Use of Cement Kiln Dust, Blast Furnace Slag and Marble Sludge in the Manufacture of Sustainable Artificial Aggregates by Means of Cold Bonding Pelletization

Abstract

:1. Introduction

2. Materials and Experimental Program

2.1. Materials

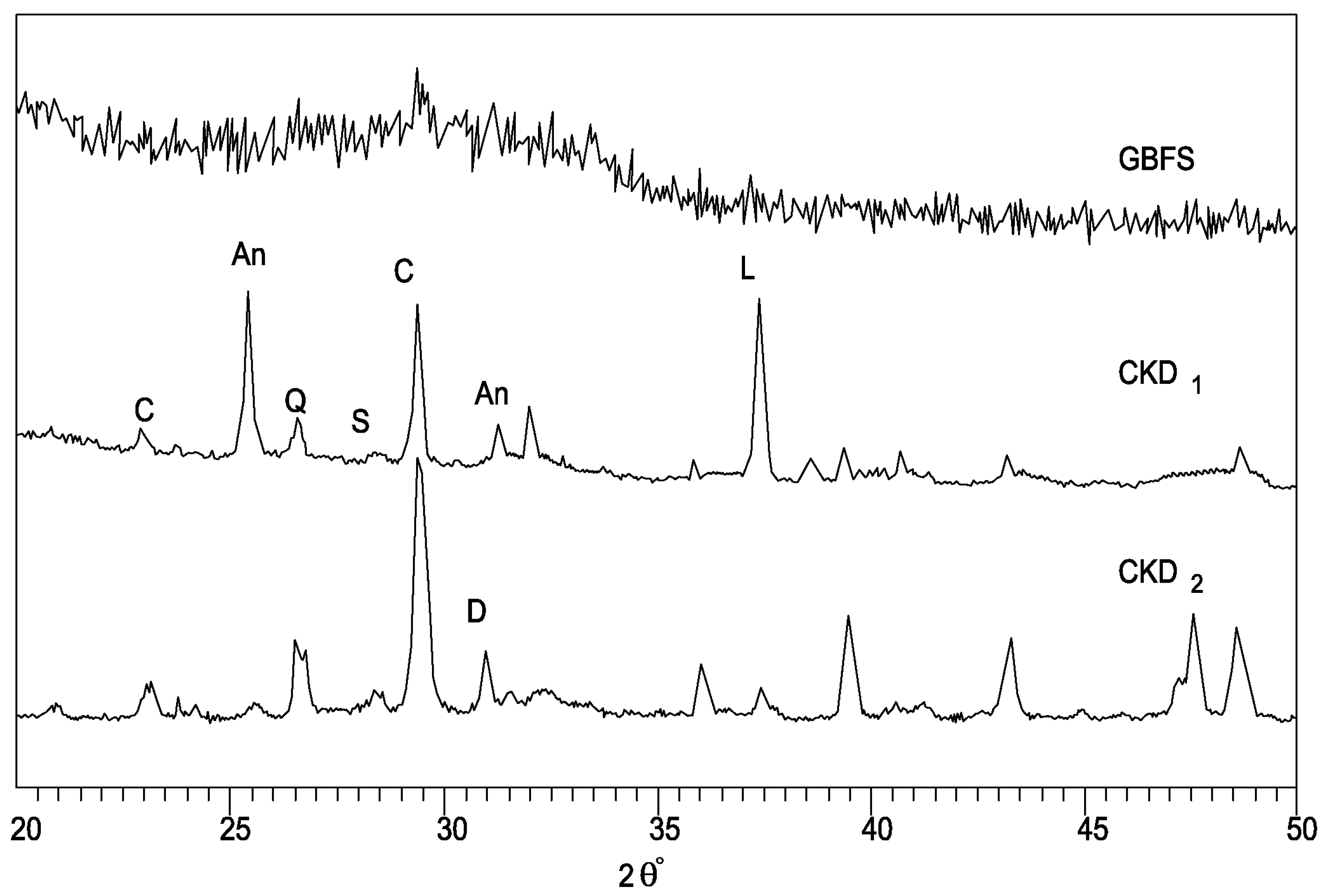

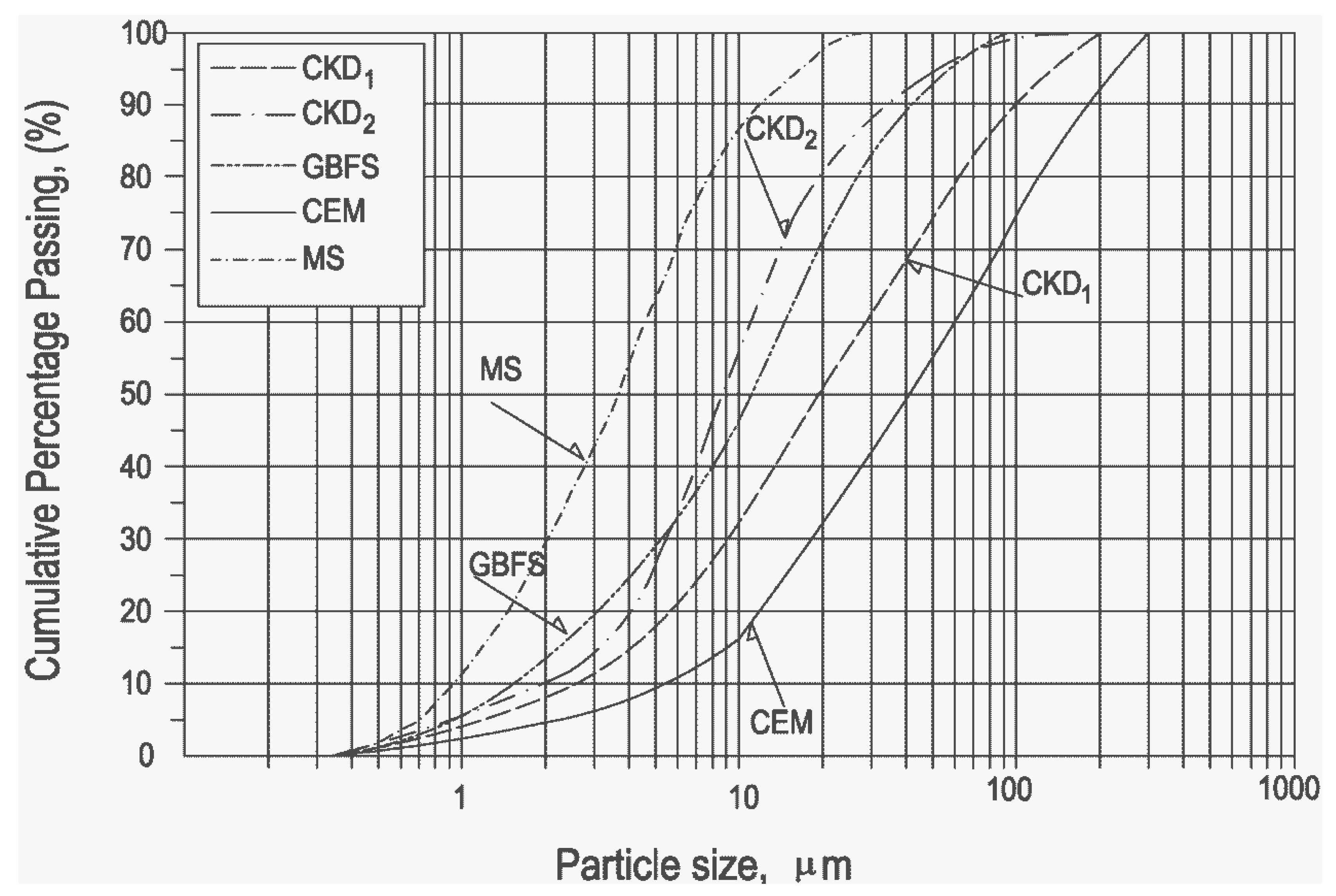

2.1.1. Chemical and Physical Characterization of Raw Materials

| Component | CKD1 | CKD2 | GBFS | MS |

|---|---|---|---|---|

| CaO | 44.72 | 50.10 | 41.91 | 52.26 |

| SiO2 | 16.35 | 12.10 | 35.16 | 1.12 |

| Al2O3 | 4.95 | 4.26 | 10.76 | 0.37 |

| Fe2O3 | 2.93 | 2.21 | 1.40 | 0.11 |

| MgO | 3.12 | 1.67 | 7.68 | 0.87 |

| SO3 | 5.72 | 17.16 | 1.92 | – |

| Na2O | 0.93 | 1.26 | 0.11 | 0.14 |

| K2O | 4.90 | 5.83 | 0.14 | 0.10 |

| Cl− | 1.78 | 0.65 | – | – |

| Alkali equivalent | 4.02 | 4.92 | 0.18 | – |

| Free-CaO | 4.61 | 13.40 | – | – |

| LoI * | 23.30 | 9.16 | 1.78 | 40.74 |

2.1.2. Preparation and Characterization of Aggregates

| Mixtures | CKD1 | CKD2 | GBFS | MS |

|---|---|---|---|---|

| M1 | 15 | – | 15 | 70 |

| M2 | 10 | – | 20 | 70 |

| M3 | 6 | – | 24 | 70 |

| M4 | 10 | – | 10 | 80 |

| M5 | 6.5 | – | 13.5 | 80 |

| M6 | 4.0 | – | 16.0 | 80 |

| M7 | – | 15 | 15 | 70 |

| M8 | – | 10 | 20 | 70 |

| M9 | – | 6 | 24 | 70 |

| M10 | – | 10 | 10 | 80 |

| M11 | – | 6.5 | 13.5 | 80 |

| M12 | – | 4.0 | 16.0 | 80 |

2.1.3. Preparation and Characterization of Concrete.

| Components | Concrete mixtures (kg/m3) | ||||||

| CC | CM1 | CM3 | CM4 | CM7 | CM9 | CM10 | |

| CEM II 42.5 R | 310 | 310 | 310 | 310 | 310 | 310 | 310 |

| Natural sand | 708 | 708 | 708 | 708 | 708 | 708 | 708 |

| NA 4–12 mm | 699 | – | – | – | – | – | – |

| NA 12–20 mm | 501 | – | – | – | – | – | – |

| AA 4–12 mm | – | 498 | 490 | 511 | 506 | 516 | 509 |

| AA 12–20 mm | – | 353 | 348 | 361 | 358 | 366 | 361 |

| Superplasticizer | 3.6 | 5.7 | 5.1 | 4.5 | 4.7 | 4.4 | 4.5 |

| W/C | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

2.2. Study of Binding Mixture Hydration Behavior

| System | CKD1 | CKD2 | GBFS |

|---|---|---|---|

| S1 | 50 | – | 50 |

| S2 | 35 | – | 70 |

| S3 | 20 | – | 80 |

| S4 | – | 50 | 50 |

| S5 | – | 35 | 70 |

| S6 | – | 20 | 80 |

3. Results and Discussion

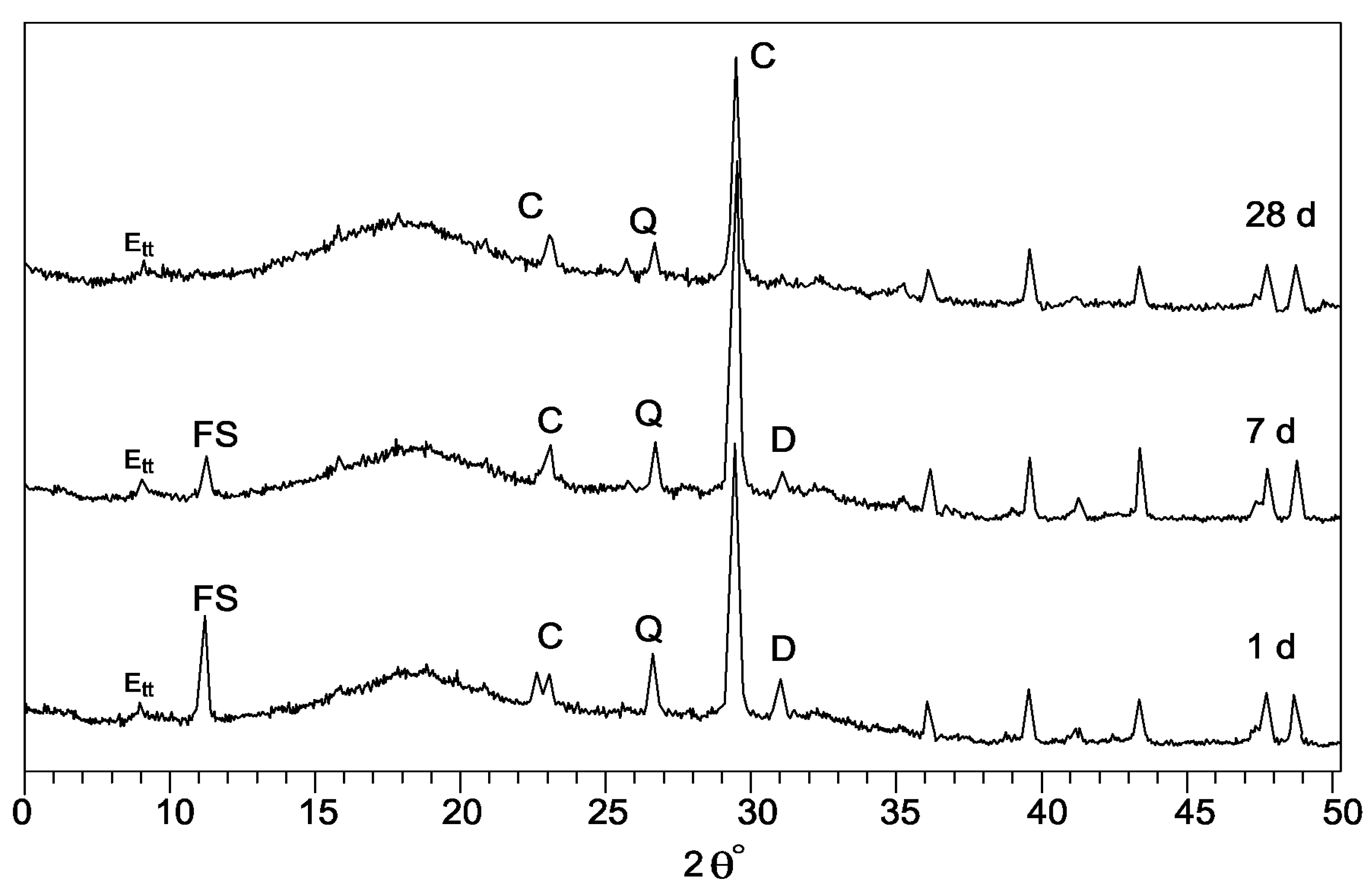

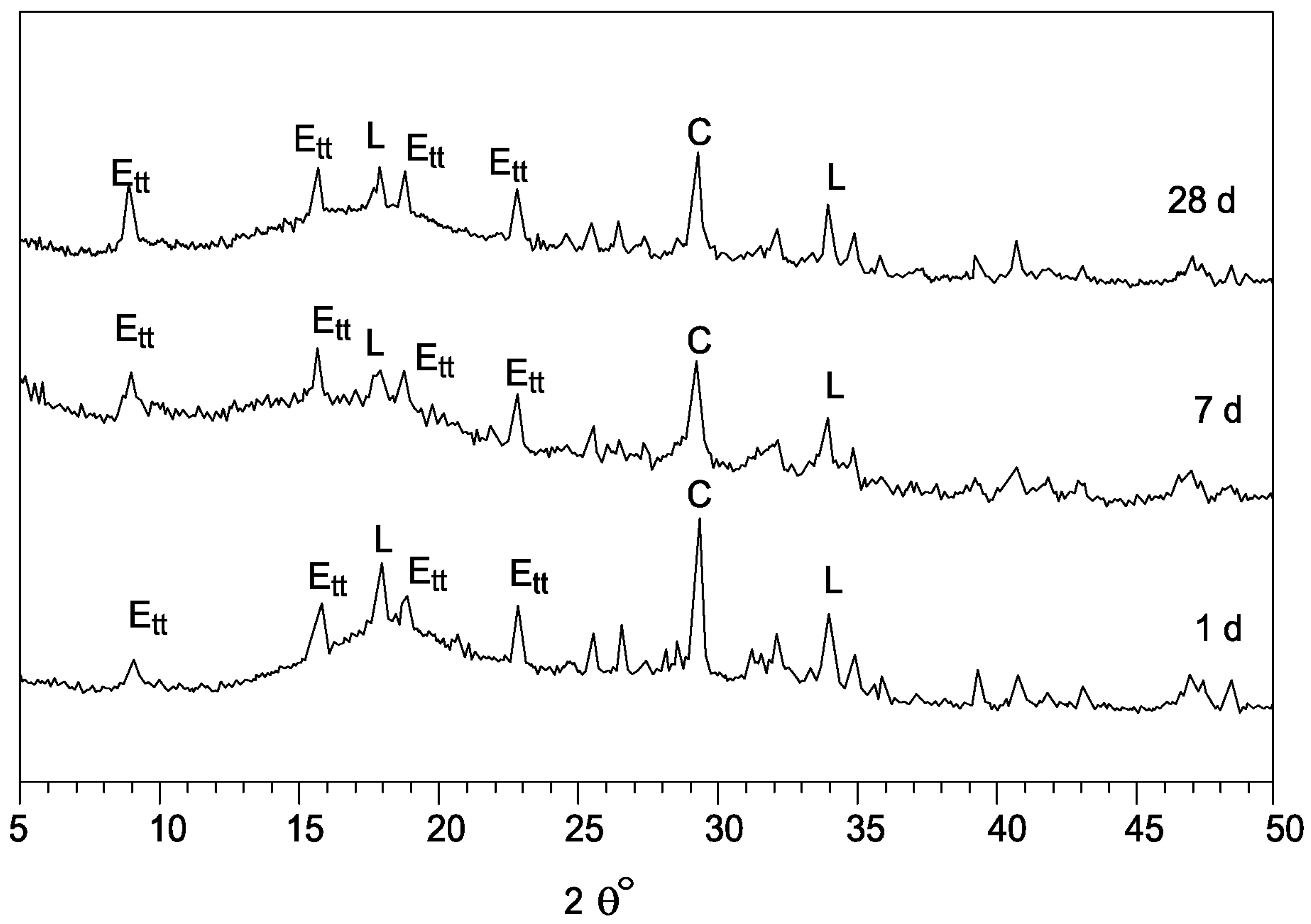

3.1. Hydration Behaviour

| System | Curing time (days) | |||

| 1 | 7 | 28 | 56 | |

| S1 | 0.5 | 1.8 | 4.5 | 5 |

| S2 | 0.6 | 2 | 5 | 6 |

| S3 | 0.9 | 2.5 | 7 | 9 |

| S4 | 2.5 | 9 | 14 | 18 |

| S5 | 4 | 11 | 16 | 20 |

| S6 | 6 | 13 | 18 | 22 |

3.2. Aggregates Properties

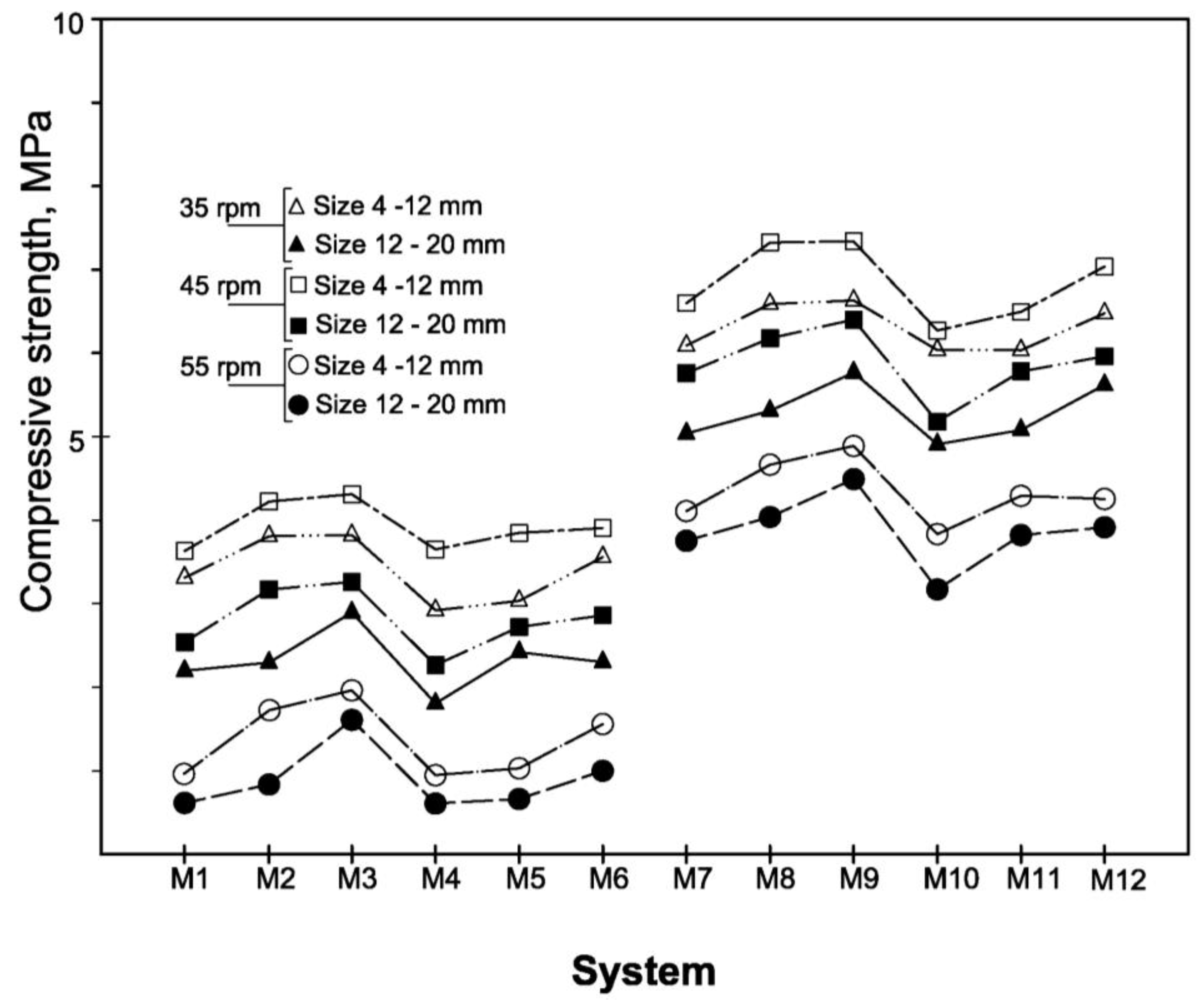

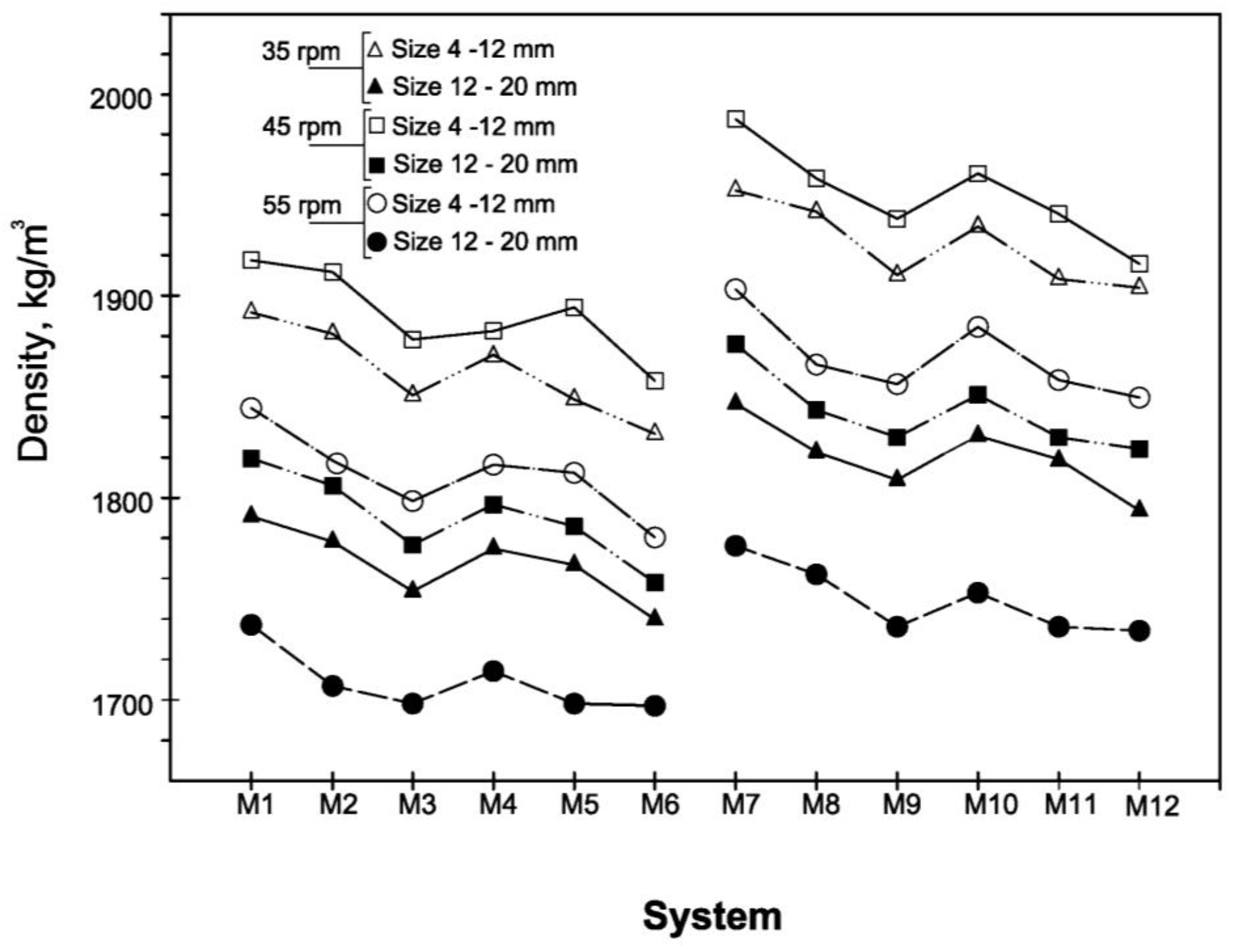

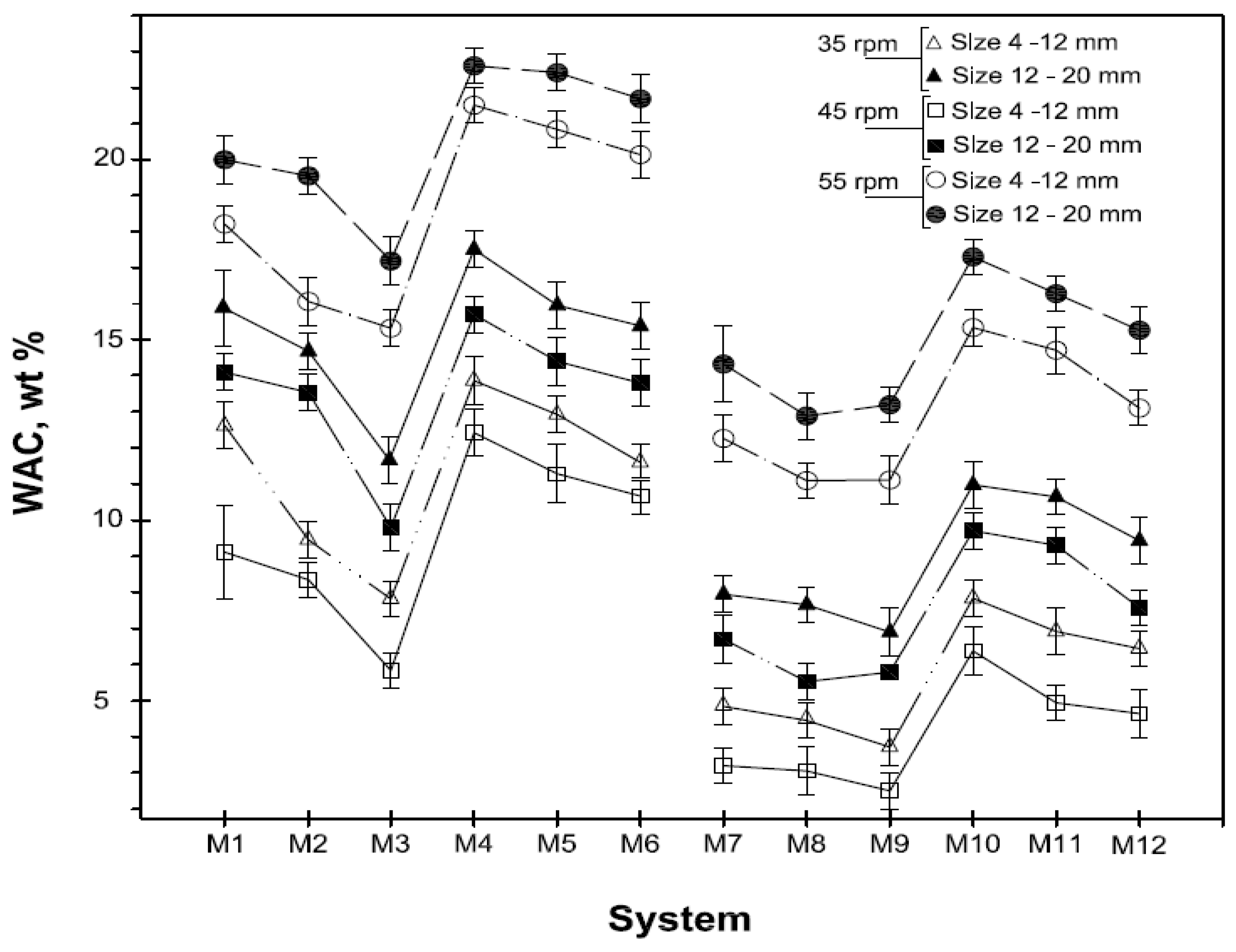

3.2.1. Effect of the Plate Revolution Speed

| Ranking | Compressive Strength | Density | WAC |

|---|---|---|---|

| 1st | 45 rpm/4–12 mm | 45 rpm/4–12 mm | 45 rpm/4–12 mm |

| 2nd | 35 rpm/4–12 mm | 35 rpm/4–12 mm | 35 rpm/4–12 mm |

| 3rd | 45 rpm/12–20 mm | 55 rpm/4–12 mm | 45 rpm/12–20 mm |

| 4th | 35 rpm/12–20 mm | 45 rpm/12–20 mm | 35 rpm/12–20 mm |

| 5th | 55 rpm/4–12 mm | 35 rpm/12–20 mm | 55 rpm/4–12 mm |

| 6th | 55 rpm/12–20 mm | 55 rpm/12–20 mm | 55 rpm/12–20 mm |

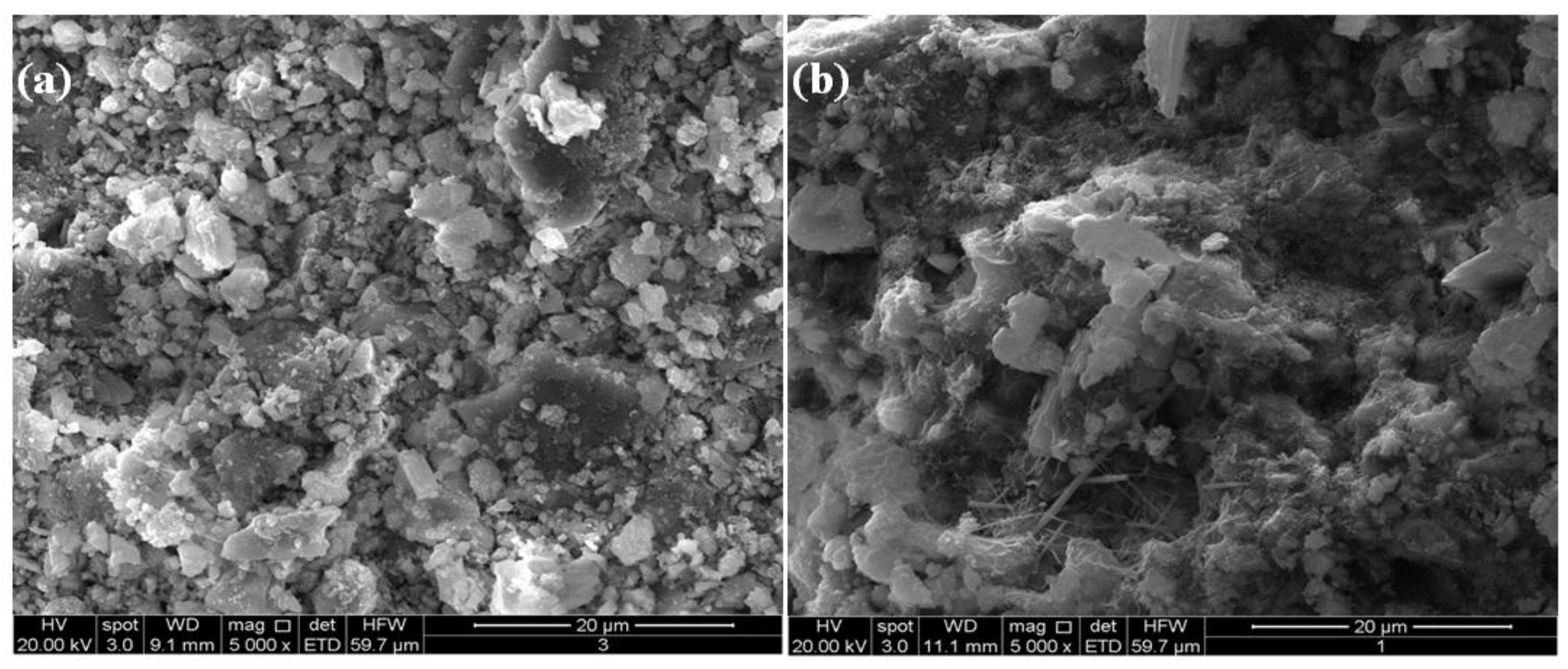

3.2.2. Effect of CKD, GBFS and MS

3.3. Concrete Characterization

| Concrete | Strength (MPa) | Strength class UNI EN 206-1 | Density [kg/m3] | Density class UNI EN 206-1 |

|---|---|---|---|---|

| CC | 37.3 ± 1.6 | 30/33 (Not LC) | 2245.8 ± 62 | Not LC |

| CM1-45 | 22.5 ± 1.2 | LC 20/22 | 1865.5 ± 41 | D2.0 |

| CM3-45 | 27.4 ± 1.1 | LC 20/22 | 1897.3 ± 44 | D2.0 |

| CM4-45 | 22.6 ± 0.8 | LC 20/22 | 1876.7 ± 50 | D2.0 |

| CM7-45 | 38.8 ± 1.0 | LC 35/38 | 1927.9 ± 32 | D2.0 |

| CM9-45 | 41.8 ± 1.7 | LC 35/38 | 1981.4 ± 71 | D2.0 |

| CM10-45 | 40.5 ± 1.5 | LC 35/38 | 1938.6 ± 87 | D2.0 |

| CM1-35 | 18.9 ± 0.8 | LC 16/18 | 1779.3 ± 22 | D1.6 |

| CM3-35 | 22.8 ± 0.9 | LC 20/22 | 1797.2 ± 69 | D1.6 |

| CM4-35 | 17.4 ± 0.6 | LC 12/13 | 1782.1 ± 51 | D1.6 |

| CM7-35 | 36.9 ± 1.2 | LC 30/33 | 1912.8 ± 42 | D2.0 |

| CM9-35 | 39.6 ± 1.2 | LC 35/38 | 1943.8 ± 88 | D2.0 |

| CM10-35 | 36.0 ± 0.9 | LC 30/33 | 1924.8 ± 67 | D2.0 |

| CM1-55 | 7.2 ± 0.3 | Nc | 1750.1 ± 22 | D1.6 |

| CM3-55 | 11.4 ± 0.4 | LC 8/9 | 1779.6 ± 43 | D1.6 |

| CM4-55 | 7.3 ± 0.4 | Nc | 1768.3 ± 52 | D1.6 |

| CM7-55 | 24.9 ± 0.5 | LC 20/22 | 1854.5 ± 38 | D2.0 |

| CM9-55 | 28.8 ± 1.2 | LC 25/28 | 1862.9 ± 62 | D2.0 |

| CM10-55 | 23.1 ± 0.9 | LC 20/22 | 1879.2 ± 38 | D2.0 |

4. Conclusions

- Mixtures containing cement kiln dust, blast furnace slag and marble sludge were used in the manufacture of cold bonded lightweight artificial aggregates, which can be employed in the preparation of structural lightweight concrete. Two different CKD samples have been employed in order to take into account the heterogeneity between two plants operating under different conditions.

- The pellets were produced making use of a easily scalable from pilot to process-scale apparatus based on a rotating and tilting plate. Starting from some experimental results present in literature and previous studies of the authors, a wide investigation range was fixed.

- Best mechanical performance of artificial aggregates was achieved for a plate revolution speed of 45 rpm and a tilt angle of 50°. In any case, depending on the CKD chemical composition, aggregates produced at 35 rpm and 55 rpm also showed adequate physical and mechanical performances.

- Almost all the lightweight concrete specimens containing the artificial aggregates prepared in this work were able to satisfy the technical requirements in force in Italy for structural use. Furthermore, artificial aggregates physico-mechanical properties have a relevant influence on concrete specimens performances.

- Assessment by technical committees of all physical, mechanical and environmental properties (of both granules and concretes) is necessary before the use of novel artificial aggregate in concrete manufacture. The sustainability of the whole proposed process needs to be quantified by means of appropriate evaluation of specific indicators such as those used in Life Cycle Assessment (LCA) and Life Cycle Cost (LCC) methodologies [59].

Conflict of Interest

References

- ATECAP: Italian Premixed Concrete Technological and Economical Association, Annual Report. Available online: http://www.atecap.com (accessed on 2 January 2011).

- Andini, S.; Cioffi, R.; Colangelo, F.; Grieco, T.; Montagnaro, F.; Santoro, L. Coal fly ash as raw material for manufacture of geopolymer-based product. Waste Manag. 2008, 28, 416–423. [Google Scholar] [CrossRef] [PubMed]

- Beretka, J.; Cioffi, R.; Marroccoli, M.; Valenti, G.L. Energy-saving cements obtained from chemical gypsum and other industrial wastes. Waste Manag. 1996, 16, 231–235. [Google Scholar] [CrossRef]

- Bignozzi, M.C.; Manzi, S.; Lancellotti, I.; Kamseu, E.; Barbieri, L.; Leonelli, C. Mix-design and characterization of alkali activated materials based on metakaolin and ladle slag. Appl. Clay Sci. 2013, 73, 78–85. [Google Scholar] [CrossRef]

- D’Auria, I.; Lamberti, M.; Mazzeo, M.; Milione, S.; Roviello, G.; Pellecchia, C. Coordination Chemistry and Reactivity of Zinc Complexes Supported by a Phosphido Pincer Ligand. Chem. Eur. J. 2012, 18, 2349–2360. [Google Scholar] [CrossRef] [PubMed]

- Duxson, P.; Fernández-Jiménez, A.; Provis, J.L.; Lukey, G.C.; Palomo, A.; van Deventer, J.S.J. Geopolymer technology: The current state of the art. J. Mater. Sci. 2007, 42, 2917–2933. [Google Scholar] [CrossRef]

- Ferone, C.; Colangelo, F.; Roviello, G.; Asprone, D.; Menna, C.; Balsamo, A.; Prota, A.; Cioffi, R.; Manfredi, G. Application-oriented chemical optimization of a metakaolin based geopolymer. Materials 2013, 6, 1920–1939. [Google Scholar] [CrossRef] [Green Version]

- Ferone, C.; Roviello, G.; Colangelo, F.; Cioffi, R.; Tarallo, O. Novel hybrid organic geopolymer materials. Appl. Clay Sci. 2013, 73, 42–50. [Google Scholar] [CrossRef]

- Menna, C.; Asprone, D.; Ferone, C.; Colangelo, F.; Balsamo, A.; Prota, A.; Cioffi, R.; Manfredi, G. Use of geopolymers for composite external reinforcement of RC members. Compos. B Eng. 2012, 45, 1667–1676. [Google Scholar] [CrossRef]

- Flatt, R.J.; Roussel, N.; Cheeseman, C.R. Concrete: An eco material that needs to be improved. J. Eur. Ceram. Soc. 2012, 32, 2787–2798. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Castro-Gomes, J.; Jalali, S. Alkali-activated binders: A review: Part 1. Historical background, terminology, reaction mechanisms and hydration products. Constr. Build. Mater. 2008, 22, 1305–1314. [Google Scholar] [CrossRef] [Green Version]

- Pera, J.; Ambroise, J. New applications of calcium sulfoaluminate cement. Cem. Concr. Res. 2004, 34, 671–676. [Google Scholar] [CrossRef]

- Peysson, S.; Péra, J.; Chabannet, M. Immobilization of heavy metals by calcium sulfoaluminate cement. Cem. Concr. Res. 2005, 35, 2261–2270. [Google Scholar] [CrossRef]

- Roviello, A.; Buono, A.; Carella, A.; Roviello, G.; Cassinese, A.; Barra, M.; Biasucci, M. Regioregular poly[3-(4-alkoxyphenyl)thiophene]s. J. Polym. Sci. A Polym. Chem. 2007, 45, 1758–1770. [Google Scholar] [CrossRef]

- Wu, K.; Shi, H.; Guo, X. Utilization of municipal solid waste incineration fly ash for sulfoaluminate cement clinker production. Waste Manag. 2011, 31, 2001–2008. [Google Scholar] [CrossRef] [PubMed]

- Bignozzi, M.C.; Saccani, A. Ceramic waste as aggregate and supplementary cementing material: A combined action to contrast alkali silica reaction (ASR). Cem. Concr. Compos. 2012, 34, 1141–1148. [Google Scholar] [CrossRef]

- Cheeseman, C.R.; Makinde, A.; Bethanis, S. Properties of lightweight aggregate produced by rapid sintering of incinerator bottom ash. Resour. Conserv. Recycl. 2005, 43, 147–162. [Google Scholar] [CrossRef]

- Chen, H.J.; Yang, M.D.; Tang, C.W.; Wang, S.Y. Producing synthetic lightweight aggregates from reservoir sediments. Constr. Build. Mater. 2012, 28, 387–394. [Google Scholar] [CrossRef]

- Cioffi, R.; Colangelo, F.; Montagnaro, F.; Santoro, L. Manufacture of artificial aggregate using MSWI bottom ash. Waste Manag. 2011, 31, 281–288. [Google Scholar] [CrossRef] [PubMed]

- Colangelo, F.; Cioffi, R.; Montagnaro, F.; Santoro, L. Soluble salt removal from MSWI fly ash and its stabilization for safer disposal and recovery as road basement material. Waste Manag. 2012, 32, 1179–1185. [Google Scholar] [CrossRef] [PubMed]

- Colangelo, F.; Cioffi, R.; Lavorgna, M.; Verdolotti, L.; de Stefano, L. Treatment and recycling of asbestos-cement containing waste. J. Hazard. Mater. 2011, 195, 391–397. [Google Scholar] [CrossRef] [PubMed]

- Andini, S.; Montagnaro, F.; Santoro, L.; Accardo, G.; Cioffi, R.; Colangelo, F. Mechanochemical processing of blast furnace slag for its reuse as adsorbent. Chem. Eng. Trans. 2013, 32, 2299–2304. [Google Scholar]

- Limbachiya, M.C. Recycled aggregates: Production, properties and value-added sustainable applications. J. Wuhan Univ. Technol. Mater. Sci. 2010, 25, 1011–1016. [Google Scholar] [CrossRef]

- Limbachiya, M.C.; Leelawat, T.; Dhir, R.K. Use of recycled concrete aggregate in high, strength concrete. Mater. Struct. 2000, 33, 574–580. [Google Scholar] [CrossRef]

- Limbachiya, M.C.; Meddah, M.S.; Ouchagour, Y. Use of recycled concrete aggregate in fly ash concrete. Constr. Build. Mater. 2012, 27, 439–449. [Google Scholar]

- Manzi, S.; Mazzotti, C.; Bignozzi, M.C. Short and long-term behaviour of structural concrete with recycled concrete aggregate. Cem. Concr. Compos. 2013, 37, 312–318. [Google Scholar] [CrossRef]

- Poon, C.S.; Kou, S.C.; Lam, L. Use of recycled aggregates in molded concrete bricks and blocks. Constr. Build. Mater. 2002, 16, 281–289. [Google Scholar] [CrossRef]

- Saccani, A.; Bignozzi, M.C. ASR expansion behavior of recycled glass fine aggregates in concrete. Cem. Concr. Res. 2010, 40, 531–536. [Google Scholar] [CrossRef]

- Sagoe-Crentsil, K.K.; Brown, T.; Taylor, A.H. Performance of concrete made with commercially produced coarse recycled concrete aggregate. Cem. Concr. Res. 2001, 31, 707–712. [Google Scholar] [CrossRef]

- Saikia, N.; de Brito, J. Use of plastic waste as aggregate in cement mortar and concrete preparation: A review. Constr. Build. Mater. 2012, 34, 385–401. [Google Scholar] [CrossRef]

- Sani, D.; Moriconi, G.; Fava, G.; Corinaldesi, V. Leaching and mechanical behaviour of concrete manufactured with recycled aggregates. Waste Manag. 2005, 25, 177–182. [Google Scholar] [CrossRef] [PubMed]

- Topcu, I.B.; Sengel, S. Properties of concretes produced with waste concrete aggregate. Cem. Concr. Res. 2004, 34, 1307–1312. [Google Scholar] [CrossRef]

- Wainwright, P.J.; Cresswell, D.J.F. Synthetic aggregates from combustion ashes using an innovative rotary kiln. Waste Manag. 2001, 21, 241–246. [Google Scholar] [CrossRef] [PubMed]

- De Schutter, G.; Taerwe, L. General hydration model for Portland cement and blast furnace slag cement. Cem. Concr. Res. 1995, 25, 593–604. [Google Scholar] [CrossRef]

- Uchikawa, H.; Uchida, S.; Ogawa, K.; Hanehara, S. Influence of CaSO4·2H2O, CaSO4·12H2O and CaSO4 on the initial hydration of clinker having different burning degree. Cem. Concr. Res. 1984, 14, 645–656. [Google Scholar] [CrossRef]

- Vuk, T.; Tinta, V.; Gabrovšek, R.; Kaučič, V. The effects of limestone addition, clinker type and fineness on properties of Portland cement. Cem. Concr. Res. 2001, 31, 135–139. [Google Scholar] [CrossRef]

- Bignozzi, M.C.; Sandrolini, F. Tyre rubber waste recycling in self-compacting concrete. Cem. Concr. Res. 2006, 36, 735–739. [Google Scholar] [CrossRef]

- Felekoglu, B. Utilisation of high volumes of limestone quarry wastes in concrete industry (self compacting concrete case). Resour. Conserv. Recycl. 2007, 51, 770–791. [Google Scholar] [CrossRef]

- Corish, A.; Coleman, T. Cement kiln dust. Concrete 1995, 29, 40–42. [Google Scholar]

- Haynes, B.W.; Kramer, G.W. Characterization of U. S. Cement Kiln Dust; Bureau of Mines, United States Department of Interior: Washington, DC, USA, 1982; Information Circular #8885.

- Huntzinger, D.N.; Gierke, J.S.; Sutter, L.L.; Kawatra, S.K.; Eisele, T.C. Carbon dioxide sequestration in cement kiln dust through mineral carbonation. Environ. Sci. Technol. 2009, 43, 1986–1992. [Google Scholar] [CrossRef] [PubMed]

- Rafat, S. Cement Kiln Dust. In Waste Materials and By-Products in Concrete; Springer: Heidelberg, Germany, 2008; pp. 351–380. [Google Scholar]

- Maslehuddin, M.; Al-Amoudi, O.S.B.; Shameem, M.; Rehman, M.K.; Ibrahim, M. Usage of cement kiln dust in cement products—Research review and preliminary investigations. Constr. Build. Mater. 2008, 22, 2369–2375. [Google Scholar] [CrossRef]

- Alyamaç, K.E.; Ince, R. A preliminary concrete mix design for SCC with marble powders. Constr. Build. Mater. 2009, 23, 1201–1210. [Google Scholar] [CrossRef]

- Cioffi, R.; Colangelo, F.; Santoro, L. Durability of Mortars Prepared with Innovative Eco Compatible Binders. In 11DBMC International Conference on Durability of Building Materials and Components, Istanbul, Turkey, 11–14 May 2008.

- Baykal, G.; Döven, A.G. Utilization of fly ash by pelletization process; theory, application areas and research results. Resour. Conserv. Recycl. 2000, 30, 59–77. [Google Scholar] [CrossRef]

- Gesoglu, M.; Güneyisi, E.; Öz, H.Ö. Properties of lightweight aggregates produced with cold-bonding pelletization of fly ash and ground granulated blast furnace slag. Mater. Struct. 2012, 45, 1535–1546. [Google Scholar] [CrossRef]

- Su, F.; Lampinen, H.O.; Robinson, R. Recycling of sludge and dust to the BOF converter by cold bonded pelletizing. ISIJ Int. 2004, 44, 770–776. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoğlu, M.; Booya, E. Fresh properties of self-compacting cold bonded fly ash lightweight aggregate concrete with different mineral admixtures. Mater. Struct. 2012, 45, 1849–1859. [Google Scholar] [CrossRef]

- Geetha, S.; Ramamurthy, K. Environmental friendly technology of cold-bonded bottom ash aggregate manufacture through chemical activation. J. Clean. Prod. 2010, 18, 1563–1569. [Google Scholar] [CrossRef]

- Bui, L.A.T.; Hwang, C.L.; Chen, C.T.; Lin, K.L.; Hsieh, M.Y. Manufacture and performance of cold bonded lightweight aggregate using alkaline activators for high performance concrete. Constr. Build. Mater. 2012, 35, 1056–1062. [Google Scholar] [CrossRef]

- Andini, S.; Cioffi, R.; Colangelo, F.; Ferone, C.; Montagnaro, F.; Santoro, L. Characterization of geopolymer materials containing MSWI fly ash and coal fly ash. Adv. Sci. Technol. 2011, 69, 123–128. [Google Scholar] [CrossRef]

- Ferone, C.; Colangelo, F.; Cioffi, R.; Montagnaro, F.; Santoro, L. Mechanical performances of weathered coal fly ash based geopolymer bricks. Procedia Eng. 2011, 21, 745–752. [Google Scholar] [CrossRef]

- Ferone, C.; Colangelo, F.; Cioffi, R.; Montagnaro, F.; Santoro, L. Use of reservoir clay sediments as raw materials for geopolymer binders. Adv. Appl. Ceram. 2013, 112, 184–189. [Google Scholar] [CrossRef]

- Aarding Lightweight Granulates BV Home Page. Available online: http://www.aardinglg.com/ (accessed on 23 July 2013).

- MAPINTEC Home Page. Available online: http://www.mapintec.it/ (accessed on 23 July 2013).

- Ballester, P.; Mármol, I.; Morales, J.; Sánchez, L. Use of limestone obtained from waste of the mussel cannery industry for the production of mortars. Cem. Concr. Res. 2007, 37, 559–564. [Google Scholar] [CrossRef]

- Sugrañez, R.; Álvarez, J.I.; Cruz-Yusta, M.; Mármol, I.; Morales, J.; Sánchez, L. Controlling microstructure in cement based mortars by adjusting the particle size distribution of the raw materials. Constr. Build. Mater. 2013, 41, 139–145. [Google Scholar] [CrossRef]

- Colangelo, F.; Vaccaro, R.; Cioffi, R. Life Cycle Assessment of Sustainable Concrete Made with Recycled Aggregates. In II International Conference on Sustainable Construction Materials and Technology, Ancona, Italy, 28–30 June 2010.

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Colangelo, F.; Cioffi, R. Use of Cement Kiln Dust, Blast Furnace Slag and Marble Sludge in the Manufacture of Sustainable Artificial Aggregates by Means of Cold Bonding Pelletization. Materials 2013, 6, 3139-3159. https://doi.org/10.3390/ma6083139

Colangelo F, Cioffi R. Use of Cement Kiln Dust, Blast Furnace Slag and Marble Sludge in the Manufacture of Sustainable Artificial Aggregates by Means of Cold Bonding Pelletization. Materials. 2013; 6(8):3139-3159. https://doi.org/10.3390/ma6083139

Chicago/Turabian StyleColangelo, Francesco, and Raffaele Cioffi. 2013. "Use of Cement Kiln Dust, Blast Furnace Slag and Marble Sludge in the Manufacture of Sustainable Artificial Aggregates by Means of Cold Bonding Pelletization" Materials 6, no. 8: 3139-3159. https://doi.org/10.3390/ma6083139

APA StyleColangelo, F., & Cioffi, R. (2013). Use of Cement Kiln Dust, Blast Furnace Slag and Marble Sludge in the Manufacture of Sustainable Artificial Aggregates by Means of Cold Bonding Pelletization. Materials, 6(8), 3139-3159. https://doi.org/10.3390/ma6083139