An Evaluation of Global and Local Tensile Properties of Friction-Stir Welded DP980 Dual-Phase Steel Joints Using a Digital Image Correlation Method

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Test Material and Welding Conditions

| Elements | C | Mn | P | S | Si | Fe |

|---|---|---|---|---|---|---|

| Composition (wt %) | 0.065 | 2.40 | 0.023 | 0.004 | 0.076 | Bal. |

| Rotation Speed (rpm) | Axial Force (kN) | Welding Speed (mm/s) | Tilt Angle (Degree) | Tool Geometry | ||

|---|---|---|---|---|---|---|

| Shoulder Diameter (mm) | Probe Diameter (mm) | Probe Height (mm) | ||||

| 600 | 14 | 4 | 2 | 10 | 2.5 | 0.85 |

2.2. Microstructure Analysis and Hardness Measurements

2.3. Tensile Tests

2.4. Assessment of Local Tensile Properties Using DIC Methodology

3. Results and Discussion

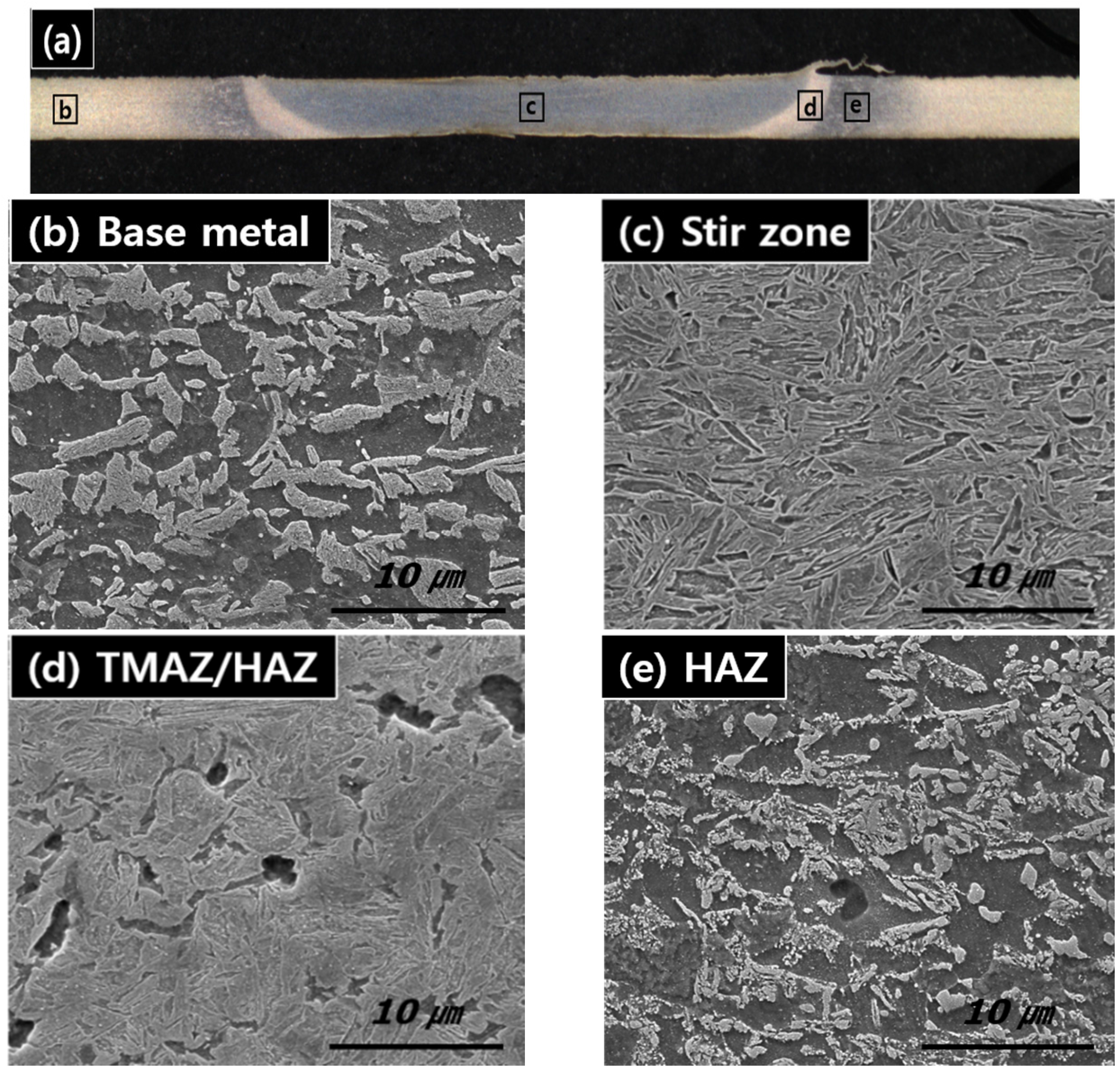

3.1. Microstructure and Hardness

3.2. Global Tensile Characteristics

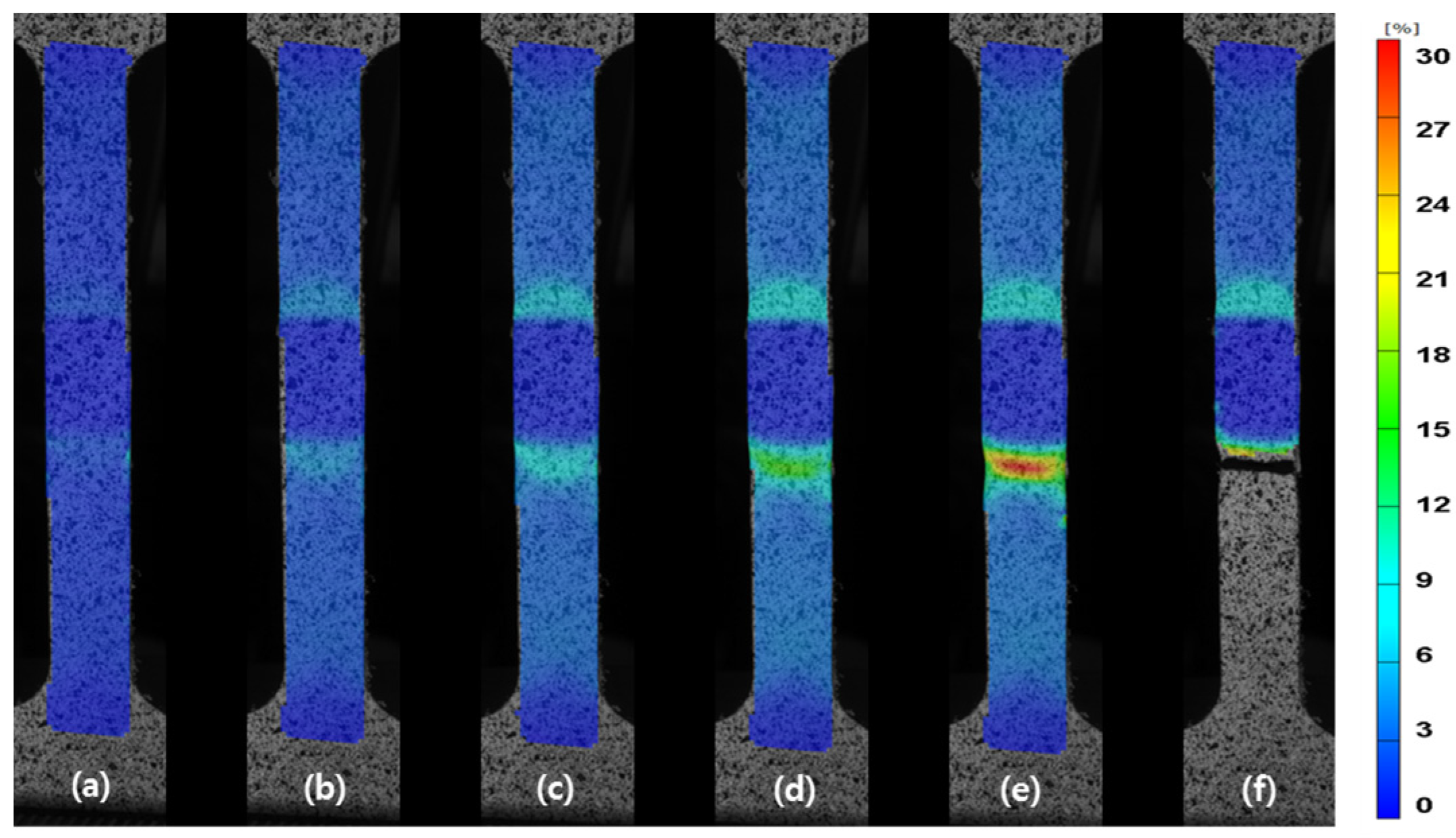

3.3. Local Tensile Characteristics

4. Conclusions

- The friction-stir welding led to the formation of martensite and significant hardness rise in the stir zone (SZ), but the presence of a soft zone in the heat-affected zone (HAZ) was caused by the tempering of the pre-existing martensite.

- Microhardness reveals that microhardness of the SZ becomes higher (average microhardness of 496 HV) than that of the BM (average microhardness of 324 HV). Furthermore, a microhardness valley is observed at the HAZ in the weld cross-section, in which local microhardness drops below the BM microhardness.

- The DP980 FSW joint showed almost 93% joint efficiency with the viewpoint of ultimate tensile strength, but showed lower ductility than the base metal due to severe soft zone in HAZ.

- The base metals of DP980 steel exhibited multi-stage work hardening, whereas their FSW joints showed only a single-stage (or stage III) work hardening where the work hardening rate decreased linearly with increasing net flow stress.

- Changes in mechanical properties on the local scale were quantitatively assessed by DIC, and stress-strain curves were calculated for different weld regions. Compared to the base metal, the local yield stress increases in the SZ but decreases in the HAZ.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Advance High Strength Steel (AHSS) Application Guidelines; Auto/Steel Partnership. 2010. Available online: http://www.a-sp.org/lightweight-programs.aspx (accessed on 10 August 2015).

- Dong, D.; Liu, Y.; Yang, Y.; Li, J.; Ma, M.; Jiang, T. Microstructure and dynamic tensile behavior of DP600 dual phase steel joint by laser welding. Mater. Sci. Eng. A 2014, 594, 17–25. [Google Scholar] [CrossRef]

- Rhodes, C.G.; Mahoney, M.W.; Bingel, W.H. Effects of friction stir welding on microstructure of 7075 aluminum. Scr. Mater. 1997, 36, 69–75. [Google Scholar] [CrossRef]

- Flores, O.V.; Kennedy, C.; Murr, L.; Brown, D.; Pappu, S.; Nowak, B.M. Microstructural issues in a friction-stir-welded aluminum alloy. Scr. Mater. 1998, 38, 703–708. [Google Scholar] [CrossRef]

- Peel, M.; Steuwer, A.; Preuss, M.; Withers, P.J. Microstructure, mechanical properties and residual stresses as a function of welding speed in aluminum AA5083 friction stir welds. Acta Mater. 2003, 51, 4791–4801. [Google Scholar] [CrossRef]

- Rao, D.; Huber, K.; Heerens, J.; dos Santos, J.F.; Huber, N. Asymmetric mechanical properties and tensile behaviour prediction of aluminum alloy 5083 friction stir welding joints. Mater. Sci. Eng. A 2013, 565, 44–50. [Google Scholar] [CrossRef]

- Park, S.H.C.; Sato, Y.S.; Kokawa, H. Effect of micro-texture on fracture location in friction stir weld of Mg alloy AZ 61 during tensile test. Scr. Mater. 2003, 49, 161–166. [Google Scholar] [CrossRef]

- Hu, Z.L.; Wang, X.S.; Yuan, S.J. Quantitative investigation of the tensile plastic deformation characteristics and microstructure for friction stir welded 2021 aluminum alloy. Mater. Charact. 2012, 73, 114–123. [Google Scholar] [CrossRef]

- Nandan, R.; DebRoy, T.; Bhadeshia, H.K.D.H. Recent advances in friction-stir welding-process, weldment structure and properties. Prog. Mater. Sci. 2008, 53, 980–1023. [Google Scholar] [CrossRef]

- Mishra, R.S.; Ma, Z.Y. Friction stir welding and processing. Mater. Sci. Eng. R Rep. 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Krishnan, K.N. On the formation of onion rings in friction stir welds. Mater. Sci. Eng. A 2002, 327, 246–251. [Google Scholar] [CrossRef]

- Elangovan, K.; Balasubramanian, V. Influences of pin profile and rotational speed of the tool on the formation of friction stir processing zone in AA2219 aluminium alloy. Mater. Sci. Eng. A 2007, 459, 7–18. [Google Scholar] [CrossRef]

- Feng, X.L.; Liu, H.J.; Sudarsanam, S.B. Effect of grain size refinement and precipitation reactions on strengthening in friction stir processed Al–Cu alloys. Scr. Mater. 2011, 65, 1057–1060. [Google Scholar] [CrossRef]

- Rajakumar, S.; Balasubramanian, V. Correlation between weld nugget grain size, weld nugget hardness and tensile strength of friction stir welded commercial grade aluminum alloy joints. Mater. Des. 2012, 34, 242–251. [Google Scholar] [CrossRef]

- Chen, Y.C.; Nakata, K. Friction stir lap joining aluminum and magnesium alloys. Scr. Mater. 2008, 58, 433–436. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Wynne, B.P.; Rainforth, W.M.; Threadgill, P.L. Microstructure, crystallographic texture and mechanical properties of friction stir welded AA2017A. Mater. Charact. 2012, 64, 107–117. [Google Scholar] [CrossRef]

- Ohashi, R.; Fujimoto, M.; Mironov, S.; Sato, Y.S.; Kokawa, H. Microstructural characterization of high-strength steel lap joint produced by friction spot joining. Metall. Mater. Trans. A 2009, 40, 2033–2035. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H.; DebRoy, T. Critical assessment: friction stir welding of steels. Sci. Technol. Weld. Join. 2009, 14, 193–195. [Google Scholar] [CrossRef]

- Fujii, H.; Ueji, R.; Takada, Y.; Kitahara, H.; Tsuji, N.; Nakata, K.; Nogi, K. Friction stir welding of ultrafine grained interstitial free steels. Mater. Trans. 2006, 47, 239–242. [Google Scholar] [CrossRef]

- Fujii, H.; Cui, L.; Tsuji, N.; Maeda, M.; Nakata, K.; Nogi, K. Friction stir welding of carbon steels. Mater. Sci. Eng. A 2006, 429, 50–57. [Google Scholar] [CrossRef]

- Ueji, R.; Fujii, H.; Cui, L.; Nishioka, A.; Kunishige, K.; Nogi, K. Friction stir welding of ultrafine grained plain low-carbon steel formed by the martensite process. Mater. Sci. Eng. A 2006, 423, 324–330. [Google Scholar] [CrossRef]

- Cui, L.; Fujii, H.; Tsuji, N.; Nakata, K.; Nogi, K.; Ikeda, R.; Matsushita, M. Transformation in stir zone of friction stir welded carbon steels with different carbon contents. ISIJ Int. 2007, 47, 299–306. [Google Scholar] [CrossRef]

- Cui, L.; Fujii, H.; Tsuji, N.; Nogi, K. Friction stir welding of a high carbon steel. Scr. Mater. 2007, 56, 637–640. [Google Scholar] [CrossRef]

- Park, S.H.C.; Sato, Y.S.; Kokawa, H.; Okamoto, K.; Hirano, S.; Inagaki, M. Microstructural characterisation of stir zone containing residual ferrite in friction stir welded 304 austenitic stainless steel. Sci. Technol. Weld. Join. 2005, 10, 550–556. [Google Scholar] [CrossRef]

- Sato, Y.S.; Nelson, T.W.; Sterling, C.J. Recrystallization in type 304L stainless steel during friction stir ring. Acta Mater. 2005, 53, 637–645. [Google Scholar] [CrossRef]

- Miles, M.P.; Pew, J.; Nelson, T.W.; Li, M. Comparison of formability of friction stir welded and laser welded dual phase 590 steel sheets. Sci. Technol. Weld. Join. 2006, 11, 384–388. [Google Scholar] [CrossRef]

- Miles, M.P.; Nelson, T.W.; Steel, R.; Olsen, E.; Gallagher, M. Effect of friction stir welding conditions on properties and microstructures of high strength automotive steel. Sci. Technol. Weld. Join. 2009, 14, 228–232. [Google Scholar] [CrossRef]

- Matsushita, M.; Kitani, Y.; Ikeda, R.; Ono, M.; Fujii, H.; Chung, Y.D. Development of friction stir welding of high strength steel sheet. Sci. Technol. Weld. Join. 2011, 16, 181–187. [Google Scholar] [CrossRef]

- Uzun, H.; Dalle Donne, C.; Argagnotto, A.; Ghidini, T.; Gambaro, C. Friction stir welding of dissimilar Al 6013-T4 To X5CrNi18-10 stainless steel. Mater. Des. 2005, 26, 41–46. [Google Scholar] [CrossRef]

- Ghosh, M.; Kar, A.; Kumar, K.; Kailas, S. Structural characterisation of reaction zone for friction stir welded aluminium-stainless steel joint. Mater. Technol. Adv. Perform. Mater. 2012, 27, 169–172. [Google Scholar] [CrossRef]

- Kimapong, K.; Watanabe, T. Effect of welding process parameters on mechanical property of FSW lap joint between aluminum alloy and steel. Mater. Trans. 2005, 46, 2211–2217. [Google Scholar] [CrossRef]

- Watanabe, T.; Takayama, H.; Yanagisawa, A. Joining of aluminum alloy to steel by friction stir welding. J. Mater. Process. Technol. 2006, 178, 342–349. [Google Scholar] [CrossRef]

- Chen, Y.C.; Liu, H.J.; Feng, J.C. Friction stir welding characteristics of different heat-treated-state 2219 aluminum alloy plates. Mater. Sci. Eng. A 2006, 420, 21–25. [Google Scholar] [CrossRef]

- Sato, Y.S.; Kokawa, H. Distribution of tensile property and microstructure in friction stir weld of 6063 aluminum. Metall. Mater. Trans. A 2001, 32, 3023–3031. [Google Scholar] [CrossRef]

- Lockwood, W.D.; Reynolds, A.P. Simulation of the global response of a friction stir weld using local constitutive behavior. Mater. Sci. Eng. A 2003, 339, 35–42. [Google Scholar] [CrossRef]

- Lockwood, W.D.; Tomaz, B.; Reynolds, A.P. Mechanical response of friction stir welded AA2024: Experiment and modeling. Mater. Sci. Eng. A 2002, 323, 348–353. [Google Scholar] [CrossRef]

- Kocks, U.F.; Mecking, H. Physics and phenomenology of strain hardening: The FCC case. Prog. Mater. Sci. 2003, 48, 171–273. [Google Scholar] [CrossRef]

- GOM: Optical Measurement Techniques. Available online: http://www.gom.com/metrology-systems/digital-image-correlation.html (accessed on 10 August 2015).

- Syed, A.; Kabir, H.; Cao, X.; Gholipour, J.; Wanjara, P.; Cuddy, J.; Birur, A.; Medraj, M. Effect of postweld heat treatment on microstructure, hardness, and tensile properties of laser-welded Ti-6Al-4V. Metall. Mater. Trans. A 2012, 43A, 4171–4184. [Google Scholar]

- Huang, G.; Sadagopan, S.; Schreier, H. Determination of forming limit and fracture limit curves using digital image correlation. SAE Int. J. Mater. Manf. 2014, 7, 574–582. [Google Scholar] [CrossRef]

- Wang, W.; Roubier, N.; Peul, G.; Allain, J.M.; Infante, I.C.; Attal, J.P.; Vennat, E. A new method combining finite element analysis and digital image correlation to assess macroscopic mechanical properties of dentin. Materials 2015, 8, 535–550. [Google Scholar] [CrossRef]

- ARAMIS Software. Available online: http://www.gom.com/3d-software/aramis-software.html (accessed on 6 June 2015).

- Farabi, N.; Chen, D.L.; Zhou, Y. Tensile properties and work hardening behavior of laser-welded dual-phase steel joints. J. Mater. Eng. Perform. 2012, 21, 222–230. [Google Scholar] [CrossRef]

- Das, D.; Chattopadhyay, P.P. Influence of martensite morphology on the work-hardening behavior of high strength ferrite-martensite dual-phase steel. J. Mater. Sci. 2009, 44, 2957–2965. [Google Scholar] [CrossRef]

- Cuddy, J.; Bassim, M.N. Study of dislocation cell structures from uniaxial deformation of AISI 4340 steel. Mater. Sci. Eng. A 1989, 113, 421–429. [Google Scholar] [CrossRef]

- Leitao, C.; Galvao, I.; Leal, R.M.; Rodrigues, D.M. Determination of local constitutive properties of aluminium friction stir welds using digital image correlation. Mater. Des. 2012, 33, 69–74. [Google Scholar] [CrossRef]

- Leitao, C.; Costa, M.I.; Khanijomdi, K.; Rodrigues, D.M. Assessing strength and local plastic behaviour of welds by shear testing. Mater. Des. 2013, 51, 968–974. [Google Scholar] [CrossRef]

- Campanelli, S.L.; Casalino, G.; Casavola, C.; Moramarco, V. Analysis and comparison of friction stir welding and laser assisted friction stir welding of aluminum alloy. Materials 2013, 6, 5923–5941. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, H.; Kim, C.; Song, J.H. An Evaluation of Global and Local Tensile Properties of Friction-Stir Welded DP980 Dual-Phase Steel Joints Using a Digital Image Correlation Method. Materials 2015, 8, 8424-8436. https://doi.org/10.3390/ma8125467

Lee H, Kim C, Song JH. An Evaluation of Global and Local Tensile Properties of Friction-Stir Welded DP980 Dual-Phase Steel Joints Using a Digital Image Correlation Method. Materials. 2015; 8(12):8424-8436. https://doi.org/10.3390/ma8125467

Chicago/Turabian StyleLee, Hyoungwook, Cheolhee Kim, and Jung Han Song. 2015. "An Evaluation of Global and Local Tensile Properties of Friction-Stir Welded DP980 Dual-Phase Steel Joints Using a Digital Image Correlation Method" Materials 8, no. 12: 8424-8436. https://doi.org/10.3390/ma8125467

APA StyleLee, H., Kim, C., & Song, J. H. (2015). An Evaluation of Global and Local Tensile Properties of Friction-Stir Welded DP980 Dual-Phase Steel Joints Using a Digital Image Correlation Method. Materials, 8(12), 8424-8436. https://doi.org/10.3390/ma8125467