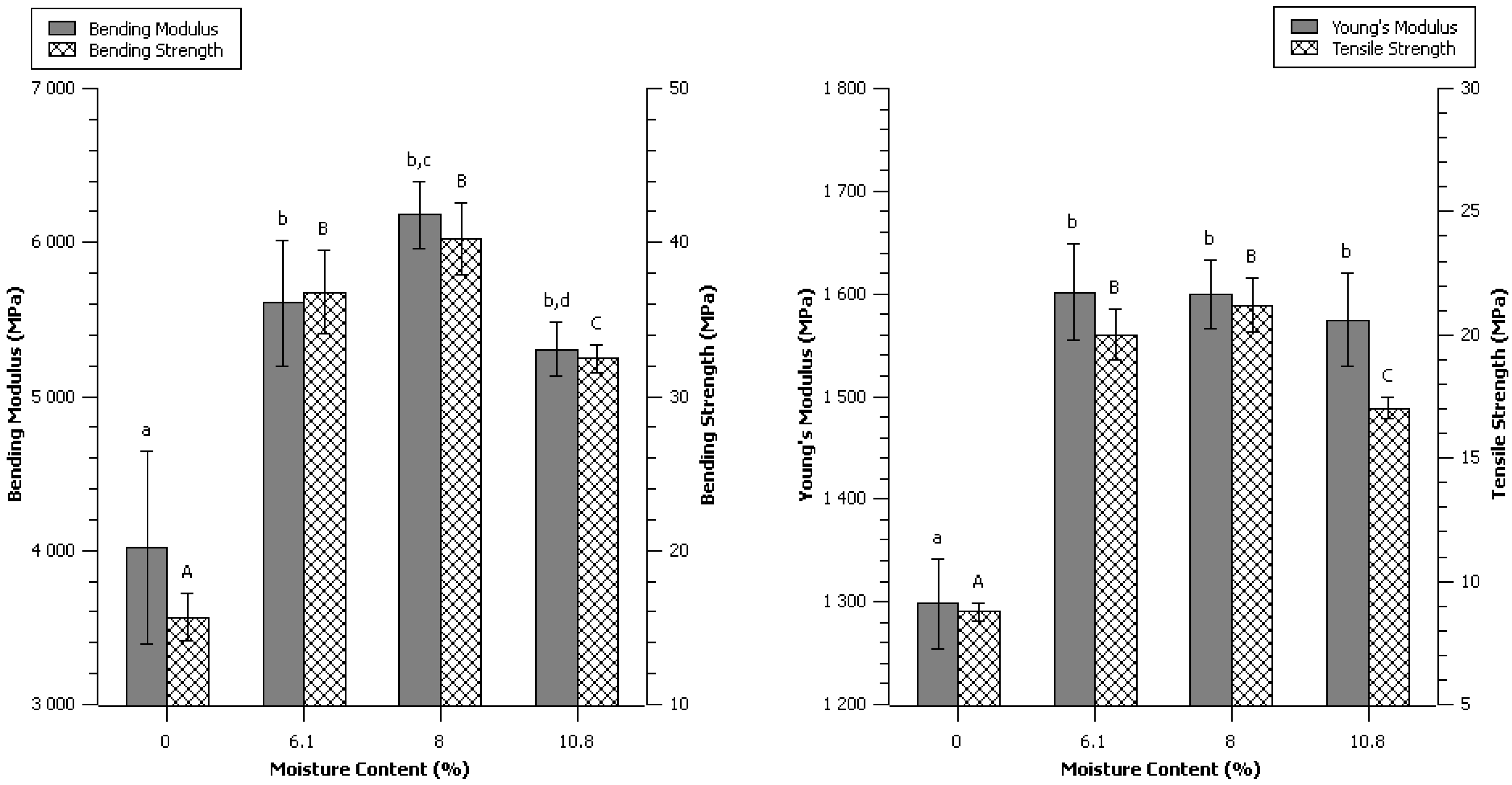

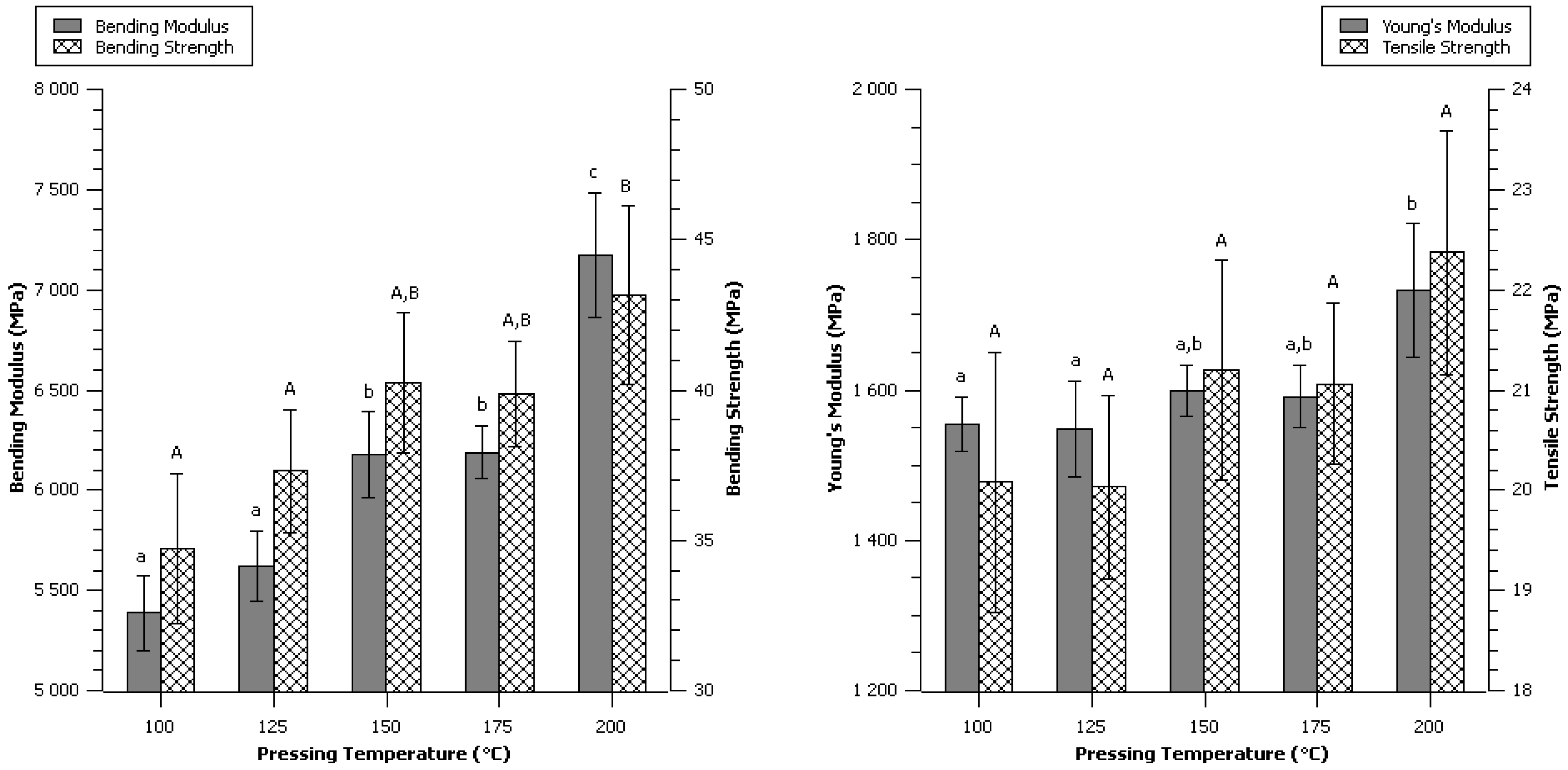

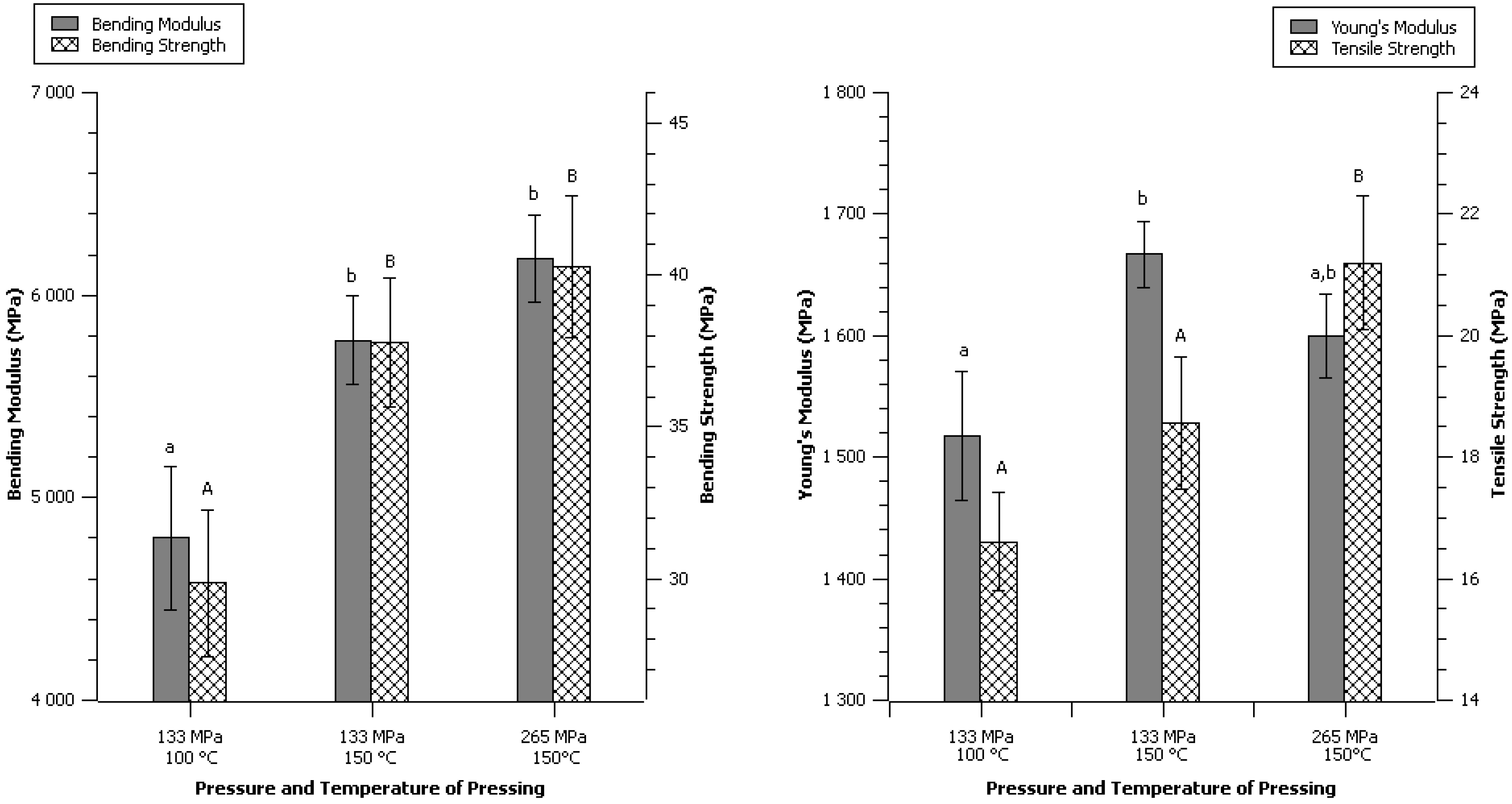

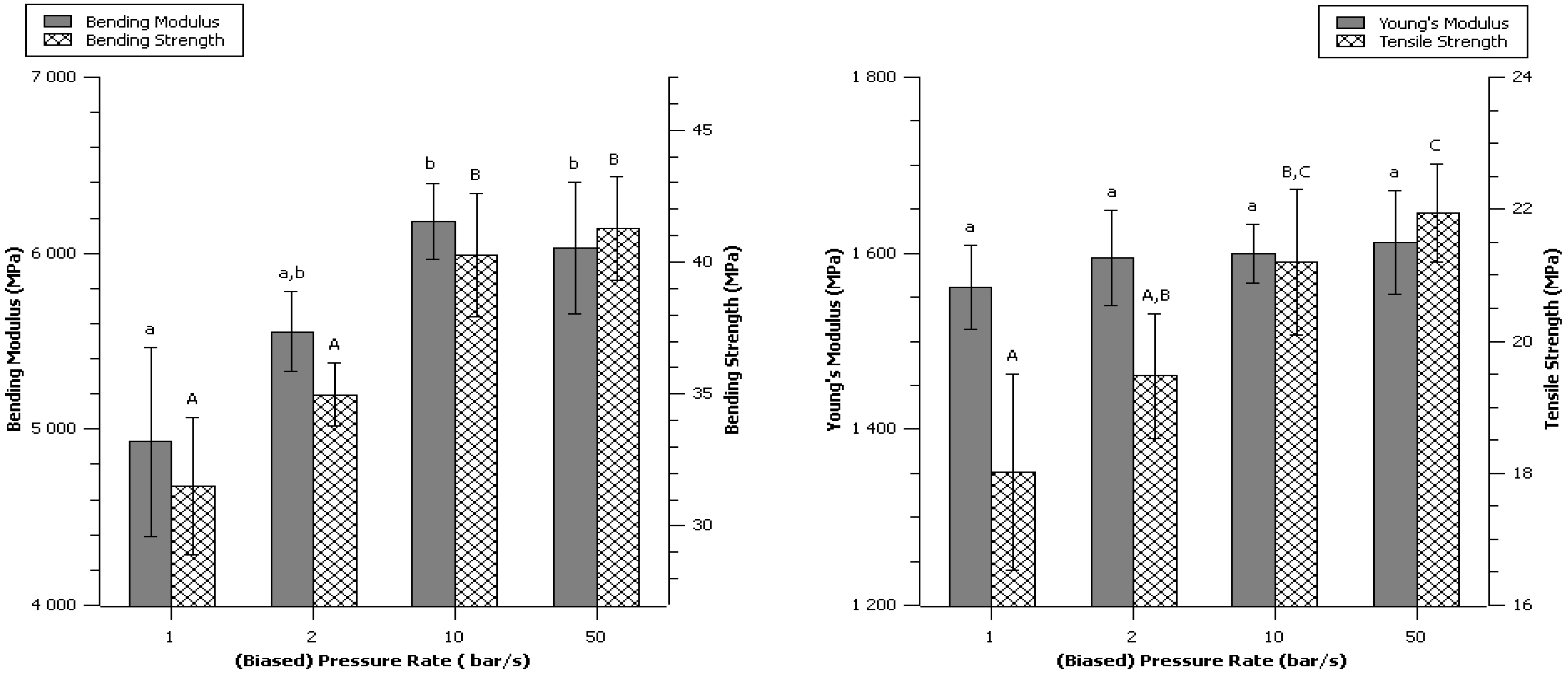

In this study, three seconds of compression molding without using any pre-treatment to fibrillate the cellulose gave specimens with decent mechanical properties: 35.5 ± 1.1 MPa of bending strength, 6.38 ± 0.10 GPa of bending modulus, 18.4 ± 0.6 MPa of tensile strength and 1.60 ± 0.00 GPa of Young’s modulus (

Table 1). These mechanical properties were not able to compete with the highly refined nanofiber cellulose papers: our specimens had about five times lower properties in bending [

15], and even 20 times in tensile considering the composites obtained by cellulose dissolution [

13] but will be sufficient in most of common applications. The absence of pre-treatment for defibrillation is therefore thought to be the most probable explanation for the much lower performances observed in this study compared to the others. Anyway, decent mechanical properties obtained in a very short processing time make it possible to consider an industrialization of this process.

It is commonly thought that density on natural fiber binderless boards brings higher mechanical properties as demonstrated by Okuda

et al. [

6,

27] and Widyorini

et al. [

8], for examples. The higher density of matter means that particles are being forced to be very close therefore increasing surface contact and the possibilities of producing hydrogen bonds and increasing van der Waals forces. Even Yano

et al. [

15] in the nanofiber paper field compared the density of the material obtained from original Kraft pulp (1.25 g/cm

3) and highly refined fibrillated nanofibers (1.48 g/cm

3), and it was reported a five times increase of the MOE and MOR with increasing the density.

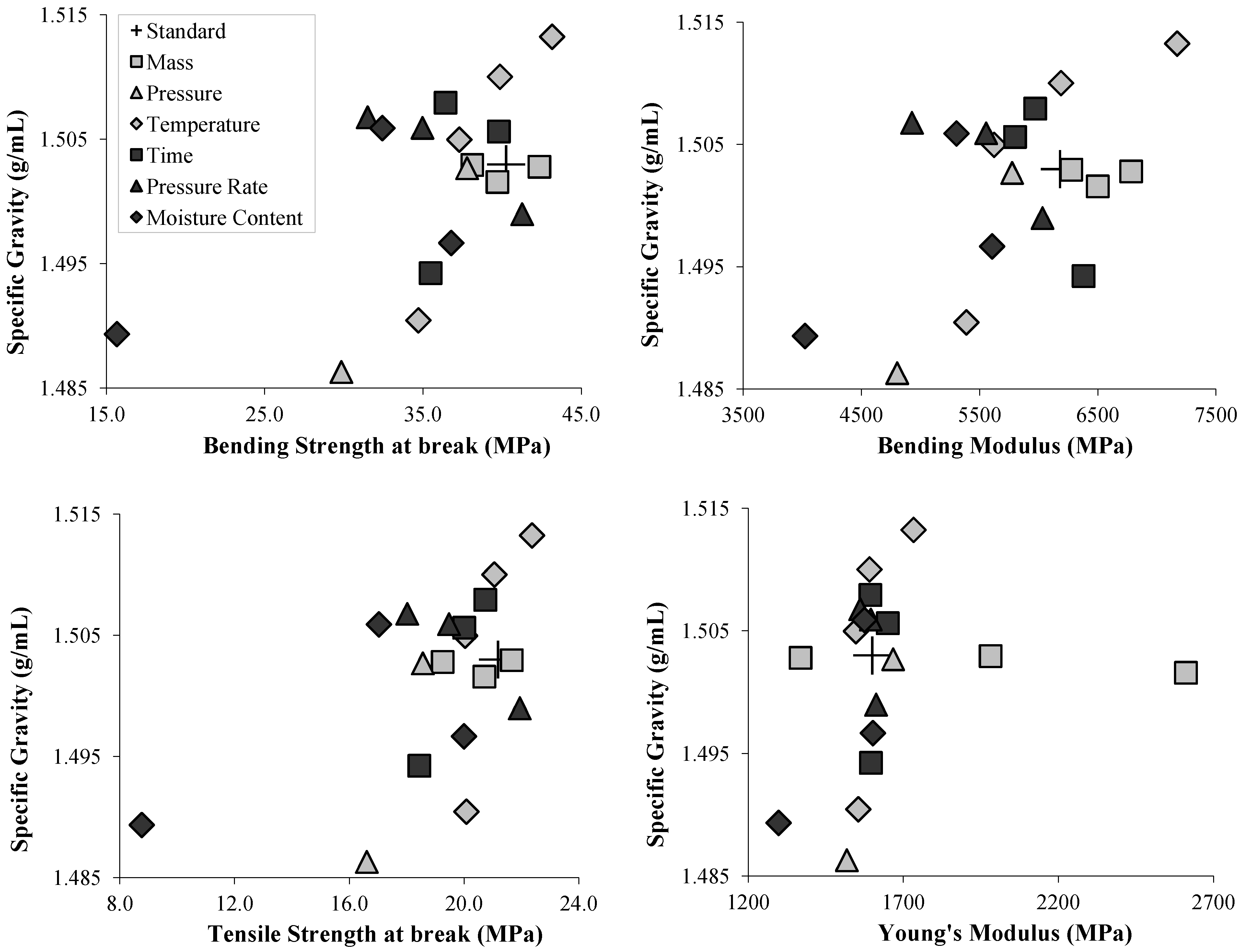

Generally in this study, a positive correlation was observed (

Figure 8) between specific gravity and the mechanical properties but some points were out of the trend. Particularly, the parameter "Mass" showed no correlation, especially for the Young’s modulus, which drastically increased when reducing the mass, although specific gravity remained the same.

Because of the use of high pressure, every specimen showed a higher density ranging from 1.486 ± 0.007 to 1.513 ± 0.008 g/cm

3. Nilsson

et al. [

19] obtained densities from 1.25 to 1.35 g/cm

3 and Zhang

et al. [

21] reported density going from 1.42 to 1.52 on compression-molded cellulose which was close to the density of 1.599 for the cellulose crystal stated by Sugiyama

et al. [

28]. Comparing with the nanofiber paper field, densities are reported from 1.30 g/cm

3 [

16] to 1.48 g/cm

3 [

15]. Our measurements showed quite high densities for cellulosic materials, in the range of what was reported with compression molding or other techniques of casting and drying. With the much lower properties obtained with our specimens, it can be confirmed that the characteristics of the starting material and precisely the refining are playing a predominant role [

15].

Figure 8.

Specific gravity expressed against Tensile and Bending Strength at break, Bending Modulus and Young’s Modulus.

Figure 8.

Specific gravity expressed against Tensile and Bending Strength at break, Bending Modulus and Young’s Modulus.

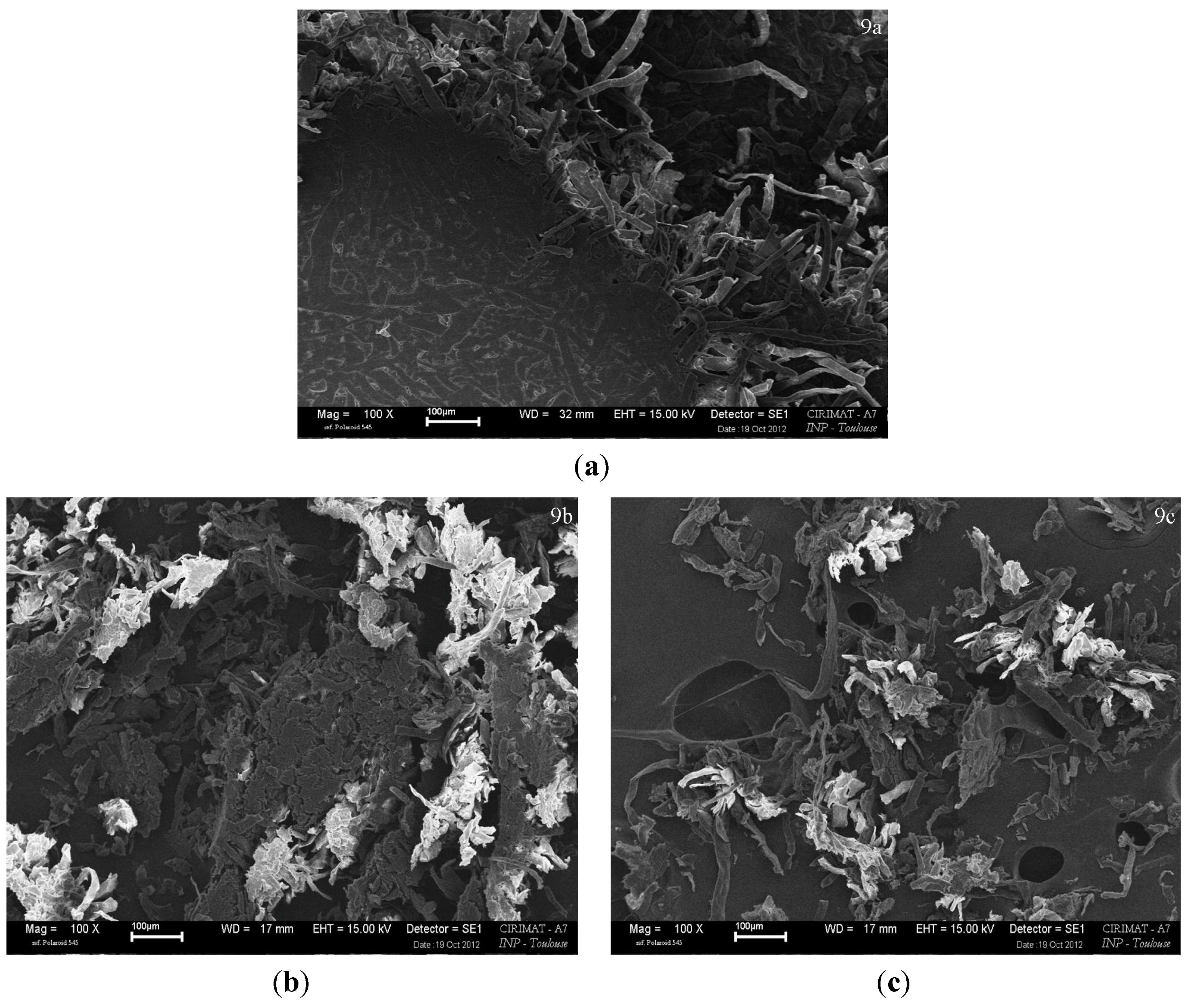

SEM observations were performed on the material itself, and a very compact network of fibers was observed on the surface of the material (

Figure 9a). On some points, the limit between two or more fibers faded, and it was not possible to tell if it was one single ramified fiber or different fibers with their contacts zone “melted” one in the others. Nilsson

et al. [

19] used CP/MAS

13C NMR to get an indication on the size of the fibril aggregates in their compressed cellulosic material, they reported that the size of the aggregates increased with temperature, showing that fibrils could aggregate one to each other. This phenomenon of fibrils aggregation could be linked to what happens during the hornification of cellulose fibers, which possible explanation was reported by Newman [

29] to be co-crystallization.

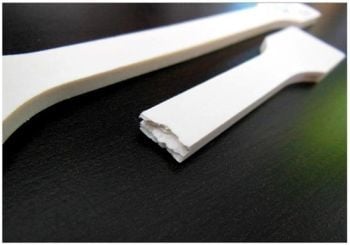

On the fracture (

Figure 9a) the inner part exhibited a less compact structure, with almost “free” fibers. In the inner part, the compact structure observed on the surface either did not exist or was destroyed during the breaking. The surface (

Figure 9b) and inner part (

Figure 9c) of one control specimen were powdered using a microtome. Blocks of packed fibers were cut out of the surface by the microtome, although in the inner part, much more free fibers were cut out by the microtome. The packed fibers cut out from the surface were considered as an indication for a higher degree of organization of this surface, compared to the core from which fibers were separated much more easily.

This organization observed on the surface (

Figure 9a,b) might be due to the higher temperature on the surface of the material, which was in direct contact with the mold. Also it has to be considered that higher temperature of molding increased (

Figure 4) the mechanical properties and that surface was confirmed to possess a higher Young’s modulus (

Figure 2). The specific gravity and moisture of this skin seem not to be different from the inner part of the material because specific gravity of specimen produced with different initial masses (different ratios surface/core) had similar specific gravities (

Table 1).

Equilibrium moisture content at 60% relative humidity and 25 °C was measured as a measure of the overall hygroscopy of the specimens, indicating the amount of accessible hydroxyl groups.

Figure 9.

(a) Surface fracture after tensile break of a specimen (standard) In the lower left corner is the intact surface, and on the opposite appears the inner structure of the material; (b) 2 μm powdered surface of a specimen produced under standard conditions; (c) 2 μm powdered core of a specimen produced under standard conditions.

Figure 9.

(a) Surface fracture after tensile break of a specimen (standard) In the lower left corner is the intact surface, and on the opposite appears the inner structure of the material; (b) 2 μm powdered surface of a specimen produced under standard conditions; (c) 2 μm powdered core of a specimen produced under standard conditions.

Nilsson

et al. [

19] reported measuring less accessible cellulose fibrils when increasing the temperature of molding. Our measurements are in accordance to their observations as the moisture content of higher temperature molded specimens is decreasing with temperature (

Table 1), showing that the fibrils are less accessible to atmospheric water vapor. For the other parameters, the correlation between moisture content and the mechanical properties was not obvious: specimens with different masses introduced in the mold had very close moisture contents (

Figure 10). In addition, the lowest time of molding produced weaker specimens with higher moisture content, which followed the trend, but highest time produced drier specimens with slightly weaker mechanical properties than the control. Thermal degradation and the shortening of the cellulose chains [

30] could be an explanation for this, although not entirely satisfactory because of the good mechanical properties obtained at 200 °C and the comparison with other molding times (Yano

et al. [

15] 30 min at 150 °C, Nilsson

et al. [

19] 20 m between 120 °C and 180 °C, Rampinelli

et al. [

20] 6 min at 160 °C) which were much longer than ours however with better mechanical properties.

Figure 10.

Moisture content of compression-molded specimens at 60% RH expressed against Tensile and Bending Strength at break, Bending Modulus and Young’s Modulus.

Figure 10.

Moisture content of compression-molded specimens at 60% RH expressed against Tensile and Bending Strength at break, Bending Modulus and Young’s Modulus.

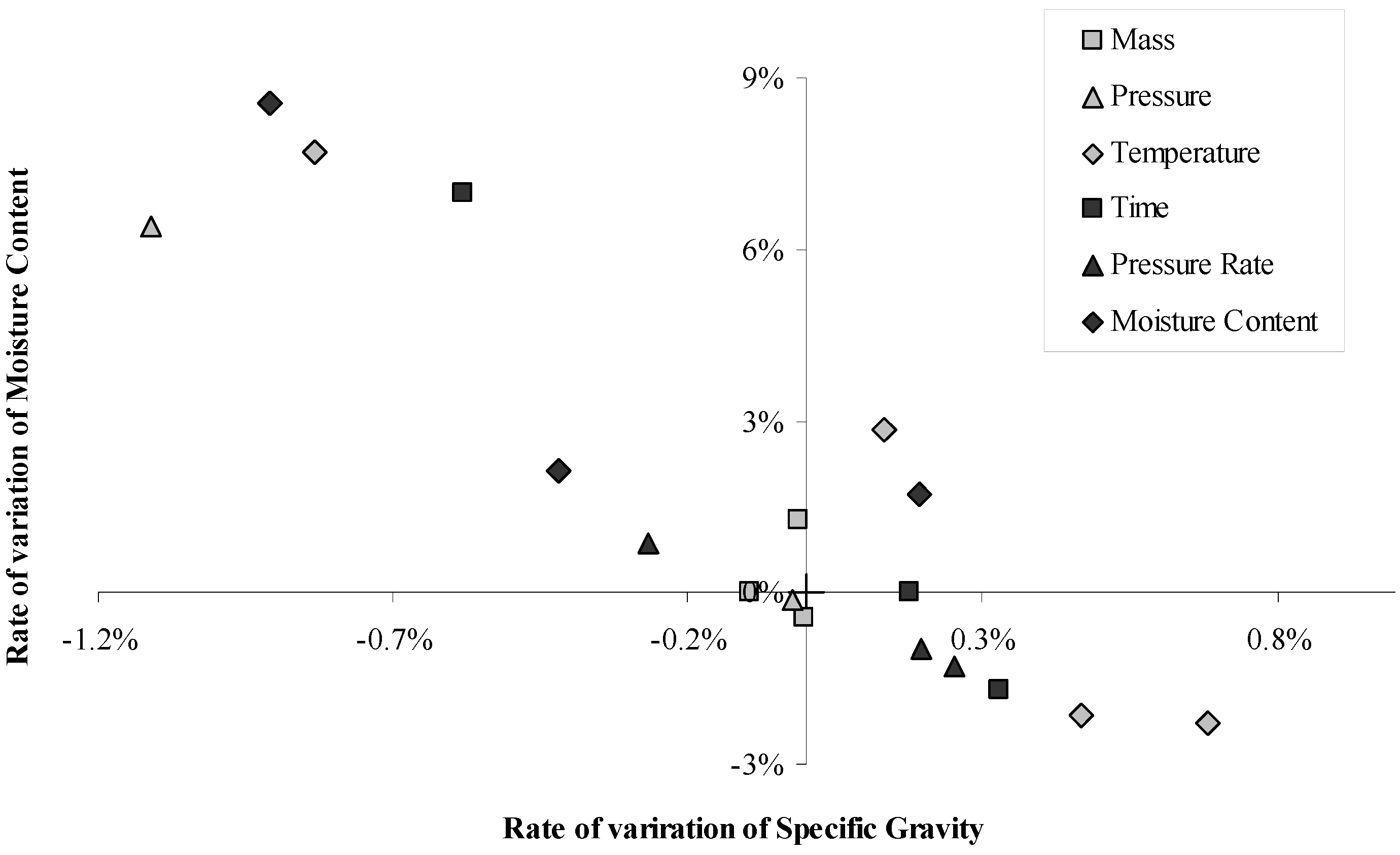

Figure 11 shows that specific gravity and moisture content were satisfactorily correlated, although the mechanical properties, representative of the bonding, could not be satisfactorily correlated to either specific gravity or moisture content, the mechanisms of bonding must therefore be complicated and imply several phenomena.

Figure 11.

Rate of variation of moisture content versus rate of variation of specific gravity. Rates of variation calculated comparing each modality to the control conditions.

Figure 11.

Rate of variation of moisture content versus rate of variation of specific gravity. Rates of variation calculated comparing each modality to the control conditions.

Molding dried alpha cellulose produced specimens with much lower mechanical properties, but specific gravity (1.489 ± 0.004 g/cm

3) and moisture content (7.62% ± 0.02%) were comparable to other conditions e.g., 3 s of pressing time (1.494 ± 0.005 g/cm

3 and 7.51% ± 0.04%), low temperature (1.486 ± 0.007 g/cm

3 and 7.56% ± 0.06%). Hornification [

24,

29] may have occur when drying the starting material, with irreversible changes preventing it from producing decent performances specimens when being processed.

The moisture content of the resulting specimen was however lower (7.62% ± 0.02%) than starting material α-cellulose (8.0%) showing that the fibers were less accessible to atmospheric water vapor on a macroscopic point of view. The evaluation of what was really happening to the fibers during the molding would have required the surface and porosity analysis, which were not performed here. Hydrogen bonding and other types of interactions which were discussed recently could occur between cellulose chains as well as co-crystallization [

29].

4. Experimental Section

4.1. α-Cellulose Compression-Molded Specimen Production

α-cellulose (96% purity according to the provider, with 4% insoluble hemicelluloses [

31]) was purchased from Sigma-Aldrich (St Louis, MO, USA) under the reference “bulk cellulose”, product was extracted from aspen trees. The crystallinity index has been measured at 62%. The crystallinity index of starting material was measured using X-ray diffraction. It was performed on a quartz-lead sampler loaded with the α-cellulose powder using a MiniFlex II Desktop X-ray Diffractometer with Cu Kα radiation (Rigaku ,Tokyo, Japan). Scans were obtained from 5 to 50 degrees 2θ in 0.05 degree steps for 15 s per step. The crystallinity index was calculated by a method developed by Segal

et al. [

32] and widely re-used since then.

Samples with different moisture contents were generated by letting α-cellulose at least two weeks to equilibrate with different controlled atmospheres at different relative humidities using a Climacell climatic chamber (Fisher Scientific, Bioblock Scientific, Illkirch, France).

Moisture content of each sample was measured in triplicate by comparing a sample's mass to its dry basis which was obtained in 48 h at 103 °C in an oven (Memmert Gmbh, Schwabach, Germany, model 600). Values are presented in

table 1.

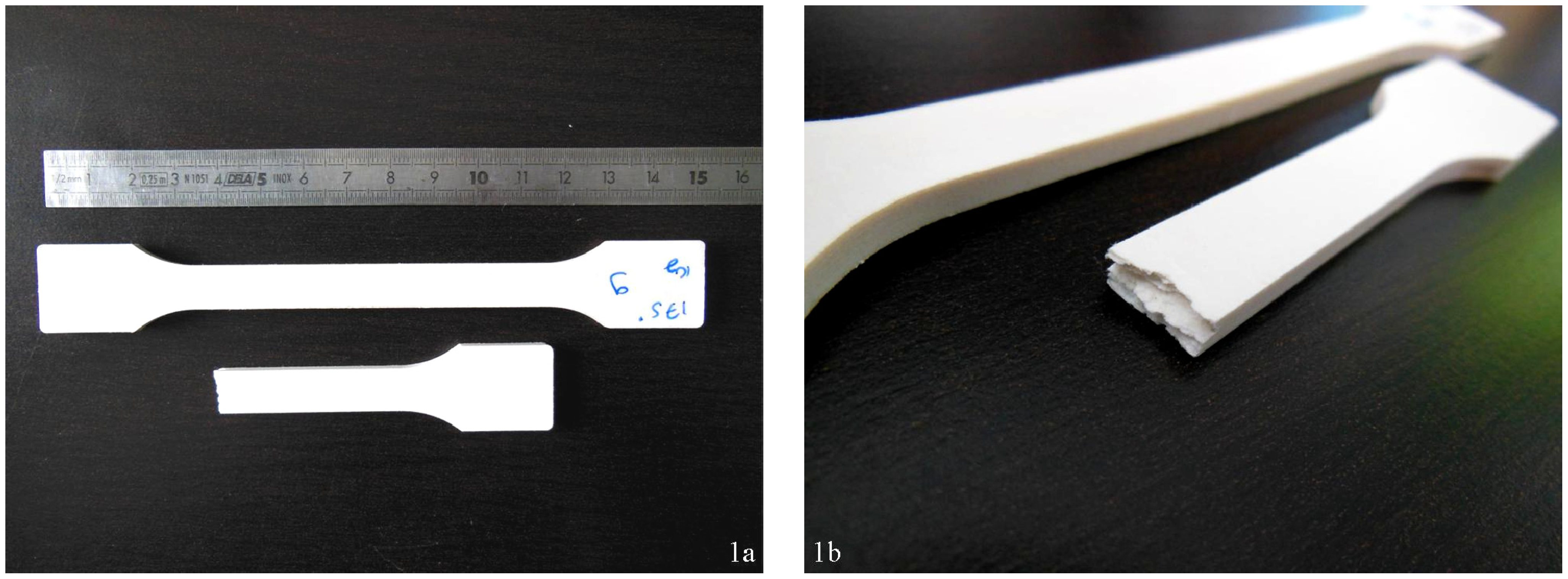

A mold was custom-machined (Cristin Electro Erosion, Grisolles, France) in order to produce 1A dog-bone tensile specimens according to ISO 3167 standard [

33], it consists in a die, a stopper at the bottom, and a punch (

Figure 12). The thickness of the samples is conditioned by the mass of matter introduced in the mold and apparent density of the final product, the average thickness obtained was 3.66 mm when 10 g of matter were charged in the mold which was little bellow the 4 mm required by the standard.

The mold was placed in a computer-controlled laboratory-scale hydraulic press (Pinette Emideceau, Chalon sur Saône, France), capable of generating a maximum of 530 kN of effort (about 50 tons). The metal plates were thermo regulated, and used to warm up the mold at least 30 m before each molding attempt. The temperature of the mold was verified to be the same as the plates with an infrared temperature sensor.

Figure 12.

NF EN ISO 3167 1A specimen compression mold: schematics.

Figure 12.

NF EN ISO 3167 1A specimen compression mold: schematics.

The α-cellulose powder was pre-weighted and taken out of the climatic chamber in a closed container to maintain moisture content as much as possible. It was charged in the mold manually, as quickly as possible to prevent change of the moisture content, and great attention was paid at trying to get a homogeneous repartition.

A control press cycle and conditions were determined, based on preliminary results. It was found that 10 g of matter, equilibrated at 60% relative humidity, compression-molded at 150 °C for 2 min was producing satisfactory pieces in terms of finish, touch, mechanical resistance, and they were intact although some other conditions made them explode. These were defined as the control conditions. Different series of experiment with various parameters were performed, in order to investigate the effect of Mass, Temperature, Pressure, Moisture Content, Time and Pressure establishment Rate on the mechanical properties of the resulting specimens (

Table 1). The process pressure was calculated with the force measured with a dedicated sensor. 265 MPa corresponded to the maximum load (50 tons) of the press.

For the investigation of the pressure rate increase influence in the process, the integral I (

Figure 13) was calculated on the control. Pressure rate was set up at 1 bar/s, 2 bar/s, 50 bar/s (hydraulic pressure) while adjusting Time to maintain equal I. Therefore, the time was different for each experiment, but also the maximum pressure of 265 MPa was not even obtained for the 1 bar/s experiments (

Table 3).

Figure 13.

Typical press cycle for control conditions. The investigation of Time used different time of phase II. The investigation of Pressure Rate Increase impacted phase I. The integral I was taken constant for the Pressure Rate investigation series.

Figure 13.

Typical press cycle for control conditions. The investigation of Time used different time of phase II. The investigation of Pressure Rate Increase impacted phase I. The integral I was taken constant for the Pressure Rate investigation series.

4.2. Tensile and 3 Points Bending Tests

Tensile and 3 point bending tests were conducted according to ISO 527-2 [

34] and ISO 178 [

35] using a H5KT Universal testing machine (Tinius Olsen, Horsham, PA, USA) at 1mm/min speed. These standards are related to the evaluation of mechanical properties of plastics.

From these tests, four variables were collected: Young’s Modulus, Tensile Strength at break, Bending Modulus and Bending Strength at break. Significance of difference between means of the 4 variables was analyzed with ANOVA and Scheffé’s contrasts test (multiple comparison of means) using Matlab (Mathworks, Natick, MA, USA). Every statistical analysis was performed with 95% confidence. The tests were performed within each series of experiment, and not on the whole set of experimental results.

Some specimens were presenting defects like cracks when compression molded at 200 °C, or sometimes heterogeneity marked by lighter spots where density seemed lower. These “low density” spots were probably generated when charging the material in the mold inhomogeneously. These specimens were marked and their results were not taken into consideration. Seven to 15 repetitions were done on each condition, the obtained specimens were let to equilibrate for two weeks at 25 °C and 60% of relative humidity before mechanical tests.

The confident interval (1) of the mean was calculated from the standard deviation:

where

x bar is the estimated mean;

tα a coefficient resulting from the Student law (1.96 for a 95% confidence);

s the standard deviation of the series, and

n the number of specimen within the series.

4.3. SEM Observations

Control sample material was observed by scanning electron microscopy: LEO 435 VP microscope, Leo Electron Microscopy Ltd (Cambridge, UK) sample silver plating before observation. One control specimen was observed on the fracture after a tensile test. The surface and the core of another standard specimen were separated and very thin shavings of 2 μm were cut out of surface and core using a RM2125RT microtome (Leica Microsystems, Wetzlar, Germany) equipped with a tungsten blade. The two powders (surface and core) were observed.

4.4. Specific Gravity and Moisture Content of the Specimen

Six 2 cm long pieces were cut out of six different dog-bone specimens (from the mechanical tests) to measure specific gravity and moisture content of the materials. These six small pieces were first let to equilibrate in a 60% relative humidity 25 °C climatic device, room and moisture content was measured on 103 °C oven-dry basis.

The dried 6 pieces were put back in the oven and then used for evaluation of specific gravity using a YDK01 Density determination kit on a Sartorius MC210P precision scale (Sartorius AG, Goettingen, Germany). The specimen were weighted in the air, and then dipped into cyclohexane (Sigma Aldrich, St Louis, MO, USA, Chromsolv for HPLC purity > 99.7%) and the resulting Buoyancy (W

air − W

fluid) was measured. Specific gravity was measured using (2):

where

ρ is the specific gravity of the materials tested;

Wair and

Wcyclohexane the weight of the tested specimen in the air and in the cyclohexane respectively;

ρcyclohexane the specific gravity of cyclohexane at the measured temperature during the experiment; 0.0012 (g/cm

3) the specific gravity of air at 20 °C and 101.325 kPa; and 0.99983 a manufacturer’s correction factor related to the increase of the fluid level and immersion of the wires in the fluid when the specimen is dipped in the fluid.

Cyclohexane was chosen arbitrary, air bubbles were chased out of the material when immersing it in the solvent, but some of the porosity of the material might remain inaccessible to the solvent, so the specific gravity measured here may differ from real absolute value of density. However, it is thought to be close to the real density and significantly higher than the apparent density.

Measuring dried specimen was thought to prevent misevaluation of specific gravity due to difference of water content between the specimens. On the control specimens, the measured specific gravity of the material equilibrated at 60% relative humidity and 25 °C was 1.485 ± 0.003 g/cm3. On the other hand, the measured specific gravity of the dried material was 1.503 ± 0.002 so the measurements on the dry matter over-estimated.

5. Conclusions

Compression molding in a hot press was successfully performed with pure α-cellulose. The specimens exhibited a smooth, plastic-like surface. The best conditions (200 °C, 265 MPa, 120 s, 8% moisture content) produced specimens with a bending strength of 43.2 ± 3 MPa, a bending modulus of 7.17 ± 0.31 GPa, a tensile strength of 22.4 ± 1.2 MPa and a Young’s modulus of 1.73 ± 0.09 GPa. Under these conditions, delamination could occur showing how precise the adjustments of the parameters must be. It appeared that these extreme conditions where specimens can explode due to steam accumulation are the ones that produced the best specimens. These properties are comparable or higher than conventional petroleum-based glassy plastics.

The effects of several parameters were investigated to study the effect on the mechanical properties of pure α-cellulose compression molded specimens. It was observed that moisture content and temperature were the most important parameters. The effects of time and pressure were not significant in the considered ranges. The moisture content and specific gravity of the resulting specimens decreased and increased respectively with the mechanical properties for the Temperature and Moisture content. A correlation was observable only for those two parameters but not on the others. The presence of water in the starting material was demonstrated to be crucial in order to elevate the mechanical properties.

The mass introduced in the mold was a significant parameter that revealed a skin-effect. The skin of the material showed a much higher Young’s modulus than the core of the material, but other parameters were similar in the skin and the core. This statement is calling for more investigations.

Very short times of three seconds of molding were observed to produce correct specimens with slightly lower strengths. The very short time of processing was an encouraging statement to consider a possible future industrialization of the process.