Sustained Release of Hydrophilic l-ascorbic acid 2-phosphate Magnesium from Electrospun Polycaprolactone Scaffold—A Study across Blend, Coaxial, and Emulsion Electrospinning Techniques

Abstract

:1. Introduction

2. Results and Discussion

2.1. ASP–PCL Scaffolds Prepared by Coaxial and Emulsion Electrospinnings

| Scaffolds (Electrospun methods) | Loading efficiency (%) | Initial release within day 1 (%) | Total release within 14 days (%) | Young’s Modular (MP) | |

|---|---|---|---|---|---|

| Coaxial | 92.6 ± 3.4 | 86.1 ± 15.3 | 99.8 | - | |

| Emulsion | 46.1 ± 7.2 | 42.5 ± 2.7 | 70.2 | 8.7 | |

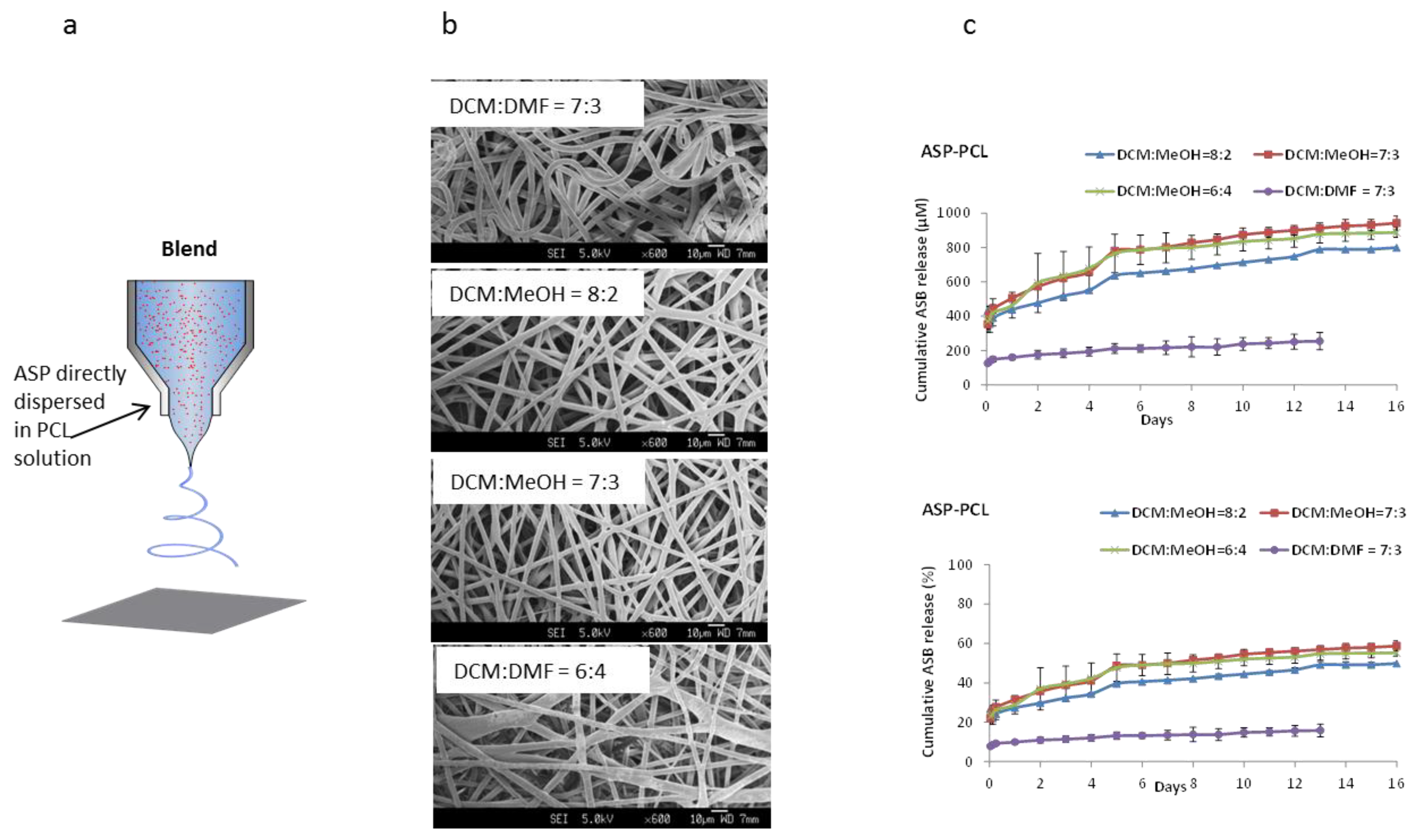

| Blend | DCM–DMF = 7:3 | 78.5 ± 9.7 | 7.8 ± 0.3 | 15.2 | 9.7 |

| DCM–MeOH = 8:2 | 73.7 ± 1.5 | 26.9 ± 0.9 | 50.2 | 6.7 | |

| DCM–MeOH = 7:3 | 80.3 ± 4.5 | 22.0 ± 1.9 | 59.1 | 6.7 | |

| DCM–MeOH = 6:4 | 81.0 ± 11.2 | 23.2 ± 4.6 | 55.4 | 6.4 | |

2.2. ASP–PCL Scaffolds Prepared by Blend Electrospinning by Using Binary Solvent Systems

2.3. Mechanical Properties of ASP–PCL Scaffolds

3. Experimental Section

3.1. Scaffold Preparation

3.1.1. Preparation of ASP–PCL Solutions for Coaxial, Emulsion and Blend Electrospinning

3.1.2. Electrospinning of ASP–PCL Scaffolds

3.2. Scaffold Characterization

3.2.1. Morphology Assessment

3.2.2. ASP Encapsulation Efficiency

3.2.3. ASP Release Study

3.2.4. Mechanical Properties

3.3. Statistical Analysis

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zhang, J.Y.; Doll, B.A.; Beckman, E.J.; Hollinger, J.O. Three-dimensional biocompatible ascorbic acid-containing scaffold for bone tissue engineering. Tissue Eng. 2003, 9, 1143–1157. [Google Scholar] [CrossRef] [PubMed]

- Bauer, T.W.; Muschler, G.F. Bone graft materials. An overview of the basic science. Clin. Orthop. Relat. Res. 2000, 371, 10–27. [Google Scholar] [CrossRef] [PubMed]

- Jabbari, E. Effect of sustained release of bone morphogenetic protein on osteogenic expression of mesenchymal stem cells. In Proceedings of 2010 Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC), Buenos Aires, Argentina, 31 August–4 September 2010; pp. 3733–3735.

- Ngiam, M.; Liao, S.; Chan, C.; Ramakrishna, S. Cell-based nanocomposites and biomolecules for bone tissue engineering. In Advanced Biomaterials; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2010; pp. 551–588. [Google Scholar]

- Choong, P.F.; Martin, T.J.; Ng, K.W. Effects of ascorbic acid, calcitriol, and retinoic acid on the differentiation of preosteoblasts. J. Orthop. Res. 1993, 11, 638–647. [Google Scholar] [CrossRef] [PubMed]

- Lam, P.L.; Kok, S.H.; Bian, Z.X.; Lam, K.H.; Gambari, R.; Lee, K.K.; Chui, C.H. Microencapsulation-protected l-ascorbic acid for the application of human epithelial hacat cell proliferation. J. Microencapsul. 2014. [Google Scholar] [CrossRef]

- Savini, I.; Rossi, A.; Pierro, C.; Avigliano, L.; Catani, M.V. Svct1 and svct2: Key proteins for vitamin c uptake. Amino Acids 2008, 34, 347–355. [Google Scholar] [CrossRef] [PubMed]

- Moteki, H.; Shimamura, Y.; Kimura, M.; Ogihara, M. Signal transduction pathway for l-ascorbic acid- and l-ascorbic acid 2-glucoside-induced DNA synthesis and cell proliferation in primary cultures of adult rat hepatocytes. Eur. J. Pharmacol. 2012, 683, 276–284. [Google Scholar] [CrossRef] [PubMed]

- Acarregui, A.; Herran, E.; Igartua, M.; Blanco, F.J.; Pedraz, J.L.; Orive, G.; Hernandez, R.M. Multifunctional hydrogel-based scaffold for improving the functionality of encapsulated therapeutic cells and reducing inflammatory response. Acta Biomater. 2014, 10, 4206–4216. [Google Scholar] [CrossRef] [PubMed]

- Mateen, R.; Hoare, T. Carboxymethyl and hydrazide functionalized beta-cyclodextrin derivatives: A systematic investigation of complexation behaviours with the model hydrophobic drug dexamethasone. Int. J. Pharm. 2014, 472, 315–326. [Google Scholar] [CrossRef] [PubMed]

- Piao, Z.G.; Kim, J.S.; Son, J.S.; Lee, S.Y.; Fang, X.H.; Oh, J.S.; You, J.S.; Kim, S.G. Osteogenic evaluation of collagen membrane containing drug-loaded polymeric microparticles in a rat calvarial defect model. Tissue Eng. A 2014. [Google Scholar] [CrossRef]

- Mishra, G.P.; Kinser, R.; Wierzbicki, I.H.; Alany, R.G.; Alani, A.W.G. In situ gelling polyvalerolactone-based thermosensitive hydrogel for sustained drug delivery. Eur. J. Pharm. Biopharm. 2014, 88, 397–405. [Google Scholar] [CrossRef]

- Guney, G.; Kutlu, H.M.; Genc, L. Preparation and characterization of ascorbic acid loaded solid lipid nanoparticles and investigation of their apoptotic effects. Colloids Surf. B Biointerfaces 2014, 121, 270–280. [Google Scholar] [CrossRef] [PubMed]

- Thiruppathi, E.; Mani, G. Vitamin-c delivery from cocr alloy surfaces using polymer-free and polymer-based platforms for cardiovascular stent applications. Langmuir 2014, 30, 6237–6249. [Google Scholar] [CrossRef]

- Szentivanyi, A.; Chakradeo, T.; Zernetsch, H.; Glasmacher, B. Electrospun cellular microenvironments: Understanding controlled release and scaffold structure. Adv. Drug Deliv. Rev. 2011, 63, 209–220. [Google Scholar] [CrossRef] [PubMed]

- Lu, X.; Wang, C.; Wei, Y. One-dimensional composite nanomaterials: Synthesis by electrospinning and their applications. Small 2009, 5, 2349–2370. [Google Scholar] [CrossRef] [PubMed]

- Huang, Z.-M.; Zhang, Y.Z.; Kotaki, M.; Ramakrishna, S. A review on polymer nanofibers by electrospinning and their applications in nanocomposites. Compos. Sci. Technol. 2003, 63, 2223–2253. [Google Scholar] [CrossRef]

- Wu, X.M.; Branford-White, C.J.; Yu, D.G.; Chatterton, N.P.; Zhu, L.M. Preparation of core-shell pan nanofibers encapsulated alpha-tocopherol acetate and ascorbic acid 2-phosphate for photoprotection. Colloids Surf. B Biointerfaces 2011, 82, 247–252. [Google Scholar] [CrossRef] [PubMed]

- Hadzir, S.N.; Ibrahim, S.N.; Abdul Wahab, R.M.; Zainol Abidin, I.Z.; Senafi, S.; Ariffin, Z.Z.; Abdul Razak, M.; Zainal Ariffin, S.H. Ascorbic acid induces osteoblast differentiation of human suspension mononuclear cells. Cytotherapy 2014, 16, 674–682. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.; Kim, H.W.; Suh, H. Sustained release of ascorbate-2-phosphate and dexamethasone from porous plga scaffolds for bone tissue engineering using mesenchymal stem cells. Biomaterials 2003, 24, 4671–4679. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.; Suh, H.; Jo, S.A.; Kim, H.W.; Lee, J.M.; Kim, E.H.; Reinwald, Y.; Park, S.H.; Min, B.H.; Jo, I. In vivo bone formation by human marrow stromal cells in biodegradable scaffolds that release dexamethasone and ascorbate-2-phosphate. Biochem. Biophys. Res. Commun. 2005, 332, 1053–1060. [Google Scholar] [CrossRef] [PubMed]

- Yoon, H.; Kim, G. Layer-by-layered electrospun micro/nanofibrous mats for drug delivery system. Macromol. Res. 2012, 20, 402–406. [Google Scholar] [CrossRef]

- Abdul Rahman, N.; Gizdavic-Nikolaidis, M.; Ray, S.; Easteal, A.J.; Travas-Sejdic, J. Functional electrospun nanofibres of poly(lactic acid) blends with polyaniline or poly(aniline-co-benzoic acid). Synth. Met. 2010, 160, 2015–2022. [Google Scholar]

- Lee, G.; Song, J.C.; Yoon, K.B. Controlled wall thickness and porosity of polymeric hollow nanofibers by coaxial electrospinning. Macromol. Res. 2010, 18, 571–576. [Google Scholar] [CrossRef]

- Ghorani, B.; Russell, S.J.; Goswami, P. Controlled morphology and mechanical characterisation of electrospun cellulose acetate fibre webs. Int. J. Polym. Sci. 2013, 2013. [Google Scholar] [CrossRef]

- Han, F.; Zhang, H.; Zhao, J.; Zhao, Y.; Yuan, X. Diverse release behaviors of water-soluble bioactive substances from fibrous membranes prepared by emulsion and suspension electrospinning. J. Biomater. Sci. Polym. Ed. 2013, 24, 1244–1259. [Google Scholar] [CrossRef]

- Hu, J.; Wei, J.; Liu, W.; Chen, Y. Preparation and characterization of electrospun plga/gelatin nanofibers as a drug delivery system by emulsion electrospinning. J. Biomater. Sci. Polym. Ed. 2013, 24, 972–985. [Google Scholar] [CrossRef] [PubMed]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.; Lui, Y.S.; Toh, P.W.J.; Loo, S.C.J. Sustained Release of Hydrophilic l-ascorbic acid 2-phosphate Magnesium from Electrospun Polycaprolactone Scaffold—A Study across Blend, Coaxial, and Emulsion Electrospinning Techniques. Materials 2014, 7, 7398-7408. https://doi.org/10.3390/ma7117398

Zhao X, Lui YS, Toh PWJ, Loo SCJ. Sustained Release of Hydrophilic l-ascorbic acid 2-phosphate Magnesium from Electrospun Polycaprolactone Scaffold—A Study across Blend, Coaxial, and Emulsion Electrospinning Techniques. Materials. 2014; 7(11):7398-7408. https://doi.org/10.3390/ma7117398

Chicago/Turabian StyleZhao, Xinxin, Yuan Siang Lui, Pei Wen Jessica Toh, and Say Chye Joachim Loo. 2014. "Sustained Release of Hydrophilic l-ascorbic acid 2-phosphate Magnesium from Electrospun Polycaprolactone Scaffold—A Study across Blend, Coaxial, and Emulsion Electrospinning Techniques" Materials 7, no. 11: 7398-7408. https://doi.org/10.3390/ma7117398