Permeation Properties and Pore Structure of Surface Layer of Fly Ash Concrete

Abstract

:1. Introduction

2. Results and Discussion

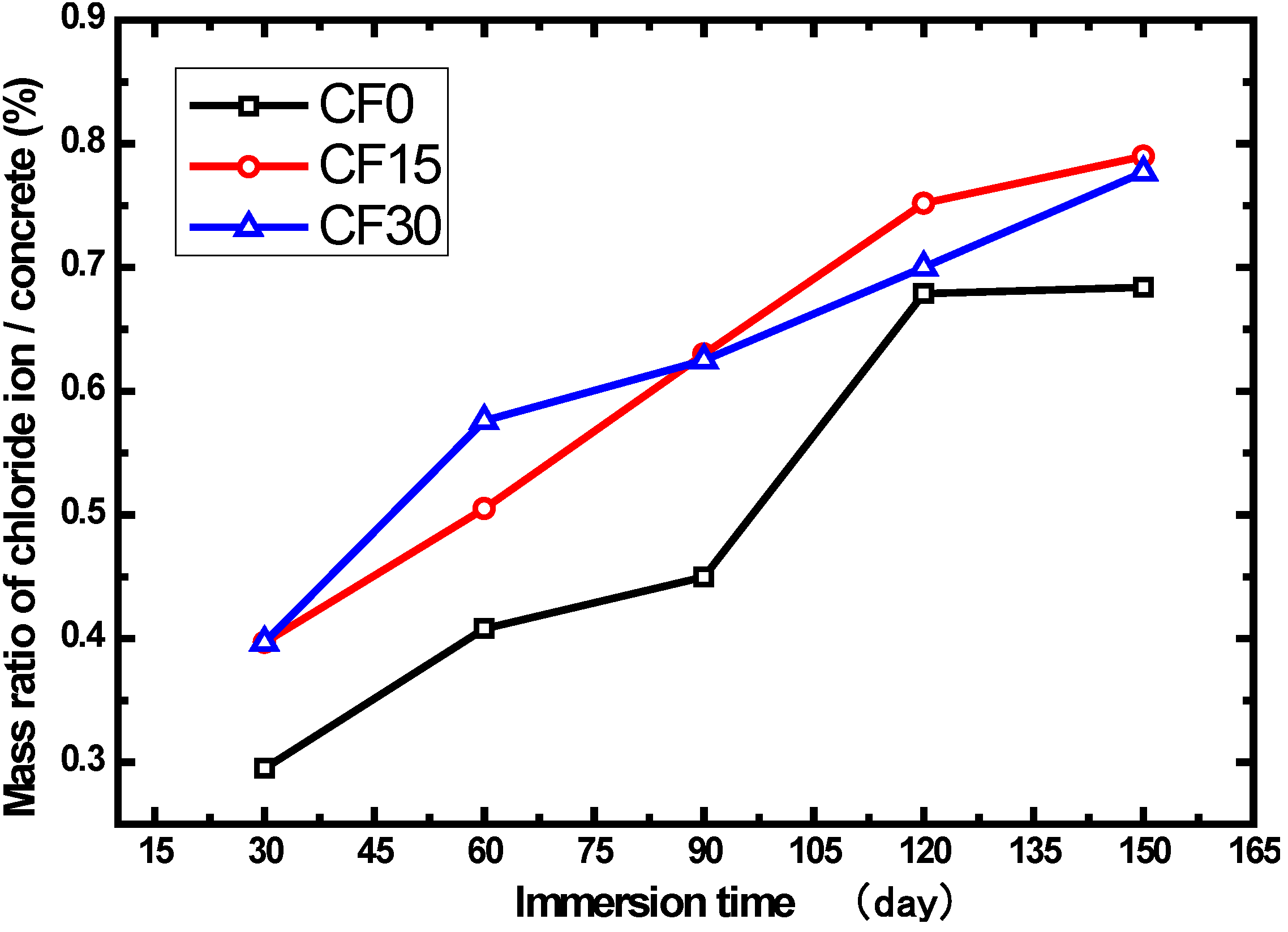

2.1. Effects of Fly Ash on Chloride Ion Ingress in the Surface Layer of Concrete

| Mix ID | Immersion Time (day) | ||||

| 30 | 60 | 90 | 120 | 150 | |

| CF0 | 0.295 | 0.408 | 0.450 | 0.679 | 0.684 |

| CF15 | 0.397 | 0.505 | 0.630 | 0.752 | 0.790 |

| CF30 | 0.397 | 0.576 | 0.625 | 0.700 | 0.777 |

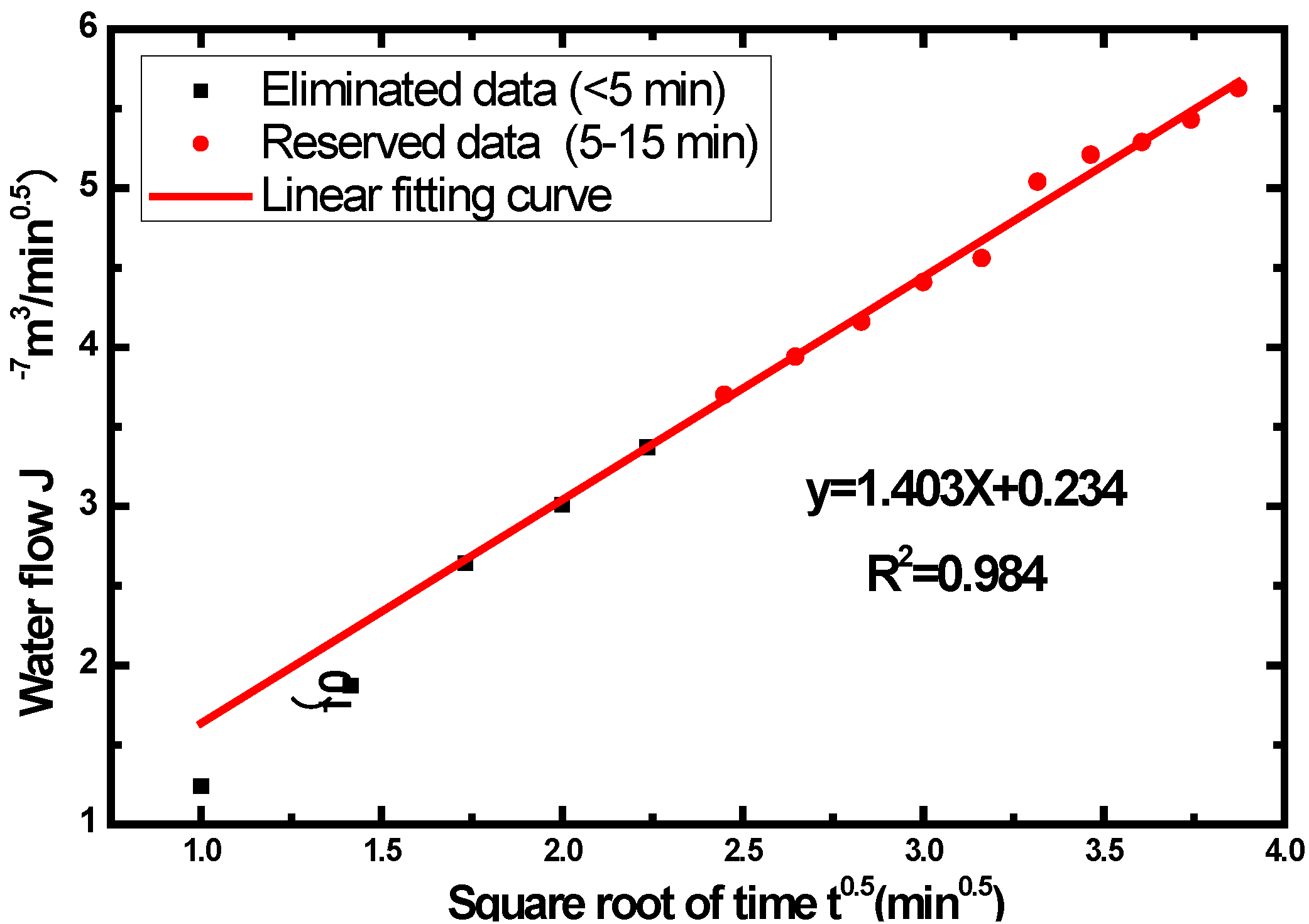

2.2. Influence of Fly Ash on the Water Permeability in the Surface Layer

| Immersion time (day) | Water permeability test time (min) | ||||||||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | |

| 0 | 124 | 187 | 264 | 301 | 337 | 370 | 394 | 416 | 441 | 456 | 1598 | 521 | 529 | 543 | 563 |

| 30 | 539 | 805 | 997 | 1125 | 1246 | 1330 | 1423 | 1488 | 1547 | 1598 | 1666 | 1713 | 1756 | 1795 | 1836 |

| 60 | 204 | 353 | 426 | 550 | 602 | 654 | 697 | 799 | 835 | 870 | 900 | 930 | 1017 | 1041 | 1069 |

| 90 | 338 | 571 | 725 | 807 | 876 | 930 | 1002 | 1047 | 1086 | 1121 | 1153 | 1203 | 1229 | 1257 | 1278 |

| 120 | 104 | 154 | 197 | 253 | 288 | 318 | 344 | 370 | 396 | 422 | 442 | 463 | 502 | 520 | 543 |

| 150 | 55 | 89 | 113 | 139 | 161 | 182 | 200 | 221 | 249 | 262 | 271 | 295 | 305 | 319 | 333 |

| Immersion time (day) | Fitting Curve | R2 |

|---|---|---|

| 0 | y = 1.403x + 0.234 | 0.984 |

| 30 | y = 3.509x + 4.893 | 0.996 |

| 60 | y = 2.916x + 3.588 | 0.992 |

| 90 | y = 2.405x − 0.546 | 0.982 |

| 120 | y = 1.590x − 0.784 | 0.994 |

| 150 | y = 1.067x − 0.786 | 0.994 |

| Sample | Immersion Period (day) | |||||

| 0 | 30 | 60 | 90 | 120 | 150 | |

| CF0 | 2.014 | 3.033 | 2.879 | 2.694 | 2.414 | 2.369 |

| CF15 | 1.403 | 3.509 | 2.916 | 2.405 | 1.590 | 1.067 |

| CF30 | 2.429 | 4.098 | 2.442 | 1.339 | 0.958 | 0.958 |

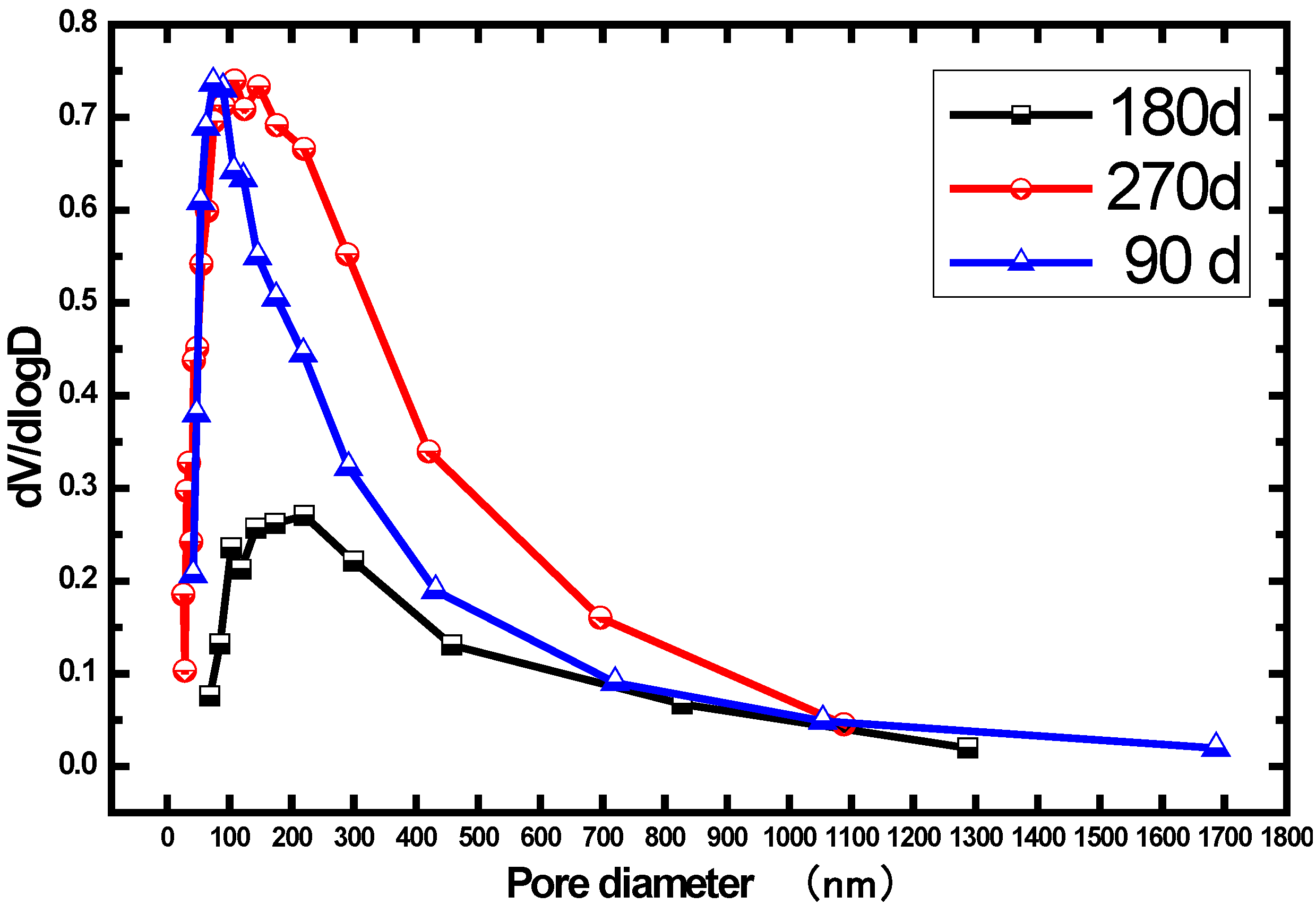

2.3. Influence of Fly Ash on the Pore Structure for Surface Layer of Concrete

3. Experimental Section

3.1. Materials and Mixture Proportions

3.1.1. Cement

| Item | Cement | Fly Ash (FA) |

|---|---|---|

| Composition (Mass % as Oxide) | ||

| Calcium oxide (CaO) | 64.67 | 4.74 |

| Silica (SiO2) | 18.59 | 62.32 |

| Alumina (Al2O3) | 4.62 | 23.95 |

| Iron Oxide (Fe2O3) | 4.17 | 1.33 |

| Magnesium oxide (MgO) | 2.35 | 2.04 |

| Sulfur trioxide (SO3) | 3.32 | 1.25 |

| Potassium oxide (K2O) | 0.92 | 0.76 |

| Sodium oxide (Na2O) | – | – |

| Loss on ignition (LOI) | 1.03 | 3.12 |

| Physical Properties | ||

| Specific surface area (m2/Kg) | 345 | 391 |

| 80 μm sieving fineness (%) | 4.15 | 8.30 |

3.1.2. Aggregates

3.1.3. Water

3.1.4. Fly Ash

3.1.5. NaCl

| Mix ID | W/B a | Composition (kg/m3) | ||||

|---|---|---|---|---|---|---|

| Cement | Sand | Crush Stone | Fly Ash | Water | ||

| CF0 | 0.47 | 409 | 720 | 1079 | 0 | 192 |

| CF15 | 0.47 | 348 | 697 | 1054 | 61 | 192 |

| CF30 | 0.47 | 286 | 689 | 1041 | 123 | 192 |

3.2. Chloride Immersion Test

3.3. Chloride Ion Concentration Accumulated in the Surface Layer

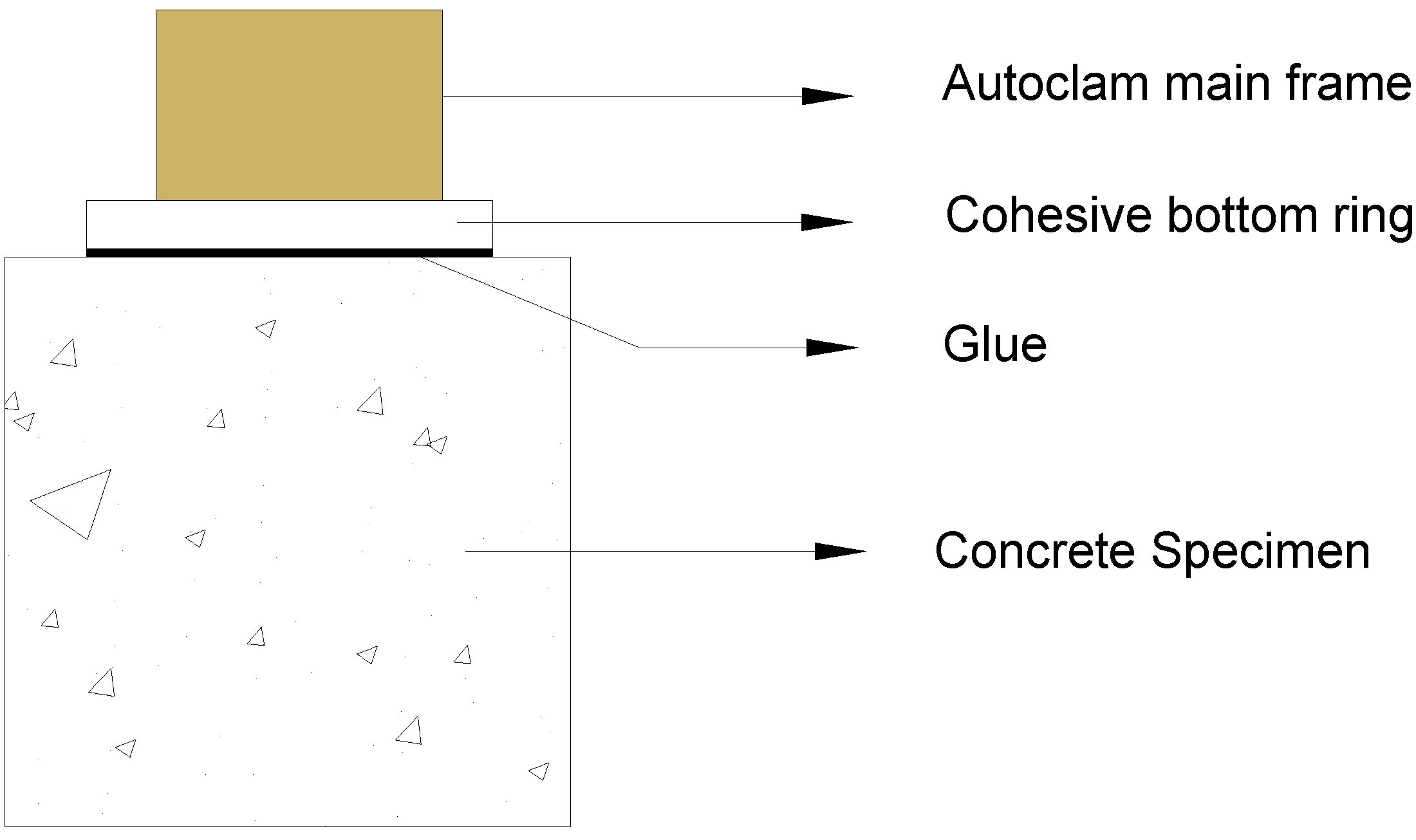

3.4. Water Permeability of the Surface Layer

3.5. Pore Structure Determination

4. Conclusions

- In the early immersion period, fly ash has a significant effect on the chloride precipitation in the surface layer. However, the dosage of fly ash has little impact on the chloride precipitation in the surface layer. With the increasing immersion period, amounts of chloride ion in the surface layer of different fly ash contents were nearly the same;

- Fly ash content has a significant influence on the water permeability of the surface layer. With the immersion process, the secondary hydration of fly ash enhances resistance of the concrete to water ingress;

- When a fly ash concrete is under water immersion, both the pozzolanic reaction of fly ash and the water dissolution influence the pore structure development. The pozzolanic reaction is more dominant at the time of 180 days while the water dissolution becomes more evident after 270 days.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Schwotzer, M.; Scherer, T.; Gerdes, A. Protective or damage promoting effect of calcium carbonate layers on the surface of cement based materials in aqueous environments. Cem. Concr. Res. 2010, 40, 1410–1418. [Google Scholar]

- Seleem, H.E.H.; Rashad, A.M.; El-Sabbagh, B.A. Durability and strength evaluation of high-performance concrete in marine structures. Constr. Build. Mater. 2010, 24, 878–884. [Google Scholar]

- Neville, A. Chloride attack of reinforced concrete: An overview. Mater. Struct. 1995, 28, 63–70. [Google Scholar]

- Moranville, M.; Kamali, S.; Guillon, E. Physicochemical equilibria of cement-based materials in aggressive environments—Experiment and modeling. Cem. Concr. Res. 2004, 9, 1569–1578. [Google Scholar]

- Koelliker, E. Skins of calciumcarbonate and their significance for the corrosion of concrete. In Proceedings of the 8th International Congress on the Chemistry of Cement and Concrete, Rio de Janeiro, Brazil, 1986; pp. 159–164.

- Sahmaran, M.; Yaman, İ.Ö.; Tokyay, M. Transport and mechanical properties of self consolidating concrete with high volume fly ash. Cem. Concr. Compos. 2009, 31, 99–106. [Google Scholar]

- Barger, G.S.; Hill, R.L.; Ramme, B.W. Use of Fly Ash in Concrete; American Concrete Institute: Farmington Hills, MI, USA, 2003. [Google Scholar]

- Williams, P.J.; Biernacki, J.J.; Walker, L.R.; Meyer, H.M.; Rawn, C.J.; Bai, J. Microanalysis of alkali-activated fly ash-CH pastes. Cem. Concr. Res. 2002, 32, 963–972. [Google Scholar]

- Yu, Z.Q.; Ye, G. The pore structure of cement paste blended with fly ash. Constr. Build. Mater. 2013, 45, 30–35. [Google Scholar]

- Sarbak, Z.; Kramer-Wachowiak, M. Porous structure of waste fly ashes and their chemical modifications. Powder Technol. 2005, 123, 53–58. [Google Scholar]

- Malhotra, V.M. Durability of concrete incorporating high-volume of low calcium (ASTM Class F) fly ash. Cem. Concr. Res. 1990, 4, 271–277. [Google Scholar]

- Varga, I.D.; Spragg, R.P.; Bella, C.D.; Castro, J.; Bentz, D.P.; Weiss, J. Fluid transport in high volume fly ash mixtures with and without internal curing. Cem. Concr. Compos. 2014, 45, 102–110. [Google Scholar]

- Duxson, P.; Provis, J.L.; Lukey, G.C.; van Deventer, J.S.J. The role of inorganic polymer technology in the development of ‘green concrete’. Cem. Concr. Res. 2007, 37, 1590–1597. [Google Scholar]

- Limbachiya, M.; Meddah, M.S.; Ouchagour, Y. Use of recycled concrete aggregate in fly-ash concrete. Constr. Build. Mater. 2012, 27, 439–449. [Google Scholar]

- Taylor, H.F.W. Cement Chemistry; Academic Press Inc: San Diego, CA, USA, 1990; pp. 1–382. [Google Scholar]

- Chindaprasirt, P.; Chotihanorm, C.; Cao, H.T.; Sirivivatnanon, V. Influence of fly ash fineness on the chloride penetration of concrete. Constr. Build. Mater. 2007, 21, 356–361. [Google Scholar]

- Chindaprasirt, P.; Jaturapitakkul, C.; Sinsiri, T. Effect of fly ash fineness on compressive strength and pore structure and related properties of fly ash cement pastes and mortars. Constr. Build. Mater. 1997, 11, 383–393. [Google Scholar]

- Danshen, S. Concrete of Fly Ash; The Publishing House of Railway of China: Beijing, China, 1982. [Google Scholar]

- Van den Heede, P.; Gruyaert, E.; de Belie, N. Transport properties of high-volume fly ash concrete: Capillary water sorption, water sorption under vacuum and gas permeability. Cem. Concr. Compos. 2010, 32, 749–756. [Google Scholar]

- Shi, X.; Yang, Z.; Liu, Y.; Cross, D. Strength and corrosion properties of Portland cement mortar and concrete with mineral admixtures. Constr. Build. Mater. 2010, 25, 3245–3256. [Google Scholar]

- Zeng, Q.; Li, K.F.; Teddy, F.C.; Patrick, D. Pore structure characterization of cement pastes blended with high-volume fly-ash. Cem. Concr. Res. 2012, 42, 194–204. [Google Scholar]

- Jiang, L.H.; Guan, Y.G. Pore structure and its effect on strength of high-volume fly ash paste. Cem. Concr. Res. 1999, 29, 631–633. [Google Scholar]

- Boğa, A.R.; Topçu, İ.B. Influence of fly ash on corrosion ressistance and chloride ion permeability of concrete. Constr. Build. Mater. 2012, 31, 258–264. [Google Scholar]

- Thomas, M.D.A.; Bamforth, P.B. Modelling chloride diffusion in concrete Effect of fly ash and slag. Cem. Concr. Res. 1999, 29, 487–495. [Google Scholar]

- Ismail, I.; Bernal, S.A.; Provis, J.L.; Nicolas, R.S.; Brice, D.G.; Kilcullen, A.R.; Hamdan, S.; van Deventer, J.S.J. Influence of fly ash on the water and chloride permeability of alkali-activated slag mortars and concretes. Constr. Build. Mater. 2013, 48, 1187–1201. [Google Scholar]

- Hughes, D. Pore structure and permeability of hardened cement paste. Mag. Concr. Res. 1985, 37, 227–233. [Google Scholar]

- Jain, J.A.; Neithalath, N. Chloride transport in fly ash and glass powder modified concretes—Influence of test methods on microstructure. Cem. Concr. Compos. 2010, 32, 148–156. [Google Scholar]

- Ho, D.W.S.; Cui, Q.Y.; Ritchie, D.J. Influence of humidity and curing time on the quality of concrete. Cem. Concr. Res. 1989, 19, 457–464. [Google Scholar]

- Mannan, M.A.; Basri, H.B.; Zain, M.F.M.; Islam, M.N. Effect of curing conditions on the properties of OPS-concrete. Build. Environ. 2002, 37, 1167–1171. [Google Scholar]

- Criado, M.; Palomo, A.; Fernández-Jiménez, A. Alkali activation of fly ashes. Part 1: Effect of curing conditions on the carbonation of the reaction products. Fuel 2005, 84, 2048–2054. [Google Scholar]

- Bonavetti, V.; Donza, H.; Rahhal, V.; Irassar, E. Influence of initial curing on the properties of concrete containing limestone blended cement. Cem. Concr. Res. 2000, 30, 703–708. [Google Scholar]

- Yan, P.Y. Mechanism of fly ash’s effects during hydration process of composite binder. J. Chin. Ceram. Soc. 2007, 1, 167–170. [Google Scholar]

- Guerrero, A.; Goni, S.; Macı́as, A.; Luxán, M.P. Effect of the starting fly ash on the microstructure and mechanical properties of fly ash-belite cement mortars. Cem. Concr. Res. 2000, 4, 553–559. [Google Scholar]

- Zhang, Y.S.; Sun, W.; Zheng, K.R. Hydration process of Portland cement-fly ash paste. J. Southeast Univ. 2006, 1, 118–123. [Google Scholar]

- Mehta, P.K.; Manmohan, D. Pore size distribution and permeability of hardened cement pastes. Int. Congr. Chem. Cem. 1980, 1–5. [Google Scholar]

- Massazza, F.; Hewlett, P.C. Lea’s Chemistry of Cement and Concrete; John Wiley & Sons, Inc: New York, NY, USA, 1988; pp. 471–631. [Google Scholar]

- Liu, J.; Xie, Y.J.; Xing, F. Influence of Fly Ash on Concrete Pore Structure in Natural Immersion Environment. Bull. Chin. Ceram. Soc. 2013, 7, 1397–1401. [Google Scholar]

- Carde, C.; Francois, R. Effect of the leaching of calcium hydroxide from cement paste on mechanical and physical properties. Cem. Concr. Res. 1997, 4, 539–550. [Google Scholar]

- Carde, C.; Francois, R. Modelling the loss of strength and porosity increase due to the leaching of cement pastes. Cem. Concr. Compos. 1999, 21, 181–188. [Google Scholar]

- JGJ52–2006 Standard for Technical Requirements and Test Method of Sand and Crushed Stone (or Gravel) for Ordinary Concrete; China Academy of Building Rsearch: Beijing, China, 2007.

- American Association of State Highway and Transportation Officials. Standard Method of Test for Resistance of Concrete to Chloride Ion Penetration. AASHTO: Washington, DC, USA, 2006. [Google Scholar]

- JTJ270–98 Testing Code of Concrete for Port and Waterog Engineering; Ministry of Communications of the People’s Republic of China: Beijing, China, 1998.

- Basheer, P.A.; Long, A.E.; Montgomary, F.R. The Autoclam––A new test for permeability. Concrete 1994, 28, 27–29. [Google Scholar]

- Liu, J.; Xing, F.; Dong, B.; Ma, H.; Pan, D. Study on water sorptivity of the surface layer of concrete. Mater. Struct. 2013. [Google Scholar] [CrossRef]

- Liu, J.; Xing, F.; Dong, B.; Ma, H.; Pan, D. Study on surface permeability of concrete under immersion. Mater. 2014, 7, 876–886. [Google Scholar]

- Feldman, R.F. Pore structure damage in blended cements caused by mercury intrusion. J. Am. Ceram. Soc. 1984, 1, 30–33. [Google Scholar]

- Diamond, S. A critical comparison of mercury porosimetry and capillary condensation pore size distributions of Portland cement pastes. Cem. Concr. Res. 1971, 5, 531–545. [Google Scholar]

- Ma, Y.; Hu, J.; Ye, G. The pore structure and permeability of alkali activated fly ash. Fuel 2013, 104, 771–780. [Google Scholar]

- Aligizaki, K.K. Pore Structure of Cement-Based Materials: Testing, Interpretation and Requirements; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Washburn, E.W. The dynamics of capillary flow. Phys. Rev. 1921, 3, 273–283. [Google Scholar]

- Ma, H. Mercury intrusion porosimetry in concrete technology: Tips of measurement pore structure parameter acquisition and application. J. Porous Mater. 2014, 21, 207–215. [Google Scholar]

- Barrett, E.P.; Joyner, L.G.; Halenda, P.H. The determination of pore volume and area distributions in porous substances-1. Computations from nitrogen isotherms. J. Am. Chem. Soc. 1951, 73, 373–380. [Google Scholar]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Liu, J.; Qiu, Q.; Xing, F.; Pan, D. Permeation Properties and Pore Structure of Surface Layer of Fly Ash Concrete. Materials 2014, 7, 4282-4296. https://doi.org/10.3390/ma7064282

Liu J, Qiu Q, Xing F, Pan D. Permeation Properties and Pore Structure of Surface Layer of Fly Ash Concrete. Materials. 2014; 7(6):4282-4296. https://doi.org/10.3390/ma7064282

Chicago/Turabian StyleLiu, Jun, Qiwen Qiu, Feng Xing, and Dong Pan. 2014. "Permeation Properties and Pore Structure of Surface Layer of Fly Ash Concrete" Materials 7, no. 6: 4282-4296. https://doi.org/10.3390/ma7064282

APA StyleLiu, J., Qiu, Q., Xing, F., & Pan, D. (2014). Permeation Properties and Pore Structure of Surface Layer of Fly Ash Concrete. Materials, 7(6), 4282-4296. https://doi.org/10.3390/ma7064282